Abstract

The modern coal chemical industry is a typical high carbon emission industry, which has formed a large-scale development in China. In the context of carbon neutrality, it is considered to be an ideal combination mode that captures high-concentration CO2 emitted by the modern coal chemical plants and transports it to oilfields through pipelines, which can both realize the low-carbon development goals of the modern coal chemical industry and reduce the cost of the whole process of Carbon Capture and Storage (CCS), as well as promote the development of CCS in China. Based on the data from modern coal chemical projects and depleted oil basins across China, a model of a pipeline network with optimal layout design was constructed, aiming to achieve specific emission reduction targets. Meanwhile, its economic effects will be analyzed. It turns out that this layout can help achieve an annual emission reduction of 280 million tons of CO2, with an average annual net income of USD 2.20 billion, and a unit net income of USD 7.85 per ton of CO2. A total of 166 pipelines up to 15,783 km in total length need to be built across China. Suitable storage sites can be found within an average radius of 94 km for emission sources. A total of 11,115 km of pipelines needs to be built in the “Three North” areas, accounting for 70.4% of the total pipeline length.

1. Introduction

In 2020, China proposed “carbon peaking and carbon neutrality” goals and the development of “high carbon emission” industries has been greatly affected. Industries, “difficult to decarbonize” in the future, such as coal-fired power, steel, cement, and chemical industries are considered to be key to reducing carbon emissions because of their high-carbon properties at the raw material end and their process characteristics. There are two main ways to reduce CO2 emissions; one is to improve energy efficiency or use cleaner fuels, the other is to capture CO2 from the atmosphere and store it [1]. Carbon Capture and Storage (CCS) is considered one of the feasible technology options for low carbon development in “high carbon emission” and “difficult to decarbonize” industries [2]. The coal chemical industry coupled with CCS technology converts coal with high CO2 emission coefficient into fuels with low emission coefficients, such as oil and natural gas. The CO2 generated in the conversion process is captured and stored to reduce the carbon emissions of energy. At present, CCS is limited by high cost and high energy consumption, and its promotion on a global scale is very slow. In particular, the capture, regeneration, and purification of CO2 from low-concentration emission sources (such as coal-fired power plants, steel plants, cement plants, etc.) will consume a large amount of water, heat, and electricity resources, resulting in higher costs. One of the research directions is to reduce the cost of the whole CCS process, and capture and utilization of CO2 from high-concentration emission sources are considered one of the early opportunities for CCS development in China [3], which can significantly reduce the cost of the capture process.

Synthetic ammonia, chemical fertilizer production, and the chemical industry are industries with high carbon emission intensities, and the modern coal chemical industry is also one of the typical high-concentration emission sources that directly discharges into the atmosphere and emits CO2 during its process are intense. In the context of “carbon neutrality”, this has become a shackle for its industrial development. The coal chemical industry is characteristic in China. With the support and encouragement of the state, it has made great progress and formed a large-scale development pattern, but its total carbon emissions should not be underestimated. The research [4] shows that the technology of coupling carbon capture devices in the coal chemical process is mature, and the capital cost of the capture process is greatly reduced compared with the low-concentration capture sources, and the operating energy consumption is lower. A modern coal chemical plant is a high-quality carbon capture source, which can reduce the capture cost and realize the low-carbon development of the modern coal chemical industry at a lower cost. At the same time, if the captured CO2 can be used to generate benefits, it will be more conducive to the development of CCS. The practice has proven that CO2-enhanced oil recovery is a very ideal CO2 utilization mode. The combination of CO2 capture and enhanced oil recovery is one of the ideals, which further reduces the whole process cost of CCS. It can reduce CO2 emissions while increasing the oil output of China’s depleted oilfields and relieve the pressure on the domestic energy supply. Meanwhile, it will help with accumulating CCS utilization experience, improving CCS technology levels, pushing forward CCS cost reduction, and making technical reserves for the widespread deployment of CCS to achieve “carbon neutrality”.

As one of the most economically feasible technology combinations, despite its significance for the early promotion, demonstration, and maturity of CCS whole process technology, the modern coal chemical industry with the combination of the CO2 capture and enhanced oil recovery is currently developing slowly in China. Reasons are manifold—“carbon neutrality” is in its infancy; the policy binding is not strong; the relevant mechanism design is not yet perfect; the enthusiasm for the relevant industry is not high; the understanding of CCS is not deep enough; the main CO2 emitters are unwilling to undertake the high cost in the capture process; and, there is a shortage of large-scale pipelines for the transportation of CO2 and worries for the storage and utilization process. In addition, various practical problems such as storage risks and poor connections between the upstream and downstream of CCS also restrict the enthusiasm of all parties and its large-scale development. Therefore, it is necessary to scientifically assess the economic and emission reduction potential of the whole process of CO2 capture combined with enhanced oil recovery in the modern coal chemical industry and plan the national pipeline layout to provide a certain reference for the early large-scale demonstration of CCS, which can promote the scale and industrialization of CCS technology in all aspects, and create technical reserves for the large-scale application of CCS.

