A Study on the Application of an Estimated Ammonia Emission Factor Reflecting the Operating Characteristics of Open Laying Hen Houses in Korea

Abstract

1. Introduction

2. Methods

2.1. Selection of a Laying Hen House

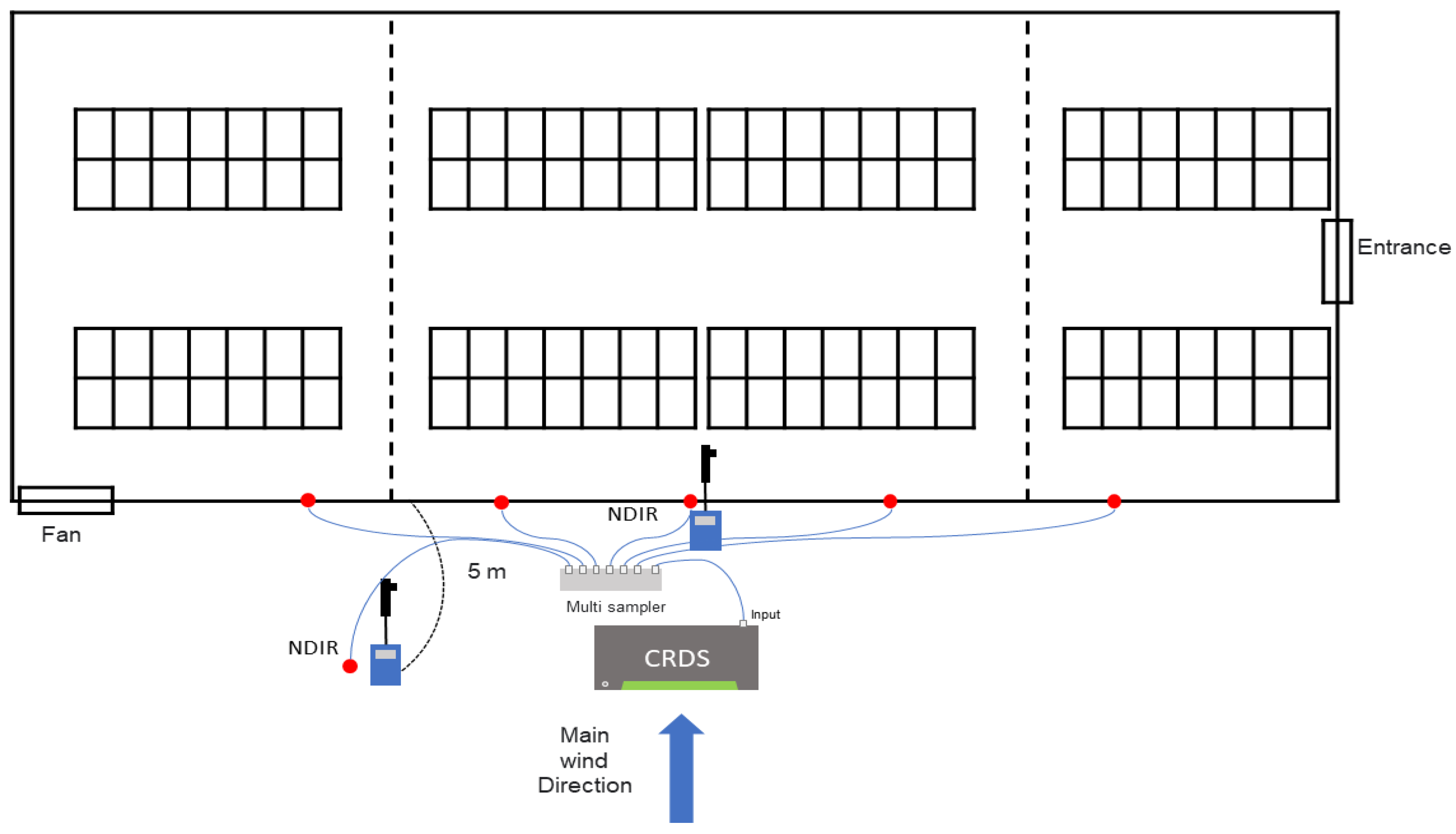

2.2. Measurement of NH3 and CO2 Concentrations

2.3. Estimation of the NH3 Emission Factor

3. Results

3.1. NH3 Concentration in the Open Laying Hen House

3.2. CO2 Concentration in the Open Laying Hen House

3.3. NH3 Emission Factor in the Open Laying Hen House

3.4. NH3 Emission Factor in Relation to the Management of the Open Laying Hen House

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- IQAir. 2023 World Air Quality Report; IQAir: Goldach, Switzerland, 2024. [Google Scholar]

- Ministry of Environment. Management Strategies to Reduce PM-2.5 Emission: Emphasis-Ammonia; Ministry of Environment: Incheon, Republic of Korea, 2017.

- Intergovernmental Panel on Climate Change (IPCC). Fifth Assessment Report—Climate Change 2013; Intergovernmental Panel on Climate Change (IPCC): Geneva, Switzerland, 2013. [Google Scholar]

- Ministry of Environment. Fine Dust, What Is It? Ministry of Environment: Incheon, Republic of Korea, 2016.

- Environmental Preservation Association. POLICY & ISSUES Environment column: Air Pollutant Total Management System. Environ. Inf. 2015, 416, 2–5. [Google Scholar]

- Rhee, V.A. Reveiw of the Special Act on the Seoul Metropolitan Air Improvement: The Total Mass emissions Managements and the Tradable Permit Programs. Public Law J. 2007, 8, 255–280. [Google Scholar]

- Moon, T.H.; Hur, J.W. Linking the Total Pollution Load Management System (TPLMS) and the Total Industrial Site Volume Control System (ISVCS) in the Capital Region, Korea. J. Korea Plan. Assoc. 2009, 44, 19–30. [Google Scholar]

