1. Introduction

Industrial activity has increased greenhouse gas (GHG) emissions, which have led to various environmental problems, such as global warming. A total of 41% of total CO

2 emissions are attributed to electricity and heat generation industries, of which coal-fired power plants are the most significant emissions sources [

1,

2]. Several factors influence the amount of CO

2 emissions produced by fossil fuel power plants, including utilized fossil fuel, power generation technology, plant size and plant efficiency. Fossil-fueled power plants can reduce their CO

2 emissions through various methods such as increasing their efficiency, switching to fuels with low carbon content, and CO

2 capture and storage. Improving the power plant efficiency can considerably reduce the CO

2 emission, by 2–3% with a 1% increase in power plant efficiency. However, the average efficiency of coal-fired power plants in the world is around 35% and there are various technical limitations to improving the efficiency further [

3]. A coal-fired power plant utilizing bituminous coal emits approximately 850 kg CO

2 per one MWh. In comparison, natural gas-fueled combined cycles (NGCC) are less carbon-intensive and generate about 350 kg CO

2 per one MWh (60% lower CO

2 emission compared to coal-fired power plants) [

4]. Furthermore, NGCC plants generate flue gases typically containing 4 to 5% CO

2 by volume, while this value is about 12 to 15% in the flue gas of coal-fired power plants).

The implementation of carbon capture, utilization, and storage (CCUS) technologies is considered a practical and economical solution for improving the sustainability of CO

2-intensive industries, such as fossil-fueled power plants [

5]. Post-combustion CO

2 capture, pre-combustion CO

2 capture and oxyfuel combustion are among the CO

2 capture technologies that have been proposed and demonstrated, among which post-combustion CO

2 capture is considered one of the best solutions for retrofitting existing power plants [

6]. In carbon capture and storage (CCS), CO

2 is captured, compressed, transported and then stored geologically. CCS costs are heavily influenced by CO

2 capture and separation as the main component of CCS. A variety of approaches can be employed for separating CO

2 from flue gas streams, such as chemical absorption using amines, physical absorption, adsorption (pressure swings and temperature swings), membrane technologies and cryogenic processes [

7,

8]. Chemical absorption has been widely used for post-combustion CO

2 capture since it can be retrofitted to existing power plants, handle a large volume of flue gas and capture up to 90% of CO

2 with high purity. Despite its benefits, this method has high energy requirements and operating costs, negatively affecting its sustainability and flexibility [

9].

Compared with traditional separation methods, membrane-based CO

2 separation is considered to be an attractive alternative for CO

2 capture, mainly because of its lower energy requirement and operation cost [

10]. In spite of the fact that the membrane-based CO

2 separation method has not been used commercially in coal-fired power plants, recent developments in membrane materials plus easy scaling-up, high packing density, small footprint and mobility make the membrane separation method a potential candidate for environmentally friendly and sustainable CO

2 capture [

11]. Using membrane technology in coal power plants presents the major challenge of low CO

2 concentration (10–15%), which requires compressors on the feed side or vacuum pumps on the permeate side to enhance the driving force across the membrane [

12].

The selectivity and permeability of the membranes available on the market make a single-stage membrane process unsuitable for recovering CO

2 at more than 90% purity from diluted- CO

2 flue gases (5 to 15 mole% CO

2), typical in fossil gas combustion [

13]. Several membrane improvements have been proposed to overcome the challenge of CO

2 capture from the power industry. Membrane materials with high selectivity and permeability, including polymeric, organic and inorganic materials, have been the subject of significant studies in recent years. It has been demonstrated that Polaris membranes developed by Membrane Technology Research Inc. can provide significant CO

2 permeances of 1000–2000 while the CO

2/N

2 selectivity is acceptable at 50 [

14]. Using facilitated transport membranes such as Poly-vinylamine/Pirazine Glycinate based membranes can also provide higher CO

2/N

2 selectivity (about 140) under normal flue gas conditions [

15]. It has been shown that membranes with high CO

2 permeability reduce the area and cost of membranes, whereas membranes with high CO

2/N

2 selectivity reduce the energy consumption and cost of operation of the system. Accordingly, future developments in membrane materials require deep insight into how membrane properties affect the operation and economy of the carbon capture system.

Considering the existing membrane properties and other technical limitations, the development and improvement of membrane process design and optimization of system operating and design conditions can play an important role in improving the sustainability and viability of the membrane process for CCS application. Due to the low partial pressure of CO

2 and low driving force in flue gas, implementing multi-stage designs of membrane and creating an internal gas recycling is essential to reach the high CO

2 recovery (90%) and high CO

2 purity (95 mole%) targets. To reach this separation target for post-combustion applications, previous authors suggested different approaches for generating higher driving forces for CO

2 permeation by combining feed compression, vacuum permeation, feed-air sweep system, retentate recycling, as well as enricher and stripper designs [

16,

17,

18,

19,

20]. In this regard, various parametric studies have been implemented to study the effect of multiple designs, operating conditions and membrane properties on the system performance and economy [

21].

