Abstract

As a major agricultural country, China is also one of the world’s most abundant sources of crop straw, with production expected to reach 900 million tons by 2025. As an agricultural by-product, straw has been widely regarded as a potential renewable resource. It is rich in organic matter and essential nutrients such as nitrogen (N), phosphorus (P), and potassium (K), playing a critical role in global carbon and nitrogen cycles, agricultural productivity, and green environmental development. The efficient and rational utilization of straw can not only meet the resource demands supporting economic growth but also contribute to environmental protection and sustainable social development in China. By closely integrating comprehensive straw utilization with the annual key tasks of agriculture, rural areas, and farmers, the focus remains on prioritizing agricultural applications while adopting diversified measures. The efforts aim to improve straw utilization methods, strengthen technological support, explore replicable and sustainable industrial development models, and establish efficient utilization mechanisms to enhance the quality of agricultural straw use. To fully leverage the agricultural potential of straw, numerous technologies and equipment for straw utilization in agriculture have been developed in recent years, including straw harvesting and collecting equipment, straw crushing and returning-to-field equipment, full-straw seeding anti-clogging technology, combined straw and green manure returning-to-field equipment, and specialized straw seedling-raising equipment. Nevertheless, many challenges remain to be addressed, including bridging the equipment gap in mechanized processing, overcoming technical bottlenecks in resource conversion, and filling the lack of agronomy-adapted technologies. Therefore, this paper aims to provide a comprehensive and critical analysis of present straw utilization technology and equipment in agriculture, discussing their potential benefits, limitations, and challenges, as well as future prospects and directions. This study provides insights from the perspective of key technologies and equipment to strengthen technological research, enhance straw’s agricultural potential, and explore green circular economy models in agriculture. By leveraging innovation in science and technology, it aims to ensure food security and improve grain production capacity.

1. Introduction

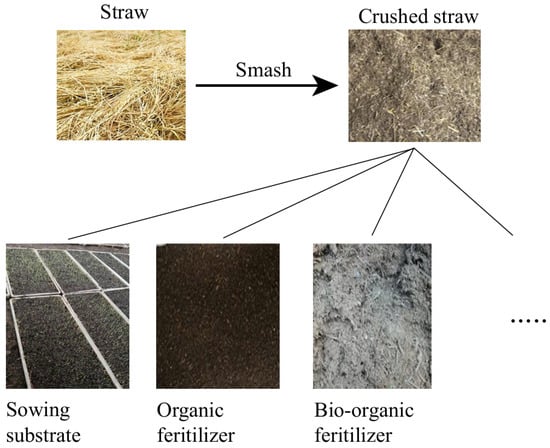

Due to its high availability, straw is widely recognized as a promising source of energy and a recyclable raw material. With the rapid development of global agriculture, the amount of straw has significantly increased. For instance, approximately 7 billion tons of straw are produced worldwide each year [1], with China contributing 900 million tons. Rice, wheat, and corn straw are the primary types, occupying approximately 90% of total production of straw [2]. As of 2024, China’s comprehensive utilization rate of major crop straw reached 88.1%, with 57.6% used for fertilizer, 20.7% for feed, and 8.3% for energy production. In key production areas such as Henan Province, the utilization rate exceeds 93%. Traditionally, the management of this residue involved open burning, leading to severe environmental consequences such as greenhouse gas emissions [3,4,5,6], volatile organic compounds [7], and particulate matter that adversely affects air quality and climate [8,9]. With increasing pressure on biomass straw management, growing attention has been focused on this issue, and the Chinese government has placed high priority on straw resource utilization [10]. Compared to other developed countries, domestic research on straw utilization has experienced slight delays. Over the years, governments have introduced a series of stringent regulations, highlighting the urgency for sustainable solutions. Since 2008, China has been promoting a crop residue retention program, which aims to retain crop residues in the field to enhance soil fertility, conserve energy, and reduce air pollutant emissions [11]. After decades of research and development, straw agricultural utilization has become diverse (Figure 1), yet the technical system remains immature, with a series of challenges awaiting resolution.

Figure 1.

Uses of crop straw for agricultural purposes.

By the early 20th century, developed countries and regions in Europe, America, and Japan had recognized the significance of sustainable agricultural ecology for economic development and environmental protection. They gradually began researching comprehensive straw utilization technologies and equipment, leading to the development of numerous mature machine models that have since been widely adopted in agriculture [12]. In the U.S., John Deere produced models like the 714 and 2633VT land preparation machines. These machines consist of disc harrow groups, blade assemblies, deep cultivation teeth, hydraulic systems, and electronic controls. Designed as multi-functional implements for large and medium-sized tractors, they efficiently perform tasks such as straw and weed stubble mulching, soil rotary tillage, and deep loosening in a single pass [13,14]. German agricultural machinery companies HORSCH and AMAZONE developed the Tiger-4MTStarr deep-tillage machine and the Cenius-2TX stubble mulching cultivator. The Tiger-4MTStarr integrates concave-tooth disc harrows, soil-mixing blades, deep loosening shovels, and ridgers, enabling full straw incorporation and deep tillage—particularly effective for high-straw crops like corn. The Cenius-2TX, equipped with disc harrows, blade groups, and rollers, serves dual purposes for stubble mulching and soil cultivation, including deep loosening and seedbed preparation. Its adaptability to varying field conditions is achieved through interchangeable blades and high-power attachments, supporting sustainable high-efficiency agriculture [15,16]. Denmark’s kverneland Agricultural Machinery Company developed the FX series straw incorporation machines. These use V-belt pulleys for power transmission and feature adjustable blades tailored to crop residues, field conditions, and post-harvest stubble, ensuring high efficiency and reliability. In summary, advanced economies have accumulated significant expertise in straw incorporation technologies, offering a diverse range of high-efficiency, reliable equipment [17,18]. However, the agricultural management models and land usage situations in foreign countries are different from those of our country regarding the handling of straw crops. Therefore, in order to meet domestic needs, we need to study and develop suitable straw returning technologies and equipment based on advanced foreign straw returning technologies and equipment, while also taking into account the agricultural techniques of domestic crops. In the 1990s, domestic research institutions and enterprises began developing mechanized straw incorporation equipment tailored to China’s agricultural planting conditions. As of today, significant progress has been made in straw incorporation technology.

Although existing literature includes some reviews on straw treatment and management [19,20], there are almost no comprehensive reviews on the key technologies and equipment for straw utilization. Therefore, this paper attempts to provide a critical and comprehensive analysis of current straw utilization technologies and equipment, including addressing equipment gaps in mechanized processing, overcoming technical bottlenecks in resource transformation, and filling the gap in agriculturally compatible technologies. By elucidating their potential benefits, limitations, and challenges, as well as future prospects and directions, the aim is to strengthen research and development in this field, enhance the potential of straw utilization, and explore green circular agricultural economic models.

