A Method to Generate Experimental Aerosol with Similar Particle Size Distribution to Atmospheric Aerosol

Abstract

:1. Introduction

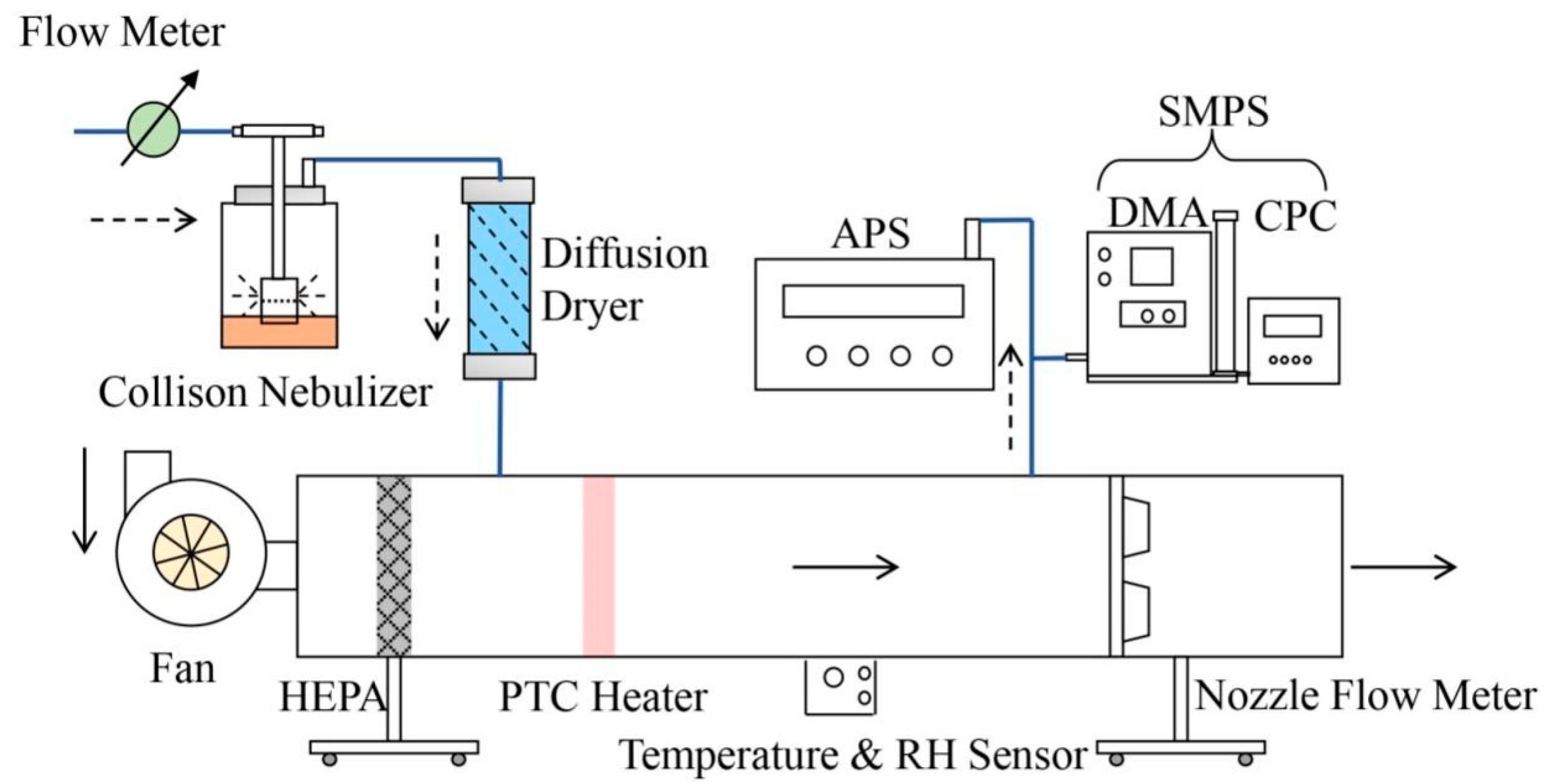

2. Methodology

2.1. Sampling and Instrumentation

2.2. Method to Combine the SMPS and the APS Data

2.3. Statistical Method

3. Results

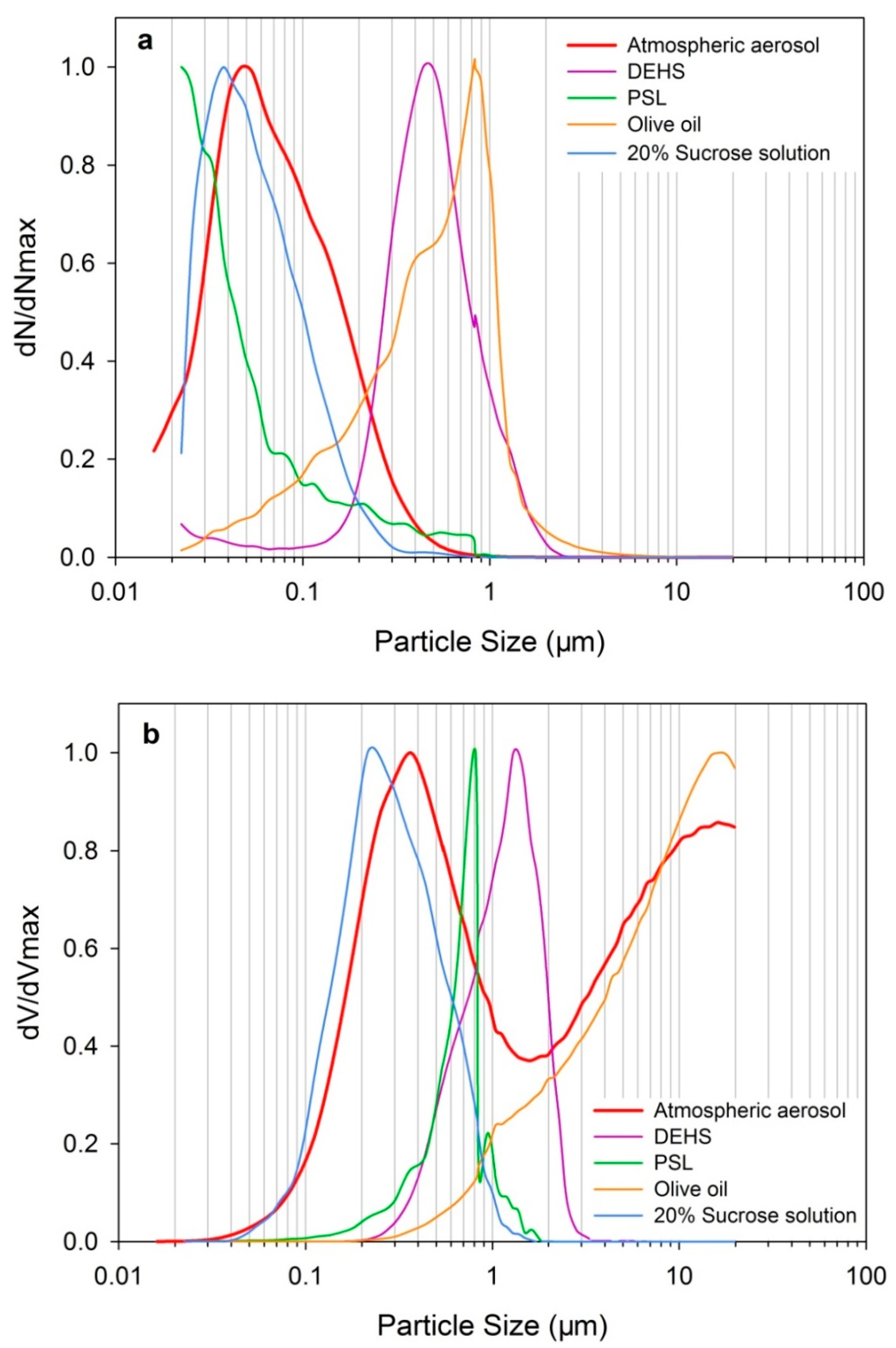

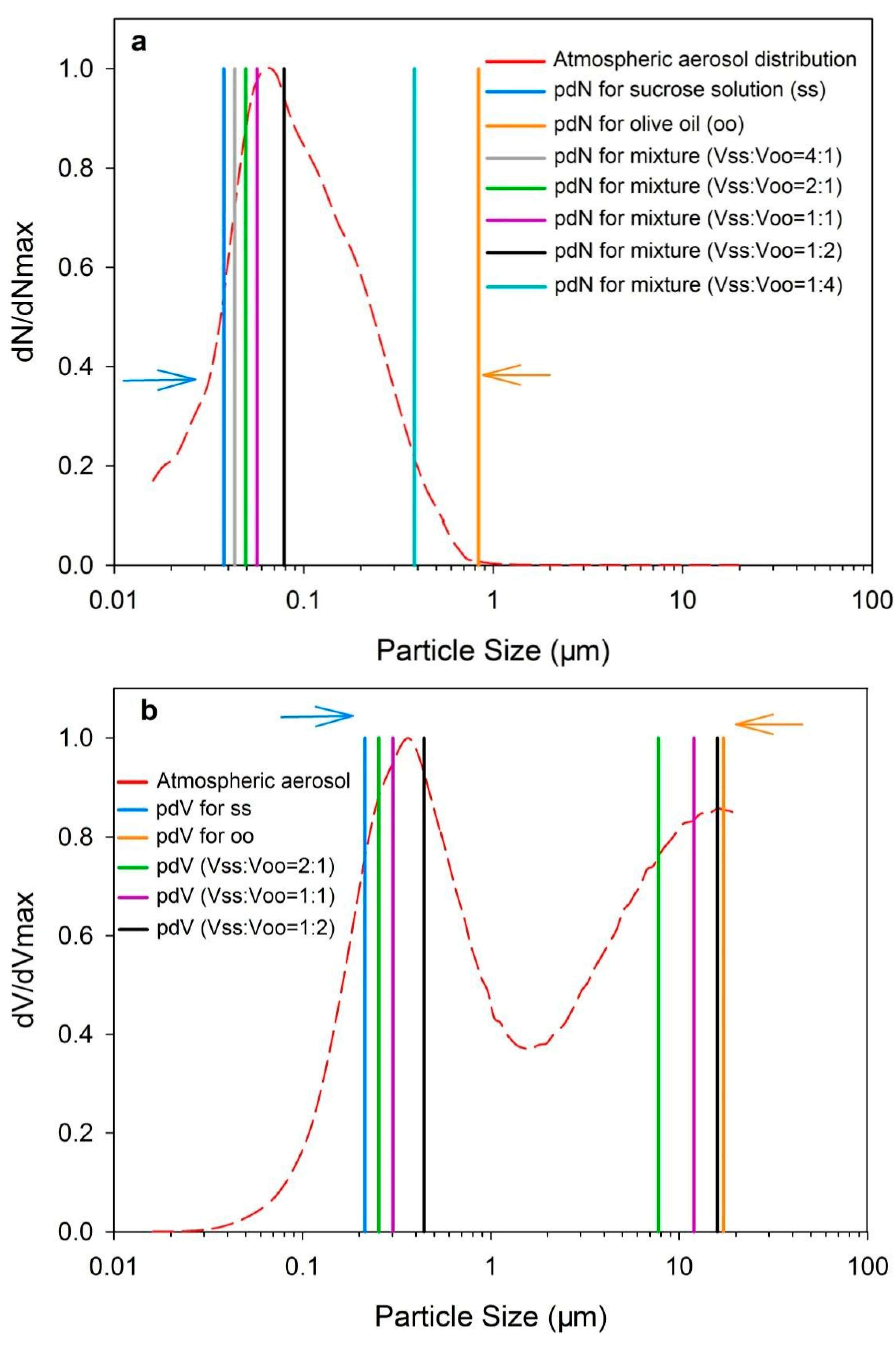

3.1. Comparison of Particle Size Distribution of Experimental Aerosols to Atmospheric Aerosol

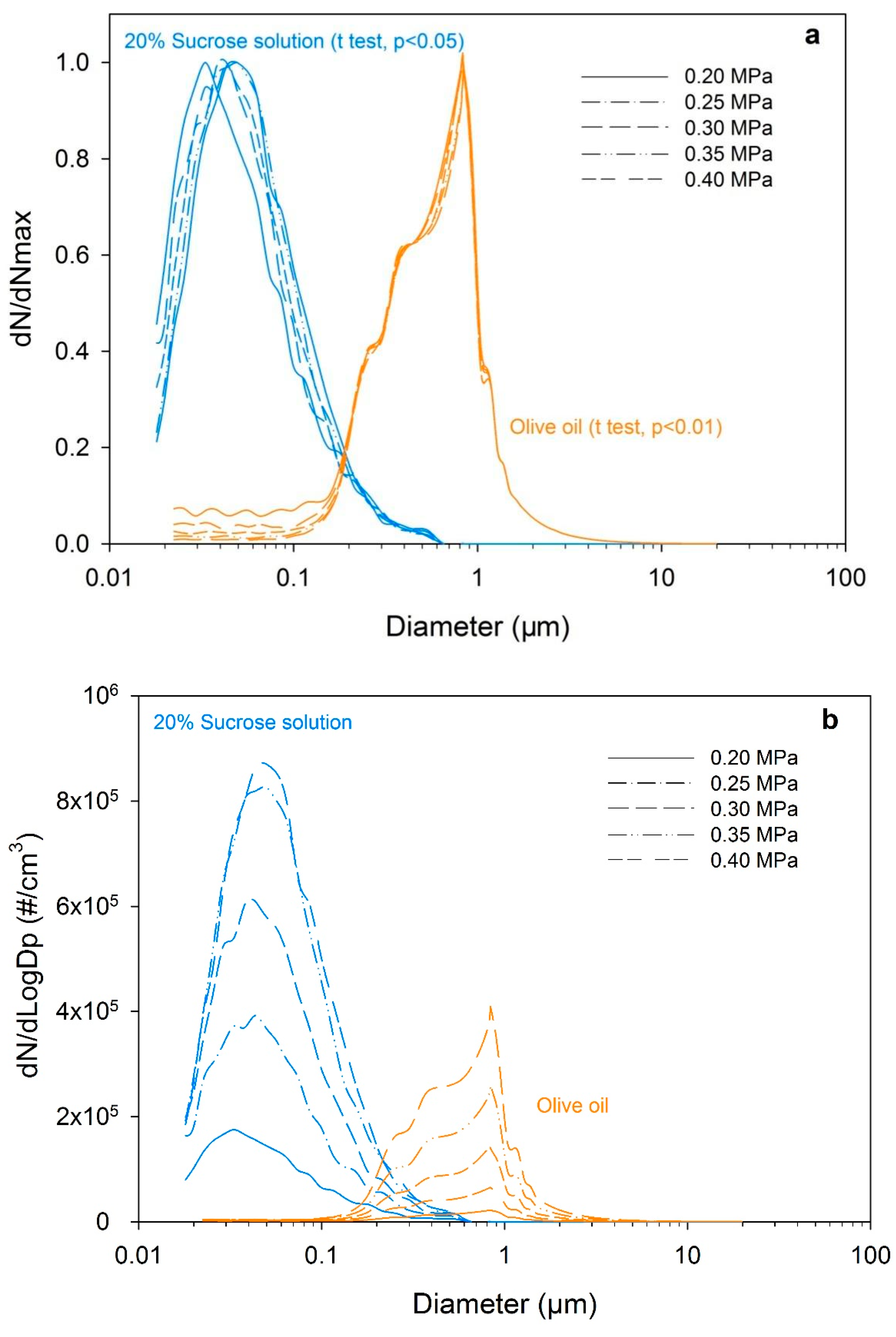

3.2. The Effect of Compressed Air Pressure on Particle Size Distribution

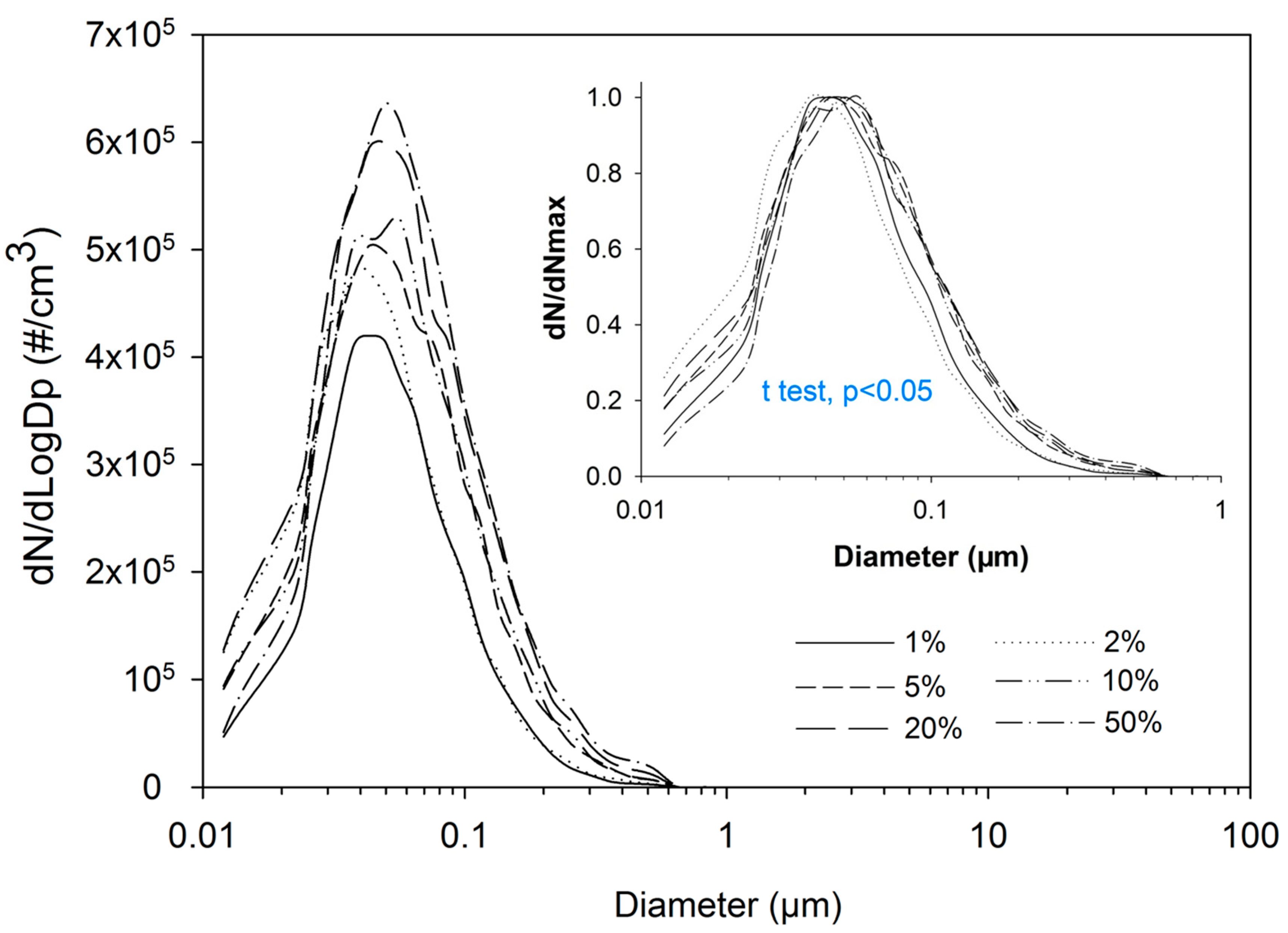

3.3. The Effect of Sucrose Solution’s Concentration on Particle Size Distribution

3.4. The Size Distribution of Particles Generated by Sucrose Solution and Olive Oil Mixture Solution

