Mould Growth Risks for a Clay Masonry Veneer External Wall System in a Temperate Climate

Abstract

1. Introduction

1.1. Condensation and Mould Problem in Homes

1.2. Impact of Condensation Problems and Mould Growth on Occupant Health

“Sufficient epidemiological evidence is available from studies conducted in different countries and under different climatic conditions to show that the occupants of damp or mouldy buildings, both houses, and public buildings, are at increased risk of respiratory symptoms, respiratory infections and exacerbation of asthma”[31]

1.3. Key Focus Study Area

2. Background to Condensation Risk and Mould Growth Analysis Concepts

- Materials can be initially wet either due to accumulated moisture or rain;

- Materials can be hygroscopic;

- Water movement takes place due to the combination of both vapour and liquid flow;

- Moisture content affects the material properties;

- Solar radiation and longwave radiation affect the hygroscopic properties of the building material;

- Two-dimensional (2D) and three-dimensional (3D) flows of heat, air, and moisture are of significance;

- Mould growth risk is significantly underrated due to ignoring the diurnal variations of the external and internal environmental conditions;

- Mould growth risk assessments cannot be performed.

- Redistribution of moisture takes place due to air movements within or through the built fabric by convection;

- Considering constant material properties is a guesstimate (e.g., the thermal conductivity of a material is dependent on its moisture content;

- Diurnal changes in the environmental conditions;

- Solar radiation effects are not considered;

- Interstitial condensation risk can be overestimated and must be dealt with caution if the built fabric encounters large diurnal fluctuations and is expected to accumulate substantial amounts of moisture;

- Considerable air movement inside the building or through the building component will lead to inaccurate results and must be dealt with caution;

- Mould growth risk is significantly underrated due to ignoring the diurnal variations of the external and internal environmental conditions

2.1. Hygrothermal Assessment Methods

2.1.1. Non-Transient Heat and Moisture Calculation Method

- The amount of condensed atmospheric moisture deposited or evaporated during each month of a year;

- The maximum amount of moisture deposited;

- The annual moisture accumulation.

2.1.2. Transient Heat and Moisture Calculation Method

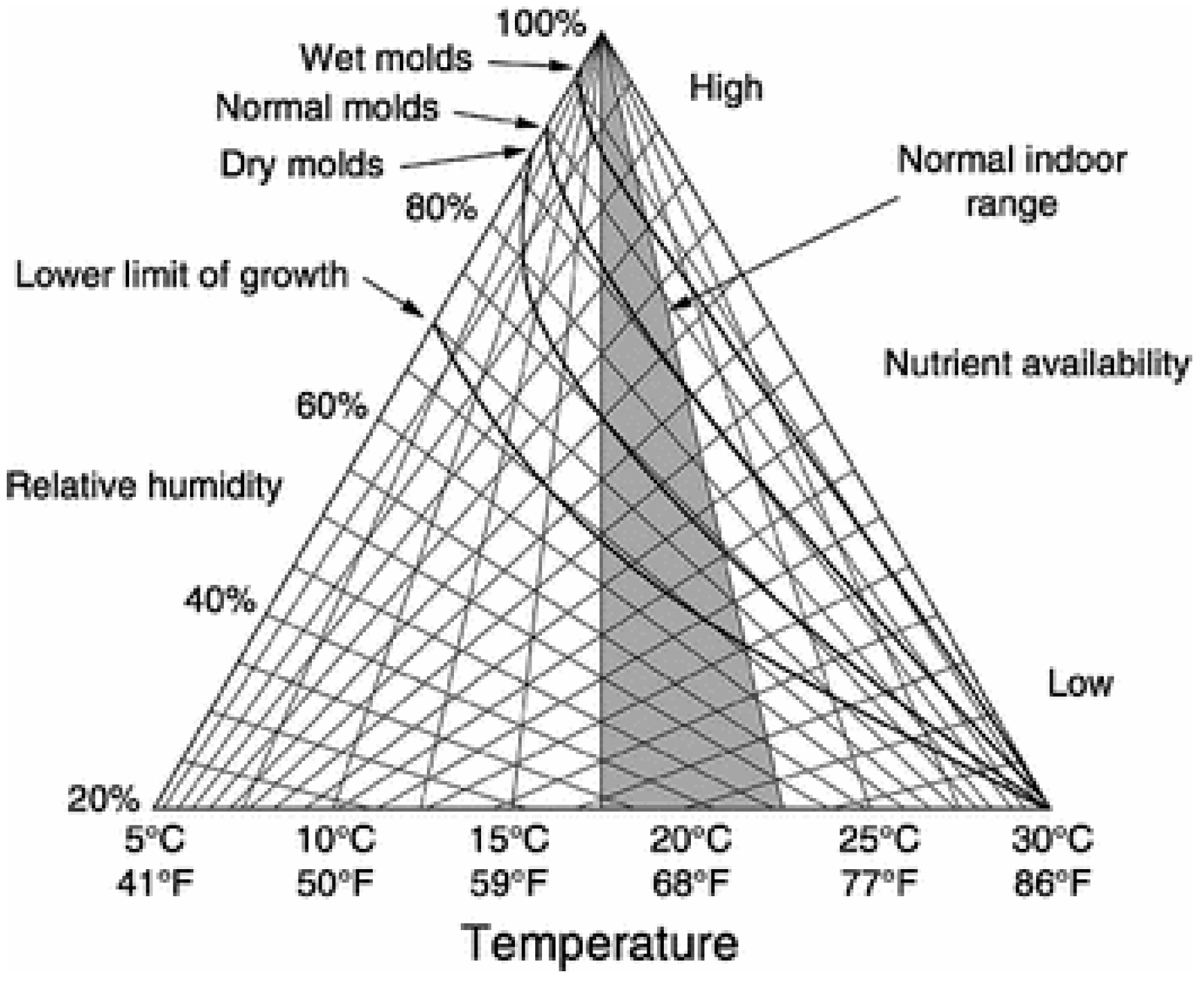

2.2. Mould Growth Simulation

- MI 0: demonstrates zero mould growth;

- MI 1: demonstrates microscopic mould growth. This is the initial stage of mould growth;

- MI 2: demonstrates a large amount of microscopic mould growth colonisation on the surface;

- MI 3: demonstrates visible results of mould on the surface, <10% coverage, or <50% coverage of microbial mould;

- MI 4: demonstrates visible results of mould on the surface, 10–50% coverage, or >50% coverage of microbial mould;

- MI 5: demonstrates a considerable amount of mould growth on the surface, >50% coverage (visual);

- MI 6: demonstrates excessive mould growth, coverage of about 100%.

