A Study on Dust-Control Technology Used for Large Mining Heights Based on the Optimization Design of a Tracking Spray Nozzle

Abstract

:1. Introduction

2. Optimization Design for Nozzle Structure of Support Tracking Spray

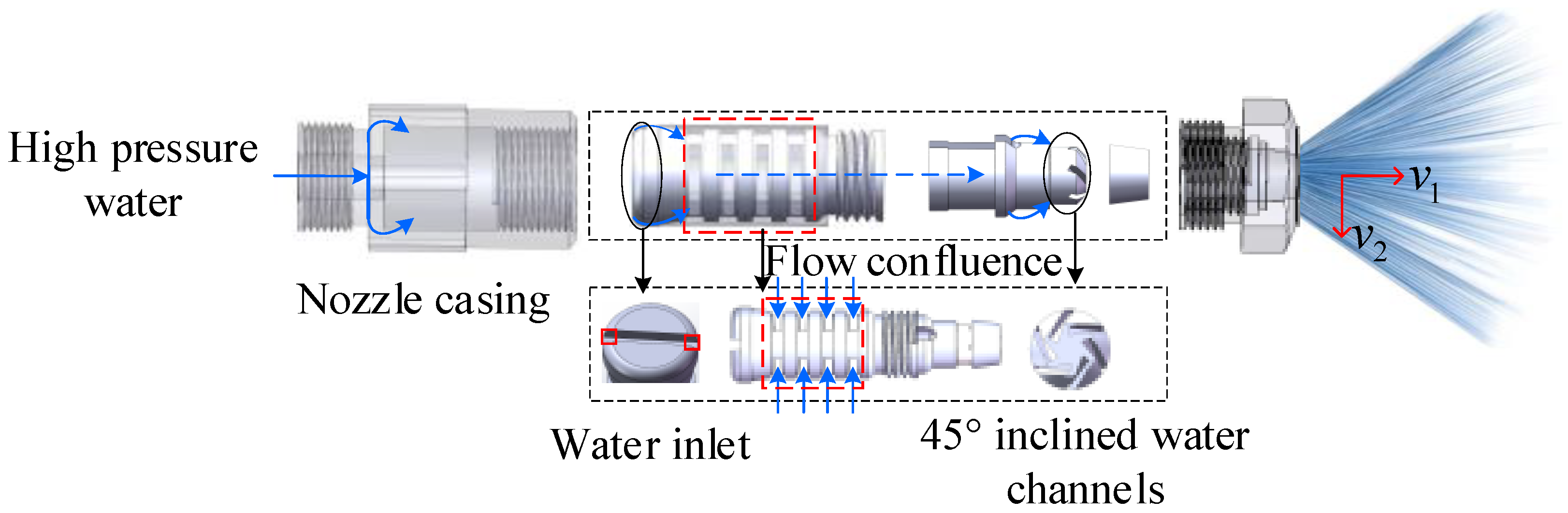

2.1. Development of a Long-Distance, Efficient Wear-Resistant Nozzle

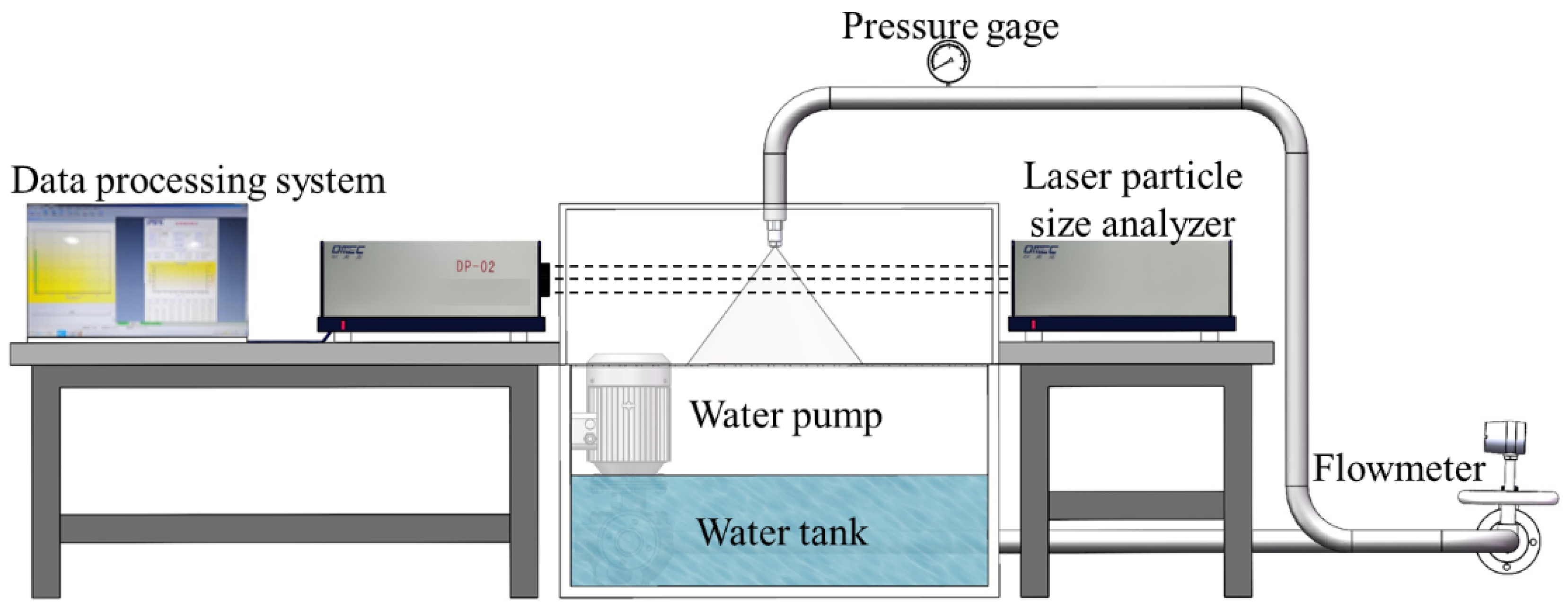

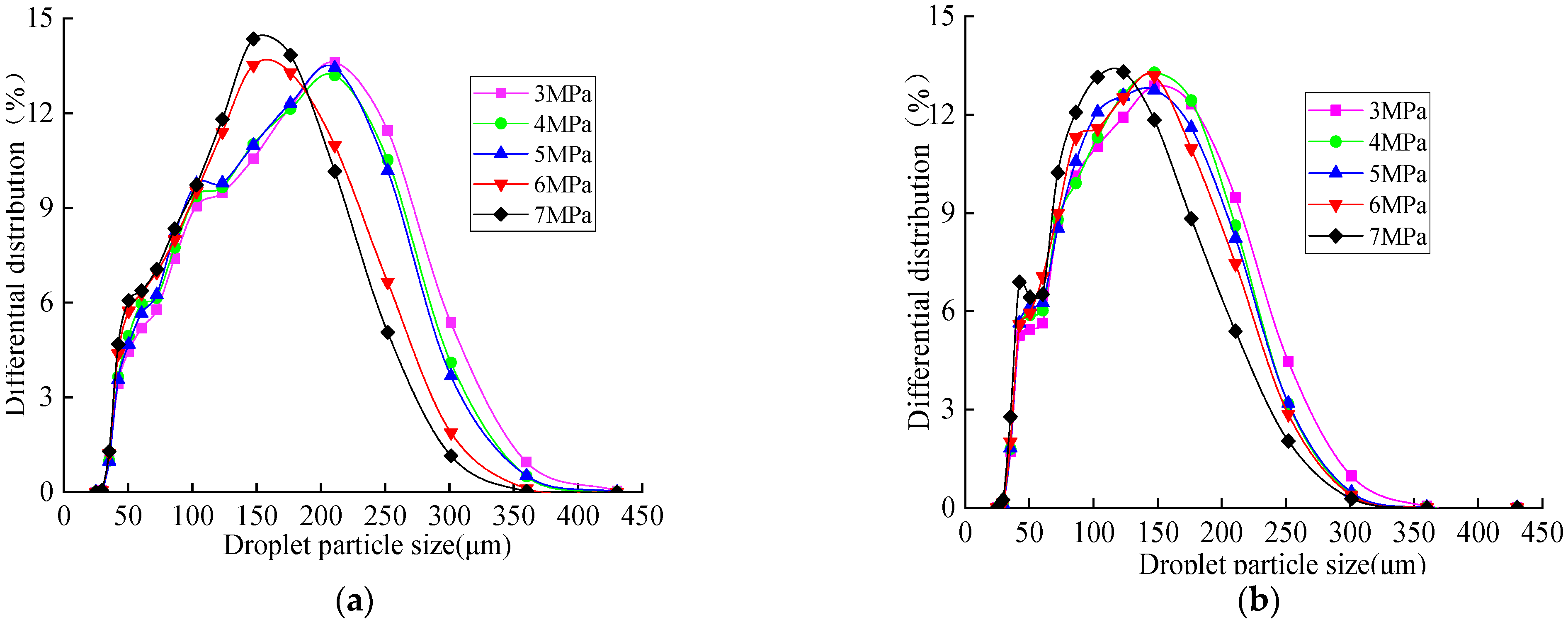

2.2. Analysis of the Atomization Performance of the New Nozzle Based on Laboratory Tests

3. Experimental Results and Analysis of Atomization Characteristics of Nozzles

