Study on the Accelerated Aging Test Method in the Development of a Self-Cleaning Topcoat for Cool Roofs

Abstract

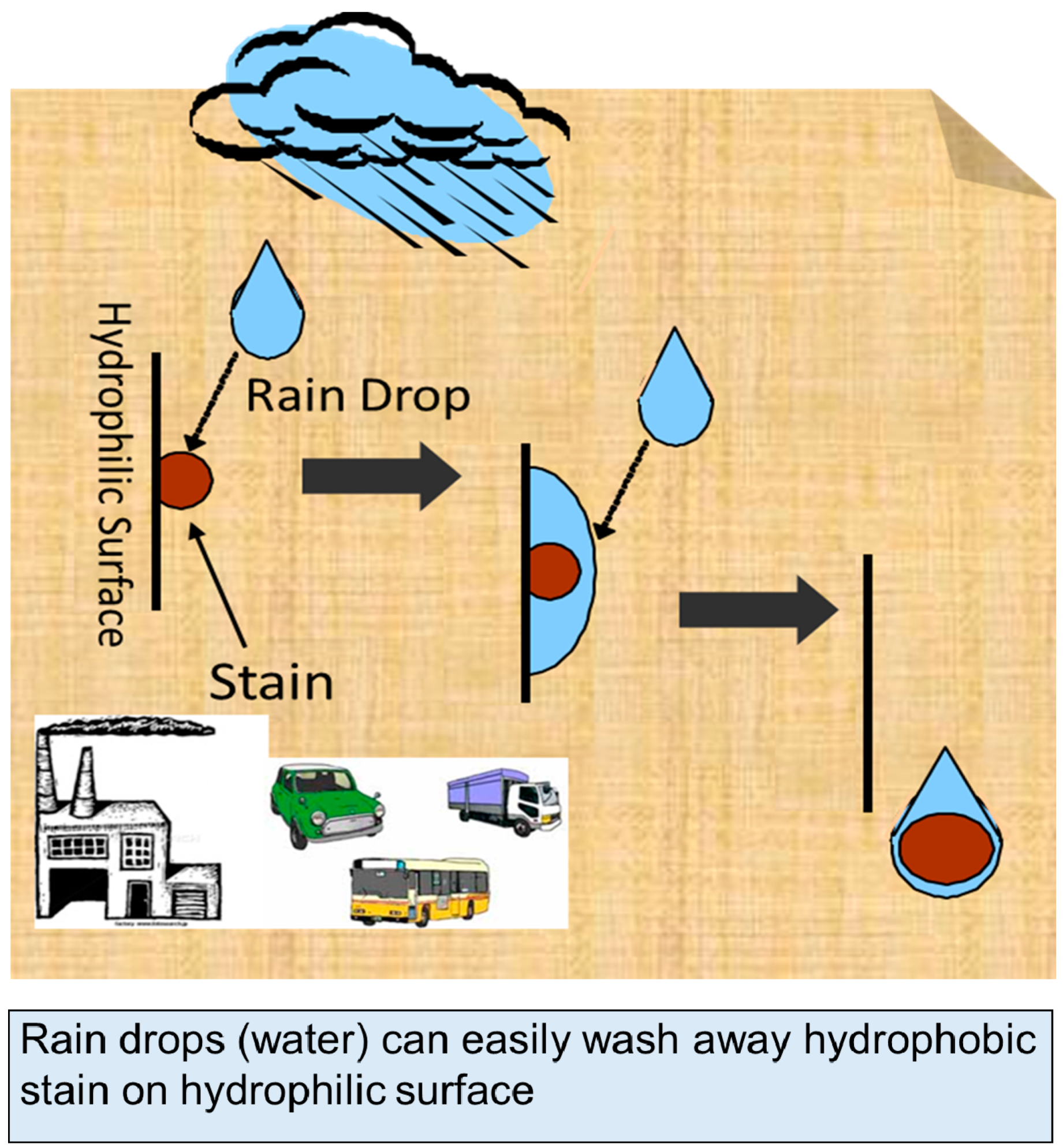

1. Introduction

2. Experiments

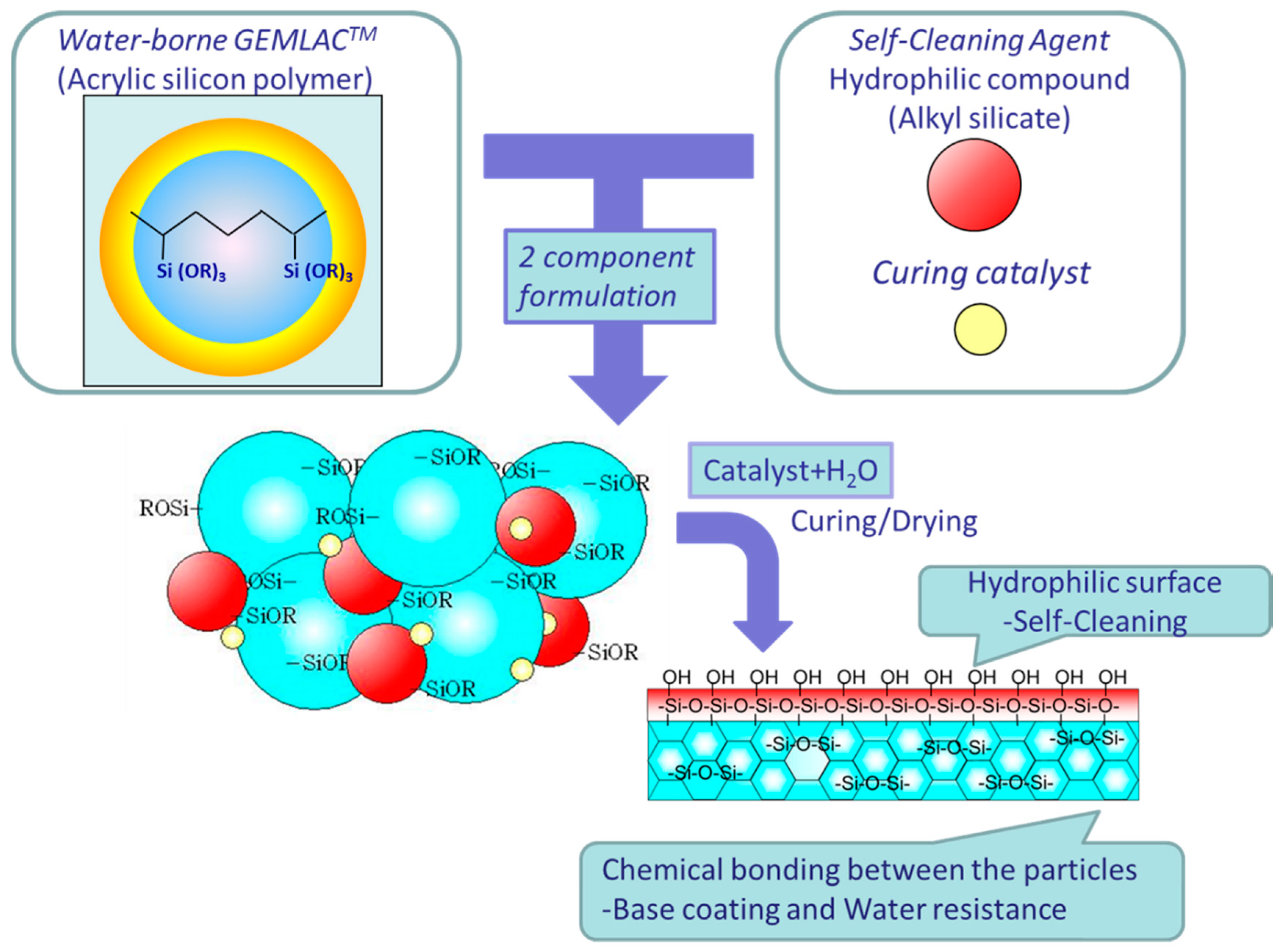

2.1. Outline of Materials

2.2. Test Specimen

2.3. Exposure Testing Method

2.4. Accelerated Testing Method

3. Results

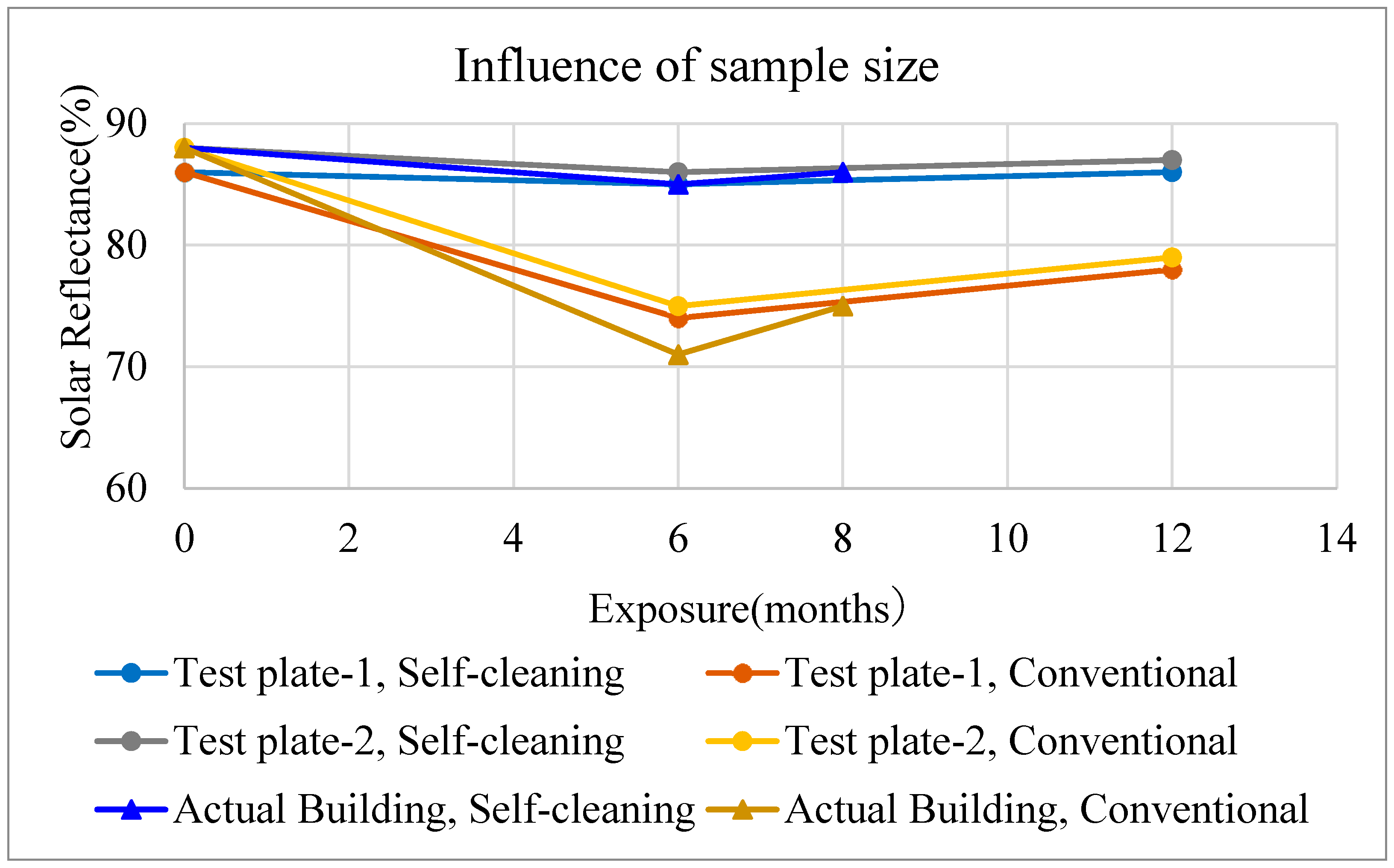

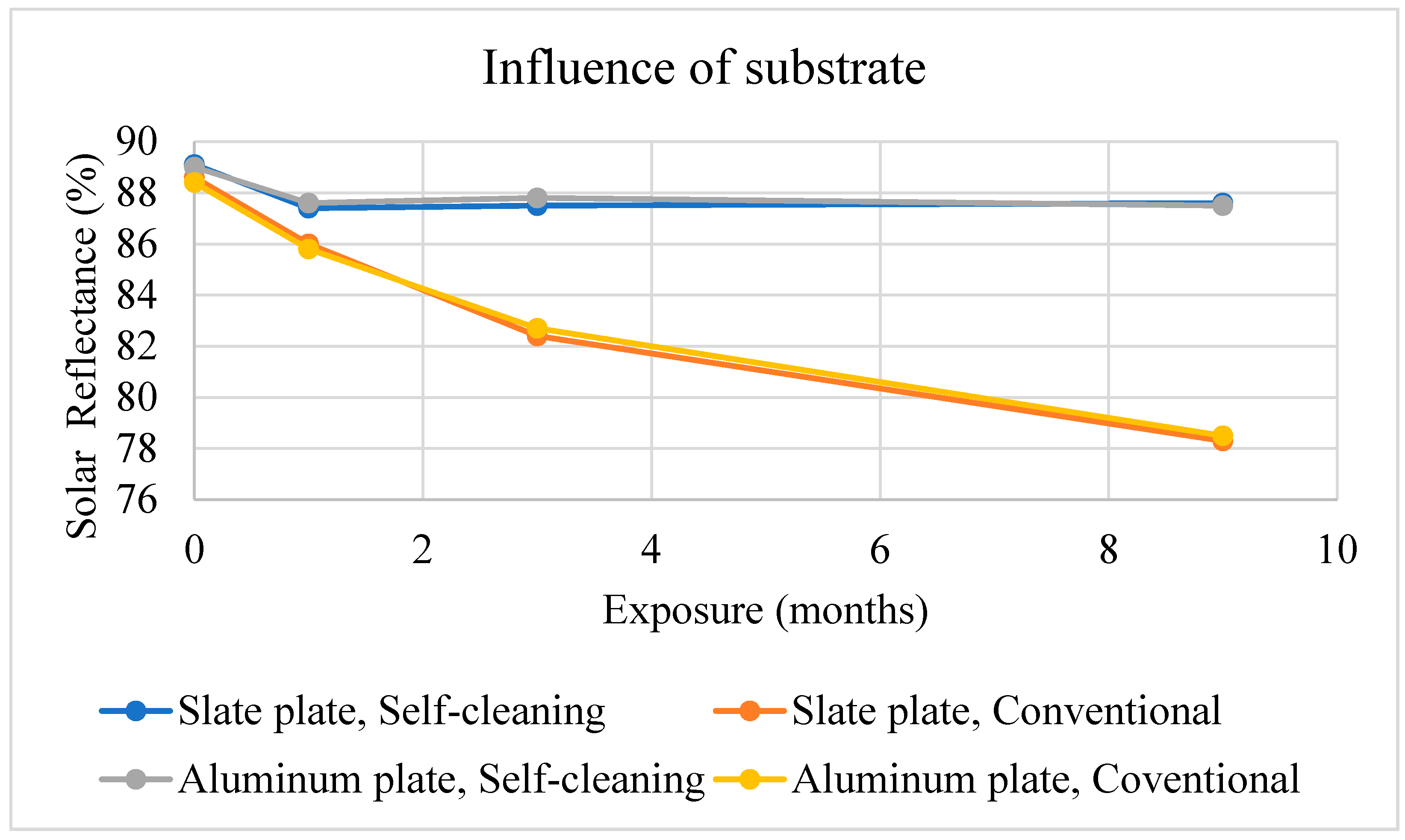

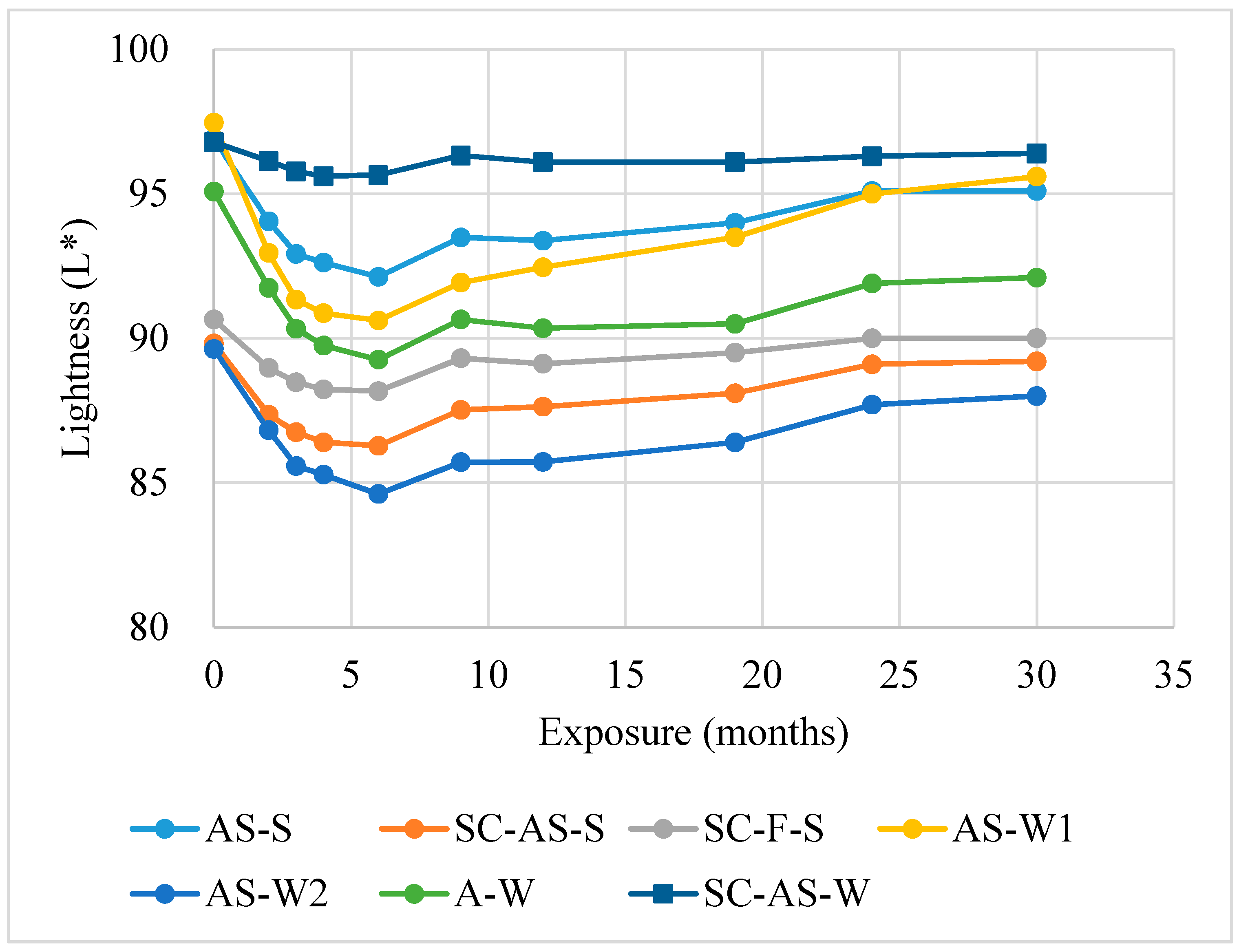

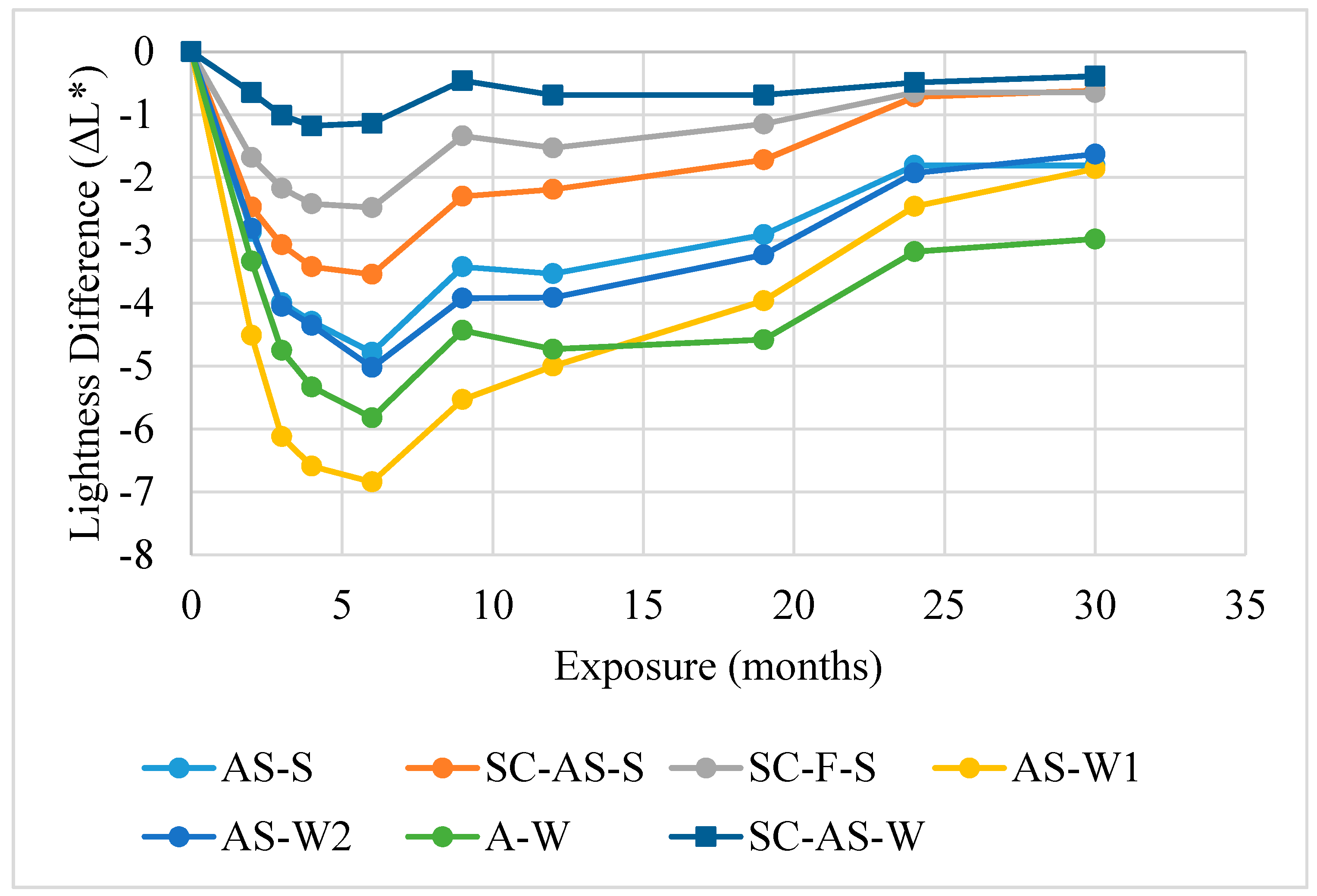

