Composting and Methane Emissions of Coffee By-Products

Abstract

1. Introduction

2. Materials and Methods

2.1. Compost Pile Construction and Mixing in the Study Area

2.2. Compost Sample Analysis

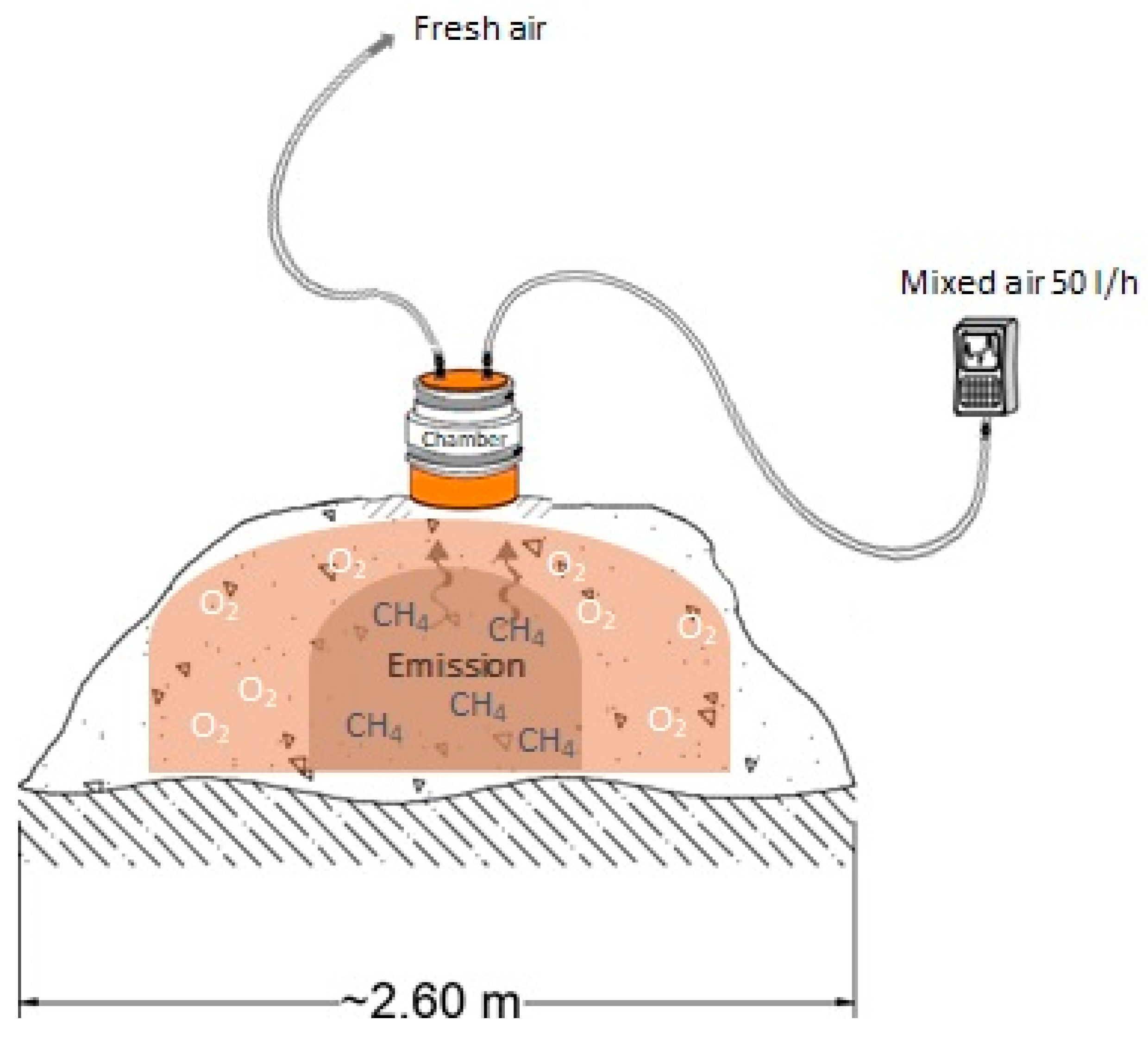

2.3. Methane Gas Sampling System

2.4. Emission Rates and Emission Factors

2.5. Statistical Analysis

3. Results and Discussions

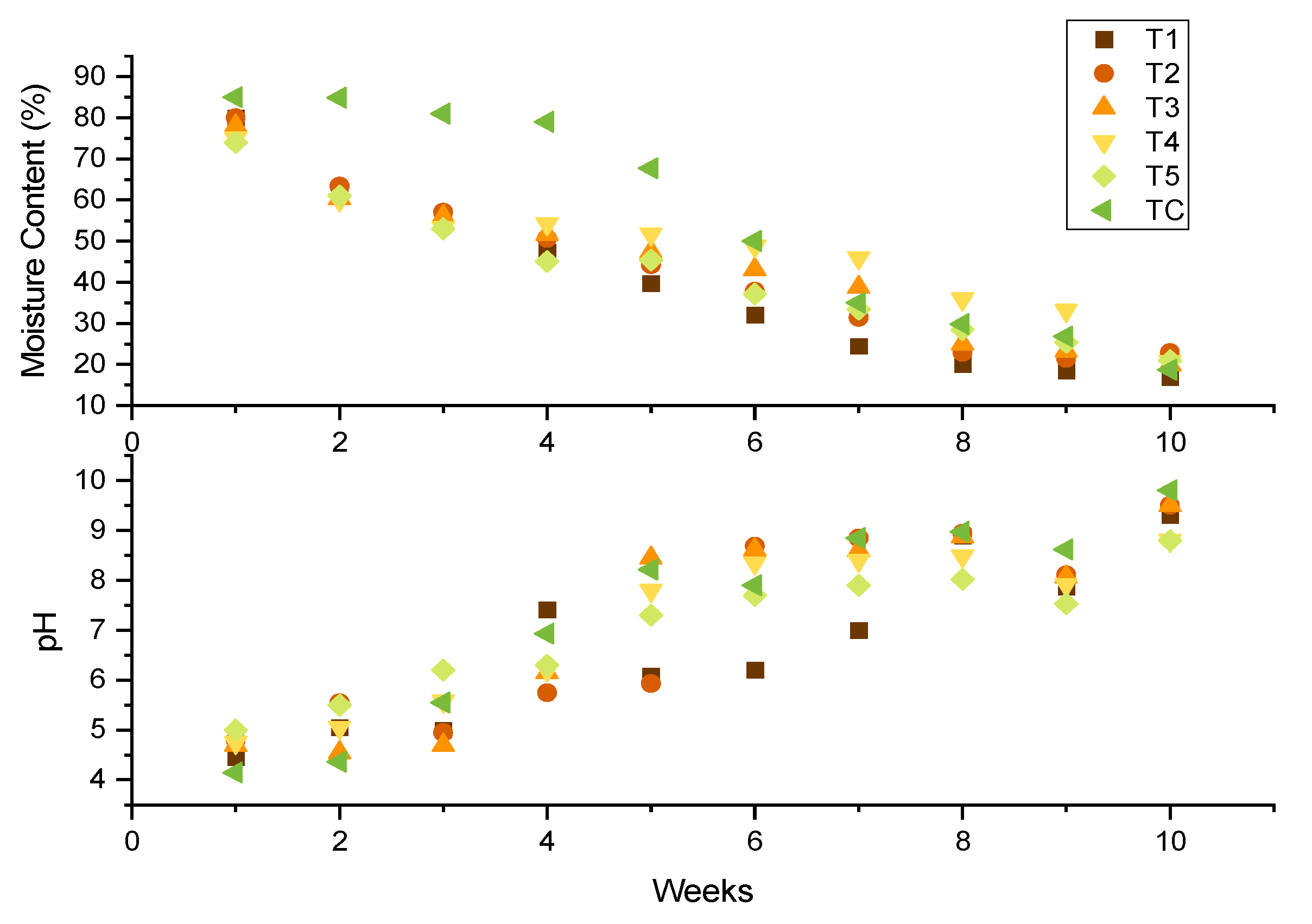

3.1. Environmental Conditions: Temperature, Moisture, and pH

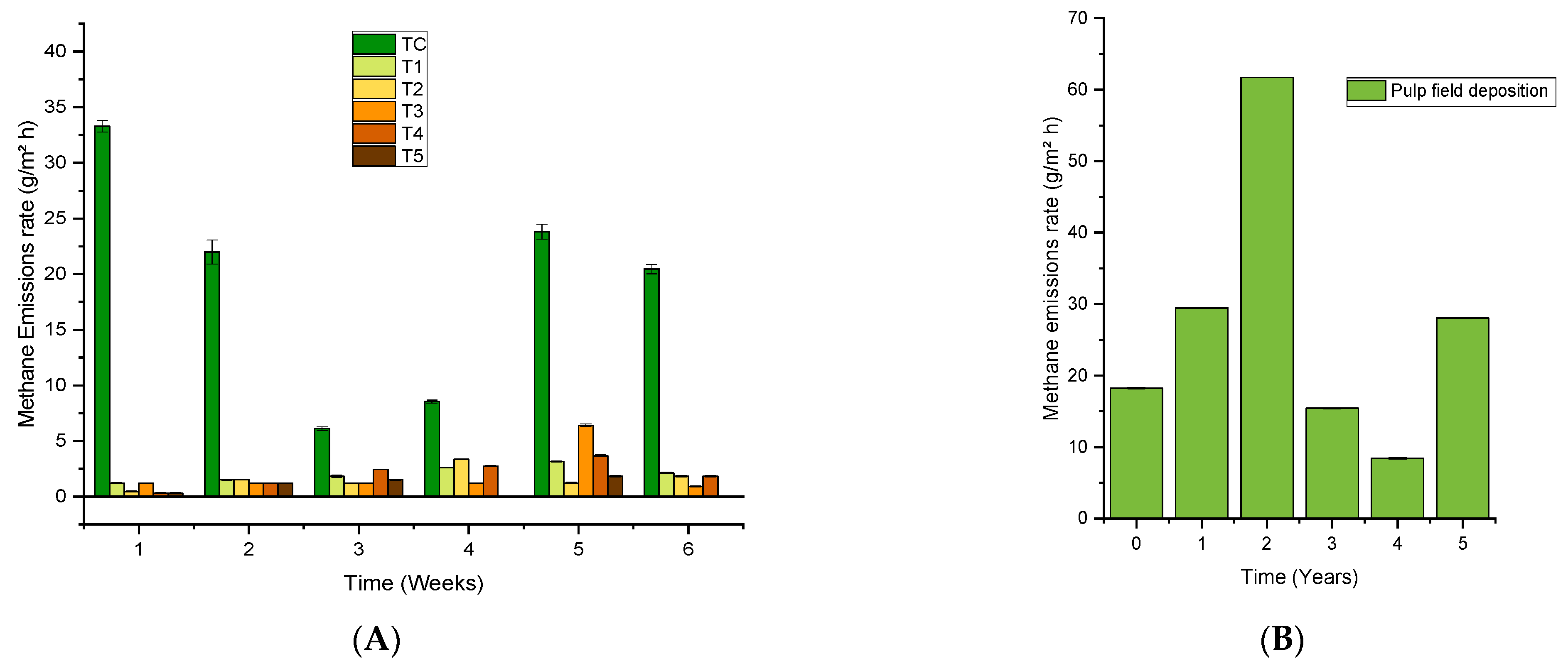

3.2. Methane Gas Emissions

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Smith, P.; Bustamante, M.; Ahammad, H.; Clark, H.; Dong, H.; Elsiddig, E.A.; Haberl, H.; Harper, R.; House, J.; Jafari, M.; et al. Agriculture, Forestry and Other Land Use (AFOLU). In Climate Change 2014 Mitigation of Climate Change