Comparison of CFD and Multizone Modeling from Contaminant Migration from a Household Gas Furnace

Abstract

1. Introduction

2. Simulations

- The concentration of contaminants, room pressures, and temperatures are uniform in each zone.

- Transport of contaminants along each flow path between zones is instantaneous.

- The air is still in each zone, so the airflow through zones does not impact zone pressures.

- Wind pressures on a building’s surface are uniform.

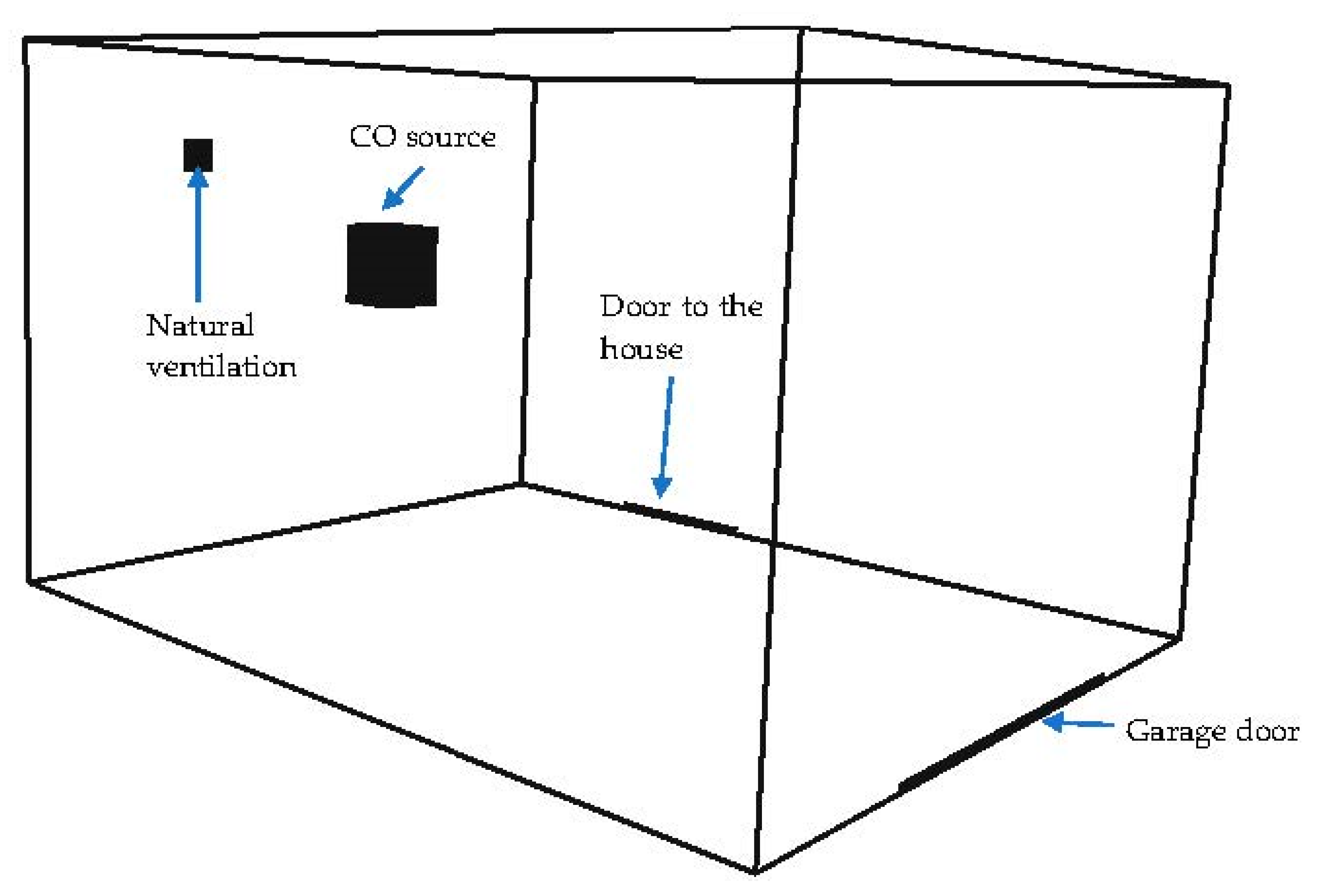

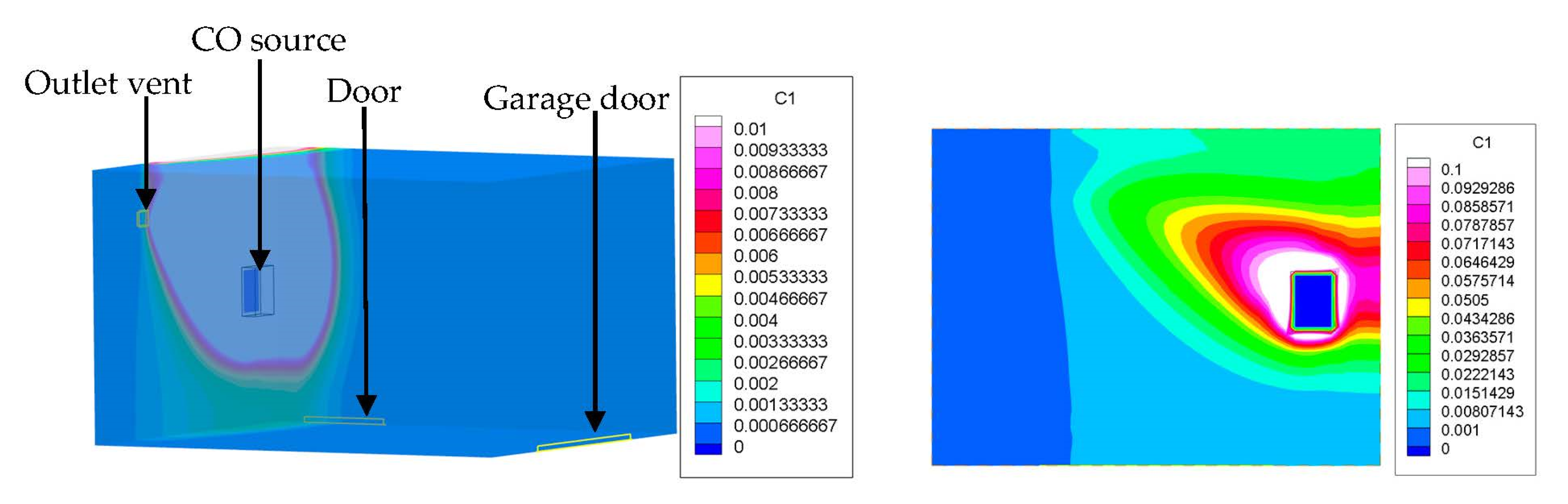

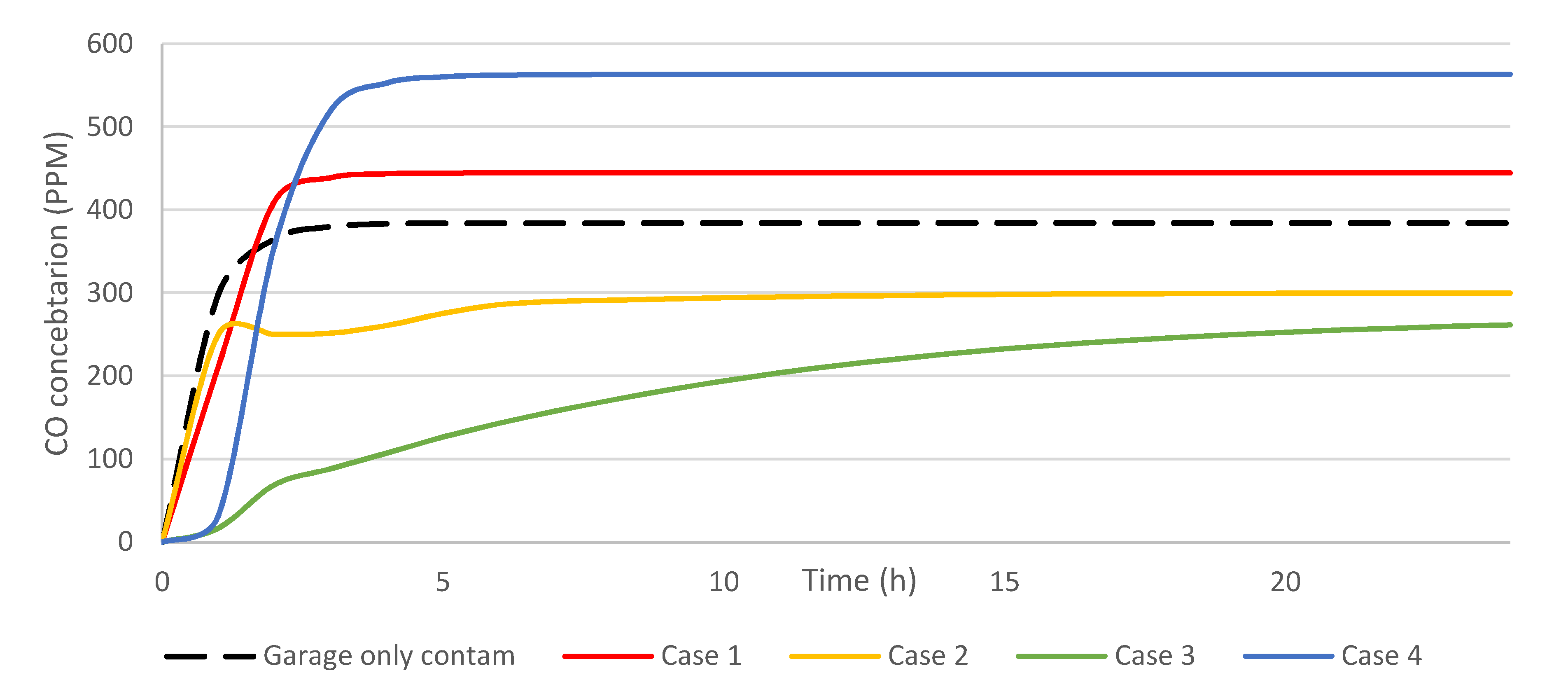

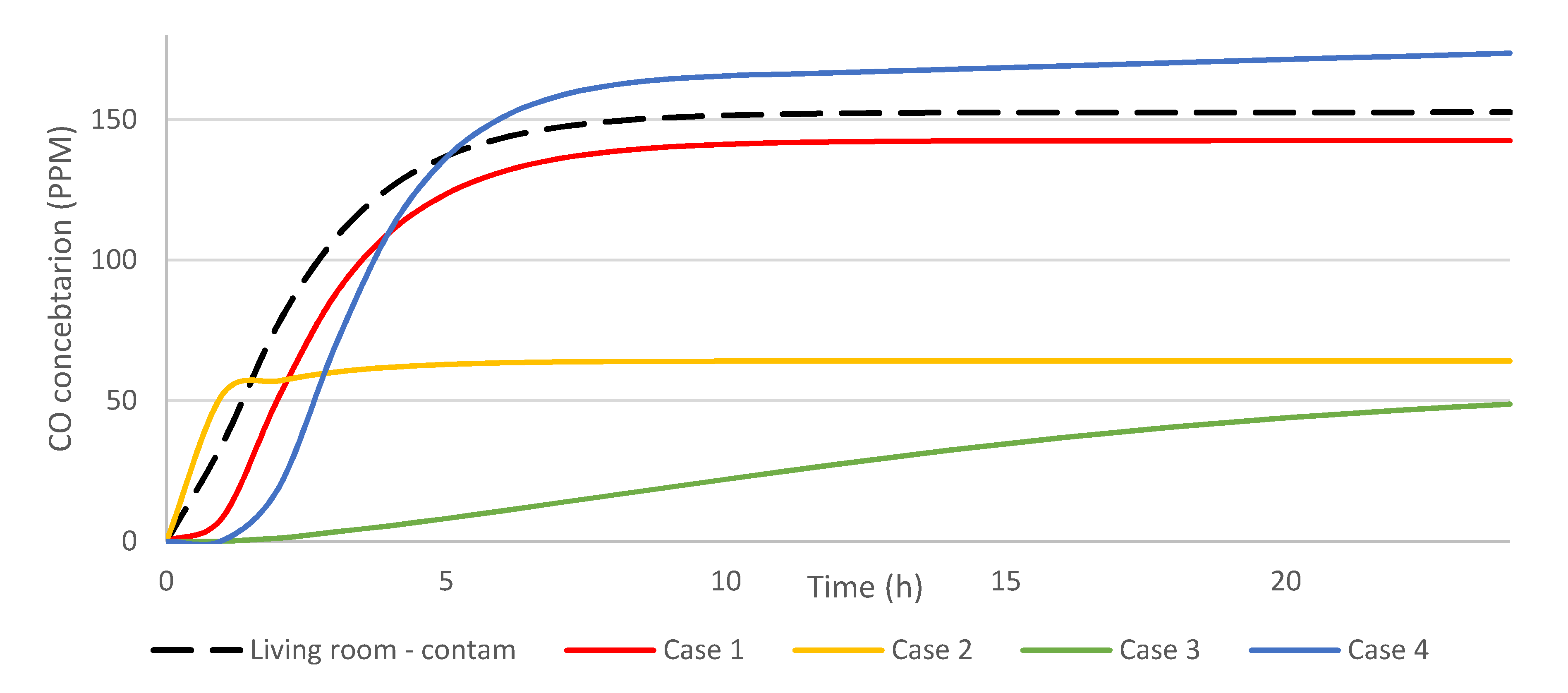

- Case 1: The furnace was on the same wall as the door to the house.