4. Discussion

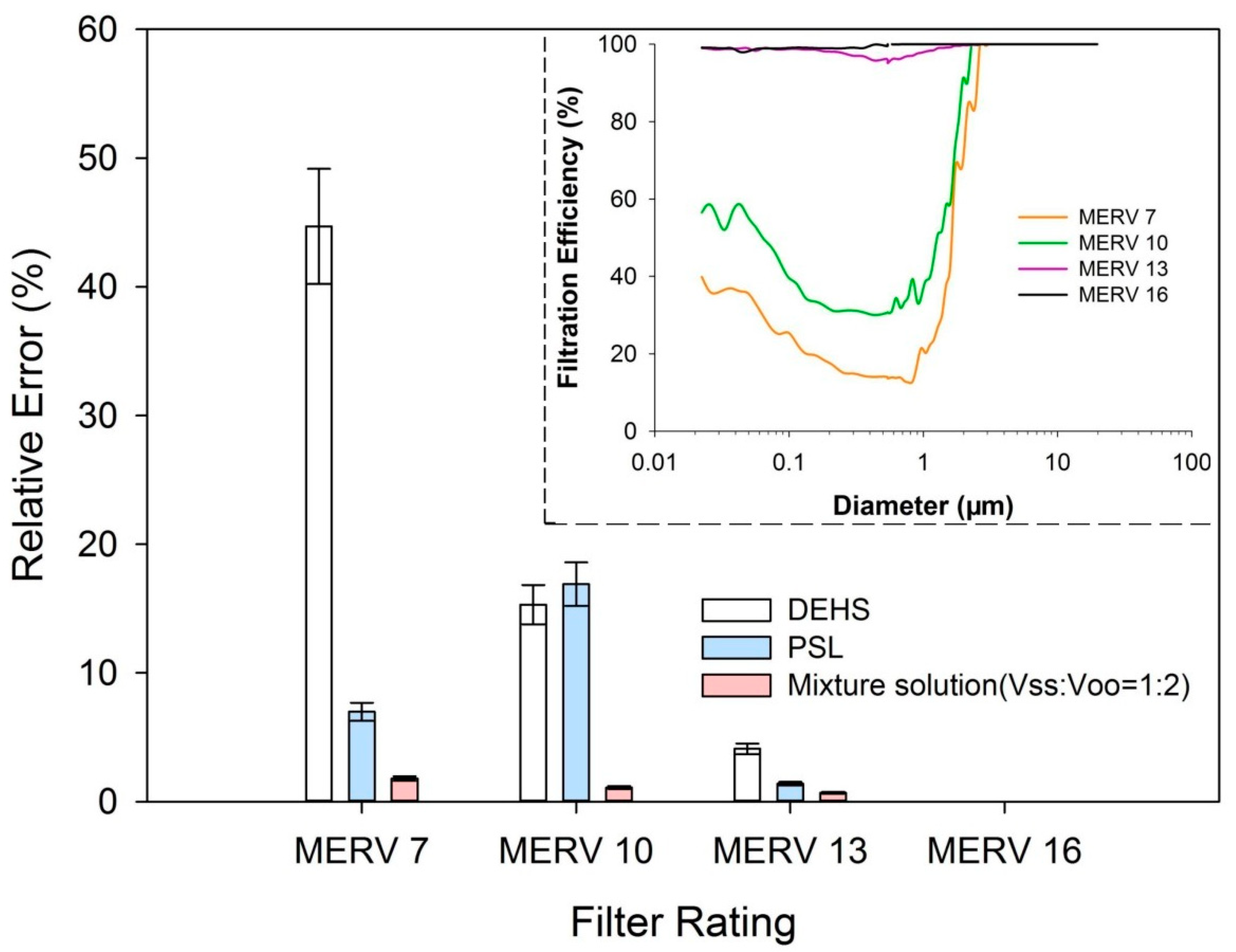

4.1. Mass-Based Filtration Efficiency Measurement

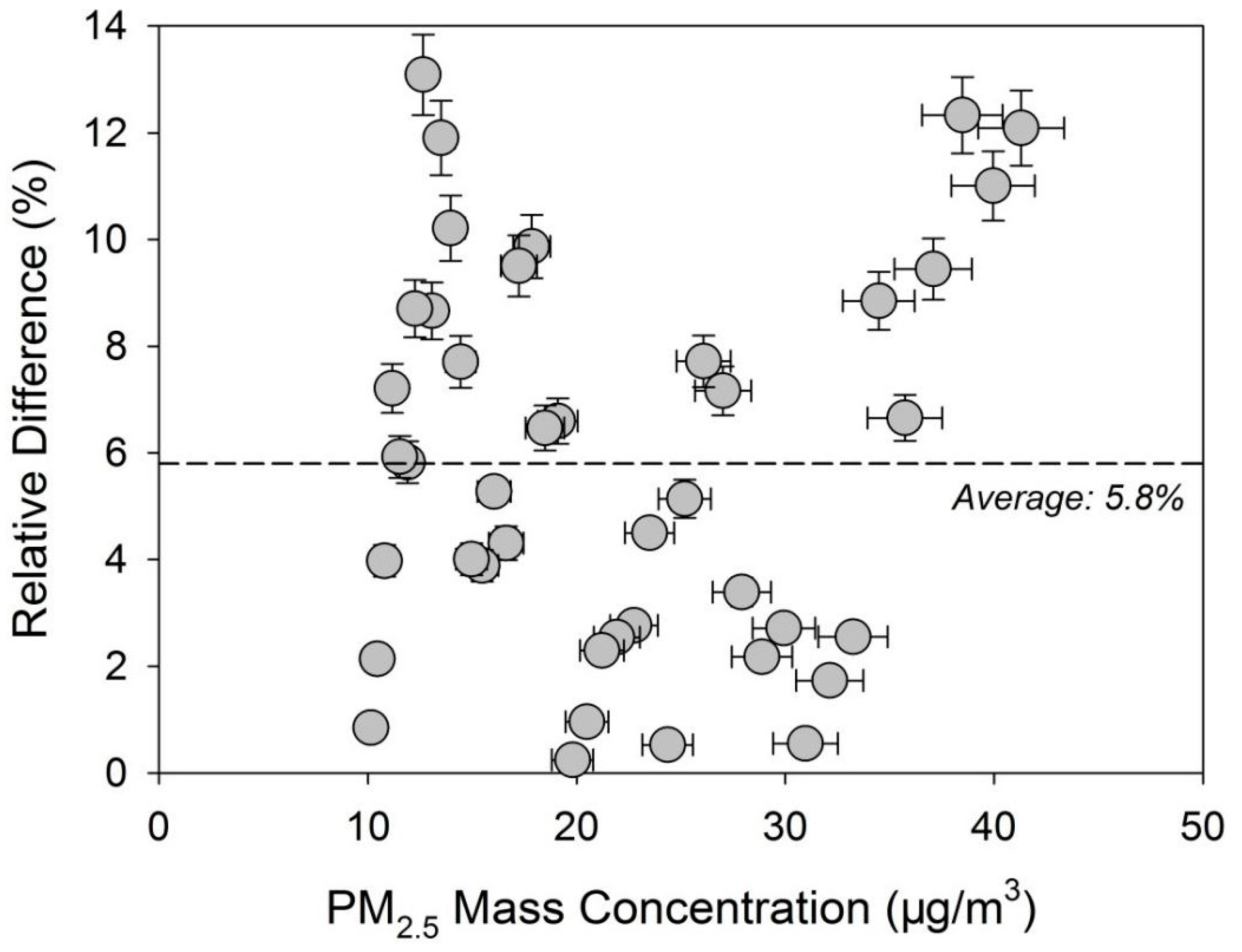

4.2. Instrument Calibration

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Conflicts of Interest

References

- Li, J.; Tartarini, F. Changes in air quality during the COVID-19 lockdown in Singapore and associations with human mobility trends. Aerosol. Air Qual. Res. 2020, 20, 1748–1758. [Google Scholar] [CrossRef]

- Pansini, R.; Fornacca, D. Early Spread of COVID-19 in the Air-Polluted Regions of Eight Severely Affected Countries. Atmosphere 2021, 12, 795. [Google Scholar] [CrossRef]

- Seposo, X.; Ng, C.F.S.; Madaniyazi, L. Immediate and Delayed Meteorological Effects on COVID-19 Time-Varying Infectiousness in Tropical Cities. Atmosphere 2020, 12, 513. [Google Scholar] [CrossRef]