2. Addressing the Equipment Gap in Mechanized Processing

2.1. Low Efficiency in Straw Harvesting and Collection Equipment

The removal of straw from large fields is typically accomplished with specialized machinery (e.g., grinders, balers, loaders, trucks), while small plots are often handled by farmers themselves using manual tools or small equipment. Despite bans on straw burning, some farmers still resist abandoning the practice due to the high costs of alternative methods. A study found that in Indonesia, 41,078 kg of straw is required to reach the break-even point when using a straw chopper [21]. However, Luo et al. [22] discovered that compared to fully manual collection, small-scale mechanical collection and large-scale mechanical collection can reduce collection costs by 54.1% and 60.3%, respectively. Additionally, many farmers prefer leaving straw in the fields rather than collecting it, as this is simpler and more convenient. Furthermore, the short window between harvest and planting seasons discourages proactive straw management, as farmers prioritize rapid field clearance to maximize crop yields [23]. The primary method for harvesting grain crops is combine harvesting. However, this approach has significant drawbacks, including high transportation costs, difficulty harvesting lodged grains, and inability to operate in wet field conditions. Moreover, a key limitation of this technology lies in the constrained throughput of threshing and separation equipment. Studies suggest this can be improved through equipment modernization [24] or by enhancing the separation process in combine harvester cleaning systems [25,26]. The technique of combing plants on the stems (including both stationary and combine-based approaches) can eliminate the drawbacks of traditional methods [27]. Compared with traditional combine harvesters, combine harvesters equipped with combing headers demonstrate superior performance can achieve higher operating speeds, improve efficiency, and enhance capability in wet conditions. The resulting productivity gains directly contribute to reduced fuel consumption, leading to better cost-effectiveness and lower production costs [28]. Nevertheless, a critical issue remains unresolved: a substantial portion of non-grain crop residues (straw) continues to be left in the field after harvest.

Scattered straw residues in fields can adversely affect agricultural production and field environments. To mitigate these issues, straw must be collected and removed from fields [29]. For straw collection and baling, Wang et al. [30] developed a straw pickup and baler. The straw pickup device developed by John Deere (Moline, IL, USA) employs closely spaced spring teeth to ensure thorough collection of high-density, wide-swath straw residues. Above the spring teeth, a small-pitch rack straw guide mechanism prevents crop material from being ejected during pickup, thereby minimizing damage. Blockages between the straw and baler can be resolved using reverse-moving mower and baler mechanisms. The forward speed of the baler serves as a key parameter for comparing performance characteristics of spring-toothed roller silage pickup [31]. Moisture content of collected straw and rotational speed of the pickup roller significantly influence both the pickup loss rate and power consumption of balers. Mechanized straw handling primarily employs two baling systems—rectangular and round bales—typically tractor-towed. The combination of tractor and baler demonstrates limited field maneuverability, contributing to low straw collection rates [32]. To improve convenience and flexibility, researchers have experimented with directly connecting or mounting existing baling equipment behind combine harvesters for intermittent pickup and baling of scattered straw [33]. Nevertheless, tractor-pulled balers present multiple operational challenges, including large turning radii and limited implement flexibility. In contrast, self-propelled balers offer smaller working radii and greater operational maneuverability [34].

2.2. Insufficient Adaptability of Straw Crushing and Incorporation Equipment

Given that crop straw contains abundant organic matter and nutrients, under the current national initiative to promote its comprehensive utilization, advancing straw crushing as fertilizer for soil application and improving land quality have become key research focuses in straw utilization [35]. Straw crushing and returning technology involves using specialized equipment to shred and scatter straw stalks and leaves across fields or incorporate them into the soil via rotary tillage. After mechanical crushing and returning, straw decomposes more efficiently, providing nitrogen (N), phosphorus (P), and potassium (K) to subsequent crops, enhancing soil fertility, improving soil structure, and promoting crop growth [36,37]. Additionally, mechanized crushing avoids harmful substances like nitrogen and sulfur oxides generated by traditional open-field burning, thereby mitigating environmental damage to some extent [38,39]. However, due to variations in straw yield, terrain, and soil compaction across different crop varieties, the challenges of straw incorporation vary, making existing equipment less adaptable to complex field conditions.

Latin America, Africa, and Asia possess the largest quantities of crop stubble and straw, yet their relatively traditional agricultural practices result in low utilization rates and underdeveloped stubble management technologies. Crop stubble consists of above-ground stalks and underground root systems, which form root-soil aggregates as roots spread and consolidate surrounding soil. The strong bonding between thick stubble and soil makes mechanical processing particularly challenging [40]. Current primary stubble management methods contain: (1) Stubble side-throwing: this method cuts main roots and flings straw sideways with minimal soil disturbance, but fails to completely crush stubborn residues [41]; (2) Stubble rotary tillage: typically employs strip tillage to mix and bury stubble with soil [42], causing significant soil disturbance, ridge platform destruction, and potential soil moisture loss [43]; (3) Stubble crushing: uses horizontal tools to effectively pulverize surface residues, yet requires high rotational speeds with substantial power consumption. At greater stubble heights, cutting may be missed as tools do not penetrate soil, leaving root-soil aggregates untreated. The strong soil-root integration makes accurate physical property measurement difficult, consequently hindering effective design of soil-contact crushing components and parameter settings for stubble-crushing simulations. Conventional approaches—whether rotary tillage (mixing roots/stubble with soil) or stubble crushing (neglecting underground roots)—face persistent challenges including soil adhesion to cutters, excessive soil disturbance, and poor root-crushing effectiveness [44,45]. Thus, the core challenge in stubble management technology lies in achieving high-quality crushing of both above-ground stalks and underground roots while minimizing soil disturbance.

Currently, the most widely adopted straw incorporation machinery in China utilizes high-speed rotating hammers or flails to repeatedly impact, cut, and rub straw into fibrous strands [46]. This crushing method requires extremely high rotor speeds while maintaining a fixed clearance above ground level, often resulting in unprocessed straw near the soil surface. As straw undergoes random impacts and cuts within the crushing chamber, the length uniformity fails to meet sowing requirements. Although significant research has been conducted on flail designs in China—including hammer-claw, Y-type, L-type, and straight-blade configurations [47]—yielding some improvement in crushing quality, the fundamental crushing mechanism remains unchanged. Persistent issues include missed crushing and inconsistent fragment sizes.