Mitigation of Climate Change. Contribution of Working Group III to the Fifth Assessment Report of the Intergovern-Mental Panel on Climate Change; Edenhofer, O., Pichs-Madruga, R., Sokona, Y., Farahani, E., Kadner, S., Seyboth, K., Adler, A., Baum, I., Brunner, S., Eickemeier, P., Eds.; Cambridge University Press: Cambridge, UK, 2014; pp. 811–922. [Google Scholar]

- Bridgham, S.D.; Richardson, C.J. Mechanisms controlling soil respiration (CO2 and CH4) in southern peatlands. Soil Biol. Biochem. 1992, 24, 1089–1099. [Google Scholar] [CrossRef]

- Vergara, S.E.; Silver, W.L. Greenhouse gas emissions from windrow composting of organic wastes: Patterns and emissions factors. Environ. Res. Lett. 2019, 14, 124027. [Google Scholar] [CrossRef]

- US EPA. AP 42, Fifth Edition Compilation of Air Pollutant Emission Factors, Volume 1: Stationary and Point Sources; US EPA: Research Triangle Park, NC, USA, 1995; pp. 1–10.

- Amlinger, F.; Peyr, S.; Cuhls, C. Green house gas emissions from composting and mechanical biological treatment. Waste Manag. Res. 2008, 26, 47–60. [Google Scholar] [CrossRef] [PubMed]

- Sánchez, A.; Gabarrell, X.; Artola, A.; Barrena, R.; Colón, J.; Font, X.; Komilis, D.; Taherzadeh, M.J.; Richards, T. Composting of Wastes. Resource Recovery to Approach Zero Municipal Waste, 1st. ed.; Taherzadeh, M.J., Richards, T., Eds.; Green Chemistry and Chemical Engineering: Boca Raton, FL, USA, 2015; pp. 77–106. [Google Scholar]

- Blinová, L.; Sirotiak, M.; Bartošová, A.; Soldán, M. Review: Utilization of Waste from Coffee Production. Res. Pap. Fac. Mater. Sci. Technol. Slovak Univ. Technol. 2017, 25, 91–101. [Google Scholar] [CrossRef]