3. Material and Methods

3.1. Hygrothermal Model Input Parameters

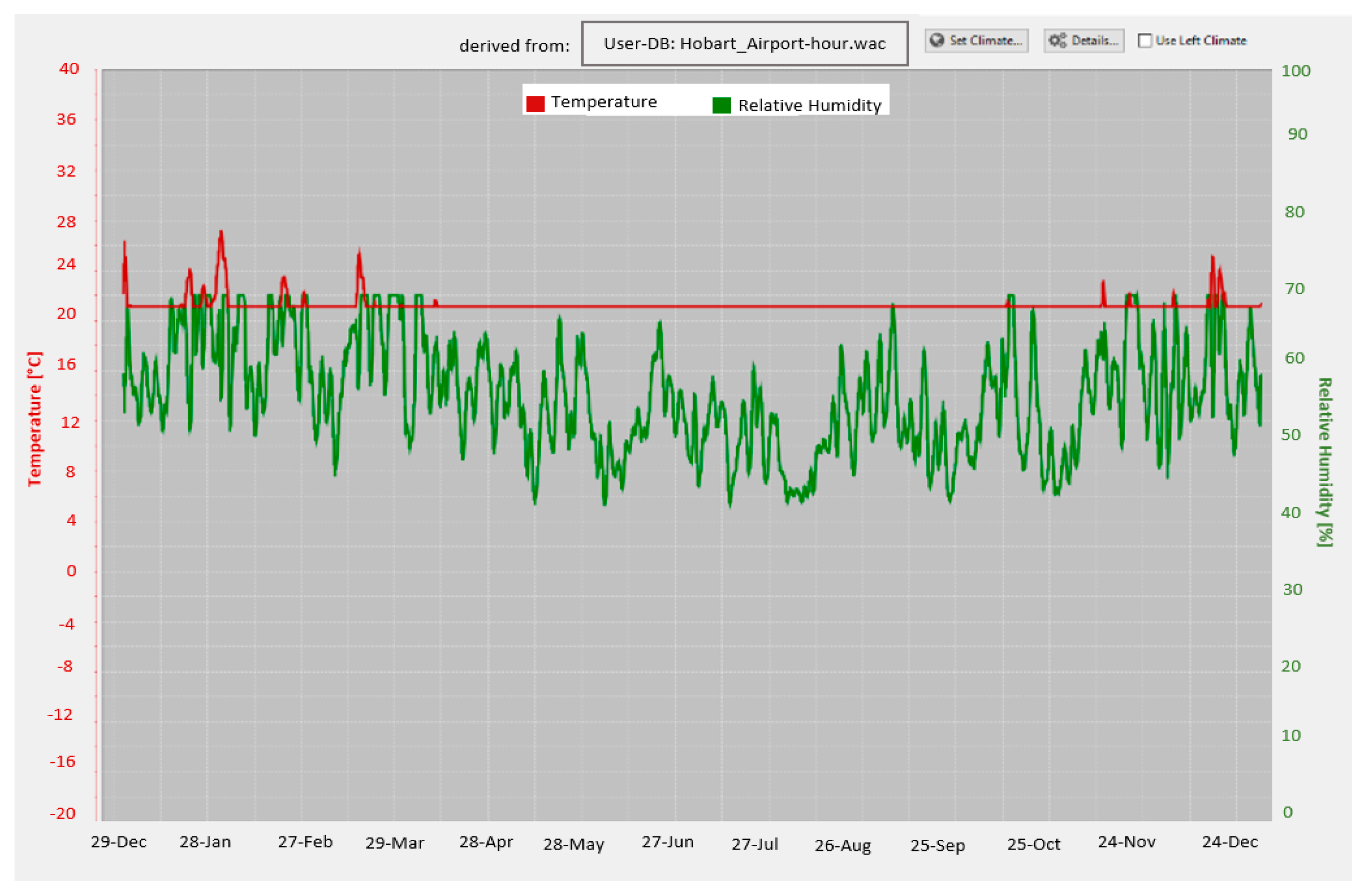

3.1.1. Selection of Australian Exterior Climate Data

3.1.2. Establishment of Australian Interior Climates

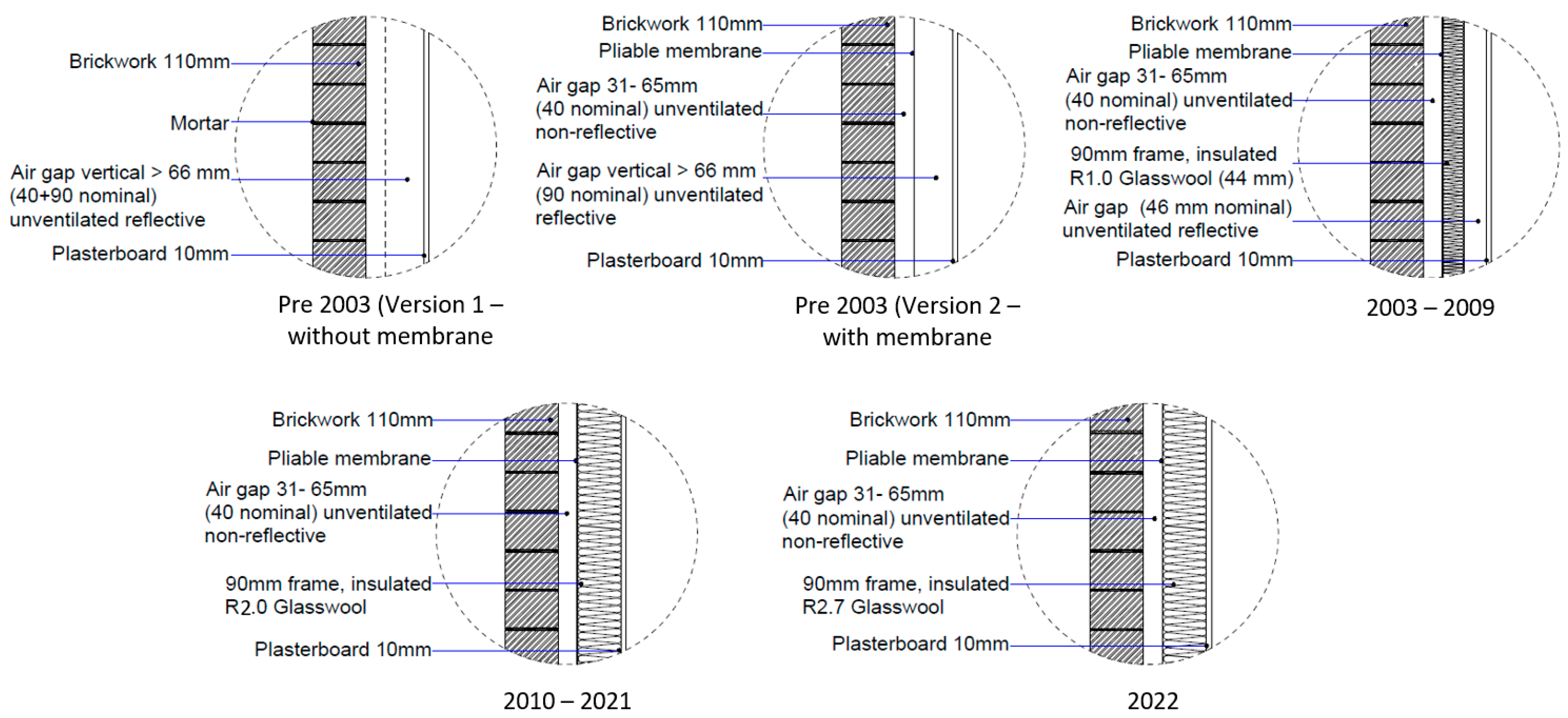

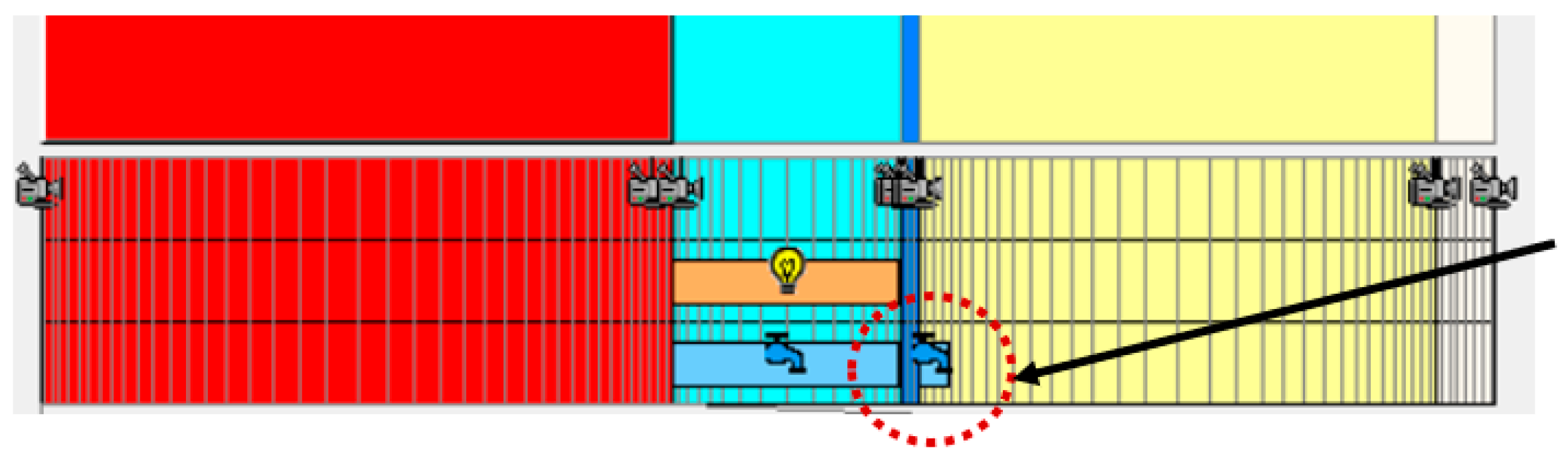

3.1.3. Timber-Framed Clay Masonry Veneer Australian Residential Wall System

- Differing added bulk insulation (as per Table 3);

- Vapour permeable and vapour impermeable membranes;

- With a vented vapour cavity between the clay masonry veneer and the pliable membrane.

