Abstract

This paper presents results from eight field studies in Asia and Africa on the emissions performance of 16 stove/fuel combinations measured during normal cooking events in homes. Characterizing real-world emissions performance is important for understanding the climate and health implications of technologies being promoted as alternatives to displace baseline cooking stoves and fuels. Almost all of the stove interventions were measured to have substantial reductions in PM2.5 and CO emissions compared to their respective baseline technologies (reductions of 24–87% and 25–80%, for PM2.5 and CO emission rates, respectively), though comparison with performance guidance from the World Health Organization (WHO) and the International Organization for Standardization (ISO) suggests that further improvement for biomass stoves would help realize more health benefits. The emissions of LPG stoves were generally below the WHO interim PM2.5 emissions target (1.75 mg/min) though it was not clear how close they were to the most aspirational ISO (0.2 mg/min) or WHO (0.23 mg/min) targets as our limit of detection was 1.1 mg/min. Elemental and organic carbon emission factors and elemental-to-total carbon ratios (medians ranging from 0.11 to 0.42) were in line with previously reported field-based estimates for similar stove/fuel combinations. Two of the better performing forced draft stoves used with pellets—the Oorja (median ET/TC = 0.12) and Eco-Chula (median ET/TC = 0.42)—were at opposite ends of the range, indicating that important differences in combustion conditions can arise even between similar stove/fuel combinations. Field-based tests of stove performance also provide important feedback for laboratory test protocols. Comparison of these results to previously published water boiling test data from the laboratory reinforce the trend that stove performance is generally better during controlled laboratory conditions, with modified combustion efficiency (MCE) being consistently lower in the field for respective stove/fuel categories. New testing approaches, which operate stoves through a broader range of conditions, indicate potential for better MCE agreement than previous versions of water boiling tests. This improved agreement suggests that stove performance estimates from a new ISO laboratory testing protocol, including testing stoves across low, medium, and high firepower, may provide more representative estimates of real-world performance than previously used tests. More representative results from standardized laboratory testing should help push stove designs toward better real-world performance as well as provide a better indication of how the tested technologies will perform for the user.

1. Introduction

Nearly 3 billion people rely primarily on solid fuels for their cooking energy [1]. Use of these fuels is estimated to be responsible for 3.8 million premature deaths per year due to exposure to health damaging pollutants that are emitted from poor quality combustion [2]. There are also considerable climate implications, as 25% of annual black carbon emissions are thought to come from this source [3]. Organizations seeking to address these impacts have largely focused on technologies and fuels that burn more efficiently and cleanly. The United Nations has set Sustainable Development Goals which include a goal to achieve universal access to clean cooking by 2030 [4]. National programs are seeking to increase the use of clean burning stoves and fuels, while also working to ensure that the potential benefits are meaningful and substantiated.

The bulk of stove performance data has been derived from laboratory testing [5], which is valuable for initial assessments and in the design phase of new technologies. Stove performance estimates from laboratory testing, however, are often determined in controlled and optimized operational conditions and do not assess how stoves or fuels are working in homes with real-world use. Several studies have shown that laboratory-based test results differ substantially from real-world performance, with particulate and carbon monoxide emission factors often several-fold different [6,7,8,9]. Field-based assessments are especially needed for a variety of technologies that are shown through laboratory testing to have promise to make substantial impacts through reduced emissions and fuel savings [10,11]. These technologies, such as forced draft biomass stoves and mass manufactured charcoal stoves, as well as fuels such as liquefied petroleum gas (LPG), are less well-characterized in homes during normal stove operation [5].

Field-based assessments are also needed to understand relationships between laboratory and real-world performance. Ideally these comparisons can be used to improve testing methodologies and improve interpretation of laboratory results to understand how stoves perform under normal in-home operating conditions. New laboratory test protocol approaches have been developed to better represent the range of these conditions by testing over a broader range of firepower and/or conditions [12,13,14,15], including the recently published International Organization for Standardization (ISO) standard for emissions and performance, safety and durability [12]. How data from new testing protocols compare with field performance is not well known.

The primary goal of this project was to fill knowledge gaps and map field emissions performance of cookstoves and fuels that, based on laboratory tests, have the potential to significantly improve fuel efficiency or lower emissions of health-damaging and climate-forcing pollutants. Specifically, we characterized fuel performance by firepower and energy used per meal, and measured emission rates (mass emitted/min) and factors (mass emitted/fuel used) of health damaging pollutants (particulate matter less than 2.5 μm in aerodynamic diameter (PM2.5) and CO) and climate forcing agents (black carbon (BC), organic carbon (OC), carbon dioxide (CO2), methane (CH4), and total non-methane hydrocarbons (TNMHC)). The stoves and fuels tested included forced draft biomass stoves, new charcoal stoves, LPG, and the relevant baseline stoves from sites in Benin, India, Kenya, Uganda, and Vietnam.

2. Methods

This work is comprised of data collected during two separate but related field studies: the United Nations Foundation (UNF) funded Cookstove Emissions Performance Survey (CEPS) project and a United States Environmental Protection Agency (USEPA) funded project. The methodologies used for the two programs were highly similar and briefly summarized in this section. Table 1 lists the stoves and study sites that were monitored. The stove technologies were selected for these field studies based on preliminary results from previous lab-based performance tests. In some locations, the projects were complimented by Kitchen Performance Test (KPT) [16] studies, which assessed household level fuel consumption. The results from the KPT components of the project can be found in Johnson et al. [17] and Garland et al. [18].

Table 1.

Study stoves, locations, and details for the project sites. More details and pictures of the stoves can be found in supplementary material.

2.1. Stove Performance Testing

Emissions and fuel consumption sampling was conducted during uncontrolled cooking events in participants’ homes. Each sample consisted of one cooking event for which the participant used their own fuels and cooking utensils, and participants were asked to not alter their cooking or fuel tending practices. The sampling started just before the participant ignited the fuel for the event and ended when he or she indicated they were finished and the combustion ended. For LPG, sampling events were restricted to boiling water (the user started their stove and set it to what they considered their most common power level) as it was observed that aerosols generated from cooking food dominated the contributions to PM emissions, which are typically very low for LPG combustion. Conversely, combustion of solid fuels can emit PM2.5 orders of magnitude greater than LPG and the contributions from food. Thus, while the omission of food-generated aerosols from the LPG emissions limits the comparability with the biomass stoves, the impact is relatively small. Emissions species measured at all sites included CO2, CO, and PM2.5. USEPA project sites included additional measurements of elemental EC, OC, CH4, and TNMHC.

