1. Introduction

Mining is the process of extracting useful materials from the Earth, which are used in various industries to create the world around us. This activity yields a range of benefits to societies. However, it can also cause harm to the environment and people. Particularly, the underground mining sector faces a number of occupational health and safety (OHS) hazards. The underground mining environment is oftentimes harsh, which, in some cases, may result in occupational diseases. Some OHS issues in this sector are related to the exposure of workers to air pollution. Confined spaces, difficulties with assuring sufficient ventilation, and various emissions can impair the quality of underground air. Hence, maintaining a healthy level of air hygiene in this sector of industry is important and has attracted increasing attention.

Pollution of underground air results mainly from (1) naturally occurring gases released from the surrounding geology; (2) mining operations (exploitation of mineral resources such as drilling, blasting, crushing, collection, storage, and transportation along the supply chain); and (3) operation of underground mobile equipment and any other moving machinery.

Currently, mining is heavily and extensively mechanized. This trend is critical for the production system. The mechanization of mining is essential to reduce operational and capital costs and to maintain high production while, at the same time, manpower and environmental threats are reduced. Mobile diesel-powered or electric equipment plays an important role in underground mining. Such equipment is used to transport personnel and extract ore, as well as to lift or load materials or to provide power to attached equipment. Diesel engines are commonly applied in underground vehicles and mining equipment because of their high efficiency, durability, reliability, and low operating cost. Diesel engines also present serious shortcomings, e.g., they make a significant contribution to air pollution underground [

1,

2,

3,

4,

5,

6,

7].

Diesel engine exhaust is a complex mixture of combustion products, which can have adverse health and/or environmental effects. Most of these substances originate from various non-ideal processes during combustion, such as incomplete combustion of fuel, reactions between mixture components under high temperature and pressure, combustion of engine lubricating oil and oil additives, as well as combustion of non-hydrocarbon components of diesel fuel, such as sulfur compounds and fuel additives. Common diesel engine exhaust includes nitrogen oxides (NOx), carbon monoxide (CO), particulate matter (PM), and unburned hydrocarbons (HC) [

8,

9,

10,

11,

12,

13]. NOx has the highest proportion of diesel pollutant emissions, PM being the second highest. Diesel engines normally emit hydrocarbons and CO at a relatively low level because they are lean combustion engines.

The impact of particular air pollutants on humans is varied. Hence, the presence of these substances in an underground atmosphere should be considered individually. Current measurement methods and techniques allow us to identify and determine the concentrations of many compounds. However, the precise analysis of underground air is expensive and time-consuming. Therefore, a holistic approach is proposed. It is based on the concept of indicators, which can represent the impact of a wide group of air pollutants. Total hydrocarbon content (THC) is an example of this. THC is used to describe the quantity of all measured hydrocarbons. Hydrocarbons consist of thousands of species, such as alkanes, alkenes, and aromatics. They are normally expressed in terms of equivalent CH4 content; but, some individual ones may be of special interest.

The aim of the study was to analyze the relationships between elemental carbon (EC), total carbon (TC), and volatile organic compounds (VOC) in air in an underground metal mine. We tested the hypothesis that the content of VOCs in the underground mine air may provide information about elemental carbon in this gas. Our attention was focused on this subject for several reasons. (1) Elemental and organic carbon pose serious health problems. They may cause premature death and harmful effects on the cardiovascular system (the heart, blood, and blood vessels). (2) TC is used as a surrogate for determining diesel particulate matter (DPM) compliance exposures in underground metal/nonmetal mines in the U.S. and some Canadian provinces. (3) Elemental carbon analysis has great importance in workplace risk evaluation associated with diesel emissions. The EU and Australia use EC as a surrogate for DPM. (4) Measurement of these parameters is a difficult and complex process. (5) Portable GC/MS allows high-performance detection and analysis of volatile organic compounds, and the measurement data are easily and quickly available. In the considered application, this is an important advantage.

2. Motivation

The engines installed in state-of-the-art mining machines are equipped with versatile exhaust after-treatment systems which are capable of substantially reducing the emission of volatile organic compounds, nitrogen oxides, and particulate matter, including EC. Unfortunately, such systems have been appearing in underground mines only recently, i.e., for about 10–12 years. In the case of small mines, which are equipped with several or several dozen machines, this period was sufficient to exchange the full stock. Although complete replacement of engines would result in the reduction of emission rates, in the case of mines where hundreds or even thousands of machines are used underground, the exchange of stock is not an immediate operation. In such mines, the replacement of the old engines by engines that comply with STAGE IV and STAGE V emission standards will take time; another 10–15 years are needed, at least. The emission standards [

14] have stimulated the process, but it is by no means completed. Most mines have phased the exchange process, and two reasons are most important here. The first is the substantial expenditure; a new machine costs several million euros. The second reason is the availability of new machines; they are highly specialized products. The number of new items offered per year is limited because of constraints throughout the production process. Currently, in the mine where the study was performed, the engines equipped with the best exhaust after-treatment systems constitute less than 50% of the stock.