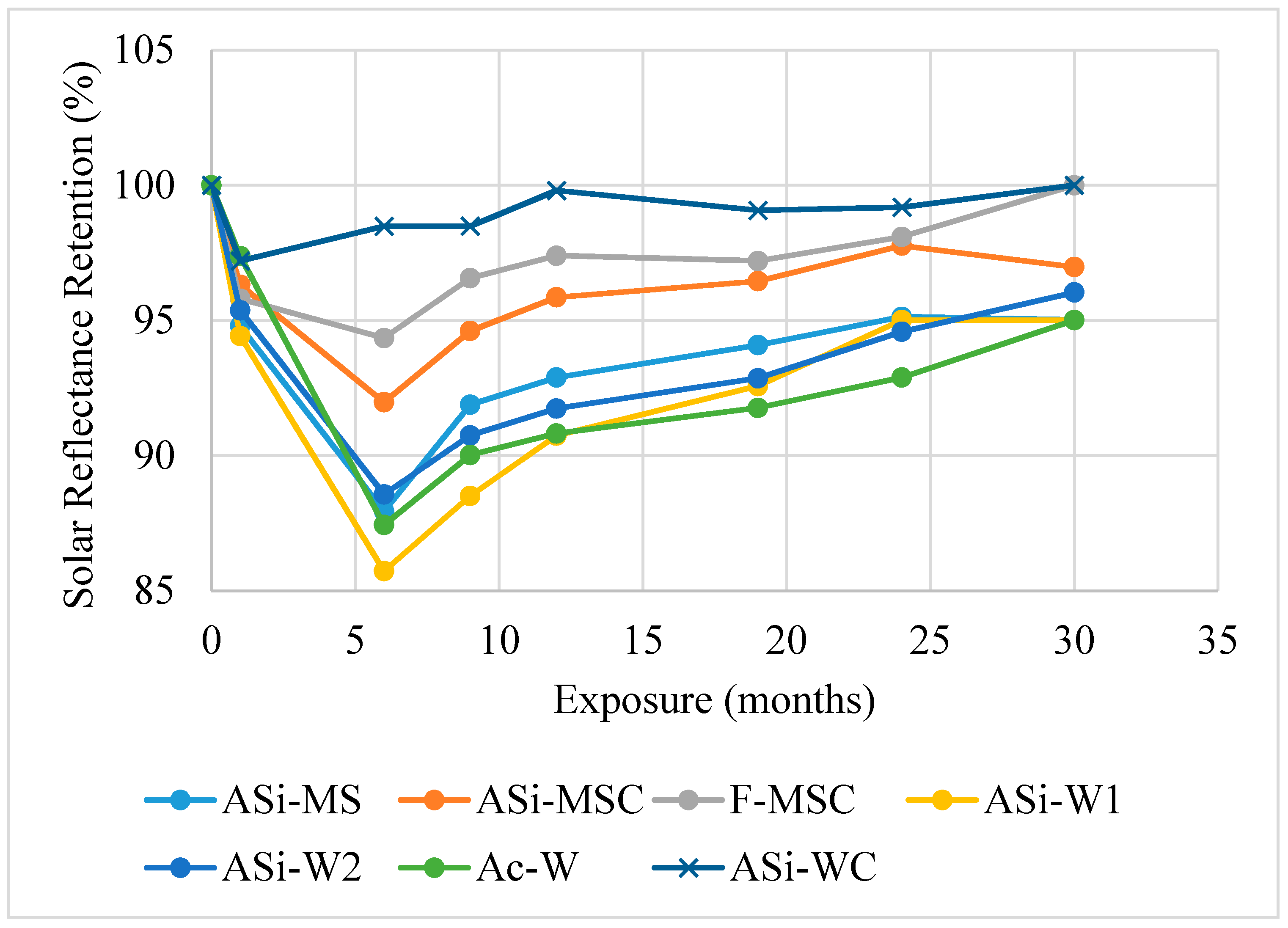

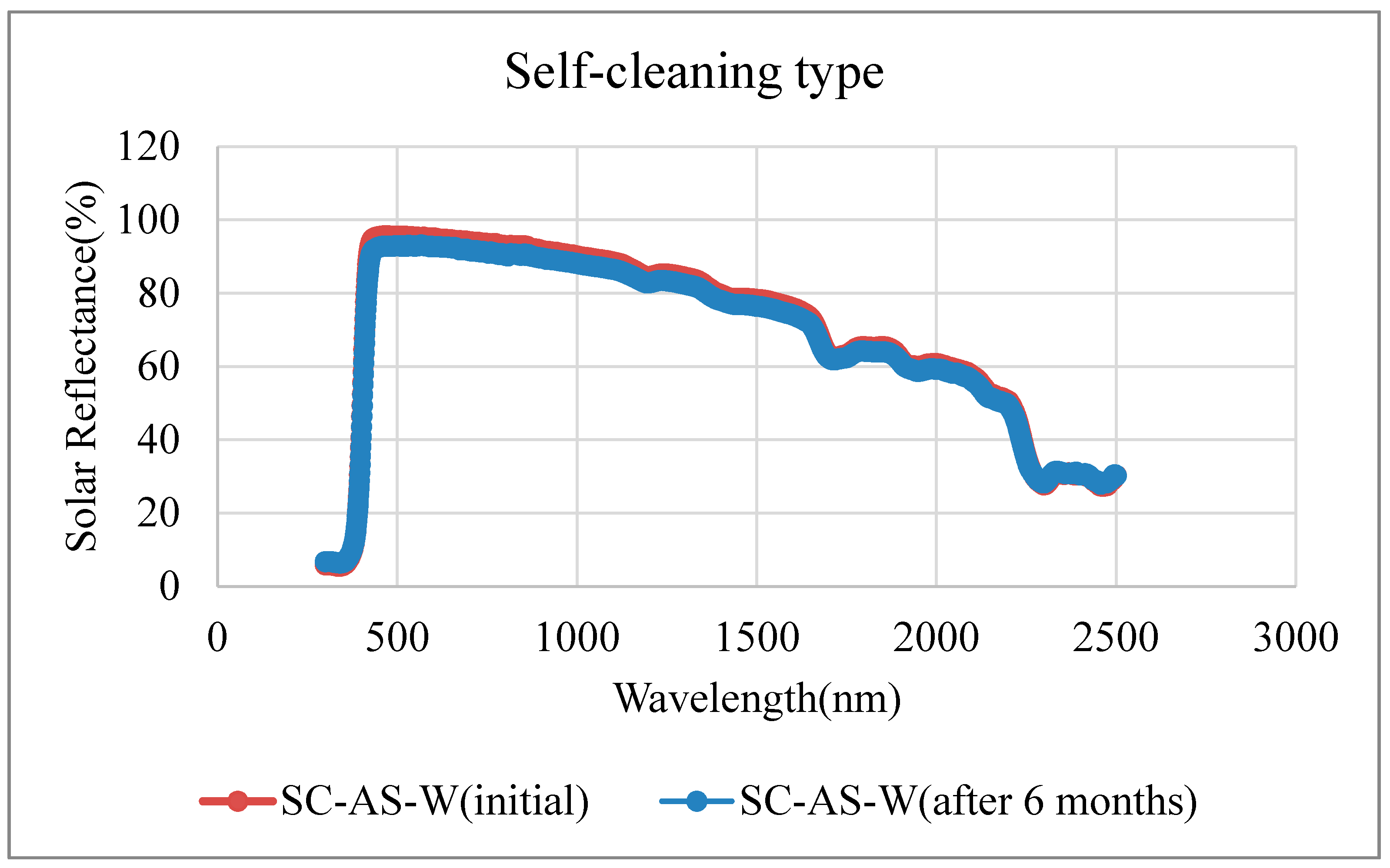

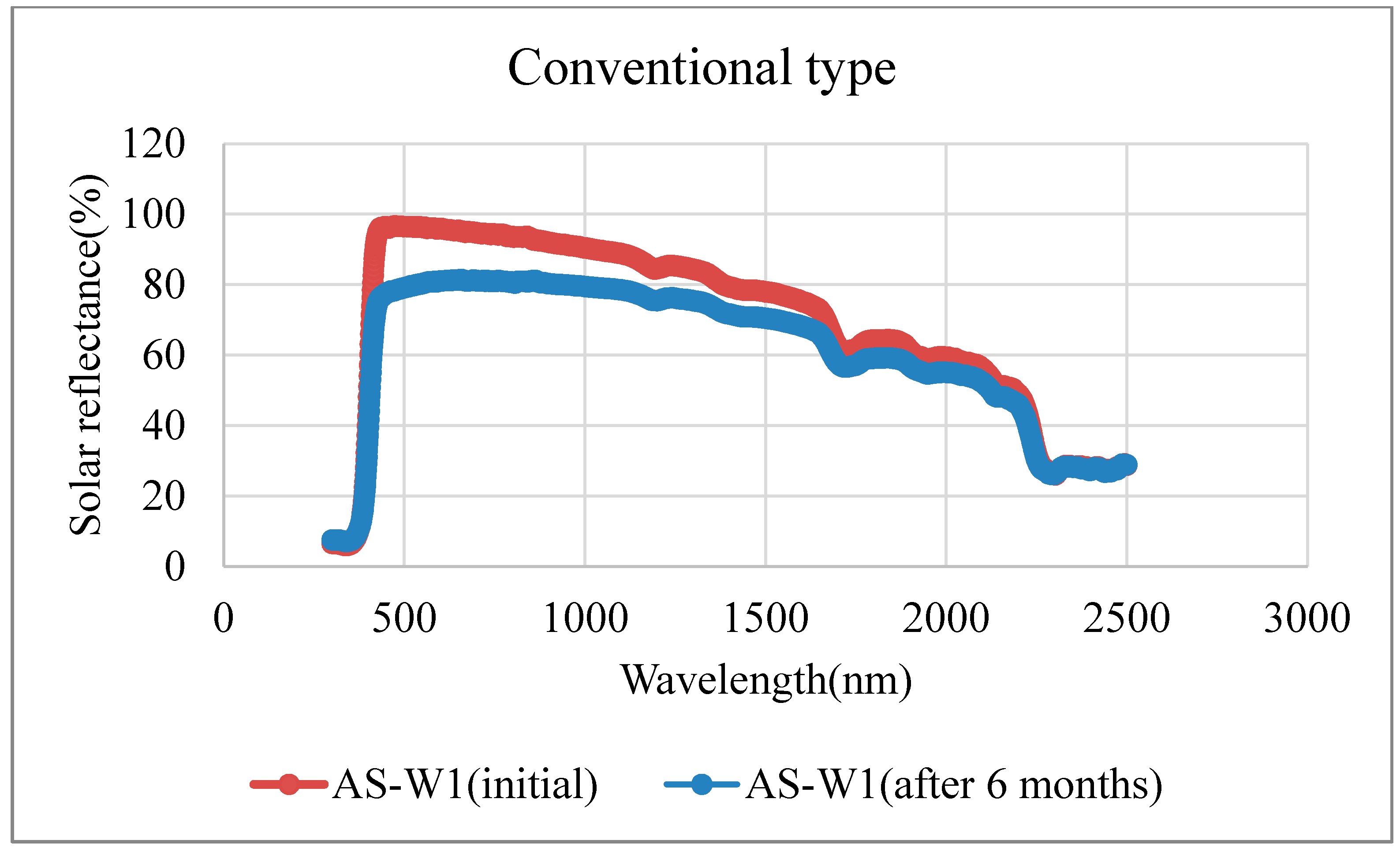

3.1. Result of Exposure Test

3.2. Result of Accelerated Aging Test

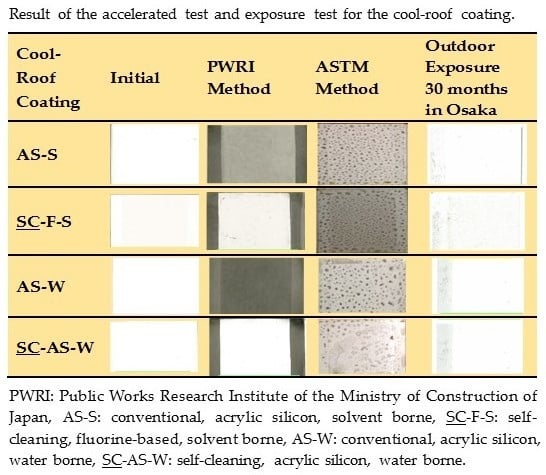

3.2.1. The State of Each Test Piece after the Exposure and Accelerated Test

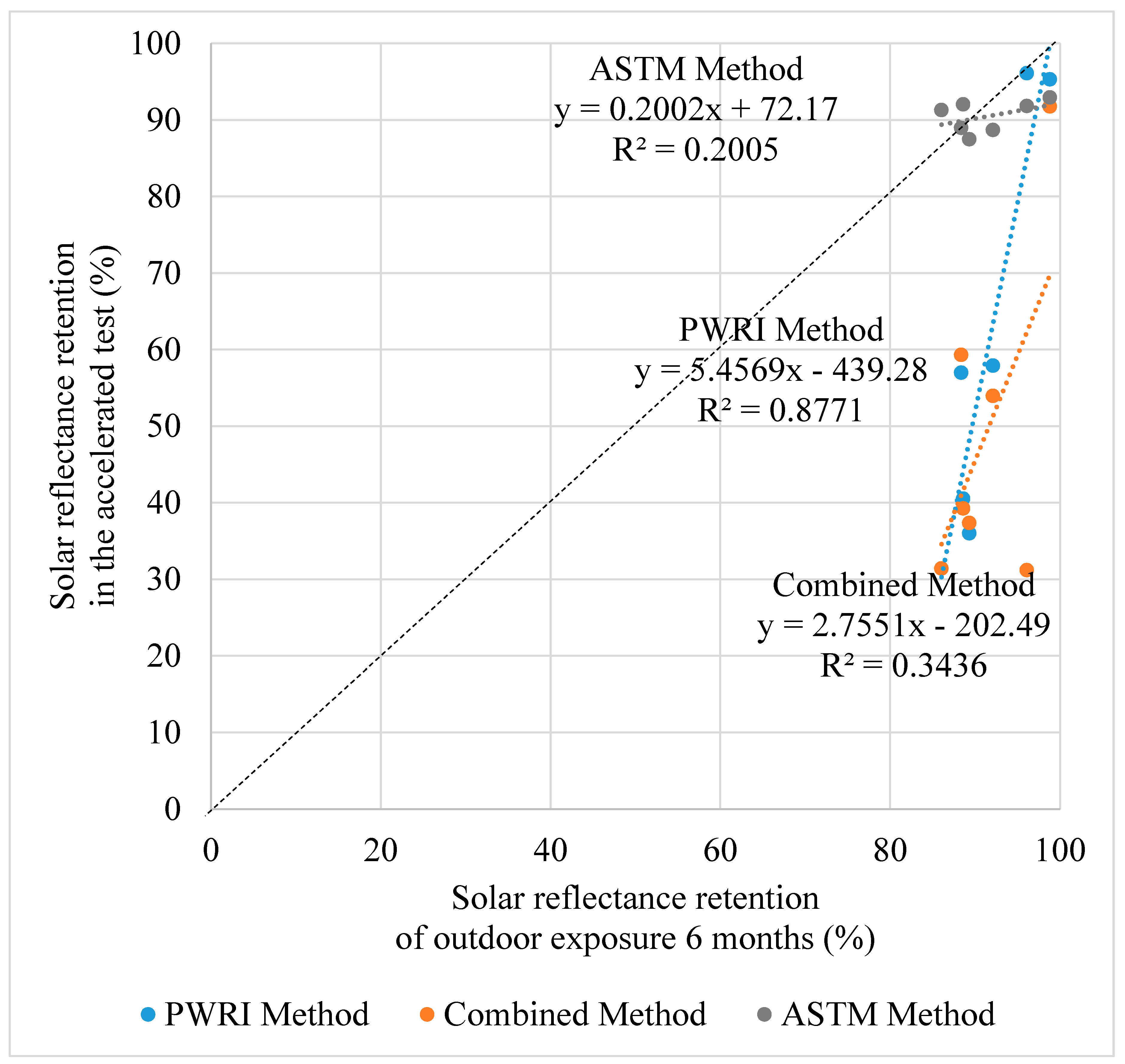

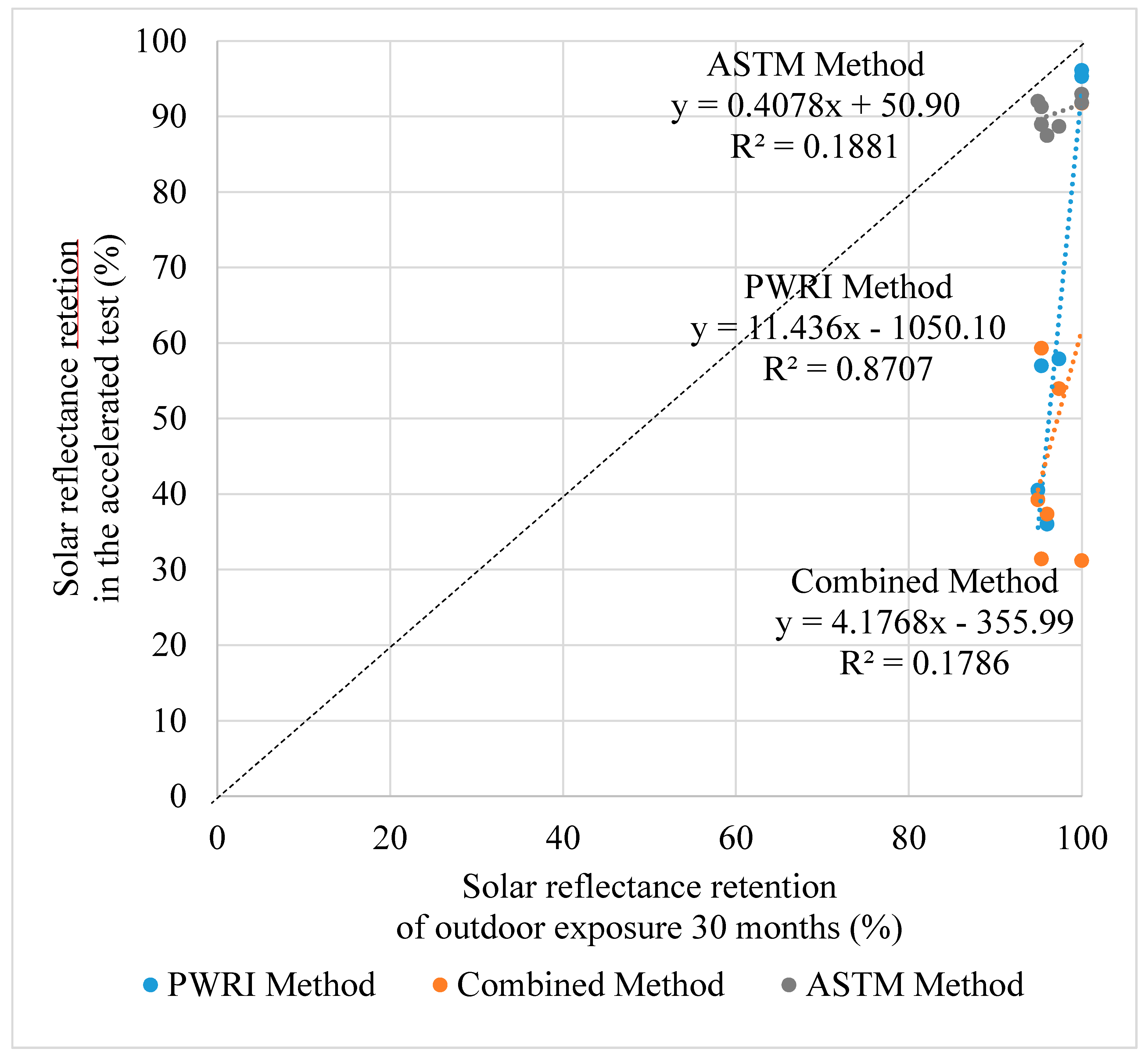

3.2.2. Relationship between Outdoor Exposure Test and Accelerated Aging Test

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

Appendix A