All samples were collected directly above the stove using a three-pronged stainless steel sampling probe with two inlet holes on the underside of each prong. A three-sided aluminum curtain was arranged around the stove to help keep the plume consistently updrafting through the sample probe. Real-time concentrations of CO and CO2 were measured using a TSI IAQ-CALC 7545 (TSI Incorporated, Shoreview USA), and gravimetric measurements of PM2.5 mass deposition were collected for analysis. Elemental carbon (EC) and OC measurements were collected at USEPA project sites using quartz filters (Pall Corporation, Port Washington, USA) that were sent to Sunset Laboratory for analysis by the thermal-optical method, using transmittance correction [19]. Mass deposition of PM2.5 was determined gravimetrically by weighing the filters on an electronic microbalance with 0.1µg resolution (Mettler Toledo, Columbus, USA).

At USEPA-funded project sites in India, Uganda, and Benin, emissions of CH4 and TNMHC were measured by drawing a sample at a constant rate into a Kynar sample bag (CEL Scientific, USA) over the test period. Approximately 200 mL of each sample was then transferred to a 0.5 L metalized bag (Cali-bond 5, Calibrated Instruments, Inc., McHenry, USA) and transported back to the Berkeley Air laboratory for analysis using a Perkin Elmer 8500 gas chromatograph (Perkin Elmer, Waltham, USA). All gases were quantified using 5-point calibration curves (all r2 > 0.995) made from NIST traceable calibration gas.

All fuel was weighed before beginning the test and unused fuel, ash, and char were weighed separately immediately after the test. These fuel masses are used in the calculations of fuel consumption and firepower, as well as emissions factors and rates with the carbon balance approach, as has been done in previous studies of stove emissions and is described in the Water Boiling Test (WBT) 4.2.3 protocol [20,21,22,23]. Information on event type and number of people being cooked for (if applicable) was collected to account for differences in energy demand between events. To normalize for the different energy demands across gender and age, individuals were weighted according to the standard adult convention used in the Kitchen Performance Test Protocol [16]. Cooking events were weighted at 1.0 for meals and 0.5 for preparing beverages such as tea or heating milk.

2.2. Quality Assurance/Quality Control

Field teams performed QA/QC checks to ensure data collected was consistent and accurate, including weekly scale checks with a standard weight; pre-, post-, and, when possible, weekly calibrations of TSI CO/CO2 monitors; collection of particulate filter field blanks, co-located measurements by partner research teams; and daily review of collected survey data. Additional details on the sampling methods, field team training, and QA/QC practices are available in supplementary material.

3. Results and Discussion

Due to the large amount of data collected during these surveys, summary statistics on the full set of output metrics, including emission factors (per unit mass and energy content), emission rates, and consumption metrics are presented in tabular format in the supplementary material.

3.1. PM2.5 and CO Emission Rates

ISO Technical Report 19867-3, Voluntary Performance Targets for Cookstoves, provides performance guidance on stove performance related to emissions, thermal efficiency, safety and durability [24]. These ISO performance targets are an update from the ISO international workshop agreement for 11:2012: Guidelines for evaluating cookstove performance [25], with a similar framework of tiered performance targets. The scale to categorize performance is 0 to 5, with Tier 0 representing the poorest performance and Tier 5 the best. Emission targets were established by modeling the fraction of homes which would fall below relative risk levels for acute lower respiratory infections for PM2.5, and for CO the fraction of homes which would meet the WHO 24-h standard (7mg/m3) [26]. Importantly, the ISO tiers are meant to be used with the ISO laboratory testing protocol [12], and are not explicitly intended to be applied to results derived from other protocols, such as the uncontrolled testing conducted for this study. Therefore, the application of the ISO tiers here should be interpreted as illustrative rather than defining the performance of these stoves within the ISO framework.

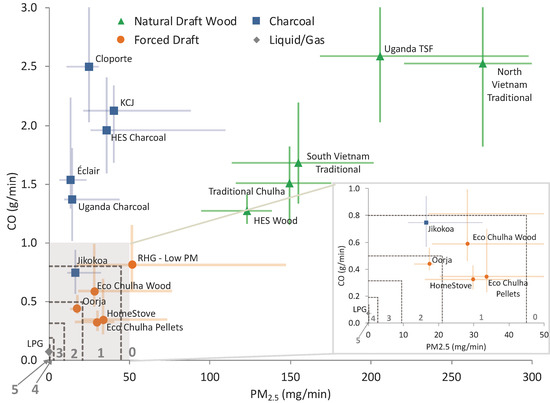

Median emission rates from field measurements are plotted in Figure 1, along with the boundaries of the laboratory-based ISO Voluntary Performance Targets for PM2.5 and CO. The graph illustrates the stove/fuel combinations evaluated represent a broad range of emissions performance. All traditional stoves were categorized as Tier 0 under the ISO tier system, which confirms the need for new stoves to reduce emissions. Nearly all of the natural draft solid biomass cookstoves, other than the Jikokoa, remained in the Tier 0 category, although in many cases significant improvement over the baseline was observed. The Éclair, for example, demonstrated a 38% improvement in the CO emission rate when compared to the Beninese traditional stoves (p < 0.01) and the PM2.5 emission rates were bordering Tier 3. The Jikokoa was the best performing charcoal stove, at Tier 2 for PM2.5 and Tier 1 for CO emission rates. The forced draft stoves all performed at Tier 1 or better, other than the RGH High PM (see Figure 1 notes). The Oorja’s PM2.5 emissions performance was at Tier 2 and demonstrated relatively low variability. The Eco Chulha emitted PM2.5 at similar rates for both wood usage and pellet usage; however, pellet combustion emitted approximately half the CO per minute compared to when it was used with wood. The HomeStove was similar to the Eco Chulha with pellets, which both demonstrated Tier 1 PM2.5 emissions and near Tier 3 CO emissions.

Figure 1.

Median PM2.5 and CO emission rates with the ISO Voluntary Performance Targets emissions tiers indicated by the dashed lines. Error bars represent interquartile ranges (IQRs). The region within the grey box is zoomed in for clarity in the bottom right hand corner. Notes: For clarity, the rice husk gasifier (RHG) high particulate matter (PM) is not included as its PM2.5 emissions far exceeded the axis scale (PM2.5: 813 mg/min; CO: 0.89 g/min).

