Evaluation of Plant-Available Water in Degraded Alfisol Using Biomass Copyrolyzed with Plastic

Abstract

1. Introduction

2. Materials and Methods

2.1. Obtaining Raw Materials

2.2. Materials Preparation

2.3. Classification of the Different Amendments

2.4. Experiment

2.5. Modeling of Water Retention Curves

2.6. Data Analysis and Experimental Design

3. Results

3.1. Properties of the Different Carbonaceous Amendments

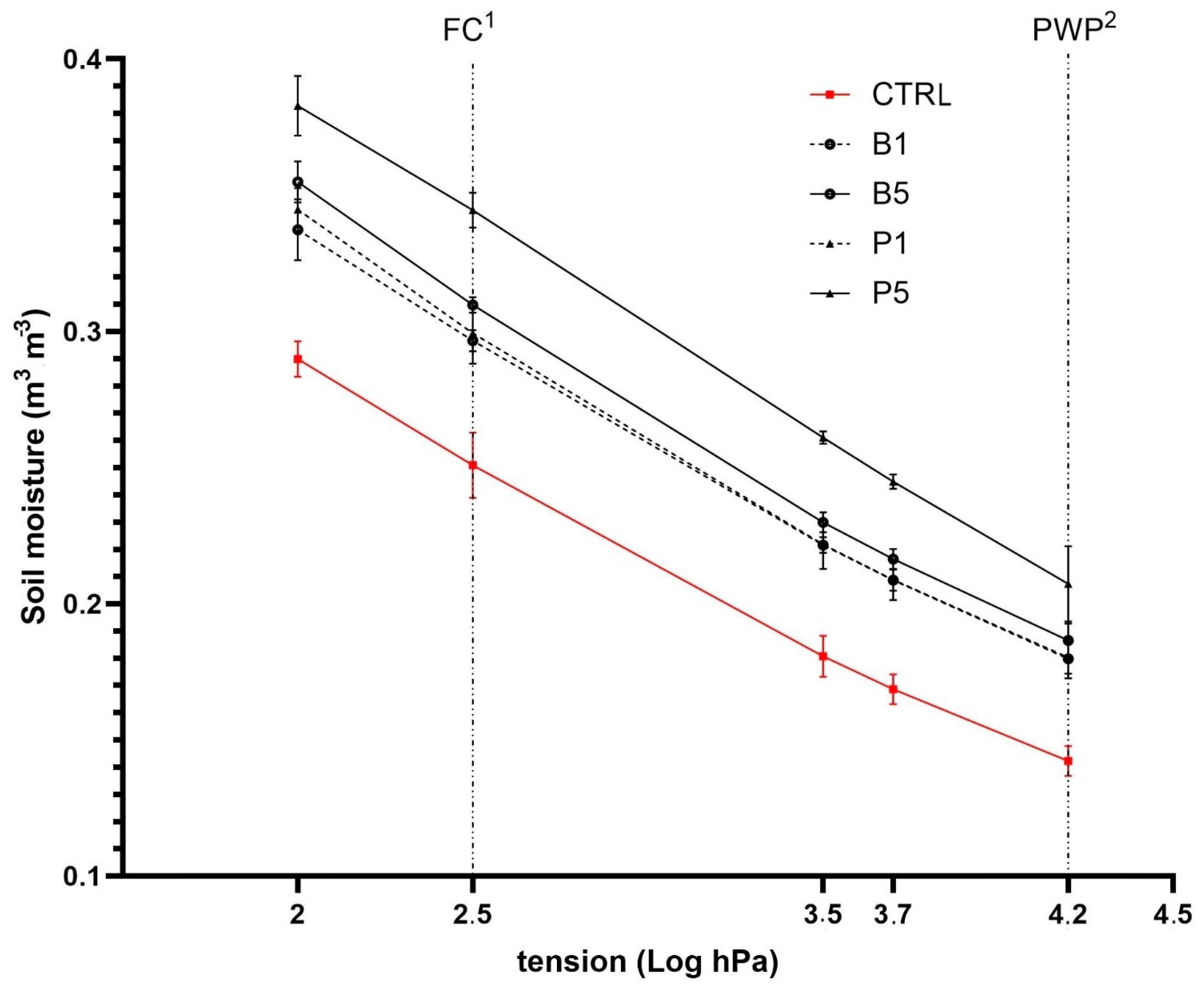

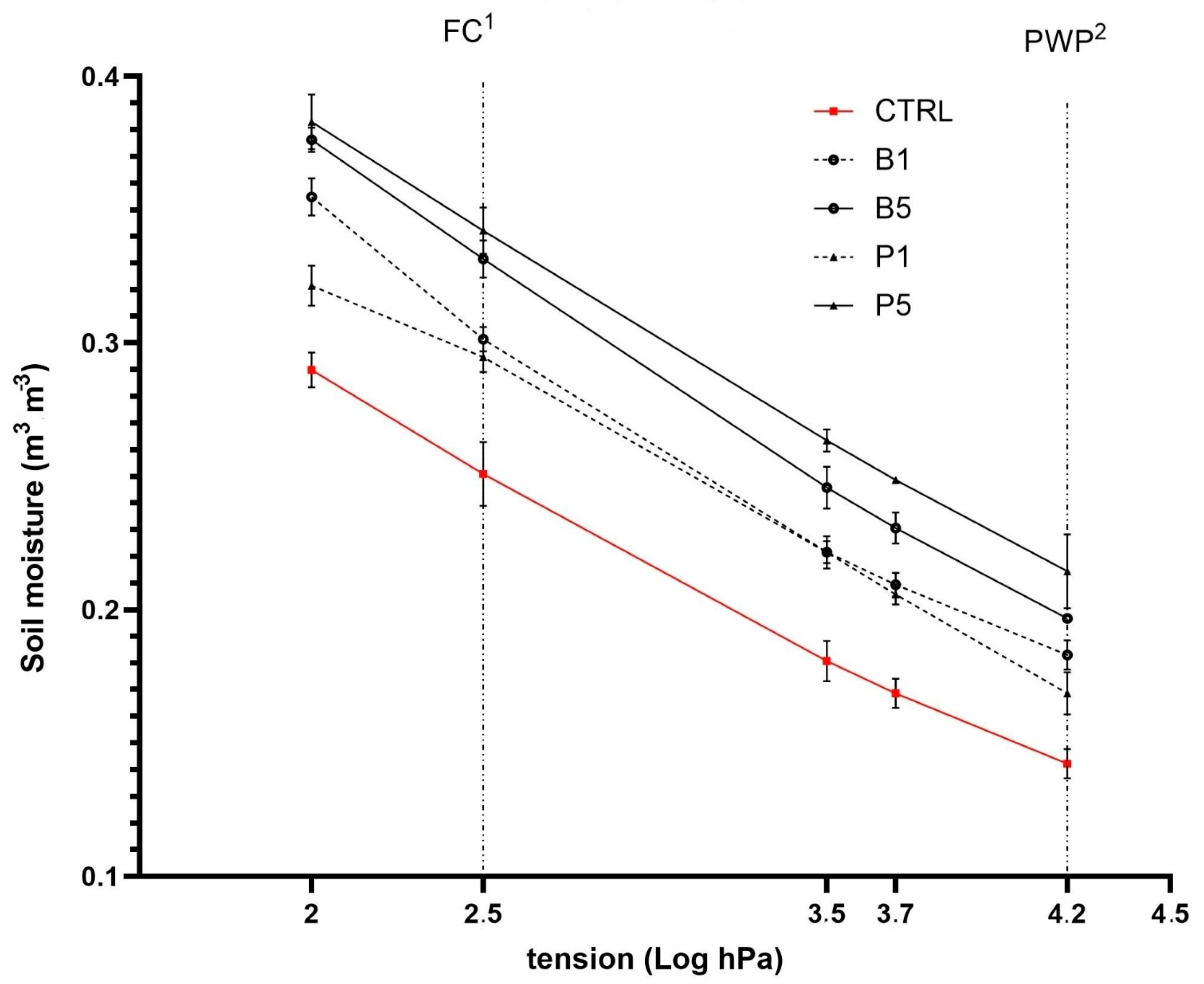

3.2. Water Released at Different Pressure Points

