Abstract

The practical implementation of the European Council Directive no. 2013/59/EURATOM in Romania requires reliable indoor measurements of the radon (222Rn) activity concentration in air. In Romania, several Testing Laboratories were designated for radon activity and/or radon activity concentration in air measurements by the Romanian National Commission for Nuclear Activities Control (CNCAN). The calibration of the instruments used for indoor radon activity concentration measurements is very important. IFIN-HH, through its Ionizing Radiation Metrology Laboratory (LMRI), performed advanced research in the field of radon metrology, using radon standard sources prepared by LMRI, its radon chamber facility and a new reference radon monitor. The most recent results are described in this article. The radon chamber facility from IFIN-HH was technically improved, and new equipment and methods were set up and tested in order to provide new calibration services for customers. Additionally, calibration of the radon monitors was performed, as well as of the systems with solid-state nuclear track detectors, used for radon in air activity concentration measurements. IFIN-HH/LMRI obtained the CNCAN designation as Calibration Laboratory for installations measuring the radon activity concentration in air.

1. Introduction

The European Council Directive no. 2013/59/EURATOM [1] was implemented in the Romanian national legislation by Law no. 63/9.03.2018, which modified and completed Law no. 111/1996 regarding the safe deployment, regulation, authorization and control of nuclear activities. During the same year, Government Decision no. 526/12.07.2018 for the approval of the National Radon Action Plan (PNAR) was issued. More recently, three Orders of the President of the Romanian National Commission for Nuclear Activities Control (CNCAN) were issued: Order no. 185/22.07.2019 for the approval of the Methodology to determine the radon activity concentration in air inside buildings and at working places, Order no. 180/17.11.2020 for the approval of the Norms for personal dosimetry and radon, and Order no. 237/12.09.2019 for the approval of the Norms regarding the designation procedure for laboratories in the nuclear field. This complex legislation adopted by the European and national authorities from Romania (and other EU countries as well) reflects the significance of the risk of radon (222Rn isotope) to public health [2]. The practical implementation of PNAR requires important efforts of several Romanian Government ministries, but also the involvement of many other institutions: local and central public authorities, academia (universities and national institutes for research and development), designated laboratories, private companies, mass media, etc. The practical implementation of the National Radon Action Plan is based on the measurements performed by the Testing Laboratories designated by CNCAN. These measurements of low activity concentrations of radon in air must be reliable (as accurate and precise as possible), taking into consideration that the national reference level of the annual average concentration of radon in air (indoor) must not exceed 300 Bq/m3.

Presently, in Romania, there are five Testing Laboratories designated by CNCAN for measurements of radon activity or radon activity concentration in air. All these laboratories are potential beneficiaries of the results reported in this article. Until recently, the calibration of the instruments used by these laboratories for radon activity concentration measurements was possible only abroad, requiring the international transport of the instruments (time-consuming and expensive calibrations). Based on the results presented in this article, IFIN-HH, through its Ionizing Radiation Metrology Laboratory (LMRI), is now offering an advantageous alternative for the calibration of the instruments measuring the radon in air activity concentration.

Advanced research in the field of radon metrology was performed at IFIN-HH during the last 15 years, by LMRI and by the former Radionuclide Metrology Laboratory (this laboratory joined the dose metrology laboratory (CMRID), and they formed a new laboratory, LMRI, founded in 2019). Important scientific results in this field were obtained in the framework of several national and European joint research projects: the bilateral collaboration agreement between IFIN-HH and CEA/LNE-LNHB (France), as presented in references [3,4]; the SEPRAD project (see the references [5,6,7,8,9]); the CARSTEAM project, [10,11,12]; the EURAMET EMPIR 16ENV10 MetroRADON joint research project (2017–2020) [13,14] and other projects. The main practical achievements resulting from these completed research projects are: the Radon Standard System (used to produce radon gaseous standard sources or standard sources with radon dissolved in liquid scintillator, in different types of vials/ampoules, with activity values up to about 200 kBq), the radon chamber of 1 m3 volume and its accessories (a vacuum pump; temperature, humidity and air pressure sensors; electrical power supply; pressurized bottle with air having a low radon content; air compressor; pipes with electrical valves for the radon admission and evacuation in the radon chamber) which are used to produce radon reference atmospheres, the assurance of the international metrological traceability and equivalence of radon activity measurements following our successful participation in international comparisons [15], and the possibility to perform reliable radon activity concentration measurements (in air) using a Radon Scout monitor calibrated by the producer SARAD in 2008 and 2019.

Most of the recent work performed at IFIN-HH in the field of radon metrology, in the framework of the Program Nucleu, project no. PN 19 06 02 04 (2020–2021), is presented in this paper. The research work had three objectives: the development and testing of a calibration method for the monitors measuring the radon activity concentration in air, the testing and improvement of the radon chamber tightness, and the controlled radon exposure of several nuclear track detectors placed in the radon chamber. The results obtained are presented and discussed, together with proposed new research objectives of IFIN-HH/LMRI in this field for the near future.

2. Materials and Methods

The materials, equipment and methods used for this work are presented below, focusing on the description of the installations introduced recently and the way these are/will be integrated by LMRI in new procedures for the calibration of the instruments measuring the radon activity concentration in air (average or integrated (exposure) values).

