Prioritization of VOCs Emitted from Co-Processing Cement Kiln Using a Fuzzy Analytic Hierarchy Process Method

Abstract

1. Introduction

2. Material and Methods

2.1. Sampling Site

2.2. Sampling and Analysis

2.3. Statistical Methods

2.3.1. Ozone Formation Potential

2.3.2. Main Odor Components Evaluation

2.4. Analysis of Priority Components

2.4.1. Assumption Principles of Estimation

2.4.2. Fuzzy Analysis

2.4.3. Analytic Hierarchy Process Analysis

- (1)

- Priority matrix

- (2)

- Importance matrix J

- (3)

- Weigh

- (4)

- Scoring

2.4.4. Evaluation

3. Results and Discussion

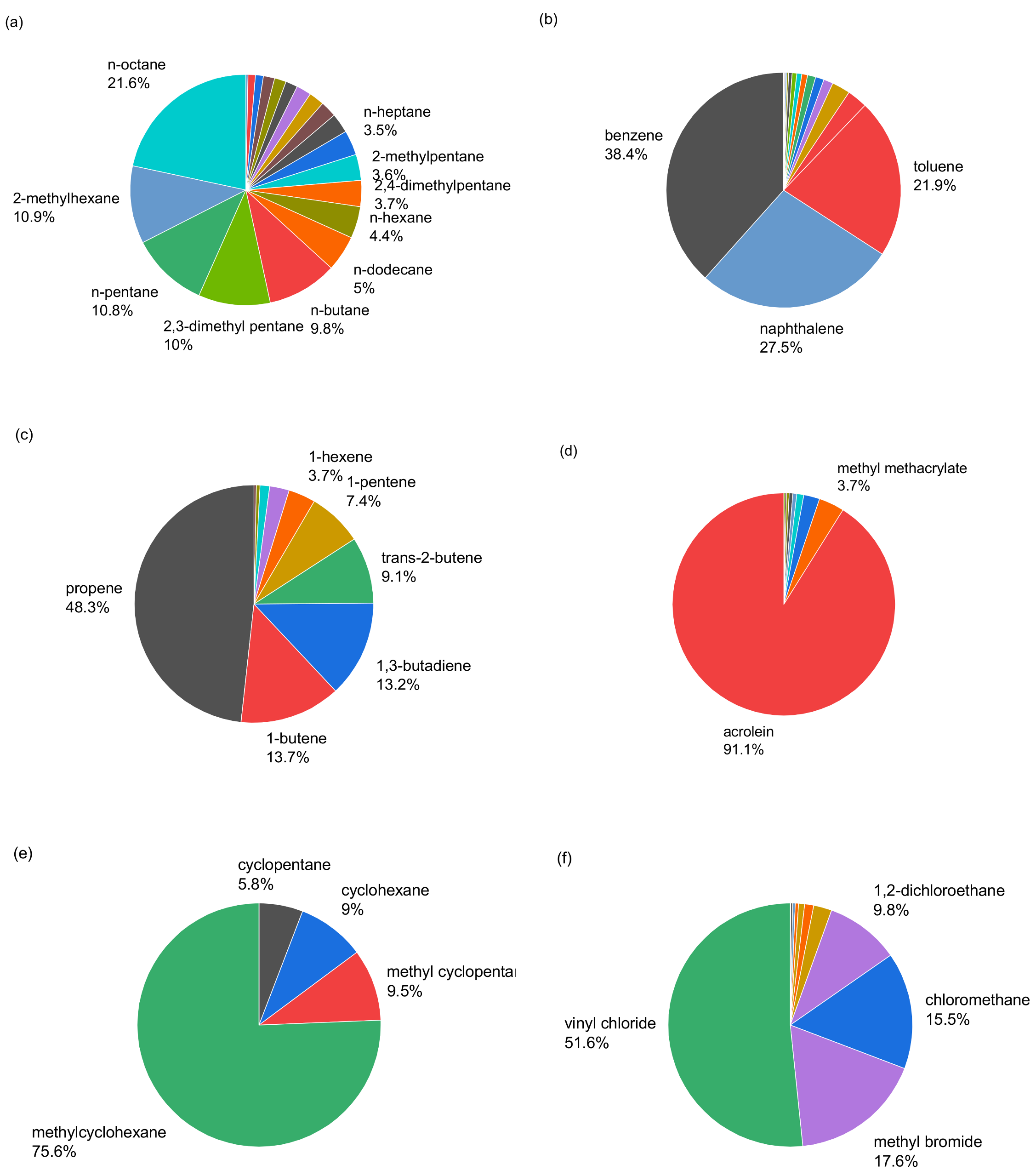

3.1. VOCs Characteristics

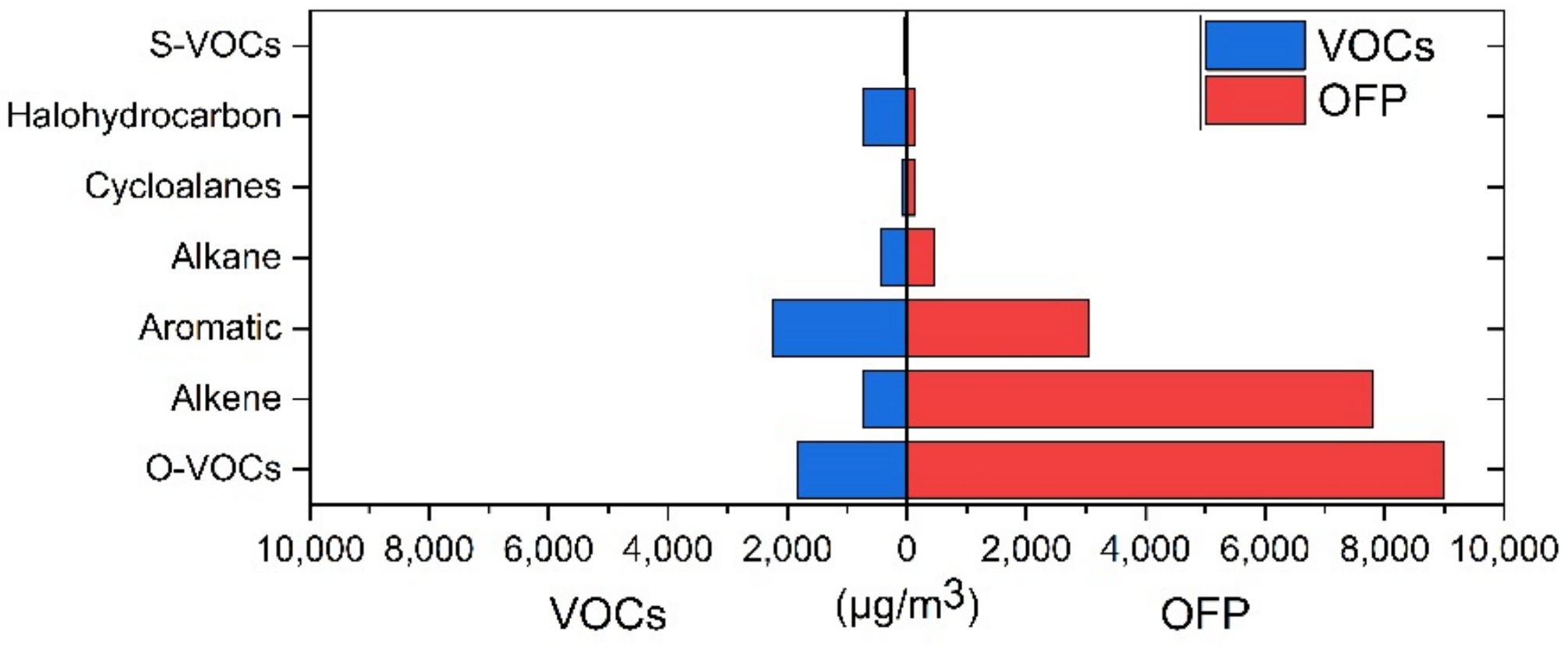