- Kong, X.; Guo, C.; Lin, Z.; Duan, S.; He, J.; Ren, Y.; Ren, J. Experimental study on the control effect of different ventilation systems on fine particles in a simulated hospital ward. Sustain. Cities Soc. 2021, 73, 103102. [Google Scholar] [CrossRef] [PubMed]

- Dong, L.; Chen, B.; Huang, Y.; Song, Z.; Yang, T. Analysis on the Characteristics of Air Pollution in China during the COVID-19 Outbreak. Atmosphere 2021, 12, 205. [Google Scholar] [CrossRef]

- Ai, Z.; Hashimoto, K.; Melikov, A.K. Airborne transmission between room occupants during short-term events: Measurement and evaluation. Indoor Air 2019, 29, 563–576. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Gorbunov, B. Aerosol particles laden with viruses that cause COVID-19 travel over 30 m distance. Preprints 2020, 546, v2. [Google Scholar] [CrossRef]

- Bhaganagar, K.; Bhimireddy, S. Local atmospheric factors that enhance air-borne dispersion of coronavirus-High-fidelity numerical simulation of COVID19 case study in real-time. Environ. Res. 2020, 191, 110170. [Google Scholar] [CrossRef]

- Srivastava, S.; Zhao, X.; Manay, A.; Chen, Q. Effective ventilation and air disinfection system for reducing Coronavirus Disease 2019 (COVID-19) infection risk in office buildings. Sustain. Cities Soc. 2021, 75, 103408. [Google Scholar] [CrossRef] [PubMed]

- Ai, Z.; Melikov, A.K. Airborne spread of expiratory droplet nuclei between the occupants of indoor environments: A review. Indoor Air 2018, 28, 500–524. [Google Scholar] [CrossRef] [PubMed]