2.3. The Non-Prevalence of Full-Straw-Load Seeding Anti-Blocking Technology

The presence of straw, stubble, and compacted soil may cause clogging issues in furrow openers and other critical machinery components [48]. The high moisture content and strong toughness of straw, along with challenges such as difficulty in crushing and uneven length distribution of crushed straw, are key factors contributing to this phenomenon, which adversely affects seeding quality [49]. Internationally, no-till seeders in other regions primarily employ passive anti-blocking solutions, mainly utilizing disc openers and wavy coulters [50,51]. However, a study has demonstrated that residue removers can effectively ensure the smooth and efficient operation of no-till seeders [52]. No-till seeding stubble cleaners are designed to handle various field residues including standing stubble, straw, root remnants, and other materials generated during cutting operations. These implements effectively sever straw roots while simultaneously reducing operational costs. By cutting surface stubble, they create favorable conditions for seeder passage, preventing residue blockage and potential damage to seeding units [53]. Current research on no-till stubble-cutting blades primarily focuses on: Structural optimization of cutting tools, material selection improvements and operational parameter refinement. Meanwhile, advanced stubble management technologies such as laser-assisted stubble removal [54] and high-pressure water jet stubble cutting [55] are under development to address diverse regional requirements. These innovations aim to provide more adaptable solutions for varying field conditions and residue characteristics.

Liu et al. [56] proposed a method for crushing and returning corn straw to fields using rollers with differential speeds and a dynamic dual-support system. Through the design of pickup crushing blades and roller sliding support blades, this system allows adjustment of straw distribution width and uniformity, achieving a qualified crushing rate of 92.58% for corn straw after operation. Tian et al. [57] developed the 1JHL-2 straw deep-burial machine, which collects and buries two rows of straw in ditches, achieving alternating deep burial of straw in ridges and furrows. Sidhu et al. [58] created a suitable 9-row turbocharged wheat no-till seeder for rice stubble fields, incorporating straw crushing and returning functions that reduced fuel consumption costs, optimized planting schedules, and facilitated direct wheat production in rice stubble fields. Wang et al. [59] developed an active straw-shifting anti-blocking device to ensure the operation of corn no-till planters in fields with high wheat stubble and complete straw return. Current research on crop planting technologies and equipment under straw mulching conditions primarily adopts methods such as crushed straw mulching, plow burial, soil mixing burial, ditch deep burial, and side straw collection to accelerate field decomposition of straw [60]. However, few studies have focused on complete straw crushing with inter-row collection and clean-zone seeding technologies and equipment [61]. High machinery costs and regional adaptability disparities of the same technology or equipment further hinder the promotion and application effectiveness of mechanized straw comprehensive utilization.

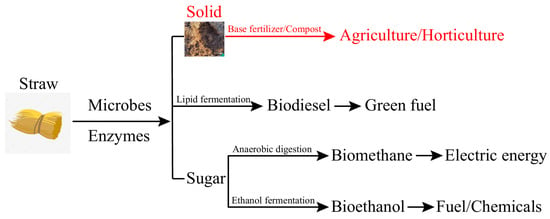

3. Breaking Through Technical Bottlenecks in Resource Conversion

Due to the natural characteristics of straw, numerous chemical treatment methods, including liquefaction, gasification, and pyrolysis, have been extensively studied, aiming to convert straw into resources and energy (e.g., biochar, syngas, bio-oil) [62] (Figure 2). Compared to chemical approaches that require harsh reagents and complex reaction conditions, biological processes demonstrate distinct advantages because of their minimal production of secondary pollutants, low costs, and mild reaction conditions. Recent advances have employed various biotechnologies—including aerobic composting, anaerobic digestion, and fermentation—to convert straw into biofuels (e.g., bioethanol and biogas) and bioresources (compost and biofertilizers) [63]. However, the inherently low biodegradability of straw, primarily composed of recalcitrant cellulose, hemicellulose, and lignin, has been considered as the limiting factor for wide-range applications. Consequently, straw pretreatment is crucial for enhancing overall process efficiency. Biological pretreatment (such as enzymatic hydrolysis and microbial degradation), compared to conventional thermal and chemical methods, is recognized as both efficient and environmentally benign. It offers multiple advantages: simple equipment requirements, low energy input, no generation of microbial inhibitors, reduced downstream costs [64], and absence of secondary pollution. Nevertheless, scaling up biological pretreatment faces several technical challenges, including suboptimal enzyme activity and degradation efficiency, high cost of commercial enzyme, and prolonged processing time [2].

Figure 2.

The integrated approach for concurrent energy and resource recovery from straw [2].

Biogas production from straw represents a viable alternative for managing this abundant agricultural resource [65]. The process concurrently generates substantial amounts of digestate, which finds widespread application in agriculture as both soil conditioner and organic fertilizer. Characterized by its carbon-rich composition and organic matter content, the digestate serves as a valuable soil amendment and energy substrate for microbial communities [66]. To maintain stable biogas production and enhance yield efficiency, straw requires preliminary pretreatment through various methodologies, including physical, chemical, biological, or combined approaches [67]. Physical methods include cutting straw into smaller sizes, ultrasonic treatment, irradiation, or steam explosion treatment, in order to increase digestibility by increasing the surface area. However, this method requires high energy input. Chemical methods, such as acid and alkali treatment, help decompose complex compounds in straw. However, these methods have potential negative impacts and high material costs. Biological methods involve pretreating straw with microorganisms (such as bacteria and fungi) to simplify the complex structure of biomass. Although these methods require less energy and chemical consumption, the treatment time is longer, and microorganisms are sensitive and require ideal growth conditions [68]. Germany can provide 15–25 million tons of straw annually. Due to its low lignin content and waxy cuticle layer, straw pellets exhibit high abrasiveness, low bulk density, and high mechanical durability, enabling highly efficient transportation and storage14. However, this equipment lacks industrial advantages and universality due to its high costs [69].

4. Addressing the Gap in Agronomic Adaptation Technologies

4.1. Technology Gap in Straw-Green Manure Co-Incorporation Equipment

In rice-wheat rotation systems and other cereal-based cropping systems, the incorporation of leguminous green manure or cereal-legume intercropping is recognized as highly beneficial due to its positive impacts on soil quality and nitrogen supply for subsequent crops [70,71]. Research has demonstrated that when wheat straw incorporation is combined with in situ cultivation of Sesbania aculeate as green manure, significant increases in rice yield have been observed [72,73,74]. Li et al. [75] found that during summer fallow periods, the combination of wheat straw mulching with soybean green manure cultivation mitigated the negative effects of increased soil water consumption by soybean growth while alleviating the reduced nitrogen availability caused by straw mulching. Liang et al. [76] developed a two-point double-screw buried straw incorporation device, but both methods require green manure to be crushed and turned over after a certain period, and they suffer from issues such as unsustainable growth, root damage, and low green manure utilization efficiency. FENDT and PERFECT Van Wamel BV have developed a multifunctional machine equipped with a front green manure crusher and a rear five- or eight-plow turning device [77]. These machines are typically large or medium-sized, expensive, and require tractors with a rated power of 220 kW or higher to operate. Current straw-green manure co-incorporation equipment still has shortcomings. Existing models cannot precisely control crop stubble height and green manure sowing depth, and they also face problems such as slow decomposition and root damage after field rotation.

