Revealing the Effects of Water Imbibition on Gas Production in a Coalbed Matrix Using Affected Pore Pressure and Permeability

Abstract

:1. Introduction

2. Effect of Fracturing Fluid on Pore System in Reservoir Matrix

2.1. Blind Pores Are Dominant in the Coal Matrix

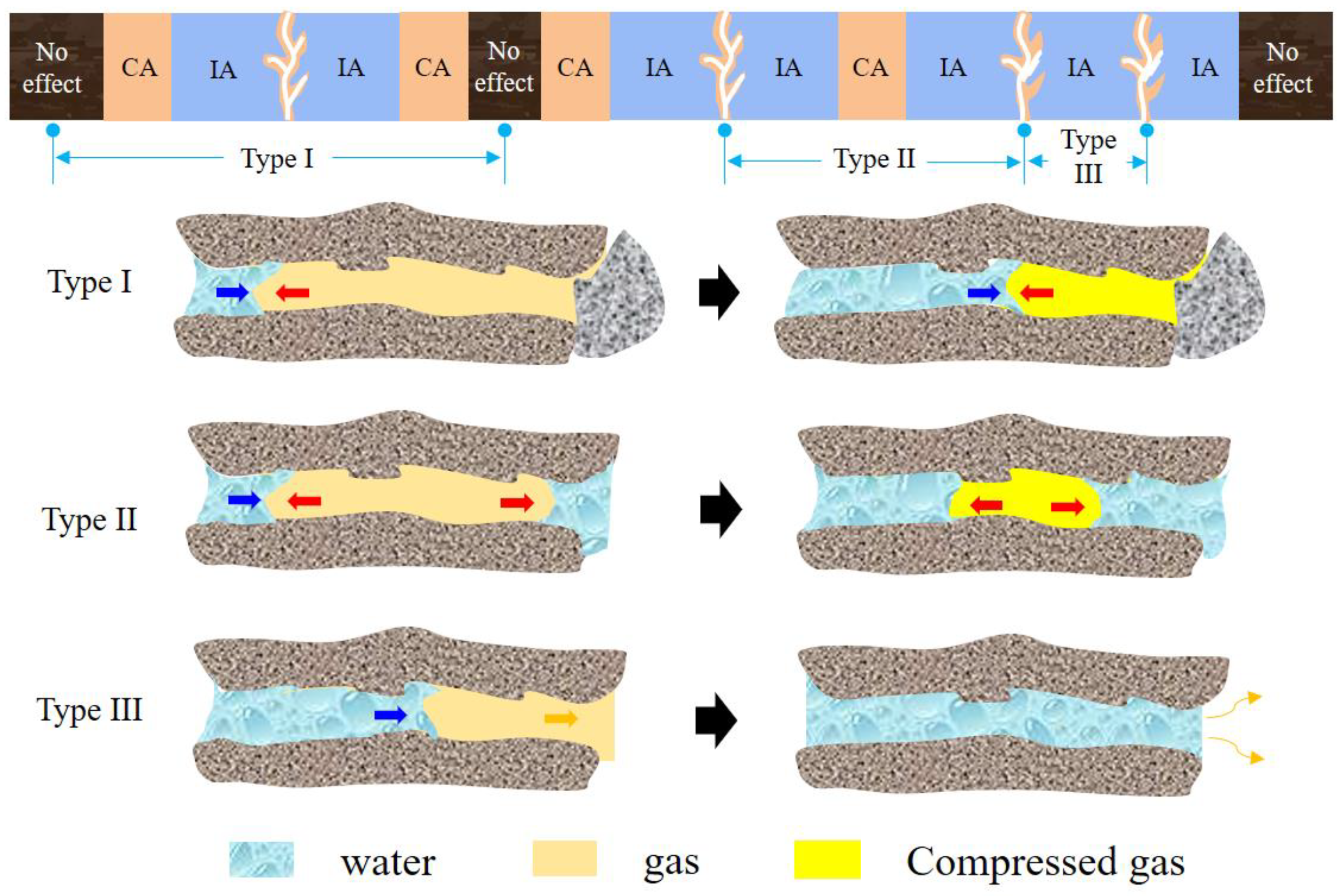

2.2. Effect of Fracturing Fluid on Pores System

- 1.

- Influence of imbibition on blind pores.

- 2.

- Influence of imbibition on through pores.