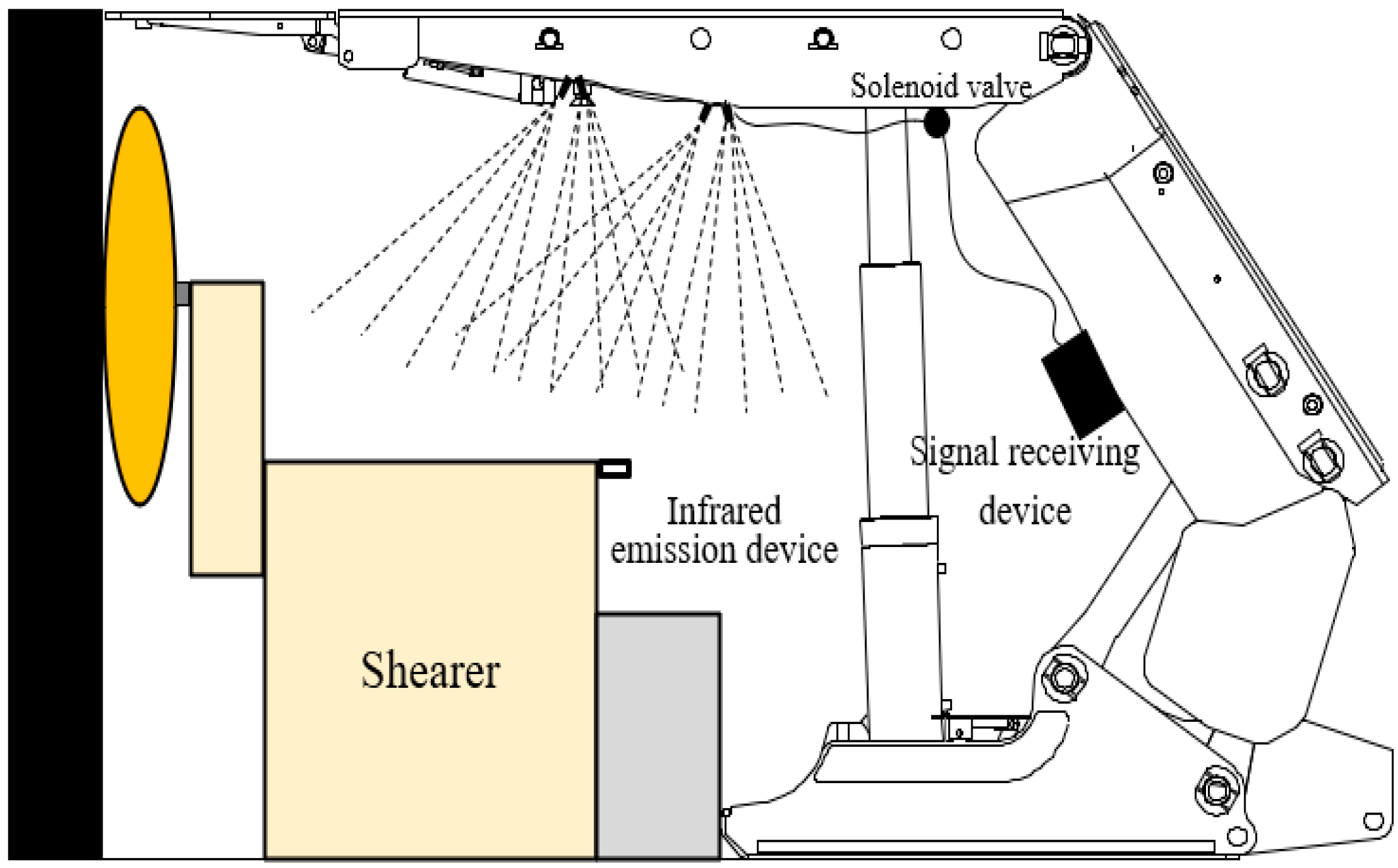

4. Practical Applications

5. Conclusions

- (1)

- Based on the mechanism of high-pressure water atomization, the nozzle with a built-in swirl core that could generate a circumferential velocity was innovatively developed from two aspects, i.e., enhancing the destructive effect of the aerodynamic force on the liquid flow and reducing the resistance effect of the internal force of the liquid. The device gave full play to inertial and aerodynamic forces to break the liquid and, due to the role of the swirl core, the liquid was ejected in the form of a thin film, reducing the surface tension in the liquid-surface cross-section. In addition, all parts were ultra-fine polished, which effectively improved the corrosion resistance of the swirl core, decreased the friction between the swirl core and nozzle shell, and reduced the energy loss when the water passed through the swirl core. The experiment showed that, under the same spray-pressure conditions, the newly developed nozzle projected water over a long and effective distance, presenting an excellent atomization performance and a large atomization angle.

- (2)