4.2. Lagging Development of Specialized Equipment for Straw-Based Seedling Nursery

Mechanical transplanting is crucial for modernizing rice cultivation in China [78]. However, the labor-intensive nature of seedling cultivation and transplantation poses significant challenges. Short seedling ages often result in underdeveloped root systems, while conventional soils and substrates may fail to form the cohesive mats essential for mechanical transplanting [79,80]. The use of panel substrates made from decomposed, fermented, and compressed crop straw offers a promising solution [81]. This approach has demonstrated superior seedling quality and more efficient transplanting compared to traditional nutrient soil methods [82,83]. The lightweight composition, abundant fibers, and enhanced root adhesion of straw-based panels provide distinct advantages [84,85]. These characteristics promote rapid root mat development in younger rice seedlings, creating ideal conditions for successful field establishment [86]. Conventional mechanical transplanting for japonica rice typically requires 120–150 seeds per tray, with approximately 420 trays needed per hectare [87,88]. While lightweight straw substrate blocks can achieve high-density sowing of 300 seeds per tray, current seeding equipment suffers from a seedling damage rate exceeding 10%, significantly limiting nursery efficiency improvements.

5. Innovation Directions

5.1. Enhancing Machine Performance

Since the seeders need to operate continuously at high speed, this imposes very high requirements on the wear resistance of the tillage equipment [89]. The traditional quenching processes and materials are no longer able to meet the economic efficiency and high-performance requirements of agricultural machinery. Processes including laser phase transformation and flame spraying should be considered for alternative treatment [90]. During the harvesting process, the cutting tools come into contact with the soil, and the soil adheres to the cutting tools, especially in soils with high moisture content, and even may hinder the normal operation of the machine [91,92]. Research indicates that mechanical vibration de-adhesion technology and biomimetic micro-electro-osmotic anti-adhesion technology can optimize the surface of cutting tools, reduce soil adhesion, lower machine energy consumption, and maintain optimal equipment performance [93,94]. However, these solutions must be adapted to local conditions. In different soil environments, regional adjustments should be made to the materials and processes of machine components to enhance operational stability. In practice, significant variations exist among different types of planters, and methods for improving their performance still require further research.

5.2. Building a Big Data Platform for Straw Crushing

A big data platform should be constructed to record row spacing and other information during sowing [89]. In subsequent harvesting and straw crushing processes, track-and-control technology is employed to follow the recorded paths in the data platform, enhancing operational efficiency [95]. If deviations occur, the platform will correct the path and issue alerts [96], enabling precise localization and efficient crushing of crop residues [97].

5.3. Promoting the Application of New Technologies and Equipment

While striving to develop new technologies and equipment, promoting their popularization and application is also a major challenge. First and foremost, farmers’ acceptance of new technologies and equipment is a critical issue. While they hope policies can address the challenges of straw disposal, they remain skeptical about the feasibility of these technologies and the flexibility of the policies. Particularly during harvest season, many farmers resort to burning or discarding large quantities of straw due to tight farming schedules and the pressure to sow crops in a timely manner, which to some extent contributes to environmental pollution and resource waste. Most farmers are only aware of some potential uses of straw, such as animal feed, composting, seed germination mats, and raw material for papermaking. These insights are primarily acquired from other farmers who recognize the value of straw [98]. By precisely targeting the target market and identifying users’ pain points, targeted promotion of technologies and equipment can be carried out [99]. For example, developing differentiated equipment for different terrains (plain/ridge) and crop types (rice/wheat) to enhance regional adaptability [100,101]. Simple operation steps can make the equipment adaptable to different environments, while optimizing the after-sales service of technologies and equipment to increase farmers’ acceptance.

5.4. Increasing Support for Mechanized Equipment for Straw Processing

The mechanized comprehensive utilization of straw is a long-term technical endeavor that requires fostering specialized cooperative organizations dedicated to this field. It is recommended that government departments enhance support for the research and development of straw processing equipment, and promote the demonstration and adoption of new technologies and machinery for straw utilization.

6. Prospects

China boasts an exceptionally high diversity of crop varieties. As a crucial source of energy and resource recovery, straw utilization urgently needs to be strengthened. Industrialization of straw utilization is the core pathway to achieving efficient straw use. To enhance the versatility and multi-scenario applicability of such equipment, breakthroughs must be made in three key areas: technological adaptability, operational efficiency optimization, and industrial chain coordination. By combining policy support with local practices, replicable solutions can be developed. The development of straw recycling must adhere to the principles of “agriculture-first, industry-driven, and multi-pronged approaches,” achieving a win-win between agricultural production and environmental protection through technological innovation and policy synergy. However, challenges such as high costs of technology and equipment, regional disparities in straw supply, and farmers’ reluctance to adopt new technologies and equipment remain pressing issues to be addressed.

Author Contributions

Conceptualization, Q.W., Y.W. (Yangyan Wei) and Y.O.; writing—original draft preparation, Q.W. and S.Y.; writing—review and editing, Q.W., Y.Q., Y.W. (Yangyan Wei), Y.W. (Yanli Wang), T.T., Z.J. and Y.O.; supervision, Z.J. and Y.O.; visualization, Q.W., T.T. and Y.O.; project administration, Y.Q., Y.W. (Yanli Wang) and Y.O. All authors have read and agreed to the published version of the manuscript.

Funding

This work was supported by the “Pioneer” and “Leading Goose” R&D Program of Zhejiang (2023C02018, Jiaoyu Wang) and the National Key Research and Development Program of China (Grant 2023YFD1400202, Jiaoyu Wang).

Data Availability Statement

Not applicable.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Sun, L.N.; Ma, X.; Liu, K.; Zheng, X.; Zhang, H.; Rong, L. A review on research advances on microbial treatment and strengthening techniques of crop straw. Nat. Sci. 2018, 30, 188–195. [Google Scholar]

- Ma, Y.; Shen, Y.; Liu, Y. State of the art of straw treatment technology: Challenges and solutions forward. Bioresour. Technol. 2020, 313, 123656. [Google Scholar] [CrossRef] [PubMed]

- Yan, X.; Cai, Z.; Ohara, T.; Akimoto, H. Methane emission from rice fields in mainland China: Amount and seasonal and spatial distribution. J. Geophys. Res. 2003, 108, 16. [Google Scholar] [CrossRef]

- Kim Oanh, N.T.; Ly, B.T.; Tipayarom, D.; Manandhar, B.R.; Prapat, P.; Simpson, C.D.; Liu, L.-J.S. Characterization of particulate matter Eemission from open burning of rice straw. Atmos. Environ. 2011, 45, 493–502. [Google Scholar] [CrossRef]

- Stockwell, C.E.; Yokelson, R.J.; Kreidenweis, S.M.; Robinson, A.L.; DeMott, P.J.; Sullivan, R.C.; Reardon, J.; Ryan, K.C.; Griffith, D.W.T.; Stevens, L. Trace gas emissions from combustion of peat, crop residue, domestic biofuels, grasses, and other fuels: Configuration and Fourier transform infrared (FTIR) component of the fourth Fire Lab at Missoula Experiment (FLAME-4). Atmos. Chem. Phys. 2014, 14, 9727–9754. [Google Scholar] [CrossRef]