3. Model Description and Construction

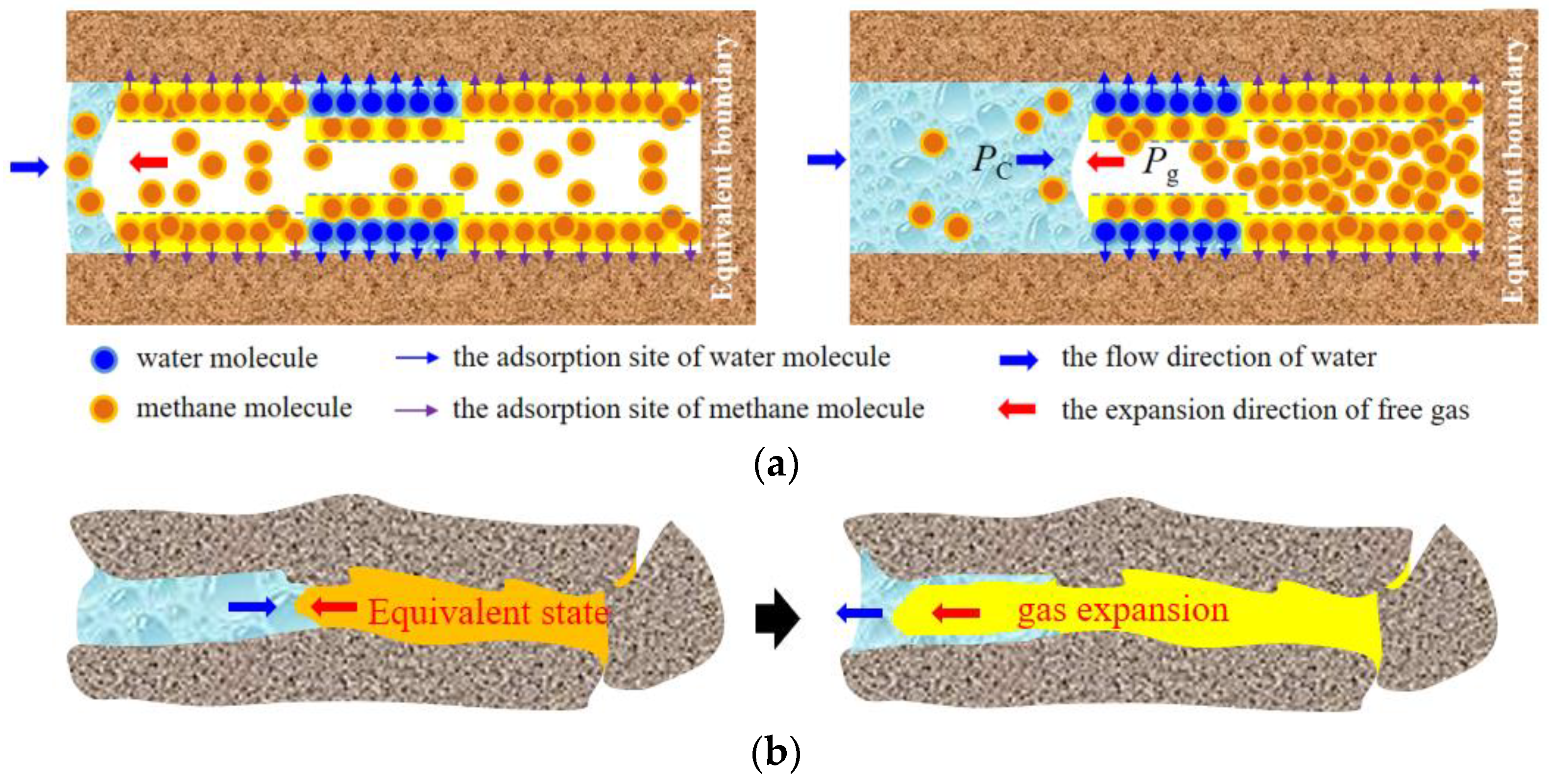

3.1. Effect of Imbibition on the Gas Pressure of Micro-Nano Blind Pores in Coal

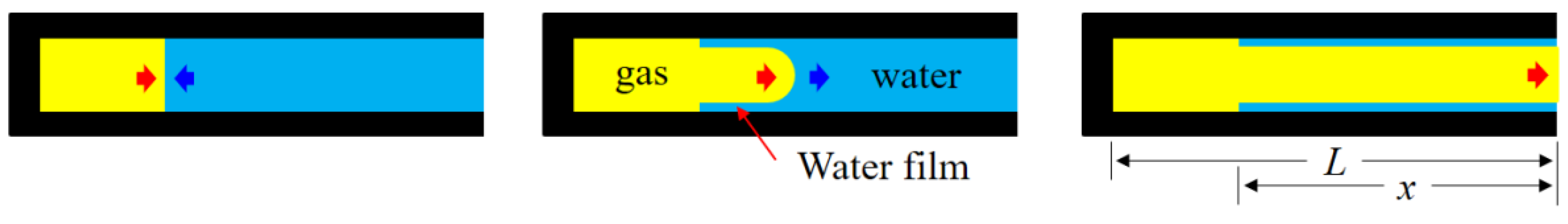

3.2. Effect of Imbibition on Coalbed Permeability

- 1.

- Effect of water imbibition on the pore diameter and Knudsen number.

- 2.

- Effect of water imbibition on the weighting coefficient.

- 3.

- Effect of water imbibition on total gas mass flux.