| Pretreatment | Soiling | Post-Treatment | |

|---|---|---|---|

| ASTM Method | Irradiation: 8 h QUV, 60 °C condensation: 4 h, 50 °C 2 times, 24 h | mixture of dust, humic acid, carbon black, low concentration | Irradiation: 8 h QUV, 60 °C condensation: 4 h, 50 °C 2 times, 24 h |

| Combined Method | Irradiation: 8 h QUV, 60 °C condensation: 4 h, 50 °C 2 times, 24 h | only carbon black, high concentration | Wash under running water |

| PWRI Method | Wet conditions, 50 ± 1 °C humidity of 95% or more 24 h | only carbon black, high concentration | Wash under running water |

Appendix B

| Solvent System | Cleaning Ability | Acrylic Silicon | Fluorine | Acrylic |

|---|---|---|---|---|

| Solvent borne | Conventional | (1) AS-S | F-S | A-S |

| Self-Cleaning | (2) SC-AS-S | (3) SC-F-S | SC-A-S * | |

| Water borne | Conventional | (4,5) AS-W1,2 | F-W | (6) A-W |

| Self-Cleaning | (7) SC-AS-W | SC-F-W | SC-A-W * |

| Abbreviation, Item | Content |

|---|---|

| AS-S | Solvent-borne acrylic silicon polymer coating, conventional |

| SC-AS-S | Solvent-borne acrylic silicon polymer coating, self-cleaning |

| SC-F-S | Solvent-borne fluorine-based polymer coating, self-cleaning |

| AS-W1 | Water-borne acrylic silicon polymer coating, conventional |

| AS-W2 | Water-borne acrylic silicon polymer coating, higher hardness, conventional |

| A-W | Water-borne acrylic polymer coating, conventional |

| SC-AS-W | Water-borne acrylic silicon polymer coating, self-cleaning |

| Outdoor exposure | Outdoor conditions at 45°in Settsu City, Osaka From 26 April 2012 to 27 April 2015, about 3 years |