- Sun, J.; Peng, H.; Chen, J.; Wang, X.; Wei, M.; Li, W.; Yang, L.; Zhang, Q.; Wang, W.; Mellouki, A. An Estimation of CO2 emission via agricultural crop residue open field burning in China from 1996 to 2013. J. Clean. Prod. 2016, 112, 2625–2631. [Google Scholar] [CrossRef]

- Zhang, Y.; Shao, M.; Lin, Y.; Luan, S.; Mao, N.; Chen, W.; Wang, M. Emission inventory of carbonaceous pollutants from biomass burning in the Pearl River Delta Region, China. Atmos. Environ. 2013, 76, 189–199. [Google Scholar] [CrossRef]

- Habib, G.; Venkataraman, C.; Bond, T.C.; Schauer, J.J. Chemical, microphysical and optical properties of primary particles from the combustion of biomass fuels. Environ. Sci. Technol. 2008, 2, 8829–8834. [Google Scholar] [CrossRef]

- Stone, E.A.; Schauer, J.J.; Pradhan, B.B.; Dangol, P.M.; Habib, G.; Venkataraman, C.; Ramanathan, V. Characterization of emissions from south Asian biofuels and application to source apportionment of carbonaceous aerosol in the Himalayas. J. Geophys. Res. Atmos. 2010, 115, 6. [Google Scholar] [CrossRef]

- Chen, W.H.; Shi, X.X. Application and research status of agricultural and forestry waste in China. Mod. Agric. Sci. Technol. 2017, 18, 148–149. [Google Scholar]

- Ren, J.; Yu, P.; Xu, X. Straw utilization in China—Status and recommendations. Sustainability 2019, 11, 1762. [Google Scholar] [CrossRef]

- Arthur, R.; Baidoo, M.F. Harnessing methane generated from livestock manure in Ghana, Nigeria, Mali and Burkina Faso. Biomass Bioenergy 2011, 35, 4648–4656. [Google Scholar] [CrossRef]

- Morrison, J.E. Development and future of conservation tillage in America. J. Res. Appl. Agric. Eng. 2002, 47, 5–13. [Google Scholar]

- Reicosky, D.C.; Allmaras, R.R. Advances in tillage research in north American cropping systems. J. Crop Prod. 2008, 8, 75–125. [Google Scholar] [CrossRef]

- Tebrugge, F.; During, R.A. Reducing tillage intensity—A review of results from a long-term study in Germany. Soil. Tillage Res. 1999, 53, 15–28. [Google Scholar] [CrossRef]

- Zikeli, S.; Gruber, S. Reduced tillage and no-till in organic farming systems, Germany—Status quo, potentials and challenges. Agriculture 2017, 7, 35. [Google Scholar] [CrossRef]

- Voytenko, Y.; Peck, P. Organisational frameworks for straw-based energy systems in Sweden and Denmark. Biomass Bioenergy 2012, 38, 34–48. [Google Scholar] [CrossRef]

- de Toro, A.; Gunnarsson, C.; Jonsson, N.; Sundberg, M. Effects of variable weather conditions on baled proportion of varied amounts of harvestable cereal straw, based on simulations. Sustainability 2021, 13, 9449. [Google Scholar] [CrossRef]

- Yu, Q.; Liu, R.; Li, K.; Ma, R. A review of crop straw pretreatment methods for biogas production by anaerobic digestion in China. Renew. Sustain. Energy Rev. 2019, 107, 51–58. [Google Scholar] [CrossRef]

- Tian, S.; Zhao, R.; Chen, Z. Review of the pretreatment and bioconversion of lignocellulosic biomass from wheat straw materials. Renew. Sustain. Energy Rev. 2018, 91, 483–489. [Google Scholar] [CrossRef]

- Sugandi, W.; Herwanto, T.; Handarto; Juliya. Test performance and economic analysis of straw chopper machine. IOP Conf. Ser. Earth Environ. Sci. 2019, 334, 012001. [Google Scholar] [CrossRef]

- Luo, W.; Xu, S.; Luo, T.; Shi, R.; Ye, Y.; Zhu, N. Carbon emissions and economic cost of different collection, storage, and transportation models for crop straw off-field utilization. Waste Biomass Valorization 2024, 15, 2989–3001. [Google Scholar] [CrossRef]

- Valle, T.M.D.; Zhu, J.; Jiang, P. Drivers of straw management in rural households: Options for the development of the bioenergy sector in China. Energy Sustain. Dev. 2022, 71, 341–351. [Google Scholar] [CrossRef]

- Sheychenko, V.; Anelak, M.; Kuzmych, A.; Gritsaka, O.; Dudnikov, I.; Tolstushko, N. Investigation of grain separation process in the three-drum threshing-separating device of a combine harvester. Mech. Agric. Conserv. Resour. 2018, 64, 42–45. [Google Scholar]

- Gabitov, I.I.; Badretdinov, I.D.; Mudarisov, S.G.; Khasanov, E.R.; Lukmanov, R.L.; Nasyrov, R.R.; Tuktarov, M.F.; Atnagulov, D.T.; Timeriashev, I.A.; Pavlenko, V.A. Modeling the process of heap separation in the grain harvester cleaning system. J. Eng. Appl. Sci. 2018, 13, 6517–6526. [Google Scholar]

- Myhan, R.; Jachimczyk, E. Grain separation in a straw walker unit of a combine harvester: Process model. Biosyst. Eng. 2016, 145, 93–107. [Google Scholar] [CrossRef]

- Halko, S.; Vershkov, O.; Horák, J.; Lezhenkin, O.; Boltianska, L.; Kucher, A.; Suprun, O.; Miroshnyk, O.; Nitsenko, V. Efficiency of combed straw harvesting technology involving straw decomposition in the soil. Agriculture 2023, 13, 655. [Google Scholar] [CrossRef]

- Drepa, E.B.; Golub, A.S.; Donets, I.A.; Walters, I.A. Efficiency of application of combing method when harvesting grain crops. IOP Conf. Ser. Earth Environ. Sci. Environ. Eng. Manag. Min. Soil. Treat. Technol. 2020, 548, 52040. [Google Scholar] [CrossRef]

- Tang, Z.; Li, Y.; Li, X.Y.; Xu, T.B. Structural damage modes for rice stalks undergoing threshing. Biosyst. Eng. 2019, 186, 323–336. [Google Scholar] [CrossRef]

- Wang, G.Q.; Yu, Q.; Bu, Y.L.; Yu, D.N.; Wang, C.M. Design of straw picking and baling machine and dynamic simulation of picker. Trans. Chin. Soc. Agric. Mach. 2001, 32, 59–61. [Google Scholar]