2.1. The Reference Radon Monitor

A new high-performance radon monitor model AlphaGuard DF2000 (produced by Bertin Instruments, Montigny-Le-Bretonneux, France) was recently introduced by IFIN-HH/LMRI, together with a dosimetry system provided with optical reading for nuclear track detectors (TASTRAK, produced by Track Analysis Systems Ltd., Bristol, UK) and several TASTRAK detectors.

The AlphaGuard DF2000 monitor [16] is used as a reference instrument for the calibration of other radon monitors received from the customers. This new reference instrument is portable, compact, and uses an ionization chamber (0.62 L volume) for measurements. The main characteristics of the monitor are: operation in diffusion mode, flow mode or sampling; the measurement range of the radon activity concentration is from 2 Bq/m3 up to 2 MBq/m3; it allows the simultaneous discrimination between radon (222Rn) and thoron (220Rn); integrated pump with tunable flow rate in the range [0.05; 2] L/minute; radon sensitivity: 1 count per minute/20 Bq/m3; integrated sensors for temperature, pressure and relative humidity, with the possibility to connect additional external sensors; three interfaces for data transfer: USB, serial RS232 and Bluetooth; DataVIEW software for recording, processing and storing the experimental data. The radon monitor AlphaGuard DF2000 (Figure 1) was calibrated by the Bundesamt für Strahlenschutz (BfS) from Germany, at three different radon activity concentrations, assuring the metrological traceability to the National Standards of Germany: (10,902 ± 545) Bq/m3, (1259 ± 63) Bq/m3 and (431 ± 36) Bq/m3 (the uncertainty corresponds to a coverage factor, k = 2). The first test of the introduced monitor was to measure the radon activity concentration in air, in the seminar room of the DRMR department (IFIN-HH), during 12–13 October 2020 (24 h). The experimental results of the test were in the range [10; 110] Bq/m3, which are normal for a well-ventilated room and are compatible with previous measurements performed in the same building using other radon activity concentration measurement systems.

Figure 1.

The new radon monitor AlphaGuard DF2000 (IFIN-HH/LMRI reference instrument).

This type of detector measures the average radon activity concentration in air (Ā) for a given time period (Δt), according to the formula:

where A(t1) is the radon activity concentration at the start of the measurement/exposure and λ (2.0984·10−6 s−1) is the decay constant of 222Rn (equal to ln(2)/T1/2, where T1/2 is the half-life of this radionuclide: (3.8232 ± 0.0008) days, according to the reference [17]).

Ā = A(t1)·(1−e−λ·Δt)/(λ·Δt),

2.2. The Solid-State Nuclear Track Detectors and the Associated Dosimetry System with Optical Reading

In the case of solid-state nuclear track detectors (SSNTDs), the radon detection is based on the interactions with the alpha-particles emitted after the radioactive decay of 222Rn and its short half-life daughters—the alpha-particle emitters 218Po and 214Po. The TASTRAK solid-state nuclear track detectors were used in the present work, purchased together with the dosimetry system with optical reading TASLIMAGE (produced by Track Analysis Systems Ltd. (TASL), Bristol, UK) and all the necessary accessories and materials. The alpha-particles are usually travelling a few centimeters in air and a few tens of micrometers in TASTRAK detectors (this distance is called “the range”). Table 1 presents the range values of the alpha-particles emitted following the 222Rn decay, in air and in a TASTRAK detector [18].

Table 1.

The range of the alpha-particles following the 222Rn decay, in air and in a TASTRAK detector.

The dimensions of the TASTRAK detectors are 25 × 25 (mm × mm) (length and width), while their thickness is 1.5 mm. These detectors are inserted in plastic external capsules allowing the radon diffusion, as shown below, in Figure 2.

Figure 2.

The plastic capsules containing TASTRAK detectors, in the IFIN-HH radon chamber.

The optical system TASLIMAGE reads an area of 1 cm2 in the center of each detector. These SSNTDs are made from a rigid plastic polymer material called “Polyallyl Diglycol Carbonate” (PADC, CR-39), having a density of 1.30 g/cm3. When it is exposed to ionizing radiation, such as alpha-particles or protons, a trail of damage is created along the path of the particles within the plastic track detector. These trails are invisible, but can be revealed by chemical etching. The TASTRAK detectors will record all natural alpha-particles at their full energy, with a cut-off angle of 20° for the standard recommended etch conditions (with a NaOH solution of 6.25 M concentration, at 98 °C, for one hour etch time).

A Clifton Digital etching equipment (20 L capacity) is used to prepare the NaOH solution where the TASTRAK detectors are placed and processed after their radon exposure (Figure 3a). This equipment includes: the heating element, the temperature regulating device, the stirrer, a chronometer, an electronic display to set up the optimum temperature and etching time, and a sensor showing the filling level in order to keep a constant volume of the NaOH solution. The optical reading system of the processed TASTRAK detectors is called TASLIMAGE and it uses a dedicated software to measure the radon exposure of these passive detectors (Figure 3b). The TASLIMAGE system has the following characteristics (references [19,20]): analysis system for multiple images captured with a microscope, fully automated, designed to analyze and evaluate the tracks produced by the ionizing radiation in the nuclear track detectors; scanning and automatic analysis of up to 49 track detectors during a single run. The main technical characteristics for radon dosimetry are: reading time per detector: between 40 s and 100 s; lower detection limit: 10 Bq/m3; upper detection limit: 10 MBq/m3; linear response within 5% accuracy for a radon exposure of 500 kBq·h·m−3; the uncertainty of the computed dose values: from 4% up to 8% in the range [200; 5000] kBq·h·m−3.