3.1.4. Building Material Database

3.1.5. Building Orientation

3.1.6. Calculation Period for Hygrothermal Modelling

3.2. Hygrothermal and Mould Growth Assessment Method

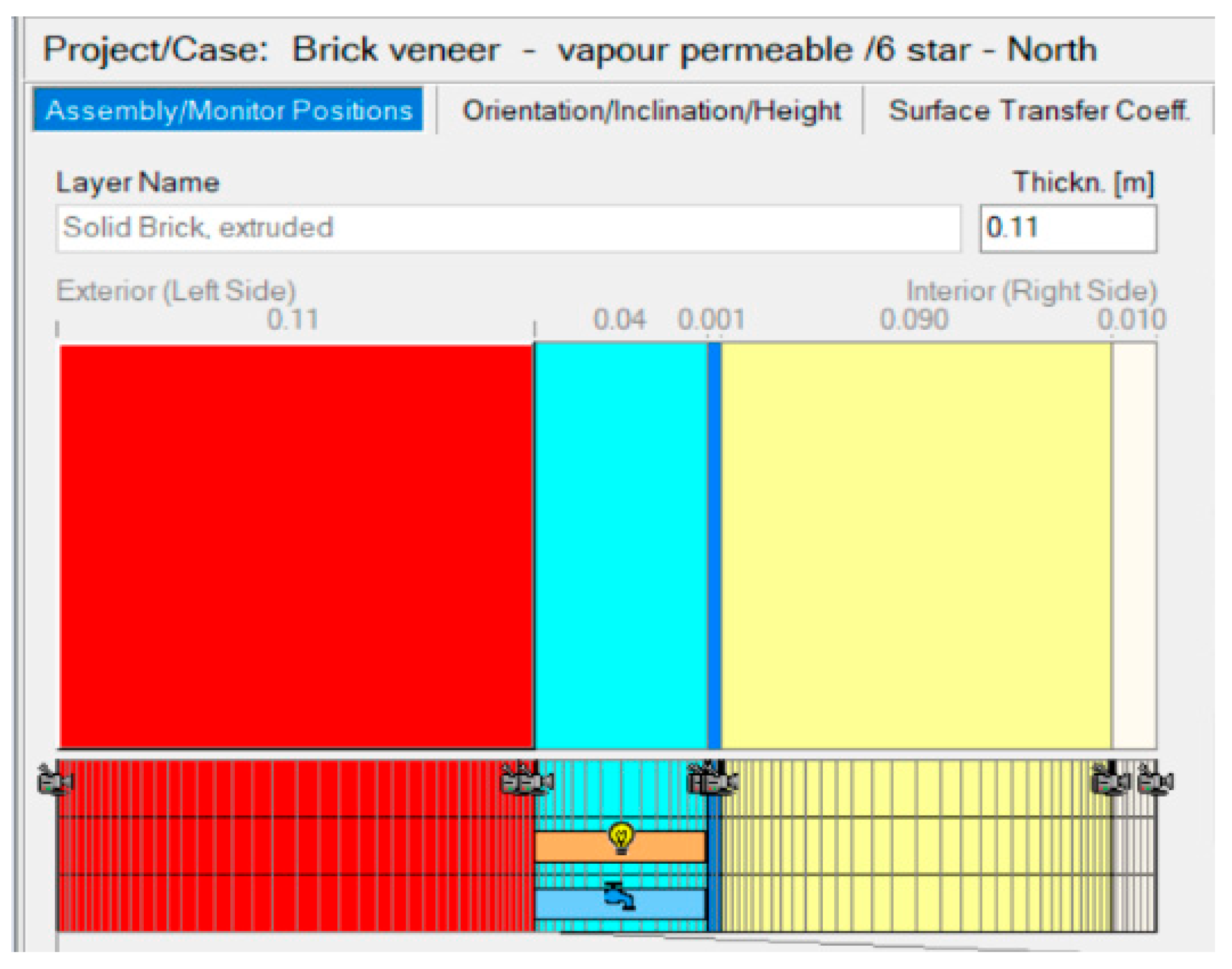

3.2.1. Base Model

3.2.2. Moisture Source Model

- Within the air cavity between the clay masonry and the pliable membrane wall;

- Five mm from the outer edge of the bulk insulation layer.