While these results suggest that biomass stoves still need to improve field emissions performance to reach more health-protective levels, a recent field study from Rwanda found that the forced draft Mimi-Moto pellet stove can achieve Tier 3–4 level performance for CO and PM emissions [27]. The study by Champion and Grieshop [27] reported PM2.5 emission rates from the pellet stove to have an interquartile quartile range (IQR) from ~2 to 9mg/min (ISO Tier 4: 2.7 mg/min; ISO Tier 3: 9.5mg/min), and the IQR for CO was ~50–200mg/min (ISO Tier 5: 133 mg/min; ISO Tier 4: 190mg/min). The low real-world emissions from the Mimi-Moto demonstrate biomass-fueled stoves have the potential to be a relatively clean household fuel, though any clean-burning stove will still need large-scale implementation and will need to substantially displace use of more polluting traditional technologies to result in meaningful impacts [28].

LPG stoves had the lowest emissions at Tier 5 levels for PM2.5 and CO, and less than the WHO intermediate PM2.5 emission rate of 1.75mg/min. LPG PM2.5 emissions were below our limit of detection of 1.1 mg/min for nine out of 12 samples. The three higher emission samples (2.0–2.3) occurred for samples where the flames were yellow and visibly blackening the bottoms of the pot (see Figure S21 in supplementary material for an example). Results from a laboratory study by Shen et al. [29] reported an LPG PM2.5 emission rate range of <0.11 to 0.61 mg/min, which is in line with the majority of the LPG events measured here emitting less that 1.1 mg/min. A recent field study by Weyant et al. [30] reported similarly low emission rates from biogas and LPG (0.6 ± 0.8 mg/min), including cooking emissions, which were near the study’s median limit of detection (0.8 mg/min). Combined, these results reinforce that LPG and likely other gas fuels can reduce emissions to health-protective levels, though care should still be taken to ensure that the stoves are operating as intended and displacing the traditional technologies to maximize household air pollution reductions.

3.2. Climate Forcing Pollutant Emissions

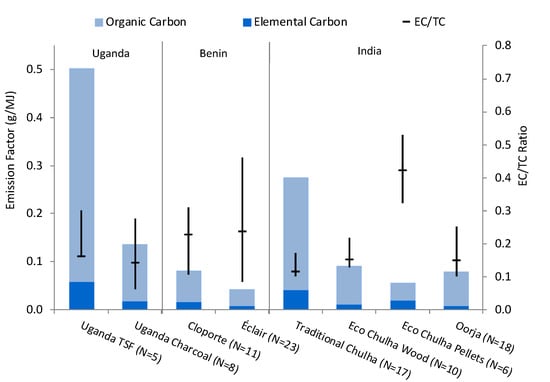

EC, OC, and total carbon (EC + OC) emissions factors are shown in Figure 2 for the stove/fuel combinations with the available data, as well as respective EC/TC ratios, which provide an indication of the relative warming impact per unit mass emitted. Garland et al. [31] presents black carbon emissions estimates for the other stoves which were measured as part of the CEPS study, which was done using a post hoc optical analysis of the Teflon filters. EC is generally a good proxy for black carbon, the light-absorbing component of particulate emissions, and a common assumption for source characterization studies [32]. The black carbon fraction of aerosols absorbs light, and therefore has a warming effect, whereas the organic carbon fractions scatter light and have a cooling impact [3,33]. All stoves emitted less EC compared to OC, which is typical for biofuel combustion [3]. The total carbon emissions were highest for the Uganda TSF and traditional chulha, which corresponds with their relatively high PM2.5 emission factors. As shown in Table 2, their median EC/TC ratios are similar to those reported for simple wood stoves from other studies, though somewhat lower than what was reported by Eilenberg et al. [34].

Figure 2.

EC and OC emission factors and EC/TC ratios for fuel stove combinations for which quartz filters samples were collected. Mean EC and OC emission factors are presented as the blue bars, while the median EC/TC ratios are indicated by the black horizontal bar markers, with respective error bars representing their IQRs.

Table 2.

Comparison of elemental carbon/total carbon (EC/TC) interquartile range (IQR) emissions ratios from simple or traditional wood stoves. Results from this study are italicized.

The Eco Chulha, when used with pellets, produced aerosols with the highest EC/TC ratios, which were approximately 3–4 times greater than the traditional chulha or Eco Chulha with wood. Although speculative, this increased EC/TC ratio may be due to higher combustion temperatures, which are able to burn more of the organic carbon, but do not completely combust the elemental carbon. A similar trend has been shown for rocket-style stoves, which have been shown to emit aerosols with higher EC/OC ratios compared to three-stone fires [20,37], and for the pellet-fed Mimi-Moto in Rwanda (IQR ~0.18–0.43) compared to traditional wood stoves (IQR ~0.17–0.32) [27]. Conversely, the forced draft pellet Oorja stove had very a very low EC/TC ratio, suggesting that the pellet type, technology, or other operating conditions can substantially affect the warming implications of a stove’s aerosol emissions.

The charcoal stoves generally had low total particulate carbon emissions, with the stoves in Benin appearing to have slightly higher EC/TC ratios compared to stoves in Uganda. The stoves with relatively low TC emissions, which are either batch-fed or have more controlled fuel feeding practices, typically demonstrate low PM emissions during relatively steady state combustion conditions and may have EC/TC ratios that are driven largely by emissions during the ignition phase [7,21,38]. Lighting practices such as fanning, use of kerosene or other accelerants, and number of lighting attempts, amongst others, may be the key drivers of overall PM emissions as well as the PM’s optical properties.

The full climate impact of stove emissions is dependent on many additional factors, including emissions of other greenhouse pollutants, cloud effects of co-emitted aerosols and precursors, the sustainability of fuel harvesting, location (e.g., proximity to glaciers), and other factors, which makes drawing conclusions about the net climate impacts of these stoves beyond the scope of this analysis. The black and organic carbon fractions, however, are still critical inputs for models and approaches for predicting climate impacts. Emission factors for CH4 and THMHC can be found in the supplementary material.