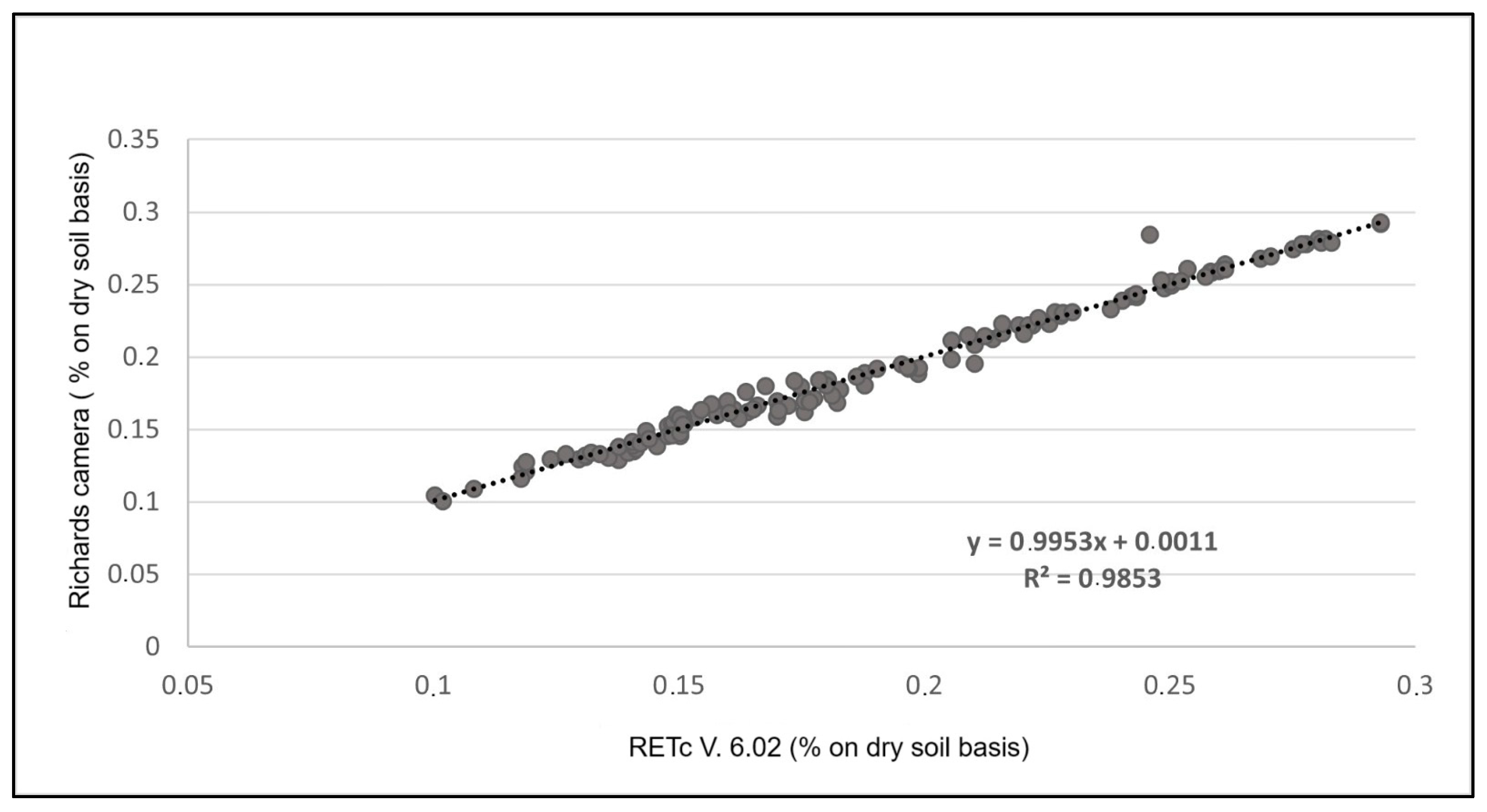

3.3. Data Insertion in Program Rosetta v 1.1

3.4. Water Retention Curves by RETc v 6.02

3.5. Analysis of the Dynamics of Water Flow

4. Discussion

4.1. Parameters Evaluated in the Amendments

4.2. Pore Structure Induced by Plastic in Biochar

4.3. Water Retention Curves in Alfisol

4.4. Air Capacity, Rapid Drainage Pores, and Plant-Available Water Pores

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| AC | Air capacity |

| PFD | Fast-draining pores |

| PAW | Pore-available water |

| FC | Field capacity |

| PWP | Permanent wilting point |

References

- Maaß, S.; Daphi, D.; Lehmann, A.; Rillig, M.C. Transport of microplastics by two collembolan species. Environ. Pollut. 2017, 225, 456–459. [Google Scholar] [CrossRef]

- PlasticsEurope. Situación en 2020: Un Análisis de Los Datos Sobre Producción, Demanda y Residuos de Plásticos en Europa; PlasticsEurope: Brussels, Belgium, 2021. [Google Scholar]

- OECD. Global Plastics Outlook: Economic Drivers, Environmental Impacts and Policy Options; OECD Publishing: Paris, France, 2022. [Google Scholar]