- Ai, Z.; Mak, C.M.; Gao, N.; Niu, J. Tracer gas is a suitable surrogate of exhaled droplet nuclei for studying airborne transmission in the built environment. Build. Simul. 2020, 13, 489–496. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Wei, P.; Zhou, B.; Tan, M.; Li, F.; Lu, J.; Dong, Z.; Xiao, Y. Study on thermal comfort under non-uniform thermal environment condition in domestic kitchen. Proc. Eng. 2017, 205, 2041–2048. [Google Scholar] [CrossRef]

- Fisk, W.J. Health benefits of particle filtration. Indoor Air 2013, 23, 357–368. [Google Scholar] [CrossRef] [PubMed]

- Ren, J.; Liu, J.; Cao, X.; Li, F.; Li, J. Ultrafine particles in the cabin of a waiting commercial airliner at Tianjin International Airport, China. Indoor Built. Environ. 2018, 27, 1247–1258. [Google Scholar] [CrossRef]

- Ren, J.; Cao, X.; Liu, J. Impact of atmospheric particulate matter pollutants to IAQ of airport terminal buildings: A first field study at Tianjin Airport, China. Atmos. Environ. 2018, 179, 222–226. [Google Scholar] [CrossRef]

- Punsmann, S.; van der Graaf, T.; Zahradnik, E.; Czibor, C.; Raulf, M.; Sander, I. Effectiveness of a portable air filtration device in reducing allergen exposure during household chores. Allergo J. Int. 2019, 28, 299–307. [Google Scholar] [CrossRef]

- Ren, J.; Tang, M.; Novoselac, A. Experimental study to quantify airborne particle deposition onto and resuspension from clothing using a fluorescent-tracking method. Build. Environ. 2022, 209, 108580. [Google Scholar] [CrossRef]

- Kong, X.; Ren, Y.; Ren, J.; Duan, S.; Guo, C. Energy-saving performance of respiration-type double-layer glass curtain wall system in different climate zones of China: Experiment and simulation. Energ. Build. 2021, 252, 111464. [Google Scholar] [CrossRef]

