Abstract

Pseudomonas pseudoalcaligenes CECT 5344 is a bacterium able to assimilate cyanide as a nitrogen source at alkaline pH. Genome sequencing of this strain allowed the detection of genes related to the utilization of furfurals as a carbon and energy source. Furfural and 5-(hydroxymethyl) furfural (HMF) are byproducts of sugars production during the hydrolysis of lignocellulosic biomass. Since they inhibit the yeast fermentation to obtain bioethanol from sugars, the biodegradation of these compounds has attracted certain scientific interest. P. pseudoalcaligenes was able to use furfuryl alcohol, furfural and furoic acid as carbon sources, but after a lag period of several days. Once adapted, the evolved strain (R1D) did not show any more prolonged lag phases. The transcriptomic analysis (RNA-seq) of R1D revealed a non-conservative punctual mutation (L261R) in BN5_2307, a member of the AraC family of activators, modifying the charge of the HTH region of the protein. The inactivation of the mutated gene in the evolved strain by double recombination reverted to the original phenotype. Although the bacterium did not assimilate HMF, it transformed it into value-added building blocks for the chemical industry. These results could be used to improve the production of cost-effective second-generation biofuels from agricultural wastes.

1. Introduction

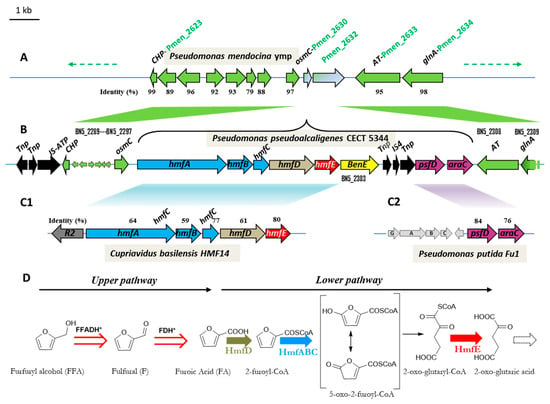

The development of renewable resources is one of the key actions to palliate climate change, which is largely a consequence of the world’s dependence on petrol. On the other hand, contamination of the environment is an inevitable consequence of human development. These are global problems that need international agreements [1]. Biotechnology can offer solutions to these challenges, such as the production of bioethanol as a substitute to gasoline [2]. Biotechnology can also offer alternatives to the physical-chemical treatment of contaminating compounds, either by avoiding their production, or by mitigating their impact once it has occurred. The biodegradation of pollutants is, in general, a technology that has good social acceptance [3]. Pseudomonas pseudoalcaligenes CECT 5344 was isolated from sludge of Guadalquivir River, and it is able to use cyanide as the only source of nitrogen [4]. Cyanide is an extremely toxic compound used in the synthesis of organic compounds such as nitriles, plastics, paints, adhesives, cosmetics, etc., while mining activities and the jewellery industry are the main source of cyanurated wastes [5,6,7,8]. This strain tolerates an unusually high concentration of cyanide (up to 30 mM) [4], but it requires a suitable carbon source for growing. The sequencing of the genome of P. pseudoalcaligenes CECT 5344 has made it possible to predict which carbon sources can be used by this bacterium, such as the assimilation of furanic compounds [9]. Furfurals are aromatic natural compounds formed by the dehydration of sugars during the thermochemical pre-treatment of the lignocellulosic materials to release fermentable sugars. The production of biofuels from lignocellulosic residues, which is part of the so-called second-generation biofuels, constitutes a viable option for reducing the greenhouse effect and for providing an alternative to fossil fuels [10,11]. There are different pre-treatment technologies of lignocellulosic residues. One of the parameters that has to be taken into account to optimize the process is avoiding the formation of potentially inhibitory compounds to the posterior yeast fermentation process [12]. From the food technology perspective, furfurals are potential carcinogenic compounds used as a marker of honey adulteration, generated by acid-catalyzed dehydration of carbohydrates of food-containing sugars [13]. In any case, furfural (F), or fufuralaldehyde, and 5-hydroxymethyl furfural (HMF) are natural products that can be eliminated by using the capacity of some microorganisms to metabolize them [14,15,16,17,18,19,20,21,22]. Other furanic derivatives are furoic acid (FA) and furfuryl alcohol (FFA), all of them with the common thread of having an aromatic furan ring. The variety of furanic compounds degrading species is limited mostly to Gram-negative aerobic bacteria and some Gram positives [17], with a few exceptions including fungi [14]. In the first degradation route currently proposed, furfural is oxidized to 2-furoic acid (FA), which is subsequently transformed into 2-oxoglutarate, a Krebs cycle intermediate [23]. The complete metabolic pathway for the assimilation of F and HMF, as well as the genetic of the process, was first described in the soil isolate Cupriavidus basilensis HMF14 [24] (Figure 1). In this strain, the hmfABCDE gene cluster is responsible for the assimilation of furoic acid. The first reaction in the pathway is catalysed by the 2-furoyl-CoA synthetase (HmfD), producing 2-furoyl-CoA from 2-furoic acid. The conversion of 2-furoyl-CoA is into 5-hydroxy-2-furoyl-CoA in C. basilensis; HMF14 is catalysed by the molybdenum-dependent 2-furoyl-CoA dehydrogenase (HmfABC). The final steps of the proposed furoic-acid metabolic pathway consist of the transformation of 5-oxo-2-furoyl-CoA into 2-oxoglutarate. No gene has been assigned to the hydrolysis of the lactone, whereas hmfE has been proposed to encode a specific 2-oxoglutaroyl-CoA thioesterase [24] (Figure 1). P. pseudoalcaligenes contains an hmfABCDE gene cluster homologous to the gene cluster shown to be essential for the assimilation of furfural in C. basilensis HMF14 (Figure 1). Concretely, the amino acid sequence of HmfA from C. basilensis HMF14 (GenBank ADE20399.1) is 64% identical to the homologous protein of P. pseudoalcaligenes (BN5_2298, 76% positives). The % identity/% similarity for the rest of the proteins are: 59%/72%, 77%/83%, 61%/75% and 80%/88%, for HmfB (GenBank ADE20400.1), HmfC (GenBank ADE20401.1), HmfD (GenBank ADE20402.1) and HmfE (GenBank ADE20403.1), respectively. Moreover, this locus also contains downstream hmfABCDE, a gene (benE) belonging to the Major Facilitator Superfamily (MSF)-family of transporters and two separate genes homologous to genes related to the assimilation of furfural in Pseudomonas putida Fu1 [9,25] (Figure 1). One of them belongs to the AraC-family of regulators. AraC from P. putida Fu1 (GenBank ACA09742.1) is 75% identical (88% similar) to its orthologous gene product in P. pseudoalcaligenes (BN5_2307, Figure 1). The other upstream gene (PsfD) codes for a putative conserved protein usually annotated as maturation factor for molybdenum containing dehydrogenases, like xanthine and CO dehydrogenases [9,25]. In that respect, the furoyl-CoA dehydrogenase was proposed to be a molydo-protein [26]. PsfD protein from P. putida Fu1 (GenBank ACA09741.1) is 81% identical (89% similar) to PsfD form P. pseudoalcaligenes (BN5_2306, Figure 1). To date, the architecture of this operon presented in Figure 1B has not been described in this context. Here we show that this operon is functional after an adaptation period ending up with the selection of a punctual mutant in the araC-type regulator. Therefore, the locus described here seems to be a hybrid furfural assimilating system containing horizontally transferred genes homologous to the catalytic genes for the assimilation of FA described in C. basilensis [24] and the regulatory and accessory genes described in P. putida Fu1 [25].

