Field Measurement and Evaluation of Effective Ventilation and Particulate Matter Discharge Efficiency of Air Shafts in Subway Tunnels

Abstract

:1. Introduction

2. Experimental Methodology

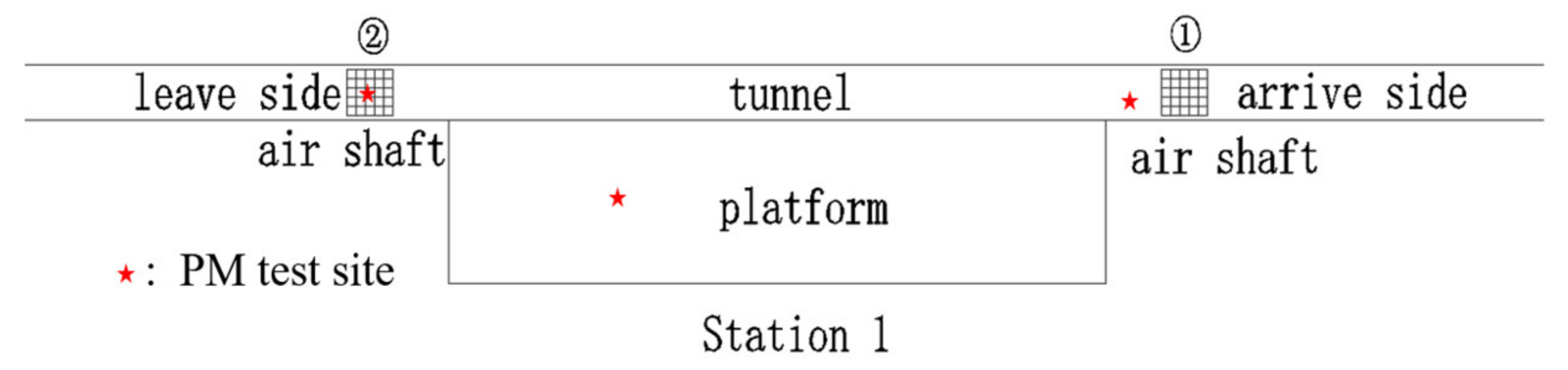

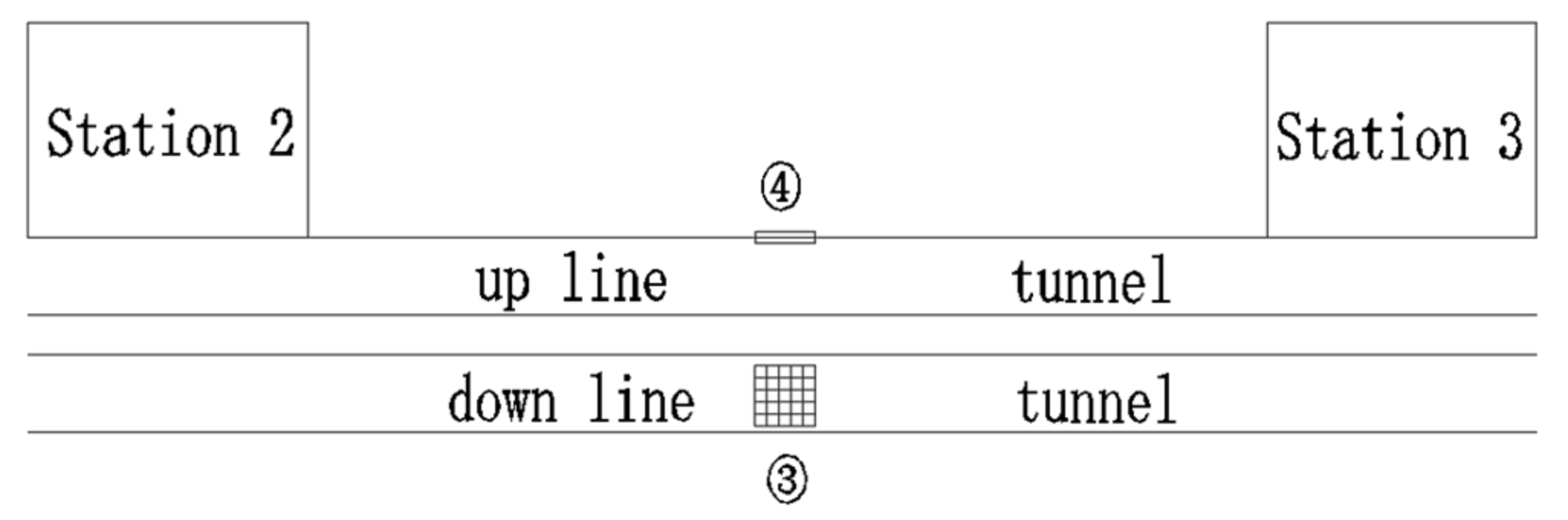

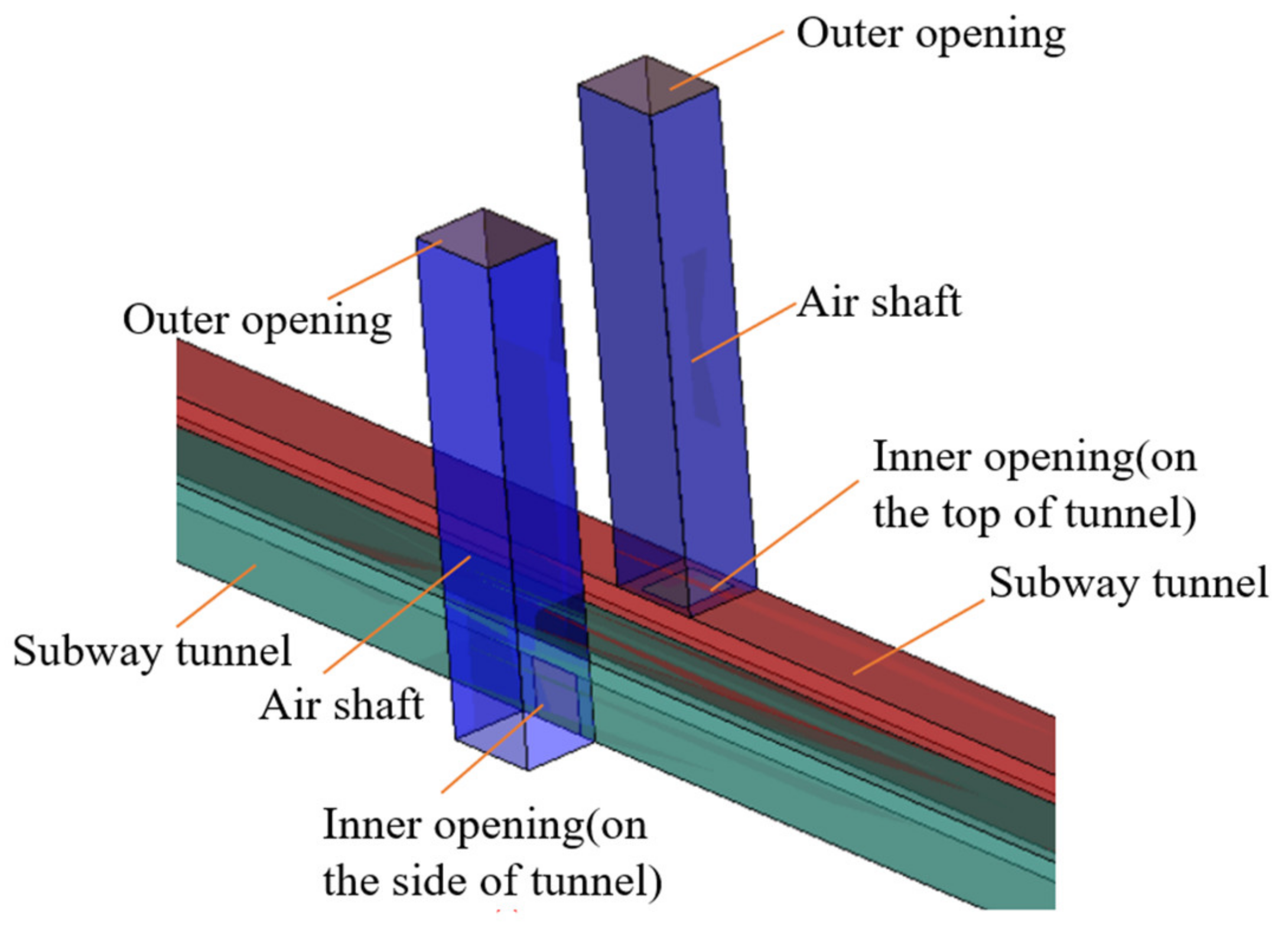

2.1. Research Object