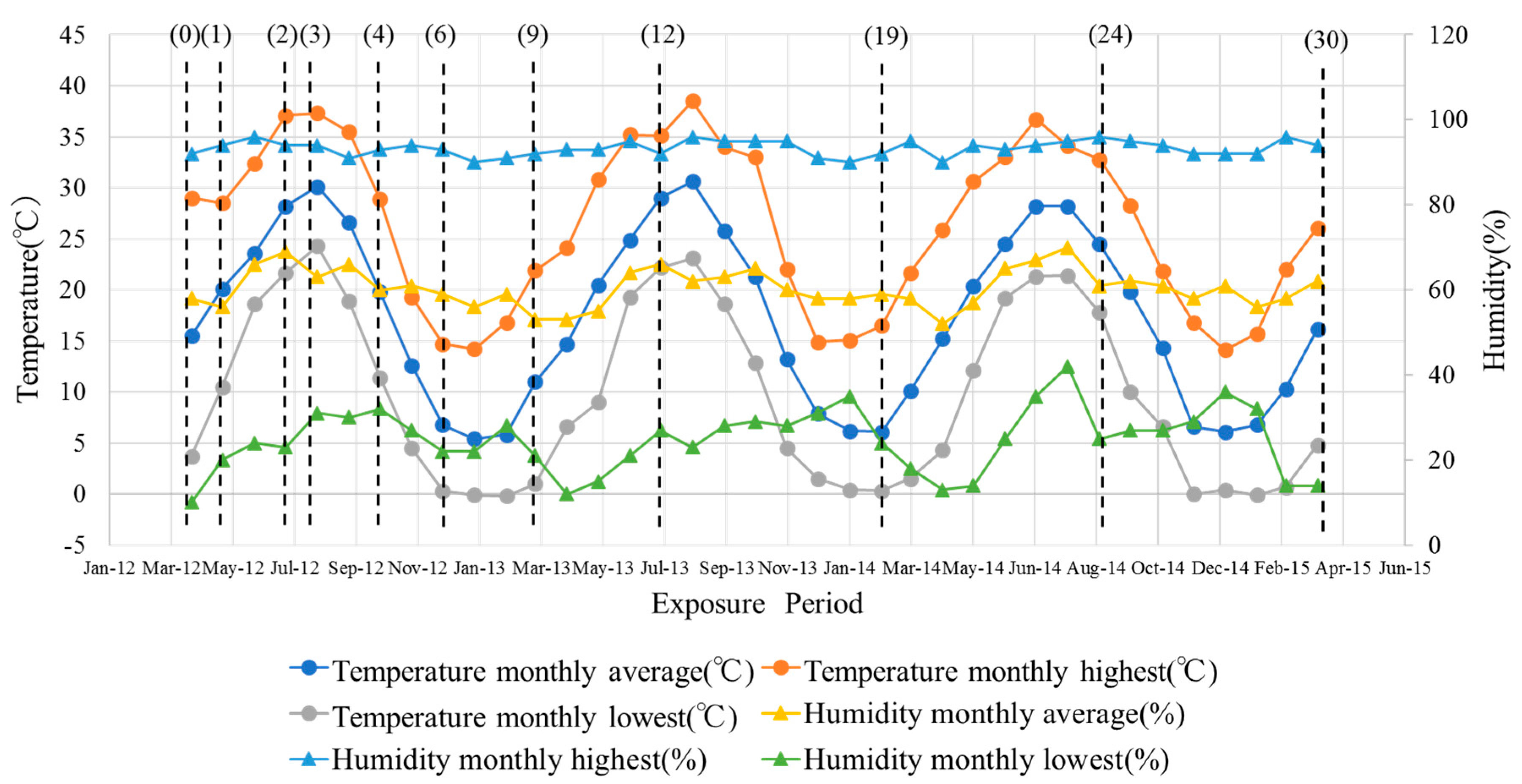

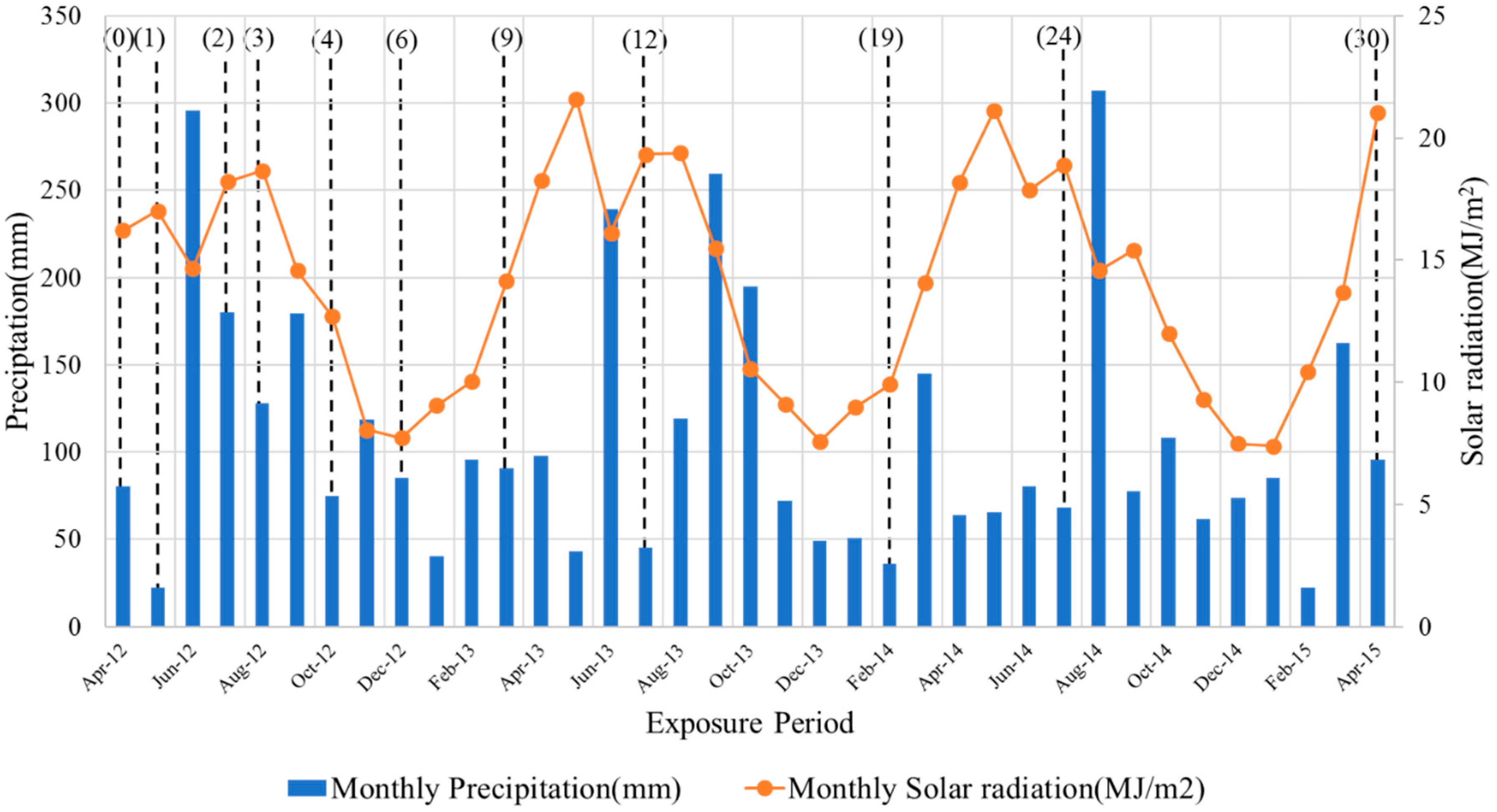

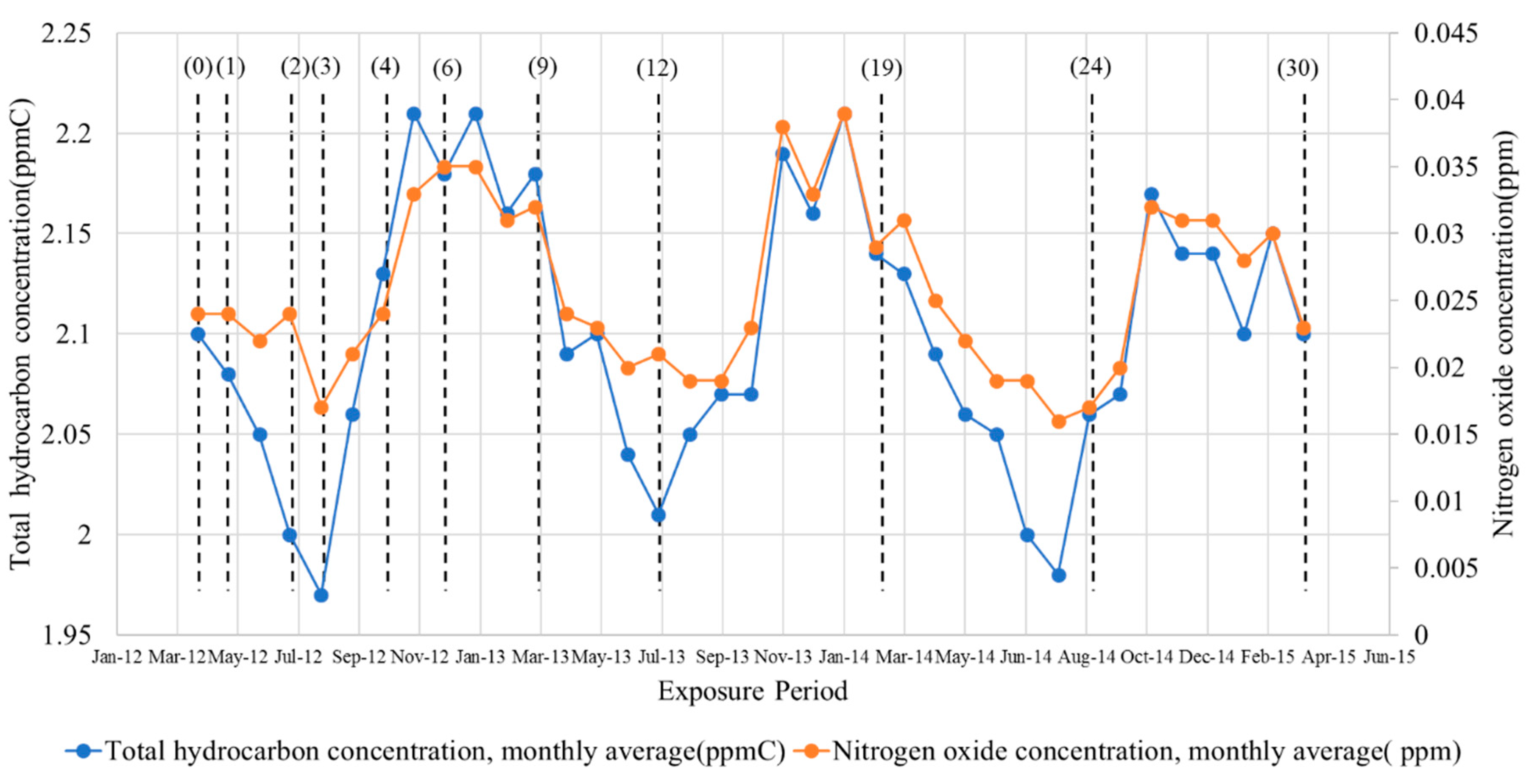

| Weather, Pollutant information | Temperature, humidity (Figure 4), precipitation, solar radiation (Figure 5) Total hydrocarbon concentration, nitrogen oxide concentration (Figure 6) Higashinari ward, Osaka City, which is close to Settsu City (http://taiki.kankyo.pref.osaka.jp/taikikanshi/) |

Appendix C

References

- Akbari, H.; Konopacki, S.; Pomerantz, M. Cooling energy saving potential of reflective roofs for residential and commercial building in the United States. Energy 1999, 24, 391–407. [Google Scholar] [CrossRef]

- Akbari, H.; Konopacki, S. Calculating energy-saving potentials of heat-island reduction strategies. Energy Policy 2005, 33, 721–756. [Google Scholar] [CrossRef]

- Akbari, H.; Menon, S.; Rosenfeld, A. Global cooling: Increasing world-wide urban albedos to offset CO2. Climatic Chang. 2009, 94, 275–286. [Google Scholar] [CrossRef]

- Romeo, C.; Zinzi, M. Impact of a cool roof application on the energy and comfort performance in an existing non-residential building. A Sicilian case study. Energy Build. 2013, 67, 647–657. [Google Scholar] [CrossRef]

- Synnefa, A.; Saliari, M.; Santamouris, M. Experimental and numerical assessment of the impact of increased reflectance on a school building in Athens. Energy Build. 2012, 55, 7–15. [Google Scholar] [CrossRef]

- Takebayashi, H.; Yamada, C. Field observation of cooling energy saving due to high-reflectance paints. Buildings 2015, 5, 310–317. [Google Scholar] [CrossRef]

- Hernandez-Perez, I.; Alvarez, G.; Xaman, J.; Zavala-Guillen, I.; Arce, J.; Sima, E. Thermal Performance of Reflective Materials Applied to Exterior Buildings Components—A Review. Energy Build. 2014, 80, 81–105. [Google Scholar] [CrossRef]

- Hernandez-Perez, I.; Xaman, J.; Macias-Melo, E.V.; Aguilar-Castro, K.M.; Zavala-Guillen, I.; Hernandez-Lopez, I.; Sima, E. Experimental thermal evaluation of building roofs with conventional and reflective coatings. Energy Build. 2018, 158, 569–579. [Google Scholar] [CrossRef]

- Hernandez-Perez, I.; Zavala-Guillen, I.; Xaman, J.; Belman-Flores, J.M.; Macias-Melo, E.V.; Aguilar-Castro, K.M. Test box experiment to assess the impact of waterproofing materials on the energy gain of building roofs in Mexico. Energy 2019, 186, 115847. [Google Scholar] [CrossRef]

- Akbari, H.; Berhe, A.A.; Levinson, R. Aging and Weathering of Cool Roofing Membranes; Lawrence Berkeley National Laboratory: Berkeley, CA, USA, 2005. [Google Scholar]

- Berdahl, P.A.; Akbari, H.; Levinson, R.; Miller, A. Weathering of roofing material—An overview. Constr. Build. Mater. 2008, 22, 423–433. [Google Scholar] [CrossRef]

- Bretz, S.E.; Akbari, H. Long-term performance of high albedo roof coating. Energy Build. 1997, 25, 159–167. [Google Scholar] [CrossRef]

- Mastrapostoli, E.; Santamouris, M.; Kolokotsa, D.; Vassilis, P.; Venieri, D.; Gompakis, K. A numerical and experimental analysis of the aging of the cool roofs for buildings in Greece. In Proceedings of the Summaries of Technical Papers of Third International Conference on Countermeasures to UHI, Venice, Italy, 13–15 October 2014; pp. 71–80. [Google Scholar]

- Paolini, R.; Sleiman, M.; Terraneo, G.; Poli, T.; Zinzi, M.; Levinson, R.; Destaillats, H. Solar spectral reflectance of building envelope materials after natural exposure in Rome and Milano, and after accelerated aging. In Proceedings of the Summaries of Technical Papers of Third International Conference on Countermeasures to UHI, Venice, Italy, 13–15 October 2014; pp. 498–509. [Google Scholar]

- Itoh, D.; Takeda, H.; Fujimoto, T.; Kondo, Y.; Ashie, Y. Study on change of performance by outdoor exposure of reflective paints. AIJ J. Technol. Des. 2011, 17, 217–220. [Google Scholar] [CrossRef]