- Dai, X.; Liu, J.; Li, X.; Zhao, L. Long-term monitoring of indoor CO2 and PM 2.5 in Chinese homes: Concentrations and their relationships with outdoor environments. Build. Environ. 2018, 144, 238–247. [Google Scholar] [CrossRef]

- Ren, J.; Liu, J. Fine particulate matter control performance of a new kind of suspended fan filter unit for use in office buildings. Build. Environ. 2019, 149, 468–476. [Google Scholar] [CrossRef]

- Zhuang, J.; Li, F.; Liu, X.; Cai, H.; Feng, L.; Li, X. An experiment-based impulse response method to characterize airborne pollutant sources in a scaled multi-zone building. Atmos. Environ. 2021, 251, 118272. [Google Scholar] [CrossRef]

- Dai, X.; Liu, J.; Zhang, X. Monte Carlo simulation to control indoor pollutants from indoor and outdoor sources for residential buildings in Tianjin, China. Build. Environ. 2019, 165, 106376. [Google Scholar] [CrossRef]

- Ren, J.; He, J.; Kong, X.; Xu, W.; Kang, Y.; Yu, Z.; Li, H. A field study of CO2 and particulate matter characteristics during the transition season in the subway system in Tianjin, China. Energ. Build. 2022, 254C, 111620. [Google Scholar] [CrossRef]

- Faridi, S.; Brook, R.D.; Hassanvand, M.S.; Nodehi, R.N.; Shamsipour, M.; Tajdini, M.; Sadeghian, S. Cardiovascular health effects of wearing a particulate-filtering respirator to reduce particulate matter exposure: A randomized crossover trial. J. Hum. Hypertens. 2021, 1–11. [Google Scholar] [CrossRef]

- Faridi, S.; Nodehi, R.N.; Sadeghian, S.; Tajdini, M.; Hoseini, M.; Yunesian, M.; Naddafi, K. Can respirator face masks in a developing country reduce exposure to ambient particulate matter? J. Expo. Sci. Env. Epid. 2020, 30, 606–617. [Google Scholar] [CrossRef]

- ISO. ISO 16890-2016, Air Filters for General Ventilation; International Organization for Standardization (ISO): Geneva, Switzerland, 2016. [Google Scholar]

- ASHRAE. ASHRAE 52.2-2012, Method of Testing General Ventilation Air-Cleaning Devices for Removal Efficiency by Particle Size; ASHRAE: Peachtree Corners, GA, USA, 2012. [Google Scholar]

- ISO. ISO 29463-2017, High-Efficiency Filters and Filter Media for Removing Particles in Air; International organization for standardization (ISO): Geneva, Switzerland, 2017. [Google Scholar]

- G.B.T. Chinese. Air Filters Standard (Standard GBT 14295-2008 in Chinese). 2008. Available online: https://www.chinesestandard.net/PDF/English.aspx/GBT14295-2008 (accessed on 12 December 2021).

- Porstendörfer, J.; Röbig, G.; Ahmed, A. Experimental determination of the attachment coefficients of atoms and ions on monodisperse aerosols. J. Aerosol. Sci 1979, 10, 21–28. [Google Scholar] [CrossRef]

- Maricq, M.M.; Xu, N. The effective density and fractal dimension of soot particles from premixed flames and motor vehicle exhaust. J. Aerosol. Sci. 2004, 35, 1251–1274. [Google Scholar] [CrossRef]

- Myers, D.L.; Arnold, B.D. Electrets and filtration: Lab testing and field performance head to head. Filtr. Separat. 2005, 42, 44–49. [Google Scholar] [CrossRef]

- Shao, L.; Cao, Y.; Jones, T.; Santosh, M.; Silva, L.F.; Ge, S.; BéruBé, K. COVID-19 mortality and exposure to airborne PM2.5: A lag time correlation. Sci. Total Environ. 2021, 806, 151286. [Google Scholar] [CrossRef] [PubMed]

- Ren, J.; Wade, M.; Corsi, R.L.; Novoselac, A. Particulate matter in mechanically ventilated high school classrooms. Build. Environ. 2020, 184, 106986. [Google Scholar] [CrossRef]

- Ge, M.; Li, Z.; Wang, Y.; Zhao, Y.; Zhu, Y.; Wang, S.; Liu, L. Experimental study on thermoelectric power generation based on cryogenic liquid cold energy. Energy 2021, 220, 119746. [Google Scholar] [CrossRef]

- Raynor, P.C.; Chae, S.J. Dust loading on electrostatitically charged filters in a standard test and a real HVAC system. Filtr. Separat. 2003, 40, 35–39. [Google Scholar] [CrossRef]

- Waring, M.S.; Siegel, J.A. Particle loading rates for HVAC filters, heat exchangers, and ducts. Indoor Air 2008, 18, 209–224. [Google Scholar] [CrossRef] [PubMed]

- Kim, J.Y.; Magari, S.R.; Herrick, R.F.; Smith, T.J.; Christiani, D.C.; Christiani, D.C. Comparison of fine particle measurements from a direct-reading instrument and a gravimetric sampling method. J. Occup. Environ. Hyg. 2004, 1, 707–715. [Google Scholar] [CrossRef] [PubMed]