Using multi-objective optimization (MOO), it is possible to address the various trade-offs between operating efficiently and design parameters in membrane-based CCS to achieve the specified CO

2 removal target. In CCS processes, evolutionary algorithms, such as NSGA (Non-dominated sorting genetic algorithm), and gradient-based methods, such as nonlinear programming, have been applied [

22]. The optimal design and operation of solvent-based CCS have been widely studied [

23,

24,

25]. For membrane-based CCS, multi-objective and superstructure-based optimization methods have also been applied [

22,

26,

27,

28,

29,

30,

31]. For a multi-stage membrane process, Arias et al. [

22] used a superstructure optimization approach to determine the optimal number of membrane stages and operating conditions for a range of CO

2 recovery objectives. According to Mat and Lipscomb [

27], a global search of the decision variable space was used to find optimal membrane properties and operating conditions for minimizing levelized electricity costs for multi-stage hybrid membrane-cryogenic design. The cost function for a novel cryogenic carbon capture system below ambient temperature was minimized by Lee et al. [

29]. To the best of our knowledge, most studies conducted on the optimization of membrane-based CCS have focused on the economic optimization of specific membrane designs with a fixed value of membrane properties. Furthermore, few publications are available addressing multi-objective and superstructure optimization in two-stage membrane CCS systems for determining simultaneously and systematically the optimal configuration variables, operating conditions and membrane properties for capturing CO

2 from coal-fired power plants to meet the separation target specified by the U.S. Department of Energy (90% CO

2 recovery).

In this paper, based on a mathematical model developed in Aspen Custom Modeler for the hollow-fiber membrane module, a sensitivity analysis was conducted to determine which operating and design parameters significantly affect the efficiency of a two-stage membrane-based CCS in terms of energy and economy. To achieve a sustainable and flexible membrane-based CCS that can integrate with fossil-fueled power plants, this paper uses an evolutionary algorithm to perform a comprehensive multi-objective superstructure optimization for a two-stage membrane-based CCS. This is aimed at identifying the optimal system design, operating conditions and membrane transport properties.

2. Methodology

2.1. Fossil-Fueled Power Plant Integrated with CO2 Capture Technologies

Combustible fuels are the main source of power generation in the world, with a share of 63.1% [

1]. Among various fossil-fueled power generation methods, coal-fired power plants generate major electricity and heat worldwide (36.7%), while producing a significant amount of CO

2 emissions. In a coal-fired power plant, pulverized coal is combusted in a boiler with preheated air. The generated heat from combustion is utilized to produce high-pressure steam in the water-steam cycle, which is further utilized for electricity generation using turbines. In order to treat NOx, SOx and fly ash from power plant flue gas prior to CO

2 capturing, exhaust gas from the boiler is passed through a denitrification system, an electrostatic precipitator and a wet flue gas desulphurization (FGD) unit [

32]. Considering the recent global push for reductions in GHG emissions to meet the climate goal specified in the Paris Climate Agreement, carbon capture, utilization and storage systems have a great potential for reducing CO

2 emissions from the power sector [

33]. Among all CO

2 mitigation technologies, post-combustion CCS is considered to be the best option for significantly enhancing the sustainability of both existing and new fossil-fueled power plants by reducing CO

2 emissions. However, the CCS technology has a profound effect on plant performance due to its energy-intensive nature. For instance, the stripper reboiler in an amine-based CO

2 capture process requires a massive amount of steam (typically 3.5–4.5 GJ/t CO

2) [

34]. This amount of steam is provided from the steam cycle of a power plant, which leads to efficiency loss. Previous studies showed that amine absorption CCS would require 30% of the generated power by the power plant in order to capture 90% of the CO

2 in flue gas, which results in a cost of

$40–100 for capturing one ton of CO

2 [

16]. In order to improve the sustainability of fossil-fueled power plants, it is of great importance to integrate a CCS technology that requires a lower amount of energy and cost. Both the industrial and scientific communities have shown increasing interest in membrane-based CO

2 separation in recent years due to several advantages over the amine-based post-combustion capture method. However, this process is still under development and requires a significant amount of energy to generate enough driving force in the membrane module to separate CO

2 from other flue gas components. Accordingly, optimal design and operation of membrane-based CCS pave the way for optimal integration and improving the sustainability of fossil-fueled power plants. In the following sections, the potential of a two-stage membrane process for optimal CO

2 capturing from a 600 MW coal-fired power plant are discussed and investigated.

