Abstract

In order to study the influence of typical coal-fired flue gas components on the supersaturation characteristics in a multisection growth tube, a two-dimensional heat and mass transfer model was used to predict the supersaturation profiles formed by the cool saturated flow into a warm-walled growth tube (Method 1) and the warm saturated flow into a cold-walled growth tube (Method 2). The calculated results show that the increase in the concentration of the three typical components CO2, SO2, and RH (relative humidity) of the flue gas is beneficial for the achievement of the supersaturated environment in Method 1. Additionally, having too many sections of the growth tube has a disadvantage in achieving the supersaturation profiles. When the content of the gas of lower Le is higher, having more sections of the growth tube is beneficial to achieving a supersaturated environment, while a lower number of sections is necessary when the gas content is lower in Method 2. In a word, the appropriate number of sections in a growth tube is significantly important for the achievement of a favorable supersaturated environment.

1. Introduction

Currently, coal burning is the main source of fine particulate matter pollution in China’s ambient air [1,2]. And the PM2.5 of coal-fired emission can not only lead to serious environmental problems such as haze and sand dust, but also result in great harm to human health [3,4]. Therefore, the effective control of fine particles provides significant support for achieving green and low-carbon development. However, traditional dust removal devices have very low removal efficiency for fine particles with a size of 0.1–1 µm [5]. Then, new dust removal technology must be developed and adopted to enhance the removal efficiency for the effective control of coal-fired fine particles. At present, the pretreatment technology of turning fine particles into a larger-sized ones before they enter traditional dust removal equipment is an important route for effective removal [6]. Specifically, particle pretreatment technology mainly includes sound agglomeration [7], electric agglomeration [8], chemical agglomeration [9], and water vapor condensation [10]. It is such a widespread concern and so widely applied that water vapor phase transformation technology has simple devices and obvious particle growth [11,12].

In the process of vapor condensation, which has appeared widely in atmospheric science, fine particles act as the condensation nuclei [13]. And once the degree of supersaturation around them exceeds the critical value, nucleation will occur and the vapor around them will begin to condense on the surfaces of the particles, causing growth [14]. Moreover, it is worth noting that the factor of supersaturation is a great influence on particle enlargement. And the growth of fine particles is exponentially related to the degree of supersaturation on the basis of the classical nucleation theory [15].

At present, there are two supersaturation construction methods widely used in experimental research [16,17]. One is the contact between a low-temperature saturated flue gas and a high-temperature liquid (Method 1). The other is a high-temperature gas meeting with a low-temperature liquid (Method 2). The experimental results demonstrated a significant relationship between the degree of supersaturation and fine-particle growth [18,19]. Thus, it is very important to achieve an efficient supersaturated environment for the excellent growth of fine particles.

Some research work has shown that having more sections is beneficial for the achievement of a supersaturated environment compared with a one-section growth tube [20]. Simulated and experimental results have demonstrated that having the appropriate number of sections is an effective method for the achievement of a better supersaturated environment and particle growth [21]. Moreover, the heat and mass transfer model with variable physical parameters has been utilized to discuss the influence of the growth tube length, the temperature difference, and different methods to achieve a supersaturated environment in a multisection growth tube [22]. It indicates that the supersaturation characteristics in a growth tube are closely related to the number of sections and the component of carrier gas with different supersaturation-achieving methods. In fact, coal-fired flue gas is composed of a variety of single-component gases and the main components are CO2, SO2, H2O, O2, and N2. For the net flue gas of coal-fired plants after desulfurization, the content of CO2 is about 15%, SO2 is about 0.1%, and the relative humidity (RH) is approaching 100% [23]. Furthermore, the burning of coal in pure oxygen is named oxy-fuel combustion, and the CO2 concentration in a carbon-dioxide-rich stream is even more than 90% [24].