3.2. Ozone Formation Potential of the Stack Gas

3.3. Main Odor Components

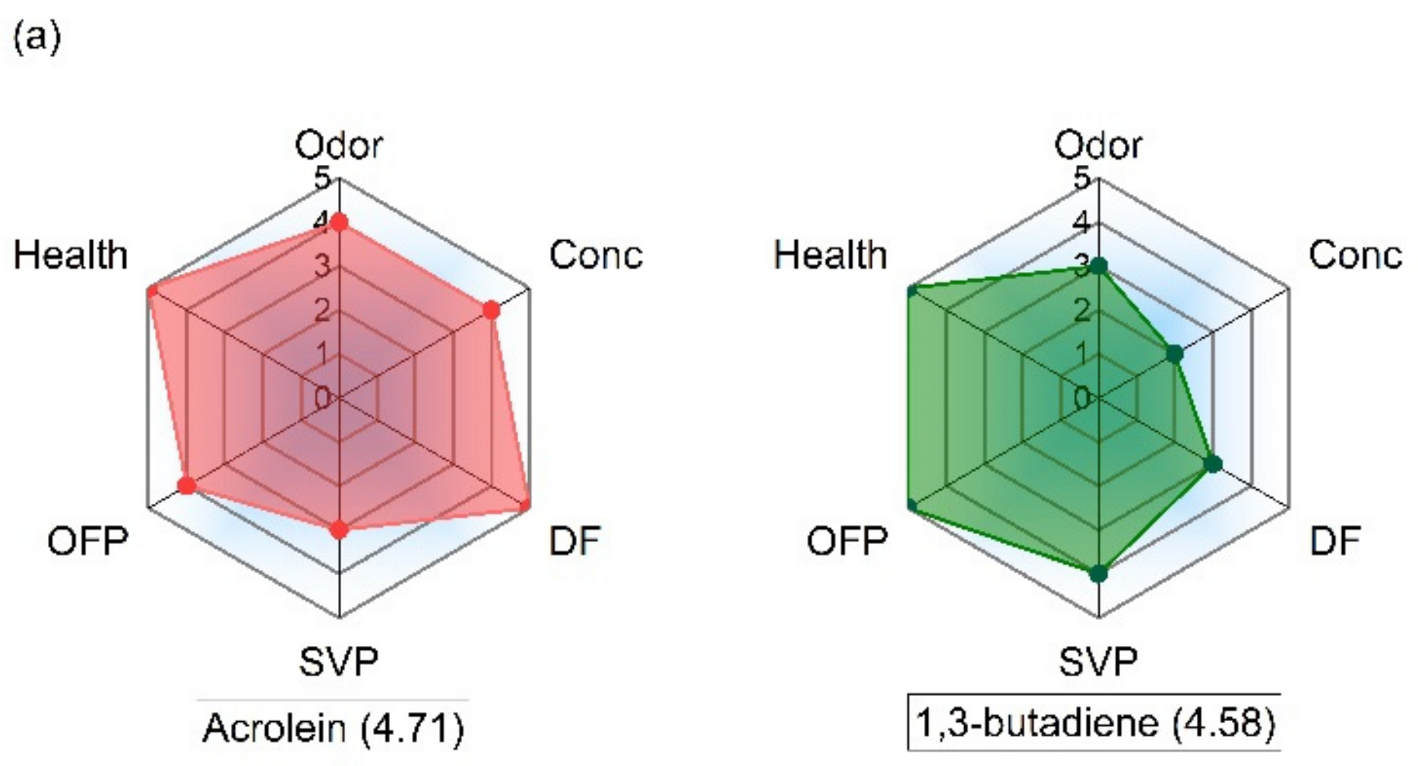

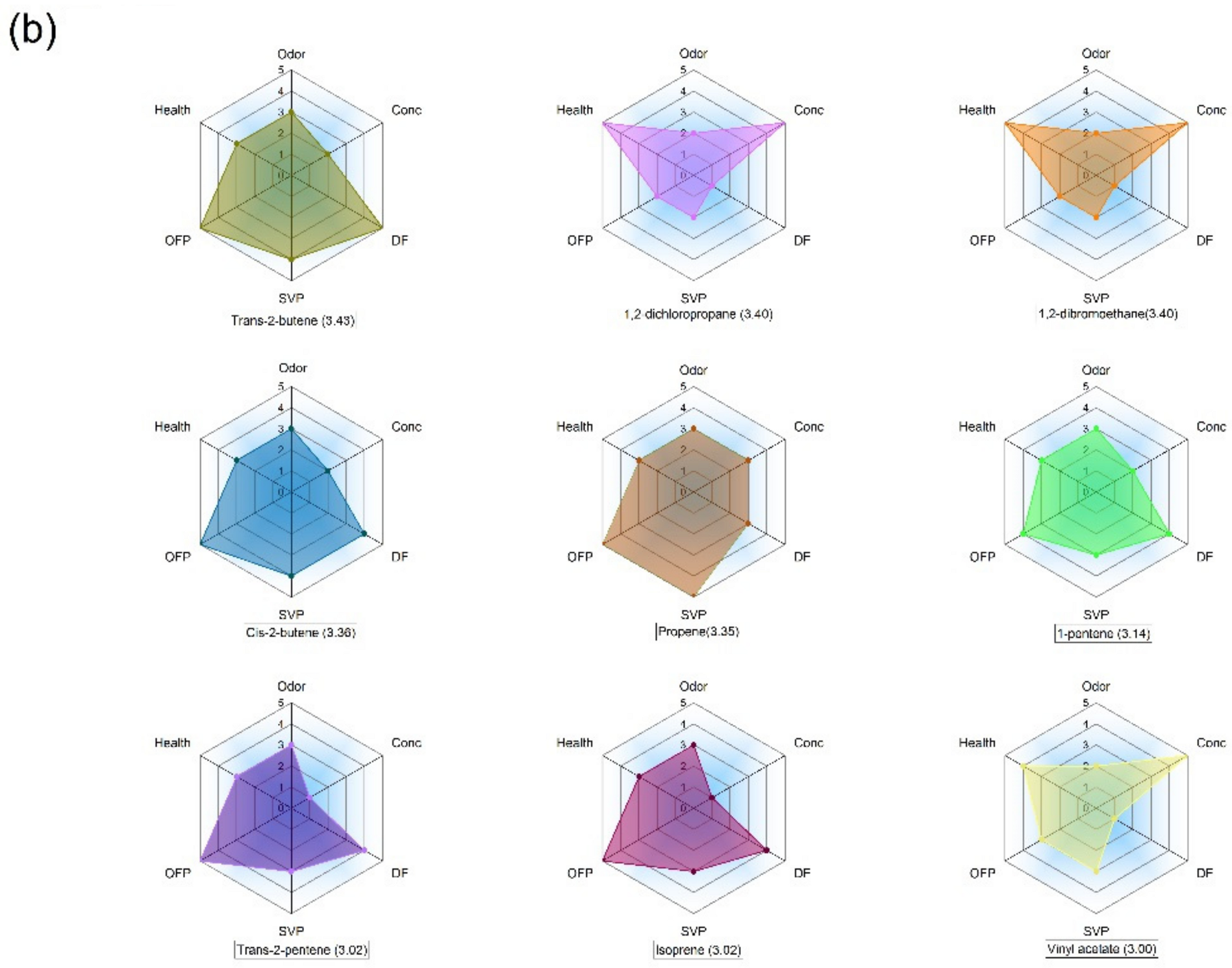

3.4. Priority Components of VOCs in a Co-Processing Cement Kiln

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Ahmed, M.; Bashar, I.; Alam, S.T.; Wasi, A.I.; Jerin, I.; Khatun, S.; Rahman, M. An overview of Asian cement industry: Environmental impacts, research methodologies and mitigation measures. Sustain. Prod. Consum. 2021, 28, 1018–1039. [Google Scholar] [CrossRef]

- Mohamad, N.; Muthusamy, K.; Embong, R.; Kusbiantoro, A.; Hashim, M.H. Environmental impact of cement production and Solutions: A review. Mater. Today Proc. 2021, 48, 741–746. [Google Scholar] [CrossRef]