Reduced emissions of pollutants (including VOCs and ECs) caused by exhaust-gas after-treatment systems also do not result in a situation where there is no longer exposure to these pollutants at workplaces in underground mines. Exposure is certainly reduced, but due to the difficult ventilation and climate conditions in underground mines, there may be situations of elevated concentrations of VOCs and ECs in certain areas of the mine, which makes it necessary to monitor them. In addition, new regulations coming into force that require the measurement of concentrations of EC and hydrocarbons from diesel exhaust at workplaces in Poland and the EU imply that even though new machines will emit fewer pollutants compared to older ones, there will still be a need to measure them in the air at workplaces.

The approach presented in this work, using SPME and GC/MS measurement, is not intended to replace existing measurement systems or become an alternative method with all the associated consequences, in particular, the possibility of using the results with reference to legal requirements regarding pollution level. The purpose of our study was to see if there is a correlation between VOCs and EC concentrations in mine air. As a result of the measurement work, it turned out that such a correlation does exist, and VOC concentrations can be used as a proxy for the EC level. This is especially true when VOCs specific to diesel exhaust are detected in the air.

According to the NIOSH 5040 methodology for the determination of EC, the path from sampling to the final result is quite long—sampling for 75% of the duration of the work shift (roughly 5–7 h, depending on the position), then transporting the samples to the laboratory and performing the analysis—typically for one workplace, taking two to five days depending on the measurement capabilities of the laboratory at the time of analysis. Measurement using the SPME technique coupled with GC/MS analysis allows the performance of a preliminary assessment of the exposure to EC at a given site or workplace in a much shorter time. Using this technique, it is possible to perform up to a dozen measurements in one day, obtaining results directly at the site where the measurement was performed. Hence, many locations can be checked in a shorter time, at a lower cost, and with less manpower involved.

This approach not only reduces the analysis time and costs but can also be used for ongoing monitoring of the state of mine air pollution with hydrocarbons and EC without having to wait for results from a stationary laboratory. This is extremely important from the point of view of the extraction operations and the work progress of the entire mine, as well as the safety of the miners. The work progressing in the extraction zones is “moving” the mine forward constantly in relation to where mining began. This results in the fact that, in a few weeks or months, the measuring site initially located in the extraction zone is no longer there but, for example, in the middle of a mining division. In this part of the mine, ventilation and climate conditions are completely different, while it is the new extraction zone that requires the checking and monitoring of pollution levels. A method using the SPME technique and GC/MS analysis seems ideal for this type of measurement because it allows for a quick, preliminary assessment of the contamination level in the area under study. The obtained results can be used to identify so-called ‘hot spots’ and select measurement sites for studying with a dedicated reference technique. The application of the method will allow for better management of health and safety in the underground working environment and rapid response to changing conditions in different areas of the mine.

3. Measurement Methods

3.1. Measurement of Volatile Organic Compounds in Mine Air

The use of diesel engines results in the emission of volatile organic compounds. They belong to many different groups, e.g., aliphatic hydrocarbons, aromatic hydrocarbons, aldehydes, ketones, and polycyclic aromatic hydrocarbons. Traditionally, these pollutants are determined using different analytical techniques: hydrocarbons, most often using a flame ionization (FID) detector; aldehydes by high-performance liquid chromatography with ultraviolet spectroscopy (HPLC/UV) or by GC/FID; and polyaromatic hydrocarbons by high-performance liquid chromatography (HPLC) coupled with a UV or fluorescence detector (FLD).

This work considers the application of GC/MS for the detection of exposure associated with diesel exhaust emissions in mine air. Compared to chromatography with other detectors, e.g., a thermal conductivity detector (TCD) or FID, GC/MS offers a wider analytical spectrum and the best selectivity. However, the key to achieving the best possible separation of individual analytes is the selection of the appropriate chromatographic column and the adjustment of the operating parameters of the chromatographic system as well as the MS detector.

From the point of view of mine air measurements, the mobile version of GC/MS is particularly attractive. With an appropriately chosen sampling method, it can significantly reduce the time for analyzing environmental contaminants and can allow for performing measurements in the field. The disadvantage of such solutions may be the limited operation time of the device, which is mainly related to battery capacity. In some cases, the length of the column and the analysis time may also be insufficient to achieve a fully satisfactory separation of the individual pollutants. This can make it difficult to interpret the results obtained.

In this work, we examined the results of measurements, which were performed using a Torion T-9 GC/MS. The parameters of the applied GC column were as follows: GC Column MXT-5, 5 m × 0.1 mm I.D., 0.4 µm df. The time for chromatographic analysis with this device was 320 s. In the statistical analyses, we utilized the total area under the chromatogram and the area under the selected individual peaks. It was assumed that the total area under the chromatogram is correlated with the concentration of total volatile organic compounds (TVOC) in mine air. The areas under peaks associated with particular hydrocarbons were taken as surrogates for their concentrations in mine air. Hydrocarbons with carbon atoms numbering from C11 to C14 were included in the analysis.

3.2. Measurement of Elemental Carbon and Total Carbon in Mine Air

Thermal-optical analysis (TOA) with an FID detector is used to determine various forms of carbon, such as elemental, organic, inorganic, and pyrolytic carbon, in air. The method requires sample collection onto quartz fiber filters. Detection is carried out by measuring changes in the transmittance of a laser beam passing through the sample and analyzing the concentration of carbon dioxide resulting from the combustion of carbon in the FID detector, taking into account the reading of the concentration of the internal standard (methane). All forms of carbon OC and EC (TC = EC + OC) are determined simultaneously in one analysis. Currently, only bench-top devices are available.