Some research work has demonstrated that carrier gases of different Lewis number (Le) values have great effects on achieving supersaturation through heterogeneous condensation. This means that a carrier gas of different values of Le would affect the heat and mass transfer process through vapor condensation. Then, a differentiated supersaturated environment would be presented in the growth tube. Furthermore, it has been demonstrated that the characteristics of particle growth would ultimately be influenced by the different components of the carrier gas [25,26], and the experimental and predicted results showed that, in a helium atmosphere, the particle growth rate is faster and the final particle diameter is larger, compared with the atmosphere of argon [27]. It is noted that, if the supersaturated environment is strongly affected, then the final particle growth is powerfully influenced by the carrier gas. In addition, the effects of the main components of coal-fired flue gas after desulfurization on the achievement of a supersaturated environment and condensational growth for SiO2 particles by water vapor were analyzed in a two-section growth tube (TGT) [28]. In detail, the mean supersaturation of the whole growth tube could be improved by 17.17% and the arithmetic mean size of the grown particles was increased by 19.05% when the content of CO2 increased from 10% to 50% in the TGT. It was concluded that the coal-fired flue gas composition has a great influence on the supersaturated environment and condensational growth using different supersaturation-achieving methods. To sum up, number of sections of the growth tube, the carrier gas components, and the supersaturation-achieving methods are vital for a favorable supersaturated environment and particle enlargement. However, the relevant research of different flue gas components affecting the supersaturated environment characteristics in a multisection growth tube is lacking.

In our work, the effect of the main components of coal-fired flue gas after desulfurization on the achievement of a supersaturated environment in a multisection growth tube is presented. In fact, the typical components of CO2, SO2, and RH (relative humidity) are discussed. And the atmosphere of N2 as compared to the carrier gas is analyzed for discussion. Meanwhile, the different supersaturation achievement methods of heating or cooling the flow are also considered. Furthermore, the results will favor satisfactory fine-particle growth and an improvement in fine-particle removal efficiency in dust-cleaning devices.

2. Theoretical Model and Analysis Method

2.1. Model of a Multisection Growth Tube

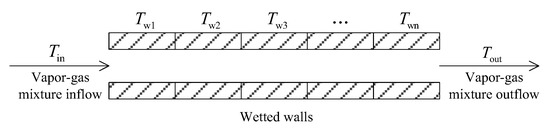

Figure 1 shows the model of a multisection growth tube. In order to study the distribution characteristics of supersaturation in the multisection growth tube, the growth tube with length L was divided into equivalent sections of n and the wall temperatures of each section were Tw1, Tw2, Tw3 …, and so on. On account of previous research [28,29], the radius of the growth tube was 7.5 mm and the whole length was 800 mm. The inlet temperature of vapor–gas flow was Tin, and the flow rate was 3.5 L/min. Moreover, the temperature difference of each section was linear, i.e., .

Figure 1.

Model of multisection growth tube.

2.2. Construction of a Supersaturated Environment using Two Typical Methods

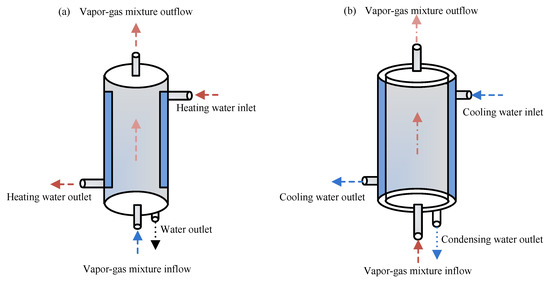

The multisection growth tube was used to construct a supersaturated environment via different supersaturation-achieving methods, as presented in Figure 2. Figure 2a shows Method 1 of a cool saturated flow meeting with a warm-walled growth tube, i.e., . For Method 1, the setting value of temperature was Tin = 298 K, Tw1 = 323 K, and Twn = 343 K. Additionally, a warm saturated flow into a cold-walled growth tube for Method 2 is presented in Figure 2b, i.e., . Correspondingly, the setting value of temperature was Tin = 343 K, Tw1 = 323 K, and Twn = 298 K for Method 2. The corresponding experiments have been carried out in some research work [16,17,21,28]. And the carrier gas of air, 100% RH air, and coal-fired flue gas were all adopted in the experiments. Meanwhile, the experimental results could verify the feasibility of two typical supersaturation-achieving methods.

Figure 2.

Construction of supersaturated environment using two typical methods.

2.3. Model of Heat and Mass Transfer Process

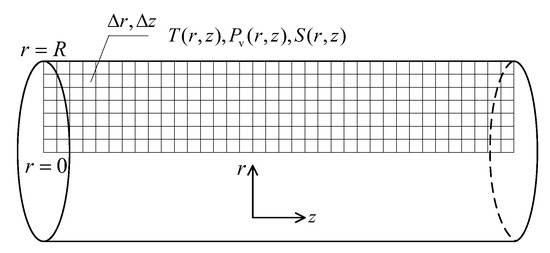

The supersaturation profiles of the multisection growth tube were calculated using the finite element analysis method. Firstly, the growth tube was regarded as a two-dimensional domain considering the tube half-plane because of the axial symmetry of the growth tube, as illustrated in Figure 3. The domain of the growth tube was divided into numerous cells (X × Y) that were defined as X radial and Y axial space intervals of size Δr and Δz. In each finite mesh, the values of vapor–gas flow temperature T(r, z) and water vapor partial pressure Pv(r, z) needed to be obtained. Some research works have shown simulated methods of temperature fields [30,31].