- Rodríguez, N.H.; Martínez-Ramírez, S.; Blanco-Varela, M.T.; Donatello, S.; Guillem, M.; Puig, J.; Fos, C.; Larrotcha, E.; Flores, J. The effect of using thermally dried sewage sludge as an alternative fuel on Portland cement clinker production. J. Clean. Prod. 2013, 52, 94–102. [Google Scholar] [CrossRef]

- Lv, D.; Zhu, T.; Liu, R.; Lv, Q.; Sun, Y.; Wang, H.; Liu, Y.; Zhang, F. Effects of co-processing sewage sludge in cement kiln on NOx, NH3 and PAHs emissions. Chemosphere 2016, 159, 595–601. [Google Scholar] [CrossRef]

- Xue, S.; Ding, W.; Li, L.; Ma, J.; Chai, F.; Liu, J. Emission, dispersion, and potential risk of volatile organic and odorous compounds in the exhaust gas from two sludge thermal drying processes. Waste Manag. 2021, 138, 116–124. [Google Scholar] [CrossRef]

- Asamany, E.A.; Gibson, M.D.; Pegg, M.J. Evaluating the potential of waste plastics as fuel in cement kilns using bench-scale emissions analysis. Fuel 2017, 193, 178–186. [Google Scholar] [CrossRef]

- Ghouleh, Z.; Shao, Y. Turning municipal solid waste incineration into a cleaner cement production. J. Clean. Prod. 2018, 195, 268–279. [Google Scholar] [CrossRef]

- Zhang, S.; Ghouleh, Z.; Shao, Y. Green concrete made from MSWI residues derived eco-cement and bottom ash aggregates. Constr. Build. Mater. 2021, 297, 123818. [Google Scholar] [CrossRef]

- Liang, T.; Yang, F.; Ding, A.; Li, F. Cement kiln co-processing promotes the redevelopment of industrially contaminated land in China: Spatio-temporal features and efficiency analysis. Sci. Total Environ. 2022, 817, 152788. [Google Scholar] [CrossRef]

- Beketie, K.T.; Angessa, A.T.; Zeleke, T.T.; Ayal, D.Y. Impact of cement factory emission on air quality and human health around Mugher and the surrounding villages, Central Ethiopia. Air Qual. Atmos. Health 2021, 15, 347–361. [Google Scholar] [CrossRef]

- García-Gusano, D.; Herrera, I.; Garraín, D.; Lechón, Y.; Cabal, H. Life cycle assessment of the Spanish cement industry: Implementation of environmental-friendly solutions. Clean Technol. Environ. Policy 2014, 17, 59–73. [Google Scholar] [CrossRef]

- Directive 2010/75/EU of the European Parliament and the Council on Industrial Emissions. Available online: https://www.legislation.gov.uk/eudr/2010/75/contents (accessed on 1 November 2022).

- MEE, China. Emission Standard of Air Pollutants for Cement Industry (GB 4915-2013). Available online: https://www.mee.gov.cn/ywgz/fgbz/bz/bzwb/dqhjbh/dqgdwrywrwpfbz/201312/t20131227_265765.shtml (accessed on 1 November 2022).

- Li, Y.; Zhang, J.; Miao, W.; Wang, H.; Wei, M. Disposal of historically contaminated soil in the cement industry and the evaluation of environmental performance. Chemosphere 2015, 134, 279–285. [Google Scholar] [CrossRef] [PubMed]

- Zhao, X.; Ma, H.; Lu, J.; Yin, T.; Zhang, S.; Zhang, Q.; Dong, X.; Shuai, Q.; Wei, T.; Gong, X. Characteristics and source apportionment of volatile organic compounds during the remediation of contaminated sites in Zhenjiang, China. Int. J. Environ. Sci. Technol. 2020, 18, 2271–2282. [Google Scholar] [CrossRef]

- Saaty, T.L. The Analytic Hierarchy Process; McGraw-Hill: New York, NY, USA, 1980. [Google Scholar]

- Sivret, E.C.; Wang, B.; Parcsi, G.; Stuetz, R.M. Prioritisation of odorants emitted from sewers using odour activity values. Water Res. 2016, 88, 308–321. [Google Scholar] [CrossRef] [PubMed]