- Yu, Z.H. Comparative experimental study on performance parameters of spring toothed roller pasture pickup. J. Agric. Mech. Res. 2017, 39, 122–127. [Google Scholar]

- Wang, C.G.; Ao, E.C.; Xing, Y.H.; Yan, J.H. Design and test of steel roller outer roll baler. Trans. Chin. Soc. Agric. Mach. 2010, 41, 103–106+102. [Google Scholar]

- Qu, H.C.; Bao, S.; Yi, S.J.; Tao, G.X.; Li, Y.F.; Mao, X.; Xu, C. Simulation analysis of bundling device for rice harvesting and bundling machine. J. Agric. Mech. Res. 2017, 39, 59–63. [Google Scholar]

- Tang, Z.; Zhang, B.; Liu, X.; Ren, H.; Li, X.; Li, Y. Structural model and bundling capacity of crawler picking and baling machine for straw wasted in field. Comput. Electron. Agric. 2020, 175, 105622. [Google Scholar] [CrossRef]

- Nie, X.D. Research on Utilization of Crop Straw Resources in Tianjin; Tianjin Agricultural University: Tianjin, China, 2021. [Google Scholar]

- Jia, L. The Effects of Straw Return on Water Quality of Paddy Field; Southwest University of Science and Technology: Mianyang, China, 2015. [Google Scholar]

- Cong, H.B.; Yao, Z.L.; Zhao, L.X. Distribution of crop straw resource and its industrial systemand utilization path in China. Trans. CSAE 2019, 35, 132–140. [Google Scholar]

- Wen, C.B.; Qian, F.J.; Liu, P. Situation and evaluation of agricultural straw resource utilization. Ecol. Econ. 2018, 34, 147–150+157. [Google Scholar]

- Flower, K.C.; Ward, P.R.; Cordingley, N.; Micin, S.F.; Craig, N. Rainfall, rotations and residue level affect no-tillage wheat yield and gross margin in a mediterranean-type environment. Field Crop Res. 2017, 208, 1–10. [Google Scholar] [CrossRef]

- Zhu, D.Q.; Shi, M.; Yu, C.; Yu, Z.; Kuang, F.; Xiong, W.; Xue, K. Tool-straw-paddy soil coupling model of mechanical rotary-tillage process based on DEM-FEM. Comput. Electron. Agric. 2023, 215, 108410. [Google Scholar] [CrossRef]

- Chen, H.T.; Zha, S.H.; Dun, G.Q.; Cong, G.B.; Li, A.; Feng, Y.N. Optimization and experiment of cleaning device of 2BMFJ type no-till precision planter. Trans. Chin. Soc. Agric. Mach. 2016, 47, 96–102. (In Chinese) [Google Scholar]

- Aikins, K.A.; Barr, J.B.; Antille, D.L.; UcguI, M.; Jensen, T.A.; Desbiolles, J.M.A. Analysis of effect of bentleg opener geometry on performance in cohesive soil using the discrete element method. Biosyst. Eng. 2021, 209, 106–124. [Google Scholar] [CrossRef]

- Guan, C.S.; Fu, J.J.; Xu, L.; Jiang, X.; Wang, S.; Cui, Z. Study on the reduction of soil adhesion and tillage force of bionic cutter teeth in secondary soil crushing. Biosyst. Eng. 2021, 213, 133–147. [Google Scholar] [CrossRef]

- Kešner, A.; Choteborský, R.; Linda, M.; Hromasova, M.; Katinas, E.; Sutanto, H. Stress distribution on a soil tillage machine frame segment with a chisel shank simulated using discrete element and finite element methods and validate by experiment. Biosyst. Eng. 2021, 209, 125–138. [Google Scholar] [CrossRef]

- Yan, D.Q.; Xue, Y.H.; Xu, Z.Y.; Sun, Y.F.; Sun, R.H.; Hu, X.F. Current utilization status, technical models and development proposals for direct crop straw returning to field in China. Chin. J. Agric. Resour. Reg. Plan. 2023, 44, 1–14. [Google Scholar]

- Johnson, J.M.F.; Acostamartinez, V.; Cambardella, C.A.; Barbour, N.W. Crop and soil responses to using corn stover as a bioenergy feedstock: Observations from the Northern US corn belt. Agriculture 2013, 3, 72–89. [Google Scholar] [CrossRef]

- Wang, Q.J.; Liu, Z.D.; He, J.; Li, H.W.; Li, W.Y.; He, J.H.; Yan, X.L. Design and experiment of chopping-type maize straw returning machine. Trans. Chin. Soc. Agric. Eng. Trans. CSAE 2018, 34, 10–17. (In Chinese) [Google Scholar]

- Melero, S.; Panettieri, M.; Madejón, E.; Macpherson, H.G.; Moreno, F.; Murillo, J.M. Implementation of chiselling and mouldboard ploughing in soil after 8 years of no-till management in SW, Spain: Effect on soil quality. Soil. Tillage Res. 2011, 112, 107–113. [Google Scholar] [CrossRef]

- Brandelero, E.M.; de Araujo, A.G.; Ralisch, R. Soil mobilization and seeding depth by no-till seeder mechanisms for residue management. Eng. Agric. 2014, 34, 263–272. [Google Scholar]

- Yao, W.; Diao, P.; Miao, H.; Li, S. Design and experiment of anti-blocking components for shallow stubble clearing based on soil bin test. Agriculture 2022, 12, 1728. [Google Scholar] [CrossRef]

- Negadi, J.; Raoufat, M.H. Field performance of a pneumatic row crop planter equipped with active toothed coulter for direct planting of corn in wheat residue. Span. J. Agric. Res. 2013, 11, 327. [Google Scholar] [CrossRef]

- Elfatih, A.; Arif, E.M.; Atef, A.E. Evaluate the modified chopper for rice straw composting. J. Appl. Sci. Res. 2010, 6, 1125–1131. [Google Scholar]

- Zhang, Z.; McHugh, A.D.; Li, H.W.; Ma, S.C.; Wang, Q.J.; Jin, H.; Zheng, C. Global overview of research and development of crop residue management machinery. Appl. Eng. Agric. 2017, 33, 329–344. [Google Scholar] [CrossRef]

- Tan, H.; Wang, G.; Zhou, S.; Jia, H.; Qu, M.; Xiang, M.; Gao, X.; Zhou, Z.; Li, H.; Zou, Z. Design and experiment of header height adaptive adjustment system for maize (Zea mays L.) harvester. Sustainability 2023, 15, 14137. [Google Scholar] [CrossRef]

- Qu, M.; Wang, G.; Zhou, Z.; Gao, X.; Li, H.; Tan, H.; Xiang, M.; Jia, H. Development and performance evaluation of a pressure adjustable waterjet stubble-cutting device with thickness detection for no-till sowing. Sustainability 2023, 15, 13065. [Google Scholar] [CrossRef]