Figure 1.

Scheme of the genetic organization of the hmf operon (A–C) (adapted from Ref. [9]) and predicted metabolic pathway for the assimilation of furfuryl alcohol in Pseudomonas pseudoalcaligenes (D). The hmf locus in P. pseudoalcaligenes CECT 5344 (delimited by a curly bracket, B) is located between BN5_2297 (osmC) and BN5_2308 (AT). The corresponding homologous genes in Pseudomonas mendocina ymp (Pmen_2630-2633) are consecutive in its genome (A) and the syntney of the homologous genes is conserved both upstream and downstream the hmf locus (green arrows). The hmf locus contains genes homologous to that described in the context of furfural degradation in Cupriavidus basilensis [24] (C1) and in Pesudomonas putida [25] (C2). The black arrows (panel B) represent genes involved in the transposition of mobile genetic elements. (D) Proposed pathway for the assimilation of FFA in P. pseudoalcaligenes R1. FFADH and FDH are furfuryl alcohol and furfural dehydrogenase, respectively. * FFADH and FDH could be the same enzyme, whose coding genes are unknown in P. pseudoalcaligenes. Both the oxidation of FFA and HMF in C. basilensis (not shown) converge in FA constituting the upper pathway. The lower pathway, encoded by the hmfABCDE operon (C1), is a series of reactions transforming FA into 2-oxo-glutaric acid. HmfA is a furoyl-CoA synthetase and HmfABC a furoyl CoA dehydrogenase. The transformation of 5-oxo-2-furoyl-CoA into 2-oxo-glutaril-CoA has no assigned gene and can be a spontaneous reaction or could be catalysed by an unspecific lactone hydrolase. Finally, HmfE was proposed to be the thioesterase rendering 2-oxo-glutaric acid from 2-oxo-glutaryl CoA [24].

2. Materials and Methods

2.1. Bacterial Strains, Media and Growth Conditions

Strain R1 is a spontaneous mutant of P. pseudoalcaligenes CECT5344 [27] resistant to rifampicin (40 μg/mL). P. pseudoalcaligenes CECT5344 strain R1D was obtained after four serial transfers of P. pseudoalcaligenes CECT5344 R1 to a M9 medium with furfural (10 mM) as the sole carbon source. A dilution 1:100 of the previously grown preculture was used as inoculum. For the rest of the growth curves, unless otherwise stated, the inoculum was the equivalent of an overnight culture diluted 1:10 into fresh medium. Bacterial growth was monitored by measuring the absorbance at 600 nm. Cells were grown in either minimal medium (M9) adjusted to pH 8.5 [4] or in LB medium [28] adjusted to pH 8.5. Cell cultures were prepared in Erlenmeyer flasks filled with 1/10 (v/v) of their nominal volume in order to ensure aerobic conditions and incubated on a rotatory shaker at 190 rpm and 30 °C. For minimal medium, ammonium chloride (5 mM) was used as the nitrogen source and 4 g/L of sodium acetate, furfural (10 mM), furfuryl alcohol (10 mM) or furoic acid (10 mM) were added as the sole carbon source. Escherichia coli XL1 blue MRF′ cells (Stratagene, Agilent Technologies, Santa Clara, CA, USA) were grown aerobically at 37 °C in complex LB medium [28] with ampicillin (100 μg/mL). Where appropriate, the following compounds were added to the media: X-Gal (5-bromo-4-chloro-3-indolyl-β-d-galactopyranoside, 0.2 mM, Appli-Chem (Barcelona, Spain), IPTG (isopropyl-β-d-1-thiogalactopyranoside, 0.5 mM, Sigma-Aldrich (St. Louis, MO, USA). Electrocompetent cells were prepared by the growth of cultures up to an optical density at 600 nm (OD600) of 0.35 and centrifugation for 20 min at 1000× g, followed by three successive washes (4 °C) in 1:1, 1:2, 1:50, and 1:500 volumes of 10% glycerol. The last solution, which yields the stock of electrocompetent cells, contained yeast extract (0.125%) and tryptone (0.25%). A mixture of 50 μL of cells (2 × 1010 to 3 × 1010 CFU/mL) and 1 to 10 ng of DNA was electroporated in 2-mm cuvettes with a Bio-Rad Gene Pulser II apparatus, (Bio-rad, Hercules, CA, USA) operated at 2.5 kV, 25 μF, and 200 Ω (4- to 5-ms time constants).

2.2. Preparation of Cell-free Extracts

The cells of P. pseudoalcaligenes CECT 5344 R1D grown with furfuryl alcohol as a carbon source (500 mL culture) were collected by centrifugation at the end of the logarithmic phase and resuspended in 50 mM Tris-HCl (pH 8), containing a complete protease inhibitor cocktail, as recommended by the supplier (Roche, Penzberg, Germany) and glycerol (10%). The cells were disrupted by two passages through a French pressure cell operated at 130 MPa and the cell debris removed by centrifugation at 18,000× g for 15 min.

2.3. Enzymatic Assays

Furfural dehydrogenase (FDH) and furfuryl alcohol dehydrogenase (FFADH) were assayed as previously described for C. basilensis [24], but optimizing the assay for P. pseudoalcaligenes (pH and temperature). FFADH (E.C.1.1.1.--) was assayed spectophotometrically at 65 °C and pH 9.5 (50 mM Tris/phosphate/carbonate) following the increment of absorbance at 340 nm due to the production of NADH (ε = 6220 M−1·cm−1). The reaction mixture contained NAD+ (1.5 mM), FFA (5 mM) and the appropriate amount of cell-free extract (50–100 μL cell-free extract, 0.5–1 mg protein, approximately) in a final volume of 1 mL. FDH (E.C. 1.2.3.1) was measured spectrophotometrically at 65 °C and pH 6.5 (50 mM Tris/phosphate/carbonate) following the increment of absorbance at 522 nm due to the reduction of the artificial electron acceptor DCPIP (ε = 21,000 M−1·cm−1). The reaction mixture contained, in a final volume of 1 mL, 0.33 mM PMS, 0.1 mM DCPIP, 5 mM F, and the appropriate amount of enzyme (50–100 μL cell-free extract, 0.5–1 mg protein, approximately).