3.2.3. Latex Paint Model

4. Results and Discussion (2 Years, 5 Years, and 10 Years)

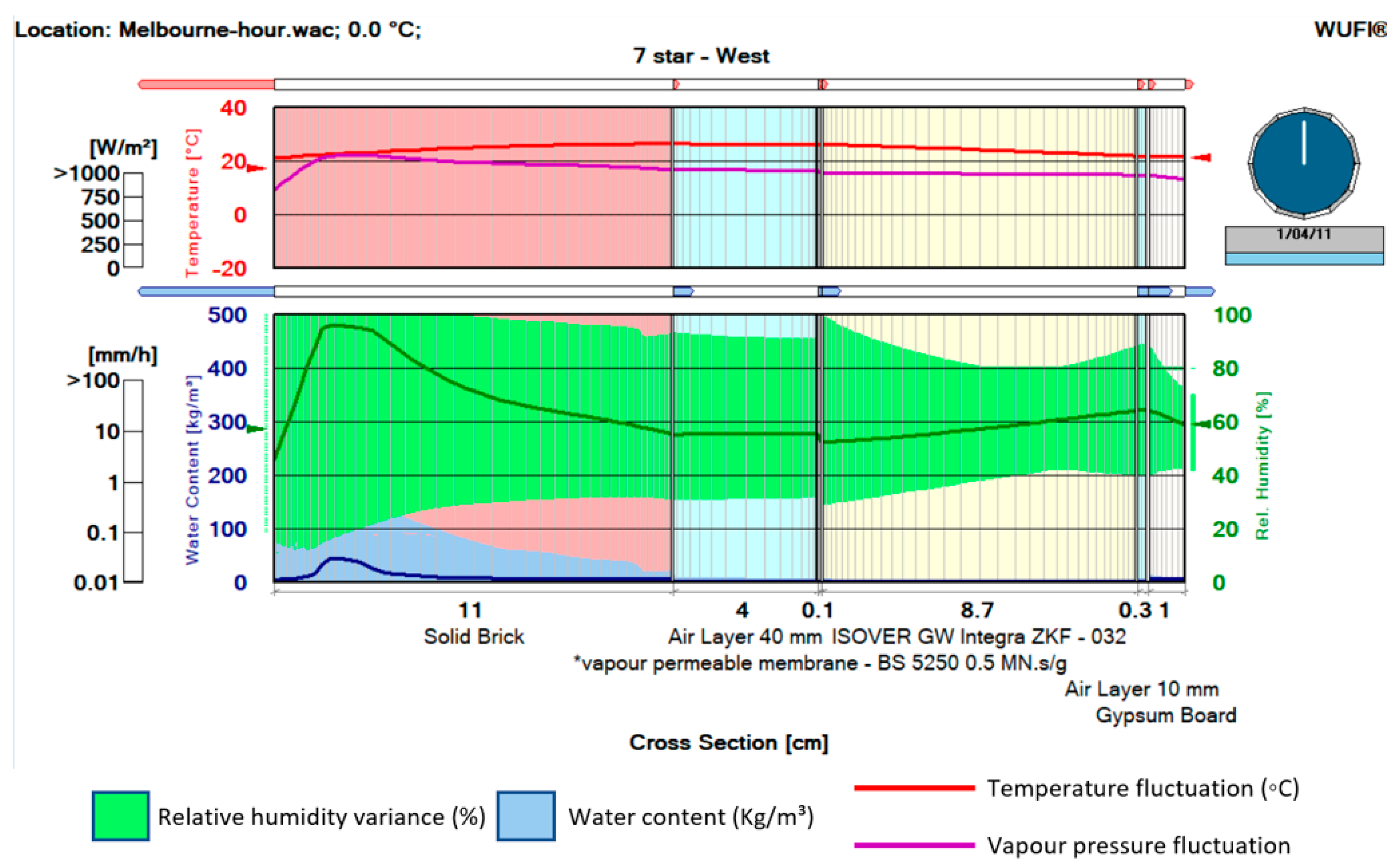

4.1. Hygrothermal Assessment

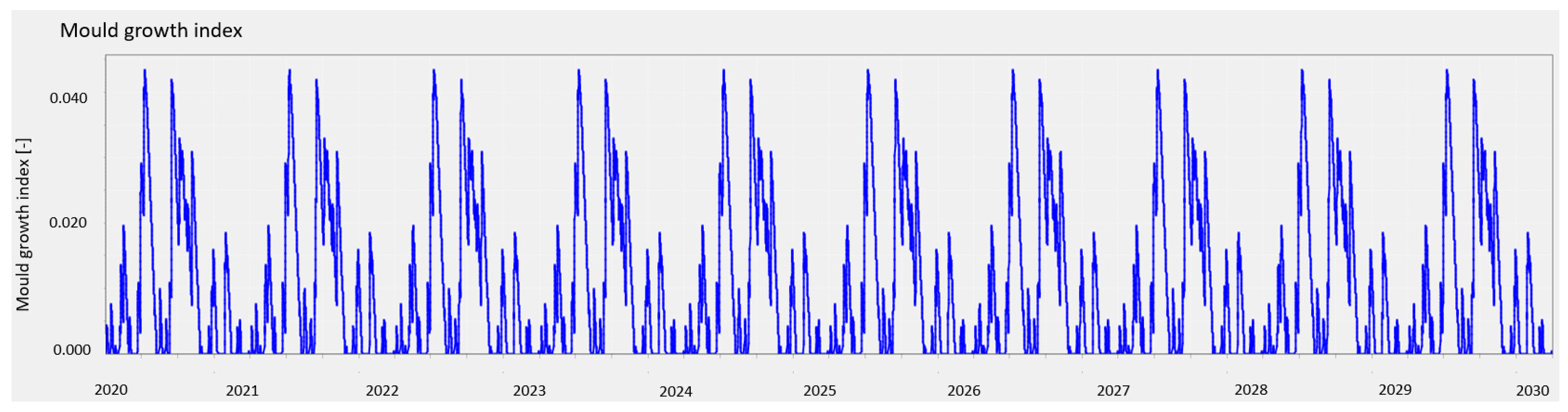

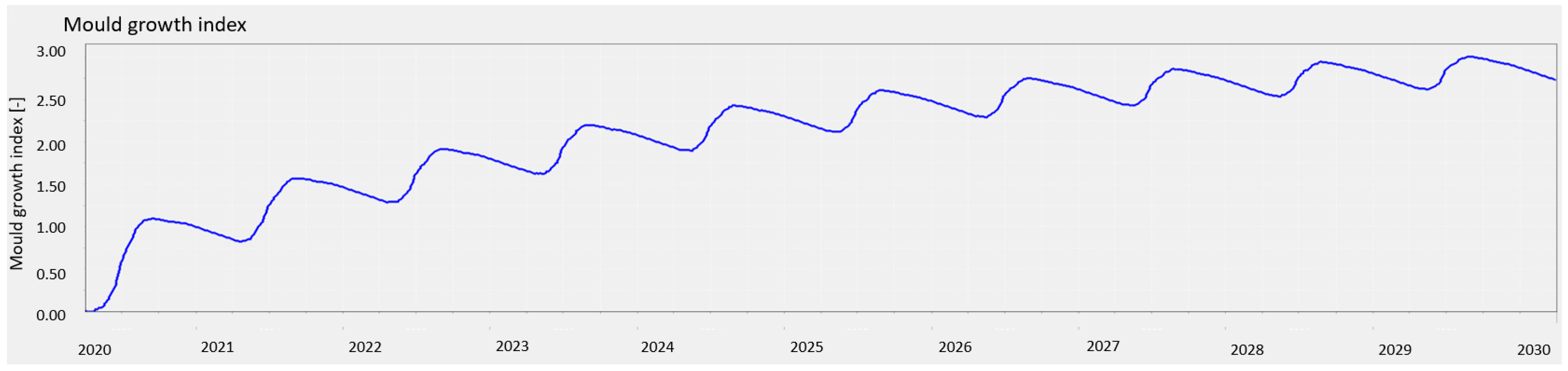

4.2. Mould Growth Assessment

- The 2-years simulation calculates a maximum mould index from 0.000 to 1.500, indicating this wall system is fine;

- The 5-years simulation calculates a maximum mould index from 0.000 to 2.500, indicating this wall would have a significant mould growth risk;

- The 10-years simulation calculates a maximum mould index from 0.000 to 3.500, indicating this wall would have a significant mould growth risk.

- Red indicates that the mould growth rate is at an unacceptable level of 2 or greater;

- Yellow indicates that the mould growth rate is a risk, and the wall system requires a more detailed analysis;

- Green indicates that the simulated mould growth is at an acceptable level.

- The 2-year mould growth simulation shows the least amount of mould growth risk;

- The 5-year mould growth simulation shows a greater amount of mould growth risk than the 2-year simulation, but a lesser amount of mould growth risk than the 10-year simulation;

- The 10-year mould growth simulation shows the greatest amount of mould growth risk.

- Exterior climate–The datasets are in the RMY and EPW format, were certified and published in 2006, and use climate data up to, and including 2003. It could be argued that more appropriate data should be used, but due to the infancy of hygrothermal research in Australia, this will occur in future research. One of the significant issues identified was the lack of precipitation data;

- Establishment of interior climate for hygrothermal simulations—Australia has no specified interior conditions within its building regulations; however, the majority of Australian new homes demonstrate envelope thermal performance via the NatHERS scheme. Through the use of NatHERS simulations, the results provided insights into the interior temperature conditions of modern homes, which have been corroborated by CSIRO studies. This article analysed the appropriateness of the interior temperature conditions recommended within ASHRAE 160 and DIN 4108. These standards recommend an interior temperature of 21.1 °C be used for hygrothermal simulations;

- Simulation span—The three mould growth graphs presented show the variability of mould growth subject to orientation. These demonstrate the need for a ten-year simulation, so as to grasp the long-term mould growth pattern and identify long-term risks within the built fabric;

- Orientation and shading—The four orientations explored in the research showed two wall systems with nil or an acceptable amount of mould growth and two wall systems with concerning amounts of mould growth. WUFI® Pro (2022) does not allow for a wall system to be shaded. In a real scenario, the external wall may be intentionally or unintentionally shaded, removing the solar-driven drying potential. The non-equatorial orientated walls always performed worse, indicating a need to focus on southern orientated simulations for the southern hemisphere.

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- ABCB. National Construction Code: Volume 2; The Australian Building Codes Board: Canberra, Australia, 2019; Volume 2.

- Ballinger, J.A.; Cassell, D. Solar efficient housing and NatHERS: An important marketing tool. Fuel Energy Abstr. 1995, 4, 273. [Google Scholar]

- Delsante, A. A Validation of the ‘AccuRate’ Simulation Engine Using BESTEST; The Australian Greenhouse Office: Canberra, Australia, 2004. [Google Scholar]

- Australian Greenhouse Office. The National Greenhouse Strategy: Strategic Framework for Advancing Australia’s Greenhouse Response; Parliament of Australia: Canberra, Australia, 1998. Available online: https://www.aph.gov.au/Parliamentary_Business/Committees/Senate/Environment_and_Communications/Completed%20inquiries/1999-02/gobalwarm/report/c04 (accessed on 21 September 2022).

- Australian Greenhouse Office. Energy Research for the Building Code of Australia; Commonwealth of Australia: Canberra, Australia, 2000. [Google Scholar]

- Dewsbury, M. The Empirical Validation Of House Energy Rating (HER) Software for Lightweight Housing in Cool Temperate Climates. Ph.D. Thesis, University of Tasmania, Launceston, Tasmania, Australia, 2011. [Google Scholar]

- McLeod, P. The Cost Effectiveness of Housing Thermal Performance Improvements in Avoiding CO2-Emissions. Ph.D. Thesis, University of Tasmania, Launceston, Tasmania, Australia, 2013. [Google Scholar]

- 5250:2002, B; Code of Practice for Control of Condensation in Buildings. British Standards Institution: London, UK, 2002.

- Hamdan, M.A. Layered wall design to prevent moisture condensation on its inside surface. Energy Convers. Manag. 2002, 43, 1821–1828. [Google Scholar] [CrossRef]

- Karagiozis, A.; Salonvaara, M. Hygrothermal system-performance of a whole building. Build. Environ. 2001, 36, 779–787. [Google Scholar] [CrossRef]

- Salonvaara, M.; Ojanen, T.; Kokko, E.; Karagiozis, A. Drying capabilities of wood frame walls with wood siding. In Proceedings of the 7th Thermal Performances of the Exterior Envelopes of Buildings Conference, Thermal VII, Clearwater Beach, United States, 6–10 December 1998. [Google Scholar]

- Dewsbury, M.; Law, T.; Potgieter, J.; Fitz-Gerald, D.; McComish, B.; Chandler, T.; Soudan, A. Scoping Study of Condensation in Residential Buildings-Final Report; Department of Industry Innovation and Science: Tasmania, Australia, 2016. [Google Scholar]

- Viitanen, H.; Krus, M.; Ojanen, T.; Eitner, V.; Zirkelbach, D. Mold risk classification based on comparative evaluation of two established growth models. In Proceedings of the 6th International Building Physics Conference, IBPC 2015, Torino, Italy, 14–17 June 2015; pp. 1425–1430. [Google Scholar]