In this work, we examined the results of TC and EC measurements in mine air, which were made using TOA. In the statistical analyses, we utilized the mass of TC and the mass of EC per sample.

4. Experimental Part

Air pollutants were sampled in underground, non-ferrous-metal-ore mines to detect diesel engine exhausts in mine air. Different sampling approaches were applied depending on the target compounds.

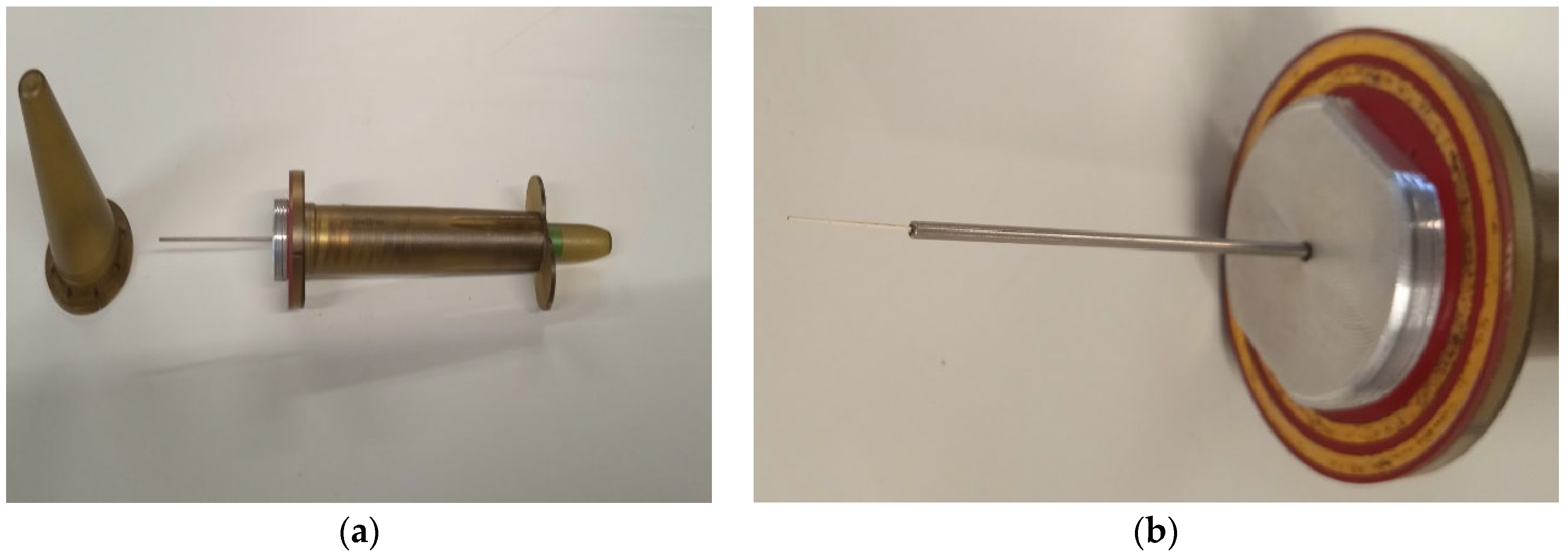

Samples for GC/MS analysis, aimed at VOCs determination, were prepared using a solid phase microextraction (SPME) technique based on an adsorption process. Analytes are adsorbed on a sorbent, which is placed on a glass or quartz fiber contained in a syringe. A CUSTODION fiber was used in our application. A universal fiber (a blend of polar and non-polar fiber) was chosen because diesel engine exhausts contain non-polar compounds (aliphatic and aromatic hydrocarbons) as well as medium polar or polar compounds like aldehydes, ketones, and their derivatives. The sampler and SPME fiber are shown in

Figure 1. A passive sampling procedure was applied. The fiber was freely exposed to mine air at the selected measurement site or at the workplace. There was no forced airflow around the sampler. The sorption of contaminants onto the fiber was governed by the diffusion phenomenon. Sampling was carried out during the work shift. The sampling time was 240 min. When samples were concentrated on the SPME fiber, no signs of saturation were observedThere is a risk of such a phenomenon, but saturation is likely to be noticeable directly during the analysis, at the site, in the mine. The sampling period we adopted for the SPME fiber was worked out in the mines where the measurements took place. At other mines, it may need to be modified and adapted to meet specific needs. The sampling time for EC should also be adjusted in parallel.

The compounds adsorbed on the SPME fiber were then analyzed according to the accepted methodology on a gas chromatograph with a mass detector. The fiber was thermo-desorbed in the chromatograph dispenser, and the mixture was resolved on the chromatographic column and detected with a mass detector. The results obtained were analyzed using software with a deconvolution function (resolving mass spectra to identify the detected compounds) and identified using the NIST mass spectral library.

It should be mentioned that dynamic SPME sampling may also be performed to prepare samples for GC/MS analysis. In that case, the sampling time would be 5 min.