4. Results and discussion

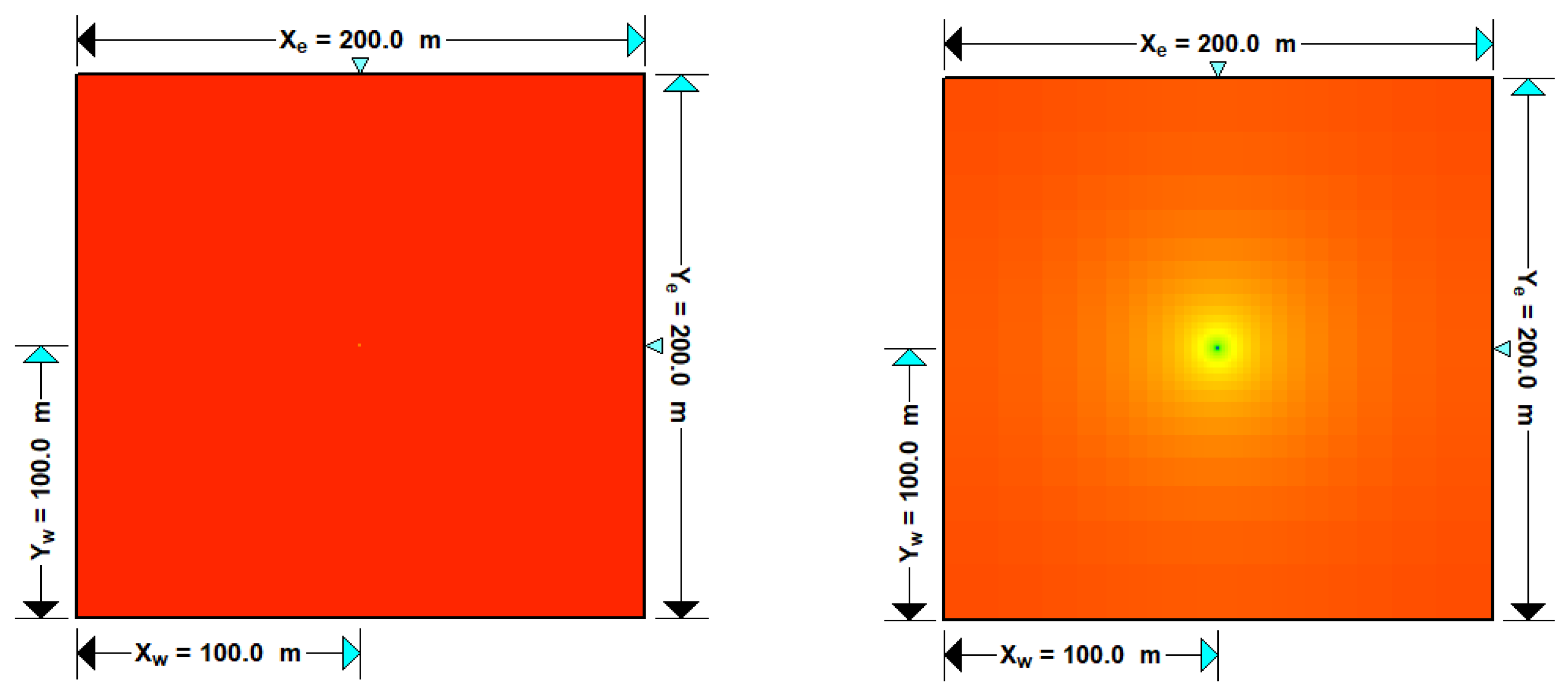

4.1. Effect of Imbibition on Water Saturation, Maximum Pore Pressure after Drainage, and Permeability

4.2. Effect of Imbibition on Gas Production

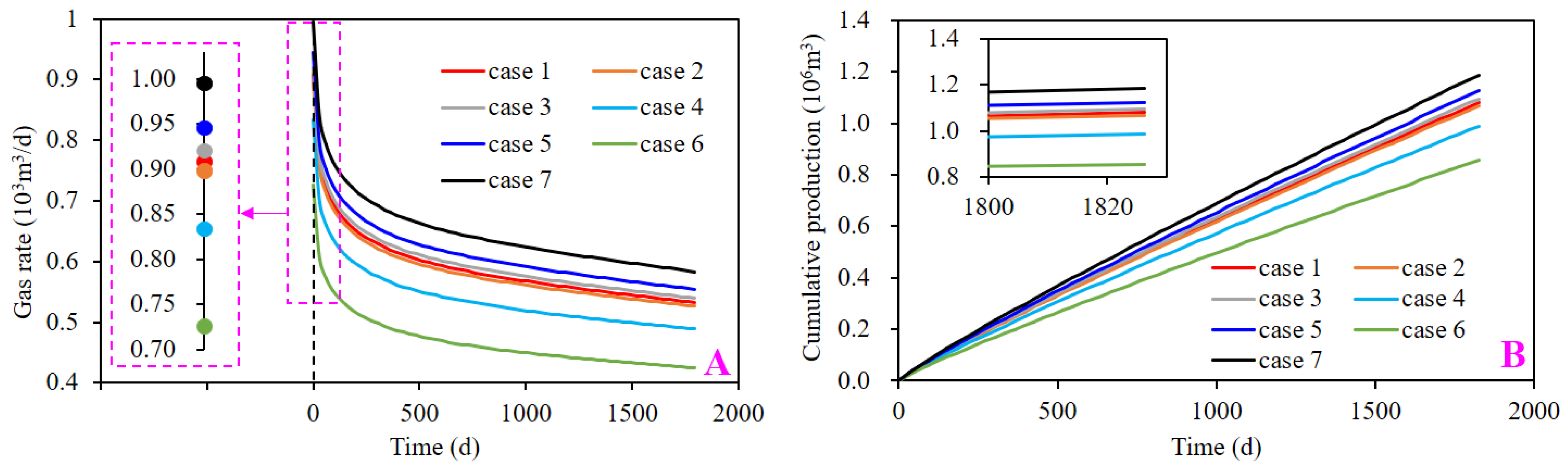

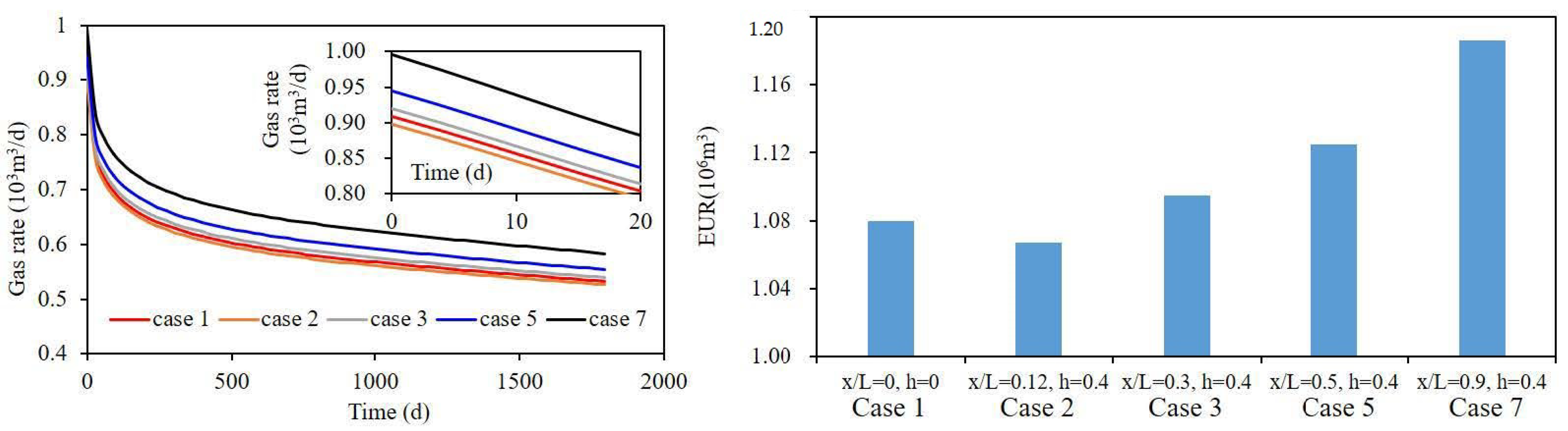

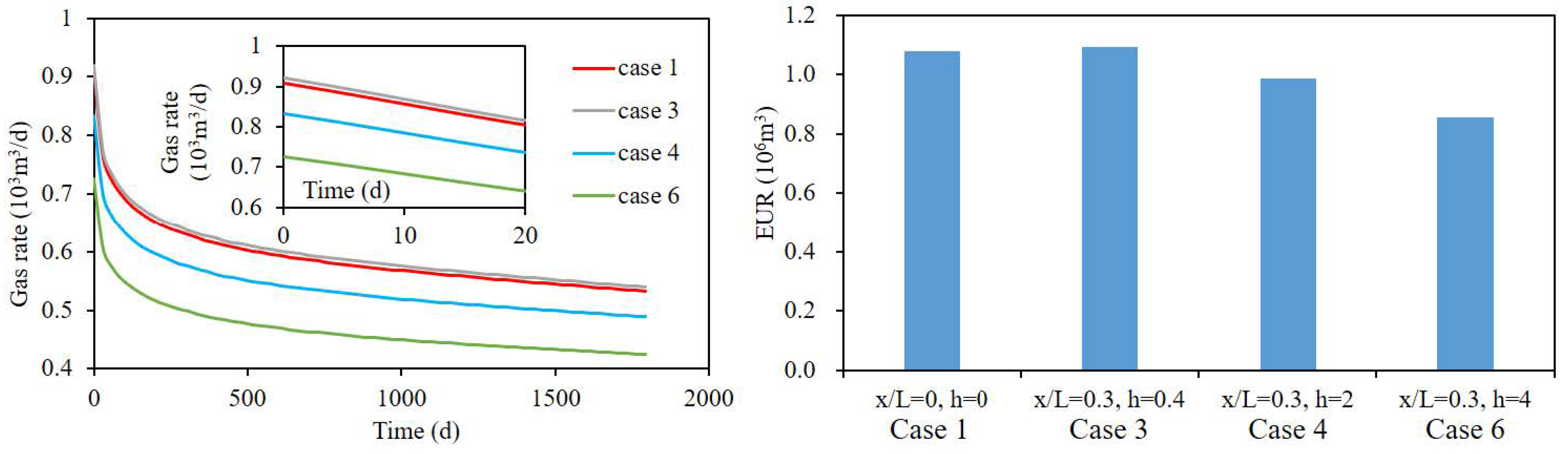

- 1.

- Permeability and pore pressure before and after imbibition.

- 2.

- Comparison of gas well productivity before and after imbibition.

5. Conclusions

- Water imbibition can increase the pore gas pressure in blind pores in two ways. Firstly, imbibed fracturing fluid promotes the desorption of adsorbed gas in the affected area, increasing the content of free gas; secondly, the water film retained on the inner wall of pores reduces the space for gas storage. The combined actions of these two aspects increase the pore gas pressure immediately after water drainage in blind pores.

- Water imbibition can reduce the effective gas permeability in blind pores in two ways. Firstly, the water film retained on the inner wall of pores reduces the effective area for gas seepage; secondly, the increase in water saturation reduces the efficiency of the gas flow. The combined actions of these two aspects reduce the effective permeability of gas in blind pores.