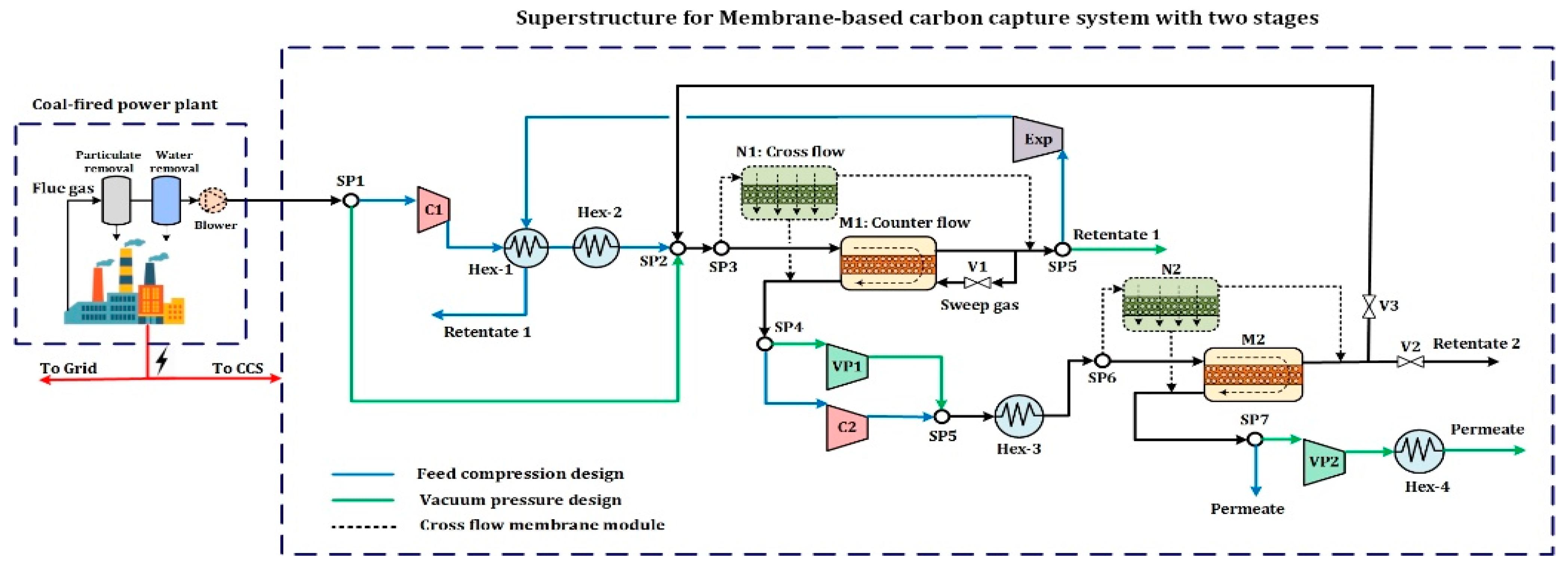

2.2. Superstructure for Two-Stage Membrane-Based CCS Process

For an optimal membrane separation process, it is necessary to develop a superstructure that includes various potential designs and all the required components (e.g., compressors, heat exchangers, splitters, membranes, vacuum pumps, etc.).

Figure 1 illustrates the general superstructure for a two-stage membrane process for separating CO

2 from flue gases of a 600 MW coal-fired power plant. Gasification or combustion exhaust flue gas must be treated before entering the membrane module in order to remove contaminants like ash, SOx, NOx and water. A membrane-based CCS feed gas primarily contains N

2 and CO

2, and the fraction of CO

2 is commonly below 15 mole%. Because the CO

2 partial pressure in flue gas is low, an additional driving force is needed to separate the gas, which can be supplied by either compressor at the membrane feed side or by a vacuum pump at the permeate side. Flue gas conditions and other fixed parameters used in this study are presented in

Table 1.

Figure 1 shows how exhaust flue gas entering the membrane CCS unit can follow various process pathways, which are determined by various splitters (SP) in the superstructure. To generate the driving force, feed compression and permeate vacuum methods are considered. The blue and green lines depict these approaches, respectively. In this regard, the splitter can be seen as a binary variable that determines the method of generating the driving force. Each method has the same main pipelines, which are represented by black lines. System performance and separation efficiency can be affected by retentate recycling and sweep gas, so different valves need to be considered in the system model, which specifies the flowrate ratio of the recycling process.

The sweep gas is a means of increasing the driving force for membrane gas separation. Recycling a portion of the retentate stream as a sweep gas to the membrane module reduces the concentration of CO2 on the permeate side, thus the CO2 partial pressure gradient across the membrane increases and CO2 can permeate through the membrane more rapidly. However, applying sweep gas reduces the CO2 concentration on the permeate side and causes downstream issues for handling and storage of CO2, which highlights the necessity of considering a second CO2 separation from the sweep. Accordingly, in the proposed superstructure, sweep gas only applies to the first membrane stages so that the second membrane stages could improve the purity of CO2 in the permeate gas for better CO2 handling and storage.