Based on the above situation, this paper intends to solve the problems of large-scale deployment of CCS in the modern coal chemical industry and transportation of CO2 to oilfields through pipelines for enhanced oil recovery. Furthermore, this paper addresses how to plan the national pipeline layout and examines how economical the whole process is.

2. Literature Review

Existing studies [5] have constructed a whole-process economic evaluation model for CO2 capture and storage to enhance oil recovery, which is essentially a cost-optimized linear optimization model, taking into account the four main parts of CO2 capture: transportation, injection, and crude oil recovery. Using the case of a coal chemical plant-pipeline-depleted oil field (CO2-EOR) to study the economics of the whole process of CCS, the annual capture of 800,000 tons of CO2, over a planning period of 20 years, could yield a total net income of RMB 936 million, indicating that coal chemical carbon capture combined with enhanced oil recovery has economic benefits; however, this is just a case study. Another study [6] constructed a techno-economic evaluation model, taking into account large-scale characteristics and representative statistics to evaluate the suitability and technical and economic feasibility of potential coal chemical CCS-EOR projects in the Songliao basin, Bohai Bay basin, Ordos basin, and Junggar basin in China. The study shows that when the CO2 tax is 15 USD/t and the CO2 price is 20 USD/t, the CCS-EOR whole process project is economical, and its essence is to consider the theoretical source-sink matching under certain restrictions. The study by [7] constructed the CCS infrastructure economic engineering optimization model, which is essentially a linear optimization model, and considers the fixed and operational as well as the maintenance investment of the whole process of capture, transportation, storage, and utilization, with the minimum total cost as the optimization goal. Various types of point emission sources (clustering first) and storage sinks in the Ordos basin are used as examples to verify the model. The model can better solve the problems of CO2 source and quantity, storage location, and how to design transportation pipelines. A simple economic analysis was carried out showing that when the CO2 tax is lower than 52 USD/t, it is more economical to capture from high-concentration emission sources such as the coal chemical industry, and capture from low-concentration CO2 emission sources such as coal-fired power plants, which also becomes economical when CO2 taxes exceed 52 USD/t; therefore, this model has well realized the pipeline network planning of multiple sources and multiple sinks, but it has only studied the Ordos basin in a particular part of China and failed to comprehensively assess the potential of capturing carbon from the modern coal chemical industry to enhance oil recovery in oil fields.

Existing studies mainly analyzed the economics of the whole process of coal chemical CCS projects in the form of cases or study local areas in China. Few studies in the literature have carried out economic research and pipeline network layout analysis on large-scale deployment of CCS combined oilfield enhanced oil recovery (CO2-EOR) in the coal chemical industry. This paper uses the data of modern coal chemical projects that have been put into operation, construction, and proposed construction in China, combined with the actual production capacity and designed production capacity of the project to calculate its CO2 emissions. The storage potential of onshore oilfields comes from existing research [8] by the U.S. Department of Energy. By comprehensively considering the capital and operation and maintenance costs of capture, transportation, and storage, an optimization model is constructed to study the nationwide pipeline layout of the modern coal chemical industry for CO2 capture combined with depleted oilfields to enhance oil recovery when a specific CO2 emission reduction scale is met. Furthermore, based on this analysis of its whole-process economy, we can provide a reference for the early large-scale demonstration of CCS in China. The main contributions of this paper are as follows:

- Based on the data of modern coal chemical projects (commissioned, construction, and proposed) and depleted oil basins, and considering the geological differences of each depleted oilfield basin, the social, environmental, geographical, and geological factors that affect the construction of the pipeline will be calculated. After quanitification, the cost factor is extracted added to the pipeline network optimization model to optimize a more economical and feasible pipeline network.

- The pipeline network in China is then given, which can help to screen the modern coal chemical projects that prioritize carbon capture retrofit and the depleted oilfield storage sites for enhanced oil recovery in order to implement pipeline network optimization. The research results can provide a reference for the government, relevant research institutions, oil production companies, and modern coal chemical plants to deploy CCUS full-process projects.

3. Methods and Data

Considering the construction, maintenance, and operation costs of the three processes of CCUS—capture, transportation, and storage—, minimizing the total emission reduction cost of the whole CCUS process is one of the goals of the scientific design of large-scale pipeline networks. In this study, by constructing a mathematical optimization model, the construction cost, maintenance cost, and variable operating cost of each part of the whole CCUS process are evaluated to obtain the cost-optimal national CCUS pipeline network layout for coal chemical companies to combine with oil fields for enhanced oil recovery. Often the cost parameters in the model are related to the technology used, and since many detailed project-level data are not available, many of the data in this paper are set at the national level using consistency.