Figure 3.

Gridding of the multisection growth tube.

In our work, the two-dimensional heat and mass transfer model was adopted for describing the process of heat and mass transfer. For the cylindrical geometry, the values of the vapor–gas flow temperature, T, throughout the growth tube were obtained using the solution of the following partial differential equation.

where r and z are the radial and axial coordinates, respectively; R is the tube radius, m; U is the average velocity of the gaseous mixture, m/s; and αt is the thermal diffusivity coefficient, m2/s. Analogously, the water vapor partial pressure was determined using the following equation:

In Equation (2), αv is the mass diffusivity coefficient, m2/s. And then, the temperature of the vapor–gas flow and water vapor partial pressure in each position of the multisection growth tube can be calculated using this model. According to these data, the degree of supersaturation, S, can be obtained. S is defined as the ratio of water vapor partial pressure Pv (Pa) to its equilibrium vapor pressure Psat,T (Pa) at the vapor–gas flow temperature T (K) described in the following formula.

Additionally, the influence of the major composition of coal-fired flue gas was considered for simulation. In accordance with research work [23] and the object (the net flue gas of coal-fired plants after desulfurization), the content range of CO2, SO2, and RH was chosen as 10–50%, 0.1–5%, and 50–120%, respectively. It can be seen the range discussed is wide on account of the significant variability in the predicted results and the generalizability of the conclusion. Moreover, it means that different components of the coal-fired flue gas correspond to the different values of the thermal and mass diffusivity coefficients. Additionally, the definition of Le is the ratio of the thermal diffusivity coefficient to the mass diffusivity coefficient to describe the relative process of heat and mass transfer. Of course, the effect of the components of coal-fired flue gas with a lower concentration, such as NO2, on the supersaturation achievement was neglected in the research work. And the variation in the vapor–gas flow rate was also not considered. Further work will consider the potential impact of other factors.