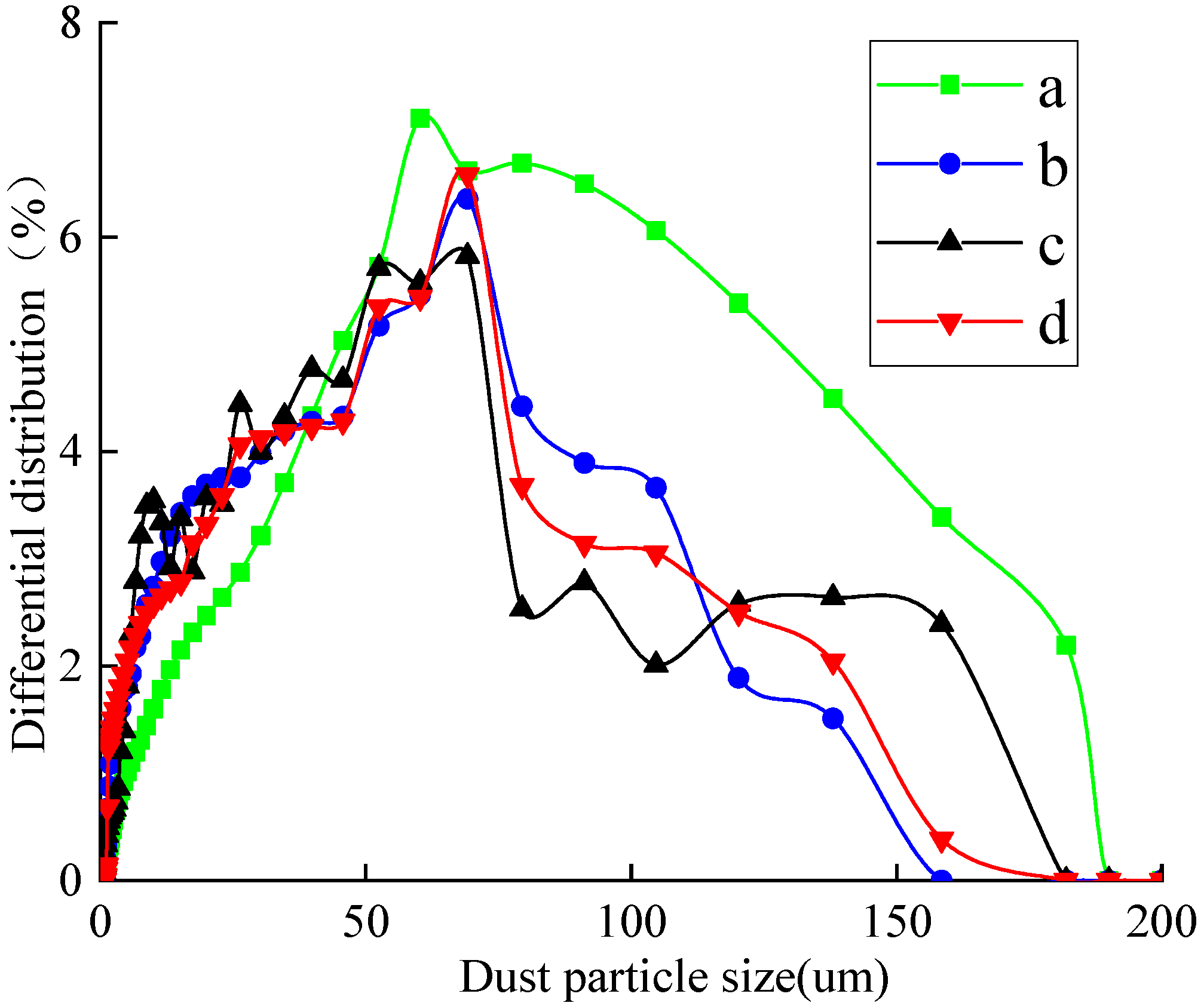

- Based on the range of the dust particle size distribution (30–60 μm) and the mechanism of dust captured by gas–liquid two-phase condensation, an optimization test design for the structural parameters of the long-distance high-efficiency nozzle was conducted. It was observed that, at a spray pressure of 6 MPa and a nozzle size of 1.6 mm, the droplet particle size distribution of the new nozzle mainly ranged from 0 to 120 μm, which can remarkably improve the droplets’ dust particle-capture efficiency in FMMFs.

- (3)