2.4. Chromatographic Separation of FDH and FFADH

Cell-free extract from FFA-grown cells was loaded into an anion exchange chromatography (mono Q 5/50 GL, GE Healthcare (Chicago, IL, USA) attached to an Akta Purifier, GE. All the chormatographies were carried out at 4 °C. The column was equilibrated in buffer A (Tris/HCl 50 mM pH 8, 2 mM DTT and glycerol (2%)). The cell-free extract (2 mL) was loaded into the column at a flow rate of 1 mL/min. The unbound protein was washed with 12.5 mL of buffer A. Then, it was applied at a gradient of 1 mL from 0 to 0.1 M NaCl, always in the same buffer, which was maintained as isocratic during 5 mL, followed by a 20 mL gradient from 0.1 to 0.5 M NaCl and 0.5 to 1 M during 10 mL. Finally, the column was regenerated with 5 mL of buffer A containing 2 M NaCl. The fractions (0.5 mL) were analyzed for the presence FFADH and FDH activities.

2.5. Analytical Methods

2.5.1. HPLC

The concentration of furanic intermediates was determined as follows. The supernatants of the culture media were obtained by centrifugation of 1.0 mL of bacterial culture in a microfuge at maximal speed (14,000 rpm) for 10 minutes at room temperature. The supernatants were further filter-sterilized using a 0.2-µm filtration unit and stored at −20 °C. Concentrations of furan derivatives were determined from sample supernatants by high-performance liquid chromatography (HPLC) on a HPLC System Gold (Beckman) system. The column used was an Anion Exchange ION-300 (ICE-99-9850) (300 × 7.8 mm, Transgenomic, Omaha, NE, USA) operated at 65 °C. As eluent H2SO4 5 mN was used at a flow of 0.6 mL·min−1. Furfural and furoic acid were detected at 278 nm and furfuryl alcohol at 217 nm.

Glucose concentration was colorimetrically measured by using a commercially available enzymatic test based on the glucose/peroxidase activities (Biosystems, Barcelona, Spain).

Protein concentration was determined by the Bradford procedure [29].

2.5.2. DNA Manipulation

DNA was sequenced using services provided by Sistemas Genómicos (Valencia, Spain). Genomic DNA was purified from P. pseudoalcaligenes CECT5344 cells grown in liquid LB medium at pH 8.5 using the GNome DNA isolation kit (QBIOgene). Plasmid DNA was purified with the Genopure plasmid Midi Kit (Roche) from E. coli XL1 blue MRF′ cells grown in liquid cultures of LB media supplemented with the antibiotic used for selection. The E. coli XL1 blue MRF′ strain was used to clone recombinant DNA, performing restriction enzyme digestion and ligation as recommended by the manufacturers (Fermentas and Promega, respectively). Plasmids were introduced into E. coli XL1 blue MRF′ and P. pseudoalcaligenes CECT5344 cells by electroporation, as described previously [27]. Mutagenesis of edd gene (BN5_3048): To amplify by PCR a section of the edd ORF based on the DNA sequence of the P. pseudoalcaligenes CECT5344 (GenBank accession no. JN408065), two couples of sets of specific primers flanking the edd gene were designed (edd9U /edd730L and edd1140U /edd1737L, Table 1). A BamHI restriction site was incorporated into edd730L and edd1140U primers. The amplified fragments were cloned separately into pGEM-T Easy vector (Promega) generating the pedd1 and the pedd2 plasmids. The pedd2 plasmid was linearized with ApaI and BamHI. The plasmid pedd1 was digested with the same enzymes and the resulting fragment was gel-purified and subcloned into pedd2 to generate pedd1-2, thus obtaining a PGEM-TE derivative plasmid with two internal sequences of edd gene separated by a BamHI restriction site. On the other hand, a 1.0 kb BamHI fragment from the pMS255 plasmid [30] containing the gentamicin resistance gene (aacC1) was cloned into BamHI-digested PGEM-TE plasmid containing the two internal edd fragments (Figure S1). Finally, the resulting suicide plasmid was transferred to P. pseudoalcaligenes CECT5344 R1D by electroporation. The mutants were selected on gentamicin (10 µg/mL, Sigma-Aldrich) and mutant strains resulting from double homologous recombination were isolated. The insertion of the gentamicin resistance gene and the loss of the plasmid backbone were confirmed by PCR. Mutagenesis araC gene (BN5_2307): Based on the DNA sequence of the P. pseudoalcaligenes CECT5344 (GenBank accession no. JN408065), one couple of specific primers (araC157U/araC823L, Table 1) flanking the araC gene was designed for amplification of a section of the araC ORF by PCR. PCR was performed and the amplified fragment that contained a KpnI restriction site at position 542 was cloned into pGEM-T Easy vector (Promega), thus obtaining a PGEM-TE derivative plasmid with one internal sequence of araC. The plasmid was digested with KpnI and ligated to a 1.0-kb KpnI fragment containing the gentamicin-resistance gene (aacC1) from the pMS255 plasmid [30]. (Figure S2). The resulting plasmid was transferred to P. pseudoalcaligenes CECT5344 R1D by electroporation. The mutants were selected on gentamicin (10 µg/mL, Sigma-Aldrich), and mutant strains resulting from double-homologous recombination were isolated. The insertion of the gentamicin resistance gene and the loss of the plasmid backbone were confirmed by PCR.

Table 1.

Primers utilized in this work.

2.5.3. PCR Reaction Conditions

PCR samples were prepared with the following components: 0.5 ng/µL DNA, 1.0 µM of each primer, 2.0 mM MgCl2, 0.2 mM each deoxynucleoside triphosphate (dNTP), 0.5 U Taq DNA polymerase, and 2 µL buffer as recommended by the manufacturer (Biotools), in a final volume of 20 μL. The PCR conditions were 2 min at 95 °C; followed by 30 cycles of 20 s at 95 °C, 10 s at 65.6 °C (edd) or 64 °C (araC) and 1 min at 72 °C, followed by a 5 min extension at 72 °C.

3. Results

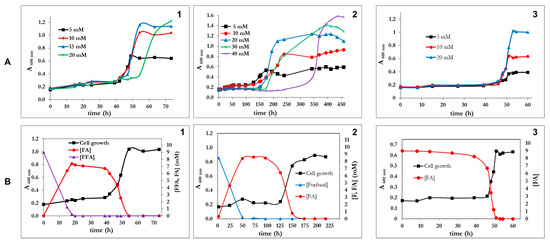

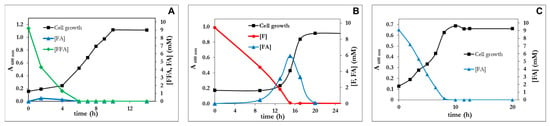

P. pseudoalcaligenes CECT5344 R1 was able to utilize furfural (up to 40 mM), furoic acid (up to 20 mM), and furfuryl alcohol (up to 20 mM) as the sole carbon and energy source, although after a very long lag phase (Figure 2A). The longest lag phase was observed with furfural as a C-source (Figure 2(A2)). In fact, furfural concentrations higher than 5 mM increased the lag phase, thus suggesting that this compound is toxic at a high concentration. Nevertheless the tolerance of P. pseudoalcaligenes CECT 5344 to furfural is relatively high (up to 40 mM) if compared to C. basilensis HMF14 (up to 12 mM) [16]. This toxic effect was not observed for furoic acid (FA), and furfuryl alcohol (FFA) was not toxic up to a concentration of 20 mM (Figure 2A). The maximum cell growth increased with the concentration of the furanic compound up to a concentration of 20 mM, indicating that below this concentration the growth was carbon limited. It is remarkable that at the same concentration of furanic compound, the maximum growth was highest with FFA, followed by F and finally FA. This is in agreement with the chemical compositions of these compounds, the alcohol being the most reduced, followed by the aldehyde and then the carboxylic acid. Both F and FFA were, in a first instance, almost stoichiometrically transformed into furoic acid (Figure 2B), thus indicating that the pathway for the assimilation of this compound is not active in the wild type strain of Pseudomonas pseudoalcaligenes CECT 5344 R1. Only after several days of incubation, a clear increase in cell growth was observed, which was concomitant with the assimilation of FA (Figure 2B).

