3.2. Emission Level and Gradient for SHED Test Procedure

To achieve an appropriate emission mass level and gradient for the SHED test procedure, data from engine SHED measurements were used as a starting point.

In a previous study, different HC traps were tested on one engine. To obtain a constant emission level from the AIS path, an engine with very low emissions originating from this source was selected. Before each SHED measurement, a specific amount of LEV III test fuel was injected into its intake manifold. This procedure resulted in an increased total emission mass, due to a higher contribution from the AIS pathway. Several data sets with different setups were available for this engine. Consequently, it was possible to calculate the emission mass emitted from the AIS path by subtracting the emission mass of the engine with prevented AIS emissions (AIS connected to SHED outlet) from the results including the AIS pathway.

Figure 7 shows the calculated emission mass of the AIS path for this engine. Due to our typical measurement procedure for engines (FTP75—1 h Hot Soak—6 h Soak—16 h Diurnal Soak), data are only available for a period of 16 h.

The calculated data for the emission mass from the AIS showed an almost linear increase.

The next step was to find suitable parameters for the AIS component test rig to achieve similar qualitative (gradient of emission mass) and quantitative results (emission mass level) in the SHED test procedure. Different options for fuel reservoir (reservoir volume, amount of injected fuel, position of the reservoir) and different orifices were tested using varying stainless steel tubes (inner diameter: 3 mm, 6 mm, 8 mm, 12 mm diameter; length between 2.5 cm and 10 cm). The length of the elongated AIS path, which consisted of vacuum parts, was also varied.

Figure 8 shows the results of four different configurations. Configuration test rig AIS #4 achieved very good agreement with the data from the engine measurements. This configuration became the default setting, and further variations in the emission mass level were made only by changing the injected fuel volume.

Table 1 summarizes the parameters of the different configurations.

3.4. First Measurements of HC Traps, Comparison to Engine Measurements

Three different types of HC traps were investigated. Sample A was a cross-flow type HC trap, a non-woven fabric containing activated carbon. Sample B was a bypass-type, teabag-style HC trap. Samples C and D were also bypass-type traps, both containing carbon paper attached directly to the surface of the upper part of the air filter box. Sample C had a larger amount (or surface area) of carbon paper, as it covers an additional area compared to Sample D.

Figure 10 shows photos of all four samples.

Table 3 presents the results for these four samples and for the measurements without an HC trap.

As expected, the cross-flow HC trap (Sample A) resulted in quite low emission masses, with a mean value of 4.3 mg. Sample B, the teabag-style HC trap, resulted in considerably higher emission masses, with a mean value of 18.5 mg. Samples C and D provided mean emission masses of 14.9 mg and 15.8 mg, respectively. The difference between these two samples correlated with their amount (or surface area) of carbon paper.

For all four samples, the efficiencies were calculated using Equation (1):

where m

noTrap is the mean value for the emission mass without HC trap, and m

sampleX is the mean value for each sample (A to D).

Table 4 shows the results. Similar measurements were performed with all four samples using an engine (4 cylinder, 1998 cm

3). The efficiencies were calculated according to the same principle.

Considering relative measurement uncertainties of about 5% to 10%, the agreement between the efficiencies determined by the AIS component test rig and those determined using the engine is quite good. This applies to both kinds of HC traps, cross-flow and bypass.

In conclusion, the AIS component test rig provides reasonable results for determining the efficiency of HC traps and is suitable for investigating different types of traps: cross-flow and bypass.

3.5. Further Measurement of HC Traps, Repeatability, and Varying Emission Mass

Two other HC traps, samples E1 and E2, were selected for further measurements. Both belong to a different AIS, so the component test rig was assembled with these parts. For confidentiality reasons, no pictures can be shown. In principle, the setup is comparable to the one shown in

Figure 2. E1 and E2 were bypass-type HC traps containing carbon paper. The only difference between the two samples was the surface area of the carbon paper. Sample E1 has the entire lid surface covered (similar to sample C, but in one piece). Sample E2 was identical but included an additional sheet of carbon paper on one side of the upper part of the air filter box. Thus, the surface area of the carbon paper was about 122% compared to sample E1. The carbon papers were directly attached to the lid surface by ultrasonic welding at several points.

For the first measurements, 200 µL LEV III test fuel was used again. A total of 17 measurements were performed without an HC trap (see

Table 5). Experiments #1 to #11 took place within one month, while experiments #12 to #17 were conducted about one month later over two weeks. The mean values and standard deviations were 31.5 mg ± 1.3 mg and 28.5 mg ± 1.2 mg, respectively. The overall mean value was 30.2 mg with a standard deviation of 2.2 mg. These data indicate that repeatability is significantly better within shorter time periods.

Measurements of the HC traps E1 and E2 were performed in between experiments #11 and #12 using the same setup. Results are summarized in

Table 6.