- Ferran, C.; Touchaei, A.G.; Sleiman, M.; Libbra, A.; Muscio, A.; Siligardi, C.; Akbari, H. Effect of ageing processes on solar reflectivity of clay roof tiles. In Proceedings of the Summaries of Technical Papers of 34th AIVC Conference, Athens, Greece, 25–26 September 2013; pp. 77–79. [Google Scholar]

- Synnefa, A.; Pantazaras, A.; Santamouris, M.; Bozonner, E.; Doya, M.; Zinzi, M.; Muscio, A.; Libbra, A.; Ferrari, C.; Coccia, V.; et al. Interlaboratory comparison of cool roofing material measurement methods. In Proceedings of the Summaries of Technical Papers of 34th AIVC Conference, Athens, Greece, 25–26 September 2013; pp. 52–54. [Google Scholar]

- Sleiman, M.; Weiss, G.B.; Gilbert, H.E.; François, D.; Berdahl, P.; Kirchstetter, T.W.; Destaillats, H.; Levinson, R. Soiling of building envelope surfaces and its effect on solar reflectance-Part I: Analysis of roofing product databases. Sol. Energy Mater. Sol. Cells 2011, 95, 3385–3399. [Google Scholar] [CrossRef]

- Sleiman, M.; Kirchstetter, T.W.; Berdahl, P.; Gilbert, H.E.; Quelen, S.; Marlot, L.; Preble, C.V.; Chen, S.; Montalbano, A.; Rosseler, O.; et al. Soiling of building envelope surfaces and its effect on solar reflectance—Part II: Development of an accelerated aging method for roofing materials. Solar Energy Mater. Solar Cells 2014, 122, 271–281. [Google Scholar] [CrossRef]

- Paolini, R.; Zani, A.; Poli, T.; Antretter, F.; Zinzi, M. Natural aging of cool walls: Impact on solar reflectance, sensitivity to thermal shocks and building energy needs. Energy Build. 2017, 153, 287–296. [Google Scholar] [CrossRef]

- Takebayashi, H.; Miki, K.; Sakai, K.; Murata, Y.; Matsumoto, T.; Wada, S.; Aoyama, T. Examination on aging experiment and accelerated aging test method of solar reflectance of the high reflectance paint in Japan. In Proceedings of the Summaries of Technical Papers of Third International Conference on Countermeasures to UHI, Venice, Italy, 13–15 October 2014; pp. 630–641. [Google Scholar]

- Akbari, H. Advance in developing standards for accelerated aging of cool roofing materials. In Proceedings of the Summaries of Technical Papers of Roof Coating Manufacturers Association International Roof Coatings Conference, Baltimore, MD, USA, 14–17 July 2014. [Google Scholar]

- Kakuta, M. Technology Trends of Anti-Soiling and Anti-Bacterium; CMC Publishing: Tokyo, Japan, 2004; pp. 99–116. [Google Scholar]

- Aoyama, T.; Sonoda, T.; Takebayashi, H. Study on aging of solar reflectance of the self-cleaning high reflectance coating. Energy Build. 2017, 157, 92–100. [Google Scholar] [CrossRef]

- Fukaumi, H.; Hamamura, T.; Sonoda, T. Coating composition and coating film obtained from coating composition. Eur. Pat. Appl. 2015, 506, EP2821450A1. [Google Scholar]

- Aoyama, T.; Sonoda, T.; Takebayashi, H. Influence of dirt and coating deterioration on the aging of solar reflectance of high reflectance paint. AIMS Mater. Sci. 2019, 6, 997–1009. [Google Scholar] [CrossRef]

- Tamura, M.; Motohashi, K.; Shimizu, R.; Miura, M.; Hayashi, A. Study on performance of high reflectance paint for building Part 7, Solar reflection after weathering test. In Proceedings of the Japan Society for Finishing Technology, Summaries of Technical Papers of Annual Meeting, Tokyo, Japan, 18–19 October 2012; pp. 16–19. [Google Scholar]

- American Society for Testing and Materials. Standard Practice for Laboratory Soiling and Weathering of Roofing Materials to Simulate Effects of Natural Exposure on Solar Reflectance and Thermal Emittance; ASTM D7897-15: Philadelphia, PA, USA, 2015. [Google Scholar]

- Nishizaki, I.; Moriya, S. Survey report on antifouling materials for civil engineering, Appendix-1, Anti-Fouling Materials Evaluation Accelerated Test Method I; Public Works Research Institute of the Ministry of Construction of Japan: Thukuba, Ibaraki, Japan, 2011; Available online: https://www.pwri.go.jp/team/imarrc/research/tech-info/tech4180.pdf (accessed on 31 May 2020).