Figure 3.

The equipment for etching and optical reading of the TASTRAK detectors exposed to radon: (a) the Clifton Digital bath; (b) the TASLIMAGE system.

The time integrated radon activity concentration (or integrated radon exposure, or sometimes called simply “radon exposure”), IA, mentioned above, can be computed according to the following formula:

where A(t1) is the radon activity concentration at the start of the exposure, λ (2.0984·10−6 s−1) is the decay constant of 222Rn (equal to ln(2)/T1/2, where T1/2 is the half-life of this radionuclide: (3.8232 ± 0.0008) days) and Δt is the time period of the radon exposure of the detector. The combined uncertainty values corresponding to the radon activity concentration (see Equation (1)) and the time integrated radon activity concentration (Equation (2)) can be computed according to the reference [21].

IA = A(t1)·(1−e−λ·Δt)/λ,

2.3. Description of the First Calibrated Radon Monitor

The first radon monitor selected for a calibration study at IFIN-HH/LMRI was a Pylon AB5 model. The instrument was kindly offered for this experiment by the SALMROM laboratory from IFIN-HH/DFVM (DFVM is the Department of Life and Environmental Physics).

For this instrument, the measurement is based on the use of Lucas scintillation cells, active and passive. The instrument manual reports a sensitivity in the range [0.0367; 0.0421] counts per minute per Bq·m−3, for different Lucas cells. This means that the counting statistics component of the relative uncertainty associated to a radon activity concentration of about 40 Bq·m−3 (the usual background level in the radon laboratory from IFIN-HH/LMRI) will be approximately equal to 21%, for a coverage factor k = 2 (when the rapid method is used, with an integrated measurement period of one hour).

The three types of Pylon scintillation cells, Continuous Passive Radon Detector (CPRD), model 110A and model 300A, are metallic, cylindrical, with a transparent window at one end (except CPRD) and an air admission entry at the other end. The interior of both types of cells has a thin deposition of a scintillator material sensitive to alpha-particles (ZnS, activated with Ag). The light produced when the scintillator is hit by alpha-particles passes through the window, is collected and the resulting signal is amplified by a photomultiplier, before being recorded and stored by a counting system.

The main characteristics of the Pylon AB5 radon monitor are presented below, in Table 2.

Table 2.

The main characteristics of the Pylon AB5 radon monitor [22] (IFIN-HH/DFVM/SALMROM).

2.4. Testing and Optimizing the Tightness of the Radon Chamber Calibration Stand

The calibration stand with the radon chamber and its accessories is an important facility from IFIN-HH/DRMR Department/LMRI. Following the experiment testing the calibration of the Pylon AB5 radon monitor (described below, in Section 3), a loss of radon gas from the radon chamber was detected. Tightness tests of the radon chamber were performed by decreasing the air pressure in the chamber (a vacuum pump was used) and checking the pressure changes in time with a pressure sensor.

Tightness problems were identified at the four lateral and two upper steel pipes crossing the radon chamber wall, after using penetration liquids (at atmospheric pressure) and, alternatively, checking the penetration inside the radon chamber (at a relative pressure of −50 kPa) of several small drops of alcohol spiked from the exterior part of the crossings. The four lateral pipes and one of the upper pipes were completely dismantled (after cutting the exterior metallic enclosure and extracting the polyurethane foam used as thermal insulator from the two areas of interest) and were mechanically processed in order to increase their thickness and resistance of the threaded ends. Finally, the pipes were mounted and welded from inside the radon chamber (continuous argon welding). In order to improve the tightness even more, at the exterior of the six crossings mentioned above a layer of a substance containing an epoxy resin (Torr Seal, used to seal vacuum enclosures, [23]) was applied. For the only crossing from the lower part of the radon chamber, a large threaded screw with a sealing gasket was mounted inside the pipe, from the interior of the radon chamber.

A reinforcement of the metallic plate from the bottom of the radon chamber was carried out by welding a “star” steel piece in the center of the plate with 6 radial steel strips. In addition, a new inner continuous argon welding of the bottom plate of the radon chamber was successfully performed.

All these improvements of the radon chamber tightness allowed to keep a preliminary vacuum (−99.5 kPa relative pressure) in the chamber for several hours (after night). More details about the results are presented in Section 3 and some of these technical improvements are shown below in Figure 4 and Figure 5.

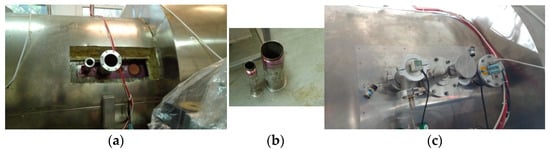

Figure 4.

The tightness improvement of the radon chamber (the four lateral pipes processing): (a) cutting the external enclosure of the radon chamber and extraction of the lateral pipes; (b) two lateral pipes dismantled; (c) the final setup of the lateral pipes (after improvement).