- Rivas, I.; Mazaheri, M.; Viana, M.; Moreno, T.; Clifford, S.; He, C.; Bischof, O.F.; Martins, V.; Reche, C.; Alastuey, A.; et al. Identification of technical problems affecting performance of DustTrak DRX aerosol monitors. Sci. Total Environ. 2017, 584, 849–855. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Hinds, W.C. Aerosol Technology: Properties, Behavior, and Measurement of Airborne Particles, 2nd ed.; Wiley: New York, NY, USA, 1999. [Google Scholar]

- Harris, S.; Smith, B. Olive oil tracer particle size analysis for optical flow investigations in a gas medium. In Proceedings of the 67th Annual Meeting of the APS Division of Fluid Dynamics, San Francisco, CA, USA, 23–25 November 2014. [Google Scholar]

- He, M.; Zhang, Y.; Ma, L.; Wang, H.; Fu, P.; Zhao, Z. Study on flow field characteristics in a reverse rotation cyclone with PIV. Chem. Eng. Process 2018, 126, 100–107. [Google Scholar] [CrossRef]

- May, K.R. The collison nebulizer: Description, performance and application. J. Aerosol. Sci. 1973, 4, 235–243. [Google Scholar] [CrossRef]

- Shi, J.P.; Harrison, R.M.; Evans, D. Comparison of ambient particle surface area measurement by epiphaniometer and SMPS/APS. Atmos. Environ. 2001, 35, 6193–6200. [Google Scholar] [CrossRef]

- Molgaard, B.; Koivisto, A.J.; Hussein, T.; Hämeri, K. A new clean air delivery rate test applied to five portable indoor air cleaners. Aerosol. Sci. Tech. 2014, 48, 409–417. [Google Scholar] [CrossRef]

- Khlystov, A.; Stanier, C.; Pandis, S.N. An algorithm for combining electrical mobility and aerodynamic size distributions data when measuring ambient aerosol special issue of aerosol science and technology on findings from the fine particulate matter supersites program. Aerosol. Sci. Tech. 2004, 38, 229–238. [Google Scholar] [CrossRef] [Green Version]

- Sioutas, C. Evaluation of the measurement performance of the scanning mobility particle sizer and aerodynamic particle sizer. Aerosol. Sci. Tech. 1999, 30, 84–92. [Google Scholar] [CrossRef] [Green Version]

- Kulkarni, P.; Baron, P.A.; Willeke, K. Aerosol Measurement: Principles, Techniques, and Applications; John Wiley & Sons: Hoboken, NJ, USA, 2011. [Google Scholar]

- Leoni, C.; Pokorná, P.; Hovorka, J.; Masiol, M.; Topinka, J.; Zhao, Y.; Krumal, K.; Cliff, S.; Mikuska, P.; Hopke, P.K. Source apportionment of aerosol particles at a European air pollution hot spot using particle number size distributions and chemical composition. Environ. Pollut. 2018, 234, 145–154. [Google Scholar] [CrossRef] [PubMed]

- Azimi, P.; Zhao, D.; Stephens, B. Estimates of HVAC filtration efficiency for fine and ultrafine particles of outdoor origin. Atmos. Environ. 2014, 98, 337–346. [Google Scholar] [CrossRef]

- Li, X.; Wang, J.; Tu, X.D.; Liu, W.; Huang, Z. Vertical variations of particle number concentration and size distribution in a street canyon in Shanghai, China. Sci. Total Environ. 2007, 378, 306–316. [Google Scholar] [CrossRef]

- Vu, T.V.; Delgado-Saborit, J.M.; Harrison, R.M. Particle number size distributions from seven major sources and implications for source apportionment studies. Atmos. Environ. 2015, 122, 114–132. [Google Scholar] [CrossRef]

- Stephens, B. Evaluating the sensitivity of the mass-based particle removal calculations for HVAC filters in ISO 16890 to assumptions for aerosol distributions. Atmosphere 2018, 9, 85. [Google Scholar] [CrossRef] [Green Version]

| Aerosol Type or Generated by | ||

|---|---|---|

| Atmospheric | 0.019 (a) | 1.95 (a) |

| 0.066 (b) | 1.85 (b) | |

| 0.134 (c) | 1.85 (c) | |

| DEHS | 0.523 | 1.97 |

| PSL | 0.047 | 2.07 |

| Olive oil | 0.731 | 2.39 |

| 20% sucrose solution | 0.054 | 1.72 |

| 20% sucrose solution + olive oil (Vss:Voo = 1:2) | 0.073 | 2.12 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ren, J.; He, J.; Li, J.; Liu, J. A Method to Generate Experimental Aerosol with Similar Particle Size Distribution to Atmospheric Aerosol. Atmosphere 2021, 12, 1669. https://doi.org/10.3390/atmos12121669

Ren J, He J, Li J, Liu J. A Method to Generate Experimental Aerosol with Similar Particle Size Distribution to Atmospheric Aerosol. Atmosphere. 2021; 12(12):1669. https://doi.org/10.3390/atmos12121669

Chicago/Turabian StyleRen, Jianlin, Junjie He, Jiayu Li, and Junjie Liu. 2021. "A Method to Generate Experimental Aerosol with Similar Particle Size Distribution to Atmospheric Aerosol" Atmosphere 12, no. 12: 1669. https://doi.org/10.3390/atmos12121669

APA StyleRen, J., He, J., Li, J., & Liu, J. (2021). A Method to Generate Experimental Aerosol with Similar Particle Size Distribution to Atmospheric Aerosol. Atmosphere, 12(12), 1669. https://doi.org/10.3390/atmos12121669