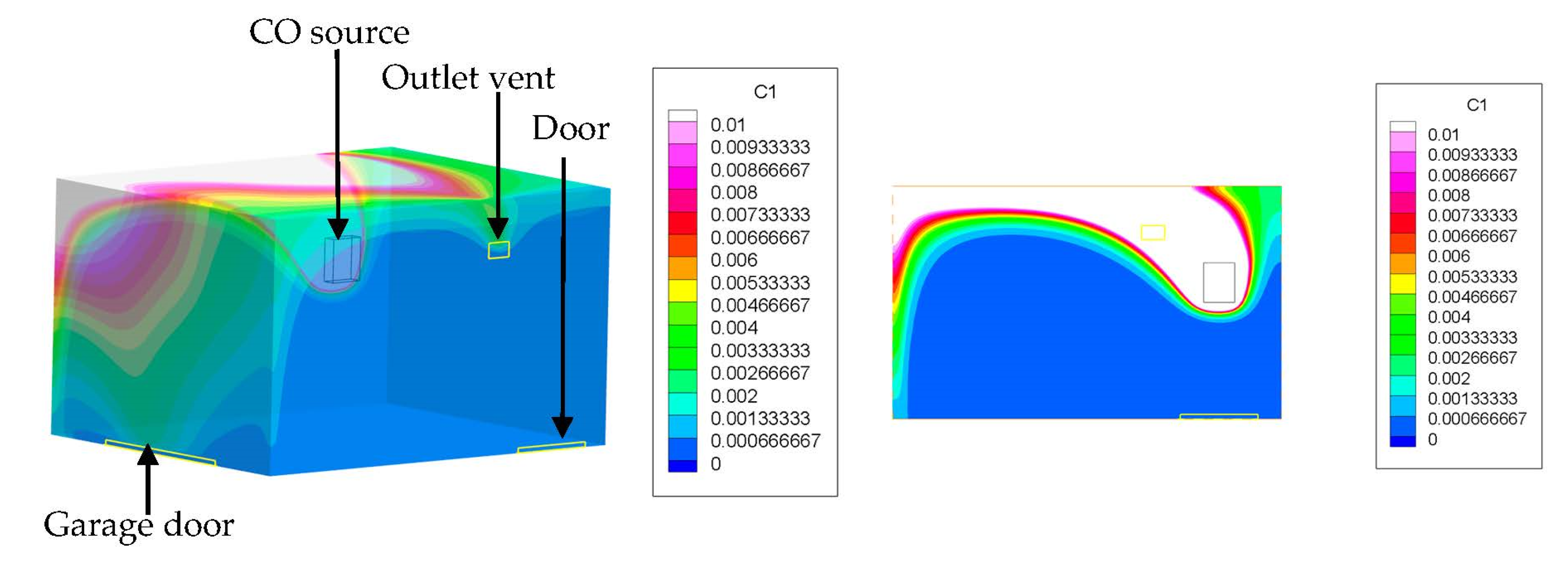

- Case 2: The furnace was on the perpendicular wall in relation to the door to the house (opposite the garage door).

- Case 3: The furnace was on the opposite wall than the door to the house.

- Case 4: The furnace was on the opposite wall than the door to the house, but the outlet vent was on the same wall as the door.