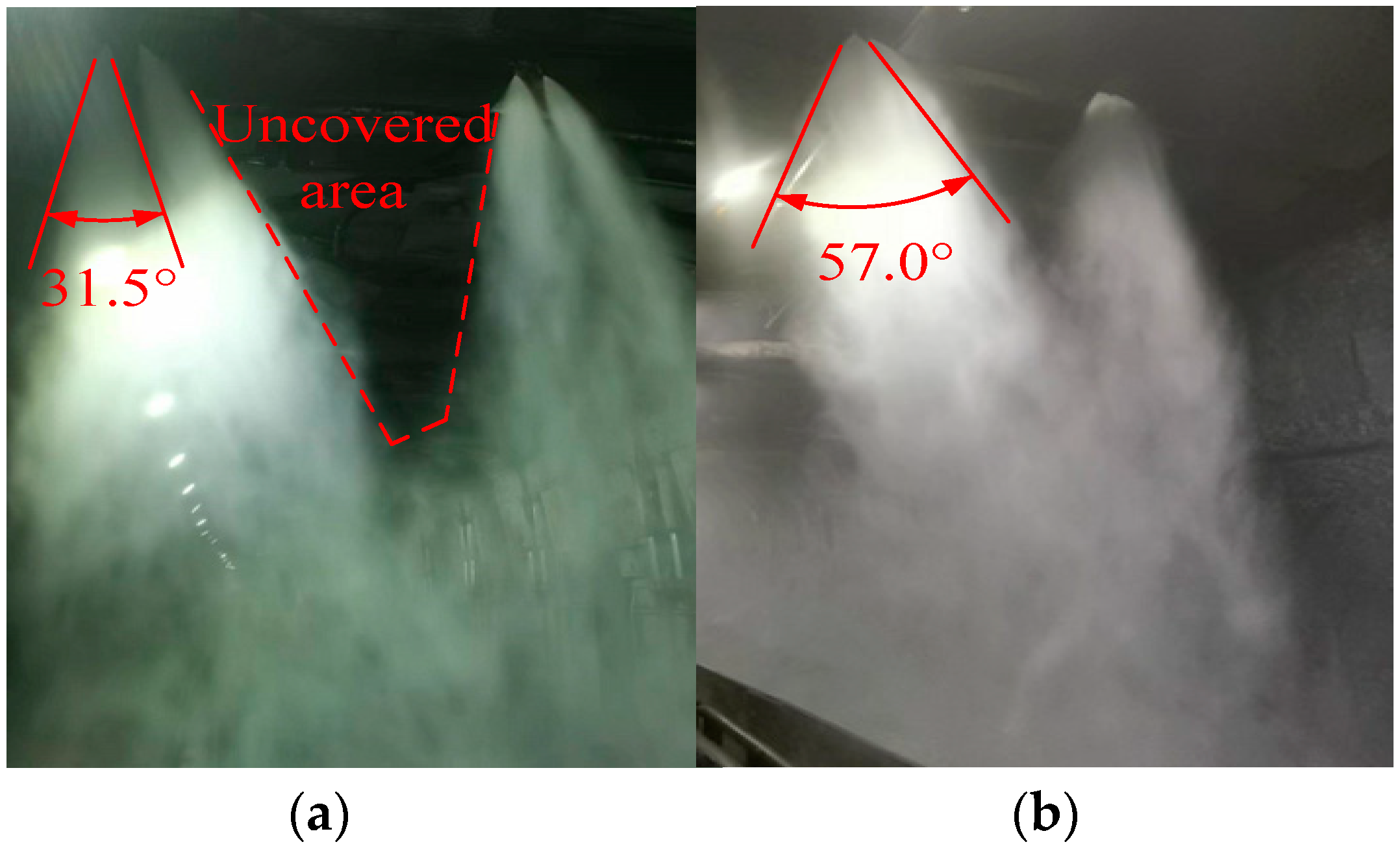

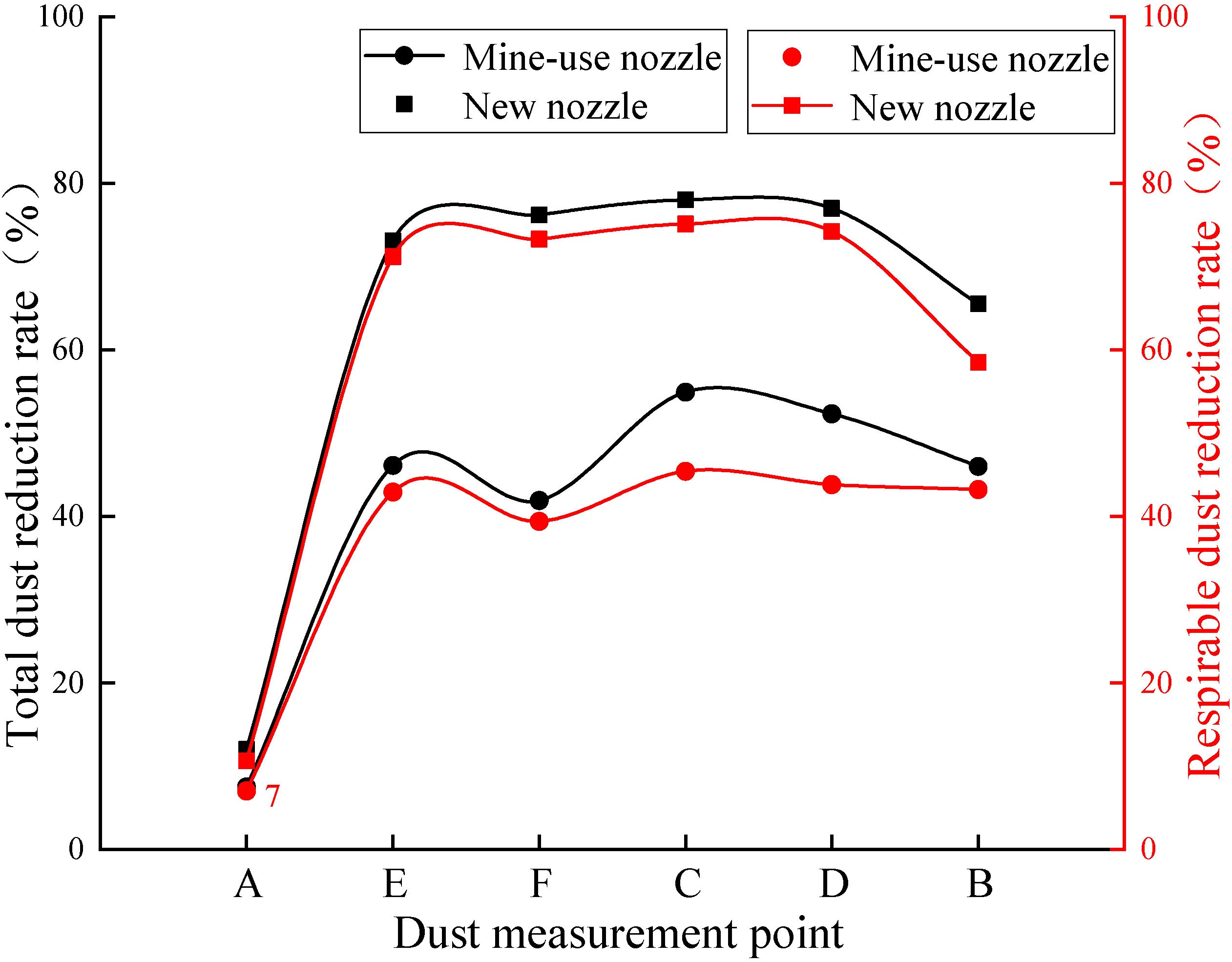

- Based on the industrial tests, the new nozzle had a high droplet density and an effective range that could cover FMMFs with large mining heights. Its spraying angle was 57°, which was 80.9% greater than that of the original nozzle (31.5°). After the new nozzle tracking spray was turned on, the dust removal efficiency was significantly improved, reaching a maximum of 78% for total dust and 75.1% for respiratory dust, which were 42% and 65% greater than those of the GZPW-16 mine-use nozzle spray, respectively. The application results suggest that its spraying performance, better than that of the GZPW-16 mine-use nozzle, is more conducive to the formation of a wide range of horizontal and vertical mist curtains.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Liang, Y. Scientific conception of coal mine dust control and occupational safety. J. China Coal Soc. 2020, 45, 1–7. [Google Scholar]

- Cheng, W.M.; Zhou, G.; Chen, L.J.; Wang, G.; Nie, W.; Zhang, Q.T. Research progress and prospect of dust control theory and technology in China’s coal mines in the past 20 years. Coal Sci. Technol. 2020, 48, 1–20. [Google Scholar]

- Yang, D.; Peng, K.; Zheng, Y.; Chen, Y.; Zheng, J.; Wang, M.; Chen, S. Study on the characteristics of coal and gas outburst hazard under the influence of high formation temperature in deep mines. Energy 2023, 268, 126645. [Google Scholar] [CrossRef]

- Wang, Z.; Ren, T. Investigation of airflow and respirable dust flow behavior above an underground bin. Powder Technol. 2013, 250, 103–114. [Google Scholar] [CrossRef]

- Mo, J.; Ma, W.; Li, D.; Zhang, S. Investigation on dust dispersion during support movement in a fully mechanized mining face and the technology with support frame enclosure dust control. Proc. Inst. Mech. Eng. Part E J. Process Mech. Eng. 2021, 235, 2098–2108. [Google Scholar] [CrossRef]

- Xie, Y.; Cheng, W.; Yu, H.; Sun, B. Microscale dispersion behaviors of dust particles during coal cutting at large-height mining face. Environ. Sci. Pollut. Res. Int. 2018, 25, 27141–27154. [Google Scholar] [CrossRef]

- Fan, T.; Zhou, G.; Wang, J. Preparation and characterization of a wet-ting-agglomeration-based hybrid coal dust suppressant. Process Saf. Environ. Prot. 2018, 113, 282–291. [Google Scholar] [CrossRef]