3.1. Research Framework

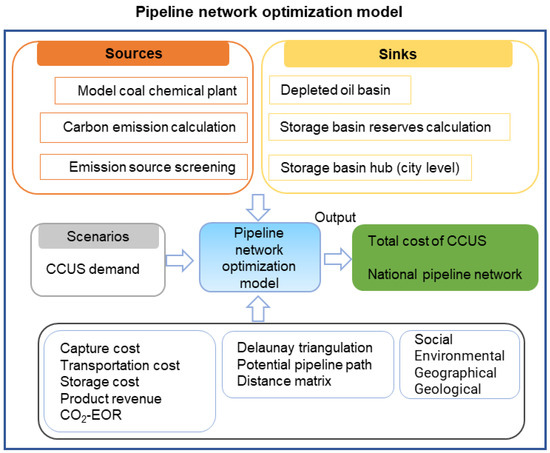

The research framework of this paper is shown in Figure 1. The main research ideas are: ① Identify candidate modern coal chemical plants for CCS retrofit in the future and establish a database of emission sources; ② according to the existing oil basin data, calculate the CO2 storage reserves of depleted oilfields with municipal administrative regions as the basic unit, and screen them to establish a storage site database; ③ calculate the distance matrix based on the latitude and longitude data of the source and sink. At the same time, comprehensively consider the social, environmental, geographical, and geological factors affecting pipeline construction, and quantify the cost of the influencing factors to extract the cost factor; ④ build a pipeline network model that allows clusters of the same type to be connected between emission sources, storage sites, and between emission sources and storage sites; and ⑤ set emission reduction scenarios and optimize the layout of modern coal chemical plants and oilfield storage sites and pipeline networks that participate in emission reduction under specific carbon emission reduction targets.

Figure 1.

Research framework.

3.2. CO2 Emissions Calculation

This study includes 248 large-scale modern coal chemical projects that have been put into production, are under construction, or are to be built. It covers coal-to-natural gas, coal-to-olefins, coal-to-oil, coal-to-ethylene glycol, coal-to-aromatics, coal-to-ethanol, and coal-based quality utilization. The CO2 emission is calculated by using the actual process emission factor data of the plant, and the CO2 emission factor in the research [9] is used according to the product type for which the process emission factor is not obtained for the actual project.

The emission of the coal chemical project comes from two parts. One part is the emission generated by coal conversion into other energy, which is called process emission. The other part is the emissions generated by the consumption of electricity and heat during the transformation process, which are called public emissions. High CO2 concentration generated by process emissions can be transported and stored only by compression. The amount of CO2 captured and calculated in this paper refers to the process emissions, and the capture rate is 90%. According to the relevant research, the process emission coefficient of the coal chemical industry involved in this paper is 3.33 tons CO2/ton oil equivalent for direct coal to oil, 5.1 tons/ton oil equivalent for indirect coal liquefaction, 2.7 tons/thousand cubic meters for coal to gas, 6.41 tons/ton for coal to olefin, 3.5 tons/ton for coal to ethylene glycol, 2.06 tons/ton for coal to methanol, and 2.8 tons/ton for coal to dimethyl ether.

According to the actual production capacity of the projects that have been put into operation, the theoretical annual CO2 emission is 437 million tons. According to the design capacity of the projects under construction and to be constructed, the theoretical annual CO2 emission is 805 million tons.

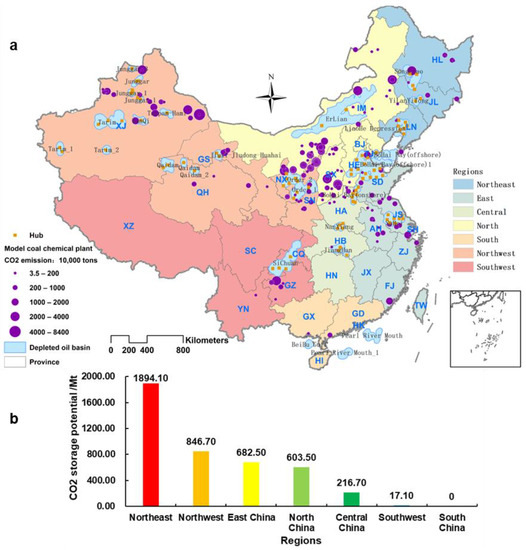

3.3. CO2 Storage Capacity Calculation

Based on the storage basin data in the BIT-CEEP study [6], the onshore storage basin is the main research body. Considering that the actual construction of CCS projects needs to be specific to the prefecture-level administrative districts, the depleted oil basins with CO2 storage potential are allocated according to the area of the prefecture-level administrative districts and the theoretical CO2 storage potential is calculated. Each allocated depleted oil basin is given a distribution center (hub, as a distribution center in a certain area), and the hub is set to the allocated depleted oil basin centroid, and 88 hubs are obtained, with a total theoretical CO2 storage potential of 4.26 billion tons. Northeast China has the largest EOR CO2 storage potential, followed by Northwest China, whereas South China has no EOR CO2 storage potential on land. Figure 2 shows the distribution of depleted oil basins by city-level administrative regions in China.

Figure 2.

Distribution of modern coal chemical plants and hub. (a) shows the source-sink layout of the country, and (b) shows the CO2 storage potential of EOR in various regions of the country.

3.4. Method

3.4.1. Objective

One of the objectives of large-scale pipeline network scientific design is to comprehensively consider the construction, maintenance, and operation costs of capture, transportation, and storage, and to minimize the total cost of the whole process. By constructing a mathematical model, the construction, maintenance, and variable operating costs of each procedure in the whole process are evaluated. Generally, these costs are related to the adopted specific technology.