- Stanton, T.; Johnson, M.; Nathanail, P.; MacNaughtan, W.; Gomes, R.L. Freshwater microplastic concentrations vary through both space and time. Environ. Pollut. 2020, 263, 114481. [Google Scholar] [CrossRef] [PubMed]

- Mandal, S.; Pu, S.; Adhikari, S.; Ma, H.; Kim, D.H.; Bai, Y.; Hou, D. Progress and prospects in biochar composites: Application and reflection in the soil environment. Crit. Rev. Environ. Sci. Technol. 2021, 51, 219–271. [Google Scholar] [CrossRef]

- Bardales, M.; Saikawa, E.; Hengstermann, M.; Ramirez, A.; McCracken, J.P.; Thompson, L. Plastic waste generation and emissions from the domestic open burning of plastic waste in Guatemala. Environ. Sci. Atmos. 2023, 3, 156–167. [Google Scholar] [CrossRef] [PubMed]

- Steinmetz, Z.; Wollmann, C.; Schaefer, M.; Buchmann, C.; David, J.; Tröger, J.; Muñoz, K.; Frör, O.; Schaumann, G.E. Plastic mulching in agriculture: Trading short-term agronomic benefits for long-term soil degradation? Sci. Total Environ. 2016, 550, 690–705. [Google Scholar] [CrossRef] [PubMed]

- Rani, N.; Thakur, B.; Dutt, R.; Kapil, A.; Soni, R.; Soni, S.K. Harnessing agricultural waste: A sustainable approach to lignocellulolytic enzymes production. Bioresour. Technol. Rep. 2024, 27, 101912. [Google Scholar] [CrossRef]

- Nguyen, B.T.; Le, L.B.; Le, L.P.; Nguyen, H.T.; Tran, T.D.; Van-Thai, N. The effects of biochar on the biomass yield of elephant grass and properties of acidic soils. Ind. Crops Prod. 2021, 161, 113224. [Google Scholar] [CrossRef]

- Ellena, D.M. (Ed.) El Avellano Europeo en Chile: Una Década de Recopilación e Investigación; Colección Libros INIA N°36; Instituto de Investigaciones Agropecuarias: Temuco, Chile, 2018. [Google Scholar]

- Ginebra, M.; Muñoz, C.; Calvelo-Pereira, R.; Doussoulin, M.; Zagal, E. Biocarbón impacts on soil chemical properties, greenhouse gas emissions and forage productivity: A field experiment. Sci. Total Environ. 2022, 806, 150465. [Google Scholar] [CrossRef]

- Lehmann, J.; Joseph, S. Biochar for Environmental Management: Science, Technology and Implementation, 2nd ed.; Routledge: New York, NY, USA, 2021. [Google Scholar]

- Yáñez, N.; Dec, D.; Clunes, J.; Dörner, J. Estimación de la curva de retención de agua de un Andisol bajo un cultivo de arándano, a través de funciones de pedotransferencia. Agro Sur 2015, 43, 63–72. [Google Scholar] [CrossRef]

- Puentes-Escobar, T.; Carlosama, A. Impacto del biocarbón en el suelo agrícola. Av. Investig. Ing. 2021, 18, 1–12. [Google Scholar] [CrossRef]

- Wu, M.; Wang, Z.; Chen, G.; Zhang, M.; Sun, T.; Wang, Q.; Zhu, H.; Guo, S.; Chen, Y.; Zhu, Y.; et al. Synergistic effects and products distribution during co-pyrolysis of biomass and plastics. J. Energy Inst. 2023, 111, 101392. [Google Scholar] [CrossRef]

- Vo, T.A.; Tran, Q.K.; Ly, H.V.; Kwon, B.; Hwang, H.T.; Kim, J.; Kim, S.-S. Co-pyrolysis of lignocellulosic biomass and plastics: A comprehensive study on pyrolysis kinetics and characteristics. J. Anal. Appl. Pyrolysis 2022, 163, 105464. [Google Scholar] [CrossRef]

- Esso, E.S.B.; Deng, W.; Zhou, J.; Bertrand, A.M.E.; Xu, J.; Jiang, L.; Su, S.; Hu, S.; Hu, X.; Wang, Y.; et al. Impact of Plastic Type on Synergistic Effects during Co-Pyrolysis of Rice Husk and Plastics. Energy 2023, 281, 128270. [Google Scholar] [CrossRef]