Calibration and routine inspection of the GC/MS apparatus was carried out by using Perkin Elmer’s “STD Calion PV Mix” calibration mixture consisting of 13 different organic compounds. The purpose of internal calibration of the chromatograph using this mixture is to check the retention times of individual compounds within a specified time interval. The check is performed by the manufacturer of the instrument. If the instrument fails this test, then recalibration is needed. Such a situation is possible; the peaks may shift, which is a normal phenomenon associated with the aging of the column or changed resistances in the system. The second test is to check the intensity of the signals from each of the compounds to confirm that the device/detector is correctly measuring standards of a certain concentration. The results must stay within the uncertainty limits defined by the manufacturer; in the event of exceedance, recalibration is required. The third test is to check whether all 13 compounds have been correctly identified by the instrument/software. This test confirms the ability of the instrument to correctly detect the individual compounds in the test samples.

Samples for TOA analysis, aimed at EC determination, were collected on the quartz filter using dynamic sampling. The applied sampling apparatus is shown in

Figure 2. It includes the air sampling pump (Sensidyne, model GilAir3), the cyclone head for collection of the respirable fraction of dust (Higgins–Dewell Cyclone FH022), and the connecting gas line. A quartz filter was mounted inside the cyclone head. The sampling flow rate was 2.2 L/min. Sampling was carried out during the work shift. The sampling time was 240 min.

Based on the scientific literature and NIOSH 5040 guidelines regarding sampling for the determination of elemental carbon in mine air, suitable sampling heads were selected that are dedicated to sampling for the determination of EC in the mine.

One of the recommended sampling heads is the DPM Cassette with Impactor” from SKC cat. NO. 225-317 in combination with the GS-A Single-inlet Cyclone” offered by SKC cat. NO. 225-105. Such a set, using the appropriately selected flow rate (1.7 to 2 L/min), allows for sampling in atmospheres where it is necessary to differentiate diesel particulate matter from other respirable dust (such as coal dust) based on particle size. According to the producer, the GS-1 Cyclone prevents particles >4 microns from clogging the DPM Cassette’s built-in impactor (precision sapphire orifice) that screens out particles ≥1 micron. Particles < 1 micron collect on a heat-treated quartz filter inside the cassette. In general, this set can be used for sampling also in non-coal mines, but there is a risk that by cutting off fractions from 1 to 4 microns, the EC concentration may be underestimated. In our mines, we decided to apply a Higgins–Dewell Cyclone head. When using the appropriate flow rate, the head allows us to cut off the respirable fraction of dust (about 4 μm). It allows us to determine EC from diesel exhaust, for both the most common size of particles from a dozen nm to 1 micrometer, but also larger particles that appear in mine air and can enter the lungs and bronchi. Because the cut-off point is about 4 μm, we can separate these particles from other, larger fractions of total dust, thus protecting the filter from clogging in dusty areas. We realize that in certain environments, for example, in the extraction zone, the concentration of PM may be very high, potentially causing filters to overload. In such circumstances, the sample was collected using two or more filters, as many as needed.

The method for the determination of elemental carbon in mine air was validated by the Centrum Badań Jakości (CBJ) [

15]. The expanded uncertainty was 23%, and the standard uncertainty was 11.5% for the sample (analytical uncertainty). The sampling uncertainty was 20%.

The EC measurement results were determined taking into account the flow rate and sampling time. Each aspirator has a built-in timer on the basis of which the sampling times for each sample were recorded. Moreover, in accordance with the quality control of the sampling apparatus, the air sampling pumps were calibrated to the appropriate flow rate, and after sampling was completed, they were also checked to see if the flow rate was within the acceptable range (±5%).

The quality control for EC analysis involved the following:

A blank sample;

A calibration curve prepared from a standard meeting the requirements of ISO 17034—sucrose, manufacturer CPA Chem;

Verification of the calibration curve at two control points (second and last level of the calibration curve) with a standard from another manufacturer—sucrose, manufacturer VWR International;

Control of the method with reference material, manufacturer NIST. Control material—dust sample for determination of EC, OC and TC concentrations—Reference Material 8785 Air Particulate Matter on Filter Media.

The samples (for VOCs and for EC) were collected in the ore extraction zone and in the maintenance shop. These two sites were chosen because of their different characteristics. Maintenance shops (MS) are usually large, spacious places compared to the drifts in the mining sections. MS are usually located closer to the fresh-air delivery shafts; therefore, the ventilation, as well as climate conditions, are better there. The movement of machinery is limited, as is the time of their operation with the engines running. Hence, the pollution level is relatively lower. The mining section, particularly the extraction zone, is usually located at a greater distance from the fresh-air delivery shaft compared to MS. This results in different climate conditions, e.g., higher temperature, different humidity, and generally less fresh air. The space is smaller and featured by the periodic accumulation of machinery running at high engine speeds that can cause elevated concentrations of pollutants in mine air. When selecting the individual sampling points, the main considerations were the presence of machines equipped with diesel engines, the number of machines in operation, the type of work performed (fed rush, auxiliary work, machine repair, and overhaul), ventilation, and general air quality.