3. Results and Discussion

3.1. The Effects of Different CO2 Concentrations on Supersaturation Profiles in Method 1

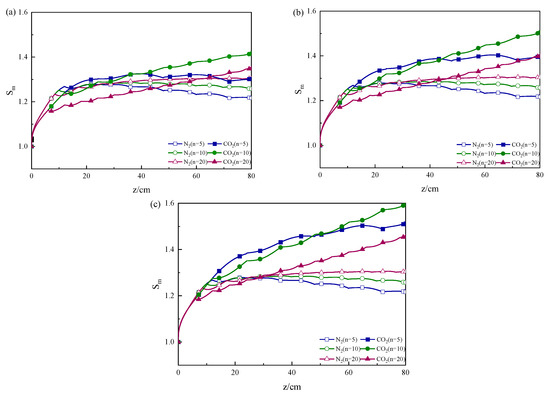

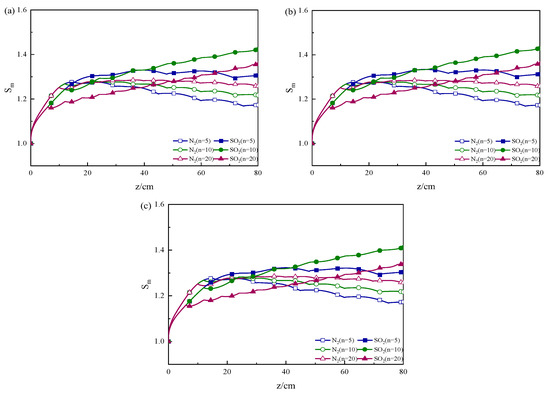

As we can see, Figure 4 provides the distribution of the mean supersaturation at different radial directions in the multisection growth tube with different CO2 concentrations in the flue gas and the conditions of section number (5, 10, and 20), with N2 as a comparison. Extensive studies of supersaturation profiles have been carried out in the field of heat and mass transfer. In our research work, the tendency of supersaturation is in accordance with other research work [16,19,22]. Moreover, the option of the working fluid, the carrier gas, the temperatures of vapor–gas flow and the tube wall, and so on would affect the supersaturated environment strongly, leading to a difference in supersaturation values in the literature. Additionally, the content of CO2 was 10%, 30%, and 50%, as shown in Figure 4a–c. It is obvious that the level of supersaturation improved with the increase in CO2 content. That is because the thermal and mass diffusion coefficients both decreased when the CO2 content increased, as reported in previous research [22]. That is because the Lewis number of CO2 is less than one, indicating relatively slower heat transfer and faster water vapor diffusion. Then, the water vapor diffusion was faster, resulting in a more supersaturated environment when the content of CO2 was increased by heating the flow. Moreover, the mass diffusion coefficient decreased slowly compared with the thermal diffusion coefficient [22].

Figure 4.

Supersaturation profiles with different CO2 concentrations in Method 1. (a–c) represent CO2 concentrations of 10%, 30%, and 50%, respectively.

Meanwhile, it can be seen that the optimum section number is existed compared with the carrier gas of N2. It is clear that the level of supersaturation and uniformity was promoted with the increase in section number under the condition of N2. There was a large difference in that the increase rate was faster at the early stage when the section number increased due to the condition of different CO2 concentrations in the flue gas. And when the section number was large, the increase rate and the overall supersaturation level were obviously reduced. That is mainly because a higher number of sections could result in a lower temperature in each section and a temperature difference between both sections. And the decrease in thermal and mass diffusion coefficients is not beneficial to the process of the heat and mass transfer of water vapor. Additionally, the condition of temperature resulting from the enhanced section number could strongly go against the process of the heat and mass transfer of water vapor. Furthermore, it could be inferred that the optimum section number is between 5 and 10 for a favorable supersaturated environment of coal-fired flue gas.

3.2. The Effects of Different SO2 Concentrations on Supersaturation Profiles in Method 1

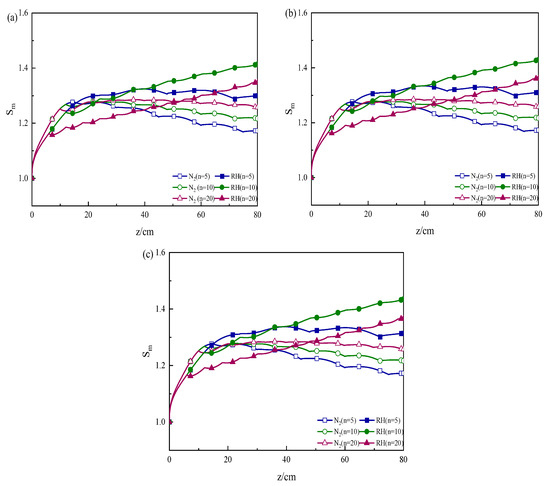

Figure 5 gives the distribution of the mean supersaturation at different radial directions in the multisection growth tube with different SO2 concentrations in the flue gas. Additionally, the condition of section number was 5, 10, and 20, with N2 as a comparison. And the content of SO2 was 0.1%, 1%, and 5% as illustrated in Figure 5a–c.

Figure 5.

Supersaturation profiles with different SO2 concentrations in Method 1. (a–c) represent SO2 concentration of 0.1%, 1%, and 5%, respectively.

It is obvious that there was a similar trend in the supersaturated environment with different SO2 concentrations in the flue gas under the conditions of different section numbers to that with the condition of different CO2 concentrations. That is because the carrier gases of CO2 and SO2 have a similar Lewis number (Le), resulting in equal processes of heat and mass transfer [22]. It is known that the Lewis numbers of CO2 and SO2 are 0.49 and 0.34 at 298 K, respectively. Meanwhile, a lower value of Le of a gas would lead to a more rapid mass diffusion of water vapor relative to heat transfer [22]. In the same conditions, a faster increase rate would be presented when the content of the lower value of Le of a gas is more.

3.3. The Effects of Different RH on Supersaturation Profiles in Method 1

Figure 6 shows the distribution of the mean supersaturation at different radial directions in the multisection growth tube with different RH concentrations of flue gas. Additionally, the condition of section number was 5, 10, and 20, with N2 as a comparison. And the content of RH was 50%, 100%, and 120%, as reported in Figure 6a–c.

Figure 6.