Based on the operational research method, this research adopts Python programming modeling and combines with geographic information system (ArcGIS) software to solve. This paper studies the pipeline network layout and economics of large-scale deployment of CCS for CO2 capture combined with depleted oil basins in China’s modern coal chemical industry to enhance oil production through modeling. The model mainly includes CO2 capture and compression, transportation and storage, and enhanced oil recovery. Each process includes capital cost, maintenance, and operation cost, and the optimization goal is to minimize the total emission reduction cost (net expenditure). EOR has benefits, which can make up for the initial capital investment to a certain extent.

3.4.2. Constraints

The annual capture of any capture source does not exceed its annual CO2 emissions. The total storage capacity of any hub during the planning period shall not be higher than its total storage potential. The annual injection capacity of the injection well in any hub shall not be lower than its actual storage capacity.

The transportation capacity of any pipeline is not less than the annual transportation amount of the pipeline. The outflow of any emission source node is equal to the sum of its capture and inflow. The outflow of any hub node is equal to the difference between its inflow and storage.

The sum of the capture amounts of all emission sources is equal to the sum of the storage amounts of all hubs, which is also equal to the total emission reduction target.

The capture and storage amount of any CO2 emission source and the hub is non-negative, and the transport amount of any pipeline is non-negative.

3.4.3. Model Parameters and Decision Variables

The parameters in the pipeline network model are divided into variables and parameters. Table 1 lists the model parameters and decision variables.

Table 1.

Variables and parameters of the pipeline network model.

4. Results and Analysis

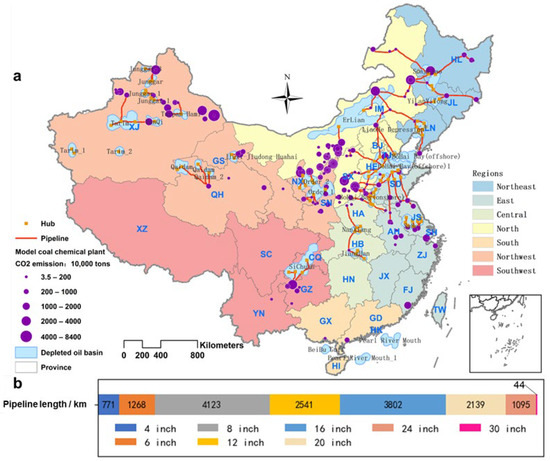

4.1. Pipeline Network Layout

The modern coal chemical industry captures CO2 in conjunction with depleted oil fields for EOR, reducing 280 million tons of CO2 annually. The modern coal chemical retrofit projects are mainly concentrated in Northeast, North, Northwest, and East China. North China is the main region for CO2 capture, as seen in Figure 3a. Oilfields for CO2-EOR are mainly distributed in Northeast China, North China, Northwest China, and East China, and Northeast China has the most CO2 stored, as shown in Figure 3a.

Figure 3.

CO2-EOR pipeline network layout of modern coal chemical industry. (a) shows the optimized national pipe network layout, and (b) shows the length of pipes with different diameters.

In total, 168 pipelines with a total length of 15,783 km need to be constructed, mainly 8, 12, and 16 inches in diameter, with fewer large-diameter pipelines. The pipeline construction is mainly concentrated in Northeast and North China, accounting for 47% of the total mileage of pipelines to be constructed nationwide, with 3263 km and 4120 km pipelines to be constructed, respectively. In general, the average pipeline length in Northeast China is longer, and the average pipeline length in East China is the shortest. The pipeline transportation around the Bohai Bay basin, the Ordos basin, the Junggar basin, and the Subei basin is relatively convenient and has the advantage of priority development, as shown in Figure 3.

4.2. Cost-Benefit Analysis

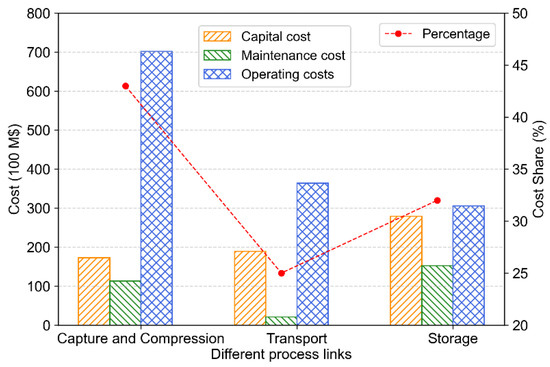

4.2.1. Economic Analysis of the Whole Process

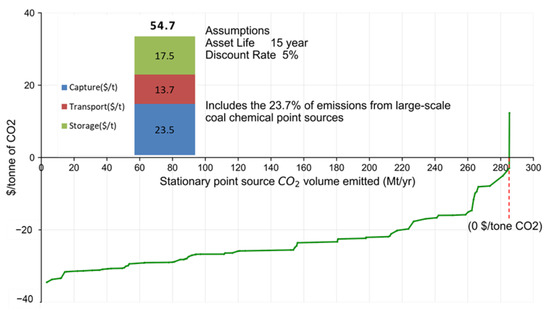

The annual emission reduction is 280 million tons of CO2. In the 15-year planning period, the total net income from EOR will be USD 32.95 billion, with an average annual net income of USD 2.2 billion. An additional 66 million tons of oil can be extracted every year, which is equivalent to 34% of domestic oil production (195 million tons) in 2020, which can greatly increase domestic oil production. The cost of the capture process accounts for the largest proportion of the total cost of the whole process, accounting for 43%, followed by the storage process, and the transportation process costs the least. Among the costs of capture, transportation, and storage, the capital cost accounts for a relatively small proportion, and the operating cost accounts for the largest proportion, especially the operating cost of the capture and compression process. The development of new low-energy-consumption capture solvents is very important to reduce the cost of the capture process.