- Engamba Esso, B.; Xiong, Z.; Chaiwat, W.; Kamara, M.F.; Longfei, X.; Xu, J.; Ebako, J.; Jiang, L.; Su, S.; Hu, S.; et al. Review on synergistic effects during co-pyrolysis of biomass and plastic waste: Significance of operating conditions and interaction mechanism. Biomass Bioenergy 2022, 159, 106415. [Google Scholar] [CrossRef]

- Nawaz, A.; Razzak, S.A. Co-pyrolysis of biomass and different plastic waste to reduce hazardous waste and subsequent production of energy products: A review on advancement, synergies, and future prospects. Renew. Energy 2024, 224, 120103. [Google Scholar] [CrossRef]

- Guo, J.; Zhou, H.; Jia, L.; Wang, Y.; Fan, M. Effects of biochar from different pyrolysis temperatures on soil physical properties and hydraulic characteristics in potato farmland of arid and semi-arid regions. Agric. Water Manag. 2025, 313, 109483. [Google Scholar] [CrossRef]

- Schmidt, H.P.; Taylor, P. Kon-Tiki flame cap pyrolysis for the democratization of biochar production. Biochar 2014, 1, 123–133. [Google Scholar]

- Van Genuchten, M.T. A closed-form equation for predicting the hydraulic conductivity of unsaturated soils. Soil Sci. Soc. Am. J. 1980, 44, 892–898. [Google Scholar] [CrossRef]

- Yogalakshmi, K.N.; Poornima Devi, T.; Sivashanmugam, P.; Kavitha, S.; Yukesh Kannah, R.; Varjani, S.; AdishKumar, S.; Kumar, G.; Banu, J.R. Lignocellulosic biomass-based pyrolysis: A comprehensive review. Chemosphere 2022, 286 Pt 2, 131824. [Google Scholar] [CrossRef]

- Zhang, R.; Dai, Q.; You, Z.; Wang, H.; Peng, C. Rheological Performance of Bio-Char Modified Asphalt with Different Particle Sizes. Appl. Sci. 2018, 8, 1665. [Google Scholar] [CrossRef]

- Instituto de Investigaciones Agropecuarias (INIA). Métodos de Análisis Recomendados Para el Compost; Serie Actas INIA N°30; INIA: Santiago, Chile, 2005. [Google Scholar]

- Stolpe, N.B. Descripciones de Los Principales Suelos de La VIII Región de Chile; Universidad de Concepción, Facultad de Agronomía: Chillán, Chile, 2006; ISBN 978-956-227-294-0. [Google Scholar]

- Sandoval, M.; Dörner, J.; Seguel, O.; Cuevas, J.; Rivera, D. Métodos de Análisis Físicos del Suelo; Publicaciones del Departamento de Suelos y Recursos Naturales, Universidad de Concepción: Chillán, Chile, 2012. [Google Scholar]

- Hartge, K.H.; Horn, R. Die Physikalische Untersuchung von Böden, 4th ed.; Schweizerbart Science Publishers: Stuttgart, Germany, 2009; ISBN 978-3-510-65246-6. [Google Scholar]

- Dec, D.; Dörner, J. Spatial variability of the hydraulic properties of a drip irrigated Andisol under blueberries. J. Soil Sci. Plant Nutr. 2014, 14, 589–601. [Google Scholar] [CrossRef]

- Li, X.; Cen, K.; Li, J.; Jia, D.; Gao, J.; Zhang, L.; Chen, D. Insights into the interactions between cellulose and hemicellulose during pyrolysis for optimizing the properties of biochar as a potential energy vector. Ind. Crops Prod. 2025, 223, 120126. [Google Scholar] [CrossRef]

- Escalante-Rebolledo, A.; Pérez-López, G.; Hidalgo-Moreno, C.; López-Collado, J.; Campo-Alves, J.; Valtierra-Pacheco, E.; Etchevers-Barra, J.D. Biocarbón I: Naturaleza, historia, fabricación y uso en el suelo. Terra Latinoam. 2016, 34, 367–382. [Google Scholar]

- Li, Y.; Feng, G.; Tewolde, H. Biochar derived from papermill factories improves soil physical and hydraulic properties in no-till cotton fields. Biochar 2023, 5, 35. [Google Scholar] [CrossRef]

- Kane, S.; Ulrich, R.; Harrington, A.; Stadie, N.P.; Ryan, C. Physical and chemical mechanisms that influence the electrical conductivity of lignin-derived biochar. Carbon Trends 2021, 5, 100088. [Google Scholar] [CrossRef]