In addition, the proposed superstructure considers two common membrane flow configurations, cross-current and counter-current flow. The membrane modules can also incorporate different polymeric membranes with a wide range of transport properties. Thus, several commercially available membranes are considered for the superstructure. In order to optimize and analyze the proposed model, a mathematical programming model including both discrete and continuous variables is developed based on the proposed superstructure.

2.3. Assumptions, Mathematical Formulation of the Membrane Unit, and Process Simulation

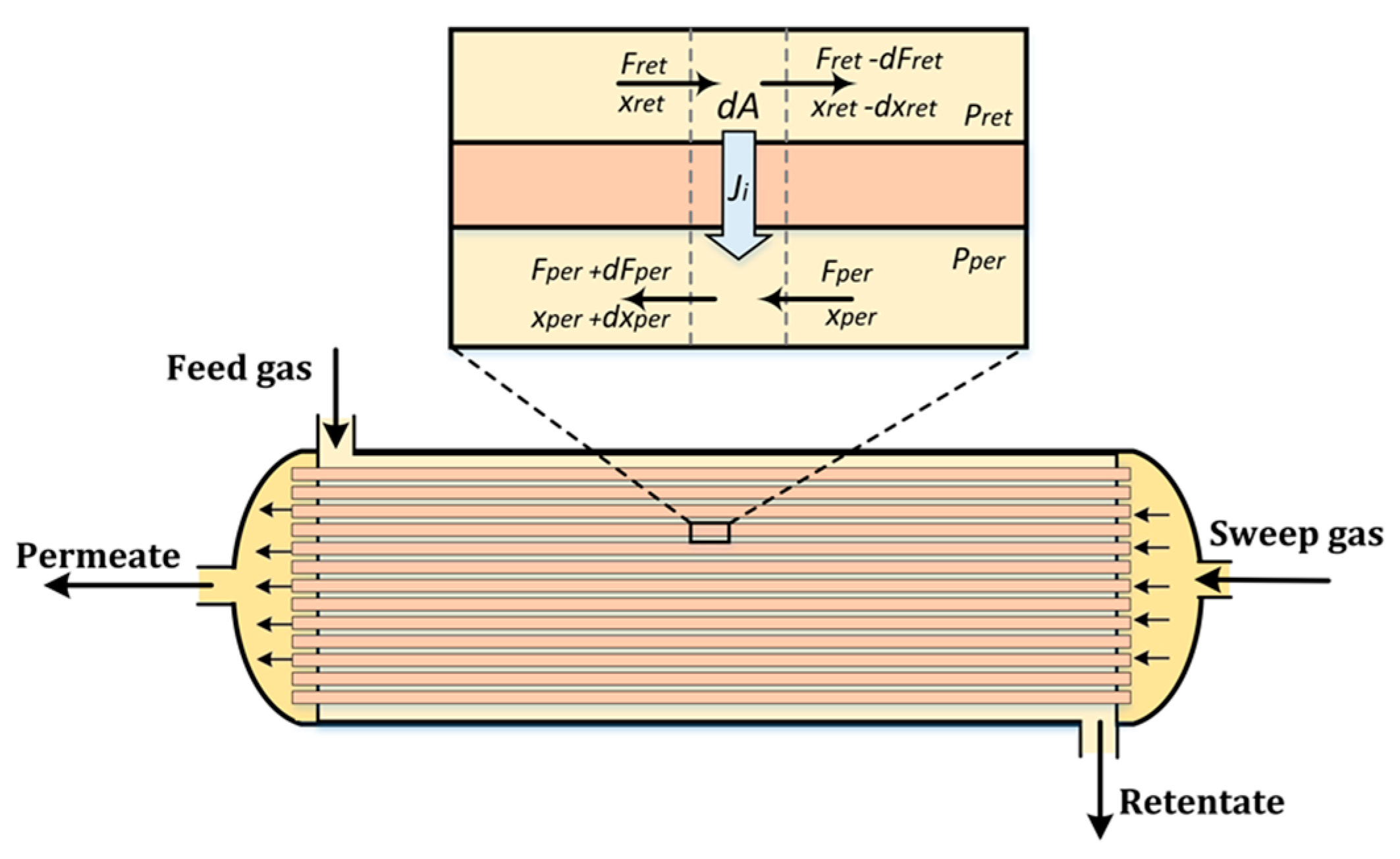

On the basis of a solution-diffusion mechanism, mathematical models for counter-current and crossflow hollow fiber membranes are developed.

Figure 2 shows a schematic of a counter-current hollow fiber membrane module with the inlet gas flowing to the module shell side and permeating to the fiber bore side. Gas enriched with N

2 (retentate stream) exits from the shell side of the module, whereas CO

2-enriched gas (permeate stream) exits from the bore side in the opposite direction. For the mathematical modeling of a membrane stage, the following assumptions have been taken into account:

All fibers have the same thickness and shape.

The gas mixtures can be described as ideal gas.

Pressure and temperature do not affect the permeability of components.

An axial pressure drop can be calculated using the Hagen-Poiseuille equation.