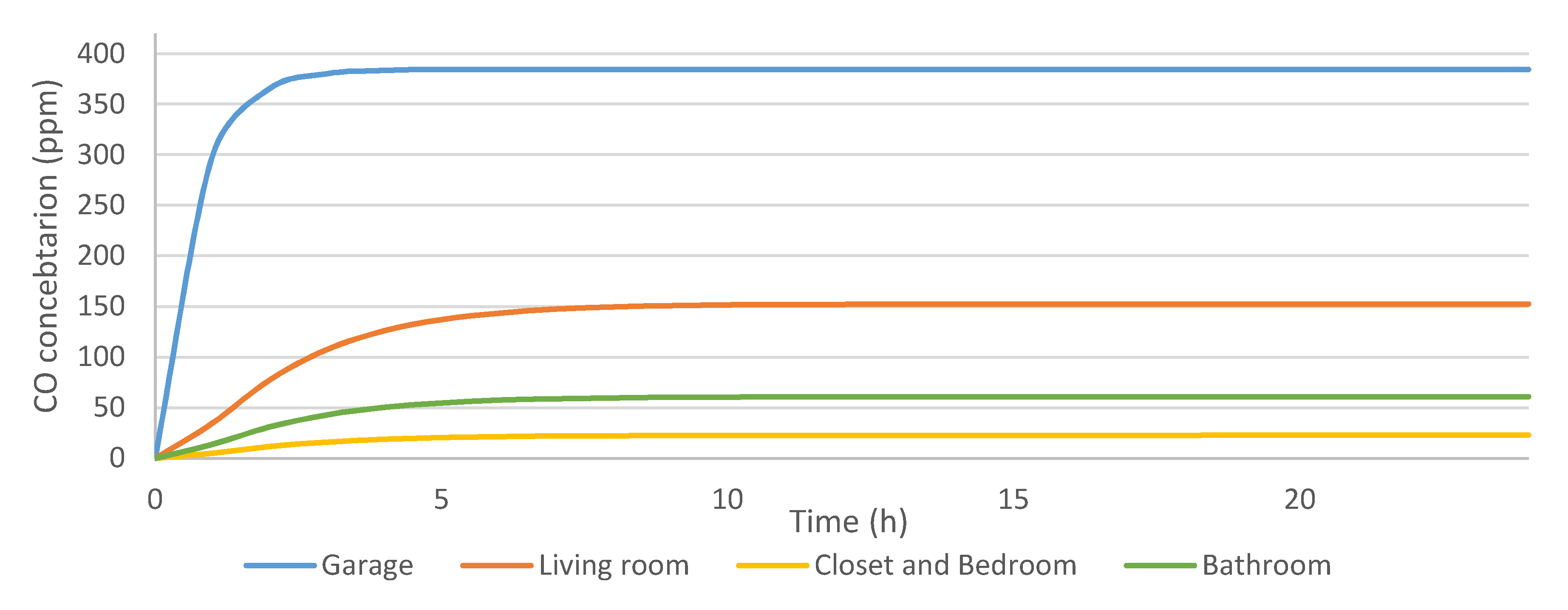

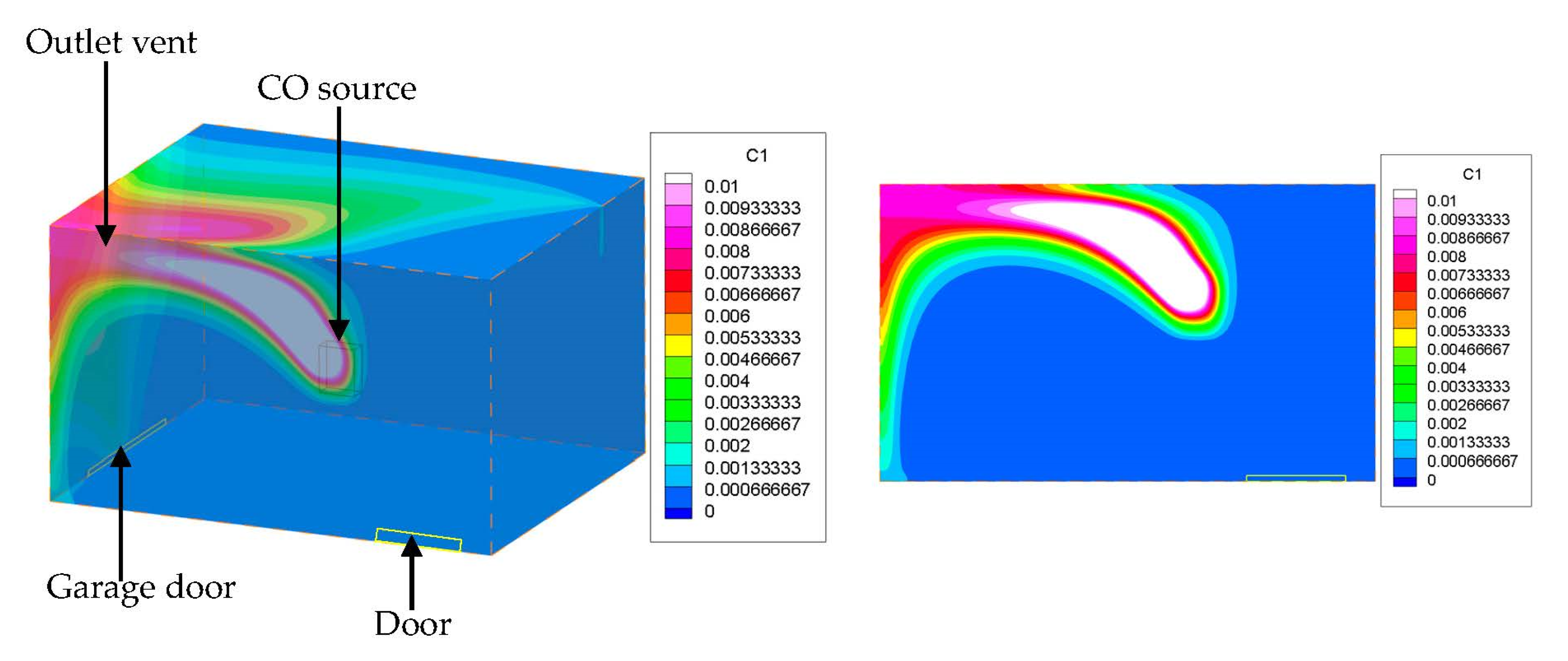

3. Results

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Pyka, I.; Wierzchowski, K. Estimated mercury emissions from coal combustion in the households sector in Poland. J. Sustain. Min. 2016, 15, 66–72. [Google Scholar] [CrossRef][Green Version]

- Central Statistical Office. Energy Consumption in Households. Statistical Information and Elaborations; Central Statistical Office: Warsaw, Poland, 2015.

- Delegature in katowice. Elimination of Boiler with Low Emission Household and Commune in the Silesia Province—Eliminacja Niskiej Emisji z Kotłowni Przydomowych i Gminnych w Województwie Śląskim; LKA.410.007.2016 Nr ewid. 191/2016/P/16/065/LKA; Supreme Audit Office: Warsaw, Poland, 2017.

- Batterman, S.; Jia, C.; Hatzivasilis, G. Migration of volatile organic compounds from attached garages to residences: A major exposure source. Environ. Res. 2007, 104, 224–240. [Google Scholar] [CrossRef] [PubMed]