3.3. Combustion Efficiency and Comparison with Laboratory Data

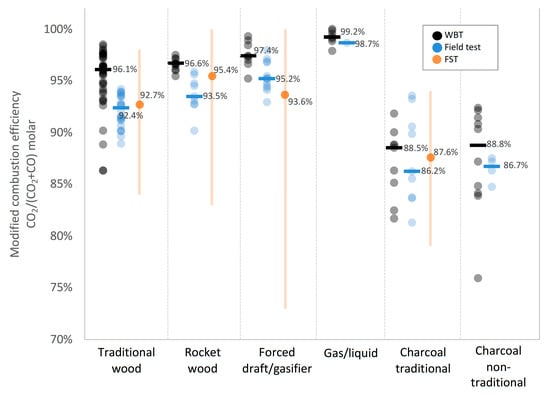

Figure 3 shows a comparison of modified combustion efficiencies (MCE: CO2/[CO2 + CO] molar) reported from several studies for various stove classes when measured using water boiling-based tests in the laboratory, uncontrolled conditions in the field, and with a newer test protocol which operates stoves over a broader range of conditions (Firepower Sweep Test (FST)–described below). Water boiling tests (WBTs) have been the most commonly applied laboratory test protocol, for which stoves are operated at a high-power phase to bring water to a boil, followed by a low-power phase to maintain a simmer [5,23]. MCE provides a general indication of how completely a fuel is being combusted. There is a consistent trend that controlled laboratory testing produces higher MCEs compared to field tests, with the median for each stove type higher when measured in the laboratory. Potential exceptions to this trend are plancha (griddle)-style chimney stoves, for which the opposite trend has been observed [6]. In contrast to these other stoves, plancha stoves are not designed to primarily boil water, and thus perform relatively poorly during standard water boiling tests. The general overestimating of combustion efficiencies during WBTs, and thus underestimating of CO, PM, and other products of incomplete combustion, is not surprising given that fire tending and fuel conditions outlined in the test protocols are typically more ideal than those used in homes. This overestimation suggests that data derived from these tests should not be directly used to indicate actual performance in homes, while still recognizing the critical role of controlled testing in stove design and standardized testing.

Figure 3.

Comparison of modified combustion efficiencies for different stove and fuel types measured from laboratory and field tests. Each data point represents the mean of a set of tests for a given stove fuel/combination, and the rectangles are the median of those data points. The error bars for the firepower sweep test (FST) represent the range of mean modified combustion efficiencies (MCEs) across the test sequences for each respective stove type. Data sources: this study and Roden et al. [9], Jetter et al. [10], Bilsback et al. [13], Johnson et al. [20], Smith et al. [22], Shen et al. [29], Garland et al. [31], Eilenberg et al. [34], Grieshop et al. [35], Weyant et al. [36], Bhattacharya et al. [39], Bhattacharya et al. [40], Jetter et al. [41], Johnson et al. [42], Tian et al. [43], Zhang et al. [44], Kituyi et al. [45], Preble et al. [46], Johnson et al. [47], MacCarty et al. [48], Johnson et al. [49], Stockwell et al. [50], Fleming et al. [51].

Across stove type, there is a trend from both WBT and field testing showing respective increases in MCE from traditional wood, to rocket, to forced draft/gasifier style stoves, with liquid and gas fuel stoves demonstrating the highest MCEs. Charcoal combustion is dominated by surface oxidation, a process which produces more CO compared to gas phase combustion, and thus the MCEs for charcoal stoves are substantially lower than for the wood burning stoves. Interestingly, and excluding charcoal stoves, the average difference between MCE in the laboratory and field tests for a given stove/fuel category decreased as the overall MCE of that category increased, with almost no difference between the laboratory and field MCE of gas stoves. This trend is likely due to the more constrained and consistent combustion conditions that are achieved by higher performing stove/fuel combinations. For example, there are very few variables which may cause a gas stove to result in poor combustion, whereas there are several factors such as wet fuel, leaving a log to smolder, and others which can cause a traditional wood stove to have low MCE.

MCEs from Bilsback et al. [13] using the FST have been included to demonstrate how new protocols have been developed to potentially bridge the gap between laboratory and field performance. Compared to the WBT, which is limited to high-power and simmering phases, the FST includes low, medium, and high firepower phases, as well as start-up and shutdown phases, which are all measured individually. This larger span of operating conditions is reflected in the range of MCE’s that encompass the mean results from both the WBT- and field-based test results. The mean estimates from the FST for traditional wood, rocket, and charcoal stoves are also between the averages of the WBT and field-based MCEs, suggesting the FST may be better at approximating field performance of MCE. The forced draft stove tested with the FST showed the largest range of MCE and had a lower average MCE than the WBT or field tests. This difference in pattern was likely due to the start-up and shutdown phases having poor performance for this specific stove. Overall, the larger range of performance measured by the FST, with the specific phases quantified individually, allows for potentially weighting phases (according to field operation) to better match field performance estimates.

While this comparison only looks at MCE as it is a commonly reported performance metric, Bilsback et al. [13] showed that similar overlap between field performance and results from FST testing can be seen for PM2.5 and CO emission factors. Medina et al. [15] also showed that testing cookstoves by replicating local cooking cycles in rural Mexico produced MCEs and PM2.5 and CO emission factors that better represented those for the local stoves during field performance. The open fire stove, for example, had a mean MCE of 92% [15], which is in line with the average for the field tests presented here and the FST, and the Patsari chimney stove had an MCE of 96%, which agreed with previous field testing [6]. The new ISO protocol was informed by these approaches and is largely a simplified version with low-, medium-, and high-power phases [12], which can be weighted by firepower to reflect those used for a specific region. Although to our knowledge no published data from the ISO protocol is yet available, the results from new testing approaches such as Bilsback et al. [13], when compared with field-based performance estimates suggest the new ISO protocol will provide step towards better linking laboratory and field-based stove performance.

3.4. Firepower and Fuel Consumption

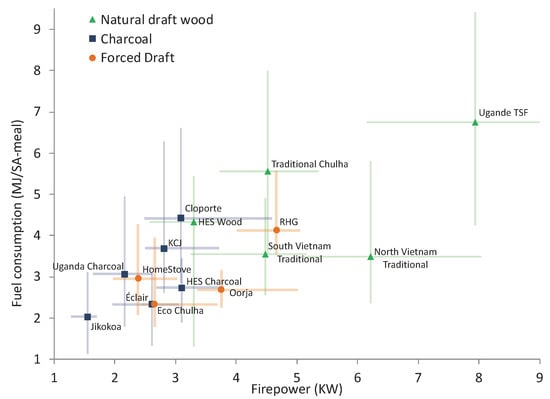

Figure 4 shows stove firepower versus fuel consumption. Firepower provides an indication of how the stove is being operated to conduct a desired task. The median firepower for all stoves ranged from ~1.5 to 8 kW, similar to the range of 1.3 to 9.9 kW for the household cookstoves tested in Jetter et al. [10] and Smith et al. [22]. There is considerable variability in the power ranges for the respective stoves, with the largest IQRs for stoves with minimal fuel loading restrictions, such as the TSF and traditional chulha, spanning 6.1 to 9.0 and 3.7 to 5.3 kW, respectively, and lower ranges for batch-fed charcoal stoves such as the Jikokoa and the Éclair with IQRs of 1.3–1.7 and 2.0–3.1 kW, respectively. Fuel consumption, as megajoules (MJ) per standard adult (SA) meal, was also widely variable, and followed a similar trend as seen with firepower, with the traditional wood stoves generally having higher fuel consumption and the more controlled, or batch-fed stoves having lower fuel consumption. The variability in firepower and fuel consumption are functions of the cooking systems, which vary in cooking demands, tending practices, thermal efficiencies, and other factors.