- Nath, S.; Dewsbury, M.; Orr, K. Is new housing a health hazard? In Proceedings of the Engaging Architectural Science: Meeting the Challenges of Higher Density, 52nd International Conference of the Architectural Science Association 2018, RMIT University, Melbourne, Australia, 28 November–1 December 2018; pp. 71–78. [Google Scholar]

- Clarke, J.A.; Johnstone, C.M.; Kelly, N.J.; McLean, R.C.; Rowan, N.J.; Smith, J.E. A technique for the prediction of the conditions leading to mould growth in buildings. Build. Environ. 1999, 34, 515–521. [Google Scholar] [CrossRef]

- Straus, D.C.; Cooley, J.D.; Wong, W.C.; Jumper, C.A. Studies on the role of fungi in sick building syndrome. Arch. Environ. Health: Int. J. 2003, 58, 475–478. [Google Scholar] [CrossRef]

- Tsongas, G.A.; Riordan, F. Minimum conditions for visible mold growth. ASHRAE 2016, 58, 32. [Google Scholar]

- Lie, S.K.; Vestøl, G.I.; Høibø, O.; Gobakken, L.R. Surface mould growth on wooden claddings–effects of transient wetting, relative humidity, temperature and material properties. Wood Mater. Sci. Eng. 2018, 14, 129–141. [Google Scholar] [CrossRef]

- Kowalski, W. Aerobiological Engineering Handbook: Airborne Disease and Control Technologies; McGraw Hill Professional: New York, NY, USA, 2005. [Google Scholar]

- Law, T. Comfort energetics: Thermal comfort under energy constraints. In The Future of Thermal Comfort in an Energy-Constrained World; Springer: Berlin/Heidelberg, Germany, 2013; pp. 83–115. [Google Scholar]

- Dewsbury, M.; Law, T. Recent increases in the occurrence of condensation and mould within new Tasmanian housing. In Proceedings of the 50th International Conference of the Architectural Science Association University of Adelaide, Adelaide, Australia, 7–9 December 2016; pp. 715–724. [Google Scholar]

- Cheng, M.; Galbally, I.; Gillett, R.; Keywood, M.; Lawson, S.; Molloy, S.; Powell, J. Indoor Air Project Part 1: Main Report—Indoor Air in Typical Australian Dwellings; CSIRO and the Bureau of Meteorology: Victoria, Australia, 2010. [Google Scholar]

- Ambrose, M. Interior Recorded Relative Humidity of Australian States; Nath, S., Ed.; CSIRO: Canberra, Australia, 2020. [Google Scholar]

- Hampton, A. Thermal mass and insulation for temperate climates. Environ. Des. Guide 2010, 1–11. [Google Scholar]

- Dewsbury, M. Condensation in Tasmanian homes-an update from UTAS. In Connections; Consumer, Building and Occupational Services, Department of Justice: Tasmania, Australia, 2018. [Google Scholar]

- Paevere, P.; Nguyen, M.; Syme, M.; Leicester, K.H. Nailplate backout—Is it a problem in plated timber trusses. In Proceedings of the 10th World Conference on Timber Engineering WCTE2008, Miyazaki, Japan, 2–5 June 2008. [Google Scholar]

- Täubel, M.; Hyvärinen, A. Occurrence of mycotoxins in indoor environments. In Environmental Mycology in Public Health; Elsevier: Amsterdam, The Netherlands, 2016; pp. 299–323. [Google Scholar]

- Cederlund, O.; Josefsson, F. An Evaluation of Two Well Insulated Roof Structures. Master’s Thesis, Lund University, Lund, Sweden, 2015. Available online: https://lup.lub.lu.se/luur/download?func=downloadFile&recordOId=7456132&fileOId=7456139 (accessed on 21 September 2022).

- Dyer, P. Something rotten in the state…. In ArchitectureNow; AGM A Division of BCI Central: Auckland, New Zealand, 2021; Available online: https://architecturenow.co.nz/articles/something-rotten-in-the-state/ (accessed on 21 September 2022).

- Künzel, H.; Dewsbury, M. Moisture control design has to respond to all relevant hygrothermal loads. In UCL Open: Environment Preprint; UCL Press: London, UK.

- WHO. WHO Guidelines for Indoor Air Quality: Dampness and Mould; WHO Regional Office for Europe: Copenhagen, Denmark, 2009.

- Dewsbury, M.; Nath, S.; Olaoye, T.S.; Künzel, H. Condensation and mould in Australian homes. In Proceedings of the 1st International Conference on Moisture in Buildings (ICMB21), London, UK, 28–29 June 2021. [Google Scholar]

- Nath, S.; Dewsbury, M.; Douwes, J. Has a singular focus of building regulations created unhealthy homes? Archit. Sci. Rev. 2019, 387–401. [Google Scholar] [CrossRef]

- Nath, S.; Dewsbury, M. Is regulation making homes unhealthy? In Proceedings of the AIRAH Building Physics Forum Conference, Wollongong, Australia, 22–23 November 2018. [Google Scholar]

- Knibbs, L.D.; Woldeyohannes, S.; Marks, G.B.; Cowie, C.T. Damp housing, gas stoves, and the burden of childhood asthma in Australia. Med. J. Aust. 2018, 208, 299–302. [Google Scholar] [CrossRef] [PubMed]

- Juel Holst, G.; Pørneki, A.; Lindgreen, J.; Thuesen, B.; Bønløkke, J.; Hyvärinen, A.; Elholm, G.; Østergaard, K.; Loft, S.; Brooks, C. Household dampness and microbial exposure related to allergy and respiratory health in Danish adults. Eur. Clin. Respir. J. 2020, 7, 1706235. [Google Scholar] [CrossRef] [PubMed]

- Mendell, M.J.; Kumagai, K. Observation-based metrics for residential dampness and mold with dose–response relationships to health: A review. Indoor Air 2017, 27, 506–517. [Google Scholar] [CrossRef]

- Thacher, J.D.; Gruzieva, O.; Pershagen, G.; Melén, E.; Lorentzen, J.C.; Kull, I.; Bergström, A. Mold and dampness exposure and allergic outcomes from birth to adolescence: Data from the BAMSE cohort. Allergy 2017, 72, 967–974. [Google Scholar] [CrossRef]

- Brambilla, A.; Gasparri, E. Hygrothermal behaviour of emerging timber-based envelope technologies in Australia: A preliminary investigation on condensation and mould growth risk. J. Clean. Prod. 2020, 276, 124129. [Google Scholar] [CrossRef]

- Brambilla, A.; Sangiorgio, A. Mould growth in energy efficient buildings: Causes, health implications and strategies to mitigate the risk. Renew. Sustain. Energy Rev. 2020, 132, 110093. [Google Scholar] [CrossRef]

- Holmes, A. Masonic Care residents given days to vacate homes in Newstead over mould fears. The Examiner, 12 September 2019. [Google Scholar]

- Moodie, C. Mould in rental homes under the spotlight as family claims health problems from mouldy house. ABC News, 20 February 2021. [Google Scholar]

- Moodie, C.; Shine, R. Mould in newly built Perth home blamed for family’s rashes, joint pain and headaches. ABC News, 25 November 2020. [Google Scholar]

- Brown, A.; Atkin, L. Mould in Melissa’s home was so bad she slept in her car. The Canberra Times, 9 December 2018. [Google Scholar]

- Farnsworth, S. Doctor had to plead for boy with lung problems to be moved out of mouldy rental house. ABC News, 18 December 2017. [Google Scholar]

- Asher, N.; Altree-Williams, A. Mould woes add strain for Melbourne renters during coronavirus stage 4 lockdown. ABC News, 30 August 2020. [Google Scholar]

- Baker, E.; Lester, L.H.; Bentley, R.; Beer, A. Poor housing quality: Prevalence and health effects. J. Prev. Interv. Community 2016, 44, 219–232. [Google Scholar] [CrossRef] [PubMed]

- Bentley, R.; Baker, E. Mould and Damp Health Costs Are about 3 Times Those of Sugary Drinks. We Need a Healthy Housing Agenda. Available online: https://www.thefifthestate.com.au/urbanism/hazmat/mould-and-damp-health-costs-are-about-3-times-those-of-sugary-drinks-we-need-a-healthy-housing-agenda/ (accessed on 27 October 2020).