- Klemens, R.; Kosinski, P.; Wolanski, P.; Korobeinikov, V.; Markov, V.; Menshov, I.; Semenov, I. Numerical study of dust lifting in a channel with vertical obstacles. J. Loss Prev. Process Ind. 2001, 14, 469–473. [Google Scholar] [CrossRef]

- Li, D.; Sui, J.; Liu, G.; Zhao, Z. Technical status and development direction of coal mine dust hazard prevention and control technology in China. Min. Saf. Environ. Prot. 2019, 46, 1–7. [Google Scholar]

- Mao, L.; Peng, L.; Wang, H. Consensus of Chinese experts on pneumoconiosis treatment (2018 Edition). Environ. Occup. Med. 2018, 35, 677–689. [Google Scholar]

- Han, H.; Wang, P.; Liu, R.; Tian, C. Experimental study on atomization characteristics and dust-reduction performance of four common types of pressure nozzles in underground coal mines. Int. J. Coal Sci. Technol. 2020, 7, 581–596. [Google Scholar] [CrossRef]

- Zhao, Y.; Zhang, Q. Technology and engineering practice of negative pressure Induced mine dust source tracking spray dust removal in Quandian Coal Mine. Coal 2022, 31, 90–94. [Google Scholar]

- Mo, J.; Ma, W. Negative-Pressure Dust Removal and Micro-Mist Purification Device for Fully-Mechanised Mining Faces with a Large Mining Height. J. China Coal Soc. 2021, 9, 1–12. [Google Scholar]

- Tao, S. Application of Dust Source Tracking Spray Dust Suppression Device in Fully Mechanized Working Face. Coal Mine Mod. 2018, 5, 119–123. [Google Scholar]

- Zhou, G. Research of Theory about Dust Prevention by Water-Cloud and Relevant Techniques for Fully Mechanized Caving Coal Face; Shandong University of Science and Technology: Qingdao, China, 2009. [Google Scholar]

- Nie, W.; Cheng, W.M.; Zhou, G.; Xue, J.; Cui, X.F. Research and application on external spray secondary dust falling device with negative pressure of road header. J. China Coal Soc. 2014, 39, 2446–2452. [Google Scholar]

- Guo, F.; Li, T.; Ma, W. Research and application of high pressure spray dust removal technology for fully mechanized mining face with large mining height. Min. Saf. Environ. Prot. 2021, 48, 92–95. [Google Scholar]

- Zhang, Q. Research on Integrated Dust Suppression Technology for Large Mining Height fully Mechanized Face. Shanxi Coking Coal Sci. Technol. 2020, 44, 50–53. [Google Scholar]