The overall number of measurements with reference to the measurement method, measured parameters, and the location of sampling points are shown in

Table 1. All measurements of volatile organic compounds were accompanied by the measurements of TC and EC. The respective samples for the same sampling locations were collected concurrently.

5. Results and Discussion

In this work, we focused on the examination of the relationship between volatile organic compounds, as well as the individual hydrocarbons C11, C12, C13, and C14) and carbon (TC and EC) in the air of an underground metal mine. The analysis of the chromatograms for the individual samples showed that their common feature was the presence in virtually all samples of aliphatic hydrocarbons C11–C14; other hydrocarbons characteristic of diesel exhaust, e.g., benzene, toluene, xylenes, PAHs, aldehydes, ketones, and others were also present, but not in all samples and measurement locations.

EC is considered the most appropriate surrogate for diesel exhaust impact, although it is TC that accounts for over 80% of particulate matter in diesel exhaust [

16,

17]. However, the measurement of TC at workplaces is subject to interference; due to this, TC may reflect more than just the impact of diesel exhaust [

16,

17]. Interferents, such as oil mist and cigarette smoke, can affect the OC results, but they do not affect EC results. We addressed this issue with reference to a situation in the investigated metal ore mine.

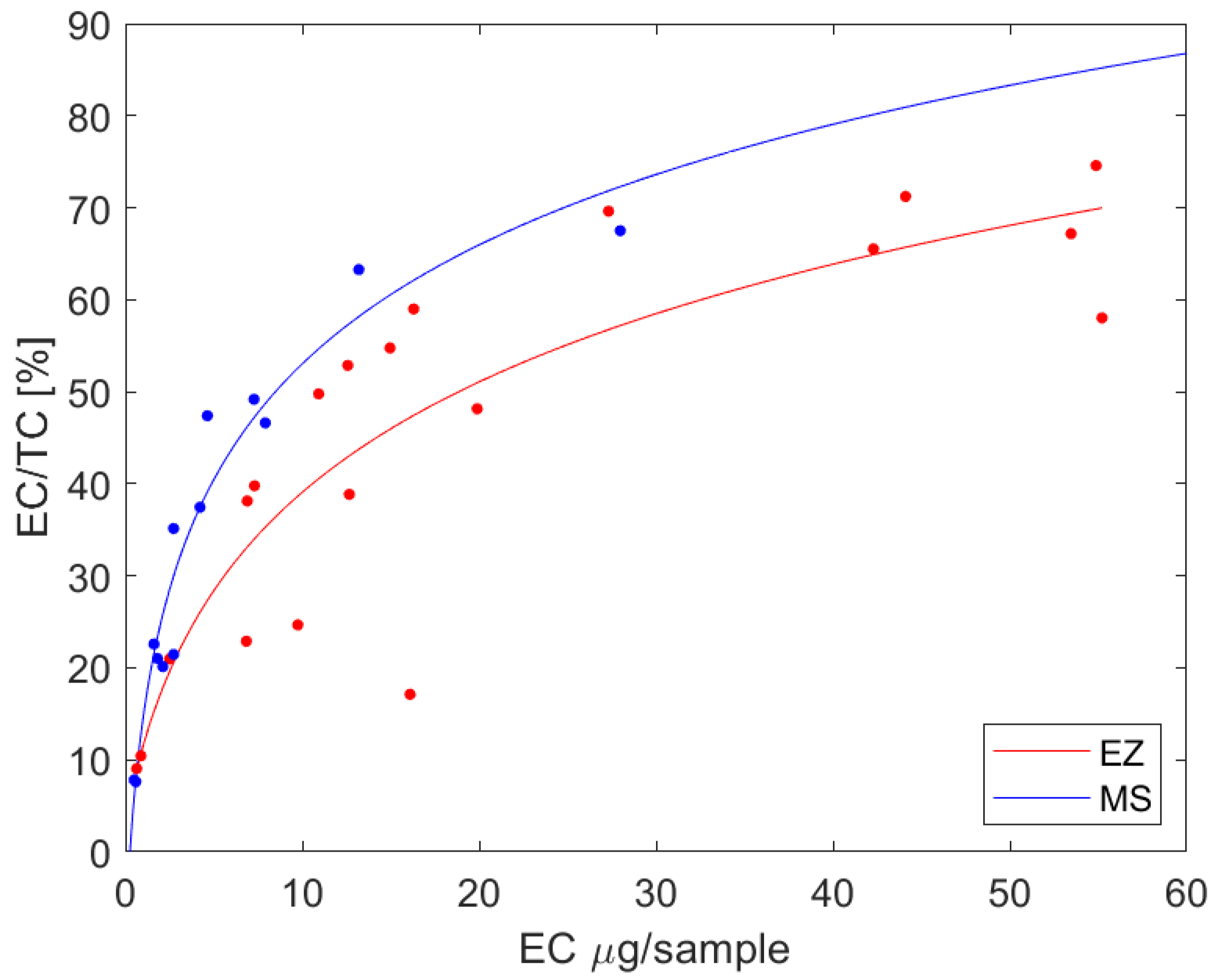

Figure 1 shows the correlation between the concentration of EC in mine air and the fraction of TC which is associated with EC.