Figure 4.

Median cookstove fuel consumption performance versus firepower. Error bars represent the IQR. Notes: LPG is not shown on the graph as meals were not prepared on the LPG stoves. LPG stove power had an IQR of 1.9–3.4 kW, with a median of 2.1 kW. The Eco Chulhas when used with pellets and wood were combined as they showed negligible difference in power and fuel consumption performance.

The positive relationship between firepower and fuel consumption across all stoves is a common trend. For example, there are strong positive linear correlations between firepower and fuel consumption (as the inverse of thermal efficiency) in the Jetter et al. [10] (r2 = 0.73) and Smith et al. [22] (r2 = 0.51) cookstove performance datasets, similar to the r2 of 0.56 (linear Pearson’s r correlation) for the data in Figure 4. This general relationship is expected, as stoves which are more fuel efficient generally deliver more energy with less firepower and vice versa. Among the stoves assessed for this study, the forced draft and charcoal stoves were the most fuel efficient (discounting the energy required to produce charcoal), with relatively low corresponding firepowers. Additional analysis of project- and region-specific comparisons of firepower and fuel consumption can be found in the supplementary material.

4. Limitations and Conclusions

While the field-based estimates of stove performance are key to characterizing real-world performance of stove/fuel combinations, they also require substantial resources, and thus are often limited by sample size and overall scope. The sample sizes here ranged from five (TSF in Uganda) to 39 (Éclair), with field campaigns conducted during single seasons in one or two communities per project site. Changes in emission performance have been shown to differ between seasons [35], likely due to changes in factors such as cooking practices, fuel conditions, and others. Given these restrictions, it is difficult to say how representative these emission factors and rates may be of the overall baseline or intervention technologies in their respective regions.

This study did not cover the full range of technologies and geographies where biomass stove interventions are occurring. The Mimi-Moto stove in Rwanda, for example, had PM2.5 and CO emissions performance at up to ISO Tier 4 levels in homes [27]. We also did not report on stoves from Latin America or chimney stoves, which can substantially reduce exposure to household air pollution [52,53,54]. Especially useful would be a field study of fugitive emissions under real-world conditions, which would complement similar laboratory efforts [55], and provide context for how well chimney stoves capture and vent health damaging pollutants in homes.

The PM2.5 emission rates from the biomass cookstoves were substantially better than their traditional counterparts, but many are still well above the aspirational health-based ISO targets, indicating room for further improvement. Biomass stoves with the best performance measured for this study were forced draft stoves as well as the Jikokoa stove in Kenya. LPG had PM2.5 emission rates below the aspirational health target, but requires significant resources to build out distribution and financing systems for it to be available and affordable in many areas, and has other implications for the climate and sustainability as a fossil fuel. The better performing biomass stoves are likely to be the most practical options for providing impact where infrastructure for LPG is unlikely to develop in the near term.

PM2.5 and CO emissions performance from stove/fuel combinations during normal daily use is generally higher than those measured under controlled conditions [5], which was reinforced by the comparison of laboratory and field MCEs presented here. New testing approaches, including the recently published ISO testing protocol [12,13], run stove/fuel combinations through a larger range of operating conditions than commonly used water boiling tests, and comparison of data from similar protocols to the ISO testing standard suggest this approach will better represent field performance.

Elemental and organic carbon emission factors were in line with previously reported estimates. In India, the EC/TC ratios were similar or higher for the new stoves, suggesting that climate benefits from aerosols would need to arise from reductions in particulate emissions rather than producing aerosols with less warming effect. Interestingly, there was a large shift towards higher EC/TC ratios for a forced draft stove when using pellets compared to wood (Eco Chulha), which demonstrates how critical it is to evaluate the stove/fuel system and not assume a given performance for a stove regardless of the fuel used.

Integration of field and laboratory evaluations is needed for better understanding the differences in performance between the two settings. The work presented here was nominally aligned with previous or planned laboratory testing, and helped identify differences in performance. Further studies which are explicitly designed to systematically test stoves and fuels under a range of laboratory and field conditions would help better define the relationship between laboratory and field emissions, and therefore be useful in understanding potential health and environmental impacts.

Finally, while this paper focused solely on the performance of the various fuel/stove combinations, the potential impacts on climate and health of lower emissions are also a function of their uptake and displacement of traditional cooking technologies [28], as well as the specific context of the intervention. Factors such as ventilation and cooking location impact household air pollution [56], and geography and meteorology impact climate implications [33]. Therefore, more comprehensive understandings of the potential health and climate implications of these technologies would require a complimentary analysis on their feasibility for scale, the extent to which they could be expected to displace less efficient and clean cooking devices, and context-specific characteristics that may affect the climate or health outcomes of interest.

Supplementary Materials

The following are available online at https://www.mdpi.com/2073-4433/10/5/290/s1: Additional information on the study sites and stoves, methods, and tabular stove performance data.

Author Contributions

Conceptualization, M.A.J., R.A.C., J.M., and D.P.; Methodology, M.A.J., C.R.G., R.E., and D.P.; Formal Analysis, M.A.J., C.R.G., K.J., and R.E.; Investigation, M.A.J., C.R.G., J.N., J.K., T.N., and R.N.; Resources, A.P., E.W., P.S., E.K., D.D.K., R.N., M.Y., R.A.C., E.D., and J.M.; Writing—Original Draft Preparation, M.A.J. and C.R.G.; Writing—Review and Editing, M.A.J., C.R.G., K.J., R.E, J.N., C.W., A.P., J.K., E.W., T.N, D.D.K., E.K., P.S., R.N., M.Y., J.M., E.D., R.A.C., and D.P..; Visualization; Supervision, M.A.J.; Project Administration, R.A.C., E.D., and J.M.