Figure 2.

(A) Growth curves of Pseudomonas pseudoalcaligenes CECT 5344 R1 with different concentrations of furfuryl alcohol (panel A1), furfural (panel A2) or furoic acid (panel A3). (B) Growth curves and concentrations of furanic intermediates in the culture media of P. pseudoalcaligenes using as a carbon source either 5 mM furfuryl alcohol (panel B2), furfural (panel B2) or furoic acid (panel B3). Three independent experiments gave similar results.

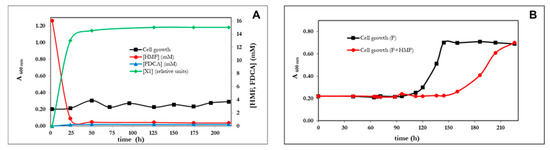

P. pseudoalcaligenes CECT 5344 R1 failed to grow on 5-(hydroxymethyl)furfural (HMF), even after a prolonged incubation period of more than 10 days (Figure 3A). The analysis of the culture media by HPLC revealed that HMF was completely exhausted after 25 h, indicating that although this bacterial strain was unable to assimilate HMF, it had the capability of transforming it. Two new compounds were detected in the couture media after consumption of HMF, 2,5-furandicarboxylic acid (FDCA) in a proportion below 5% of the HMF consumed and an unknown aromatic compound (Figure 3A). In C. basilensis HMF14, HmfH catalyzes the oxidation of 5-hydroxymethyl-2-furoic acid (HMFA) to FDCA, whereas HmfFG catalyzes the decarboxylation of FDCA to FA [24]. Therefore, in this strain, the metabolic pathways for the assimilation of HMF, FFA and F converge in FA. In the genome of P. pseudoalcaligenes CECT 5344 R1, no homologous genes to hmfH and hmfFG of C. basilensis were observed. This genotype agrees with the fact that this bacterium does not assimilate HMF. Since HMFA is the substrate of HMFH, the unknown compound accumulated in the culture media from HMF (Figure 3A) could be HMFA. To test if the incapacity of P. pseudoalcaligenes was due to a problem of induction, the bacterium was inoculated in media containing both F and HMF (Figure 3B). The result was that the bacterium exclusively used F and that the presence of HMF resulted in being toxic (Figure 3B). Therefore, the absence of catalytic enzymes for the assimilation of FA was not the reason for the inability of P. psedoalcaligens to assimilate HMF, but the absence of reactions connecting HMFA and FDCA to FA. The transformation of FFA into FA takes place in two consecutive oxidative steps. In Pseudomonas putida Fu1, two different and inducible enzymes catalyze these reactions [23], but in C. basilensis, although no concrete genes have been assigned, it could be possible that the same enzyme catalyzes both oxidations [24]. In P. pseudoalcaligenes CECT5344 R1, both dehydrogenase activities (FFADH and FDH in the scheme of Figure 1D) co-eluted after anion exchange chromatography (not shown), thus suggesting that it is the same enzyme. Again, both activities had the same optimum temperature at 65 °C. Furfural dehydrogenase activity was clearly induced by furfuryl alcohol, if compared with acetate, FA or LB medium (not shown). Although these results suggest that the same enzyme could catalyze the oxidation of FFA to F and of F to FA, the only clear conclusion is that transformation of FFA to FA and conversion of FA to 2-oxoglutaric acid takes place through different pathways.

Figure 3.

Biotransformation of HMF by P. pseudoalcaligenes CECT 5344 R1. (A) Cell growth (black line), concentration of HMF and FDCA (mM), and an unknown metabolite in cell cultures of P. pseudoalcaligenes. (B) Effect of HMF (5 mM) on the cell growth of P. pseudoalcaligenes at the expense of 10 mM furfural (F+HMF) in comparison with the cell growth with 10 mM furfural (F, black line). Similar results were obtained in three different experiments.

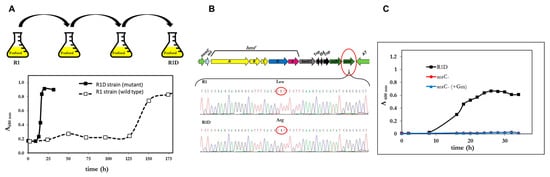

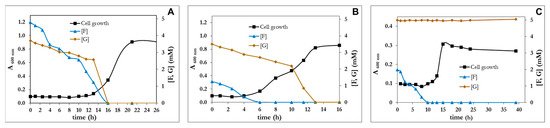

Once grown on furfural as a C-source, the serial dilutions of a culture of P. pseudoalcaligenes CECT 5344 R1 spread on solid minimal medium with furfural or FA giving colonies with two morphologies, big or small colonies. The small colonies had the same phenotype as the original stain (R1), but the big colonies grew faster on furfural even after successive generations on non-selective medium (LB). In fact, after four serial re-inoculations of the bacteria in in fresh media with furfural (10 mM) as the sole carbon source, allowed the selection of a mutant (big colonies in FA plates) in which the growth lag phase was drastically reduced and had a reproducible growth rate of 0.29 h−1 on furfural (5 mM). Figure 4A illustrates the isolation of the mutant, thereafter called R1D, and its phenotype in comparison to the wt. The selection of mutants with improved capacities has been widely used in biotechnological processes for the selection of evolved phenotypes, although having poor knowledge of their underlying genotype [31], also in the context of furfural assimilation [32]. For example, P. putida S12 expressing the hmfABCDE genes from C. basilensis HMF14 strain, was only able to efficiently assimilate furfural when adapted by repeated inoculation in media with furfural. The same has been recently described for Pseudomonas putida KT2440 expressing a 12 kb DNA fragment containing the hmf gene cluster from Burkholderia phytofirmans [33]. The next generation sequence (ngs) techniques open the possibility to analyze the genotypic variation associated with the evolved phenotypes. Adaptive laboratory evolution (ALE) takes profit of this advantage and may have a tremendous application in the rational design of genetically manipulated microorganisms, as well as in understanding some basic evolving mechanisms of living beings [31,34,35]. In our laboratory, the transcriptomic analysis of the R1D mutant in response to furfuryl alcohol was analyzed and it revealed to be more complex than expected (not shown). Interestingly, the transcriptomic reads sequences (RNA-seq) were obtained from the mutant strain (R1D), whereas the genome sequences available are from the wt strain [36]. The comparison of both sequences in the hmf locus revealed that the R1D mutant had a point mutation in a possible regulatory gene of the araC family. The presence of the mutation was confirmed by re-sequencing the araC gene (BN5_2307) (Figure 4B). The observed point mutation was a transversion (782T>G), leading to the non-conservative change of the triplet CTT (Leu) to CGT (Arg) (Figure 4B). The alignment of several AraC proteins revealed that the Arg in position 261 is a conserved residue in most members of this family of regulators (not shown). This position is located in the HTH domain of the protein and it is also conserved in E. coli [37], thus suggesting its essentiality. In conclusion, it seems that the pathway for the assimilation of FA is not active in the wt strain of P. pseudoalcaligens because AraC is not functional, and that the L262R mutation generates the active and functional regulator (AraC*) in the evolved R1D strain. In order to check this hypothesis, a mutant of the araC* gene of P. pseudoalcaligenes CECCT 5344 R1D was generated by double recombination. As expected, the mutant strain was unable to use furfural as a C-source (Figure 4C).