On the membrane surface, concentration polarization is negligible.

Isothermal and steady-state conditions are assumed in the membrane model.

The mathematical formulation of a membrane stage is shown in

Table 2, assuming solution-diffusion is the primary mechanism for CO

2 permeation. Detailed descriptions of the mathematical modeling for the counter-flow membrane module are available in [

21,

35].

As for the crossflow membrane module, the local concentration of each component on the permeate side is equal to the fraction of gas passing through the membrane at a given point. Detailed mathematical modeling of a crossflow membrane module is presented by [

36]. In our previous study [

21], we validated the above-mentioned mathematical model of the membrane module.

By utilizing the 2nd order central finite discretization method with 200 elements, we have programmed and solved the mentioned differential equations using the Aspen Custom Modeler and DMO solver. Following the creation of the membrane models, the user-defined models are imported into Aspen PLUS for further analysis and optimization.

As mentioned in

Table 1, the flue gas that exits from the power plant is assumed to have constant temperature and pressure. Despite the fact that oxygen and water are more realistically present in flue gases, it is assumed that the flue gas has been sent to treatment units before entering membrane-based CCS, and the treated flue gas is a binary gas, including CO

2 and N

2. This is in line with previous works [

21,

37]. Peng-Robinson thermodynamic package is used to model the thermodynamic properties and gas behavior. In addition, single-stage compressors and vacuum pumps are assumed with a fixed efficiency of 85%, and heat exchangers are used for cooling down the gas streams to process operational temperatures after a feed or permeate compression.

2.4. Economic Evaluation

A detailed description of the equations used to calculate CO

2 capture cost (

$/tonCO

2) is presented in

Table 3. These equations include fixed operating and maintenance (O & M) costs, annual capital costs, equipment purchase costs and utility costs. We assume that the system operating hours are 8000 per year. It is assumed also that compressors, expanders, vacuum pumps, heat exchangers and membrane modules depreciate over a period of 25 years, while membranes have a lifespan of 5 years. The corresponding depreciation factors for the CCS unit and membrane are mentioned in

Table 3.

2.5. System Optimization Procedure

Optimization of membrane-based CCS system design and operating parameters requires a rigorous optimization procedure that simultaneously optimizes conflicting objective functions with both continuous and discrete decision variables. As there can be no single optimal solution to the multi-objective optimization (MOO) problem because the objective functions compete with each other, the optimization solution leads to a Pareto frontier containing a set of optimal points [

38]. As a consequence, the Pareto solutions represent the optimal trade-off between objective functions, which is critical for the design and operation of systems.

Mixed Integer Nonlinear Programming (MINLP) has been formulated to describe the best design and operation of a membrane-based CCS, which can be solved with heuristics and deterministic methods [

31]. For optimization, the heuristic optimization algorithms are selected due to their robustness and capability of generating Pareto solution sets. Additionally, the Multi Leader Multi-Objective Particle Swarm Optimization algorithm (MLMOPSO) as a heuristic algorithm proposed by [

39] has been employed, which is capable of handling and optimizing constrained MINLP problems efficiently. An innovative approach to updating particle positions by multiple leaders is employed based on this algorithm, which allows particles to use the information of several non-dominated solutions rather than just the closest. Additionally, there is a parameter called the Social Influence Factor (SIF) that controls the influence of leaders on velocity vectors [

39]. In previous works [

40,

41,

42], this method has proven successful in maintaining the diversity and quality of Pareto solution sets.

The membrane-based CCS optimization problem can be expressed as MINLP as follows:

Subjected to:

where

F represents the vector of objective functions,

x represents the vector of model decision variables,

hm(

x) is the vector of equality constraints and

gn(

x) is the vector of inequality constraints.

The objective functions vector includes the following performance indicators:

CO2 capture cost: an economic indicator that shows the required cost to capture one ton of CO2 from flue gas ($/tCO2).

CCS energy penalty: this indicator shows the energy consumption of the CCS process per power plant net capacity.

CO2 removal percentage: this indicator shows the removal efficiency of CCS, which can be calculated as the flow rate of CO2 in permeate gas per the flow rate of CO2 in the flue gas.

In order to generate the best possible trade-offs for enhancing the sustainability and flexibility of membrane-based CCS, the CO2 capture cost and the total energy consumption and CO2 capture cost need to be minimized, and CO2 removal should be maximized.