- Dodson, R.E.; Levy, J.I.; Spengler, J.D.; Shine, J.P.; Bennett, D.H. Influence of basements, garages, and common hallways on indoor residential volatile organic compound concentrations. Atmos. Environ. 2008, 42, 1569–1581. [Google Scholar] [CrossRef]

- Gładyszewska-Fiedoruk, K.; Nieciecki, M. Indoor Air Quality in a Multi-car Garage. Energy Procedia 2016, 95, 132–139. [Google Scholar] [CrossRef][Green Version]

- Mallach, G.; St-Jean, M.; MacNeill, M.; Aubin, D.; Wallace, L.; Shin, T.; Van Ryswyk, K.; Kulka, R.; You, H.; Fugler, D.; et al. Exhaust ventilation in attached garages improves residential indoor air quality. Indoor Air 2017, 27, 487–499. [Google Scholar] [CrossRef]

- Zhao, Y.; Song, X.; Wang, Y.; Zhao, J.; Zhu, K. Seasonal patterns of PM10, PM2.5, and PM1.0 concentrations in a naturally ventilated residential underground garage. Build. Environ. 2017, 124, 294–314. [Google Scholar] [CrossRef]

- Debia, M.; Trachy-Bourget, M.-C.; Beaudry, C.; Neesham-Grenon, E.; Perron, S.; Lapointe, C. Characterization of indoor diesel exhaust emissions from the parking garage of a school. Environ. Sci. Pollut. Res. 2017, 24, 4655–4665. [Google Scholar] [CrossRef][Green Version]