- Chong, J.A.; Dumas, J.A. Coffee pulp compost: Chemical properties and distribution of humic substances. J. Agric. Univ. Puerto Rico 2012, 96, 77–87. [Google Scholar] [CrossRef]

- Braham, J.; Bressani, R. Coffee Pulp: Composition, Technology, and Utilization; IDRC: Ottawa, ON, Canada, 1979. [Google Scholar]

- San Martin Ruiz, M.; Reiser, M.; Hafner, G.; Kranert, M. A Study about Methane Emissions from Different Composting Systems for Coffee By-products on Costa Rica. Environ. Ecol. Res. 2018, 6, 461–470. [Google Scholar] [CrossRef]

- Chala, B.; Oechsner, H.; Latif, S.; Müller, J. Biogas Potential of Coffee Processing Waste in Ethiopia. Sustainability 2018, 10, 2678. [Google Scholar] [CrossRef]

- Beyene, A.; Kassahun, Y.; Addis, T.; Assefa, F.; Amsalu, A.; Legesse, W.; Kloos, H.; Triest, L. The impact of traditional coffee processing on river water quality in Ethiopia and the urgency of adopting sound environmental practices. Environ. Monit. Assess. 2011, 184, 7053–7063. [Google Scholar] [CrossRef]

- Desai, N.M.; Varun, E.; Patil, S.; Pimpley, V.; Murthy, P.S. Environment Pollutants During Coffee Processing and Its Valorization BT. In Handbook of Environmental Materials Management; Hussain, C.M., Ed.; Springer International Publishing: Cham, Switzerland, 2020; pp. 1–13. [Google Scholar]

- Misra, R.V.; Roy, R.N.; Hiraoka, H.; Food and Agriculture Organisation of the United Nations. FAO On-farm com-posting methods, Composting Methods and Techniques, Rome. 2003. Available online: http://www.fao.org/docrep/007/y5104e/y5104e05.htm (accessed on 17 February 2021).

- Sánchez, A.; Artola, A.; Font, X.; Gea, T.; Barrena, R.; Gabriel, D.; Sánchez-Monedero, M.Á.; Roig, A.; Cayuela, M.L.; Mondini, C. Greenhouse Gas from Organic Waste Composting: Emissions and Measurement. In CO2 Sequestration, Biofuels and Depollution. Environmental Chemistry for a Sustainable World; Lichtfouse, E., Schwarzbauer, J., Robert, D., Eds.; Springer: Cham, Switzerland, 2015; Volume 5. [Google Scholar] [CrossRef]

- Diaz, L.F.; De Bertoldi, M.; Bidlingmaier, W. Compost Science and Technology; Elsevier: Amsterdam, The Netherlands, 2007. [Google Scholar]

- Haug, R.T. The Practical Handbook of Compost Engineering, 1st ed.; Lewis Publishers: Atascadero, CA, USA, 1993. [Google Scholar]

- Shemekite, F.; Gómez-Brandón, M.; Franke-Whittle, I.H.; Praehauser, B.; Insam, H.; Assefa, F. Coffee husk composting: An investigation of the process using molecular and non-molecular tools. Waste Manag. 2014, 34, 642–652. [Google Scholar] [CrossRef]

- VDI Guideline: Emission Control Mechnical-Biological Treatment Facilities for Municipal Solid Waste; VDI 3475 Part 3; Beuth Verlag GmbH: Berlin, Germany, 2006.

- Kranert, M. Einführung in die Kreislaufwirtschaft: Planung-Recht-Verfahren; Springer: Vieweg, Wiesbaden, 2017. [Google Scholar]

- Shilev, S.; Naydenov, M.; Vancheva, V.; Aladjadjiyan, A. Composting of Food and Agricultural Wastes. In Utilization of By-Products and Treatment of Waste in the Food Industry; Springer: Berlin, Germany, 2006; pp. 283–301. [Google Scholar]

- Ghazifard, A.; Kasra-Kermanshahi, R.; Far, Z.E. Identification of thermophilic and mesophilic bacteria and fungi in Esfahan (Iran) municipal solid waste compost. Waste Manag. Res. 2001, 19, 257–261. [Google Scholar] [CrossRef]

- Azim, K.; Soudi, B.; Boukhari, S.; Perissol, C.; Roussos, S.; Alami, I.T. Composting parameters and compost quality: A literature review. Org. Agric. 2018, 8, 141–158. [Google Scholar] [CrossRef]

- IVillar, I.; Alves, D.; Garrido, J.; Mato, S. Evolution of microbial dynamics during the maturation phase of the composting of different types of waste. Waste Manag. 2016, 54, 83–92. [Google Scholar] [CrossRef]

- Zhu-Barker, X.; Bailey, S.K.; Paw, U.K.T.; Burger, M.; Horwath, W.R. Greenhouse gas emissions from green waste composting windrow. Waste Manag. 2017, 59, 70–79. [Google Scholar] [CrossRef]

- VDI Guideline: Emission Control Biological Waste Treatment Facilities Composting and Anaerobic Digestion Plant Capacities More Than Approx. 6; VDI 3575 Part 1; Beuth Verlag GmbH: Berlin, Germany, 2003.