Continuous decision variables are critical process parameters affecting system performance and economic indicators. These variables include feed gas pressure, CO

2 concentration in the feed gas and retentate recycling ratio, which are considered as the vector of continuous decision variables. As discrete decision variables, we consider three membranes with varying selectivity and permeability (first- and second-generation Polaris membranes and PVAM/PG membrane). In addition, various layouts of the process in the superstructure model are represented through the value of nodes (splitter) as binary variables in the MINLP problem. The SP3 and SP7 splitters value indicate whether the membrane module is counter flow (SP3 = SP7 = 1) or crossflow (SP3 = SP7 = 0). The values of other splitters also determine whether the compression strategy is feed compression (SP1, SP2, SP4, SP5, SP6, SP8 = 1) or permeate vacuum (SP1, SP2, SP4, SP5, SP6, SP8 = 0). The process simulator applies mass and energy balance constraints along with other design specifications automatically. The programmed MINLP has inequalities constraints involving the range of decision variables as well as the CO

2 removal objective function, which according to previous studies must be above 70%. The lower and upper range of decision variables is shown in

Table 4.

It should be mentioned that a higher vacuum level is not achievable at an industrial scale (<0.2 bar) [

28].

The steady-state simulation of the process is performed in Aspen Plus and the MINLP problem and MLMOPSO optimization algorithm are implemented in MATLAB 2021a. Aspen Plus and MATLAB are then linked using the Actxserver function in MATLAB through a Component Object Model (COM) server, which enables information about equipment and streams to be exchanged between the two software.

3. Results and Discussion

3.1. Parametric Study of Membrane-Based CCS

Prior to performing process optimization, it is beneficial to have an understanding of the process behavior under different operating conditions. In our previous work [

21], a detailed technical evaluation of the two-stage membrane process was performed considering fixed CO

2 recovery (90%) and fixed CO

2 purity in the permeate gas (95 mole%). In this study, we have considered a fixed membrane area in the module

Here, a parametric study for counter-flow configuration has been discussed in this subsection, where the membrane areas of the modules are fixed and the CO2 recovery varies.

Considering the first generation of Polaris™ membrane (CO2/N2 selectivity: 50, CO2 permeance: 1000 GPU) in the first and second module membrane with a fixed area equal to 6.6 × 105 and 3.5 × 104 m2, respectively, the effect of various operating parameters on the system performance has been analyzed. It should be noted that, at the considered membrane areas, the compressors discharge pressure of 8 bar, zero sweep gas and full retentate recycling, the CCS unit leads to 90% CO2 recovery and 95 mole% CO2 purity.

The influence of the compressor outlet pressure on the membrane separation performance and the economic and energy indicators is illustrated in

Figure 3. The results show that, when the feed pressure is increased, the total energy requirement of the CCS unit increases because of the extra power required by the compressors. There is also an optimum compressor discharge pressure (~7 bar) at which the CO

2 capture cost of the system is minimum (~25.2

$/tCO

2). In addition, since there is a low driving force for CO

2 separation at lower pressures, lower CO

2 flow rates at permeate stream can be obtained, leading to a declining trend in CO

2 capturing cost. However, by further increasing the compressor discharge pressure, although CO

2 recovery increases, the increasing slope becomes slow at high pressures and negatively impacts CO

2 capture cost.

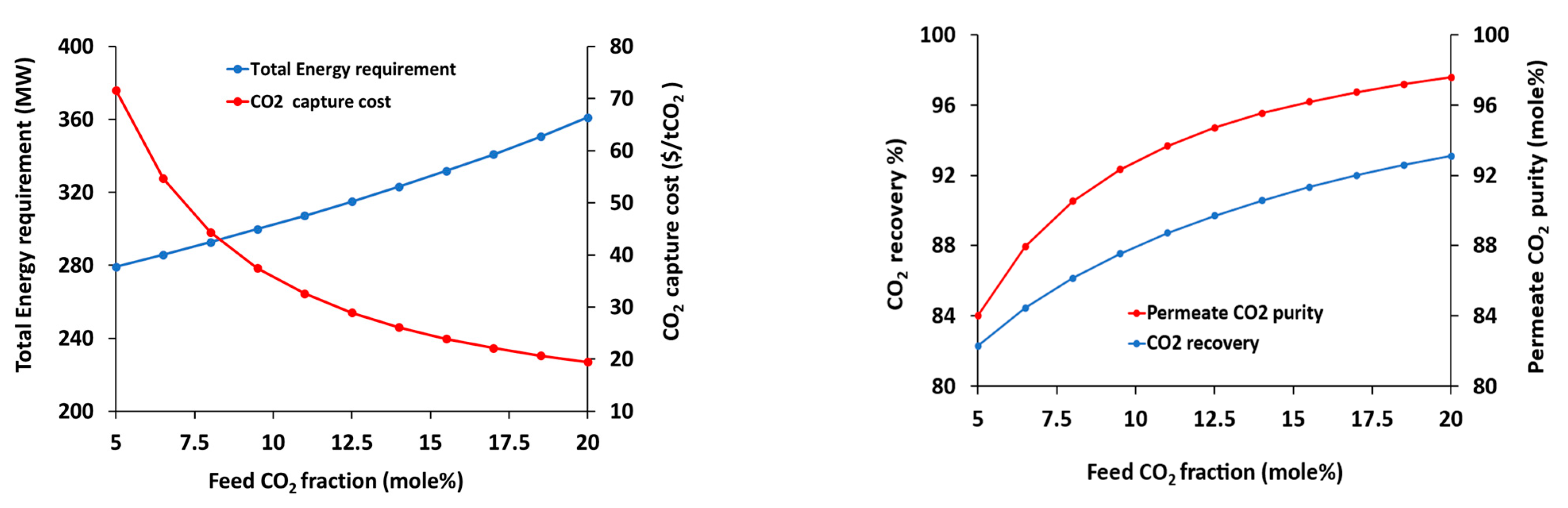

Depending on the operational conditions imposed by the grid and power plant fuel type, the CO