- Cincinelli, A.; Martellini, T. Indoor air quality and health. Int. J. Environ. Res. Public Health 2017, 14, 1286. [Google Scholar] [CrossRef] [PubMed]

- Lades, L.K.; Laffan, K.; Daly, M.; Delaney, L. Daily emotional well-being during the COVID-19 pandemic. Br. J. Health Psychol. 2020, 25, 902–911. [Google Scholar] [CrossRef] [PubMed]

- Zachary, Z.; Brianna, F.; Brianna, L.; Garrett, P.; Jade, W.; Alyssa, D.; Mikayla, K. Self-quarantine and weight gain related risk factors during the COVID-19 pandemic. Obes. Res. Clin. Pract. 2020, 14, 210–216. [Google Scholar] [CrossRef]

- Nath, S.; Dewsbury, M. The use of an innovative hygrothermal simulation method to develop built fabric recommendations for southern Australia. In Proceedings of the 53rd International Conference of the Architectural Science Association (ANZAScA)IIT Roorkee, Roorkee, India, 28–30 November 2019; pp. 1–10. [Google Scholar]

- Nath, S.; Dewsbury, M.; Watson, P.; Lovell, H.C.; Künzel, H.M. A bio-hygrothermal mould growth analysis of typical Australian residential wall systems. In Proceedings of the 54th International Conference of the Architectural Science Association (ANZAScA), Auckland, New Zealand, 26–27 November 2020; pp. 1–11. [Google Scholar]

- Dewsbury, M.; Soudan, A.; Su, F.; Geard, D.; Cooper, A.; Law, T. Condensation Risk Mitigation for Tasmanian Housing; UTAS: Tasmania, Australia, 2018. [Google Scholar]

- Mumovic, D.; Ridley, I.; Oreszczyn, T.; Davies, M. Condensation risk: Comparison of steady-state and transient methods. Build. Serv. Eng. Res. Technol. 2006, 27, 219–233. [Google Scholar] [CrossRef]

- Janssens, A.; Hens, H. Condensation risk assessment. In Proceedings of the Thermal Performance of the Exterior Envelopes of Buildings VII: Conference Proceedings, Clearwater beach, FL, USA, 6–10 December 1998; pp. 199–206. [Google Scholar]

- Little, J.; Ferraro, C.; Arregi, B. Assessing Risks in Insulation Retrofits Using Hygrothermal Software Tools; Historic Environment Scotland Technical Paper: Edinburgh, Scotland, 2015; Available online: https://www.researchgate.net/profile/Joseph-Little/publication/283710903_Assessing_risks_in_insulation_retrofits_using_hygrothermal_software_tools_-_Heat_and_moisture_transport_in_internally_insulated_stone_walls/links/5643a40908aef646e6c6c367/Assessing-risks-in-insulation-retrofits-using-hygrothermal-software-tools-Heat-and-moisture-transport-in-internally-insulated-stone-walls.pdf (accessed on 21 September 2022).

- British Standards. BS5250:2011; Code of Practice for Control of Condensation in Buildings. British Standards Institution: London, UK, 2011. Available online: https://isolergrund.uk/wp-content/uploads/2020/06/BS-5250-2011-A1-2016e.pdf (accessed on 21 September 2022).

- Künzel, H.M.; Zirkelbach, D. Advances in hygrothermal building component simulation: Modelling moisture sources likely to occur due to rainwater leakage. J. Build. Perform. Simul. 2013, 6, 346–353. [Google Scholar] [CrossRef]

- Cascione, V.; Marra, E.; Zirkelbach, D.; Liuzzi, S.; Stefanizzi, P. Hygrothermal analysis of technical solutions for insulating the opaque building envelope. Energy Procedia 2017, 126, 203–210. [Google Scholar] [CrossRef]

- Lstiburek, J.; Carmody, J. Moisture Control Handbook: Principles and Practices for Residential and Small Commercial Buildings; John Wiley & Sons: Hoboken, NJ, USA, 1996. [Google Scholar]

- Liu, J.; Aizawa, H.; Yoshino, H. CFD prediction of surface condensation on walls and its experimental validation. Build. Environ. 2004, 39, 905–911. [Google Scholar] [CrossRef]

- Arens, E.A.; Baughman, A. Indoor humidity and human health: Part II--buildings and their systems. ASHRAE 1996. [Google Scholar]

- Künzel, H.M.; Holm, A.; Zirkelbach, D.; Karagiozis, A.N. Simulation of indoor temperature and humidity conditions including hygrothermal interactions with the building envelope. Sol. Energy 2005, 78, 554–561. [Google Scholar] [CrossRef]

- Choidis, P.; Kraniotis, D.; Lehtonen, I.; Hellum, B. A Modelling Approach for the Assessment of Climate Change Impact on the Fungal Colonization of Historic Timber Structures. Forests 2021, 12, 819. [Google Scholar] [CrossRef]

- JPA TL Ltd. Development of Transient Condensation Risk Analysis Software Initial Considerations; Dewsbury, M., Ed.; JPA TL Ltd.: Launceston, TAS, Australia, 2017. [Google Scholar]

- Künzel, H.M. Simultaneous Heat and Moisture Transport in Building Components—One-and Two-Dimensional Calculation Using Simple Parameters; Fraunhofer Institute of Building Physics: Stuttgart, Germany, 1995; Available online: https://wufi.de/de/wp-content/uploads/sites/9/2014/12/K%C3%BCnzel-1995-Simultaneous-Heat-and-Moisture-Transport1.pdf (accessed on 21 September 2022).

- Law, T. Condensation in TAS Houses; Building Designers Australia: Campbell Town, TAS, Australia, 2015. [Google Scholar]

- BS EN 15026; Hygrothermal Performance of Building Components and Building Elements—Assessment of Moisture Transfer by Numerical Simulation. British Standards: London, UK, 2007.

- JPA TL Ltd. SAP 9.92 Module & U-Value Modules & Condensation Risk; JPA TL Ltd: Newcastle upon Tyne, UK, 2016; Available online: https://www.techlit.co.uk/downloads/JPAUserManualUK6.03.pdf (accessed on 21 September 2022).

- Thomann, F.S.; Hall, M.R.; Mokaya, R.; Stevens, L.A. Hygrothermal simulation-informed design of mesoporous desiccants for optimised energy efficiency of mixed mode air conditioning systems. J. Mater. Chem. A 2015, 3, 17290–17303. [Google Scholar] [CrossRef]

- Chang, S.J.; Kim, S. Hygrothermal performance of exterior wall structures using a heat, air and moisture modeling. Energy Procedia 2015, 78, 3434–3439. [Google Scholar] [CrossRef]

- Fraunhofer Institute of Building Physics. WUFI® 2021; Fraunhofer Institute of Building Physics: Stuttgart, Germany; Available online: https://wufi.de/en/software/wufi-pro/ (accessed on 21 September 2022).

- Antretter, F.; Klingenberg, K.; Pazold, M. All-in-One Design Tool Solution for Passive Houses and Buildings—Monthly Energy Balance and Hygrothermal Simulation. In Proceedings of the Thermal Performance of the Exterior Envelopes of Whole Buildings XII International Conference, Clearwater, FA, USA, 1–5 December 2013; pp. 626–640. [Google Scholar]

- Olaoye, T.S.; Dewsbury, M.; Künzel, H. A Method for Establishing a Hygrothermally Controlled Test Room for Measuring the Water Vapor Resistivity Characteristics of Construction Materials. Energies 2021, 14, 4. [Google Scholar] [CrossRef]

- Harriman, L. Mold and dampness. ASHRAE J. 2012, 54, 132. [Google Scholar]

- Olaoye, T.S.; Dewsbury, M. Establishing an environmentally controlled room to quantify water vapour resistivity properties of construction materials. In Proceedings of the 53rd International Conference of the Architectural Science Association, IIT Roorkee, Roorkee, India, 28–30 November 2019. [Google Scholar]

- Vereecken, E.; Vanoirbeek, K.; Roels, S. A preliminary evaluation of mould prediction models based on laboratory experiments. Energy Procedia 2015, 78, 1407–1412. [Google Scholar] [CrossRef]

- Dewsbury, M.; Law, T. Temperate climates, warmer houses and built fabric challenges. Procedia Eng. 2017, 180, 1065–1074. [Google Scholar] [CrossRef]

- Dewsbury, M.; Law, T.; Henderson, A. Investigation of Destructive Condensation in Australian Cool Temperate Buildings; Building Standards and Occupational Licensing, Department of Justice Tasmania: Tasmania, Australia, 2016; Available online: https://www.researchgate.net/profile/Mark-Dewsbury-2/publication/301894751_Final_report_-_Investigation_of_destructive_condensation_in_Australian_cool-temperate_buildings/links/572c319908ae057b0a095c80/Final-report-Investigation-of-destructive-condensation-in-Australian-cool-temperate-buildings.pdf (accessed on 21 September 2022).