Supersaturation profiles with different relative humidity (RH) in Method 1. (a–c) represent relative humidity of 50%, 100%, and 120%, respectively.

It can be seen that the level of supersaturation slightly improved with the increase in RH content. That is mainly because the thermal diffusion coefficient decreased while the mass diffusion coefficient increased when the content of RH improved [28]. Similarly, it can be seen that the optimum section number existed compared with the carrier gas of N2. And having too many sections in the growth tube was not beneficial to the level of supersaturation and the uniformity of the supersaturated environment in the growth tube.

Table 1 presents the overall mean supersaturation in the multisection growth tube with different concentrations of CO2, SO2, and RH in the flue gas under the condition of different numbers of sections. It is clear that the supersaturation level was promoted with the increase in the content of CO2 and RH. However, the supersaturation level reduced when the content of SO2 was higher. That is due to the more rapid reduction in the mass diffusion coefficient when the SO2 concentration was higher, while the process of mass transfer played an important role in the method of heating the flow.

Table 1.

Mean value of saturation ratio of the whole multisection growth tube in Method 1.

It was calculated that the decrease in the overall mean supersaturation was 4.30%, 6.09%, and 7.52% when the number of sections increased from 10 to 20 with the increase in content of CO2 from 10% to 50%, respectively. And the reduction was 4.30%, 4.44%, and 4.58% when the section number increased from 10 to 20 with the increase in content of SO2 from 0.1% to 5%, respectively. Moreover, there was little difference in the supersaturation decline with a content of RH from 50% to 120% when the number of sections increased from 10 to 20. And the decline was about 4.3%. Hence, it can be inferred that too many sections in a growth tube has a disadvantage in achieving a supersaturated environment. The appropriate number of sections in a growth tube is significantly important for the achieving a favorable supersaturated environment.

3.4. Effects of Different CO2 Concentration on Supersaturation Profiles in Method 2

According to the previous research [22,28] and the above discussion, it can be seen that the content of CO2 and SO2 in the flue gas had an obvious effect on the achievement of the supersaturated environment. On account of the low content of RH, the effect on the supersaturation was not evident. In the following, the influence of CO2 and SO2 concentration on the supersaturation profiles in Method 2 will be discussed.

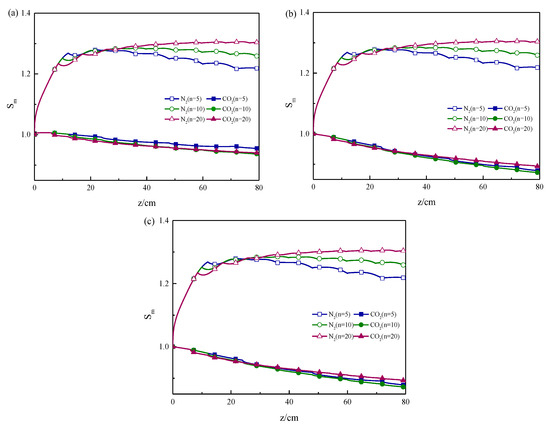

In Figure 7, the distribution of the mean supersaturation at different radial directions in the multisection growth tube with different CO2 concentrations in the flue gas is presented. And the condition of section number was 5, 10, and 20, with N2 as a comparison. Additionally, the content of CO2 was 10%, 30%, and 50%, as shown in Figure 7a–c. It could be concluded that the increased content of CO2 had a disadvantage in achieving supersaturation in Method 2. That is due to the Lewis number of CO2 being less than one, indicating relatively slower heat transfer and faster water vapor diffusion. Then, the process of cooling the vapor–gas flow is slower, resulting in a less supersaturated environment when the content of CO2 is higher due to the cooling of the flow.

Figure 7.

Supersaturation profiles with different CO2 concentration in Method 2. (a–c) represent CO2 concentration of 10%, 30%, and 50%, respectively.

And a smaller number of sections is necessary for a favorable supersaturated environment under the condition of lower CO2 concentration in the flue gas, as illustrated in Figure 7a. Moreover, an increase in the number of sections would be beneficial for supersaturation improvement, especially at the latter stage of the growth tube where the content of CO2 is higher, as seen from Figure 7b,c. It can be explained by the fact that water vapor condensation from the flow to the wall is quick, but the decline in the flow temperature is very slow, resulting in a fast decrease in the water vapor partial pressure and a slow decrease in the equilibrium vapor pressure leading to the poor supersaturated environment. When the CO2 concentration in the flue gas is lower, the thermal and mass diffusion coefficients are not very low. This means that the flow temperature would have the advantage of being declined strongly under the condition of a smaller number of sections, contributing to the achievement of supersaturation. As we all know, an obvious reduction in thermal and mass diffusion coefficients is presented with an increase in CO2 concentration. When the CO2 concentration of a flue gas is higher, the water vapor partial pressure is being decreased more slowly under the condition of more sections.