The efficiencies of E1 and E2 were calculated using their mean emission mass and the mean emission mass of all 17 measurements without an HC trap, according to Equation (1). The results were 66% and 79% for E1 and E2, respectively. Both HC traps were also tested on the engine, yielding results of 61% (E1) and 69% (E2). While the values for E1 agreed quite well, the deviation for E2 was larger. It is also interesting to note that the efficiencies determined with the AIS test rig for these two HC traps were higher than those determined on the engine. For samples A to D, it was vice versa.

For the next experiments, the emission mass level was varied to observe any influence on the determined efficiencies. As mentioned previously, the test rig setup was kept unchanged, but the volume of LEV III test fuel was adjusted. A lower emission mass level was achieved by reducing the volume to 100 µL, and a higher emission mass level by increasing the volume to 300 µL. The emission mass decreased to about 17 mg for the lower fuel volume and increased to about 40 mg for the higher fuel volume. According to our knowledge, this is a reasonable range for modern engines.

Table 7 summarizes the results of the measurements for the volume of 100 µL LEV III test fuel, and

Table 8 shows the results for a fuel volume of 300 µL.

Again, the efficiencies for HC traps E1 and E2 were calculated using Equation (1). For a fuel volume of 100 µL, values of 67% and 76% were obtained. For a volume of 300 µL, the efficiencies were 69% for E1 and 74% for E2. A more detailed discussion of these results is given after checking repeatability.

Most of the measurements shown in this section were repeated several times to evaluate repeatability and assess the uncertainty of the results. The highest number of repetitions was performed for the measurement with a volume of 200 µL fuel and no HC trap. As mentioned previously, there may be a small difference between measurements number #1 to #11 (first time period) and #12 to #17 (second time period), but for further consideration, only the mean and standard deviation of all values, 30.2 mg and 2.2 mg, were used.

Table 9 shows all mean values and standard deviations of the different scenarios sorted by their total number of measurements. The relative standard deviations are also presented in this table, ranging from 3% to 11%, with most values at 6% or 7%.

Based on these data, the uncertainty of this type of measurement was assessed to be about 7%.

The standard deviations for the different scenarios presented in

Table 9 were further used to calculate the uncertainties for the determined efficiencies of the HC traps. The diagram in

Figure 11 shows the results.

Obviously, the uncertainties in relation to the differences in efficiencies for the three scenarios were quite large. For HC trap E1, the efficiencies were 67% ± 7%, 66% ± 6%, and 69% ± 6% for 100 µL, 200 µL, and 300 µL of test fuel, respectively. Considering the uncertainties, it was not possible to identify any differences between the efficiencies for the three scenarios.

For HC trap E2, the result was comparable. The efficiencies were 76% ± 6%, 79% ± 7%, and 74% ± 9% (100 µL, 200 µL, and 300 µL). Again, it was not possible to determine differences in the efficiencies for varying test fuel volumes.

Altogether, the efficiency of at least these two HC traps seemed to be independent of the emission mass level. However, it should be noted that the emission mass varied in a range from about 17 mg (100 µL test fuel) to about 40 mg (300 µL). For higher values, it might be different.

Results also indicate that comparing HC traps with quite similar efficiencies is challenging. On the one hand, all three scenarios resulted in lower efficiencies for HC trap E1. This correlated with the area of carbon paper. HC trap E2 contained a surface area of carbon paper of about 122% compared to E1. Therefore, higher efficiencies were expected for E2. On the other hand, the uncertainties of the data were so high that this difference could not be clearly revealed.