Figure 4.

Role of araC in the assimilation of furfural by P. pseudoalcaligenes. (A) Scheme of the selection process (upper panel), and growth curve (lower panel) of the R1D mutant in comparison with the wt strain (R1), in media with furfural (10 mM) as the sole carbon source. (B) Scheme of the point mutation detected in the araC gene of the R1D mutant. (C) Growth curve of the R1D mutant and its derived mutant generated by the inactivation of the araC* gene by insertion of the gentamicin resistance gene (aacC1) by double recombination. Similar results were obtained in three different experiments (panels A and C).

In addition to furfural, the mutant R1D was also capable to assimilate furfuryl alcohol and furoic acid (Figure 5). However, this strain remained unable to use HMF as a carbon source.

Figure 5.

Growth curves of P. pseudoalcaligenes CECT 5344 R1D with furfuryl alcohol (A), furfural (B) or furoic acid (C) as the sole carbon sources (10 mM). The concentration of furanic intermediates in the culture media was measured by HPLC at the indicated times. Each experiment was done in triplicate giving similar results.

It is evident that R1D grew faster than R1 and with similar rates to other furfural-degrading strains reported in the literature. Table 2 summarizes the growth parameters of R1 and R1D strains of P. pseudoalcaligenes CECT 5344 in comparison to reference strains. In addition to the shorter lag phases and higher growth rates, a notable difference between the wild strain (R1) and the R1D mutant was the accumulation of FA during the lag phase. As shown in Figure 2, the wt strain stoichiometrically transformed FFA and F to FA. By contrast, in the RD1 mutant, FA was the only transiently accumulated form F (Figure 5B), whereas it was hardly detectable in media with FFA (Figure 5A). No lag phase was observed in the R1D strain growing with FA. Therefore, the presence of FA immediately induces its assimilation in R1D, thus suggesting that FA could be the inducer of the process. It is evident that the difference between R1 and R1D relies on the process of assimilation of furoic acid, not in the oxidation of alcohol and aldehyde to furoic acid. In analogy with the assimilation of toluene and xylenes in P. putida mt-2 [38], we can divide the pathway in two segments, the upper pathway and the lower pathway. We can consider the upper pathway as the oxidation of the alcohol group (-CH2OH) and aldehyde (-CHO) to acid (-COOH). In the case of C. basilensis, the decarboxylase has to be included in the upper pathway, making the metabolism of HMF converge to FA. The lower pathway consists in the mineralization of furoic acid.

Table 2.

Growth parameters of P. pseudoalcaligenes CECT 5344 R1 (wt) and the R1D mutant in comparison to bibliographic data.

It is worth noting that these experiments confirmed the fact that the maximal cell growth of P. pseudoalcaligenes with FFA was higher than with F followed by FA (Table 2).

It is evident that R1D is an evolved strain much more efficient than the wt in the assimilation of FFA, F and FA. Nevertheless, the utilization of these capabilities for the elimination of the inhibitory compounds from lignocellulosic hydrolysates requires that the bacterium leave the sugars intact for their further fermentation process. P. pseudoalcaligenes CECT 5334 was unable to use as a C-source neither xylose, sucrose, arabinose, mannose, nor galactose. The capability of P. pseudoalcaligenes to use sugars was restricted to glucose. The chemical composition of the lignocellulosic hydrolysates depends on the raw material utilized and the treatment employed [39]. Therefore, the capacity of P. pseudoalcaligenes CECT 5344 R1D to use glucose and furfural simultaneously was studied. As expected, R1D assimilated both compounds simultaneously in blended media (Figure 6). From Figure 6, it became evident that F is toxic, since maintaining the concentration of glucose, the lag phase increased when furfural concentration increased (Figure 6A,B). In any case, since both glucose and F were assimilated simultaneously by P. Pseudoalcaligenes, the construction of a mutant impaired in glucose assimilation was designed. Most Pseudomonas, which have a relatively limited ability to assimilate sugars, usually assimilate glucose through the Entner-Doudoroff pathway [40], and the inactivation of the edd gene usually causes the inability to assimilate glucose [41]. As shown in Figure 6C, the edd− strain was as efficient as R1D assimilating furfural but glucose remains unaltered in the culture media. The edd− mutant was also able to use furfuryl alcohol and furoic acid as a C-source.

Figure 6.

Cell growth of P. pseudoalcaligenes CECT 5344 R1D with glucose 5 mM, supplemented with furfural 5 mM (A) or 2 mM (B) as carbon sources. (C) Cell growth of P. pseudoalcaligenes CECT 5344 R1D edd− with furfural (2.5 mM) and glucose (5 mM) as carbon sources. Glucose and furfural concentration were determined at the indicated times. Similar results were obtained in three different experiments.

4. Discussion

The biodegradation of contaminants and the production of renewable energies are among the most important challenges of modern society. Bioethanol is a sustainable fuel that can be obtained by the yeast fermentation of sugars [42]. When using sugars from lignocellulosic by-products instead of sugars from food crops, the product is called second-generation bioethanol. However, the hydrolysis of these polymers generates, in addition to fermentable sugars, compounds that act as inhibitors of the yeast catalyzing further fermentation. The formation of furfural from pentoses was described many years ago [43]. Furfurals, and specially HMF and its derivatives, are feedstock for the synthesis of numerous valuable products. Therefore, their production in a sustainable manner is receiving an increasing interest [44]. On the other hand, from the bioethanol-production point of view, it is a challenge eliminating these inhibitors leaving sugars intact, with the purpose of increasing efficiency in second-generation ethanol production. Furfural and 5-hydroxymethyl furfural (HMF) are not the only inhibitory compounds present in the hydrolysates, but many others are not so well characterized, such as methanol or acetate [39]. The selection of yeast resistant to aldehydes may partially circumvent the problem. In fact, yeasts resistant up to 40 mM furfural and 80 mM HMF have been described recently [45,46]. Nevertheless, and taking into account the diversity of hydrolysates, the direct elimination of inhibitory compounds has to be taken into account as an alternative (bio)technology.