3.5. The Effects of Different SO2 Concentration on Supersaturation Profiles in Method 2

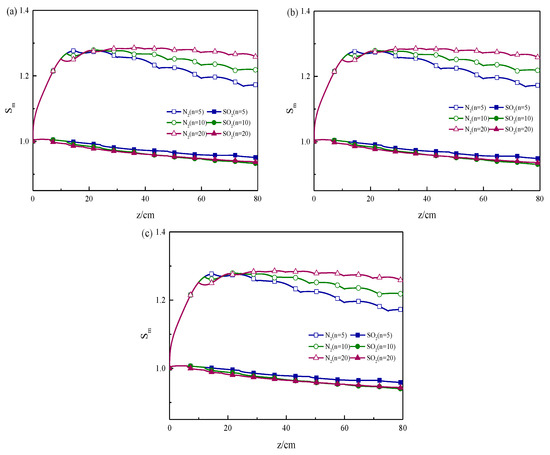

Figure 8 shows the distribution of the mean supersaturation at different radial directions in the multisection growth tube with different SO2 concentrations in the flue gas. Additionally, the condition of section number was 5, 10, and 20, with N2 as a comparison. And the content of SO2 was 0.1%, 1%, and 5%, as illustrated in Figure 8a–c.

Figure 8.

Supersaturation profiles with different SO2 concentration in Method 2. (a–c) represent SO2 concentration of 10%, 30%, and 50%, respectively.

It is worth noting that an obvious disadvantage in achieving the supersaturated environment was presented in Method 2 under the condition of different SO2 concentrations in the flue gas. And a smaller section number was necessary for a favorable supersaturated environment under the condition of a SO2 concentration from 0.1% to 5%. A similar trend was presented under the condition of the lower content of CO2, as shown in Figure 7a. That is because the flow temperature would favor being declined faster under the condition of fewer sections, leading to the achievement of a supersaturated environment.

As can be seen from Table 2, cooling the flow was not beneficial to achieving the supersaturated environment with the increase in CO2 and SO2 concentration in the flue gas. According to the calculation, the increase in the overall mean supersaturation was 0.02%, 1.52%, and 1.52% when the number of sections increased from 10 to 20 with the content of CO2 from 10% to 50%, respectively. And the improvement was 0.08%, 13.7%, and −0.02% when the number of sections increased from 10 to 20 with the content of SO2 from 0.1% to 5%, respectively. On the basis of the previous research [22], the Lewis numbers of CO2 and SO2 are 0.49 and 0.34 at 298 K, respectively. This means that CO2 would have the advantage in supersaturation achievement compared with SO2 in Method 2. It can be inferred that when the content of CO2 or SO2 is higher, a larger number of sections is beneficial to the supersaturation achievement, while a smaller number of sections is necessary when the content of CO2 and SO2 is lower from cooling the flow. Meanwhile, because the content of gas of a lower Le is too high, too many sections in the growth tube would have a disadvantage in supersaturation achievement using Method 2.

Table 2.

Mean value of saturation ratio of the whole multisection growth tube in Method 2.

4. Conclusions

The effects of coal-fired flue gas composition on the supersaturated environment in a multisection growth tube using two methods to achieve supersaturation were investigated. Meanwhile, the typical components of coal-fired flue gas (CO2, SO2, and RH) were discussed, and the numbers of sections in the growth tube which were considered were 5, 10, and 20. It was found that the supersaturation level was improved with increased contents of CO2 and RH from heating the flow. However, the supersaturation level was reduced when the content of SO2 was higher. Moreover, the overall mean supersaturation was promoted at first and then declined when the number of growth tube sections increased from 5 to 20 by heating the flow. Additionally, an increase in the number of growth tube sections would have an advantage in achieving an improvement in supersaturation when the CO2 and SO2 concentrations are higher from cooling the flow. However, a smaller number growth tube sections is necessary when the concentration of CO2 or SO2 is lower. This work will be helpful for optimizing the design of industrial devices for coal-fired fine-particle pretreatment. Meanwhile, it will be beneficial for the performance of enlarging fine particles and of fine-particle removal efficiency.