- Wang, X.; Xie, D.; Chen, J. Optimization of spray dust removal technology between shelves of fully mechanized caving face. Coal Eng. 2008, 50–52. [Google Scholar] [CrossRef]

- Ma, X. Design of Automatic Spray Dust Reduction System in Fully Mechanized Mining Face. Coal Mine Mach. 2018, 39, 23–25. [Google Scholar]

- Peng, H.; Nie, W.; Zhang, S.; Cheng, W.; Liu, Q.; Guo, C.; Ma, Q.; Zhou, Z.; Xu, C.; Hua, Y.; et al. Research on negative pressure jet dust-removal water curtain technology for coal mine cleaner production. Fuel 2021, 310, 122378. [Google Scholar] [CrossRef]

- Peng, H.; Nie, W.; Zhang, X.; Xu, C.; Meng, X.; Cheng, W.; Liu, Q.; Hua, Y. Research on the blowing-spraying synergistic dust removal technology for clean environment in large-scale mechanization coal mine. Fuel 2022, 324, 124508. [Google Scholar] [CrossRef]

- Xu, C.; Nie, W.; Liu, Z.; Peng, H.; Yang, S.; Liu, Q. Multi-factor numerical simulation study on spray dust suppression device in coal mining process. Energy 2019, 182, 544–558. [Google Scholar] [CrossRef]

- Nie, W.; Liu, Y.H.; Cheng, W.M.; Zhou, G.; Ma, X. Dust removal technology of eject spraying between hydraulic supports on fully mechanized mining face. J. Cent. South Univ. Sci. Technol. 2015, 46, 4384–4390. [Google Scholar]

- Zhou, G.; Yin, W.; Feng, B. Numerical simulation on the distribution characteristics of dust-droplet field during support movement in a fully mechanized mining face and related engineering applications. J. China Coal Soc. 2018, 43, 3425–3435. [Google Scholar]

- Li, R.; Gan, Y.; Li, S. Application of the Dust-Tracking and Spraying Dust Suppression System at Fully Mechanized Coal Face. Saf. Coal Mines 2013, 44, 114–115. [Google Scholar]

- Zhi, J. Application of automatic dust source tracking spray dust removal technology in coal face. Mech. Manag. Dev. 2020, 35, 152–153. [Google Scholar]

- Bu, X. Design of Automatic Spray Dust Removal Device for Coal Mine. J. Hebei Energy Coll. Vocat. Technol. 2018, 18, 77–78. [Google Scholar]

- Faeth, G.M.; Hsiang, L.P.; Wu, P.K. Structure and breakup properties of sprays. Int. J. Multiph. Flow 1995, 21, 99–127. [Google Scholar] [CrossRef]

- Wei, H. Analysis and application of high pressure spray dust removal technology and equipment for dust source tracking of shearer. Mech. Manag. Dev. 2019, 34, 171–172. [Google Scholar]

- Yang, J. Application of Automatic Spray and Dust Suppression System in Fully Mechanized Coal Mining Face. Mech. Electr. Eng. Technol. 2019, 48, 255–256. [Google Scholar]

- Han, Q. Optimization Design of Spray Dust Suppression Nozzle for Hydraulic Support. Mod. Chem. Res. 2020, 149–150. [Google Scholar]

- Zhang, D. Improvement and application of spraying dust control method for hydraulic powered support in high cutting fully mechanized coal mining face. Coal Sci. Technol. 2017, 45, 206–211. [Google Scholar]

- Guo, M. Application analysis of coal mining dust removal system in fully mechanized mining face. Petrochem. Ind. Technol. 2020, 27, 147–148. [Google Scholar]

- Xie, Y. Study on Dust Pollution Regularity of Cutting and Dust Control in Spray Field in Fully Mechanized Mining Face with Large Mining Height; Shandong University of Science and Technology: Qingdao, China, 2019. [Google Scholar]

- Su, J.; Zhang, Z.; Pan, Y. Experimental Study on Atomization Characteristics of High Pressure Spray. Coal Mine Mach. 2021, 42, 48–50. [Google Scholar]

- Wang, Z. Study on Optimization of Mining Swirl Mixed Nozzle Structure and Characteristics of Atomization and Dust Control; China University of Mining and Technology: Beijing, China, 2021. [Google Scholar]

- Wang, T. Nozzle Structure Optimization of High Pressure Pulsed Water Jet; Zhejiang Sci-Tech University: Hangzhou, China, 2020. [Google Scholar]

- Wang, J.; Liu, R.; Wang, P. Study on Atomization Characteristics and Dust Reduction Performance of Common Pressure Nozzles. Saf. Coal Mines 2019, 50, 36–40. [Google Scholar]

- Chen, C.; Guo, Z.; Bai, S. Numerical Simulation and Field Application of Swirling-cored Nozzle for Dust Suppression. Saf. Coal Mines 2019, 50, 186–189. [Google Scholar]

- Cheng, W.; Yu, H.; Zhou, G.; Nie, W. The diffusion and pollution mechanisms of airborne dusts in fully-mechanized excavation face at mesoscopic scale based on CFD-DEM. Process Saf. Environ. Prot. 2016, 104, 240–253. [Google Scholar] [CrossRef]