Figure 5.

The tightness improvement of the radon chamber (the continuous argon welding): (a) inner welding (detail) of the bottom steel plate of the radon chamber; (b) general view inside the radon chamber, with the “star” steel piece and the 6 radial steel strips welded on the bottom plate.

3. Results

Three main results were obtained: the capability of IFIN-HH/LMRI to calibrate radon monitors was demonstrated, the tightness of our radon chamber was significantly improved, and for the first time, nuclear track detectors were exposed to radon for more than 6 days, in a controlled manner, inside the radon chamber.

3.1. The Calibration of the Radon Monitor Model Pylon AB5

The Radon Standard System from IFIN-HH/LMRI was used to prepare a standard radon gas source in a stainless-steel recipient (volume of about 100 cm3), perfectly sealed (source no. 3), according to a specific LMRI working instruction regarding the preparation of radon standard sources. The radon activity, after reaching the secular equilibrium with its daughters (214Pb, 214Bi), was measured with the radon calibrated high-resolution gamma-ray spectrometer from DRMRLAB (IFIN-HH/DRMR). This equipment and the testing method are described in references [24,25,26]. The source was measured at 45.5 cm above the HPGe detector of the gamma-ray spectrometry system. According to the experimental data from the Testing Report no. 85/02.12.2020, issued by IFIN-HH/DRMRLAB, the radon activity of source no. 3 was (387 ± 30) Bq (the uncertainty corresponds to a coverage factor k = 1, similar with the other uncertainties reported in this section, with the exception of the data for which a different coverage factor is mentioned) at the reference date and time (3 December 2020, 12:00 h Romanian time (UTC + 2)). The radon from the source was transferred into the closed radon chamber, which contained three radon monitors: Pylon AB5 (for calibration), described in Section 2.3, AlphaGuard DF2000 (the new reference instrument) and Radon Scout. The radon background, measured with the AlphaGuard monitor before the radon transfer from source no. 3, was (58 ± 24) Bq/m3. One must note that the radon background activity concentration values were measured several times with the two monitors (AlphaGuard DF2000 and Radon Scout) and the corresponding values were in good agreement, within the reported uncertainties. The experimental setup is shown in Figure 6. The calibration experiment in the radon reference atmosphere created in the closed radon chamber was performed during a 24 h period (the reference date and time were mentioned above), with repeated radon activity concentration measurements (every hour with the Pylon AB5 monitor, and every 10 min with the reference monitor AlphaGuard DF2000) and the monitoring of temperature, relative humidity and air pressure indicated by the sensors from the radon chamber. The calibration was performed according to the specifications from the specific working procedure adopted by the LMRI. Table 3 presents the obtained results. At the reference date and time, the temperature, pressure and relative humidity of the air inside the radon chamber were 22.21 °C, 101.22 kPa and 37.65%, respectively, as indicated by the monitor AlphaGuard DF2000 (see the data from Table 3, crt. no. 1). For the other data (from Table 3, crt. no. 2), the corresponding temperature, pressure and relative humidity of the air inside the radon chamber were 22.53 °C, 101.11 kPa and 37.39%, respectively (according to the monitor AlphaGuard DF2000).

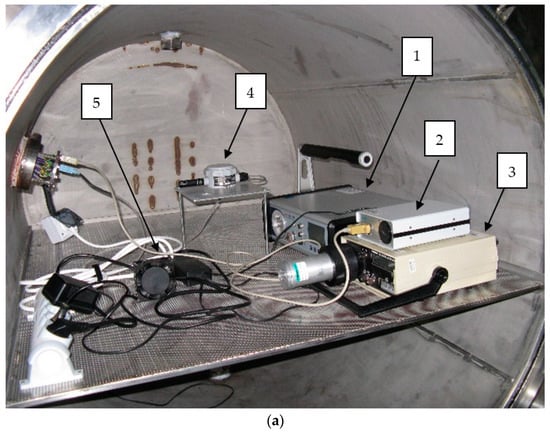

Figure 6.

(a) Experimental setup in the radon chamber for the calibration of the Pylon AB5 monitor: 1—the AlphaGuard DF2000 monitor; 2—the Radon Scout monitor; 3—the Pylon monitor; 4—humidity sensor; 5—fan. (b) Diagram of the radon chamber, its accessories and the connections used for monitor calibrations: 1—the AlphaGuard DF2000 monitor; 2—the Radon Scout monitor; 3—the customer monitor; 4 and 5—temperature and humidity sensors, respectively; 6—radon activity-decaying source in a closed steel recipient; 7—computer with specific software; 8—air pressure sensor; 9—vacuum pump; 10—two fans used for the uniformity of the radon distribution.

Table 3.

The results obtained in the calibration of the Pylon AB5 radon monitor.

IFIN-HH, through LMRI, obtained the CNCAN designation as Calibration Laboratory for the instruments measuring the radon activity concentration in air (Designation Certificate no. LE 338/2020). The Calibration Certificate includes extensive experimental data and technical information, such as: the temperature, humidity and air pressure inside the radon chamber at the reference time (from the sensors reading), the nuclear decay data used for computations, the technical characteristics of the customer monitor and the experimental values of the radon activity concentration indicated by the customer monitor and the reference monitor, and the relative difference between these two values.