- Sun, Z.; Cheng, Z.; Wang, L.; Lou, Z.; Zhu, N.; Zhou, X.; Feng, L. The typical MSW odorants identification and the spatial odorants distribution in a large-scale transfer station. Environ. Sci. Pollut. Res. 2017, 24, 7705–7713. [Google Scholar] [CrossRef] [PubMed]

- Sarkar, K.; Majumder, M. Application of AHP-based water quality index for quality monitoring of peri-urban watershed. Environ. Dev. Sustain. 2020, 23, 1780–1798. [Google Scholar] [CrossRef]

- Chabok, M.; Asakereh, A.; Bahrami, H.; Jaafarzadeh, N.O. Selection of MSW landfill site by fuzzy-AHP approach combined with GIS: Case study in Ahvaz, Iran. Environ. Monit. Assess. 2020, 192, 433. [Google Scholar] [CrossRef]

- Ramya, S.; Devadas, V. Integration of GIS, AHP and TOPSIS in evaluating suitable locations for industrial development: A case of Tehri Garhwal district, Uttarakhand, India. J. Clean. Prod. 2019, 238, 117872.1–117872.14. [Google Scholar] [CrossRef]

- Şener, E.; Karagüzel, R. Solid waste disposal site selection with GIS and AHP methodology: A case study in Senirkent–Uluborlu (Isparta) Basin, Turkey. Environ. Monit. Assess. 2010, 173, 533–554. [Google Scholar] [CrossRef]

- Putra, M.A.; Teh, K.C.; Tan, J.; Choong, T.S.Y. Sustainability assessment of Indonesian cement manufacturing via integrated life cycle assessment and analytical hierarchy process method. Environ. Sci. Pollut. Res. 2020, 27, 29352–29360. [Google Scholar] [CrossRef]

- Xue, R.; Wang, C.; Liu, M.; Zhang, D.; Li, K.; Li, N. A new method for soil health assessment based on Analytic Hierarchy Process and meta-analysis. Sci. Total Environ. 2018, 650, 2771–2777. [Google Scholar] [CrossRef] [PubMed]

- Gorai, A.K.; Kanchan, U.A.; Tuluri, F.; Goyal, P.; Tchounwou, P.B. An innovative approach for determination of air quality health index. Sci. Total Environ. 2015, 533, 495–505. [Google Scholar] [CrossRef] [PubMed]

- Bui, N.T.; Kawamura, A.; Du Bui, D.; Amaguchi, H.; Bui, D.D.; Truong, N.T.; Do, H.H.T.; Nguyen, C.T. Groundwater sustainability assessment framework: A demonstration of environmental sustainability index for Hanoi, Vietnam. J. Environ. Manag. 2019, 241, 479–487. [Google Scholar] [CrossRef] [PubMed]

- Carter, W.P.L. Updated Maximum Incremental Reactivity Scale and Hydrocarbon Bin Reactivities for Regulatory Applications. 2010. Available online: https://ww2.arb.ca.gov/sites/default/files/barcu/regact/2009/mir2009/mir10.pdf (accessed on 1 November 2022).

- Carter, W.P. Development of the SAPRC-07 chemical mechanism. Atmos. Environ. 2010, 44, 5324–5335. [Google Scholar] [CrossRef]

- Nagata, Y. Measurement of Odor Threshold by Triangle Odor Bag Method. Odor Meas. Rev. 2003, 118, 118–127. [Google Scholar]

- Federation A-CE. Technical Specification for Identification of Odorous Substances on Pesticide Contaminated Land. T/ACEF. 2021. Available online: http://www.ttbz.org.cn/StandardManage/Detail/54772 (accessed on 1 November 2022).