2.2. Equipment and Method

3. Result and Discussion

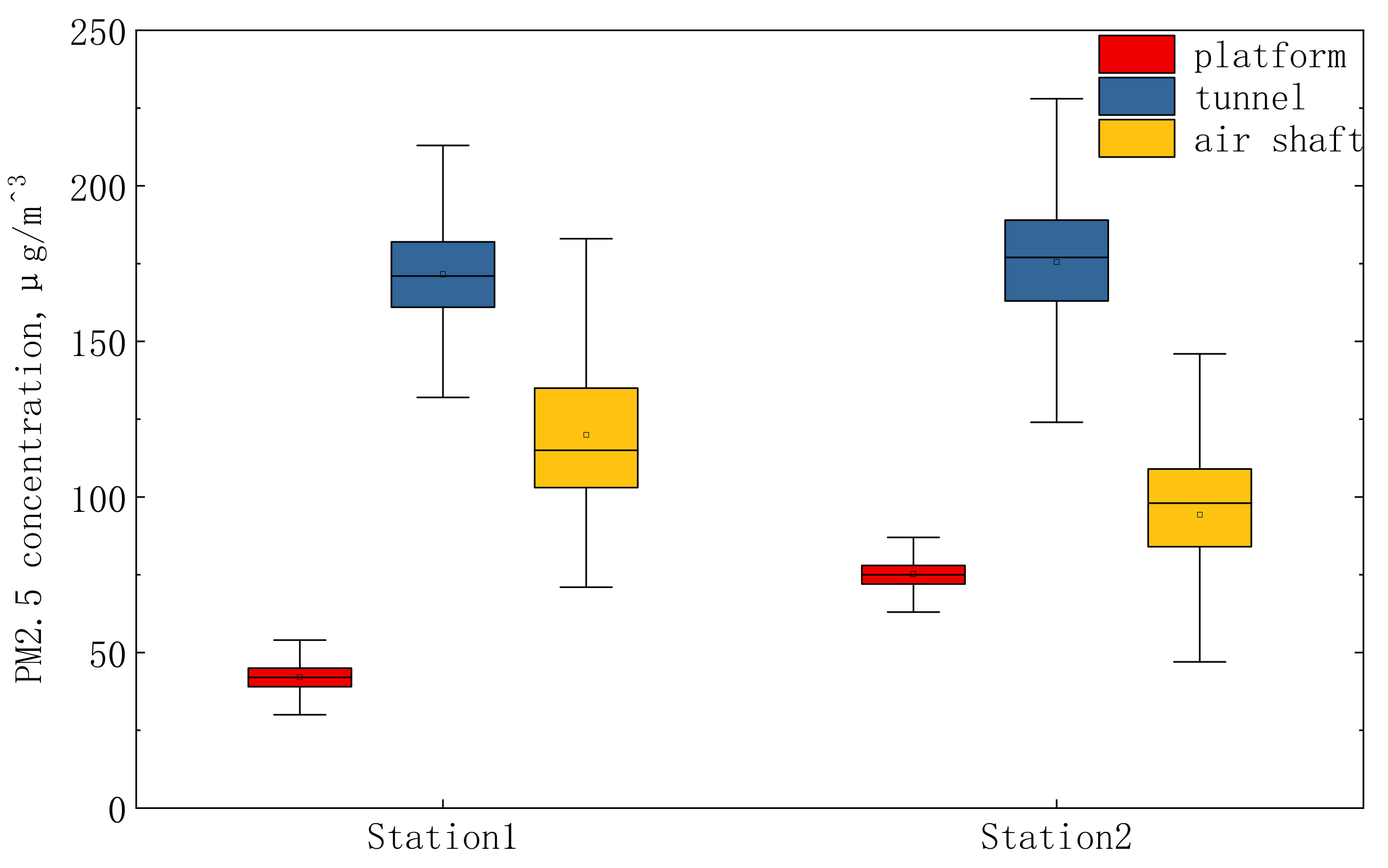

3.1. Particulate Matter Size and Concentration

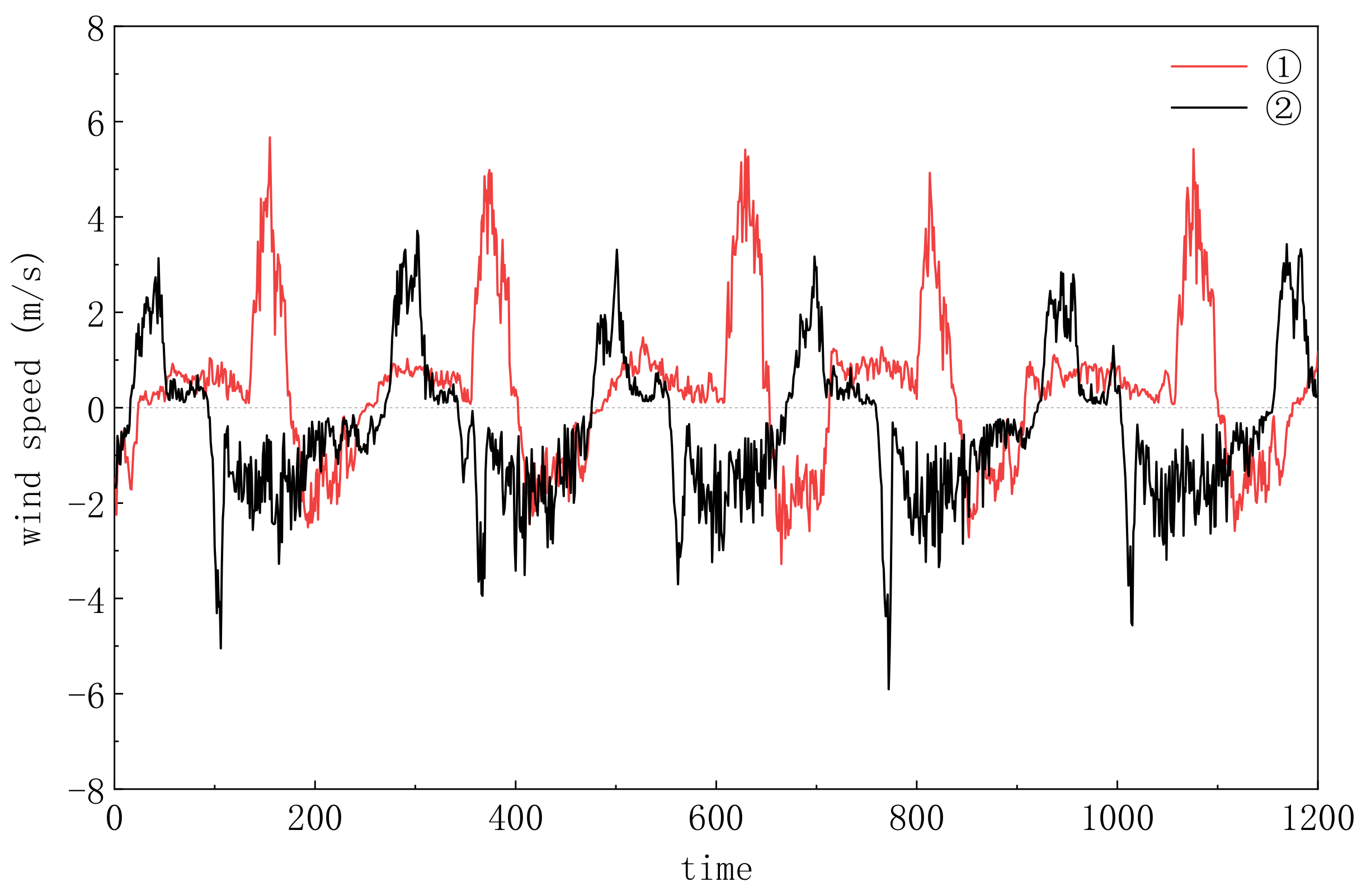

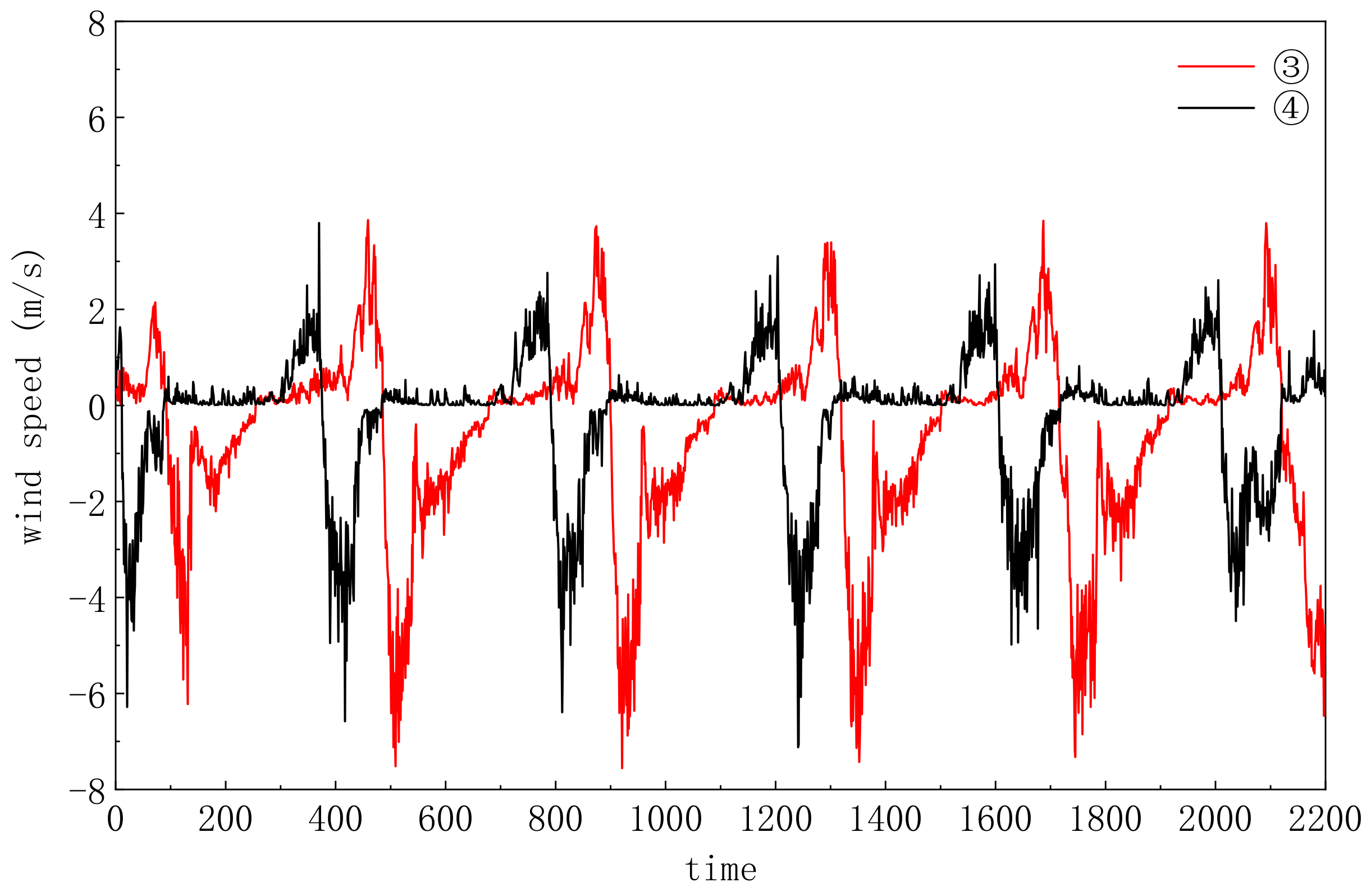

3.2. Piston wind Speed

3.3. Effective Ventilation Volume of Air Shafts

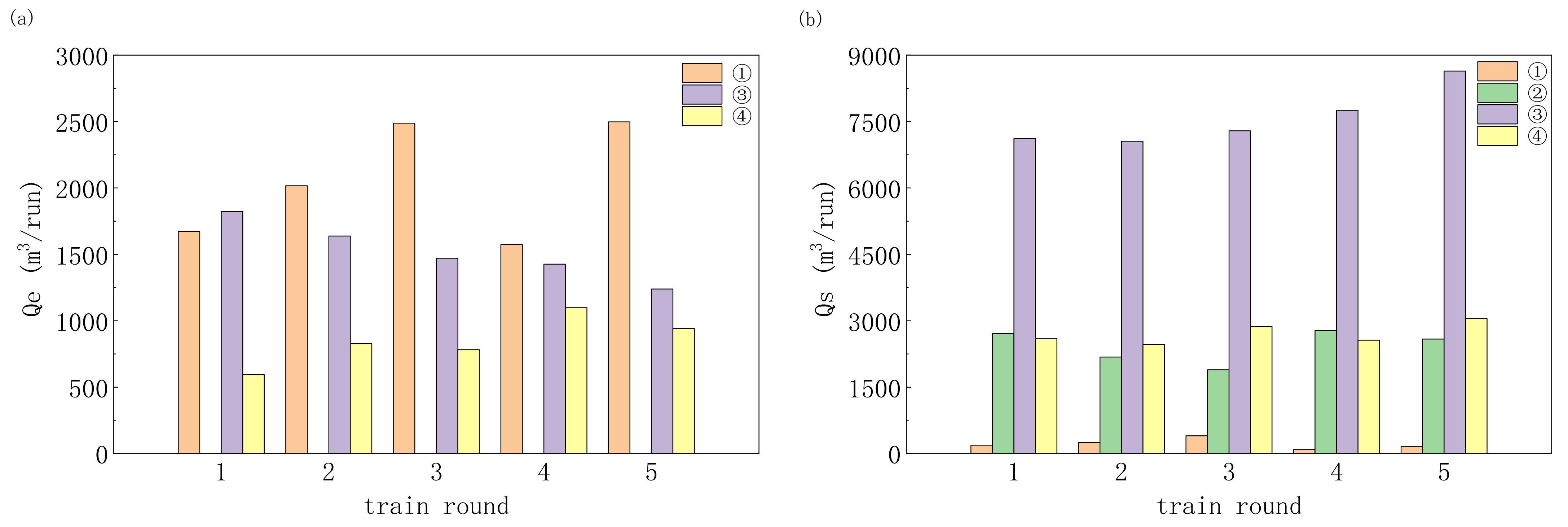