3.2. The Tightness Improvement of the Radon Chamber

During the calibration experiment described in the previous Section 3.1, a linearity test with the Pylon AB5 monitor was performed as well. The activity concentration value measured on 4 December 2020, 8:24 h, which was 379 Bq/m3, is lower than the value measured the day before (3 December 2020, 16:24 h) corrected for the radioactive decay: 400 Bq/m3 (value corresponding to 4 December 2020, 8:24 h). The relative difference between these two values is about −5.2%. This was a strong indication that there was a loss of radon gas from the closed radon chamber during the considered time period (16 h).

Following this experimental result, the tightness of the radon chamber was significantly improved, by performing the technical work described above in Section 2.4. This improvement was experimentally confirmed during the period 26 November–1 December 2021 (about 4.5 days), by performing radon activity concentration measurements with the AlphaGuard DF2000 monitor placed in a reference radon atmosphere (in the same radon chamber). This time, the experimental data trend was much better: from an initial value of 2820 Bq/m3 the activity concentration went down to 2770 Bq/m3 (reference date and time for all these measurements: 26 November 2021, 12:00 h (UTC + 2)), which estimates a radon relative loss of only about 1.8% in 4.5 days (see Figure 7). This means that, after the technical improvements, the radon loss from the closed radon chamber was reduced about 20 times.

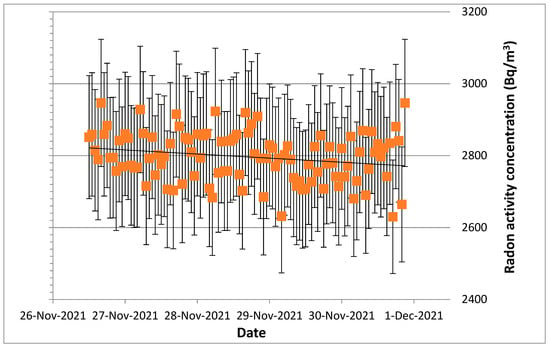

Figure 7.

Evolution of the radon activity concentration in the radon chamber, as indicated by the AlphaGuard DF2000 monitor (all the data are calculated at the reference date and time of 26 November 2021, 12:00 h (UTC + 2)).

3.3. The Radon Exposure of the TASTRAK Nuclear Track Detectors in the Radon Chamber

A radon decaying reference atmosphere was produced recently (26 November 2021–2 December 2021) in the radon chamber from IFIN-HH/LMRI, in a similar method as described above in Section 3.1. The radon was kept in the radon chamber for about 6 days (147 h), in order to perform a controlled integrated exposure of several solid-state nuclear track detectors (TASTRAK and RADOSYS types). Only the results obtained with the TASTRAK detectors are reported in this work. The experimental arrangement of the TASTRAK detectors in different regions inside the radon chamber is presented in Figure 8 (two other detectors were placed outside the radon chamber for the radon background monitoring).

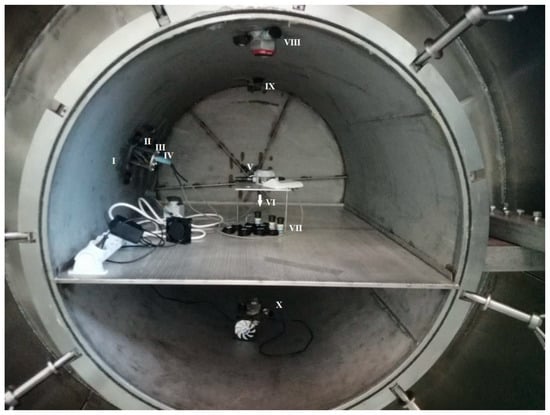

Figure 8.

Experimental arrangement of the TASTRAK and RADOSYS nuclear track detectors (I–X) inside the radon chamber (small black disks and cylinders, respectively): close to the radon injection pipe (I–IV), at the bottom plate and in the center of the chamber (V and VI–VII, respectively), near the two upper pipes (VIII–IX) and near the bottom pipe (X).

The radon activity concentration in air, inside the radon chamber, was monitored with the monitors AlphaGuard DF2000 and Radon Scout (LMRI). For the radiation protection of the staff, during all the experiments with radon, the radon activity concentration in air in the radon laboratory of LMRI was monitored using a portable, small monitor model AlphaE (produced and calibrated by Saphymo GmbH, Frankfurt am Main, Germany).

The radon background inside the radon chamber was measured with the Radon Scout monitor for several hours before and after the exposure of the nuclear track detectors: the radon activity concentration values were in the range [121; 354] Bq/m3, with an estimated average of 270 Bq/m3.

Table 4 presents the experimental results of the time integrated radon activity concentration obtained with the TASTRAK detectors. As this was the first experiment of this type at IFIN-HH, the experimental data are in a satisfactory agreement with the calculated value (according to Equation (2) in Section 2.2) based on the radon maximum activity concentration value indicated by the monitor AlphaGuard DF2000 ((2992 ± 175) Bq/m3), corresponding to the beginning of the radon exposure of the detectors inside the radon chamber: (271 ± 20) kBq·h·m−3 (k = 1). This estimated value includes the radon background exposure contribution as well. One must note that the arithmetic mean of the integrated radon exposure values of the SSNTDs placed inside the radon chamber (from I to X) is (262 ± 17) kBq·h·m−3 (the relative difference from the calculated value is only −3.3%).