3.6. HC Measurements within the Air Filter Box

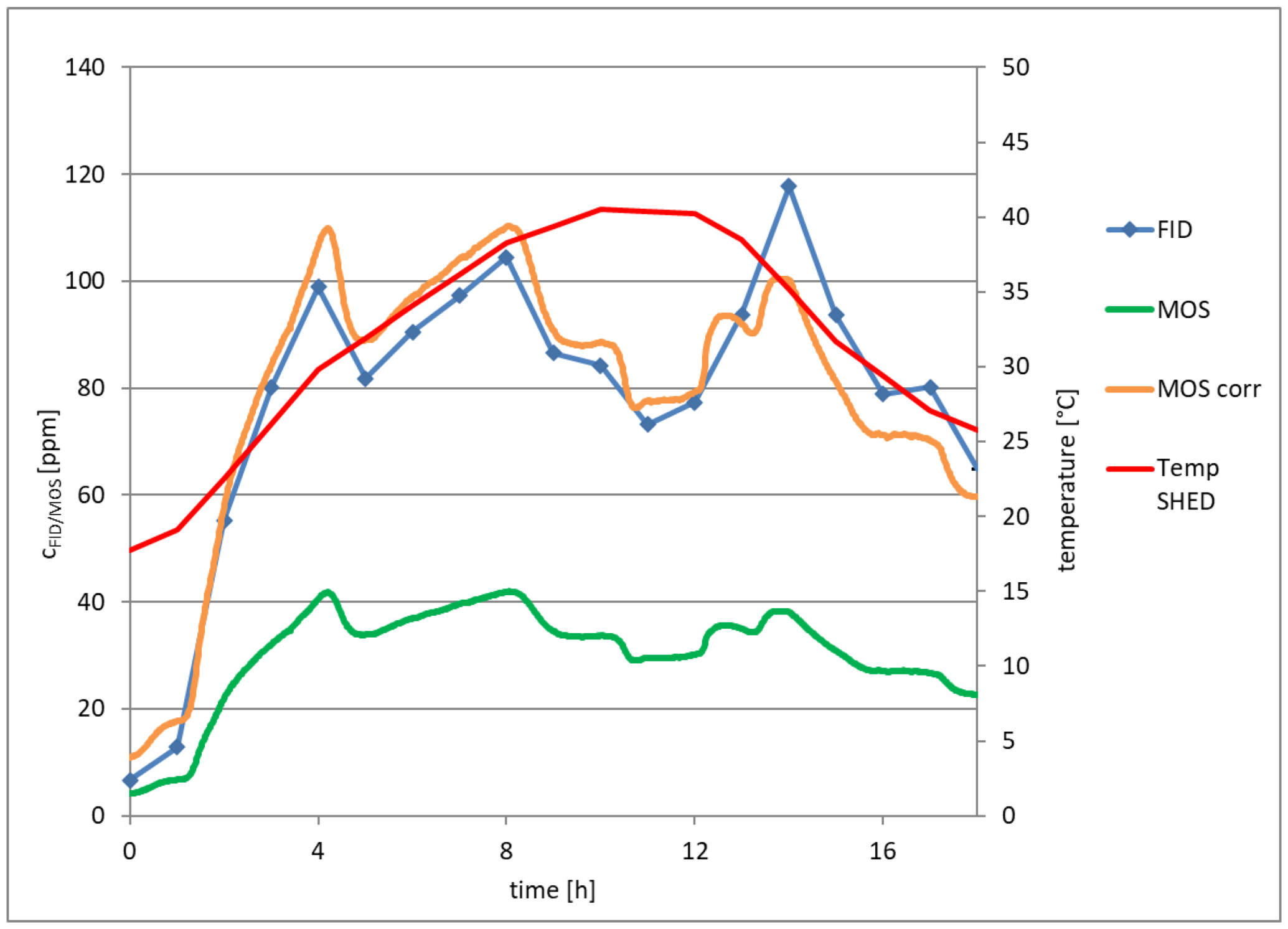

In many experiments, the HC concentration was measured not only in the SHED system but also in the clean air section of the air filter box. This was performed by MOS sensor and/or point source FID sampling. As mentioned in the method section, only FID data provided meaningful absolute values. MOS sensor data were solely for verifying qualitative changes in the HC concentration.

Figure 12 shows all measurements with a 200 µL test fuel volume. As expected, experiments without an HC trap exhibited the highest HC concentrations, typically above 60 ppm, with a maximum of around 120 ppm. Only at the beginning of an experiment, the HC concentration was lower. The results for measurements with HC traps E1 and E2 were significantly lower. The maximum value for E1 was about 20 ppm, and for E2, it was about 15 ppm. Values for experiments without an HC trap were quite unsteady. In contrast, the data with HC traps showed a more uniform gradient.

Figure 13 presents the recorded data for the MOS sensor measurements. As mentioned in the method section, the quantitative information of the basic MOS sensor data is poor. Thus, only a qualitative comparison with the FID values shown in

Figure 12 was meaningful. In principle, the agreement between FID and MOS sensor data was quite good. Only the maximum values for measurements without an HC trap at approximately 15 h seemed to be significantly increased for the FID data. Furthermore, some measurements without an HC trap (#6, #7, #8) were conducted using the MOS sensor but without FID sampling. The trends of these measurements did not differ considerably from those with additional FID sampling. Thus, FID sampling seemed to have no detectable effect on the measured HC concentrations.

The data for experiments with 100 µL and 300 µL test fuel volumes were qualitatively identical, differing only in absolute values.

Moreover, a correlation was identified between the HC concentrations determined in the air filter box by FID sampling and the resulting emission mass within the SHED. The arithmetic mean of all HC concentrations measured in the air filter box (time period 0–16 h) was calculated for each experiment.

Figure 14 shows these values plotted against the corresponding SHED test result (emission mass [mg]). Overall, it appears to be a linear correlation. However, most data of the experiments shown in

Figure 14 were without an HC trap, especially for emission masses above 20 mg. Data from measurements with HC trap were limited to HC traps E1 and E2 and a corresponding emission mass level below 20 mg. Considering this, a linear correlation was evident for experiments without an HC trap. For experiments with HC traps E1 and E2, the correlation was not as clear, but the trend appeared to be analogous.

This correlation might be useful for SHED tests of entire vehicles. Additional point source measurement within the air intake system could indicate whether there is an elevated contribution of the AIS pathway. This information may help to localize specific failures (e.g., leaky injector(s), problems with crankcase ventilation) in case of an increased result for the entire vehicle.