Funding

Funding was provided by the United States Environmental Protection Agency (contract numbers: EP-10-H-000942 and EP-11-H-000964) and the United Nations Foundation (contract number: UNF-12-404).

Acknowledgments

Olaf Sorensen, Pedro Sung Hoe Kim, Amy Cao, and Maneet Kaur of Berkeley Air assisted with data processing and analysis, and we thank James Jetter from the USEPA for his feedback. We also thank Kasra Kakavand and Kunaal Kapoor from the University of California-Irvine and Cheryl Weyant from the University of Illinois, for their integral help during the field campaigns in in Benin, Gujarat, and Maharashtra, respectively. We are grateful to our field partners, who worked hard to ensure the success of the training programs and field campaigns. We extend our greatest thanks to the participants who graciously accepted us into their homes during the field campaigns. The author’s views expressed in this publication do not necessarily reflect the views of the United States Environmental Protection agency nor the United Nations Foundation.

Conflicts of Interest

Ashwin Patel (Apha Energy, Eco-Chulha), Emmy Wasirwa (Wana Energy, LPG), Do Duc Khoi (Rice Husk Gasifier), Ethan Kay (Biolite, HomeStove), Peter Scott (Burn Manufacturing, Jikokoa), Raphael Nguyen (GIZ, Éclair), and Mahesh Yagnaraman (First Energy, Oorja) were involved in the development and/or promotion of the respective stove technologies included in the article. They helped facilitate and support logistical activities on the ground, including access to the homes and communities where the studies were conducted. These authors reviewed the paper, provided specific information about their technologies and programs, and reviewed that information for clarity and accuracy. They were not involved in the data analysis or interpretation of results.

References

- Bonjour, S.; Adair-Rohani, H.; Wolf, J.; Bruce, N.G.; Mehta, S.; Prüss-Ustün, A.; Lahiff, M.; Rehfuess, E.A.; Mishra, V.; Smith, K.R. Solid Fuel Use for Household Cooking: Country and Regional Estimates for 1980–2010. Environ. Health Perspect. 2013, 121, 784–790. [Google Scholar] [CrossRef] [PubMed]

- World Health Organization. Household Air Pollution and Health. Available online: https://www.who.int/news-room/fact-sheets/detail/household-air-pollution-and-health (accessed on 1 March 2019).

- Bond, T.C.; Doherty, S.J.; Fahey, D.W.; Forster, P.M.; Berntsen, T.; DeAngelo, B.J.; Flanner, M.G.; Ghan, S.; Kärcher, B.; Koch, D.; et al. Bounding the role of black carbon in the climate system: A scientific assessment. J. Geophys. Res. Atmos. 2013, 118, 5380–5552. [Google Scholar] [CrossRef]

- United Nations Sustainable Development Goals: Ensure access to affordable, reliable, sustainable and modern energy Energy. In United Nations Sustainable Development. Available online: https://www.un.org/sustainabledevelopment/energy/ (accessed on 28 March 2019).

- Berkeley Air. Stove Performance Inventory Report; Prepared for the Global Alliance for Clean Cookstoves; Berkeley Air Monitoring Group: Berkeley, CA, USA, 2012. [Google Scholar]

- Johnson, M.; Edwards, R.; Berrueta, V.; Masera, O. New Approaches to Performance Testing of Improved Cookstoves. Environ. Sci. Technol. 2010, 44, 368–374. [Google Scholar] [CrossRef] [PubMed]

- Chen, Y.; Roden, C.A.; Bond, T.C. Characterizing Biofuel Combustion with Patterns of Real-Time Emission Data (PaRTED). Environ. Sci. Technol. 2012, 46, 6110–6117. [Google Scholar] [CrossRef]

- Bailis, R.; Berrueta, V.; Chengappa, C.; Dutta, K.; Edwards, R.; Masera, O.; Still, D.; Smith, K.R. Performance testing for monitoring improved biomass stove interventions: Experiences of the Household Energy and Health Project (1). Energy Sustain. Dev. 2007, 11, 57–70. [Google Scholar] [CrossRef]

- Roden, C.A.; Bond, T.C.; Conway, S.; Osorto Pinel, A.B.; MacCarty, N.; Still, D. Laboratory and field investigations of particulate and carbon monoxide emissions from traditional and improved cookstoves. Atmos. Environ. 2009, 43, 1170–1181. [Google Scholar] [CrossRef]

- Jetter, J.; Zhao, Y.; Smith, K.R.; Khan, B.; Yelverton, T.; DeCarlo, P.; Hays, M.D. Pollutant Emissions and Energy Efficiency under Controlled Conditions for Household Biomass Cookstoves and Implications for Metrics Useful in Setting International Test Standards. Environ. Sci. Technol. 2012, 46, 10827–10834. [Google Scholar] [CrossRef]

- Habib, G.; Venkataraman, C.; Bond, T.C.; Schauer, J.J. Chemical, Microphysical and Optical Properties of Primary Particles from the Combustion of Biomass Fuels. Environ. Sci. Technol. 2008, 42, 8829–8834. [Google Scholar] [CrossRef] [PubMed]

- ISO. Standard 19867-1: Clean Cookstoves and Clean Cooking Solutions—Harmonized Laboratory Test Protocols—Part. 1: Standard Test Sequence for Emissions and Performance, Safety and Durability; International Organization for Standardization: Geneva, Switzerland, 2018. [Google Scholar]

- Bilsback, K.R.; Eilenberg, S.R.; Good, N.; Heck, L.; Johnson, M.; Kodros, J.K.; Lipsky, E.M.; L’Orange, C.; Pierce, J.R.; Robinson, A.L.; et al. The Firepower Sweep Test: A novel approach to cookstove laboratory testing. Indoor Air 2018, 28, 936–949. [Google Scholar] [CrossRef]

- SeTAR. Indonesian Clean Stove Initiative Pilot Programme: Water Boiling Test Methods and Product Evaluation Criteria (v 30.03.02); Sustainable Energy Technology and Research Centre: Johannesburg, 2014; Available online: http://cleancookingalliance.org/binary-data/DOCUMENT/file/000/000/87-1.pdf (accessed on 20 May 2019).

- Medina, P.; Berrueta, V.; Martínez, M.; Ruiz, V.; Ruiz-Mercado, I.; Masera, O.R. Closing the gap between lab and field cookstove tests: Benefits of multi-pot and sequencing cooking tasks through controlled burning cycles. Energy Sustain. Dev. 2017, 41, 106–111. [Google Scholar] [CrossRef]

- Bailis, R. Kitchen Performance Protocol: Version 3.0. 2007. Available online: https://www.cleancookingalliance.org/binary-data/DOCUMENT/file/000/000/604-1.pdf (accessed on 20 May 2019).