Table 4.

Experimental results of the time integrated radon activity concentration obtained with different TASTRAK detectors (all the reported uncertainty values correspond to k = 2).

4. Discussion

A few considerations regarding the results presented in Section 3 are necessary. Regarding the results from Table 3, the activity concentration values indicated by the two monitors (Pylon AB5 and AlphaGuard DF2000) at the same reference time (3 December 2020, 12:00 h (UTC + 2)) are in agreement within the stated uncertainties (for k = 1). One must note that the values measured later (between 16:24–17:24) are closer, which suggests either that a longer time is needed to obtain a homogeneous radon distribution in the radon chamber, or the Pylon AB5 monitor needs more working time in order to perform correct measurements of relatively low radon concentrations (results must be considered after 3.5 h). The higher uncertainty of the results indicated by the AlphaGuard DF2000 monitor is explained by the fact that the measurements were performed in a short period of time (measurements series, each only 10 min long). A future improvement of the calibration procedure for these types of radon monitors consists in using technical air (or nitrogen gas) with very low radon content inside the radon chamber or another enclosure, in order to measure the radon background.

As presented in Section 3.2, the radon losses from the radon chamber were minimized after the technical improvements implemented. This now allows performing radon exposures of nuclear track detectors for a longer period of time (for a period of up to about 10 days). For even longer exposures in the radon decaying reference atmosphere, the estimation of a correction factor for radon loss would be necessary. A new working procedure for the calibration of the systems using nuclear track detectors should be drawn in the near future and implemented in the LMRI Quality Management System.

The results from Table 4 appear to illustrate a non-homogeneous distribution of radon inside the radon chamber (see the references [27,28]). This might be explained by the fact that the two fans placed in the radon chamber were active only for a few hours after the radon transfer. The highest time integrated radon activity concentrations were recorded close to the pipe used for the radon transfer (IV) and the nearby bottom plate of the chamber (V), but also in the central area of the radon chamber (VI–VII). The lower values indicated by the other detectors (positions I–III, VIII–X) might be determined also by some wall effects (further investigations are necessary). The fact that the lowest value of the integrated exposure was recorded by the exterior detectors is normal, because it corresponds to the radon background in the laboratory. Nevertheless, it is important to underline that the detectors placed in the center of the radon chamber had the closest values to the one obtained by the AlphaGuard DF2000 monitor. A uniform radon distribution in the radon chamber is important for the calibrations. Presently, when only radon activity-decaying sources are used (and not continuous radon flow sources), the air tightness of the radon chamber is essential for the metrological traceability of the activity of the radon source transferred into the radon chamber.

In the future, a better solution to perform long radon exposures of nuclear track detectors in the radon chamber (for two weeks or more) would be to use low activity radium (226Ra) sources with certified radon emission rates, directly connected to the radon chamber (in a closed/open circuit). Such a new experimental setup would allow us to obtain radon activity concentrations in air at values to be kept (relatively) constant in time. This option will be investigated in the frame of the European joint research project EURAMET EMPIR 19ENV01 traceRadon (2020–2023), where IFIN-HH/LMRI participates as a funded partner [29,30].

Other future improvements to be considered are related to the assurance of the international metrological traceability of the radon activity concentration measurements. LMRI has primary and secondary standard installations for radon activity measurements. This equipment and the activity standardization methods were successfully confirmed by our participation in two international comparisons. As mentioned in Section 2.1, IFIN-HH/LMRI assures the metrological traceability of the radon activity concentration in air measurements using the reference radon monitor AlphaGuard DF2000 (tertiary standard), calibrated by the BfS, with traceability to the National Standards of Germany. The precise calibration of the radon chamber volume (m3) would allow IFIN-HH/LMRI to assure the metrological traceability of radon activity concentration measurements (Bq/m3), using the Romanian National Standard of activity. The future use of automatic data processing programs (including the possibility to issue Calibration Certificates), together with continuous measurements of the radon background, are considered as well.

5. Conclusions

The new equipment introduced (a high-performance radon monitor to be used as a reference instrument and a modern system for the complete processing and analysis of nuclear track detectors exposed to radon) were successfully tested at the Ionizing Radiation Metrology Laboratory (LMRI) from IFIN-HH. The new pieces of equipment are used for radon metrology research and for metrology services offered to the customers.

The radon chamber of IFIN-HH was technically improved (minimization of the radon loss), allowing the calibration of systems with nuclear track detectors and new research work with low-level radon activity concentrations in air.

The most important future improvements foreseen have the aim to assure the metrological traceability of the radon activity concentration measurements, based on the Romanian primary activity standard for radon.

As a recognition of the results obtained in the field of Ionizing Radiation Metrology, it must be underlined that IFIN-HH, through LMRI, is a Calibration Laboratory, designated by CNCAN in 2020, to perform calibrations of the activity of radioactive sources and of different installations used for ionizing radiation measurements (radioactivity, dosimetry), including, for the first time in Romania, the instruments measuring the radon activity concentration in air, in the range [100; 10,000] Bq/m3.