The operation and maintenance costs account for more than 70% of the total cost. Improving the CO2-EOR technical process and reducing the operating cost of the project will be the key to optimizing the economics of the whole process project, as seen in Figure 4. The average cost of CO2-EOR in the modern coal chemical industry is 54.7 USD/t CO2, the average storage benefit is 62.6 USD/t CO2, and the average net income is 7.9 USD/t CO2, indicating that it has economic benefits. Overall, the full-process CO2-EOR break-even oil price is 44.5 USD/bbl, but when accurate to the specific project, the result may fluctuate to a certain extent due to the difference in transportation distance and oil displacement oil ratio.

Figure 4.

Cost and proportion of each process in the whole process.

4.2.2. Economic Analysis by Region

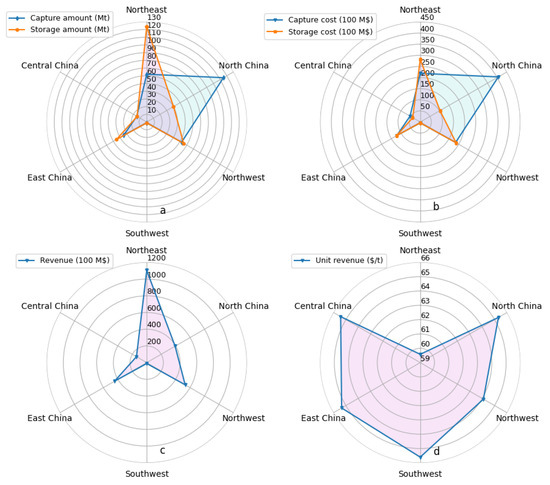

CO2-EOR in all regions can bring net incomes, with an average storage cost of 17.5 USD/t CO2 and an average storage profit of 62.6 USD/t CO2. The average storage cost in Northeast China is the lowest at 15.6 USD/t CO2, which is lower than the national average storage cost, but the unit storage profit is also the lowest, with an average of 59.6 USD/t CO2, which is lower than the national average storage profit. Due to the total storage potential being large in Northeast China, the total EOR profit is the highest; see Figure 5a,c,d. Northeast China has better storage potential and would be the main storage region in the future.

Figure 5.

Regional annual capture, storage volume, capture cost, storage cost, total storage revenue, and average storage revenue. (a) shows the amount of capture and storage in each region, (b) shows the cost of capture and storage in each region, (c) shows the EOR revenue in each region, and (d) shows the unit storage revenue in each region.

The average storage cost in Southwest China is the highest at 22 USD/t CO2, which is higher than the national average storage cost, but the unit storage benefit is also the highest, with an average of 65.6 USD/t CO2. Due to the total small amount of storage, the total storage benefit is the smallest; see Figure 5a,c,d. The storage potential of East China, Southwest China, and Central China is relatively small, but the storage benefit per unit is relatively high. Due to the short distance between the source and sink, it is suitable for carrying out early small-scale demonstration projects.

Under the background of “carbon peaking and carbon neutrality”, the pressure of emission reduction in various industries will increase, especially in industries where it is difficult to reduce emissions to achieve a net zero emission and where CCS will be an essential technology choice. Carbon sequestration in oil-bearing regions will inevitably compete with other industries. The potential of carbon sequestration that can be used in the coal chemical industry will be less than the existing assessment value, which will reduce the economic feasibility of projects in specific regions to a certain extent. In general, the combination of capturing CO2 from the coal chemical industry for enhanced oil recovery in oil-bearing areas can greatly reduce the cost of the whole process of the CCS project, which has the advantage of giving priority to CCS demonstration.

4.2.3. Economic Analysis of the Project

Based on the CO2-EOR source-sink matching layout in modern coal chemical projects, the average emission reduction cost of the whole process is lower than the average storage benefit, and most CCS projects can bring benefits, as shown in Figure 6. The Bohai Bay basin and the Ordos basin have priority for the development of source and sink conditions, with a large number of emission sources, short source-sink distance, and great oil displacement potential. In general, they have better conditions to carry out large-scale demonstration projects and can plan their layout in advance.

Figure 6.

CCS cost curve of CO2-EOR whole process project in modern coal chemical industry.

Based on the results of this study, in the average cost composition of the whole CCS process, the cost of storage is the largest proportion of the whole process cost, followed by the cost of capture and transportation. The main reason is that this study assumes that the original oil infrastructure cannot be reused, and EOR storage infrastructure needs to be built. In the actual EOR project, the original oil infrastructure can be partially reused, which can reduce the project cost to a certain extent, but this requires special research based on the actual situation. At the same time, other factors will also affect the economy of the project, such as oil prices, geological conditions, etc.