Author Contributions

Writing—original draft, funding acquisition, Y.Y.; software, S.G.; writing—review and editing, C.X.; formal analysis, C.F.; data curation, M.H. and T.N.; validation, Y.H. All authors have read and agreed to the published version of the manuscript.

Funding

This work was supported by the Science and Technology Project of Hebei Education Department (grant number QN2020243), the Science Foundation of Hebei Normal University (grant number L2020B27), and the Shijiazhuang Science and Technology Plan Project (grant number 221790441).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Research data from this study will be made available on request from the corresponding author.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Ruan, R.; Xu, X.; Tan, H.; Zhang, S.; Lu, X.; Zhang, P.; Han, R.; Xiong, X. Emission characteristics of particulate matter from two ultralow-emission coal-fired industrial boilers in Xi’an, China. Energy Fuels 2019, 33, 1944–1954. [Google Scholar]

- Xue, Y.; Tian, H.; Yan, J.; Zhou, Z.; Wang, J.; Nie, L.; Pan, T.; Zhou, J.; Hua, S.; Wang, Y.; et al. Temporal trends and spatial variation characteristics of primary air pollutants emissions from coal-fired industrial boilers in Beijing, China. Environ. Pollut. 2016, 213, 717–726. [Google Scholar] [PubMed]

- Chen, S.; Li, Y.; Shi, G.; Zhu, Y. Gone with the wind? Emissions of neighboring coal-fired power plants and local public health in China. China Econ. Rev. 2021, 69, 101660. [Google Scholar]

- Kushta, J.; Paisi, N.; Van Der Gon, H.D.; Lelieveld, J. Disease burden and excess mortality from coal-fired power plant emissions in Europe. Environ. Res. Lett. 2021, 16, 045010. [Google Scholar]

- De Joannon, M.; Cozzolino, G.; Cavaliere, A.; Ragucci, R. Heterogeneous nucleation activation in a condensational scrubber for particulate abatement. Fuel Process. Technol. 2013, 107, 113–118. [Google Scholar]

- Zhang, Y.; Jin, R.; Dong, S.; Wang, Y.; Dong, K.; Wei, Y.; Wang, B. Heterogeneous condensation combined with inner vortex broken cyclone to achieve high collection efficiency of fine particles and low energy consumption. Powder Technol. 2021, 382, 420–430. [Google Scholar]

- Zhou, D.; Luo, Z.; Jiang, J.; Chen, H.; Lu, M.; Fang, M. Experimental study on improving the efficiency of dust removers by using acoustic agglomeration as pretreatment. Powder Technol. 2016, 289, 52–59. [Google Scholar]

- Wang, K.; Gu, H.; Zhang, G.; Luo, K.; Zhang, Q.; Chen, G.; Zhan, M.; Chi, Z. A novel fire smoke elimination technology using electric agglomeration: The concept, experimental verification and mechanisms. J. Hazard. Mater. 2023, 441, 129950. [Google Scholar]

- Guo, Y.; Zhang, J.; Zhao, Y.; Wang, S.; Jiang, C.; Zheng, C. Chemical agglomeration of fine particles in coal combustion flue gas: Experimental evaluation. Fuel 2017, 203, 557–569. [Google Scholar]

- Wu, H.; Pan, D.; Zhang, R.; Yang, L.; Peng, Z.; Yang, B. Reducing fine particle emissions by heterogeneous vapor condensation after wet desulfurization process. J. Chem. Technol. Biotechnol. 2017, 92, 2342–2350. [Google Scholar]

- Yang, L.; Bao, J.; Yan, J.; Liu, J.; Song, S.; Fan, F. Removal of fine particles in wet flue gas desulfurization system by heterogeneous condensation. Chem. Eng. J. 2010, 15, 25–32. [Google Scholar]

- Wang, J.; Duan, X.; Wang, S.; Wen, J.; Tu, J. Experimental and numerical investigation on the separation of hydrophilic fine particles using heterogeneous condensation preconditioning technique in gas cyclones. Sep. Purif. Technol. 2021, 259, 118126. [Google Scholar]