- Pipatprapa, A.; Huang, H.-H.; Huang, C.-H. Enhancing the effectiveness of AHP for environmental performance assessment of Thailand and Taiwan’s food industry. Environ. Monit. Assess. 2018, 190, 748. [Google Scholar] [CrossRef]

- Cheng, L.; Wei, W.; Zhang, C.; Xu, X.; Sha, K.; Meng, Q.; Jiang, Y.; Cheng, S. Quantitation study on VOC emissions and their reduction potential for coking industry in China: Based on in-situ measurements on treated and untreated plants. Sci. Total Environ. 2022, 836, 155466. [Google Scholar] [CrossRef]

- Xu, J.; Lyu, Y.; Zhuo, J.; Xu, Y.; Zhou, Z.; Yao, Q. Formation and emission characteristics of VOCs from a coal-fired power plant. Chin. J. Chem. Eng. 2021, 35, 256–264. [Google Scholar] [CrossRef]

- Simayi, M.; Shi, Y.; Xi, Z.; Ren, J.; Hini, G.; Xie, S. Emission trends of industrial VOCs in China since the clean air action and future reduction perspectives. Sci. Total Environ. 2022, 826, 153994. [Google Scholar] [CrossRef]

- Ma, Y.; Fu, S.; Gao, S.; Zhang, S.; Che, X.; Wang, Q.; Jiao, Z. Update on volatile organic compound (VOC) source profiles and ozone formation potential in synthetic resins industry in China. Environ. Pollut. 2021, 291, 118253. [Google Scholar] [CrossRef]

- Mo, Z.; Lu, S.; Shao, M. Volatile organic compound (VOC) emissions and health risk assessment in paint and coatings industry in the Yangtze River Delta, China. Environ. Pollut. 2020, 269, 115740. [Google Scholar] [CrossRef] [PubMed]

- Ariyaratne, W.; Melaaen, M.; Tokheim, L. The effect of alternative fuel combustion in the cement kiln main burner on production capacity and improvement with oxygen enrichment. World Acad. Sci. Eng. Technol. 2013, 76, 557–563. [Google Scholar]

- Giannopoulos, D.; Kolaitis, D.I.; Togkalidou, A.; Skevis, G.; Founti, M.A. Quantification of emissions from the co-incineration of cutting oil emulsions in cement plants—Part I: NOx, CO and VOC. Fuel 2006, 86, 1144–1152. [Google Scholar] [CrossRef]

- Mozaffar, A.; Zhang, Y.-L. Atmospheric Volatile Organic Compounds (VOCs) in China: A Review. Curr. Pollut. Rep. 2020, 6, 250–263. [Google Scholar] [CrossRef]

- MEE, China. Ambient Air Quality Standards (GB 3095-2012). Available online: https://www.mee.gov.cn/ywgz/fgbz/bz/bzwb/dqhjbh/dqhjzlbz/201203/t20120302_224165.shtml (accessed on 1 November 2022).

- Cheng, N.; Jing, D.; Zhang, C.; Chen, Z.; Li, W.; Li, S.; Wang, Q. Process-based VOCs source profiles and contributions to ozone formation and carcinogenic risk in a typical chemical synthesis pharmaceutical industry in China. Sci. Total. Environ. 2020, 752, 141899. [Google Scholar] [CrossRef] [PubMed]

- Liu, Y.; Kong, L.; Liu, X.; Zhang, Y.; Li, C.; Zhang, Y.; Zhang, C.; Qu, Y.; An, J.; Ma, D.; et al. Characteristics, secondary transformation, and health risk assessment of ambient volatile organic compounds (VOCs) in urban Beijing, China. Atmos. Pollut. Res. 2021, 12, 33–46. [Google Scholar] [CrossRef]

- Chai, F.; Li, P.; Li, L.; Qiu, Z.; Han, Y.; Yang, K. Dispersion, olfactory effect, and health risks of VOCs and odors in a rural domestic waste transfer station. Environ. Res. 2022, 209, 112879. [Google Scholar] [CrossRef]

- Cheng, Z.; Sun, Z.; Zhu, S.; Lou, Z.; Zhu, N.; Feng, L. The identification and health risk assessment of odor emissions from waste landfilling and composting. Sci. Total Environ. 2018, 649, 1038–1044. [Google Scholar] [CrossRef]

- Han, Z.; Li, R.; Shen, H.; Qi, F.; Liu, B.; Shen, X.; Zhang, L.; Wang, X.; Sun, D. Emission characteristics and assessment of odors from sludge anaerobic digestion with thermal hydrolysis pretreatment in a wastewater treatment plant. Environ. Pollut. 2021, 274, 116516. [Google Scholar] [CrossRef]