- Fontaras, G.; Zacharof, N.G.; Ciuffo, B. Fuel consumption and CO2 emissions from passenger cars in Europe—Laboratory versus real-world emissions. Prog. Energy Combust. Sci. 2017, 60, 97–131. [Google Scholar] [CrossRef]

- Szczepanik-Ścisło, N.; Ścisło, Ł. Air leakage modelling and its influence on the air quality inside a garage. In Proceedings of the E3S Web of Conferences, EDP Sciences, Polanica-Zdrój, Poland, 16–18 April 2018; Volume 44. [Google Scholar]

- Badania, C. Badanie pilotażowe parametrów powietrza w garażu. Ciepłownictwo Ogrzew. Went. 2012, 8, 347–350. [Google Scholar]

- Byard, R.W. Carbon monoxide—The silent killer. Forensic Sci. Med. Pathol. 2019, 15, 1–2. [Google Scholar] [CrossRef]

- Can, G.; Saylll, U.; Aksu Sayman, Ö.; Kuyumcu, Ö.F.; Yllmaz, D.; Esen, E.; Yurtseven, E.; Erginöz, E. Mapping of carbon monoxide related death risk in Turkey: A ten-year analysis based on news agency records. BMC Public Health 2019, 19. [Google Scholar] [CrossRef] [PubMed]

- Mazo, J.; Mukhtar, E.; Mazo, Y.; Nagaraj, A.; Mantello, M.T. Delayed brain injury post carbon monoxide poisoning. Radiol. Case Rep. 2020, 15, 1845–1848. [Google Scholar] [CrossRef] [PubMed]

- Hurley, R.A.; Hopkins, R.O.; Bigler, E.D.; Taber, K.H. Applications of functional imaging to carbon monoxide poisoning. J. Neuropsychiatry Clin. Neurosci. 2001, 13, 157–160. [Google Scholar] [CrossRef] [PubMed]

- Veiraiah, A. Carbon monoxide poisoning. Medicine (UK) 2020, 48, 197–198. [Google Scholar] [CrossRef]

- Dols, W.S.; Polidoro, B.J. CONTAM User Guide and Program; Documentation Version 3.4; National Institute of Standards and Technology: Gaithersburg, MD, USA, 2020.

- National Institute of Standards and Technology|NIST. Available online: https://www.nist.gov/ (accessed on 16 November 2020).

- Emmerich, S.J.; Zimmerman, S.M.; Nabinger, S.J.; Brookman, M.J.; Zimmerman, S.M. Carbon Monoxide Concentrations and Carboxyhemoglobin Profiles from Portable Generators with a CO Safety Shutoff Operating in a Test House; US Department of Commerce: Washington, DC, USA, 2019.

- Ng, L.C.; Ojeda Quiles, N.; Dols, W.S.; Emmerich, S.J. Weather correlations to calculate infiltration rates for U.S. commercial building energy models. Build. Environ. 2018, 127, 47–57. [Google Scholar] [CrossRef]

- Fine, J.P.; Gray, J.; Tian, X.; Touchie, M.F. An investigation of alternative methods for determining envelope airtightness from suite-based testing in multi-unit residential buildings. Energy Build. 2020, 214, 109845. [Google Scholar] [CrossRef]

- Lin, W.; Li, L.; Liu, X.; Zhang, T. On-site measurement and numerical investigation of the airflow characteristics in an aquatics center. J. Build. Eng. 2020, 101968. [Google Scholar] [CrossRef]

- Andrew, K.; Brian, J.; Steven, J. Residential Carbon Monoxide Exposure due to Indoor Generator Operation: Effects of Source Location and Emission Rate; US Department of Commerce: Washington, DC, USA, 2013.

- Barbosa, B.P.P.; de Carvalho Lobo Brum, N. Validation and assessment of the CFD-0 module of CONTAM software for airborne contaminant transport simulation in laboratory and hospital applications. Build. Environ. 2018, 142, 139–152. [Google Scholar] [CrossRef]

- Liu, W.; Liu, D.; Gao, N. CFD study on gaseous pollutant transmission characteristics under different ventilation strategies in a typical chemical laboratory. Build. Environ. 2017, 126, 238–251. [Google Scholar] [CrossRef]

- Jose, R.S.; Pérez, J.L.; Gonzalez-Barras, R.M. Multizone airflow and pollution simulations of indoor emission sources. Sci. Total Environ. 2020, 142593. [Google Scholar] [CrossRef]

- Argyropoulos, C.D.; Hassan, H.; Kumar, P.; Kakosimos, K.E. Measurements and modelling of particulate matter building ingress during a severe dust storm event. Build. Environ. 2020, 167, 106441. [Google Scholar] [CrossRef]

- Hurnik, M.; Specjal, A.; Popiolek, Z. On-site diagnosis of hybrid ventilation system in a renovated single-family house. Energy Build. 2017, 149, 123–132. [Google Scholar] [CrossRef]

- Sun, Z.; Wang, S. A CFD-based test method for control of indoor environment and space ventilation. Build. Environ. 2010, 45, 1441–1447. [Google Scholar] [CrossRef]

- Du, Z.; Xu, P.; Jin, X.; Liu, Q. Temperature sensor placement optimization for VAV control using CFD–BES co-simulation strategy. Build. Environ. 2015, 85, 104–113. [Google Scholar] [CrossRef]