- Ministry of Environment National Fine Dust Information Center. 2018 Air Pollutant Emissions; Ministry of Environment National Fine Dust Information Center: Cheongju, Republic of Korea, 2020.

- Ministry of Environment National Fine Dust Information Center. National Air Pollutant Emission Calculation Method Handbook (IV); Ministry of Environment National Fine Dust Information Center: Cheongju, Republic of Korea, 2020.

- European Environment Agency. EMEP/CORINAIR Atmospheric Emission Inventory Guidebook, 2nd ed.; European Environment Agency: Copenhagen, Danmark, 2000. [Google Scholar]

- U.S. Environmental Protection Agency. Development and Selection of Ammonia Emission Factors Final Report; U.S. Environmental Protection Agency: Washington, DC, USA, 1994.

- Statistics Korea. 2020 Census of Agriculture, Forestry and Fisheries; Statistics Korea: Daejeon, Republic of Korea, 2020. [Google Scholar]

- Jae-Hwan, S. Ammonia Flux from Cow Manure in Relation to the Environmental Factors in Livestock Facilities. J. Korean Soc. Atmos. Environ. 2010, 26, 432–442. [Google Scholar]

- National Institute of Animal Science. Investigation and Analysis of Particulate Matters and Ammonia Concentrations in Mechanically Ventilated Broiler House According to Seasonal Change, Measurement Locations, and Age of Broilers; National Institute of Animal Science: Wanju County, Republic of Korea, 2020. [Google Scholar]

- Janke, D.; Willink, D.; Ammon, C.; Hempel, S.; Schrade, S.; Demeyer, P.; Hartung, E.; Amon, B.; Ogink, N.; Amon, T. Calculation of ventilation rates and ammonia emissions: Comparison of sampling strategies for a naturally ventilated dairy barn. Biosyst. Eng. 2020, 198, 15–30. [Google Scholar] [CrossRef]

- Edouard, N.; Mosquera, J.; Hendrik, J.C.D.; Mendes, L.B.; Ogink, N.W.M. Comparison of CO2 and SF6 based tracer gas methods for the estimation of ventilation rates in a naturally ventilated dairy barn. Biosyst. Eng. 2016, 149, 11–30. [Google Scholar] [CrossRef]