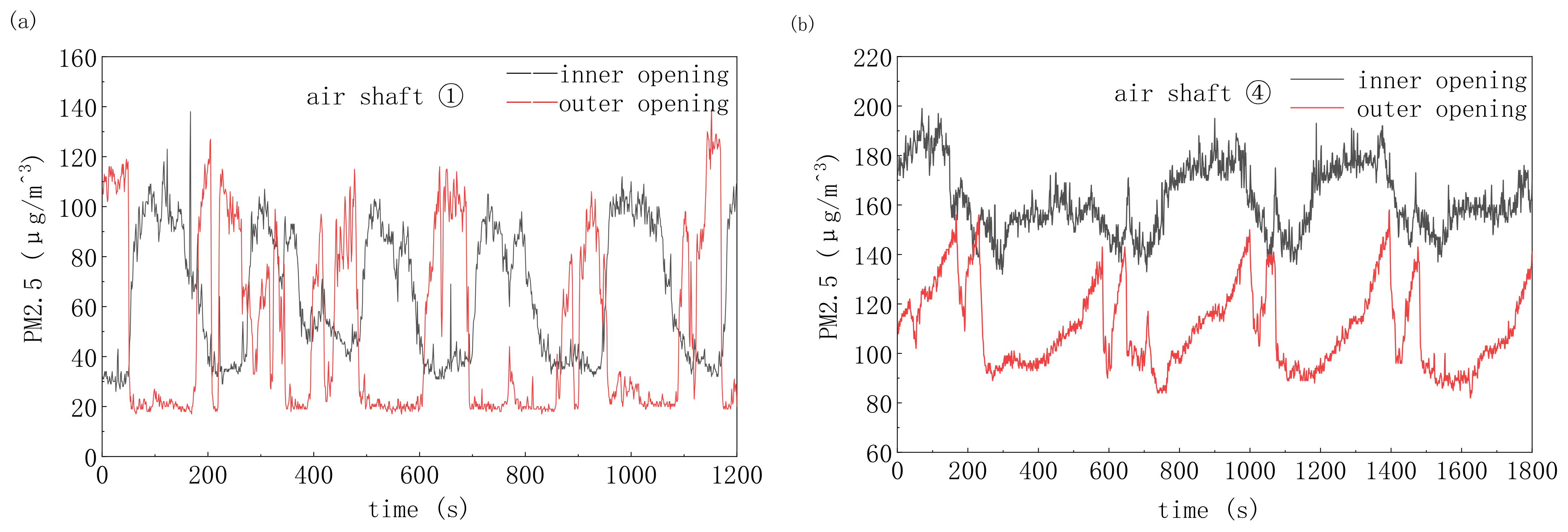

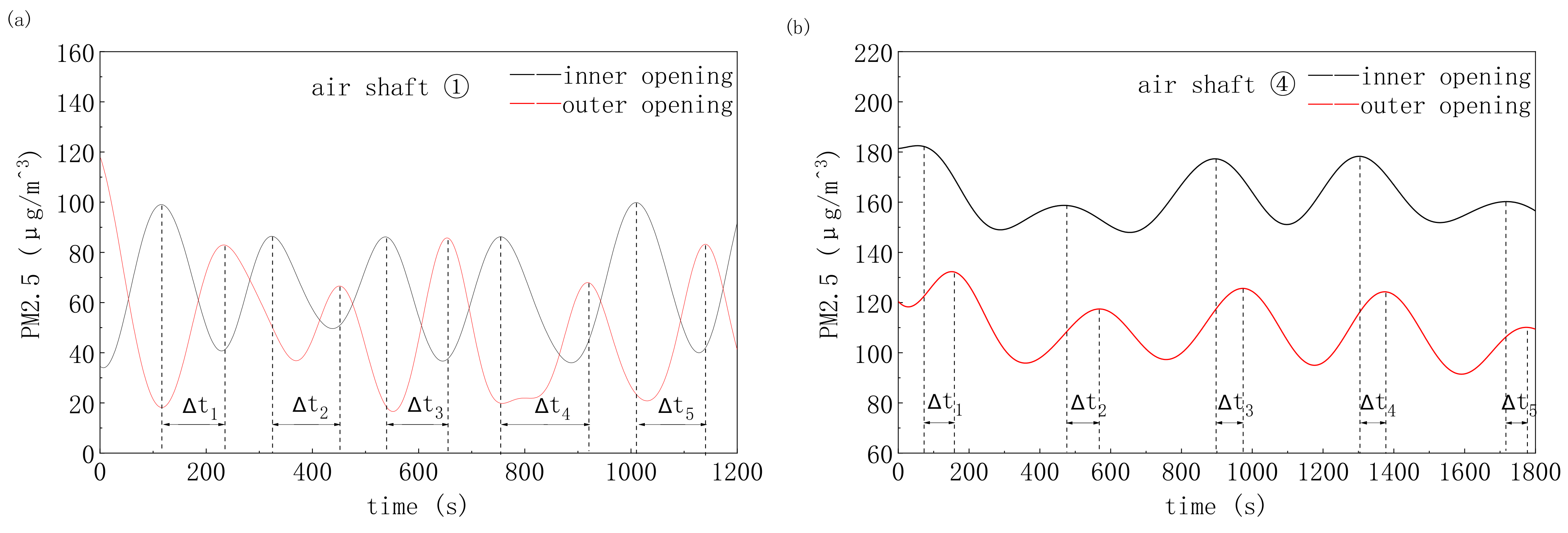

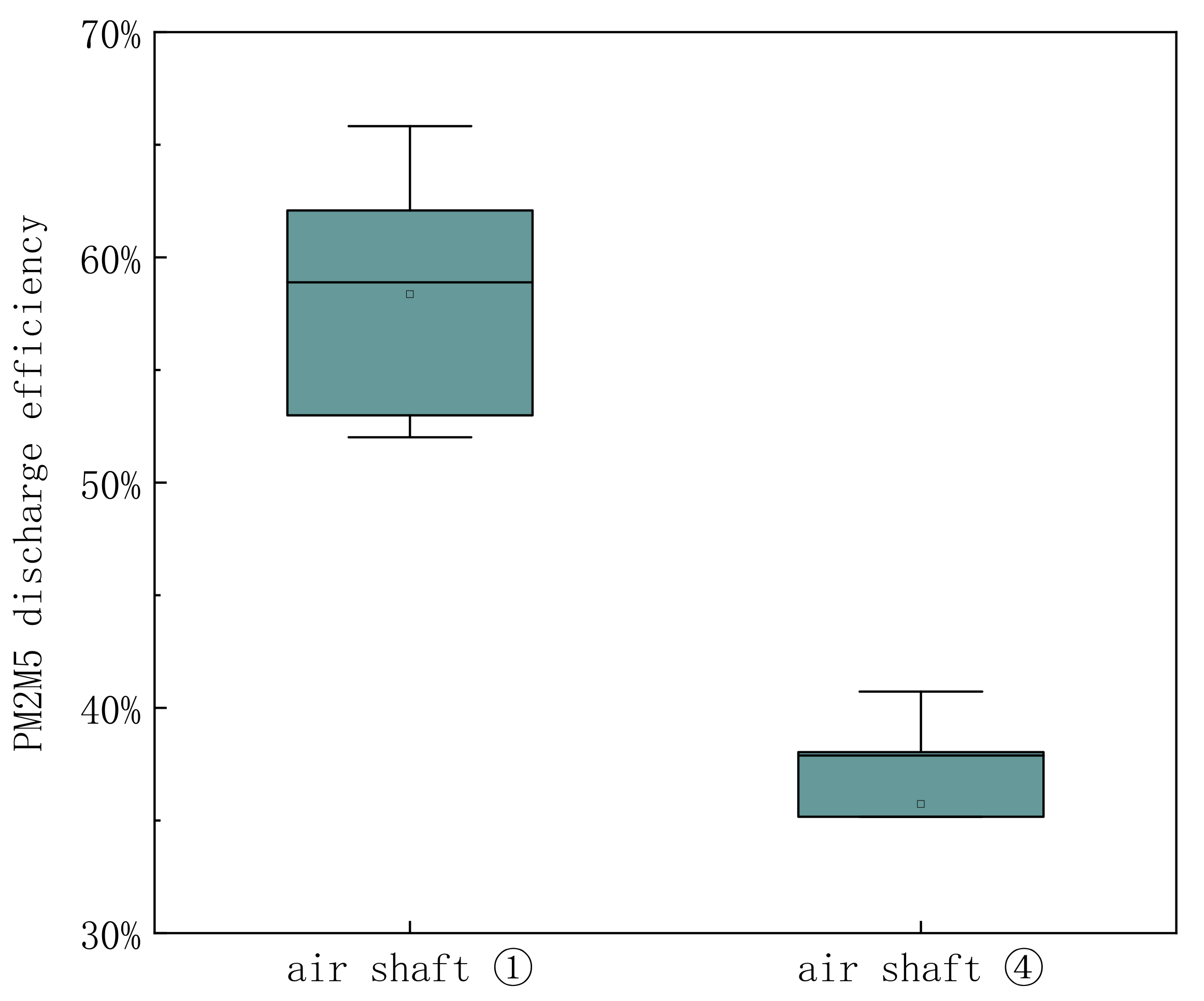

3.4. PM2.5 Discharge Efficiency of Air Shafts

4. Conclusions

- (1)

- PM1 accounted for more than 85% of the inhalable particulate matter in the subway systems, which puts forward a higher requirement for the material of air conditioner filters in subway trains. The value of PM 2.5 mass concentration at different locations is: tunnel > air shaft > platform.

- (2)

- The station air shaft on the train-arriving side can effectively exhaust 2050 m3 of dirty air in the tunnel and inhale 218 m3 of fresh air per train, while the station air shaft on the train-leaving side can effectively inhale 2430 m3 of fresh air from the outside atmosphere per train but can hardly discharge the dirty air in the tunnel. The middle air shaft can not only effectively exhaust dirty air (1519 m3 per train) but can also inhale a large amount of fresh air (7273 m3 per train), and the effective air suction/exhaust volume is significantly larger than the that of the station air shafts.

- (3)

- The air shaft has better ventilation performance if its inner opening is set on the top of the tunnel rather than on the side of the tunnel. When designing a new tunnel, it is better to set the inner opening of the air shaft at the top of the tunnel to obtain a better ventilation performance.