- Wang, Y.; Henning, S.; Poulain, L.; Lu, C.; Stratmann, F.; Wang, Y.; Niu, S.; Pöhlker, M.L.; Herrmann, H.; Wiedensohler, A. Aerosol activation characteristics and prediction at the central European ACTRIS research station of Melpitz, Germany. Atmos. Chem. Phys. 2022, 22, 15943–15962. [Google Scholar]

- Smorodin, V.Y.; Hopke, P.K. Condensation activation and nucleation on heterogeneous aerosol nanoparticles. J. Phys. Chem. B 2004, 108, 9147–9157. [Google Scholar]

- Kalikmanov, V.I. Nucleation Theory; Springer: Berlin/Heidelberg, Germany, 2013. [Google Scholar]

- Hering, S.V.; Stolzenburg, M.R.; Quant, F.R.; Oberreit, D.R.; Keady, P.B. A laminar-flow, water-based condensation particle counter (WCPC). Aerosol Sci. Technol. 2005, 39, 659–672. [Google Scholar]

- Hering, S.V.; Stolzenburg, M.R. A method for particle size amplification by water condensation in a laminar, thermally diffusive flow. Aerosol Sci. Technol. 2005, 39, 428–436. [Google Scholar]

- Xu, J.; Yu, Y.; Zhang, J.; Meng, Q.; Zhong, H. Heterogeneous condensation of water vapor on particles at high concentration. Powder Technol. 2017, 305, 71–77. [Google Scholar]

- Fisenko, S.P.; Wang, W.N.; Shimada, M.; Okuyama, K. Vapor condensation on nanoparticles in the mixer of a particle size magnifier. Int. J. Heat Mass Transf. 2007, 50, 2333–2338. [Google Scholar]

- Roberts, G.C.; Nenes, A. A continuous-flow streamwise thermal-gradient CCN chamber for atmospheric measurements. Aerosol Sci. Technol. 2005, 39, 206–221. [Google Scholar]

- Bian, J.; Gui, H.; Xie, Z.; Yu, T.; Wei, X.; Wang, W.; Liu, J. Simulation of three-stage operating temperature for supersaturation water-based condensational growth tube. J. Environ. Sci. 2020, 90, 275–285. [Google Scholar]

- Yu, Y.; Xu, J.; Zhang, J.; Chen, G.; Zhong, H. Study on effects of different carrier gases on characteristics of the supersaturated environment in the one-/multi-section growth tube. Energy Fuels 2018, 32, 4586–4592. [Google Scholar]

- Bao, J.J. Study on Improving the Removal of Fine Particles by Heterogeneous Condensation in WFGD System. Ph.D. Thesis, Southeast University, Nanjing, China, 2012. [Google Scholar]

- Zebian, H.; Rossi, N.; Gazzino, M.; Cumbo, D.; Mitsos, A. Optimal design and operation of pressurized oxy-coal combustion with a direct contact separation column. Energy 2013, 49, 268–278. [Google Scholar]

- Lihavainen, H.; Viisanen, Y. A laminar flow diffusion chamber for homogeneous nucleation studies. J. Phys. Chem. B 2001, 105, 11619–11629. [Google Scholar]

- Lihavainen, H.; Viisanen, Y.; Kulmala, M. Homogeneous nucleation of n-pentanol in a laminar flow diffusion chamber. J. Chem. Phys. 2001, 114, 10031–10038. [Google Scholar]

- Fisenko, S.P.; Brin, A.A. Heat and mass transfer and condensation interference in a laminar flow diffusion chamber. Int. J. Heat Mass Transf. 2006, 49, 1004–1014. [Google Scholar]

- Yu, Y.; Xu, C.; Zhang, J.; Fu, C. Effects of coal-fired flue gas composition on condensational growth by water vapor for fine SiO2 particles. Process Saf. Environ. Prot. 2022, 158, 34–41. [Google Scholar]

- Yu, Y.; Zhang, J.; Zhong, H. Heterogeneous condensation of water vapor on fine SiO2 particles in two-section growth tube. Energy Fuels 2018, 32, 12750–12757. [Google Scholar]

- Zhong, Q.; Chen, Y.; Zhu, B.; Liao, S.; Shi, K. A temperature field reconstruction method based on acoustic thermometry. Measurement 2022, 200, 111642. [Google Scholar]

- Tammaro, M.; Di Natale, F.; Salluzzo, A.; Lancia, A. Heterogeneous condensation of submicron particles in a growth tube. Chem. Eng. Eng. Sci. 2012, 74, 124–134. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).