In this manuscript, we describe the selection of an adaptive mutant of Pseudomonas pseudoalcaligenes CECT 5344 able to assimilate furfural. The mutation was found to be located in a regulatory gene of the AraC/XylS family of activators [47]. In E. coli, araC is necessary for the assimilation of L-arabinose, a five carbon sugar [37]. Although speculative, perhaps it is not casual that the homologous gene in P. pseudoalcaligenes CECT 5344 could recognize as an activator the five-carbon dehydrated and oxidized pentose FA. This hypothesis has to be tested experimentally in the future. AraC homologous are proteins approximately 300 aa long, whose C-terminal segment is the HTH domain interacting with DNA. The mutation in the adapted strain was detected just in this domain. The substitution of a hydrophobic amino acid by a basic one (L262R) introduces a positive charge in the protein that seems to be essential for interacting with the negatively-charged DNA molecule. The less-conserved N-terminal domain of the AraC family is presumed to contain binding sites for specific activator molecules that confer specificity to each member [47].

Adaptive mutations frequently target regulatory genes [34], although there are interesting examples in which the genetic adaptation lies in catabolic genes. For example, in P. putida KT2440, a single point mutation was detected causing the suppression of a frameshift mutation in the transporter (galT), thus allowing the evolved strain to grow in gallic acid [48]. The hmf locus in P. pseudoalcaligenes contains two different modules, a catabolic one homologous to C. baisilensis HMF14 (plus benE) and another one homologous to P. putida Fu1 containing the regulatory gene araC (Figure 1B). As far as we know, no gene homologous to benE has been described in the context of FA assimilation. benE is a member of the MSF-family of transporters, homologous to the benzoate transporters. Since both compounds, benzoate and furoate, are aromatic monocarboxylic acids, it can be speculated that BenE is a furoate transporter, although this hypothesis needs further experimental evidence. The hmf locus (Figure 1) is flanked by mobile genetic elements, thus suggesting that it has been horizontally transferred. Furthermore, this hypothesis is in agreement with the sequence composition of the locus. The average GC content of the genes flanking the hmf locus in P. pseudoalcaligenes (green genes in the Figure 4B) is around 62%, which is also the %GC content of the genome of P. mendocina ymp (Figure 4A, 62.8%) and P. pseudoalcaligenes CECT 5344 itself (62.34%). By contrast, the average composition (%GC) of the hmf operon (BN5_2298 to BN5_2305) is 66.5%, close to the composition of Cupriavidus basislensis (65.3%) and other betaproteobacteria. The other two genes present in the island are BN5_2306 (psfD) and BN5_2307 (araC), whose %GC are 67.69% and 57.16%, respectively. It is also remarkable that all genes present in the hmf locus (Figure 1B) are singletons in relation to most Pseudomonaceae, except psfD and benE. In the evolution of prokaryotic metabolic networks and their regulation, the number of transcriptional regulators grows faster than the metabolic genes [49]. The horizontally transferred hmf pathway homologous to that described in C. basilensis HMF14 does not include its dedicated transcriptional regulator, but it seems that it has been acquired in a separate module from a second donor strain. Curiously, the regulator was originally in an inactive form, but evolved to the active form under selective pressure (Figure 4).

Even though P. pseudoalcalignes CEC T 5344 R1D assimilates furfural very efficiently, it could not be useful for the pre-treatment of lignocellulosic residues because it simultaneously assimilates glucose. By contrast, the edd− mutant assimilated furfural leaving the glucose intact (Figure 6). This is an important feature in comparison to the equivalent mutant in P. putida KT2440, that accumulates 6-phosphoogluconate from glucose [40]. On the other hand, P. pseudoalcaligens could not assimilate HMF (Figure 3), the other main inhibitory component of hydrolysates. In fact, the genome analyses anticipated this result due to the absence of homologous genes to hmfH and hmfFG genes. These genes in C. basilensis code for the enzymes catalyzing the oxidation of HMFA to FDCA and the decarboxylation of the latter to generate furoic acid, respectively. FA is the metabolite in which converges the assimilation of HMF and furfural in C. basilensis HMF14 [24]. To circumvent the problem, it would be convenient to have bacteria capable of eliminating HMF. We have isolated, by selective enrichment from ashes, some bacterial strains belonging to the genus Pseudomonas, which are able to assimilate HMF in addition to furfural, furoic acid or furfuryl alcohol [50]. These abilities could be used in mixed cultures, provided that they do not assimilate sugars, or by constructing the required traits using the available genetic modules. Even though P. pseudomonas CECT 5344 R1D fully transformed HMF into two new compounds, 5-Hydroxymethylfuranoic acid (HMFA) and 2,5-furandicarboxylic acid (FDCA), both of which are versatile chemical intermediates of high industrial potential [51,52]. Therefore, the edd− mutant of the evolved R1D strain of P. pseudoalcaligenes described in this manuscript may increase the productivity of second generation bioethanol both by eliminating yeasts’ inhibitory chemicals and by producing value-added chemicals from biomass.

Supplementary Materials

The following are available online at https://www.mdpi.com/2073-4425/10/7/499/s1, Figure S1: Schematic construction of PGEM-TE edd aacC1 plasmid. Figure S2. Schematic construction of PGEM-TE araC aacC1 plasmid.

Author Contributions

Conceptualization, R.B. and M.I.I.; methodology, R.B. and M.I.I.; investigation, D.M. and M.I.I., writing, R.B.; visualization, R.B., D.M. and M.I.I.; supervision, R.B. and M.I.I.; project administration, R.B.; funding acquisition, R.B.

Funding

This research was funded by IB16062, Junta de Extremadura (Consejería de Economía e Infraestructuras), GR18031, Fondo Europeo de Desarrollo Regional (FEDER), European Union. The work of Daniel Macias was supported by a fellowship from Universidad de Extremadura (Accion III-41, UEX 2010-2014).

Acknowledgments

The technical support of Gloria Gutiérrez and Gracia Becerra are gratefully acknowledged.

Conflicts of Interest

The authors declare no conflict of interest. The funders had no role in the design of the study; in the collection, analyses, or interpretation of data; in the writing of the manuscript, or in the decision to publish the results.

References

- Tavoni, M.; Kriegler, E.; Riahi, K.; van Vuuren, D.P.; Aboumahboub, T.; Bowen, A.; Calvin, K.; Campiglio, E.; Kober, T.; Jewell, J.; et al. Post-2020 climate agreements in the major economies assessed in the light of global models. Nat. Clim. Chang. 2014, 5, 119. [Google Scholar] [CrossRef]

- Gray, K.A.; Zhao, L.; Emptage, M. Bioethanol. Curr. Opin. Chem. Biol. 2006, 10, 141–146. [Google Scholar] [CrossRef]

- Blasco, R.; Castillo, F. Acerca de la biotecnología ambiental. Arbor 2014, 190, a157. [Google Scholar] [CrossRef][Green Version]

- Luque-Almagro, V.M.; Huertas, M.J.; Martinez-Luque, M.; Moreno-Vivian, C.; Roldan, M.D.; Garcia-Gil, L.J.; Castillo, F.; Blasco, R. Bacterial degradation of cyanide and its metal complexes under alkaline conditions. Appl. Environ. Microbiol. 2005, 71, 940–947. [Google Scholar] [CrossRef] [PubMed]

- Akcil, A. Destruction of cyanide in gold mill effluents: Biological versus chemical treatments. Biotechnol. Adv. 2003, 21, 501–511. [Google Scholar] [CrossRef]