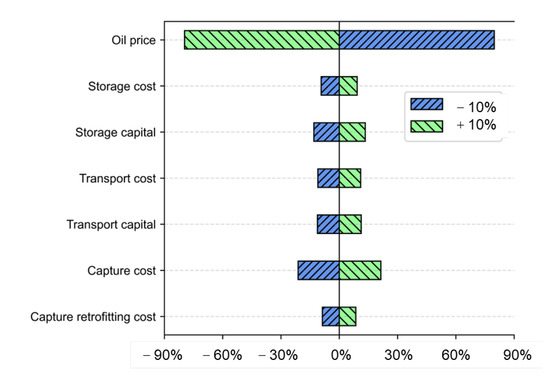

4.3. Sensitivity Analysis

Sensitivity analysis shows that: ① Changes in oil prices have the greatest impact on project economics, up to 80% (See Figure 7 for details), which is consistent with the fact that EOR economics in operating demonstration projects are greatly affected by oil price changes. Only when oil prices are high can companies make profits. If the CO2 emission reduction and oil displacement incentive (10 USD/t CO2) are implemented concerning the policies of the US 45Q Act, 110 modern coal chemical projects need to participate in emission reduction; the profitable CO2 storage potential can be increased based on the original emission reduction scale of 25%, and the newly added oil production capacity is 12.5 million tons per year, which greatly improves the enthusiasm of oil companies to participate in emission reduction. ② The sensitivity of capture and compression operating cost fluctuates the most, reaching 21.2% See Figure 7 for details), and the sensitivity is the largest in capture and compression, transportation, and storage, indicating the importance of reducing energy consumption in capture and compression. The capital cost of capture transformation has the lowest sensitivity, which is more in line with reality. After reasonable optimization, the deep coupling of the capture process with the modern coal chemical production process can greatly reduce the initial capture capital investment. ③ The impact of pipeline transportation construction capital and storage infrastructure construction capital is 11.3% and 13.4% (See Figure 7 for details), respectively, which are the two factors with the largest variation in the three major links of CCS, indicating the importance of overall planning pipeline infrastructure construction and selecting storage land with good geological conditions.

Figure 7.

Sensitivity of key parameters to total abatement costs.

The sensitivity study shows that the total cost of a CCS project is very sensitive to these main parameters. The uncertainty study based on the uncertainty value should be considered the best representative. The size and relative nature of the cost should not be absolute. Further technical and economic evaluation must be carried out to carry out more detailed work, such as more detailed site characteristics, site performance evaluation, and budget evaluation.

5. Discussion

The combined enhanced oil recovery of CO2 captured by the modern coal chemical industry will be one of the early large-scale promotion opportunities of CCS in China. As far as we know, this is the first time in China that the pipeline network optimization model has been used for optimal planning and modern coal chemical projects and oil-bearing areas for EOR have been prioritized for retrofit. It is also the first time the pipeline network for large-scale deployment of CCS has been optimized, and its economics were analyzed. The whole process of combined enhanced oil recovery by capturing CO2 emitted from modern coal chemical projects can generate economic benefits. The modern coal chemical industry is suitable for the early large-scale promotion of CCS and has potential opportunities for priority development. Northeast China, North China, Northwest China, and East China are the main regions for capture, storage, and pipeline construction, and the layout can be planned in advance. The research results provide a reference for the large-scale deployment of CCS in China’s modern coal chemical industry and the construction of a CO2 pipeline network.

The reliability of this study was verified by comparison with existing studies. Research [4] established a whole-process economic evaluation model of CO2 capture combined with EOR and carried out a case study combined with the actual project in China. The cost of the whole process of coal-to-liquid CCS-EOR is 42.9 USD/t CO2 (274.4 RMB/t CO2), and the net income of the whole process is 9.1 USD/t CO2. The unit cost of the whole process of this study is 54.7 USD/t CO2, and the unit net income is 7.9 USD/t CO2, which is higher than the above research cost and lower, mainly because the unit transportation cost of this paper is higher. In addition, the average transportation distance is longer (94 km), and the oil displacement CO2 ratios of different storage basins in this paper are conservative, resulting in a small net income.

Research [15] states that the Shenhua full-process CCS deep saline aquifer storage demonstration project has a full-process (capture and storage cost) cost of 37.4 USD/t CO2 (273 RMB/t CO2). The cost of capture and storage in this study is 41 USD/t CO2, which is slightly higher than the cost of the above study. Considering that this study increases the cost of transportation through pipeline transportation, the average distance of pipeline transportation is 94 km, which is farther than the 17 km distance of the whole Shenhua process demonstration project, and the cost is higher and more reasonable. The average break-even oil price in this study is 44.5 USD/bbl, which is close to the break-even oil price of 45 USD/bbl for operating pilot demonstration projects in China. By comparing with existing research, the rationality of this research is verified to a certain extent.