- National Department of Emergency Management. Coal Mine Safety Regulations; Emergency Management Press: Beijing, China, 2022. [Google Scholar]

| Type | Size/mm | Material | Swirl-Core Structure |

|---|---|---|---|

| New nozzle | 1.6 | Copper | No swirl core |

| GZPW-16 mine-use nozzle | 1.6 | Stainless steel | Multi-fluid circle structure |

| Nozzle | Spray Pressure (MPa) | Spray Flow Rate (L/min) | Effective Spray Range (m) | Atomization Angle (°) |

|---|---|---|---|---|

| New nozzle | 3.0 | 5.52 | 3.90 | 62.7 |

| 4.0 | 6.47 | 4.40 | 60.9 | |

| 5.0 | 7.08 | 4.90 | 58.3 | |

| 6.0 | 7.95 | 5.50 | 57.6 | |

| 7.0 | 8.46 | 5.90 | 55.2 | |

| GZPW-16 mine-use nozzle | 3.0 | 5.42 | 3.80 | 52.5 |

| 4.0 | 6.24 | 4.20 | 50.7 | |

| 5.0 | 6.92 | 4.50 | 48.2 | |

| 6.0 | 7.55 | 4.80 | 47.2 | |

| 7.0 | 8.19 | 5.20 | 44.2 |

| Nozzle | Spray Pressure (MPa) | D10/μm | D25/μm | D50/μm | D75/μm | D90/μm |

|---|---|---|---|---|---|---|

| New nozzle | 3.0 | 46.11 | 69.89 | 106.73 | 152.25 | 192.67 |

| 4.0 | 45.08 | 67.82 | 104.1 | 146.86 | 183.78 | |

| 5.0 | 45.01 | 67.37 | 101.56 | 144.51 | 183.08 | |

| 6.0 | 44.91 | 66.53 | 101.49 | 143.88 | 180.27 | |

| 7.0 | 42.43 | 63.01 | 92.38 | 129.27 | 167.91 | |

| GZPW-16 mine-use nozzle | 3.0 | 52.74 | 82.43 | 132.96 | 191.76 | 235.12 |

| 4.0 | 51.26 | 78.36 | 126.75 | 184.49 | 227.52 | |

| 5.0 | 49.07 | 73.07 | 121.88 | 173.07 | 210.29 | |

| 6.0 | 48.45 | 72.88 | 117.34 | 163.96 | 205.23 | |

| 7.0 | 47.57 | 71.46 | 114.77 | 157.57 | 196.26 |

| Location | Dust Concentration/mg/m3 | A-15 m from the Inlet Airway | E-5 m on the Leeward Side of the Support | F-Driver of the Shearer | C-5 m on the Leeward Side of the Tracking Spray | D-10 m on the Leeward Side of the Tracking Spray | B-15 m from the Return Airway | |

|---|---|---|---|---|---|---|---|---|

| State | ||||||||

| Tracking spray off | Total dust | 24.1 | 730.2 | 620.5 | 599.1 | 530.9 | 165.1 | |

| Respirable dust | 14.2 | 435.1 | 330.8 | 310.3 | 300.2 | 89.9 | ||

| Tracking spray on (GZPW-16 mine-use nozzle) | Total dust | 22.3 | 393.4 | 360.5 | 270.3 | 253.5 | 89.1 | |

| Dust reduction rate (%) | 7.5 | 46.1 | 41.9 | 54.9 | 52.3 | 46 | ||

| Respirable dust | 13.2 | 238.4 | 187.2 | 146.3 | 148.5 | 48.6 | ||

| Dust reduction rate (%) | 7.0 | 45.2 | 43.4 | 54.6 | 51.5 | 45.9 | ||

| Tracking spray on (new nozzle) | Total dust | 21.2 | 196.6 | 148.9 | 131.8 | 122.1 | 56.9 | |

| Dust reduction rate (%) | 12.0 | 73.1 | 76.2 | 78.0 | 77 | 65.5 | ||

| Respirable dust | 12.7 | 125.3 | 88.3 | 77.3 | 77.5 | 37.3 | ||

| Dust reduction rate (%) | 10.6 | 71.2 | 73.3 | 75.1 | 74.2 | 58.5 | ||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hu, Z.; Zhang, B.; Chang, H. A Study on Dust-Control Technology Used for Large Mining Heights Based on the Optimization Design of a Tracking Spray Nozzle. Atmosphere 2023, 14, 627. https://doi.org/10.3390/atmos14040627

Hu Z, Zhang B, Chang H. A Study on Dust-Control Technology Used for Large Mining Heights Based on the Optimization Design of a Tracking Spray Nozzle. Atmosphere. 2023; 14(4):627. https://doi.org/10.3390/atmos14040627

Chicago/Turabian StyleHu, Zuxiang, Benyi Zhang, and Haoqian Chang. 2023. "A Study on Dust-Control Technology Used for Large Mining Heights Based on the Optimization Design of a Tracking Spray Nozzle" Atmosphere 14, no. 4: 627. https://doi.org/10.3390/atmos14040627

APA StyleHu, Z., Zhang, B., & Chang, H. (2023). A Study on Dust-Control Technology Used for Large Mining Heights Based on the Optimization Design of a Tracking Spray Nozzle. Atmosphere, 14(4), 627. https://doi.org/10.3390/atmos14040627