Author Contributions

Conceptualization, A.L. and I.R.; methodology, A.L., I.R., C.T., C.S.T., C.B. and C.L.T.; validation, C.C. and A.A.; formal analysis, A.A., C.L.T. and I.L.; investigation, A.L., I.R. and C.S.T.; resources, C.P. (experimental and technical support); writing—original draft preparation, A.L. and I.R.; writing—review and editing, I.R., C.B., V.F. and I.L.; supervision, M.-R.I. and V.F.; project administration, V.F. and M.-R.I. All authors have read and agreed to the published version of the manuscript.

Funding

This research work was performed in the frame of the Program Nucleu, conducted with the support of the MINISTRY OF RESEARCH, INNOVATION AND DIGITIZATION (MCID) from ROMANIA, project no. PN 19 06 02 04.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Data sharing not applicable.

Acknowledgments

The authors are grateful to: Maria Sahagia (IFIN-HH/DRMR/LMRI) for her essential contribution in the establishment of the primary radon activity standard in Romania (at IFIN-HH, more than 10 years ago) and for the constant support offered for the development of the radon metrology in LMRI, including useful suggestions for the improvement of this manuscript; Marian Romeo Călin (IFIN-HH/DFVM) for making available the Pylon AB5 monitor for the research work; Eng. Constantin Teodor and co-workers from the company Nuclear & Vacuum S.A., for the technical work performed in order to improve the radon chamber tightness; Elena Manea (IFIN-HH/DRMR) for her work related to public acquisition formalities (materials, equipment and third-party services); Ştefania Stanciu and Florența Andrei for the accounting work related to the Program Nucleu research project PN 19 06 02 04.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Council Directive 2013/59/Euratom of 5 December 2013 Laying down Basic Safety Standards for Protection against the Dangers Arising from Exposure to Ionising Radiation, and Repealing Directives 89/618/Euratom, 90/641/Euratom, 96/29/Euratom, 97/43/Euratom and 2003/122/Euratom. Off. J. L 2014, 13, 1–73. Available online: https://eur-lex.europa.eu/eli/dir/2013/59/oj (accessed on 3 January 2022).

- Cosma, C.; Ciorba, D.; Timar, A.; Szacsvai, K.; Dinu, A. Radon exposure and lung cancer risk in Romania. J. Environ. Prot. Ecol. 2009, 10, 94–103. [Google Scholar]

- Cassette, P.; Sahagia, M.; Grigorescu, L.; Lépy, M.C.; Picolo, J.L. Standardization of Rn-222 by LSC and comparison with alpha and gamma spectrometry. Appl. Radiat. Isot. 2006, 64, 1465–1470. [Google Scholar] [CrossRef] [PubMed]

- Sahagia, M.; Stanescu, G.; Luca, A.; Antohe, A.; Calin, M.R.; Radulescu, I. Education and training tradition at IFIN-HH in radon measurement and evaluation of radiological impact. Rom. Rep. Phys. 2019, 71, 906. [Google Scholar]

- Realisation of the Romanian Radon Primary Standard System Aimed to Assure the National and International Traceability of the Measurements (SEPRAD). Available online: https://www.nipne.ro/proiecte/pn2/19-projects.html (accessed on 3 January 2022).

- Sahagia, M.; Stanga, D.; Wätjen, A.C.; Luca, A.; Cassette, P.; Ivan, C.; Antohe, A. The Rn-222 standard system established at IFIN-HH, Romania. Appl. Radiat. Isot. 2010, 68, 1503–1506. [Google Scholar] [CrossRef] [PubMed]

- Sahagia, M.; Luca, A.; Wätjen, A.C.; Antohe, A.; Ivan, C.; Stanga, D.; Varlam, C.; Faurescu, I.; Toro, L.; Noditi, M.; et al. The primary Romanian radon standard, a common project: IFIN-HH, Bucharest; ICSI, Rm. Valcea; ISP, Timisoara; CEA/LNE-LNHB, Saclay (France). Prog. Cryog. Isot. Sep. 2010, 63, 113–129. [Google Scholar]

- Sahagia, M.; Luca, A.; Wätjen, A.C.; Antohe, A.; Ivan, C.; Stanga, D.; Varlam, C.; Faurescu, I.; Toro, L.; Noditi, M.; et al. Results obtained in measurements of Rn-222 with the Romanian standard system. Rom. J. Phys. 2011, 56, 682–691. [Google Scholar]

- Sahagia, M.; Luca, A.; Wätjen, A.C.; Antohe, A.; Ivan, C.; Varlam, C.; Faurescu, I.; Cassette, P. Establishment of the Rn-222 traceability chain with the Romanian Standard System. Nucl. Instrum. Meth. Phys. Res. A 2011, 631, 73–79. [Google Scholar] [CrossRef]

- Realization of a Radon Chamber—Calibration Stand for the Equipment Used in the Measurement of Radon and Daughter Products Concentration in Air (CARSTEAM). Available online: https://www.nipne.ro/proiecte/pn2/141-projects.html (accessed on 3 January 2022).