2 concentration of flue gas can fluctuate considerably. Accordingly, the influence of the CO

2 fraction of flue gas on the CCS unit performance has been analyzed and the results are presented in

Figure 4. It is shown that, by raising the feed CO

2 concentration, the total energy requirement for membrane-based CCS units increases, which can be described by the higher energy consumption of the compressor and cooler upstream of the second membrane module. The increment of feed CO

2 concentration also increases the CO

2 recovery of process and CO

2 purity of permeate gas due to the availability of extra driving force. The higher increasing slope of CO

2 purity compared with CO

2 recovery is associated with the influence of membrane selectivity to improve the permeate purity at low availability of driving force. Although increasing the CO

2 concentration in the feed gas increases the energy cost, the CO

2 capture cost significantly decreases due to the higher flow rate of CO

2 in permeate gas which is the denominator of the economic indicator.

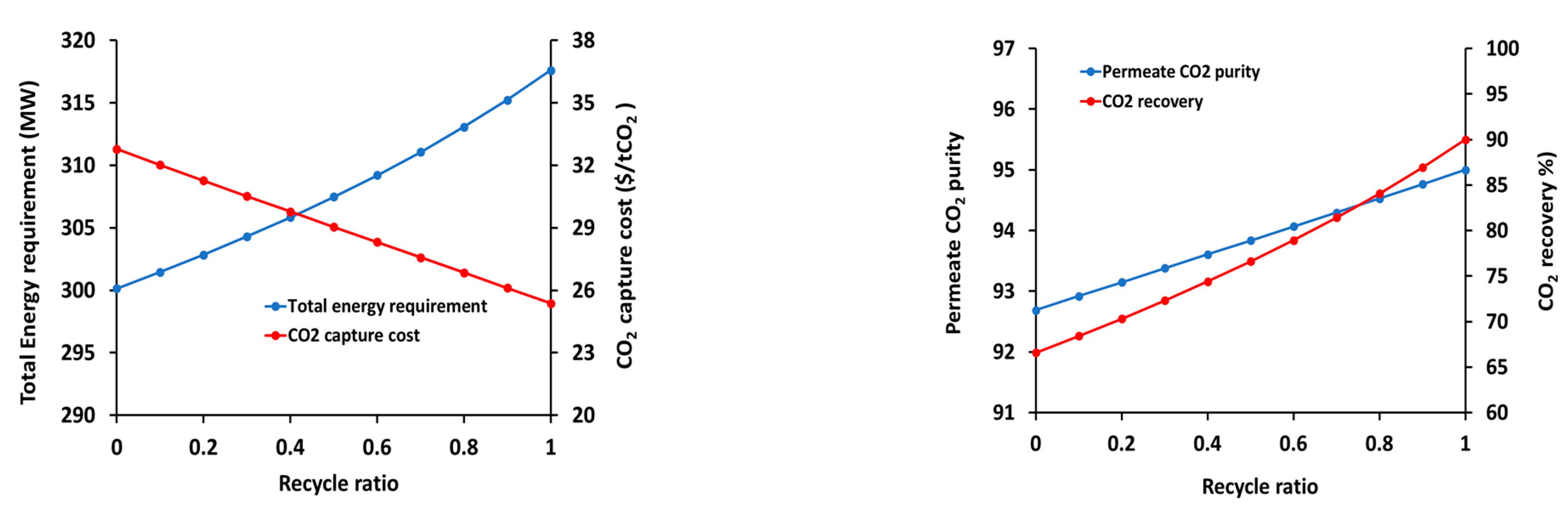

The influence of retentate recycling on the system performance indicator is illustrated in

Figure 5. By increasing the retentate recycling, it can be concluded that the permeate CO

2 purity and CO

2 recovery improve due to the recirculation concept and high availability of driving force. Although recycling the second stage retentate stream increases the process energy consumption, since a higher flow rate enters the compressors, it improves the economic indicator of the membrane CCS unit as the system can capture a larger amount of CO

2. It is shown here that it is necessary to recirculate the retentate gas from the second stage back to the first stage in order to guarantee high CO

2 purity in the permeate, although the energy consumption increases compared with a design without retentate recirculation.