The data shown in

Figure 3 confirm the earlier findings of other authors [

16,

17] that the EC/TC ratio is variable in mine air. However, the plots additionally reveal that there is a correlation between the EC/TC ratio and EC content. Namely, the EC fraction steadily increases with the increasing overall amount of EC in mine air. The relationship was nonlinear and, we proposed, could be fitted by a logarithmic function. The parameters of the models representing the relationship between EC/TC and EC are shown in

Table 2.

The models representing the relationship between EC/TC and EC in the extraction zone (model M1) and in the maintenance shop (model M2) were statistically significant. This implies that a logarithmic function may be applied to fit this kind of relationship. Based on the features of the logarithmic function, the contribution of EC to TC increases when the EC content in mine air becomes high, but the rate of increase becomes smaller and smaller. Hence, in the case of high EC levels, TC could be considered as a surrogate for EC content, provided the conversion factor is available. Based on

Figure 3, for EC at the level of 50 μg/sample, the conversion factor between EC and TC may be estimated at 1.20 and less in the extraction zone and at 1.46 and less in the maintenance shop. The conversion factors at this level generally agree with the literature findings [

17]. The conversion is highly questionable when the content of EC in mine air is small. The overall uncertainty about establishing a conversion factor is primarily due to uncertainty associated with determining OC concentrations.

Furthermore, we examined the possibility of EC content determination based on the correlation with volatile organic compounds in mine air.

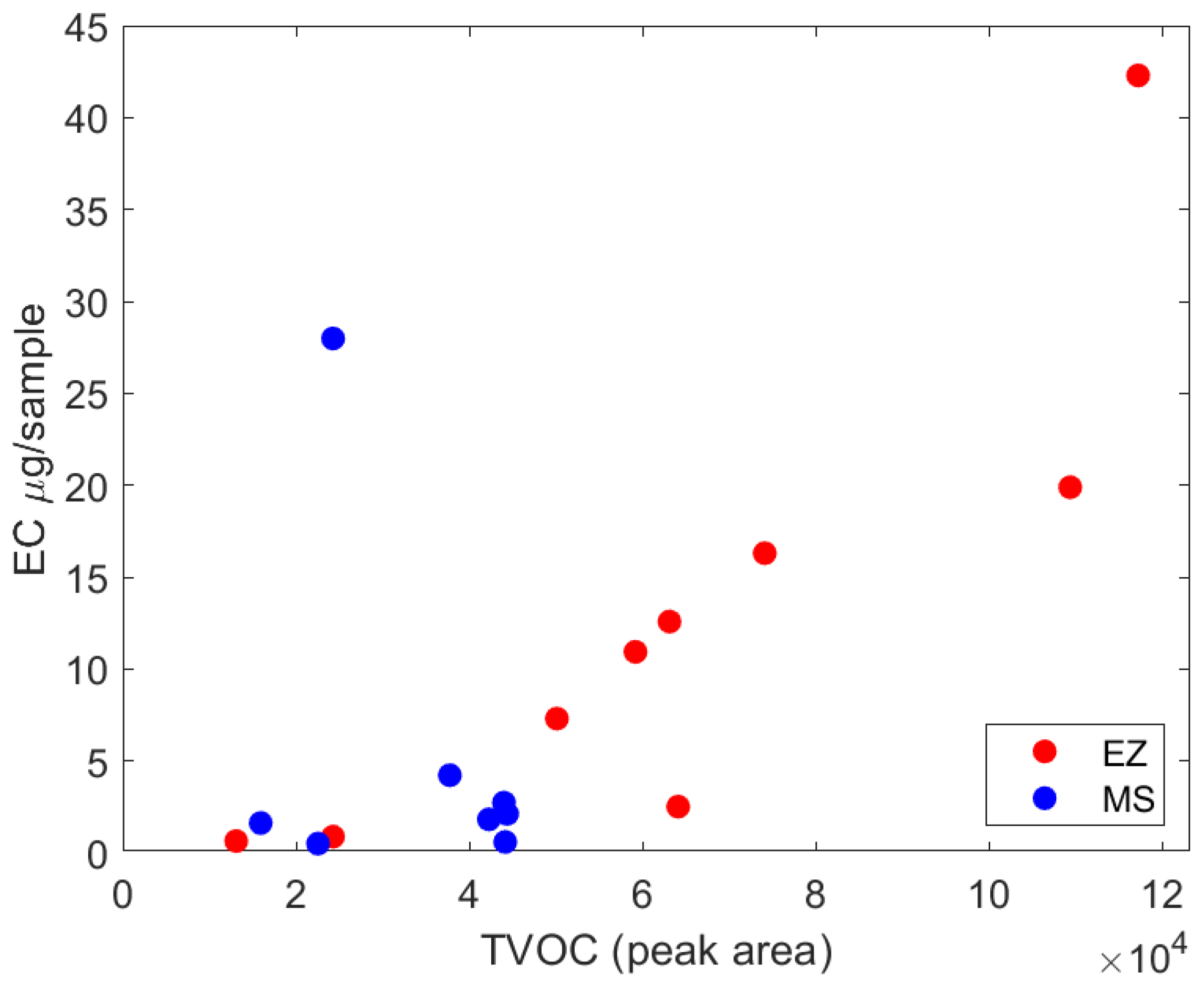

Figure 4 presents a scatter plot of the EC and TVOC measurement results, which were obtained for the concurrently collected samples. The data associated with the maintenance shop and the extraction zone are distinguished by colors.