- Water imbibition is not always deleterious to coalbed methane production and EUR. When the relative imbibition length is constant, a thicker water film results in a more obvious decrease in gas production and EUR; when the thickness of water film is constant, more imbibition results in a more obvious increase in gas production and EUR.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Nomenclature

| r | average pore radius, m | b | gas slip constant, dimensionless |

| d* | diameter of circular pore considering water film, m | Cg | gas compressibility, 1/MPa |

| τ | pore tortuosity, dimensionless | α* | rarefaction coefficient of ideal gas, dimensionless |

| x | imbibition length, m | α0 | rarefaction coefficient when Knudsen number tends to infinity, dimensionless |

| average gas thermal kinematic velocity, m/s | |||

| L | pore length, m | α1 | fitting constant, dimensionless |

| ϕ | coal porosity, % | χ | fitting constant, dimensionless |

| Z | gas compressibility factor, dimensionless | Knudsen diffusion mass flux through circular pores, kg/(m2·s) | |

| R | gas constant, 8.314 J/(K∙mol) | ||

| T | reservoir temperature, K | viscous flow mass flux through circular pores, kg/(m2·s) | |

| h | thickness of water film on pore walls, m | integrated mass flux through circular pores, kg/(m2·s) | |

| mean free path of gas considering water film, m | gas permeability for circular pores considering the influence of imbibition, mD | ||

| μg | gas viscosity, mPa·s | ||

| M | the molar mass of methane molecule, g/mol | Knudsen number in circular pores considering water film, dimensionless | |

| P | gas pressure, MPa | ||

| Pg0 | original gas pressure, MPa | Swi | original water saturation, % |

| Pcg | maximum pore pressure after drainage, MPa | Scw | water saturation considering the influence of imbibition, % |

| ρN | molar density of gas molecules, mol/m3 | Va | desorption amount of adsorbed gas in affected area, mol |

| collision direction of gas molecules and wall. | na | molar content of adsorbed gas per unit pore area, mol/m2 | |

| qg | gas rate, 103 m3/d | Gp | cumulative production, 106 m3 |

| m | frequency of intermolecular collision considering water film, mol/s | w | frequency of molecular-wall collision considering water film, mol/s |

| fc-v | weighting coefficient for viscous flow that is dominated by molecule-wall collisions, dimensionless | fc-Kn | weighting coefficients for Knudsen diffusion that are dominated by intermolecular collisions, dimensionless |

References

- Peng, X.L.; Wang, X.Z.; Zhou, X.; Lin, Z.Y.; Zeng, F.H.; Huang, X.L. Lab-on-a-chip systems in imbibition processes: A review and applications/issues for studying tight formations. Fuel 2021, 306, 121603. [Google Scholar] [CrossRef]

- Meng, M.M.; Ge, H.K.; Ji, W.M.; Wang, X.Q. Research on the auto-removal mechanism of shale aqueous phase trapping using low field nuclear magnetic resonance technique. J. Pet. Sci. Eng. 2016, 137, 63–73. [Google Scholar] [CrossRef]

- Xia, P.; Hao, F.; Tian, J.Q.; Zhou, W.X.; Fu, Y.; Guo, C.; Yang, Z.; Li, K.J.; Wang, K. Depositional Environment and Organic Matter Enrichment of Early Cambrian Niutitang Black Shales in the Upper Yangtze Region, China. Energies 2022, 15, 4551. [Google Scholar] [CrossRef]

- Abbasi, M.A.; Ezulike, D.O.; Dehghanpour, H.; Hawkes, R.V. A comparative study of flowback rate and pressure transient behavior in multifractured horizontal wells completed in tight gas and oil reservoirs. J. Nat. Gas Sci. Eng. 2014, 17, 82–93. [Google Scholar] [CrossRef]

- Wang, K.; Jiang, B.B.; Li, H.T.; Ye, K.R.; Tan, Y.S. Spontaneous imbibition model for micro–nano–scale pores in shale gas reservoirs considering gas–water interaction. J. Pet. Sci. Eng. 2022, 209, 109893. [Google Scholar] [CrossRef]

- Wang, J.J.; Rahman, S.S. Investigation of water leak-off considering the component variation and gas entrapment in shale during hydraulic-fracturing stimulation. SPE Reserv. Eval. Eng. 2016, 19, 511–519. [Google Scholar] [CrossRef]

- Zhou, Z.; Abass, H.; Li, X.; Bearinger, D.; Frank, W. Mechanisms of imbibition during hydraulic fracturing in shale formations. J. Pet. Sci. Eng. 2016, 141, 125–132. [Google Scholar] [CrossRef]

- Xiong, J.; Liu, X.J.; Liang, L.X.; Zeng, Q. Investigation of methane adsorption on chlorite by grand canonical Monte Carlo simulations. Pet. Sci. 2017, 14, 37–49. [Google Scholar] [CrossRef]

- Hu, Z.M.; Mu, Y.; Gu, Z.B.; Duan, X.G.; Li, Y.L. Law of imbibition effect on shale gas occurrence state. Nat. Gas Ind. B 2020, 7, 624–630. [Google Scholar] [CrossRef]