- Khan, F.I.; Sadiq, R. Risk-Based Prioritization of Air Pollution Monitoring Using Fuzzy Synthetic Evaluation Technique. Environ. Monit. Assess. 2005, 105, 261–283. [Google Scholar] [CrossRef]

- Sahin, F.; Kara, M.K.; Koc, A.; Sahin, G. Multi-criteria decision-making using GIS-AHP for air pollution problem in Igdir Province/Turkey. Environ. Sci. Pollut. Res. 2020, 27, 36215–36230. [Google Scholar] [CrossRef] [PubMed]

| Calcareous | Silica Materials | Iron Materials | Admixture | Hazard Waste | Sludge | Soft Coal | Diesel |

|---|---|---|---|---|---|---|---|

| 1203.7 | 495.1 | 22.5 | 151.3 | 73.6 | 31.5 | 170 | 0.344 |

| Score | 1 | 2 | 3 | 4 | 5 | |

|---|---|---|---|---|---|---|

| Odor threshold (mg/m3) | >100 | 1–100 | 0.01–1 | 0.0001–0.01 | <0.0001 | |

| VOCs concentration (mg/m3) | 0–0.01 | 0.01–0.1 | 0.1–1 | 1–10 | >10 | |

| Detection frequency (%) | 0–20 | 20–40 | 40–60 | 60–80 | 80–100 | |

| Saturated vapor pressure (kPa, 25 °C) | 0–1 | 1–10 | 10–100 | 100–500 | >500 | |

| Health assessment | LC50fish (mg/L) | >1000 | 100–1000 | 10–100 | 1–10 | 0–1 |

| LC50mice (ppm) | >10,000 | 5000–10,000 | 1000–5000 | 100–1000 | 0–100 | |

| RfC (mg/m3) | <0.01 | 0.01–0.1 | 0.1–1 | 1–10 | >10 | |

| MIR (g O3/g VOCs) | <0.1 | 0.1–2 | 2–6 | 6–10 | >10 | |

| Intensity of Importance | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 |

|---|---|---|---|---|---|---|---|---|---|

| Explanation | Si/Sj = 1 | 1 < Si/Sj < 2 | Si/Sj = 2 | 2 < Si/Sj < 3 | Si/Sj = 3 | 3 < Si/Sj < 4 | Si/Sj = 4 | 4 < Si/Sj < 5 | Si/Sj = 5 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, Y.; Li, G.; Wang, Y.; Wang, Z.; Jiang, B.; Bai, H.; Nie, L.; Chen, X.; Jing, X.; Li, G.; et al. Prioritization of VOCs Emitted from Co-Processing Cement Kiln Using a Fuzzy Analytic Hierarchy Process Method. Atmosphere 2022, 13, 1952. https://doi.org/10.3390/atmos13121952

Yang Y, Li G, Wang Y, Wang Z, Jiang B, Bai H, Nie L, Chen X, Jing X, Li G, et al. Prioritization of VOCs Emitted from Co-Processing Cement Kiln Using a Fuzzy Analytic Hierarchy Process Method. Atmosphere. 2022; 13(12):1952. https://doi.org/10.3390/atmos13121952

Chicago/Turabian StyleYang, Yong, Guoao Li, Yaling Wang, Zhiping Wang, Bao Jiang, Huahua Bai, Lei Nie, Xue Chen, Xianglong Jing, Guohao Li, and et al. 2022. "Prioritization of VOCs Emitted from Co-Processing Cement Kiln Using a Fuzzy Analytic Hierarchy Process Method" Atmosphere 13, no. 12: 1952. https://doi.org/10.3390/atmos13121952

APA StyleYang, Y., Li, G., Wang, Y., Wang, Z., Jiang, B., Bai, H., Nie, L., Chen, X., Jing, X., Li, G., & Sun, C. (2022). Prioritization of VOCs Emitted from Co-Processing Cement Kiln Using a Fuzzy Analytic Hierarchy Process Method. Atmosphere, 13(12), 1952. https://doi.org/10.3390/atmos13121952