- Kilic, I.; Yaslioglu, E. Ammonia and Carbon Dioxide Concentrations in a Layer House. Asian Australas J. Anim. 2014, 27, 1211–1218. [Google Scholar] [CrossRef] [PubMed]

- Ogink, N.W.M.; Mosquera, J.; Calvet, S.; Zhang, G. Methods for measuring gas emissions from naturally ventilated livestock buildings: Developments over the last decade and perspectives for improvement. Biosyst. Eng. 2013, 116, 298–308. [Google Scholar] [CrossRef]

- Verification of Environmental Technologies for Agricultural Production. VERA TEST PROTOCOL for Livestock Housing and Management Systems Version 3:2018-09; Verification of Environmental Technologies for Agricultural Production: Vliderweg, The Netherlands, 2018. [Google Scholar]

- International Commission of Agricultural Engineering. 4th Report of Working Group on Climatization of Animal Houses Heat and Moisture Production at Animal and House Levels; International Commission of Agricultural Engineering: Gainesville, FL, USA, 2002. [Google Scholar]

- Durmuş, I.; Kamanli, S. Effects of cold and heat stress on egg quality traits of a newly developed native hybrid layer. Turk. Tarim. Gida. Bilim. Teknol. Derg. 2015, 3, 444–447. [Google Scholar] [CrossRef]

- CORINAIR. EMEP/CORINAIR Atmospheric Emission Inventory Guidebook, 2nd ed.; CORINAIR: Copenhagen, Denmark, 1999. [Google Scholar]

- Hinz, T.; Winter, T.; Linke, S. Luftfremde stoffe in und aus verschiedenen haltungssystemen fürlegehennen—Teil 1: Ammoniak. Landbauforschung 2010, 60, 139–150. (In German) [Google Scholar]

- Liang, Y.; Xin, H.; Li, H.; Wheeler, E.F.; Zajaczkowski, J.L.; Topper, P.A.; Gates, R.S.; Casey, K.D.; Behrends, B.B.; Burnham, D.J.; et al. Ammonia emissions from U.S. Laying hen houses in Iowa and Pennsylvania. Trans. ASAE 2005, 48, 1927–1941. [Google Scholar] [CrossRef]

- Nimmermark, S.; Lund, V.; Gustafsson, G.; Eduard, W. Ammonia, dust and bacteria in welfare-oriented systems for laying hens. Ann. Agric. Environ. Med. 2009, 16, 103–113. [Google Scholar] [PubMed]

- Costa, A.; Ferrari, S.; Guarino, M. Yearly emission factors of ammonia and particulate matter from three laying-hen housing systems. Anim. Prod. Sci. 2012, 52, 1089–1098. [Google Scholar] [CrossRef]

- Zhao, Y.; Shepherd, T.A.; Li, H.; Xin, H. Environmental assessment of three egg production systems—Part I: Monitoring system and indoor air quality. Poult. Sci. 2015, 94, 518–533. [Google Scholar] [CrossRef] [PubMed]

- Park, J.S.; Ryoo, J.Y.; Jee, J.B.; Song, M.J. Origins and Distributions of Atmospheric Ammonia in Jeonju during 2019~2020. J. Korean Soc. Atmos. Environ. 2020, 36, 262–274. [Google Scholar] [CrossRef]

- Sanchis, E.; Clavet, S.; Prado, A.d. A meta-analysis of environmental factor effects on ammonia emissions from dairy cattle houses. Biosyst. Eng. 2019, 178, 176–183. [Google Scholar] [CrossRef]

- Simsek, E.; Kilic, I.; Yaslioglu, E.; Arici, I. Ammonia Emissions from Dairy Cattle Barns in Summer Season. J. Anim. Vet. Adv. 2012, 11, 2116–2120. [Google Scholar] [CrossRef][Green Version]