- Vereecken, E.; Saelens, D.; Roels, S. A comparison of different mould prediction models. In Proceedings of the Building Simulation 2011: 12th Conference of International Building Performance Simulation Association, Sydney, Australia, 14–16 November 2011. [Google Scholar]

- ISO. ISO 13788:2012; Hygrothermal Performance of Building Components and Building Elements—Internal Surface Temperature to Avoid Critical Surface Humidity and Interstitial Condensation—Calculation Methods. International Organization for Standardization: Geneva, Switzerland, 2012.

- ABCB. Climate Zone Map: Australia Wide; The Australian Building Codes Board: Canberra, Australia, 2019. Available online: https://www.abcb.gov.au/Resources/Tools-Calculators/Climate-Zone-Map-Australia-Wide# (accessed on 21 September 2022).

- Reardon, C.; Milne, G.; McGee, C.; Downton, P. Your Home Technical Manual, Australia’s Guide to Environmentally Sustainable Homes, 4th ed.; Australian Government: Canberra, Australia, 2010. Available online: https://www.hort360.com.au/wordpress/uploads/Energy/Lighting/Your%20home%20technical%20manual%20(4th%20Edition).pdf (accessed on 21 September 2022).

- DIN. DIN 4108-3: 2018-10; Thermal Protection and Energy Economy in Buildings—Part 3. Protection against Moisture Subject to Climate Conditions—Requirements, Calculation Methods and Directions for Planning and Construction. German Institute for Standardisation (Deutsches Institut für Normung): Berlin, Germany, 2018. Available online: https://infostore.saiglobal.com/en-us/standards/din-4108-3-2018-10-409818_saig_din_din_2678066/ (accessed on 21 September 2022).

- Su, F.; Dewsbury, M.; Fay, R.; Kuenzel, H.M. The Southern Hemisphere’s Vulnerability to Climate Change; AIRAH Building Physics: Sydney, NSW, Australia, 12 October 2022. [Google Scholar]

- Nationwide House Energy Rating Scheme. Software Accreditation Protocol; Australia; 2019. Available online: https://www.nathers.gov.au/sites/default/files/2019-10/2019%20NatHERS%20Software%20Accreditation%20Protocol.pdf (accessed on 21 September 2022).

- Künzel, H.M. Accounting for unintended moisture sources in hygrothermal building analysis. In Proceedings of the 10th Nordic Symposium of Building Physics, Lund, Sweden, 15–19 June 2014; pp. 947–953. [Google Scholar]

- ABCB. Building Code of Australia: Volume 2; The Australian Building Codes Board: Canberra, Australia, 1996.

- ABCB. Building Code of Australia: Volume 2; The Australian Building Codes Board: Canberra, Australia, 2005.

- ABCB. Building Code of Australia: Volume 2; The Australian Building Codes Board: Canberra, Australia, 2009.

- AS4200.2; Pliable Building Membranes and Underlays Part 2: Installation. Australian Standard: Sydney, Australia, 2017. Available online: https://infostore.saiglobal.com/preview/as/as4000/4200/4200.2-2017.pdf?sku=1911465 (accessed on 21 September 2022).

- AS/NZS4200.1; Pliable Building Membranes and Underlays Part 1: Materials. Australian Standard: Sydney, Australia. 2017. Available online: https://infostore.saiglobal.com/en-us/standards/as-4200-1-2017-99530_saig_as_as_209243/ (accessed on 21 September 2022).

- ABCB. Building Code of Australia: Volume 2; The Australian Building Codes Board: Canberra, Australia, 2010.

- ABCB. National Construction Code: Volume 2; The Australian Building Codes Board: Canberra, Australia, 2016.

- AIRAH. AIRAH Technical Handbook edition 5—Heat transfer, thermal properties and insulation. The Australian Institute of Refrigeration, Air Conditioning and Heating: Canberra, Australia, 2013. [Google Scholar]

- Law, T.; Chen, D. Hygrothermal Extension to the Residential House Energy Rating Software Used in Australia. Int. Build. Perform. Simul. Assoc. 2020. Available online: http://www.ibpsa.org/proceedings/BSO2020/BSOV2020_Law.pdf (accessed on 21 September 2022).

- ASHRAE. Standard 160-2016; Criteria for Moisture-Control Design Analysis in Buildings (ANSI Approved). American Society of Heating, Refrigerating and Air-Conditioning Engineers: Atlanta, GA, USA, 2016.

- Zirkelbach, D.; Schafaczek, B.; Künzel, H. Long-term hygrothermal performance of green roofs. In Proceedings of the Buildings XI, Atlanta, GA, USA, 4 December 2010. [Google Scholar]

- Gasparri, E.; Brambilla, A.; Aitchison, M. Hygorthermal analysis of timber-based external walls across different Australian climate zones. In Proceedings of the WCTE 2018, World Conference on Timber Engineering, Seoul, South Korea, 20–23 August 2018. [Google Scholar]

- Bastholm, C.J.; Madsen, A.M.; Frisvad, J.C.; Richter, J. Xerophilic fungi in museum repositories challenge our perception of healthy buildings and the preservation of cultural heritage. In Proceedings of the 17th International Healthy Buildings Conference, Online, 21–23 June 2021; SINTEF Academic Press: Trondheim, Norway. [Google Scholar]

- Van Den Bossche, N.; Lacasse, M.; Janssens, A. Watertightness of masonry walls: An overview. In Proceedings of the 12th International conference on Durability of Building Materials and Components (XII DBMC-2011), Porto, Portugal, 12–15 April 2011; pp. 49–56. [Google Scholar]

- Künzel, H.M. Addition of Moisture Source Inputs for Hygrothermal Simulations in the Australian Context; Nath, S., Ed.; School of Architecture & Design, University of Tasmania: Tasmania, Australia, 2019. [Google Scholar]

- Künzel, H.M. Addition of Latex Paint and Appropriate sd-Value Selection in the Australian Context; Nath, S., Ed.; School of Architecture & Design, University of Tasmania: Tasmania, Australia, 2020. [Google Scholar]

| Criterion | WUFI® VTT/Viitanen Model | WUFI® Bio/Biohygrothermal Model |

|---|---|---|

| Assessment method | The Viitanen model is an empirically verified experimental model based on research laboratory studies on mould growth. This model uses a strong multi-step assessment: the mould index (MI), which explains the mould growth intensity on the surface in percentage. [13]. | The transient biohygrothermal model is a theoretical model [13]. |

| Mould growth rate | This model restricts the projected mould growth rate to a climate-specific maximum value [13]. | The biohygrothermal model permits constant growth if there are suitable boundary conditions [13]. |

| Mould index | With the use of this model, a low level of the mould index is achieved during the unfavourable mould growth conditions [81]. | Using the biohygrothermal model, the mould index remains constant during unfavourable mould growth conditions [81]. |

| Results | For both models, WUFI® VTT and WUFI® Bio, the results can be presented in a simplified multi-year mould index graph. Subject to the maximum mould index during the simulation period, a graphical traffic light system is used to highlight the mould growth risk [13]. | |

| Software Graphic | Lamp Colour | Description |

|---|---|---|

| Red | Corresponds to a mould index of approximately ≤3.0. This type of construction is usually unacceptable. |

| Amber/yellow | Corresponds to a mould index of >1.0 and <3.0. Additional criteria or investigations are needed to assess the suitability. |

| Green | Corresponds to a mould index of approximately ≤1.0. This type of construction is usually acceptable. |

| Building Regulation Period | Added Insulation (R-Value) | ||

|---|---|---|---|

| Cool-Temperate | Temperate | Warm-Humid | |

| 1996–2002 | No insulation | No insulation | No insulation |

| 2003–2005 | R1.0 | R0.6 | R0.5 |

| 2006–2009 | R1.5 | R1.0 | R1.0 |

| 2010–2021 | R2.0 | R2.0 | R2.0 |

| 2022 | R2.7 | R2.7 | R2.7 |

| S.N. | Layer | Source | Thickness (mm) | NatHERS or Manufacturer | WUFI® | ||||

|---|---|---|---|---|---|---|---|---|---|

| R-Value (K/W) | Density (kg/m3) | R-Value (K/W) | Porosity (m3/m3) | Bulk Density (kg/m3) | Specific Heat Capacity (J/kg·K) | ||||

| 1. | Acrylic paint | ||||||||

| 2. | Paper-faced plasterboard lining | NatHERS | 10 | R0.06 | R0.05 | 0.65 | 850 | 850 | |

| Knauf | 10 | R0.06 | 650 | ||||||

| Gyprock | 10 | R0.04–R0.05 | 570 | ||||||

| 3. | Glass-wool bulk insulation (reflective) | NatHERS | 90 | R2.0 | - | R2.00 | 0.861 | 200 | 1400 |