- Luca, A.; Sahagia, M.; Antohe, A.; Ioan, M.R.; Serbina, L.; Ivan, C. Radon gas activity measurements in the frame of an international comparison. J. Radioanal. Nucl. Chem. 2017, 311, 1075–1079. [Google Scholar] [CrossRef]

- Sima, O.; Luca, A.; Sahagia, M. Monte Carlo simulation of air sampling methods for the measurement of radon decay products. Appl. Radiat. Isot. 2017, 126, 4–8. [Google Scholar] [CrossRef] [PubMed]

- MetroRADON—Metrology for Radon Monitoring. Available online: http://www.metroradon.eu/ (accessed on 3 January 2022).

- Luca, A.; Serbina, L.; Varlam, C.; Sahagia, M.; Schitea, D.; Faurescu, I.; Sima, O.; Ioan, M.R.; Antohe, A.; Teodorescu, C.; et al. Designing and construction of a new radon calibration facility in Romania. In IRPA 2018 Book of Abstracts, 25 January 2019, Proceedings of the 5th European IRPA Congress, “Encouraging Sustainability in Radiation Protection”, The Hague, The Netherlands, 4–8 June 2018; Version 1.1; Smetsers, R., Ed.; Subject: Radon/Thoron; p. 217. Available online: https://irpa2018europe.com/ (accessed on 3 January 2022).

- Pierre, S.; Cassette, P.; Sabot, B.; Fréchou, C.; Antohe, A.; Barna, C.; Blahusiak, P.; Cardellini, F.; Dersch, R.; Honig, A.; et al. International comparison of activity measurements of radon 222—EURAMET Project no. 1475—EURAMET.RI(II)-S8.Rn-222. Metrologia 2021, 58, 06015. [Google Scholar] [CrossRef]

- AlphaGuard—Radon Monitor. Available online: https://www.bertin-instruments.com/product/radon-professional-monitoring/radon-alphaguard/ (accessed on 3 January 2022).

- Chisté, V.; Bé, M.-M. 222Rn nuclear decay data. In Monographie BIPM-5: Table of Radionuclides (Vol. 4 − A = 133 to 252); Bé, M.-M., Chisté, V., Dulieu, C., Browne, E., Chechev, V., Kuzmenko, N., Kondev, F., Luca, A., et al., Eds.; Bureau International des Poids et Mesures (BIPM): Sèvres, France, 2008; Volume 4, pp. 143–147. ISBN 92-822-2230-6. Available online: https://www.bipm.org/en/publications/monographies (accessed on 3 January 2022).

- TASLImage©. Training Notes; Track Analysis Systems Ltd.: Bristol, UK, 2020. [Google Scholar]

- TASLImage. Manual and Installation Guide; Track Analysis Systems Ltd.: Bristol, UK, 2020; Available online: https://www.tasl.co.uk/tasl-image.php; https://www.tasl.co.uk/radon.php; (accessed on 3 January 2022). [Google Scholar]

- TASLImage©. Training Courses; Track Analysis Systems Ltd.: Bristol, UK, 2020. [Google Scholar]

- SR Ghid ISO/CEI 98-3; Incertitudine de Măsurare, Partea 3: Ghid Pentru Exprimarea Incertitudinii de Măsurare (GUM:1995). National Standardisation Body—ASRO: Bucharest, Romania, 2010. Available online: https://www.asro.ro/en/ (accessed on 3 January 2022). (In Romanian)

- Pylon® Models 110A & 300A Lucas Cell. Use with the Pylon Model AB-5/AB-5R Instruction Manual; Pylon Electronics Inc.: Ottawa, ON, Canada, 2002. [Google Scholar]

- Torr Seal® Low Vapor Pressure Epoxy. Available online: https://www.lesker.com/newweb/fluids/sealants-epoxy/torrseal/ (accessed on 3 January 2022).

- Calin, M.R.; Radulescu, I.; Chiper, D.; Barna, C.; Cimpeanu, C. Chemical characterization and radiation exposure from the natural radioactivity in Romanian building materials. Radiochim. Acta 2018, 106, 413–425. [Google Scholar] [CrossRef]

- Chiper, D.; Cimpeanu, C.; Barna, C.; Ilie, S. Determination of the radioactivity levels and heavy metals content of the local natural rocks widely used as raw materials in industry. Rom. J. Phys. 2018, 63, 808. [Google Scholar]

- Mostafa, M.Y.A.; Vasyanovich, M.; Zhukovsky, M. Prototype of a primary calibration system for measurement of radon activity concentration. Appl. Radiat. Isot. 2016, 107, 109–112. [Google Scholar] [CrossRef] [PubMed]

- Stajic, J.M.; Markovic, V.M.; Milenkovic, B.; Stevanovic, N.; Nikezic, D. Distribution of alpha particle tracks on CR-39 detector in radon diffusion chamber. Rad. Phys. Chem. 2021, 181, 109340. [Google Scholar] [CrossRef]

- Fialova, E.; Otahal, P.P.S.; Vosahlik, J.; Mazanova, M. Equipment for testing measuring devices at a low-level radon activity concentration. Int. J. Environ. Res. Public Health 2020, 17, 1904. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Trace Radon Project. Available online: http://traceradon-empir.eu/ (accessed on 3 January 2022).

- Radulescu, I.; Calin, M.R.; Luca, A.; Röttger, A.; Grossi, C.; Done, L.; Ioan, M.R. Inter-comparison of commercial continuous radon monitors responses. Nucl. Instrum. Meth. Phys. Res. A 2022, 1021, 165927. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).