- (4)

- The PM2.5 discharge efficiency of the station air shaft on the train-arriving side was 52.0%~62.8%, higher than that of the middle air shaft, which was 26.8%~40.7%. This index can be used to evaluate the ventilation performance from another angle.

Author Contributions

Funding

Conflicts of Interest

References

- Colombi, C.; Angius, S.; Gianelle, V.; Lazzarini, M. Particulate matter concentrations, physical characteristics and elemental composition in the Milan underground transport system. Atmos. Environ. 2013, 70, 166–178. [Google Scholar] [CrossRef]

- Font, O.; Moreno, T.; Querol, X.; Martinsa, V.; Rodasb, D.S.; Miguelc, E.; Capdevilac, M. Origin and speciation of major and trace PM elements in the Barcelona subway system. Transp. Res. Part D Transp. Environ. 2019, 72, 17–35. [Google Scholar] [CrossRef]

- Guo, L.; Hu, Y.; Hu, Q.; Lin, J.; Li, C.; Chen, J.; Li, L.; Fu, H. Characteristics and chemical compositions of particulate matter collected at the selected metro stations of Shanghai, China. Sci. Total Environ. 2014, 496, 443–452. [Google Scholar] [CrossRef] [PubMed]

- Lee, Y.; Lee, Y.C.; Kim, T.; Choi, J.S.; Park, D. Sources and Characteristics of Particulate Matter in Subway Tunnels in Seoul, Korea. Int. J. Environ. Res. Public Health 2018, 15, 2534. [Google Scholar] [CrossRef] [Green Version]

- Lu, S.; Liu, D.; Zhang, W.; Liu, P.; Fei, Y.; Gu, Y.; Wu, M.; Yu, S.; Yonemochi, S.; Wang, X.; et al. Physico-chemical characterization of PM2.5 in the microenvironment of Shanghai subway. Atmos. Res. 2015, 153, 543–552. [Google Scholar] [CrossRef]

- Kang, S.; Hwang, H.; Park, Y.; HyeKyoung, K.; Chul-Un, R. Chemical Compositions of Subway Particles in Seoul, Korea Determined by a Quantitative Single Particle Analysis. Environ. Sci. Technol. 2008, 42, 9051–9057. [Google Scholar] [CrossRef]

- Lennart, L.K.; Asa, H.; Lennart, M. Subway particles are more genotoxic than street particles and induce oxidative stress in cultured human lung cells. Chem. Res. Toxicol. 2005, 18, 726–731. [Google Scholar]

- Jung, M.H.; Kim, H.R.; Park, Y.J.; Park, D.S.; Chung, K.H.; Oh, S.M. Genotoxic effects and oxidative stress induced by organic extracts of particulate matter (PM 10) collected from a subway tunnel in Seoul, Korea. Mutat. Res. 2012, 749, 39–47. [Google Scholar] [CrossRef]

- Ngoc, L.T.N.; Lee, Y.; Chun, H.S.; Ju-Young, M.; Jin, S.C.; Duckshin, P.; Young-Chul, L. Correlation of alpha/gamma-Fe2O3 nanoparticles with the toxicity of particulate matter originating from subway tunnels in Seoul stations, Korea. J. Hazard Mater. 2020, 382, 121175. [Google Scholar] [CrossRef]

- Zhang, Y.; Chu, M.; Zhang, J.; Duan, J.; Hu, D.; Zhang, W.; Yang, X.; Jia, X.; Deng, F.; Sun, Z. Urine metabolites associated with cardiovascular effects from exposure of size-fractioned particulate matter in a subway environment: A randomized crossover study. Env. Int. 2019, 130, 104920. [Google Scholar] [CrossRef]

- Debananda, R.; Yong-Chil, S.; Hyeong, G.; Namgung, S.; Bark, K. Inhalation cancer risk from PM10 in the metropolitan subway stations in Korea-ScienceDirect. J. Transp. Health 2019, 14, 100580. [Google Scholar]

- Bachoual, R.; Boczkowski, J.; Goven, D.; Amara, N.; Tabet, L.; On, D.; Leçon-Malas, V.; Aubier, M.; Lanone, S. Biological effects of particles from the Paris subway system. Chem. Res. Toxicol. 2007, 20, 1426–1433. [Google Scholar] [CrossRef] [PubMed]

- Son, Y.S.; Oh, Y.H.; Choi, I.Y.; Dinh, T.; Chung, S.; Lee, J.; Park, D.; Kim, J. Development of a magnetic hybrid filter to reduce PM10 in a subway platform. J. Hazard Mater. 2019, 368, 197–203. [Google Scholar] [CrossRef] [PubMed]

- Woo, S.-H.; Cheon, T.-W.; Lee, G.; Kim, J.B.; Bae, G.-N.; Kwon, S.-B.; Hong, R.J.; Yook, S.-J. Performance evaluation of a hybrid dust collector for removing particles during subway train operation. Aerosol Sci. Technol. 2019, 53, 562–574. [Google Scholar] [CrossRef]

- Sim, J.-B.; Woo, S.-H.; Yook, S.-J.; Kim, J.B. Baffle dust collector for removing particles from a subway tunnel during the passage of a train. J. Mech. Sci. Technol. 2018, 32, 1415–1421. [Google Scholar] [CrossRef]

- Sim, J.-B.; Yoon, H.H.; Woo, S.-H.; Yook, S.; Kim, J.B.; Bae, G.; Yoon, H.H. Performance Estimation of a Louver Dust Collector Attached to the Bottom of a Subway Train Running in a Tunnel. Aerosol Air Qual. Res. 2017, 17, 1954–1962. [Google Scholar] [CrossRef] [Green Version]