According to the above parametric study of membrane-based CCS, along with the results provided in our previous work [

21], there are various conflicts between the effect of operating and design variables of the CCS unit on the system performance, which need to be addressed for flexible and sustainable operation and design. In this regard, multi-objective optimization of the system has been performed and the results are presented in the following section.

3.2. Process Optimization

The multi-objective optimization of the two-stage membrane CCS process has been implemented by linking Aspen Plus and MATLAB using the MLMOPSO technique. As mentioned before, the membrane area is considered to be fixed and their values for various membrane types are considered as the system reaches 90% CO2 recovery and 95 mole% CO2 purity at the pressure of 8 bar, 13 mole% CO2 in the feed gas and full recycling. For the case of the Polaris gen1 membrane, the first and second module membrane areas are fixed at 6.6 × 105 m2 and 3.5 × 104 m2, respectively. These values are 3.41 × 105 and 1.79 × 104 for the case of the Polaris gen2 membrane.

To reach acceptable Pareto solution sets, several algorithm parameters are evaluated, and it has been concluded to consider maximum archive size = 200, swarm size = 50, number of leaders = 5, maximum iteration = 100, SIF = 2, global learning coefficient = 2.8 and personal learning coefficient = 1.2. The stopping criteria were met at the iteration number of 64, and 73 Pareto optimal solutions are found, as shown in

Figure 6.

Figure 6A presents the Pareto optimum solutions for the CO

2 capture cost and energy penalty of the process. Two Pareto points of A and B are marked, corresponding to the minimum total power requirement and the minimum CO

2 capture cost, respectively. Based on point (A), using the PVAM/PG membrane in the counter flow module and permeate vacuum approach led to the most energy-saving approach compared to the other designs, leading to the minimum energy penalty, equal to 10.02%. Although a turboexpander is unavailable in the vacuum design, since this design handles the permeate stream with a lower flow rate compared to the feed stream, which mostly consists of nitrogen, it requires a lower amount of power to recover more than 70% of CO

2. However, the CO

2 capture cost at point (A) is the maximum (194

$/tCO

2), which is mainly due to the higher capital cost, as the prespecified required area of vacuum design (1.3 × 10

7 m

2) is significantly higher than feed compression, to reach the separation target.

The minimum CO2 capture cost (point B) is equal to 13.1 $/tCO2 resulting from using the feed compression method and Polaris gen2 in the counter flow membrane module, which can be related to the low required membrane area resulting from using a membrane with high permeance and efficient design. It should be noted that, at this point, the values of energy penalty and CO2 recovery are relatively high (35.5% and 92%, respectively), which is because of the high discharge pressure of compressors.

The Pareto optimum solutions for the CO

2 recovery and total power requirement of the process are shown in

Figure 6B, in which Point C represents the highest possible CO

2 removal of the system (99.99%). Considering a fixed membrane area, using feed compression and counter flow module equipped with Polaris gen1 leads to the highest separation efficiency in the Pareto solution set. At this point, the second stage is fully recycled and flue gas CO

2 concentration and feed pressure are 20 mole% and 10.57 bar, respectively.

Along with the inherent benefits of membrane-based CCS, such as modularity, compactness, easy installation, ease for a remote area such as offshore, and easy operation and maintenance, the proposed membrane-based CCS could provide a lower CO

2 capture cost compared to the conventional solvent-based CCS. As shown in the Pareto optimum solutions set (

Figure 6) of the proposed membrane-based CCS, most Pareto solutions have a CO

2 capture cost lower than 40

$/tCO

2 with a minimum of 13.1

$/tCO

2. However, the CO

2 capture cost of the solvent-based post-combustion CCS (conventional process for CCS) is between 50–110

$/tCO

2, depending on the solvent type and the level of heat integration [

44,

45].

Besides having appropriate permeability and selectivity, industrially desirable membranes for CCS application should be chemically and mechanically compatible with the process environment, stable, fouling-free, have a reasonable useful lifespan, be easily fabricated and packaged and be resistant to high pressures. However, many studies on CO2 capture membrane materials focus on improving perm-selectivity without addressing other important factors.

Due to the low CO2 content of flue gas, single-stage membrane configurations, even by using a membrane with high perm-selectivity properties, are not viable for integrating with fossil-fueled power plants. However, in multi-stage membrane systems, both high product purity and high CO2 removal efficiency can be simultaneously achieved. This study proved that using an appropriate driving force generation method and optimal operating and design conditions for membrane gas separation are critical to reducing the energy penalty and the capture cost of the systems and enhancing the sustainability of fossil-fueled power plants integrated with membrane-based CCS. Accordingly, through the integration of a counter-current membrane module and feed compression approach, a post-combustion carbon capture process can be considerably improved in terms of sustainability. Additionally, generating driving force by means of permeate vacuum is more energy-efficient, enhancing the flexibility of the system. The results of the process analysis and optimization presented here can help process developers and decision-makers to select the sustainable design and operating conditions for the membrane-based carbon capture systems.