- Wang, K.; Ye, K.R.; Jiang, B.B.; Li, H.T.; Tan, Y.S. The mechanism of gas-water extraction in micro- and nanoscale pores in shale gas reservoirs: Based on gas-water interactions. Chem. Eng. Sci. 2022, 248, 117259. [Google Scholar] [CrossRef]

- Lin, H.; Yang, B.; Song, X.X.; Sun, X.Y.; Dong, L.F. Fracturing fluid retention in shale gas reservoir from the perspective of pore size based on nuclear magnetic resonance. J. Hydro. 2021, 601, 126590. [Google Scholar]

- Sun, Z.; Shi, J.T.; Wu, K.L.; Xu, B.X.; Zhang, T.; Chang, Y.C.; Li, X.F. Transport capacity of gas confined in nanoporous ultra-tight gas reservoirs with real gas effect and water storage mechanisms coupling. Int. J. Heat Mass Transf. 2018, 126, 1007–1018. [Google Scholar] [CrossRef]

- He, M.X.; Zhou, Y.F.; Wu, K.L.; Hu, Y.L.; Feng, D.; Zhang, T.; Liu, Q.; Li, X.F. Pore network modeling of thin water film and its influence on relative permeability curves in tight formations. Fuel 2021, 289, 119828. [Google Scholar] [CrossRef]

- Zhou, D.S.; Yuan, H. A new model for predicting gas-well liquid loading. SPE Prod. Oper. 2010, 25, 172–181. [Google Scholar] [CrossRef]

- Sun, B.J.; Pan, S.W.; Zhang, J.B.; Zhao, X.X.; Zhao, Y.; Wang, Z.Y. A dynamic model for predicting the geometry of bubble entrapped in yield stress fluid. Chem. Eng. J. 2020, 391, 123569. [Google Scholar]

- Wilson, K. Analysis of drawdown sensitivity in shale reservoirs using coupled-geomechanics models. In Proceedings of the SPE Annual Technical Conference and Exhibition, Houston, TX, USA, 28–30 September 2015. SPE-175029-MS. [Google Scholar]

- Xu, M.; Gupta, A.; Dehghanpour, H. How significant are strain and stress induced by water imbibition in dry gas shales? J. Pet. Sci. Eng. 2019, 176, 428–443. [Google Scholar] [CrossRef]

- Yan, Q.; Lemanski, C.; Karpyn, Z.T.; Ayala, L.F. Experimental investigation of shale gas production impairment due to fracturing fluid migration during shut-in time. J. Nat. Gas Sci. Eng. 2015, 24, 99–105. [Google Scholar] [CrossRef]

- Bazin, B.; Bekri, S.; Vizika, O.; Herzhaft, B.; Aubry, E. Fracturing in tight gas reservoirs: Application of special-core-analysis methods to investigate formation damage mechanisms. SPE J. 2010, 15, 969–976. [Google Scholar] [CrossRef]

- Chakraborty, N.; Karpyn, Z.T.; Liu, S.; Yoon, H. Permeability evolution of shale during spontaneous imbibition. J. Nat. Gas Sci. Eng. 2017, 38, 590–596. [Google Scholar] [CrossRef]

- Zhang, D.J.; Kang, Y.L.; Selvadurai, A.P.S.; You, L.J.; Tian, J. The role of phase trapping on permeability reduction in an ultra-deep tight sandstone gas reservoirs. J. Pet. Sci. Eng. 2019, 178, 311–323. [Google Scholar] [CrossRef]

- Tian, J.; Kang, Y.L.; You, L.J.; Jia, N.; Xi, Z.Y.; Luo, P.Y. Investigation on water phase trapping mechanisms in tight gas reservoirs: Pore-scale visualization observation and core-scale flooding analysis. J. Pet. Sci. Eng. 2021, 198, 108185. [Google Scholar] [CrossRef]

- Bai, J.J.; Kang, Y.L.; Chen, Z.X.; You, L.J.; Chen, M.J.; Li, X.C. Changes in retained fracturing fluid properties and their effect on shale mechanical properties. J. Nat. Gas Sci. Eng. 2020, 75, 103163. [Google Scholar] [CrossRef]

- Zhang, J.J.; Kamenov, A.; Zhu, D.; Hill, A.D. Development of new testing procedures to measure propped fracture conductivity considering water damage in clay-rich shale reservoirs: An example of the Barnett Shale. J. Pet. Sci. Eng. 2015, 135, 352–359. [Google Scholar] [CrossRef]

- Lin, S.; Lai, B. Experimental investigation of water saturation effects on Barnett shale’s geomechanical behaviors. In Proceedings of the SPE Annual Technical Conference and Exhibition, New Orleans, LA, USA, 30 September–2 October 2013. SPE 166234. [Google Scholar]

- Liu, D.; Wang, Z.; Zhang, X.; Wang, Y.; Zhang, X.; Li, D. Experimental investigation on the mechanical and acoustic emission characteristics of shale softened by water absorption. J. Nat. Gas Sci. Eng. 2018, 50, 301–308. [Google Scholar] [CrossRef]

- Xia, P.; Fu, Y.; Guo, C.; Yang, Z.; Huang, J.Q.; Mou, Y.L. Shale Gas Reservoir Evaluation by Geophysical Measurements: A Case Study of the Upper Ordovician–Lower Silurian in the Fenggang Block, Northern Guizhou Province. Acta Geol. Sin. 2021, 95, 1310–1321. [Google Scholar] [CrossRef]