- Sánchez, A.; Artola, A.; Font, X.; Gea, T.; Barrena, R.; Gabriel, D.; Sanchez-Monedero, M.A.; Roig, A.; Cayuela, M.L.; Mondini, C. Greenhouse gas emissions from organic waste composting. Environ. Chem. Lett. 2015, 13, 223–238. [Google Scholar] [CrossRef]

- Díaz, M.V.; Prada, P.; Mondragon, M. Optimización del proceso de compostaje de productos post-cosecha (cereza) del café con la aplicación de microorganismos nativos. Nova 2010, 8, 214. [Google Scholar] [CrossRef]

- Muzaifa, M.; Rahmi, F.; Syarifudin. Utilization of Coffee By-Products as Profitable Foods—A Mini Review. IOP Conf. Ser. Earth Environ. Sci. 2021, 672, 012077. [Google Scholar] [CrossRef]

- Ijanu, E.M.; Kamaruddin, M.A.; Norashiddin, F.A. Coffee processing wastewater treatment: A critical review on current treatment technologies with a proposed alternative. Appl. Water Sci. 2019, 10, 11. [Google Scholar] [CrossRef]

- Duong, B.; Marraccini, P.; Maeght, J.-L.; Vaast, P.; Lebrun, M.; Duponnois, R. Coffee Microbiota and Its Potential Use in Sustainable Crop Management. A Review. Front. Sustain. Food Syst. 2020, 4, 237. [Google Scholar] [CrossRef]

- Government of Costa Rica. National Decarbonization Plan, Costa Rica. 2019. Available online: https://unfccc.int/sites/default/files/resource/NationalDecarbonizationPlan.pdf (accessed on 16 February 2021).

- Moldvaer, A. Coffee Obsession, 1st ed.; Dorling Kindersley Limited: London, UK, 2014. [Google Scholar]

- San Martin Ruiz, M.; Reiser, M.; Kranert, M. Enhanced composting as a way to a climate-friendly management of coffee by-products. Environ. Sci. Pollut. Res. 2020, 27, 24312–24319. [Google Scholar] [CrossRef]

- SEPSA. Costa Rica. Equivalencias, Rendimientos, Pesos y Factores de Conversión Utilizados en Algunos Productos Agro-pecuarios. SEPSA, 2017. Available online: http://www.infoagro.go.cr/BEA/BEA24/BEA24/img_superficie_produccion/superficie_produccion_17.pdf (accessed on 16 February 2021).

- Ramírez, S.M.; Ballestero, Y.Q. Boletín Estadístico Agropecuario №29 |Serie Cronológica 2015–2018, Costa Rica. 2019. Available online: http://www.mag.go.cr/bibliotecavirtual/BEA-0029.PDF (accessed on 16 February 2021).

- BGK. Qualitätsmanagement-Handbuch (QMH), RAL-Gütesicherung Kompost (RAL-GZ 251). In QM-Handbuch Kompost; BGK- Bundesgütegemeinschaft Kompost e.V: Köln, Germany, 2017; p. 45. [Google Scholar]

- Hermann Sewering: Technisches Datenblatt · Multitec 540; Hermann Sewerin GmbH: Gütersloh, Germany, 2012.

- Bidlingmaier, W. Methods Book for the Analysis of Compost, 3rd ed.; Federal Compost Quality Assurance Organisation (FCQAO) Bundesgütegemeinschaft Kompost e.V. (BGK): Köln, Germany, 2003. [Google Scholar]

- VDI Guideline: Emission Control Facilities for Biological Waste Composting an Anaerobic (Co-)Digestion Plant Capacities up to Approx 6000 Mg/a A; VDI 3475 Part 2; Beuth Verlag GmbH: Berlin, Germany, 2005.

- VDI Guideline: Olfactometry Static Sampling; VDI 3880; Beuth Verlag GmbH: Berlin, Germany, 2011.