- Gangisetti, K.; Claridge, D.E.; Srebric, J.; Paulus, M.T. Influence of reduced VAV flow settings on indoor thermal comfort in an office space. Build. Simul. 2016, 9, 101–111. [Google Scholar] [CrossRef]

- Nada, S.A.; El-Batsh, H.M.; Elattar, H.F.; Ali, N.M. CFD investigation of airflow pattern, temperature distribution and thermal comfort of UFAD system for theater buildings applications. J. Build. Eng. 2016, 6, 274–300. [Google Scholar] [CrossRef]

- Mu, Y.; Liu, M.; Ma, Z.; Zhang, J. Resistance characteristic analysis based study on a novel damper torque airflow sensor for VAV terminals. Build. Environ. 2020, 175, 106813. [Google Scholar] [CrossRef]

- Hurnik, M. Novel cylindrical induction controller and its application in VAV air conditioning system in an office building. Energy Build. 2016, 130, 341–349. [Google Scholar] [CrossRef]

- Liu, R.; Wen, J.; Waring, M.S. Improving airflow measurement accuracy in VAV terminal units using flow conditioners. Build. Environ. 2014, 71, 81–94. [Google Scholar] [CrossRef]

- Pasut, W.; Bauman, F.; De Carli, M. The use of ducts to improve the control of supply air temperature rise in UFAD systems: CFD and lab study. Appl. Energy 2014, 134, 490–498. [Google Scholar] [CrossRef]

- Methodology for Optimization of Laboratory Hood Containment—Volumes I and II. Available online: https://www.orf.od.nih.gov/TechnicalResources/Bioenvironmental/Pages/labhoodcontainm.aspx (accessed on 19 November 2020).

- Memarzadeh, F. Effect of reducing ventilation rate on indoor air quality and energy cost in laboratories. J. Chem. Health Saf. 2019, 16, 20–26. [Google Scholar] [CrossRef]

- WHO. WHO|Environmental Health Criteria 213: Carbon Monoxide; World Health Organization: Geneva, Switzerland, 2013. [Google Scholar]

- Liangzhu, W. Coupling of Multizone and CFD Programs for Building Airflow and Contaminant Transport Simulations. Ph.D. Thesis, Purdue University, West Lafayette, IN, USA, 2007. [Google Scholar]

- Wang, L.L.; Dols, W.S.; Chen, Q. Using CFD Capabilities of CONTAM 3.0 for Simulating Airflow and Contaminant Transport in and around Buildings. HVAC R Res. 2010, 16, 749–763. [Google Scholar] [CrossRef]

- Brown, C. Furnace Co Emissions Under Normal and Compromised Vent Conditions; United States Consumer Product Safety Commission: Washington, DC, USA, 2000; pp. 1–39.

- Versteeg, H.K.; Malalasekera, W. An Introduction to Computational Fluid Dynamits, 2nd ed.; Pearson Prentice Hall: Upper Saddle River, NJ, USA, 2007. [Google Scholar]

- Geng, L.; Liu, H.; Wei, X. CFD analysis of the fl ashing fl ow characteristics of subcritical refrigerant R134a through converging-diverging nozzles. Int. J. Therm. Sci. 2019, 137, 438–445. [Google Scholar] [CrossRef]

- Shan, X.; Luo, N.; Sun, K.; Hong, T.; Lee, Y.; Lu, W.; Engineering, C.; Kong, H.; Administrative, S. Coupling CFD and building energy modelling to optimize the operation of a large open office space for occupant comfort. Sustain. Cities Soc. 2020, 60, 102257. [Google Scholar] [CrossRef]

| CO Concentration (ppm) | Effect on the Human Body |

|---|---|

| 9 | Maximum allowable concentration in living areas |

| 50 | Maximum allowable concentration for a continuous 8 h period |

| 200 | Headache, nausea, and dizziness after 2 h |

| 400 | Headache, nausea, and dizziness—life-threatening after 3 h of exposure |

| 800 | Dizziness, nausea, and convulsions within 45 min, death within 2 h |

| 1600 | Dizziness, nausea, and convulsions within 20 min, death within 1 h |

| 3200 | Dizziness, nausea, and convulsions within 5–10 min, death within 30 min |

| 6400 | Dizziness, nausea, and convulsions within 1–2 min, death within 10–15 min |