- Hu, Y.N.; Devegowda, D.; Striolo, A.; Civan, F.; Sigal, R. Microscopic dynamics of water and hydrocarbon in shale-kerogen pores of potentially mixed-wettability. SPE J. 2015, 20, 112–124. [Google Scholar] [CrossRef]

- De Leeuw, N.H.; Higgins, F.M.; Parker, S.C. Modeling the surface structure and stability of α-quartz. J. Phys. Chem. B 1999, 103, 1270–1277. [Google Scholar] [CrossRef]

- Zhan, S.Y.; Su, Y.L.; Jin, Z.H.; Wang, W.D.; Li, L. Effect of water film on oil flow in quartz nanopores from molecular perspectives. Fuel 2020, 262, 116560. [Google Scholar] [CrossRef]

- Wolthers, M.; Tommaso, D.D.; Du, Z.; Leeuw, N.H. Calcite surface structure and reactivity: Molecular dynamics simulations and macroscopic surface modelling of the calcite–water interface. Phys. Chem. Chem. Phys. 2012, 14, 15145–15157. [Google Scholar] [CrossRef]

- Cao, P.; Liu, J.; Leong, Y.K. A multiscale-multiphase simulation model for the evaluation of shale gas recovery coupled the effect of water flowback. Fuel 2017, 199, 191–205. [Google Scholar] [CrossRef]

- Ghanbari, E.; Dehghanpour, H. The fate of fracturing water: A field and simulation study. Fuel 2016, 163, 282–294. [Google Scholar] [CrossRef]

- Gupta, A.; Xu, M.; Dehghanpour, H.; Bearinger, D. Experimental investigation for microscale stimulation of shales by water imbibition during the shut-in periods. In Proceedings of the SPE Unconventional Resources Conference, Calgary, AB, Canada, 15–16 February 2017. SPE-185058-MS. [Google Scholar]

- Lin, H.; Song, X.X.; Sun, X.Y.; Hu, S.L.; Luo, C.; Qu, H.; Yang, B. Dynamic displacement of adsorbed methane by fracturing fluid during soaking in a shale gas reservoir based on low-field nuclear magnetic resonance. J. Pet. Sci. Eng. 2022, 208, 109582. [Google Scholar] [CrossRef]

- Zhang, T.; Ellis, G.S.; Ruppel, S.C.; Milliken, K.; Yang, R. Effect of organic-matter type and thermal maturity on methane adsorption in shale-gas systems. Org. Geochem. 2012, 47, 120–131. [Google Scholar] [CrossRef]

- Qin, C.; Jiang, Y.D.; Zhou, J.P.; Zuo, S.Y.; Chen, S.W.; Liu, Z.J.; Yin, H.; Li, Y. Influence of supercritical CO2 exposure on water wettability of shale: Implications for CO2 sequestration and shale gas recovery. Energy 2021, 242, 122551. [Google Scholar] [CrossRef]

- Bostrom, N.; Chertov, M.; Pagels, M.; Willberg, D.; Chertova, A.; Davis, M.; Zagorski, W. The time-dependent permeability damage caused by fracture fluid. In Proceedings of the SPE International Symposium and Exhibition on Formation Damage Control, Lafayette, LA, USA, 26–28 February 2014. SPE-168140-MS. [Google Scholar]

- Yang, L.; Ge, H.K.; Shen, Y.H.; Ren, K.; Sheng, M.; Gao, Z.Y.; Qin, X.L.; Su, S. Experimental research on the shale imbibition characteristics and its relationship with microstructure and rock mineralogy. In Proceedings of the SPE Asia Pacific Unconventional Resources Conference and Exhibition, Brisbane, Australia, 9–11 November 2015. SPE 176882. [Google Scholar]

- Meng, M.M.; Ge, H.K.; Shen, Y.H.; Li, L.L.; Tian, T.H.; Chao, J. The effect of clay-swelling induced cracks on shale permeability during liquid imbibition and diffusion. J. Nat. Gas Sci. Eng. 2020, 83, 103514. [Google Scholar] [CrossRef]

- Faisal, U.R.A.; Muhammad, A.; Stefan, I.; Alireza, K. Coal fines migration: A holistic review of influencing factors. Adv. Colloid Interface Sci. 2022, 301, 102595. [Google Scholar]

- Javadpour, F.; Fisher, D.; Unsworth, M. Nanoscale gas flow in shale sediments. J. Can. Petrol. Technol. 2007, 46, 55–61. [Google Scholar] [CrossRef]

- Civan, F.; Rai, C.S.; Sondergeld, C.H. Shale-gas permeability and diffusivity inferred by improved formulation of relevant retention and transport mechanisms. Transp. Porous Media 2011, 86, 925–944. [Google Scholar] [CrossRef]

- Wu, K.L.; Chen, Z.X.; Li, X.F. Real gas transport through nanopores of varying cross-section type and shape in shale gas reservoirs. Chem. Eng. J. 2015, 281, 813–825. [Google Scholar] [CrossRef]

- Wu, K.L.; Chen, Z.X. Real gas transport through complex nanopores of shale gas reservoirs. In Proceedings of the SPE Europec featured at 78th EAGE Conference and Exhibition, Vienna, Austria, 30 May–2 June 2016. SPE-180086-MS. [Google Scholar]