- Clauß, T.; Reinelt, T.; Vesenmaier, A.; Flandorfer, C.; Reiser, M.; Ottner, R.; Huber-Humer, M.; Flandorfer, C.; Stenzel, C.; Piringer, M.; et al. Recommendations for Reliable Methane Emission Rate Quantification at Biogas Plants; Deutsches Bio-masseforschungszentrum gemeinnützige GmbH: Leipzig, Germany, 2019. [Google Scholar]

- Liebetrau, J.; Reinelt, T.; Clemens, J.; Hafermann, C.; Friehe, J.; Weiland, P. Analysis of greenhouse gas emissions from 10 biogas plants within the agricultural sector. Water Sci. Technol. 2013, 67, 1370–1379. [Google Scholar] [CrossRef]

- Taiwo, L.B.; Oso, B.A. Influence of composting techniques on microbial succession, temperature and pH in a composting municipal solid waste. Afr. J. Biotechnol. 2004, 3, 239–243. [Google Scholar]

- Miyatake, F.; Iwabuchi, K. Effect of compost temperature on oxygen uptake rate, specific growth rate and enzymatic activity of microorganisms in dairy cattle manure. Bioresour. Technol. 2006, 97, 961–965. [Google Scholar] [CrossRef]

- Inserra, R.N.; Hampton, M.O.; Schubert, T.S.; Stanley, J.D.; Brodie, M.W.; Bannon, J.H.O. Guidelines for compost sanitation. Proc. Soil Crop Sci. Soc. Florida 2006, 65, 31–37. [Google Scholar]

- Jenkins, J. Sanitation by Composting, United States. 2011. Available online: https://humanurehandbook.com/downloads/Compost_Sanitation_Paper_9_2011.pdf (accessed on 22 April 2019).

- MHimanen, M.; Hänninen, K. Composting of Bio-Waste, Aerobic and Anaerobic Sludges–Effect of Feedstock on the Process and Quality of Compost. Bioresour. Technol. 2010, 102, 2842–2852. [Google Scholar] [CrossRef]

- Richard, T.; Hamelers, H.; Veeken, A.; Silva, T. Moisture Relationships in Composting Processes. Compos. Sci. Util. 2002, 10, 286–302. [Google Scholar] [CrossRef]

- Richard, T.L.; Veeken, A.H.M.; De Wilde, V.; Hamelers, H. Air-Filled Porosity and Permeability Relationships during Solid-State Fermentation. Biotechnol. Prog. 2004, 20, 1372–1381. [Google Scholar] [CrossRef]

- Liang, C.; Das, K.; McClendon, R. The influence of temperature and moisture contents regimes on the aerobic microbial activity of a biosolids composting blend. Bioresour. Technol. 2003, 86, 131–137. [Google Scholar] [CrossRef]

- Kim, E.; Lee, D.-H.; Won, S.; Ahn, H. Evaluation of Optimum Moisture Content for Composting of Beef Manure and Bedding Material Mixtures Using Oxygen Uptake Measurement. Asian-Australas. J. Anim. Sci. 2016, 29, 753–758. [Google Scholar] [CrossRef] [PubMed]

- Sundberg, C. Low pH as an inhibiting factor in the transition from mesophilic to thermophilic phase in composting. Bioresour. Technol. 2004, 95, 145–150. [Google Scholar] [CrossRef] [PubMed]

- Burg, P.; Zemánek, P.; Michálek, M. Evaluating of selected parameters of composting process by composting of grape pomace. Acta Univ. Agric. Silvic. Mendel. Brun. 2014, 59, 75–80. Available online: https://acta.mendelu.cz/media/pdf/actaun_2011059060075.pdf (accessed on 23 April 2019). [CrossRef]

- Sundberg, C. Improving Compost Process Efficiency by Controlling Aeration, Temperature and pH. Ph.D. Thesis, Swedish University of Agricultural Sciences, Uppsala, Sweden, 2005. [Google Scholar]

- Sánchez-Monedero, M.; Roig, A.; Paredes, C.; Bernal, M.P. Nitrogen transformation during organic waste composting by the Rutgers system and its effects on pH, EC and maturity of the composting mixtures. Bioresour. Technol. 2001, 78, 301–308. [Google Scholar] [CrossRef]

- Suler, D.J.; Finstein, M.S. Effect of Temperature, Aeration, and Moisture on CO2 Formation in Bench-Scale, Continuously Thermophilic Composting of Solid Waste. Appl. Environ. Microbiol. 1977, 33, 345–350. [Google Scholar] [CrossRef] [PubMed]

- Yeo, D.; Dongo, K.; Mertenat, A.; Lüssenhop, P.; Körner, I.; Zurbrügg, C. Material Flows and Greenhouse Gas Emissions Reduction Potential of Decentralized Composting in Sub-Saharan Africa: A Case Study in Tiassalé, Côte d’Ivoire. Int. J. Environ. Res. Public Heal. 2020, 17, 7229. [Google Scholar] [CrossRef] [PubMed]

- Zoca, S.M.; Penn, C.J.; Rosolem, C.A.; Alves, A.R.; Neto, L.O.; Martins, M.M. Coffee processing residues as a soil potassium amendment. Int. J. Recycl. Org. Waste Agric. 2014, 3, 155–165. [Google Scholar] [CrossRef]