- Akcil, A.; Mudder, T. Microbial destruction of cyanide wastes in gold mining: Process review. Biotechnol. Lett. 2003, 25, 445–450. [Google Scholar] [CrossRef] [PubMed]

- Baxter, J.; Cummings, S.P. The current and future applications of microorganism in the bioremediation of cyanide contamination. Antonie Leeuwenhoek 2006, 90, 1–17. [Google Scholar] [CrossRef]

- Raybuck, S.A. Microbes and microbial enzymes for cyanide degradation. Biodegradation 1992, 3, 3–18. [Google Scholar] [CrossRef]

- Luque-Almagro, V.M.; Acera, F.; Igeño, M.I.; Wibberg, D.; Roldán, M.D.; Sáez, L.P.; Hennig, M.; Quesada, A.; Huertas, M.J.; Blom, J.; et al. Draft whole genome sequence of the cyanide-degrading bacterium Pseudomonas pseudoalcaligenes CECT5344. Environ. Microbiol. 2013, 15, 253–270. [Google Scholar] [CrossRef]

- Barakat, A.; Monlau, F.; Steyer, J.-P.; Carrere, H. Effect of lignin-derived and furan compounds found in lignocellulosic hydrolysates on biomethane production. Bioresour. Technol. 2012, 104, 90–99. [Google Scholar] [CrossRef]

- Palmqvist, E.; Hahn-Hägerdal, B. Fermentation of lignocellulosic hydrolysates. II: Inhibitors and mechanisms of inhibition. Bioresour. Technol. 2000, 74, 25–33. [Google Scholar] [CrossRef]

- Alvira, P.; Tomas-Pejo, E.; Ballesteros, M.; Negro, M.J. Pretreatment technologies for an efficient bioethanol production process based on enzymatic hydrolysis: A review. Bioresour. Technol. 2010, 101, 4851–4861. [Google Scholar] [CrossRef] [PubMed]

- Ortu, E.; Caboni, P. Levels of 5-hydroxymethylfurfural, furfural, 2-furoic acid in sapa syrup, Marsala wine and bakery products. Int. J. Food Prop. 2017, 20, S2543–S2551. [Google Scholar] [CrossRef]

- Zhang, J.; Zhu, Z.; Wang, X.; Wang, N.; Wang, W.; Bao, J. Biodetoxification of toxins generated from lignocellulose pretreatment using a newly isolated fungus, Amorphotheca resinae ZN1, and the consequent ethanol fermentation. Biotechnol. Biofuels 2010, 3, 26. [Google Scholar] [CrossRef]

- Ran, H.; Zhang, J.; Gao, Q.; Lin, Z.; Bao, J. Analysis of biodegradation performance of furfural and 5-hydroxymethylfurfural by Amorphotheca resinae ZN1. Biotechnol. Biofuels 2014, 7, 51. [Google Scholar] [CrossRef]

- Wierckx, N.; Koopman, F.; Bandounas, L.; Winde, J.H.d.; Ruijssenaars, H.J. Isolation and characterization of Cupriavidus basilensis HMF14 for biological removal of inhibitors from lignocellulosic hydrolysate. Microb. Biotechnol. 2010, 3, 336–343. [Google Scholar] [CrossRef]

- Wierckx, N.; Koopman, F.; Ruijssenaars, H.; de Winde, J. Microbial degradation of furanic compounds: Biochemistry, genetics, and impact. Appl. Microbiol. Biotechnol. 2011, 92, 1095–1105. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Y.; Han, B.; Ezeji, T.C. Biotransformation of furfural and 5-hydroxymethyl furfural (HMF) by Clostridium acetobutylicum ATCC 824 during butanol fermentation. N. Biotechnol. 2012, 29, 345–351. [Google Scholar] [CrossRef] [PubMed]

- Koopman, F.; Wierckx, N.; de Winde, J.H.; Ruijssenaars, H.J. Efficient whole-cell biotransformation of 5-(hydroxymethyl)furfural into FDCA, 2,5-furandicarboxylic acid. Bioresour. Technol. 2010, 101, 6291–6296. [Google Scholar] [CrossRef]

- Liu, Z.L.; Slininger, P.J.; Dien, B.S.; Berhow, M.A.; Kurtzman, C.P.; Gorsich, S.W. Adaptive response of yeasts to furfural and 5-hydroxymethylfurfural and new chemical evidence for HMF conversion to 2,5-bis-hydroxymethylfuran. J. Ind. Microbiol. Biotechnol. 2004, 31, 345–352. [Google Scholar] [CrossRef]

- Taherzadeh, M.J.; Gustafsson, L.; Niklasson, C.; Liden, G. Physiological effects of 5-hydroxymethylfurfural on Saccharomyces cerevisiae. Appl. Microbiol. Biotechnol. 2000, 53, 701–708. [Google Scholar] [CrossRef] [PubMed]

- Zheng, D.; Bao, J.; Lu, J.; Lv, Q. Biodegradation of furfural by Bacillus subtilis strain DS3. J. Environ. Biol. 2015, 36, 727–732. [Google Scholar] [PubMed]

- Koenig, K.; Andreesen, J.R. Xanthine dehydrogenase and 2-furoyl-coenzyme A dehydrogenase from Pseudomonas putida Fu1: Two molybdenum-containing dehydrogenases of novel structural composition. J. Bacteriol. 1990, 172, 5999–6009. [Google Scholar] [CrossRef] [PubMed]

- Koopman, F.; Wierckx, N.; de Winde, J.H.; Ruijssenaars, H.J. Identification and characterization of the furfural and 5-(hydroxymethyl)furfural degradation pathways of Cupriavidus basilensis HMF14. Proc. Natl. Acad. Sci. USA 2010, 107, 4919–4924. [Google Scholar] [CrossRef] [PubMed]

- Nichols, N.N.; Mertens, J.A. Identification and transcriptional profiling of Pseudomonas putida genes involved in furoic acid metabolism. FEMS Microbiol. Lett. 2008, 284, 52–57. [Google Scholar] [CrossRef] [PubMed]

- Koenig, K.; Andreesen, J.R. Molybdenum Involvement in Aerobic Degradation of 2-Furoic Acid by Pseudomonas putida Fu1. Appl. Environ. Microbiol. 1989, 55, 1829–1834. [Google Scholar] [PubMed]

- Quesada, A.; Guijo, M.I.; Merchan, F.; Blazquez, B.; Igeño, M.I.; Blasco, R. Essential role of cytochrome bd-related oxidase in cyanide resistance of Pseudomonas pseudoalcaligenes CECT5344. Appl. Environ. Microbiol. 2007, 73, 5118–5124. [Google Scholar] [CrossRef]

- Sambrook, J.; Russel, D.W. Molecular Cloning: A Laboratory Manual, 3rd ed.; Cold Spring Harbor Laboratory: New York, NY, USA, 2001. [Google Scholar]

- Bradford, M.M. A rapid and sensitive method for the quantitation of microgram quantities of protein utilizing the principle of protein-dye binding. Anal. Biochem. 1976, 72, 248–254. [Google Scholar] [CrossRef]