- Liu, P.; He, J.; Li, Y.J.; Li, H.W.; Wang, Q.J.; Lu, C.Y.; Zhang, Z.G.; Li, S.H. Design and experiment of double rollers maize stalk chopping device with different rotation speeds. Trans. CSAE 2020, 36, 69–79. (In Chinese) [Google Scholar]

- Tian, Y.; Lin, J.; Li, B.F.; Zhang, T.J.; Qi, L.; Wang, J.Q. Design and test of pneumatic 1JH-2 style straw deep burying and returning machine. Trans. CSAE 2018, 34, 10–18. (In Chinese) [Google Scholar]

- Sidhu, H.S.; Singh, M.; Singh, Y.; Blackwell, J.; Lohan, S.K.; Humphreys, E.; Jat, M.L.; Singh, V.; Singh, S. Development and evaluation of the turbo happy seeder for sowing wheat into heavy rice residues in NW India. Field Crop Res. 2015, 184, 201–212. [Google Scholar] [CrossRef]

- Wang, W.W.; Zhu, C.X.; Chen, L.Q.; Li, Z.D.; Huang, X.; Li, J.C. Design and experiment of active straw-removing anti-blocking device for maize no-tillage planter. Trans. CSAE 2017, 33, 10–17. (In Chinese) [Google Scholar]

- Matin, M.A.; Desbiolles, M.A.; Fielke, J.M. Strip-tillage using rotating straight blades: Effect of cutting-edge geometry on furrow parameters. Soil. Tillage Res. 2016, 155, 271–279. [Google Scholar] [CrossRef]

- Shi, Y.; Ye, J.; Wang, X.; Yu, H.; Liu, H.; Chen, J. Innovation of strip fertilization planting for rice straw crushing with back-throwing and interrow-laying. Plant Methods 2022, 18, 31. [Google Scholar] [CrossRef]

- Okolie, J.A.; Nanda, S.; Dalai, A.K.; Kozinski, J.A. Hydrothermal gasification of soybean straw and flax straw for hydrogen-rich syngas production: Experimental and thermodynamic modeling. Energ. Convers. Manag. 2020, 208, 112545. [Google Scholar] [CrossRef]

- Elsayed, M.; Abomohra, A.E.; Ai, P.; Wang, D.; El-Mashad, H.M.; Zhang, Y. Biorefining of rice straw by sequential fermentation and anaerobic digestion for bioethanol and/or biomethane production: Comparison of structural properties and energy output. Bioresour. Technol. 2018, 268, 183–189. [Google Scholar] [CrossRef]

- Zabed, H.M.; Akter, S.; Yun, J.; Zhang, G.; Awad, F.N.; Qi, X.; Sahu, J.N. Recent advances in biological pretreatment of microalgae and lignocellulosic biomass for biofuel production. Renew. Sustain. Energy Rev. 2019, 105, 105–128. [Google Scholar] [CrossRef]

- Röder, M.; Jamieson, C.; Thornley, P. (Stop) burning for biogas. Enabling positive sustainability trade-offs with business models for biogas from rice straw. Biomass Bioenerg. 2020, 138, 105598. [Google Scholar] [CrossRef]

- Logan, M.; Visvanathan, C. Management strategies for anaerobic digestate of organic fraction of municipal solid waste: Current status and future prospects. Waste Manag. Res. 2019, 37, 27–39. [Google Scholar] [CrossRef] [PubMed]

- Mothe, S.; Polisetty, V.R. Review on anaerobic digestion of rice straw for biogas production. Environ. Sci. Pollut. Res. 2021, 28, 24455–24469. [Google Scholar] [CrossRef]

- Alengebawy, A.; Ran, Y.; Ghimire, N.; Osman, A.; Ai, P. Rice straw for energy and value-added products in China: A review. Environ. Chem. Lett. 2023, 21, 2729–2760. [Google Scholar] [CrossRef]

- Verena, E.M.S.; Martin, K. Pelletizing of wheat straw: How to influence mechanical-physical properties. Biofuel 2012, 3, 35–46. [Google Scholar]

- Parihar, C.M.; Yadav, M.R.; Jat, S.L.; Singh, A.K.; Kumar, B.; Pradhan, S.; Chakraborty, D.; Jat, M.L.; Jat, R.K.; Saharawat, Y.S.; et al. Long term effect of conservation agriculture in maize rotations on total organic carbon, physical and biological properties of a sandy loam soil in north-western Indo Gangetic Plains. Soil. Till Res. 2016, 16, 116–128. [Google Scholar] [CrossRef]

- Saikia, R.; Sharma, S.; Thind, H.S.; Sidhu, H.S.; Yadvinder-Singh. Temporal changes in biochemical indicators of soil quality in response to tillage, crop residue and green manure management in a rice-wheat system. Ecol. Indic. 2019, 103, 383–394. [Google Scholar] [CrossRef]

- Yadvinder, S.; Bijay, S.; Ladha, J.K.; Khind, C.S.; Gupta, R.K.; Mcclu, O.P.; Pasuquin, E. Long-term effects of organic inputs on yield and soil fertility in the rice-wheat rotation. Soil. Sci. Soc. Am. J. 2004, 68, 845–853. [Google Scholar] [CrossRef]

- Arrobas, M.; Aguiar, P.; Rodrigues, M.A. A comparison of a pasture ley with a maize monoculture on the soil fertility and nutrient release in the succeeding crop. Arch. Agron. Soil. Sci. 2016, 62, 829–839. [Google Scholar] [CrossRef]

- Thind, H.S.; Sharma, S.; Singh, Y.; Sidhu, H.S. Rice-wheat productivity and profitability with residue, tillage and green manure management. Nutr. Cycl. Agroecosyst 2019, 113, 113–125. [Google Scholar] [CrossRef]

- Li, F.C.; Wang, Z.H.; Dai, J.; Li, Q.; Xue, C.; Zhao, H.; Wang, X.; Olesen, J.E. Summer fallow soil management-impact on rainfed winter wheat. Acta Agric. Scand. Sect. B Soil Plant Sci. 2014, 64, 398–407. [Google Scholar] [CrossRef]

- Liang, F.; Deng, W.H.; Luo, L.Q.; Wang, J.K.; Zhan, S.P. Optimizing double-screw burying device for rape straw returning. Trans. Chin. Soc. Agric. Eng. Trans. CSAE 2023, 39, 12–20. [Google Scholar]

- Zhang, Q.; Zhao, J.; Yang, X.; Wang, L.; Su, G.; Liu, X.; Shan, C.; Rahim, O.; Yang, B.; Liao, J. Design and testing of an offset straw-returning machine for green manures in orchards. Agriculture 2024, 14, 1932. [Google Scholar] [CrossRef]

- Ling, Y.; Liu, M.; Feng, Y.; Xing, Z.; Gao, H.; Wei, H.; Hu, Q.; Zhang, H. Effects of increased seeding density on seedling characteristics, mechanical transplantation quality, and yields of rice with crop straw boards for seedling cultivation. J. Integr. Agric. 2025, 24, 101–113. [Google Scholar] [CrossRef]