In

Table 3, we present the results of the correlation analysis between the results of the measurement of EC and TVOC as well as hydrocarbons with a carbon number from C11 to C14 in mine air. The data associated with the maintenance shop and the extraction zone were examined separately.

The plot in

Figure 4 indicates a lack of correlation between EC and TVOC in the air of the maintenance shop. The results of the correlation analysis confirm this observation. Based on

Table 3, the correlation between EC and TVOC measurements in this part of mine was not statistically significant (

p = 0.54) at the significance level α = 0.1. Additionally, for the individual hydrocarbons, the measurement results did not correlate with EC content (minimum

p = 0.40). The situation was different in the case of the extraction zone. The plot in

Figure 4 indicates the correlation between EC and TVOC measurements in the air of the extraction zone. The results of the correlation analysis confirm this observation. Based on

Table 3, the correlation between EC and TVOC measurements in this part of mine was statistically significant (

p = 0.00) at the significance level α = 0.1. Additionally, for the individual hydrocarbons, C12, C13, and C14, the measurement results correlated significantly with EC content (maximum

p = 0.06). Only for hydrocarbons with the lowest carbon number, C11, did the measurement results remain uncorrelated with EC.

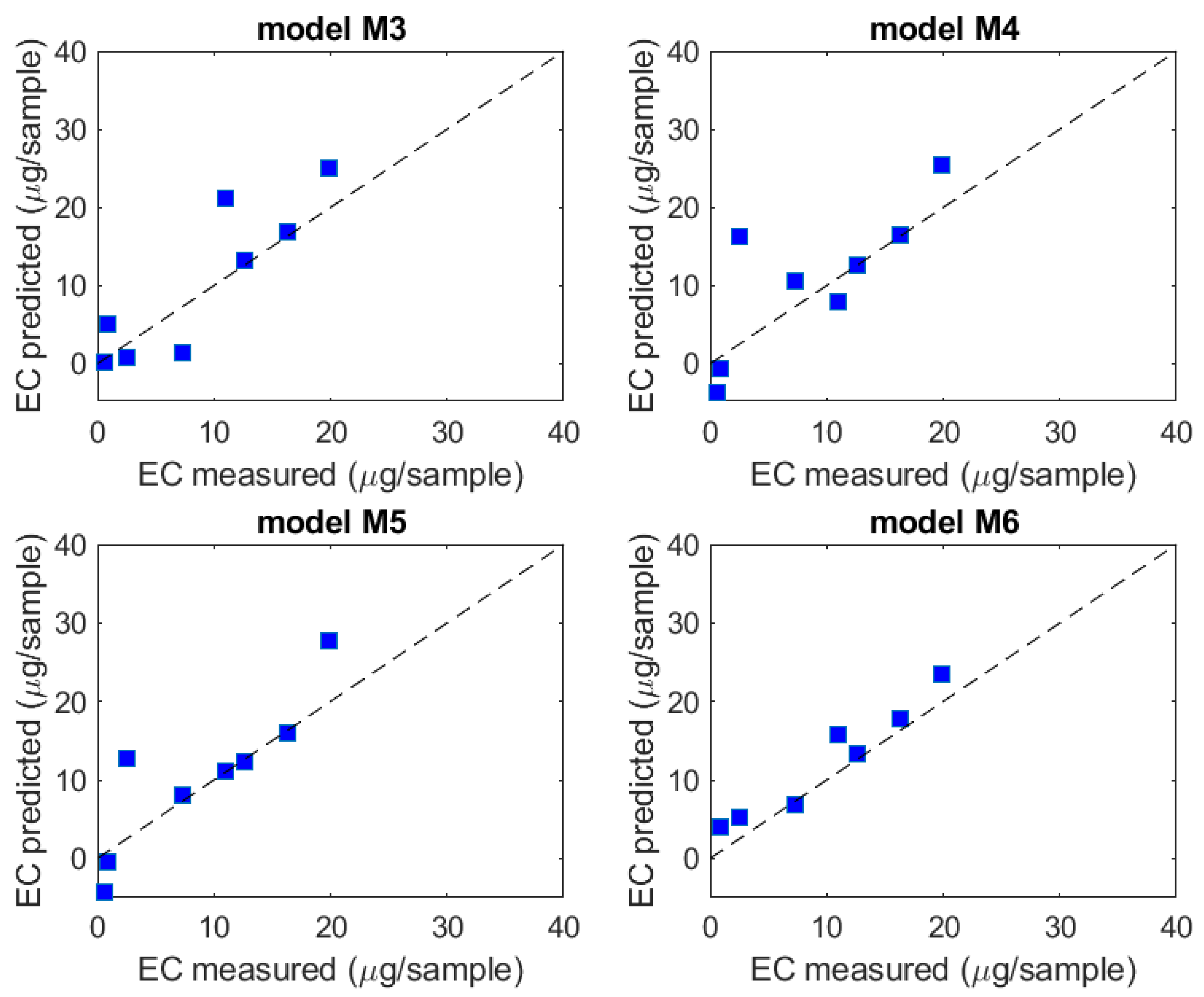

A linear regression model was fitted to the measurement data collected in the extraction zone. The following explanatory variables were involved in the analysis: The peak area for hydrocarbons C12, C13, and C14 individually; the total area under the entire chromatogram representing TVOC; and the subtotal area under the chromatogram, STVOC = TVOC-C12-C13-C14, representing VOCs detected without C12, C13, and C14. Four models were proposed. Model M3 predicts the EC content based on C12, C13, and C14. Model M4 determines EC content based on STVOC. Model M5 utilizes TVOC for EC determination. Model M6 is based on STVOC, C12, C13, and C14. The parameters of the regression models are presented in

Table 4. The diagnostic plots comparing the measurement data and model predictions are shown in

Figure 5.

Based on

Table 4 and

Figure 5, model M6 best fits the measurement data (R

2 = 0.861), but it requires multiple input variables (

n = 4) and its statistical significance is second best (

p = 0.053). This model utilizes the information about hydrocarbons C12–C14, considered individually, and about the remaining VOCs taken in total (SVTOC). The regression model, which uses only SVOCs as the explanatory variable (model M4), most poorly fits the data (R

2 = 0.663), although it is statistically significant (

p = 0.008). Contrarily, when the individual hydrocarbons are utilized as the independent variables (in model M3), the fit improves (R

2 = 0.740), although statistical significance is weakest compared to other models (

p = 0.063). Additionally, TVOC alone performs very well as the explanatory variable (model M5) in terms of experimental data fitting (R

2 = 0.754) as well as model significance (

p = 0.002). The comparison of regression-model performance measures presented in

Table 4 reveals the high information potential of the matrix of individual compounds identified in air and related to diesel emission. However, the hydrocarbons selected for our analysis, C12–C14, clearly do not constitute the exhaustive set of meaningful compounds. The information about other compounds, even if considered jointly (STVOC), improves model performance (compare models M3 and M6). Model M6 deserves attention. The EC content prediction error using M6 is RMSE = 4.60 µg/sample. However, the obtained results justify a further search for other compounds which could individually contribute to more accurate EC determination based on VOC content in mine air.