| Bradford | 90 | R2.0 | - | ||||||

| 4. | Pliable membrane (Vapour impermeable) | NatHERS | 1 | R0.0 | N.A. | R0.00 | 0.001 | 2400 | 1000 |

| 5. | Pliable membrane (Vapour permeable) | NatHERS | 1 | R0.0 | N.A. | R0.00 | 0.001 | 130 | 2300 |

| 6. | Reflective vapour cavity | NatHERS | ~40 mm | R0.133–R0.68 | N.A. | R0.17 | 0.999 | 1.3 | 1000 |

| 7. | Clay masonry | NatHERS | 110 | R0.6 | - | R0.18 | 0.41 | 1650 | 850 |

| Class | VCM Category | Min | Max |

|---|---|---|---|

| 1 | Vapour barrier | 0.0000 | 0.0022 |

| 2 | Vapour barrier | 0.0022 | 0.1429 |

| 3 | Vapour permeable | 0.1429 | 1.1403 |

| 4 | Vapour permeable | 1.1403 | No max |

| No | Material/Layer | Thickness (m) | Water Content (kg/m3) |

|---|---|---|---|

| 1 | Solid clay masonry extruded | 0.110 | 9.20 |

| 2 | Air layer | 0.040 | 1.88 |

| 3 | Foil—BS5250 1000 MN·s/g | 0.001 | 0.00 |

| 4 | Insulation (Isover Integra AP HWF Top) | 0.090 | 19.60 |

| 5 | Air layer | 0.040 | 1.88 |

| 6 | Gypsum board | 0.010 | 6.30 |

| Item | Value | Justification |

|---|---|---|

| Heat resistance ((m2·K)/W) | 0.0588 | The standard value for outer surface air film resistance |

| Sd-value (m) | NIL | No coating for unpainted clay masonry |

| Shortwave radiation absorptivity | 0.8 | Representing red clay masonry |

| Ground shortwave reflectivity | 0.2 | Standard value representing suburban grass |

| Item | Value | Justification |

|---|---|---|

| Heat resistance ((m2·K)/W) | 0.125 | The standard value for inner surface air film resistance |

| Sd-value (m) | NIL | The initial analysis did not consider the vapour control effect of paint due to the regular service penetrations through the plasterboard lining system and the standard ‘glue and screw’ fixing system |

| Material | Initial Moisture Content | 2 Years | 5 Years | 10 Years | ||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Final | Min | Max | Final | Min | Max | Final | Min | Max | ||

| Brick | 9.20 | 4.86 | 2.51 | 9.42 | 4.86 | 2.51 | 9.42 | 4.86 | 2.51 | 9.42 |

| 40 mm air cavity | 1.88 | 0.67 | 0.21 | 2.03 | 0.67 | 0.21 | 2.03 | 0.67 | 0.21 | 2.03 |

| Membrane | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 |

| Insulation | 0.82 | 0.70 | 0.37 | 0.82 | 0.70 | 0.37 | 0.82 | 0.70 | 0.37 | 0.82 |

| Air gap | 1.88 | 1.15 | 0.27 | 3.13 | 1.15 | 0.27 | 3.13 | 1.15 | 0.27 | 3.13 |

| Plasterboard | 6.30 | 5.62 | 2.53 | 6.53 | 5.62 | 2.53 | 6.53 | 5.62 | 2.53 | 6.53 |

| Material | Initial Moisture Content | 2 Years | 5 Years | 10 Years | ||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Final | Min | Max | Final | Min | Max | Final | Min | Max | ||

| Brick | 9.20 | 5.33 | 2.23 | 9.42 | 5.33 | 2.23 | 9.42 | 5.33 | 2.23 | 9.42 |

| 40 mm air cavity | 1.88 | 0.89 | 0.20 | 3.13 | 0.89 | 0.20 | 3.13 | 0.89 | 0.20 | 3.13 |

| Membrane | 0.00 | 0.00 | 0.00 | 0.01 | 0.00 | 0.00 | 0.01 | 0.00 | 0.00 | 0.01 |

| Insulation | 0.82 | 0.72 | 0.37 | 0.84 | 0.72 | 0.37 | 0.84 | 0.72 | 0.37 | 0.84 |

| Air gap | 1.88 | 1.17 | 0.27 | 2.00 | 1.17 | 0.27 | 2.00 | 1.17 | 0.27 | 2.00 |

| Plasterboard | 6.30 | 5.63 | 2.50 | 6.30 | 5.63 | 2.50 | 6.30 | 5.63 | 2.50 | 6.30 |

| Material | 2 Years | 5 Years | 10 Years |

|---|---|---|---|

| Max Mould Index | Max Mould Index | Max Mould Index | |

| Clay masonry (exterior surface) | 0.002 | 0.002 | 0.005 |

| Clay masonry (interior surface) | 0.004 | 0.004 | 0.0013 |

| Membrane (exterior surface) | 0.006 | 0.002 | 0.006 |

| Insulation (exterior surface) | 0.025 | 0.025 | 0.025 |

| Plasterboard (exterior surface) | 0.003 | 0.003 | 0.003 |

| Plasterboard (interior surface) | 0.003 | 0.003 | 0.003 |

| Material | 2 Years | 5 Years | 10 Years |

|---|---|---|---|

| Max Mould Index | Max Mould Index | Max Mould Index | |

| Clay masonry (exterior surface) | 0.008 | 0.008 | 0.008 |

| Clay masonry (interior surface) | 1.250 | 1.500 | 2.000 |

| Membrane (exterior surface) | 0.750 | 1.250 | 2.000 |

| Insulation (exterior surface) | 1.500 | 2.500 | 3.500 |

| Plasterboard (exterior surface) | 0.000 | 0.000 | 0.000 |

| Plasterboard (interior surface) | 0.000 | 0.000 | 0.000 |

| Material | 2 Years | 5 Years | 10 Years |

|---|---|---|---|

| Max Mould Index | Max Mould Index | Max Mould Index | |

| Clay masonry (exterior surface) | 0.005 | 0.005 | 0.005 |

| Clay masonry (interior surface) | 0.200 | 0.200 | 0.200 |

| Membrane (exterior surface) | 0.125 | 0.125 | 0.075 |

| Insulation (exterior surface) | 0.500 | 1.00 | 1.00 |

| Plasterboard (exterior surface) | 0.002 | 0.002 | 0.002 |

| Plasterboard (interior surface) | 0.002 | 0.002 | 0.002 |

| Material | 2 Years | 5 Years | 10 Years |

|---|---|---|---|

| Max Mould Index | Max Mould Index | Max Mould Index | |

| Clay masonry (exterior surface) | 0.008 | 0.003 | 0.008 |

| Clay masonry (interior surface) | 0.500 | 0.500 | 0.750 |

| Membrane (exterior surface) | 0.300 | 0.300 | 0.300 |

| Insulation (exterior surface) | 1.250 | 1.500 | 2.000 |

| Plasterboard (exterior surface) | 0.000 | 0.000 | 0.000 |

| Plasterboard (interior surface) | 0.000 | 0.000 | 0.000 |

| 2 Years | 5 Years | 10 Years | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| North | South | East | West | North | South | East | West | North | South | East | West | |

| Clay masonry (exterior surface) | ||||||||||||

| Clay masonry (interior surface) | ||||||||||||

| Air cavity (exterior surface) | ||||||||||||

| Membrane (exterior surface) | ||||||||||||

| Insulation (exterior surface) | ||||||||||||

| Insulation (interior surface) | ||||||||||||

| Plasterboard (exterior surface) | ||||||||||||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nath, S.; Dewsbury, M.; Künzel, H.; Watson, P. Mould Growth Risks for a Clay Masonry Veneer External Wall System in a Temperate Climate. Atmosphere 2022, 13, 1755. https://doi.org/10.3390/atmos13111755

Nath S, Dewsbury M, Künzel H, Watson P. Mould Growth Risks for a Clay Masonry Veneer External Wall System in a Temperate Climate. Atmosphere. 2022; 13(11):1755. https://doi.org/10.3390/atmos13111755

Chicago/Turabian StyleNath, Shruti, Mark Dewsbury, Hartwig Künzel, and Phillipa Watson. 2022. "Mould Growth Risks for a Clay Masonry Veneer External Wall System in a Temperate Climate" Atmosphere 13, no. 11: 1755. https://doi.org/10.3390/atmos13111755

APA StyleNath, S., Dewsbury, M., Künzel, H., & Watson, P. (2022). Mould Growth Risks for a Clay Masonry Veneer External Wall System in a Temperate Climate. Atmosphere, 13(11), 1755. https://doi.org/10.3390/atmos13111755