- An, Z.D.; Guan, H.; Zhu, Y.P.; Chai, R.S.; Gao, H.J.; Hua, S.; Wang, Y.K. Effects of combined application of humic acid with seedling raising substrate on seedling quality and rice yield. Soil. Fertil. Sci. China 2022, 59, 173–181. (In Chinese) [Google Scholar]

- Zhu, Q.; Wang, X.; Xu, X.; Gao, S.; Liu, S.; Chen, H.; Zhang, Y. Optimization of manufacturing parameters and experimental study of rice straw fiber-based plant fiber seedling pots. Agronomy 2023, 13, 1782. [Google Scholar] [CrossRef]

- Ling, Y.F.; Xu, F.F.; Wei, P.Y.; Yan, C.; Wei, H.Y.; Zhang, H.C.; Liu, G.D. Effects of rice straw matrix board on seedling quality and transplanting quality. Acta Agric. Univ. Jiangxie 2021, 43, 9–17. (In Chinese) [Google Scholar]

- Hua, J.; Zhu, Q.B.; Gao, W.W.; Yang, Y.P.; Xue, G.X.; Wang, G.P.; Wang, X.Y.; Zhang, X.C.; Wang, Y.; Feng, Y.F. The effect of crop straw board seedling cultivation on the quality and yield of mechanized rice seedlings. Bull. Agric. Sci. Technol. 2023, 52, 76–78. (In Chinese) [Google Scholar]

- Youbi, S.B.T.; Tagne, N.R.S.; Harzallah, O.; Huisken, P.W.M.; Stanislas, T.T.; Njeugna, E.; Drean, J.Y.; Bistac-Brogly, S. Effect of alkali and silane treatments on the surface energy and mechanical performances of raphia vinifera fibres. Ind. Crops Prod. 2022, 190, 115854. [Google Scholar] [CrossRef]

- Yong, C. A Multi-Layer Rice Straw Board and Seedling Raising Method for Machine Transplanting. China National Intellectual Property Administration (CNIPA). China Patent Application No. 201910772006.3, 25 June 2021. (In Chinese). [Google Scholar]

- Fuentes, R.A.; Berthe, J.A.; Barbosa, S.E.; Castillo, L.A. Development of biodegradable pots from different agroindustrial wastes and byproducts. Sustain. Mater. Technol. 2021, 30, e00338. [Google Scholar] [CrossRef]

- Ren, H.; Gray, W.M. SAUR proteins as effectors of hormonal and environmental signals in plant growth. Mol. Plant 2015, 8, 1153–1164. [Google Scholar] [CrossRef]

- Long, R.P.; Leng, S.C.; Zhao, L.J.; Yin, J.; Yang, J.; Li, G.; Xia, Q.; Zhu, H.; Zhang, Y.; Yang, C. Preliminary study on mechanical transplanting technique of small indica rice seedlings in Yunnan Province. China Rice 2021, 27, 134–137. (In Chinese) [Google Scholar]

- Zhang, Y.; Zhu, Q.; Gao, S.; Liu, S.; Li, L.; Chen, H. Optimization of technological parameters of straw fiber-based plant fiber seedling pot raw materials. Appl. Sci. 2021, 11, 7152. [Google Scholar] [CrossRef]

- Sun, H.; Lin, G.; Li, H.W.; Gao, X.L.; Yao, G.C. Influence of scanning interval on microstructure and abrasive wear resistance of 45 steel by laser melting. Trans. CSAE 2011, 27, 156–160. (In Chinese) [Google Scholar]

- Li, C.S.; Tang, Y.L.; McHugh, A.D.; Wu, X.; Liu, M.; Li, M.; Xiong, T.; Ling, D.; Tang, Q.; Liao, M.; et al. Development and performance evaluation of a wet-resistant strip-till seeder for sowing wheat following rice. Biosyst. Eng. 2022, 220, 146–158. [Google Scholar] [CrossRef]

- Li, J.W.; Li, X.Y.; Hu, B.; Gu, T.; Wang, Z.; Wang, H. Analysis of the resistance reduction mechanism of potato bionic digging shovels in clay and heavy soil conditions. Comput. Electron. Agric. 2023, 214, 108315. [Google Scholar] [CrossRef]

- Wang, J.Y.; Zhao, S.H.; Gao, L.L.; Yuan, Y.W.; Yang, Y.Q. Design and experiment of passive disc cutting blade in corn ridges. Trans. CSAM 2021, 52, 59–67. [Google Scholar]

- Sun, J.F.; Chen, H.; Wang, Z.; Ou, Z.; Yang, Z.; Liu, Z.; Duan, J. Study on plowing performance of EDEM low-resistance animal bionic device based on red soil. Soil. Tillage Res. 2020, 196, 104336. [Google Scholar] [CrossRef]

- Li, H.; Ju, W.L.; Song, Y.M.; Cao, Y.; Yang, W.; Li, M. Soil organic matter content prediction based on two-branch convolutional neural network combining image and spectral features. Comput. Electron. Agric. 2024, 217, 108561. [Google Scholar] [CrossRef]

- Gao, Y. Research progress of stubble control deep pine land preparation combined operation machine. Use Maint. Agric. Mach. 2023, 8, 99–102. [Google Scholar]

- Rosmiza, M.Z.; Davies, W.P.; Rosniza, A.C.R.; Mazdi, M.; Jabil, M.J. Farmers’ knowledge on potential uses of rice straw: An assessment in MADA and Sekinchan, Malaysia. Malays. J. Soc. Space 2014, 10, 30–43. [Google Scholar]

- Silva, R.D.; Cielniak, G.; Gao, J.F. Vision based crop row navigation under varying field conditions in arable fields. Comput. Electron. Agric. 2024, 217, 108581. [Google Scholar] [CrossRef]

- Wang, J.C.; Zheng, H.; Yu, Y.; He, Y.; Liu, Y. Robust multiple obstacle tracking method based on depth aware OCSORT for agricultural robots. Comput. Electron. Agric. 2024, 217, 108580. [Google Scholar] [CrossRef]

- Shang, X.L.; Cao, J.B.; Wang, Y.; Yang, B.N.; Li, D.Y.; Wang, H. Current situation and prospect of conservation tillage technology. J. Chin. Agric. Mech. 2021, 42, 191–201. [Google Scholar]

- Guo, F.; Jin, J.J.; Zhang, C.Y.; He, R.; Qiu, X. A review of farmers’ conservation tillage technology adoption behavior and influencing factors. Prog. Geogr. 2022, 41, 2165–2177. [Google Scholar] [CrossRef]

- Wei, G.J.; Jian, S.; Fang, H.; Peng, Q.; Niu, M. Current situation and prospect of conservation tillage technology in dry-farming areas of north China. J. Chin. Agric. Mech. 2019, 40, 195–200. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).