- Rahmanian, M.; Aguilera, R.; Kantzas, A. A new unified diffusion viscous flow model based on pore-level studies of tight gas formations. SPE J. 2013, 18, 38–49. [Google Scholar] [CrossRef]

- Beskok, A.; Karniadakis, G.E. Report: A model for flows in channels, pipes, and ducts at micro and nano scales. Nanoscale Microscale Thermophys. Eng. 1999, 3, 43–77. [Google Scholar]

- Wu, K.L.; Li, X.F.; Guo, C.H.; Wang, C.C.; Chen, Z.X. A unified model for gas transfer in nanopores of shale-gas reservoirs: Coupling pore diffusion and surface diffusion. SPE J. 2016, 21, 1583–1611. [Google Scholar] [CrossRef]

- Lei, T.; Yin, X.Y.; Zong, Z.Y. Pore pressure prediction in orthotropic medium based on rock physics modeling of shale gas. J. Nat. Gas Sci. Eng. 2020, 74, 103091. [Google Scholar] [CrossRef]

- Zhao, C.J.; Li, J.; Jin, Y.X.; Zaman, M.; Miao, Y.N. Investigation of dynamic pore pressure in shale gas reservoir during the multi-fracturing and its influence on fault slip. J. Nat. Gas Sci. Eng. 2021, 95, 104190. [Google Scholar] [CrossRef]

| Coal Sample | Tested by Saturated Samples | Tested by Displaced Samples (1 MPa) | Tested by Displaced Samples (2 MPa) | Tested by Displaced Samples (4 MPa) | Tested by the Samples with Residual Water |

|---|---|---|---|---|---|

| D-1 | 100 | 88.52 | 85.28 | 83.91 | 66.72 |

| D-2 | 100 | 97.53 | 85.40 | 76.11 | 40.90 |

| D-3 | 100 | 81.37 | 76.94 | 71.32 | 42.60 |

| Parameters | Value | Reference | Parameters | Value | Reference |

|---|---|---|---|---|---|

| Average pore radius r (nm) | 25 | NMR test | Reservoir temperature T (K) | 309 | Well logging |

| Original water saturation Swi | 0.1 | Well logging | Porosity ϕ | 0.06 | NMR test |

| Original pore pressure Pg0 (MPa) | 16 | Well logging | Pore tortuosity τ | 1.3 | Micro CT |

| Pore length L (m) | 0.1 | Hypothesis | Gas compressibility Cg (1/Pa) | 0.00609 | Industry-standard chart |

| Gas compressibility factor Z | 0.771 | Industry-standard chart | Gas viscosity μg (Pa·s) | 0.000018 | Industry-standard chart |

| Gas constant R (J/(K·mol)) | 8.314 | Industry-standard chart | Mole content of adsorbed gas per unit area na (mol/m2) | 0.000008 | Isothermal adsorption experiment |

| Examples | x/L, h (m) | Pcg, MPa | , mD | Scw | qg, Gp |

|---|---|---|---|---|---|

| Case 1 | x/L = 0, h = 0 | 16 | 0.003253 | 0.1 | qg, Gp |

| Case 2 | x/L = 0.12, h = 0.4 | 16.214 | 0.003136 | 0.1038 | qg1, Gp1 |

| Case 3 | x/L = 0.3, h = 0.4 | 16.538 | 0.003116 | 0.10952 | qg2, Gp2 |

| Case 4 | x/L = 0.3 m, h = 2 | 17.172 | 0.002612 | 0.14608 | qg3, Gp3 |

| Case 5 | x/L = 0.5, h = 0.4 | 16.902 | 0.003094 | 0.11587 | qg4, Gp4 |

| Case 6 | x/L = 0.3 m, h = 4 | 17.967 | 0.002070 | 0.18832 | qg5, Gp5 |

| Case 7 | x/L = 0.9 m, h = 0.4 | 17.645 | 0.003050 | 0.12857 | qg6, Gp6 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lou, Y.; Su, Y.; Wang, K.; Xia, P.; Wang, W.; Xiong, W.; Shao, L.; Yang, F. Revealing the Effects of Water Imbibition on Gas Production in a Coalbed Matrix Using Affected Pore Pressure and Permeability. Atmosphere 2022, 13, 1314. https://doi.org/10.3390/atmos13081314

Lou Y, Su Y, Wang K, Xia P, Wang W, Xiong W, Shao L, Yang F. Revealing the Effects of Water Imbibition on Gas Production in a Coalbed Matrix Using Affected Pore Pressure and Permeability. Atmosphere. 2022; 13(8):1314. https://doi.org/10.3390/atmos13081314

Chicago/Turabian StyleLou, Yi, Yuliang Su, Ke Wang, Peng Xia, Wendong Wang, Wei Xiong, Linjie Shao, and Fuqin Yang. 2022. "Revealing the Effects of Water Imbibition on Gas Production in a Coalbed Matrix Using Affected Pore Pressure and Permeability" Atmosphere 13, no. 8: 1314. https://doi.org/10.3390/atmos13081314

APA StyleLou, Y., Su, Y., Wang, K., Xia, P., Wang, W., Xiong, W., Shao, L., & Yang, F. (2022). Revealing the Effects of Water Imbibition on Gas Production in a Coalbed Matrix Using Affected Pore Pressure and Permeability. Atmosphere, 13(8), 1314. https://doi.org/10.3390/atmos13081314