- Kitsutaka, Y. Accelerating test method for soiling on finishing materials of external walls; study on an evaluating method for the soiling on finishing materials of external building walls (Part 3). J. Struct. Constr. Eng. AIJ 1989, 404, 15–24. [Google Scholar]

- Heat Island Countermeasure Technology Certification System, Related documents 4, Acceleration aging Test Method (Summary Version); Osaka Heat Island Countermeasure Technology Consortium (Osaka HITEC): Osaka, Japan, 2018; Available online: http://osakahitec.com/cert/ninsyou_mousikomi.pdf (accessed on 31 May 2020).

- Itatani, T. Study on evaluation method for stain on exterior coating materials, part 1–4. In Proceedings of the AIJ Summaries of Technical Papers of Annual Meeting, Kobe, Hyogo, Japan, 12–14 September 2014; pp. 845–852. [Google Scholar]

- Ozano, T. Study on evaluation method for stain on exterior coating materials, part 5–8. In Proceedings of the AIJ Summaries of Technical Papers of Annual Meeting, Hirathuka, Kanagawa, Japan, 4–6 September 2015; pp. 875–887. [Google Scholar]

- Tanabe, J.; Takebayashi, H.; Sonoda, T.; Aoyama, T. Study on aging of solar reflectance on high reflectance paint by exposure experiment. In Proceedings of the AIJ Summaries of Technical Papers of Annual Meeting, Hirathuka, Kanagawa, Japan, 4–6 September 2015; pp. 723–724. [Google Scholar]

| Mark | Self- Cleaning | Polymer Component | Solvent System | Comparison |

|---|---|---|---|---|

| (1) AS-S | Conventional | Acrylic silicon | Solvent borne | ・conventional acrylic silicon polymer coating |

| (2) SC-AS-S | Self- cleaning | Acrylic silicon | Solvent borne | ・comparison with (1) AS-S for Self-Cleaning |

| (3) SC-F-S | Self- cleaning | Fluorine-based | Solvent borne | ・comparison with (2) SC-AS-S for using fluorine as the polymer species |

| (4) AS-W1 | Conventional | Acrylic silicon | Water borne | ・water borne, conventional acrylic silicon polymer coating |

| (5) AS-W2 | Conventional | Acrylic silicon | Water borne | ・comparison with (4) AS-W1 for higher hardness and lower contamination |

| (6) A-W | Conventional | Acrylic | Water borne | ・comparison with (4) AS-W1 for using acrylic as the polymer species |

| (7) SC-AS-W | Self- cleaning | Acrylic silicon | Water borne | ・comparison with (4)AS-W1 for Self-Cleaning |

| Method | ASTM Method [28] | Combined Method | PWRI Method [29] |

|---|---|---|---|

| Pretreatment | Conditioning by QUV: ASTM G154 Cycle * 2 times, 24 h | Conditioning: Wet conditions, 50 ± 1 °C, humidity of 95% or more, 24 h | |

| Soiling treatment | Mixing soiling solution (see Table 3) spray coating Uniformly applying an 8 ± 1 mg/cm2 2–10 min dried using an infrared lamp (250 W) ** | Carbon black aqueous dispersion (see Table 3) spray coating Uniformly on the surface After 1 h drying at 60 °C, allowed to cool to 23 °C | |

| Post-treatment | Conditioning by QUV: ASTM G154 Cycle * 2 times, 24 h | Wash under running water until the dirt substance is no longer fall with a gauze (BEMCOT M-3 “manufactured by Asahi Kasei Co., Ltd.”) | |

| Soiling Materials | ASTM Method (%) | PWRI Method (%) | |

|---|---|---|---|

| Soot | Aquablack 001 (TOKAI Carbon, Inc.) | 0.0065 | |

| Color Black FW200 (Orion Engineered Carbons) | 5.0000 | ||

| Dust | Iron oxide(Fe2O3) | 0.0075 | |

| Montmorionite | 0.0250 | ||

| Bentonite | 0.0250 | ||

| Salts | Sodium chloride | 0.0075 | |

| Sodium nitrate | 0.0075 | ||

| Calcium sulfate dehydrate | 0.0100 | ||

| POM | Humic Acid | 0.0350 | |

| Solvent | Deionized water | 99.8760 | 95.0000 |

| Total | 100.0000 | 100.0000 | |

| Initial | PWRI Method | Combined Method | ASTM Method | Outdoor Exposure 30 Months in Osaka | |

| (1) AS-S |  |  |  |  |  |

| (2) SC-AS-S |  |  |  |  |  |

| (3) SC-F-S |  |  |  |  |  |

| Initial | PWRI Method | Combined Method | ASTM Method | Outdoor Exposure 30 Months in Osaka | |

| (4) AS-W1 |  |  |  |  |  |

| (5) AS-W2 |  |  |  |  |  |

| (6) A-W |  |  |  |  |  |

| (7) SC-AS-W |  |  |  |  |  |

| After Pretreatment | After Sprayinga Pollutant | After Dryinga Pollutant | AfterPost-Treatment |

|---|---|---|---|

|  |  |  |

| After Pretreatment | After Sprayinga Pollutant | After Dryinga Pollutant | AfterPost-Treatment |

|---|---|---|---|

|  |  |  |

| Mark | Initial Solar Reflectance | Solar Reflectance (%) | ||||

|---|---|---|---|---|---|---|

| PWRI Method | Combined Method | ASTM Method | Outdoor Exposure Test (6 months) | Outdoor Exposure Test (30 months) | ||

| (1) AS-S | 86 | 49 | 51 | 77 | 76 | 82 |

| (2) SC-AS-S | 76 | 44 | 41 | 67 | 70 | 74 |

| (3) SC-F-S | 79 | 76 | 25 | 73 | 76 | 79 |

| (4) AS-W1 | 86 | 27 | 27 | 79 | 74 | 82 |

| (5) AS-W2 | 76 | 27 | 28 | 66 | 68 | 73 |

| (6) A-W | 80 | 32 | 31 | 74 | 71 | 76 |

| (7) SC-AS-W | 86 | 82 | 79 | 80 | 85 | 86 |

| Mark | Solar Reflectance Retention (%) | ||||

|---|---|---|---|---|---|

| PWRI Method | Combined Method | ASTM Method | Outdoor Exposure Test (6 months) | Outdoor Exposure Test (30 months) | |

| (1) AS-S | 57 | 59 | 89 | 88 | 95 |

| (2) SC-AS-S | 58 | 54 | 89 | 92 | 97 |

| (3) SC-F-S | 96 | 31 | 92 | 96 | 100 |

| (4) AS-W1 | 31 | 31 | 91 | 86 | 95 |

| (5) AS-W2 | 36 | 37 | 87 | 89 | 96 |

| (6) A-W | 41 | 39 | 92 | 89 | 95 |

| (7) SC-AS-W | 95 | 92 | 93 | 99 | 100 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Aoyama, T.; Sonoda, T.; Takebayashi, H. Study on the Accelerated Aging Test Method in the Development of a Self-Cleaning Topcoat for Cool Roofs. Atmosphere 2020, 11, 605. https://doi.org/10.3390/atmos11060605

Aoyama T, Sonoda T, Takebayashi H. Study on the Accelerated Aging Test Method in the Development of a Self-Cleaning Topcoat for Cool Roofs. Atmosphere. 2020; 11(6):605. https://doi.org/10.3390/atmos11060605

Chicago/Turabian StyleAoyama, Taizo, Takeshi Sonoda, and Hideki Takebayashi. 2020. "Study on the Accelerated Aging Test Method in the Development of a Self-Cleaning Topcoat for Cool Roofs" Atmosphere 11, no. 6: 605. https://doi.org/10.3390/atmos11060605

APA StyleAoyama, T., Sonoda, T., & Takebayashi, H. (2020). Study on the Accelerated Aging Test Method in the Development of a Self-Cleaning Topcoat for Cool Roofs. Atmosphere, 11(6), 605. https://doi.org/10.3390/atmos11060605