- Johnson, M.A.; Pilco, V.; Torres, R.; Joshi, S.; Shrestha, R.M.; Yagnaraman, M.; Lam, N.L.; Doroski, B.; Mitchell, J.; Canuz, E.; et al. Impacts on household fuel consumption from biomass stove programs in India, Nepal, and Peru. Energy Sustain. Dev. 2013, 17, 403–411. [Google Scholar] [CrossRef]

- Garland, C.; Jagoe, K.; Wasirwa, E.; Nguyen, R.; Roth, C.; Patel, A.; Shah, N.; Derby, E.; Mitchell, J.; Pennise, D.; et al. Impacts of household energy programs on fuel consumption in Benin, Uganda, and India. Energy Sustain. Dev. 2015, 27, 168–173. [Google Scholar] [CrossRef]

- Birch, M.E.; Cary, R.A. Elemental carbon-based method for monitoring occupational exposures to particulate diesel exhaust. Aerosol Sci. Technol. 1996, 25, 221–241. [Google Scholar] [CrossRef]

- Johnson, M.; Lam, N.; Pennise, D.; Charron, D.; Bond, T.; Modi, V.; Ndemere, J.A. In-Home Emissions of Greenhouse Gas Pollutants from Traditional and Rocket Biomass Stoves in Uganda; United States Agency for International Development: Washington, DC, USA, 2011.

- Roden, C.A.; Bond, T.C.; Conway, S.; Pinel, A.B.O. Emission factors and real-time optical properties of particles emitted from traditional wood burning cookstoves. Environ. Sci. Technol. 2006, 40, 6750–6757. [Google Scholar] [CrossRef]

- Smith, K.R.; Uma, R.; Kishore, V.V.N.; Lata, K.; Joshi, V.; Zhang, J.; Rasmussen, R.A.; Khalil, M.A.K. Greenhouse Gases from Small-Scale Combustion Devices in Developing Countries; Prepared for Office of Air and Radiation; United States Environmental Protection Agency: Washington, DC, USA, 2000.

- WBT Technical Committee. Water Boiling Test Protocol: Version 4.2.2; WBT Technical Committee. Available online: http://cleancookstoves.org/binary-data/DOCUMENT/file/000/000/399-1.pdf (accessed on 20 May 2019).

- ISO. Technical Report 19867-3: Clean Cookstoves and Clean Cooking Solutions—Harmonized Laboratory Test Protocols—Part 3: Voluntary Performance Targets for Cookstoves Based on Laboratory Testing; International Organization for Standardization: Geneva, Switzerland, 2018. [Google Scholar]

- ISO. IWA 11:2012: Guidelines for Evaluating Cookstove Performance; ISO: Geneva, Switzerland, 2012. [Google Scholar]

- WHO. WHO Guidelines for Indoor Air Quality: Selected Pollutants; World Health Organization Regional Office for Europe: Bonn, Germany, 2010. [Google Scholar]

- Champion, W.M.; Grieshop, A.P. Pellet-fed gasifier stoves approach gas-stove like performance during in-home use in Rwanda. Environ. Sci. Technol. 2019. [Google Scholar] [CrossRef]

- Johnson, M.A.; Chiang, R.A. Quantitative Guidance for Stove Usage and Performance to Achieve Health and Environmental Targets. Environ. Health Perspect. 2015, 123, 820–826. [Google Scholar] [CrossRef] [PubMed]

- Shen, G.; Jetter, J.; Smith, K.; Williams, C.; Faircloth, J.; Hays, M. Evaluating the Performance of Household Liquefied Petroleum Gas Cookstoves. Environ. Sci. Technol. 2018, 52, 904–915. [Google Scholar] [CrossRef]

- Weyant, C.; Thompson, R.; Lam, N.; Upadhyay, B.; Shrestha, B.; Maharjan, S.; Rai, K.; Adhikari, C.; Fox, M.C.; Pokhrel, A. In-field emission measurements from biogas and liquid petroleum gas (LPG) stoves, In preparation.

- Garland, C.; Delapena, S.; Prasad, R.; L’Orange, C.; Alexander, D.; Johnson, M. Black carbon cookstove emissions: A field assessment of 19 stove/fuel combinations. Atmos. Environ. 2017, 169, 140–149. [Google Scholar] [CrossRef]

- Bond, T.C.; Streets, D.G.; Yarber, K.F.; Nelson, S.M.; Woo, J.H.; Klimont, Z. A technology-based global inventory of black and organic carbon emissions from combustion. J. Geophys. Res. Atmos. 2004, 109. [Google Scholar] [CrossRef]

- Arvesen, A.; Cherubini, F.; Serrano, G.A.; Astrup, R.; Becidan, M.; Belbo, H.; Goile, F.; Grytli, T.; Guest, G.; Lausselet, C.; et al. Cooling aerosols and changes in albedo counteract warming from CO 2 and black carbon from forest bioenergy in Norway. Sci. Rep. 2018, 8, 3299. [Google Scholar] [CrossRef]

- Eilenberg, S.R.; Bilsback, K.R.; Johnson, M.; Kodros, J.K.; Lipsky, E.M.; Naluwagga, A.; Fedak, K.M.; Benka-Coker, M.; Reynolds, B.; Peel, J.; et al. Field measurements of solid-fuel cookstove emissions from uncontrolled cooking in China, Honduras, Uganda, and India. Atmos. Environ. 2018, 190, 116–125. [Google Scholar] [CrossRef]

- Grieshop, A.P.; Jain, G.; Sethuraman, K.; Marshall, J.D. Emission factors of health- and climate-relevant pollutants measured in home during a carbon-finance-approved cookstove intervention in rural India. GeoHealth 2017, 1, 222–236. [Google Scholar] [CrossRef]

- Weyant, C.L.; Chen, P.; Vaidya, A.; Li, C.; Zhang, Q.; Thompson, R.; Ellis, J.; Chen, Y.; Kang, S.; Shrestha, G.R.; et al. Emission Measurements from Traditional Biomass Cookstoves in South Asia and Tibet. Environ. Sci. Technol. 2019, 53, 3306–3314. [Google Scholar] [CrossRef]

- MacCarty, N.; Ogle, D.; Still, D.; Bond, T.; Roden, C. A laboratory comparison of the global warming impact of five major types of biomass cooking stoves. Energy Sustain. Dev. 2008, 12, 56–65. [Google Scholar] [CrossRef]