The models presented in our work were based on the results obtained from nine measurement points. This number is limited. In principle, it is due to the fact that organizing and performing measurements in an underground mine is a complex technical and procedural operation. This particularly refers to multi-parametric measurements involving numerous and versatile pieces of measuring equipment, which have to be delivered, transported, operated, supervised, and then removed from the mine. Additional difficulty is associated with the location of measurement points, the extraction zone in our case. Problems are mainly caused by safety concerns related to the presence of third parties in the areas most prone to accidents. They involve gaining multiple approvals, including mine board consent and the involvement of additional staff, as well as the temporary interference with the work of regular miners. However, measurements were successfully performed in three different mines. In spite of similar profiles in terms of the kind of extracted resource, the mines are different, e.g., regarding geology. The measurement points themselves featured different characteristics. Some were located, for example, at a depth of 700 m underground, others at 1100 m, differing in the intensity of ventilation, climate conditions, the amount of machinery in operation, the type of engines used, and the performance of the applied exhaust-gas after-treatment systems. As a consequence, the models which are based on data from such measurements account for versatile conditions in different underground mines. Nevertheless, we do not claim their general applicability to any underground environment.

Regardless of the small measurement dataset and the resulting limitations regarding the generic character of the developed models, the proposed method is applicable to any environment, provided statistically significant correlations between VOC concentrations and EC are found.

6. Conclusions

EC is used as a surrogate for monitoring diesel particulate matter at workplaces. The paper examines the possibility of estimating EC content in mine air on the basis of measurements of volatile organic compounds. The analysis was based on measurements conducted in two types of space: the extraction zone and the maintenance shop.

A correlation was found between the measurements of TVOC and EC in the extraction zone, but it was not found in the maintenance shop. We hypothesize that this fact may be related to the generally low pollution level in the maintenance shop.

The relationship between EC and TVOC measurements in the extraction zone was fitted with a linear regression model (R2 = 0.754), which was highly significant (p = 0.002). The model is capable of predicting the EC content in air based on the TVOC measurement with an RMSE of 6.10 µg/sample. By including the input data related to individual hydrocarbons C12–C14, model performance still improves (R2 = 0.861), and EC content prediction error decreased down to RMSE = 4.60 µg/sample.

The obtained results are attractive from a practical point of view. Namely, they confirm the possibility of using VOC measurements for the preliminary estimation of EC concentrations in mine air. They also underline the important role of utilizing data related to individual compounds which are indicative of diesel emissions in the model.

Upon the application of a highly efficient sampling procedure and the use of high-performance portable GC/MS, it is possible to obtain qualitative and quantitative data about the relevant VOCs in a short measurement time, approximately 10 min. It gives an opportunity to perform screening measurements which are aimed at selecting locations to perform EC measurements with the certified methodology.

It would be valuable to confirm the identified correlation model between EC and VOC measurements for a larger database of measurements. It would also be interesting to check the existence of such correlations for other workplaces.