- Beck-Friis, B.; Smårs, S.; Jónsson, H.; Eklind, Y.; Kirchmann, H. Composting of Source-Separated Household Organics At Different Oxygen Levels: Gaining an Understanding of the Emission Dynamics. Compos. Sci. Util. 2003, 11, 41–50. [Google Scholar] [CrossRef]

- Roy, R.N.; Finck, A.; Blair, G.J.; Tandon, H.L.S. Plant Nutrition for Food Security. A Guide for Integrated Nutrient Management. In Fertilizer and Plant Nutrition Bulletin 16; FAO, Ed.; Food and Agricultural Organization of United Nations: Rome, Italy, 2006; p. 348. [Google Scholar]

- Tong, J.; Sun, X.; Li, S.; Qu, B.; Wan, L. Reutilization of Green Waste as Compost for Soil Improvement in the Afforested Land of the Beijing Plain. Sustainability 2018, 10, 2376. [Google Scholar] [CrossRef]

- Gondek, M.; Weindorf, D.C.; Thiel, C.; Kleinheinz, G. Soluble Salts in Compost and Their Effects on Soil and Plants: A Review. Compos. Sci. Util. 2020, 28, 59–75. [Google Scholar] [CrossRef]

- Nzeyimana, I.; Hartemink, A.E.; de Graaff, J. Coffee Farming and Soil Management in Rwanda. Outlook Agric. 2013, 42, 47–52. [Google Scholar] [CrossRef]

- Senbayram, M.; Gransee, A.; Wahle, V.; Thiel, H. Role of magnesium fertilisers in agriculture: Plant–soil continuum. Crop. Pasture Sci. 2015, 66, 1219–1229. [Google Scholar] [CrossRef]

- Paradelo, R.; Devesa-Rey, R.; Cancelo-González, J.; Basanta, R.; Peña, M.; Diaz-Fierros, F.; Barral, M.T. Effect of a compost mulch on seed germination and plant growth in a burnt forest soil from NW Spain. J. Soil Sci. Plant Nutr. 2012, 12, 73–86. [Google Scholar] [CrossRef][Green Version]

- Hao, X.; Benke, M.B. Nitrogen Transformation and Losses during Composting and Mitigation Strategies; Global Science Books: Isleworth, UK, 2008. [Google Scholar]

- Taconi, K.A.; Zappi, M.E.; French, W.T.; Brown, L.R. Methanogenesis under acidic pH conditions in a semi-continuous reactor system. Bioresour. Technol. 2008, 99, 8075–8081. [Google Scholar] [CrossRef] [PubMed]

- Ermolaev, E.; Sundberg, C.; Pell, M.; Smårs, S.; Jönsson, H. Effects of moisture on emissions of methane, nitrous oxide and carbon dioxide from food and garden waste composting. J. Clean. Prod. 2019, 240, 118165. [Google Scholar] [CrossRef]

- Jiang, T.; Schuchardt, F.; Li, G.; Guo, R.; Zhao, Y. Effect of C/N ratio, aeration rate and moisture content on ammonia and greenhouse gas emission during the composting. J. Environ. Sci. 2011, 23, 1754–1760. [Google Scholar] [CrossRef]

- Jäckel, U.; Thummes, K.; Kämpfer, P. Thermophilic methane production and oxidation in compost. FEMS Microbiol. Ecol. 2005, 52, 175–184. [Google Scholar] [CrossRef] [PubMed]

- IMN. Factores de Emisión Gases Efecto Invernadero, San José, Costa Rica. 2020. Available online: http://cglobal.imn.ac.cr/index.php/publications/factores-de-emision-gei-decima-edicion-2020/ (accessed on 10 February 2021).

- IPCC. Volume 5 Waste-Chapter 4 Biological Treatment of Solid Waste, 2006 IPPC Guidel. National Greenhouse Gas Inventories. 2006, pp. 4.1–4.8. Available online: http://www.ipcc-nggip.iges.or.jp/public/2006gl/vol5.html (accessed on 5 February 2021).