- Just, B.; Rogak, S.; Kandlikar, M. Characterization of Ultrafine Particulate Matter from Traditional and Improved Biomass Cookstoves. Environ. Sci. Technol. 2013, 47, 3506–3512. [Google Scholar] [CrossRef] [PubMed]

- Bhattacharya, S.C.; Albina, D.O.; Salam, P.A. Emission factors of wood and charcoal-fired cookstoves. Biomass Bioenergy 2002, 23, 453–469. [Google Scholar] [CrossRef]

- Bhattacharya, S.C.; Albina, D.O.; Khaing, A.M. Effects of selected parameters on performance and emission of biomass-fired cookstoves. Biomass Bioenergy 2002, 23, 387–395. [Google Scholar] [CrossRef]

- Jetter, J.J.; Kariher, P. Solid-fuel household cook stoves: Characterization of performance and emissions. Biomass Bioenergy 2009, 33, 294–305. [Google Scholar] [CrossRef]

- Johnson, M.; Edwards, R.; Alatorre Frenk, C.; Masera, O. In-field greenhouse gas emissions from cookstoves in rural Mexican households. Atmos. Environ. 2008, 42, 1206–1222. [Google Scholar] [CrossRef]

- Tian, L.; Lucas, D.; Fischer, S.L.; Lee, S.C.; Hammond, S.K.; Koshland, C.P. Particle and Gas Emissions from a Simulated Coal-Burning Household Fire Pit. Environ. Sci. Technol. 2008, 42, 2503–2508. [Google Scholar] [CrossRef]

- Zhang, J.; Smith, K.R.; Ma, Y.; Ye, S.; Jiang, F.; Qi, W.; Liu, P.; Khalil, M.A.K.; Rasmussen, R.A.; Thorneloe, S.A. Greenhouse gases and other airborne pollutants from household stoves in China: A database for emission factors. Atmos. Environ. 2000, 34, 4537–4549. [Google Scholar] [CrossRef]

- Kituyi, E.; Marufu, L.; Wandiga, S.O.; Jumba, I.O.; Andreae, M.O.; Helas, G. Carbon monoxide and nitric oxide from biofuel fires in Kenya. Energy Convers. Manag. 2001, 42, 1517–1542. [Google Scholar] [CrossRef]

- Preble, C.V.; Hadley, O.L.; Gadgil, A.J.; Kirchstetter, T.W. Emissions and Climate-Relevant Optical Properties of Pollutants Emitted from a Three-Stone Fire and the Berkeley-Darfur Stove Tested under Laboratory Conditions. Environ. Sci. Technol. 2014, 48, 6484–6491. [Google Scholar] [CrossRef] [PubMed]

- Johnson, M.; Lam, N.; Brant, S.; Gray, C.; Pennise, D. Modeling indoor air pollution from cookstove emissions in developing countries using a Monte Carlo single-box model. Atmos. Environ. 2011, 45, 3237–3243. [Google Scholar] [CrossRef]

- MacCarty, N.; Still, D.; Ogle, D. Fuel use and emissions performance of fifty cooking stoves in the laboratory and related benchmarks of performance. Energy Sustain. Dev. 2010, 14, 161–171. [Google Scholar] [CrossRef]

- Johnson, M.; Lam, N.; Wofchuck, T.; Edwards, R.; Pennise, D. In-field charcoal stove emission factors and indoor air pollution in Nairobi, Kenya; Berkeley Air Monitoring Group: Berkeley, CA, USA, 2009. [Google Scholar]

- Stockwell, C.E.; Christian, T.J.; Goetz, J.D.; Jayarathne, T.; Bhave, P.V.; Praveen, P.S.; Adhikari, S.; Maharjan, R.; DeCarlo, P.F.; Stone, E.A.; et al. Nepal Ambient Monitoring and Source Testing Experiment (NAMaSTE): Emissions of trace gases and light-absorbing carbon from wood and dung cooking fires, garbage and crop residue burning, brick kilns, and other sources. Atmos. Chem. Phys. 2016, 16, 11043–11081. [Google Scholar] [CrossRef]

- Fleming, L.T.; Weltman, R.; Yadav, A.; Edwards, R.D.; Arora, N.K.; Pillarisetti, A.; Meinardi, S.; Smith, K.R.; Blake, D.R.; Nizkorodov, S.A. Emissions from village cookstoves in Haryana, India and their potential impacts on air quality. Atmos. Chem. Phys. 2018, 18, 15169–15182. [Google Scholar] [CrossRef]

- Smith, K.R.; McCracken, J.P.; Thompson, L.; Edwards, R.; Shields, K.N.; Canuz, E.; Bruce, N. Personal child and mother carbon monoxide exposures and kitchen levels: Methods and results from a randomized trial of woodfired chimney cookstoves in Guatemala (RESPIRE). J. Expo. Sci. Environ. Epidemiol. 2010, 20, 406–416. [Google Scholar] [CrossRef] [PubMed]

- Rajkumar, S.; Clark, M.L.; Young, B.N.; Benka-Coker, M.L.; Bachand, A.M.; Brook, R.D.; Nelson, T.L.; Volckens, J.; Reynolds, S.J.; L’Orange, C.; et al. Exposure to household air pollution from biomass-burning cookstoves and HbA1c and diabetic status among Honduran women. Indoor Air 2018, 28, 768–776. [Google Scholar] [CrossRef] [PubMed]

- Cynthia, A.A.; Edwards, R.D.; Johnson, M.; Zuk, M.; Rojas, L.; Jiménez, R.D.; Riojas-Rodriguez, H.; Masera, O. Reduction in personal exposures to particulate matter and carbon monoxide as a result of the installation of a Patsari improved cook stove in Michoacan Mexico. Indoor Air 2008, 18, 93–105. [Google Scholar] [CrossRef]

- Ruiz-García, V.M.; Edwards, R.D.; Ghasemian, M.; Berrueta, V.M.; Princevac, M.; Vázquez, J.C.; Johnson, M.; Masera, O.R. Fugitive Emissions and Health Implications of Plancha-Type Stoves. Environ. Sci. Technol. 2018, 52, 10848–10855. [Google Scholar] [CrossRef] [PubMed]

- Johnson, M.A.; Chiang, R.A. Quantitative Stove Use and Ventilation Guidance for Behavior Change Strategies. J. Health Commun. 2015, 20, 6–9. [Google Scholar] [CrossRef] [PubMed]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).