- Lin, C.J.; Chuah, Y.K.; Liu, C.W. A study on underground tunnel ventilation for piston effects influenced by draught relief shaft in subway system. Appl. Therm. Eng. 2008, 28, 372–379. [Google Scholar] [CrossRef]

- Kim, J.Y.; Kim, K.Y. Effects of vent shaft location on the ventilation performance in a subway tunnel. J. Wind. Eng. Ind. Aerodyn. 2009, 97, 174–179. [Google Scholar] [CrossRef]

- Lee, K.B.; Park, J.S.; Myung Do, O. Field measurement and estimation of ventilation flow rates by using train-induced flow rate through subway vent shafts. J. Mech. Sci. Technol. 2014, 28, 2677–2686. [Google Scholar] [CrossRef]

- Huang, Y.D.; Li, C.; Kim, C.N. A numerical analysis of the ventilation performance for different ventilation strategies in a subway tunnel. J. Hydrodyn. 2012, 24, 193–201. [Google Scholar] [CrossRef]

- Huang, Y.D.; Gong, X.Y.; Pen, Y.J.; Lin, X.Y.; Kim, C.N. Effects of the ventilation duct arrangement and duct geometry on ventilation performance in a subway tunnel. Tunn. Undergr. Space Technol. Inc. Trenchless Technol. Res. 2011, 26, 725–733. [Google Scholar]

- Yang, Z.A.; Yang, Y.A.; Zahali, B.; Rongwei, B.; Junhui, G.; Yixiao, W.; Liang, Y. Analytical and numerical study on natural ventilation performance in single- and gable-slope city tunnels. Sustain. Cities Soc. 2019, 45, 258–270. [Google Scholar]

- Huang, Y.D.; Gao, W.; Kim, C.N. A numerical study of the train-induced unsteady airflow in a subway tunnel with natural ventilation ducts using the dynamic layering method. J. Hydrodyn. 2010, 22, 164–172. [Google Scholar] [CrossRef]

- Wu, Y.; Gao, N.P.; Wang, L.H.; Yan, W.; Naiping, G.; Lihui, W.; Xiping, W. A numerical analysis of airflows caused by train-motion and performance evaluation of a subway ventilation system. Indoor Built Environ. 2013, 23, 1420326X13479623. [Google Scholar]

- Ji, J.; Han, J.Y.; Fan, C.G.; Gao, Z.H.; Sun, J.H. Influence of cross-sectional area and aspect ratio of shaft on natural ventilation in urban road tunnel. Int. J. Heat Mass Transf. 2013, 67, 420–431. [Google Scholar] [CrossRef]

- Fan, C.G.; Ji, J.; Wang, W.; Sun, J.H. Effects of vertical shaft arrangement on natural ventilation performance during tunnel fires. Int. J. Heat Mass Transf. 2014, 73, 158–169. [Google Scholar] [CrossRef]

- Liu, Y.; Shi, K.F.; Zhang, Y.; Li, X.F.; Yu, Y.B. Influence of train operating organization on airflow exchange volume of air shafts. HAVC 2019, 49, 7–13. [Google Scholar]

- Zhang, Z.; Zhang, H.; Tan, Y.; Yang, H. Natural wind utilization in the vertical shaft of a super-long highway tunnel and its energy saving effect. Build. Environ. 2018, 145, 140–152. [Google Scholar] [CrossRef]

- Wang, L.H.; Gong, W.; Song, J.; Shen, Z.Q.; Yan, Z.C. Field Measurement Study on Velocity Characteristics of Horizontal Piston Wind Valve in Subway. J. Refrig. 2012, 33, 54–59+65. [Google Scholar]

- Zhang, Y.; Zhang, Q.; Bi, H.Q.; Yang, X. Field Measurement and Analysis of the Wind Speed of the Air Passage at the Airshaft for Subway. Refrig. Air Cond. 2020, 34, 463–467. [Google Scholar]

| Air Shaft | Location | Damper Area, m2 | Total Duct Volume, m3 | Inner Opening Location |

|---|---|---|---|---|

| ① | Train-arriving side of station | 20.14 | 1634 | Top of tunnel |

| ② | Train-leaving side of station | 20.14 | 1634 | Top of tunnel |

| ③ | Middle of interval tunnel | 20.14 | 1500 | Top of tunnel |

| ④ | Middle of interval tunnel | 20.14 | 1500 | Side of tunnel |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Qu, H.; Zang, J.; Wu, Y. Field Measurement and Evaluation of Effective Ventilation and Particulate Matter Discharge Efficiency of Air Shafts in Subway Tunnels. Atmosphere 2022, 13, 1040. https://doi.org/10.3390/atmos13071040

Qu H, Zang J, Wu Y. Field Measurement and Evaluation of Effective Ventilation and Particulate Matter Discharge Efficiency of Air Shafts in Subway Tunnels. Atmosphere. 2022; 13(7):1040. https://doi.org/10.3390/atmos13071040

Chicago/Turabian StyleQu, Haibo, Jianbin Zang, and Yan Wu. 2022. "Field Measurement and Evaluation of Effective Ventilation and Particulate Matter Discharge Efficiency of Air Shafts in Subway Tunnels" Atmosphere 13, no. 7: 1040. https://doi.org/10.3390/atmos13071040

APA StyleQu, H., Zang, J., & Wu, Y. (2022). Field Measurement and Evaluation of Effective Ventilation and Particulate Matter Discharge Efficiency of Air Shafts in Subway Tunnels. Atmosphere, 13(7), 1040. https://doi.org/10.3390/atmos13071040