In this study, the operation research optimization model was used to optimize the pipeline network layout of modern coal chemical projects combined with depleted oilfields for EOR, and economic analysis was carried out. However, the limitations and deficiencies of the research are unavoidable. The construction of a CO2 transportation pipeline network is complex and requires detailed geographic parameters and quantitative verification models [16]. Therefore, there will be some differences in the research results. The parameter settings in the model will lead to differences in results and are discussed in Sensitivity Analysis, and the difference between transportation cost and maximum transportation distance is a specific factor. China’s current CCS demonstration projects are conducted mainly transport CO2 through tankers. In the future, in large-scale deployments of CCS, the source-sink matching distance is estimated to be between 0–250 km [17]. Considering that most regions of China are mountainous and densely populated, it will have a greater impact on pipeline construction and operation. In this study, the transportation cost between 50–200 km in reference [18] is combined with the cost data of domestic gas pipeline projects in operation, and the transportation cost of this model is determined.

The assessment of storage potential requires detailed geological parameters. Due to the unavailability of detailed geological data nationwide, this paper evaluates the theoretical storage potential of corresponding regions based on representative geological data of typical regions. The research results will inevitably have limitations at the national level. In addition, there are many uncertain factors such as environmental risk [19], earthquake risk [20], public acceptance [21], investment uncertainty [22], and so on. These limitations cannot be completely avoided, and more people are required to participate in further research and analysis in the future.

6. Conclusions and Policy Implications

6.1. Main Conclusions

- (1)

- Capturing CO2 emitted by the modern coal chemical industry to enhance oil recovery has great potential for emission reduction. The annual emission reduction of CO2 is 280 million tons, and the annual oil production can be increased by 66 million tons (equivalent to increasing domestic oil production by 34% in 2020), which can effectively improve oil self-sufficiency. Northeast, North China, and Northwest China are the main concentration areas for CO2 capture and EOR, and they are also the main area sfor pipeline construction, especially in Songliao basin, Bohai Bay basin, Ordos basin, and Junggar basin, where a CCS demonstration layout can be carried out in advance.

- (2)

- The annual emission reduction of CO2 is 280 million tons, and the total net revenue of the 15-year planning period is USD 32.95 billion. Furthermore, the average CO2 reduction cost of the whole process is 54.7 USD/ton, the average CO2 storage profit is 62.6 USD/ton, and the average net profit of CO2 emission reduction is 7.9 USD/ton. CO2 captured in the modern coal chemical industry combined with enhanced oil recovery has good economic benefits.

- (3)

- In the 15-year planning period, the cost of emission reduction is mainly concentrated in the capture process, accounting for more than 40% of the total cost. The second is the cost of storage, accounting for 35%. The proportion of transportation cost is the smallest, at only 25%. The oil price has a significant impact on the economics of the whole process of the CCS project, and the break-even oil price of the project is 45 USD/barrel.

6.2. Policy Implications

- (1)

- Early planning and deployment of CCS in the modern coal chemical industry, combined with oil fields for EOR, especially in the Songliao basin, Bohai Bay basin, Ordos basin, and Subei basin, where there are abundant CO2 sources and close proximity to oil fields, can effectively reduce the cost of the CCS project for the whole process. When the oil price is high, the project has obvious economic benefits. The carbon capture in modern coal chemicals combined with oilfields to enhance oil recovery is one of the good source-sink combinations for the early large-scale industrial demonstration of CCS in China.

- (2)

- Explore innovative business models and break through the process barriers that restrict the development of CCS throughout the process, so that the country can issue relevant incentive policies at an appropriate time.

- (3)

- Carry out large-scale demonstration projects, promote the development of related technologies such as pipeline transportation and storage, and make necessary technical reserves for the country to achieve “carbon neutrality” through CCS large-scale emission reduction in the future.

Author Contributions

Conceptualization, X.L. and J.X.; methodology, X.L.; software, X.L.; validation, J.X.; formal analysis J.X.; investigation, X.G.; resources, X.G.; data curation, X.L.; writing—original draft preparation, X.L.; writing—review and editing, X.L.; visualization, J.X.; supervision, J.X.; project administration, X.L.; funding acquisition, X.G. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

This study does not involve research on humans or animals, so there are no ethical issues.

Data Availability Statement

Not applicable.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Board Ocean Studies. National Academies of Sciences Engineering; Medicine. In Negative Emissions Technologies and Reliable Sequestration: A Research Agenda; National Academies Press: Dulles, VI, USA, 2019. [Google Scholar]

- Xie, Z.; He, J.; Li, Z.; Zhang, X.; Wang, H.; Tian, Z.; Yang, X.; Zhou, L.; Chen, S.; Zhao, X. Comprehensive Report on “China’s Long-term Low-Carbon Development Strategy and Transformation Path Research”. China Popul. Resour. Environ. 2020, 30, 1–25. [Google Scholar]

- Li, Q.; Wei, Y.N.; Chen, Z.A. Water-CCUS nexus: Challenges and opportunities of China’s coal chemical industry. Clean Technol. Environ. Policy 2016, 18, 775–786. [Google Scholar] [CrossRef]

- Wang, W.; Tang, R.; Jiang, S.; Wang, H.; Yang, H.; Wang, W. The engineering practice of CO2 capture, utilization and storage(CCUS) in coal chemical industry of Yanchang Petroleum. Unconv. Oil Gas 2021, 8, 1–7, 106. [Google Scholar]