- Zhang, G.; Strøm, J.S.; Li, B.; Rom, H.B.; Morsing, S.; Dahl, P.; Wang, C. Emission of Ammonia and Other Contaminant Gases from Naturally Ventilated Dairy Cattle Buildings. Biosyst. Eng. 2005, 92, 355–364. [Google Scholar] [CrossRef]

| Laying Hens (This Study) | Laying Hens (VERA Test Protocol) | |

|---|---|---|

| Permitted weight range (kg) | 1.8 | - |

| Minimal period of use of the housing system | More than 2 months | 2 months |

| Feed requirements’ crude protein (CP) | 16–18% CP | DK: 16–18% CP DE: 15–20% CP |

| Minimum number of animals | 4000 | 750 |

| Classification | NH3 (ppm) | n | Operation | ||

|---|---|---|---|---|---|

| In | Out | ||||

| 1st | Mean | 5.60 | 0.46 | 41 | Closed operation of the winch curtain |

| Max | 9.59 | 0.49 | |||

| Min | 3.22 | 0.24 | |||

| 2nd | Mean | 0.20 | 0.17 | 32 | Open operation of the winch curtain |

| Max | 0.33 | 0.30 | |||

| Min | 0.10 | 0.08 | |||

| 3rd | Mean | 0.70 | 0.31 | 43 | Intermittent operation of the winch curtain |

| Max | 1.72 | 0.62 | |||

| Min | 0.27 | 0.17 | |||

| Mean | 2.36 | 0.38 | |||

| Max | 9.59 | 0.62 | |||

| Min | 0.10 | 0.08 | |||

| Classification | CO2 (ppm) | n | Operation | ||

|---|---|---|---|---|---|

| In | Out | ||||

| 1st | Mean | 746.09 | 457.66 | 41 | Closed operation of the winch curtain |

| Max | 967.47 | 471.65 | |||

| Min | 534.60 | 438.25 | |||

| 2nd | Mean | 487.50 | 396.52 | 32 | Open operation of the winch curtain |

| Max | 577.13 | 421.00 | |||

| Min | 434.00 | 369.00 | |||

| 3rd | Mean | 494.08 | 427.04 | 43 | Intermittent operation of the winch curtain |

| Max | 634.50 | 478.25 | |||

| Min | 494.08 | 345.33 | |||

| Mean | 709.22 | 427.07 | - | ||

| Max | 967.47 | 471.65 | |||

| Min | 434.40 | 369.00 | |||

| Classification | NH3 Emission Factor (kgNH3/Year/AP) | Operation |

|---|---|---|

| 1st | 0.44 | Closed operation of the winch curtain |

| 2nd | 0.01 | Open operation of the winch curtain |

| 3rd | 0.19 | Intermittent operation of the winch curtain |

| Mean | 0.31 | - |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kang, S.; Jeon, E.-c.; Lee, S. A Study on the Application of an Estimated Ammonia Emission Factor Reflecting the Operating Characteristics of Open Laying Hen Houses in Korea. Atmosphere 2025, 16, 581. https://doi.org/10.3390/atmos16050581

Kang S, Jeon E-c, Lee S. A Study on the Application of an Estimated Ammonia Emission Factor Reflecting the Operating Characteristics of Open Laying Hen Houses in Korea. Atmosphere. 2025; 16(5):581. https://doi.org/10.3390/atmos16050581

Chicago/Turabian StyleKang, Seongmin, Eui-chan Jeon, and Sihyoung Lee. 2025. "A Study on the Application of an Estimated Ammonia Emission Factor Reflecting the Operating Characteristics of Open Laying Hen Houses in Korea" Atmosphere 16, no. 5: 581. https://doi.org/10.3390/atmos16050581

APA StyleKang, S., Jeon, E.-c., & Lee, S. (2025). A Study on the Application of an Estimated Ammonia Emission Factor Reflecting the Operating Characteristics of Open Laying Hen Houses in Korea. Atmosphere, 16(5), 581. https://doi.org/10.3390/atmos16050581