- ARB. Air Resources Board (ARB): Method for Estimating Greenhouse Gas Emission Reduction from Diversion of Organic Waste from Landfills to Compost Facilities. 2017. Available online: https://ww2.arb.ca.gov/sites/default/files/classic/cc/waste/cerffinal.pdf (accessed on 18 February 2021).

| Treatment | Windrow Percentage Based on Volume | Total CP in Mg per Treatment | Total Number of Windrows | Total of Fanegas per Treatment ** |

|---|---|---|---|---|

| T1 | 80% CP–20% GW | 98.54 | 7 | 937 |

| T2 | 75% CP–25% GW | 36.95 | 3 | 351 |

| T3 | 70% CP–30% GW | 49.27 | 4 | 468 |

| T4 | 60% CP–40 % GW | 18.48 | 2 | 176 |

| T5 | 50% CP–50% GW | 9.24 | 1 | 88 |

| TC | 100% CP (Control) | 105.58 | 6 | 1004 |

| Parameters | MC (%) | pH | CE (mscm 1) | C/N | VS (%) DM * | C (%) | N (%) | P (%) | K (%) | Ƿt g/L |

|---|---|---|---|---|---|---|---|---|---|---|

| SM 1 | 55 | 6.2 | 2.7 | 59.3 | 77.2 | 47 | 0.8 | 0.08 | 0.7 | 95.4 |

| CP 2 | 82 | 4.9 | 3.9 | 16.1 | 94.76 | 44 | 2.3 | 0.11 | 3.17 | 432 |

| DGW 3 | 7.9 | 7 | 5.8 | 35 | 91.27 | 38 | 1.1 | 0.39 | 2.5 | 31.4 |

| Parameters | Units | TC | T1 | T2 | T3 | T4 | T5 |

|---|---|---|---|---|---|---|---|

| Plant Nutrients | |||||||

| Total Nitrogen (N) | % * | 1.61 | 1.14 | 1.06 | 1.37 | 1.36 | 1.31 |

| Total Phosphate (P2O5) | % * | 0.59 | 0.44 | 0.46 | 0.46 | 0.44 | 0.47 |

| Total Potassium (K2O) | % * | 4.28 | 2.95 | 2.87 | 3.19 | 2.96 | 2.93 |

| Total Magnesium (MgO) | % * | 0.36 | 0.29 | 0.36 | 0.35 | 0.33 | 0.33 |

| Nitrate CaCl2-soluble (NO3-N) | mg/L ** | 8 | 114 | 128 | 103 | 276 | 162 |

| Ammonia CaCl2-soluble (NH4-N) | mg/L ** | 45 | 40 | 22 | 23 | 66 | 108 |

| Phosphate CaCl2-soluble (P2O5) 1 | mg/L ** | 298 | 133 | 150 | 122 | 65 | 51 |

| Potassium CaCl2-soluble (K2O) | mg/L ** | 10,700 | 10,900 | 11,400 | 9750 | 9920 | 10,400 |

| Soil Amendment | |||||||

| Organic Substances | % * | 60.4 | 43.9 | 37.5 | 47.3 | 45.1 | 40.4 |

| Alkaline Active Ingredients (CaO) | % * | 2.4 | 2.31 | 2.25 | 2.69 | 2.28 | 2.18 |

| Magnesium CaCl2-soluble | mg/L ** | 19 | 27 | 44 | 30 | 48 | 43 |

| Physical Parameters | |||||||

| Degree of Rotting | - | 3 | 4 | 4 | 5 | 5 | 5 |

| Salinity | g KCl/L ** | 5.97 | 5.14 | 3.96 | 3.76 | 4.53 | 3.68 |

| Bulk density | g/L ** | 345 | 502 | 520 | 414 | 464 | 504 |

| PC 1 50% Substrate | % * | 75 | 97 | 95 | 103 | 100 | 102 |

| PC 25% Substrate | % * | 52 | 82 | 90 | 87 | 88 | 95 |

| C/N Ratio | - | 22 | 22 | 21 | 20 | 19 | 18 |

| Treatment | EF (g CH4/kg CP) | EF (g CH4/kg Input) | SD * |

|---|---|---|---|

| T1 | 43.9 | 35.1 | 0.23 |

| T2 | 14.4 | 10.8 | 0.17 |

| T3 | 20 | 14 | 0.23 |

| T4 | 23.4 | 14 | 0.24 |

| T5 | 11.6 | 5.8 | 0.14 |

| TC | 129 | 129 | 2.96 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

San Martin Ruiz, M.; Reiser, M.; Kranert, M. Composting and Methane Emissions of Coffee By-Products. Atmosphere 2021, 12, 1153. https://doi.org/10.3390/atmos12091153

San Martin Ruiz M, Reiser M, Kranert M. Composting and Methane Emissions of Coffee By-Products. Atmosphere. 2021; 12(9):1153. https://doi.org/10.3390/atmos12091153

Chicago/Turabian StyleSan Martin Ruiz, Macarena, Martin Reiser, and Martin Kranert. 2021. "Composting and Methane Emissions of Coffee By-Products" Atmosphere 12, no. 9: 1153. https://doi.org/10.3390/atmos12091153

APA StyleSan Martin Ruiz, M., Reiser, M., & Kranert, M. (2021). Composting and Methane Emissions of Coffee By-Products. Atmosphere, 12(9), 1153. https://doi.org/10.3390/atmos12091153