- Becker, A.; Schmidt, M.; Jäger, W.; Pühler, A. New gentamicin-resistance and lacZ promoter-probe cassettes suitable for insertion mutagenesis and generation of transcriptional fusions. Gene 1995, 162, 37–39. [Google Scholar] [CrossRef]

- Winkler, J.; Reyes, L.H.; Kao, K.C. Adaptive Laboratory Evolution for Strain Engineering. Syst. Metab. Eng. 2013, 985, 211–222. [Google Scholar]

- Abdulrashid, N.; Clark, D.P. Isolation and genetic analysis of mutations allowing the degradation of furans and thiophenes by Escherichia coli. J. Bacteriol. 1987, 169, 1267–1271. [Google Scholar] [CrossRef] [PubMed]

- Guarnieri, M.T.; Ann Franden, M.; Johnson, C.W.; Beckham, G.T. Conversion and assimilation of furfural and 5-(hydroxymethyl)furfural by Pseudomonas putida KT2440. Metab. Eng. Commun. 2017, 4, 22–28. [Google Scholar] [CrossRef] [PubMed]

- Conrad, T.M.; Lewis, N.E.; Palsson, B.O. Microbial laboratory evolution in the era of genome-scale science. Mol. Syst. Biol. 2011, 7, 509. [Google Scholar] [CrossRef] [PubMed]

- Dragosits, M.; Mattanovich, D. Adaptive laboratory evolution—Principles and applications for biotechnology. Microb. Cell Factories 2013, 12, 64. [Google Scholar] [CrossRef] [PubMed]

- Wibberg, D.; Luque-Almagro, V.M.; Igeño, M.I.; Bremges, A.; Roldán, M.D.; Merchán, F.; Sáez, L.P.; Guijo, M.I.; Manso, M.I.; Macías, D.; et al. Complete genome sequence of the cyanide-degrading bacterium Pseudomonas pseudoalcaligenes CECT5344. J. Biotechnol. 2014, 175, 67–68. [Google Scholar] [CrossRef] [PubMed]

- Schleif, R. AraC protein, regulation of the l-arabinose operon in Escherichia coli, and the light switch mechanism of AraC action. FEMS Microbiol. Rev. 2010, 34, 779–796. [Google Scholar] [CrossRef] [PubMed]

- Worsey, M.J.; Williams, P.A. Metabolism of toluene and xylenes by Pseudomonas (putida (arvilla) mt-2: Evidence for a new function of the TOL plasmid. J. Bacteriol. 1975, 124, 7–13. [Google Scholar] [PubMed]

- Almeida, J.R.; Bertilsson, M.; Gorwa-Grauslund, M.F.; Gorsich, S.; Liden, G. Metabolic effects of furaldehydes and impacts on biotechnological processes. Appl. Microbiol. Biotechnol. 2009, 82, 625–638. [Google Scholar] [CrossRef] [PubMed]

- Daddaoua, A.; Krell, T.; Ramos, J.-L. Regulation of Glucose Metabolism in Pseudomonas: The phosphorylative branch and entner-doudoroff enzymes are regulated by a repressor containing a sugar isomerase domain. J. Biol. Chem. 2009, 284, 21360–21368. [Google Scholar] [CrossRef] [PubMed]

- Blevins, W.T.; Feary, T.W.; Phibbs, P.V., Jr. 6-Phosphogluconate dehydratase deficiency in pleiotropic carbohydrate-negative mutant strains of Pseudomonas aeruginosa. J. Bacteriol. 1975, 121, 942–949. [Google Scholar]

- Mohd Azhar, S.H.; Abdulla, R.; Jambo, S.A.; Marbawi, H.; Gansau, J.A.; Mohd Faik, A.A.; Rodrigues, K.F. Yeasts in sustainable bioethanol production: A review. Biochem. Biophys. Rep. 2017, 10, 52–61. [Google Scholar] [CrossRef] [PubMed]

- Hurd, C.D.; Isenhour, L.L. Pentose reacions. I. Furfural formation. J. Am. Chem. Soc. 1932, 54, 317–330. [Google Scholar] [CrossRef]

- Hu, L.; Lin, L.; Wu, Z.; Zhou, S.; Liu, S. Recent advances in catalytic transformation of biomass-derived 5-hydroxymethylfurfural into the innovative fuels and chemicals. Renew. Sustain. Energy Rev. 2017, 74, 230–257. [Google Scholar] [CrossRef]

- De Mello, F.d.S.B.; Coradini, A.L.V.; Tizei, P.A.G.; Carazzolle, M.F.; Pereira, G.A.G.; Teixeira, G.S. Static microplate fermentation and automated growth analysis approaches identified a highly-aldehyde resistant Saccharomyces cerevisiae strain. Biomass Bioenergy 2019, 120, 49–58. [Google Scholar] [CrossRef]

- Nagamatsu, S.T.; Teixeira, G.S.; de Mello, F.d.S.B.; Tizei, P.A.G.; Nakagawa, B.T.G.; de Carvalho, L.M.; Pereira, G.A.G.; Carazzolle, M.F. Genome Assembly of a Highly Aldehyde-Resistant Saccharomyces cerevisiae SA1-Derived Industrial Strain. Microbiol. Resour. Announc. 2019, 8, e00071. [Google Scholar] [CrossRef] [PubMed]

- Gallegos, M.T.; Schleif, R.; Bairoch, A.; Hofmann, K.; Ramos, J.L. Arac/XylS family of transcriptional regulators. Microbiol. Mol. Biol. Rev. 1997, 61, 393–410. [Google Scholar] [PubMed]

- Nogales, J.; Canales, A.; Jimenez-Barbero, J.; Serra, B.; Pingarron, J.M.; Garcia, J.L.; Diaz, E. Unravelling the gallic acid degradation pathway in bacteria: The gal cluster from Pseudomonas putida. Mol. Microbiol. 2011, 79, 359–374. [Google Scholar] [CrossRef] [PubMed]

- Maslov, S.; Krishna, S.; Pang, T.Y.; Sneppen, K. Toolbox model of evolution of prokaryotic metabolic networks and their regulation. Proc. Natl. Acad. Sci. USA 2009, 106, 9743–9748. [Google Scholar] [CrossRef] [PubMed]

- Igeño, M.I.; Sánchez-Clemente, R.; Población, A.G.; Guijo, M.I.; Merchán, F.; Blasco, R. Biodegradation of 5-(Hydroxymethyl)-furfural and Furan Derivatives. Proceedings 2018, 2, 1283. [Google Scholar] [CrossRef]

- Kang, E.-S.; Chae, D.W.; Kim, B.; Kim, Y.G. Efficient preparation of DHMF and HMFA from biomass-derived HMF via a Cannizzaro reaction in ionic liquids. J. Ind. Eng. Chem. 2012, 18, 174–177. [Google Scholar] [CrossRef]

- Deng, J.; Liu, X.; Li, C.; Jiang, Y.; Zhu, J. Synthesis and properties of a bio-based epoxy resin from 2,5-furandicarboxylic acid (FDCA). RSC Adv. 2015, 5, 15930–15939. [Google Scholar] [CrossRef]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).