- Zhong, L.-F.; Lin, Q.-G.; Wang, X.-Z.; Wang, H.; Zhai, M.-Y. Economic evaluation of carbon capture and storage enhanced oil recovery technology. Mod. Chem. Ind. 2016, 36, 7–10. [Google Scholar]

- Wei, N.; Li, X.; Liu, S.; Dahowski, R.T.; Davidson, C.L. Early Opportunities of CO2 Geological Storage Deployment in Coal Chemical Industry in China. Energy Procedia 2014, 63, 7307–7314. [Google Scholar] [CrossRef]

- Stauffer, P.; Middleton, R.; Bing, B.; Ellett, K.; Rupp, J.; Xiaochun, L. System integration linking CO2 Sources, Sinks, and Infrastructure for the Ordos Basin, China. Energy Procedia 2014, 63, 2702–2709. [Google Scholar] [CrossRef][Green Version]

- Wei, Y.-M.; Kang, J.-N.; Liu, L.-C.; Li, Q.; Wang, P.-T.; Hou, J.-J.; Liang, Q.-M.; Liao, H.; Huang, S.-F.; Yu, B. A proposed global layout of carbon capture and storage in line with a 2 degrees C climate target. Nat. Clim. Chang. 2021, 11, 112–118. [Google Scholar] [CrossRef]

- Zhang, Y.; Wang, Y.; Tian, Y. Comparative studies on carbon dioxide emissions of typical modern coal chemical processes. Chem. Ind. Eng. Prog. 2016, 35, 4060–4064. [Google Scholar]

- Middleton, R.S.; Bielicki, J.M. A scalable infrastructure model for carbon capture and storage: SimCCS. Energy Policy 2009, 37, 1052–1060. [Google Scholar] [CrossRef]

- Bock, B.; Rhudy, R.; Herzog, H.; Klett, M.; Davison, J.G.D.; Simbeck, D. Economic Evaluation of CO2 Storage and Sink Enhancement Options; Tennessee Valley Authority: Knoxville, TN, USA, 2003. [Google Scholar]

- Ramírez, A.; Hagedoorn, S.; Kramers, L.; Wildenborg, T.; Hendriks, C. Screening CO2 storage options in the Netherlands. Energy Procedia 2009, 1, 2801–2808. [Google Scholar] [CrossRef]

- Budinis, S.; Krevor, S.; Dowell, N.M.; Brandon, N.; Hawkes, A. An assessment of CCS costs, barriers and potential. Energy Strateg. Rev. 2018, 22, 61–81. [Google Scholar] [CrossRef]

- US DOE. FE/NETL CO2 Saline Storage Cost Model: Model Description and Baseline Results; National Energy Technology Laboratory (NETL): Pittsburgh, PA, USA, 2014. [Google Scholar]

- Wu, J.; Han, J.; Xu, X.; Zhao, Y. Analysis on CCUS technical development roadmap for coal-based energy and chemical base in Xinjiang. China Coal 2018, 44, 20–24. [Google Scholar]

- Munkejord, S.T.; Hammer, M.; Lovseth, S.W. CO2 transport: Data and models—A review. Appl. Energy 2016, 169, 499–523. [Google Scholar] [CrossRef]

- Dahowski, R.T.; Davidson, C.L.; Li, X.C.; Wei, N. Examining CCS Deployment Potential in China Via Application of an Integrated CCS Cost Curve. Energy Procedia 2013, 37, 2487–2494. [Google Scholar] [CrossRef]

- Koelbl, B.S.; van den Broek, M.A.; van Ruijven, B.J.; Faaij, A.P.C.; van Vuuren, D.P. Uncertainty in the deployment of Carbon Capture and Storage (CCS): A sensitivity analysis to techno-economic parameter uncertainty. Int. J. Greenh. Gas Control 2014, 27, 81–102. [Google Scholar] [CrossRef]

- Li, Q.; Liu, G. Risk Assessment of the Geological Storage of CO2: A Review. In Geologic Carbon Sequestration: Understanding Reservoir Behavior; Vishal, V., Singh, T.N., Eds.; Springer International Publishing: Cham, Switzerland, 2016; pp. 249–284. [Google Scholar]

- Diao, Y.; Zhang, S.; Wang, Y.; Li, X.; Cao, H. Short-term safety risk assessment of CO2 geological storage projects in deep saline aquifers using the Shenhua CCS Demonstration Project as a case study. Environ. Earth Sci. 2015, 73, 7571–7586. [Google Scholar] [CrossRef]

- Seigo, S.L.O.; Dohle, S.; Siegrist, M. Public perception of carbon capture and storage (CCS): A review. Renew. Sustain. Energy Rev. 2014, 38, 848–863. [Google Scholar] [CrossRef]

- Li, J.-Q.; Yu, B.-Y.; Tang, B.-J.; Hou, Y.; Mi, Z.; Shu, Y.; Wei, Y.-M. Investment in carbon dioxide capture and storage combined with enhanced water recovery. Int. J. Greenh. Gas Control 2020, 94, 102848. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).