| 12,800 | Death within 1–3 min |

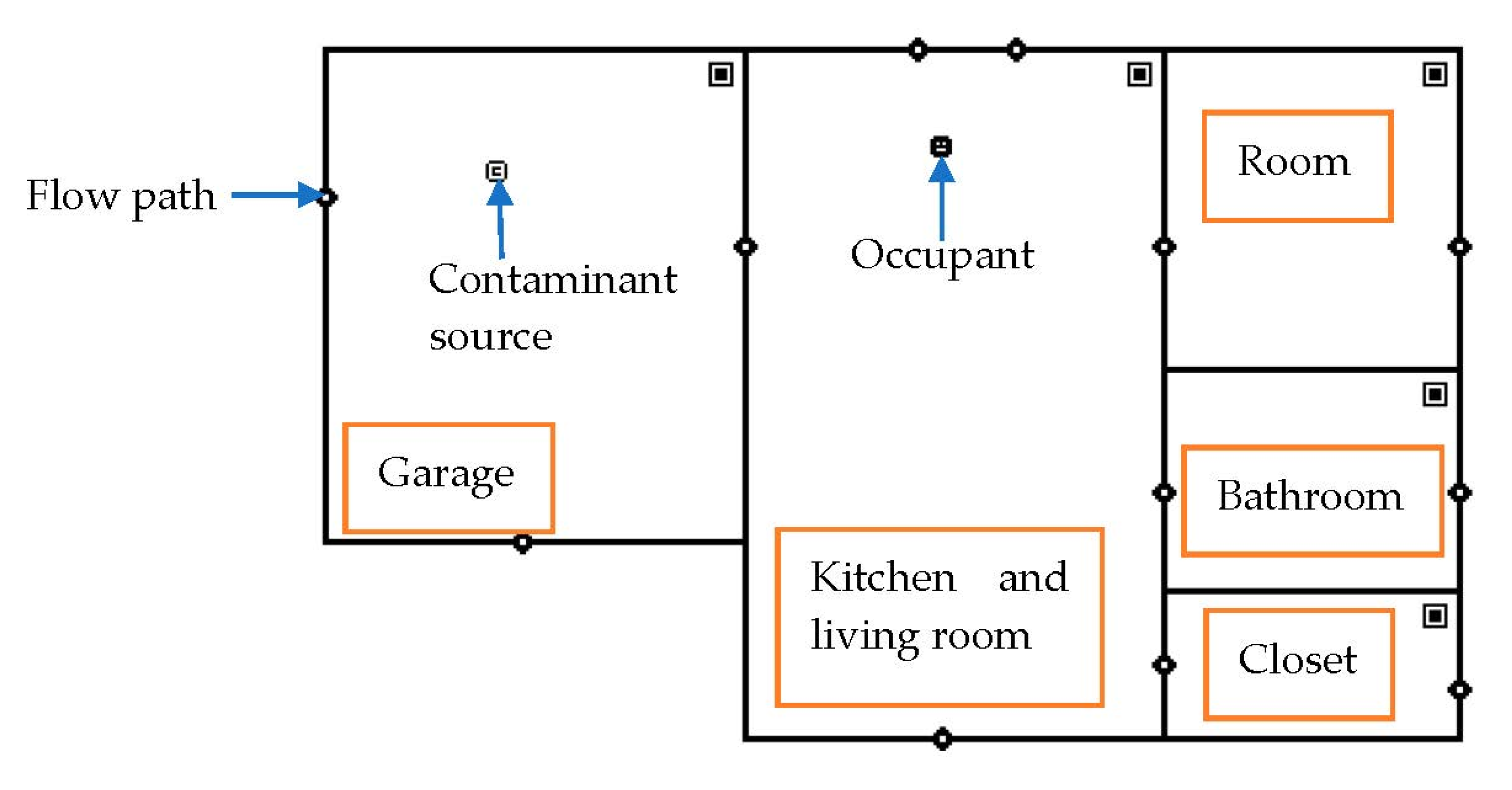

| Zone | Room Volume (m3) | Flow Path | Flow Path Area (m2) | Exchange Rate (m3/h) |

|---|---|---|---|---|

| Garage | 60 | Garage door | 0.02 | |

| Door to the house | 0.009 | 90 | ||

| Natural ventilation | 0.04 | |||

| Kitchen and Living Room | Window | 0.005 | ||

| 60 | Natural ventilation | 0.04 | 70 | |

| Door | 0.009 | |||

| Room | 18 | Door | 0.01 | 30 |

| Window | 0.005 | |||

| Bathroom | 18 | Door | 0.01 | 50 |

| Natural ventilation | 0.04 | |||

| Closet | 18 | Door | 0.009 | 30 |

| Window | 0.005 |

| Number of Elements | Average Air Velocity V (m/s) | Convergence Rate (%) | |

|---|---|---|---|

| Calculated | Numerical | ||

| 500,000 | 0.625 | 0.724 | 13.67 |

| 1,000,000 | 0.634 | 1.42 | |

| 1,500,000 | 0.638 | 2.03 | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Szczepanik-Scislo, N.; Scislo, L. Comparison of CFD and Multizone Modeling from Contaminant Migration from a Household Gas Furnace. Atmosphere 2021, 12, 79. https://doi.org/10.3390/atmos12010079

Szczepanik-Scislo N, Scislo L. Comparison of CFD and Multizone Modeling from Contaminant Migration from a Household Gas Furnace. Atmosphere. 2021; 12(1):79. https://doi.org/10.3390/atmos12010079

Chicago/Turabian StyleSzczepanik-Scislo, Nina, and Lukasz Scislo. 2021. "Comparison of CFD and Multizone Modeling from Contaminant Migration from a Household Gas Furnace" Atmosphere 12, no. 1: 79. https://doi.org/10.3390/atmos12010079

APA StyleSzczepanik-Scislo, N., & Scislo, L. (2021). Comparison of CFD and Multizone Modeling from Contaminant Migration from a Household Gas Furnace. Atmosphere, 12(1), 79. https://doi.org/10.3390/atmos12010079