- Xiong, S.; Zhang, L.; Lu, X. Conductivities enhancement of poly(3,4-ethylenedioxythiophene)/poly (styrene sulfonate) transparent electrodes with diol additives. Polym. Bull. 2013, 70, 237–247. [Google Scholar] [CrossRef]

- Bruun, E.W.; Ambus, P.; Egsgaard, H.; Hauggaard-Nielsen, H. Effects of slow and fast pyrolysis biochar on soil C and N turnover dynamics. Soil Biol. Biochem. 2011, 43, 2108–2116. [Google Scholar] [CrossRef]

- Mukherjee, A.; Zimmerman, A.R.; Harris, W. Surface chemistry variations among a series of laboratory-produced biochars and their effects on biochar stability. Soil Biol. Biochem. 2014, 68, 139–149. [Google Scholar]

- Li, C.; Li, D.; Jiang, Y.; Zhang, L.; Huang, Y.; Li, B.; Wang, S.; Hu, X. Biomass-derived volatiles for activation of the biochar of same origin. Fuel 2023, 332, 126034. [Google Scholar] [CrossRef]

- Li, C.; Sun, Y.; Dong, D.; Gao, G.; Zhang, S.; Wang, Y.; Xiang, J.; Hu, S.; Mortaza, G.; Hu, X. Co-pyrolysis of cellulose/lignin and sawdust: Influence of secondary condensation of the volatiles on characteristics of biochar. Energy 2021, 226, 120442. [Google Scholar] [CrossRef]

- Mohanty, S.K.; Cantrell, K.B.; Nelson, K.L.; Boehm, A.B. Efficacy of biochar to remove Escherichia coli from stormwater under steady and intermittent flow. Water Res. 2014, 61, 288–296. [Google Scholar] [CrossRef] [PubMed]

- Spokas, K.A.; Novak, J.M.; Venterea, R.T. Biochar’s role as an alternative N-fertilizer: Ammonia capture. Plant Soil 2012, 350, 35–42. [Google Scholar] [CrossRef]

- Sun, K.; Guo, T.; Li, Y.; Li, Y.J.; Wang, W.; Wang, H.; Li, Z.; Geng, P.; Fu, P. Rapid pyrolysis of cellulose: Revealing the role of volatile matter and char structure evolution. J. Anal. Appl. Pyrolysis 2024, 182, 106704. [Google Scholar] [CrossRef]

- Adeniyi, A.G.; Iwuozor, K.O.; Emenike, E.C.; Ajala, O.J.; Ogunniyi, S.; Muritala, K.B. Thermochemical Co-Conversion of Biomass-Plastic Waste to Biochar: A Review. Green Chem. Eng. 2024, 5, 31–49. [Google Scholar] [CrossRef]

- Hongthong, S.; Sangsida, W.; Wongcharee, S.; Chanthakhot, A.; Aungthitipan, P.; Suwannahong, K.; Kreetachat, T.; Rioyo, J. Enhanced Biochar Production via Co-Pyrolysis of Biomass Residual with Plastic Waste after Recycling Process. Int. J. Chem. Eng. 2024, 2024, 1176275. [Google Scholar] [CrossRef]

- Hilber, I.; Agostini, F.; Bachmann, H.; Brändli, R.C.; Cayuela, M.L.; Chang, S.X.; Domene, X.; Hagemann, N.; Hale, S.E.; Hayeck, N.; et al. Biochar Production from Plastic-Contaminated Biomass: Bridging the Knowledge Gap on Co-Pyrolysis Processes for a Circular Bioeconomy. GCB Bioenergy 2024, 16, 3–23. [Google Scholar] [CrossRef]

- López-Acosta, N.P.; Mendoza, J.A. Flujo de Agua en Suelos Parcialmente Saturados y su Aplicación a la Ingeniería Geotécnica; Instituto de Ingeniería, UNAM: Mexico City, Mexico, 2016; ISBN 978-607-02-7753-5. [Google Scholar]

- Abel, S.; Peters, A.; Trinks, S.; Schonsky, H.; Facklam, M.; Wessolek, G. Impact of biochar and hydrochar addition on water retention and water repellency of sandy soil. Geoderma 2013, 202–203, 183–191. [Google Scholar] [CrossRef]

- Mukherjee, A.; Lal, R. Biochar impacts on soil physical properties and greenhouse gas emissions. Agronomy 2013, 3, 313–339. [Google Scholar] [CrossRef]

- Acharya, B.S.; Dodla, S.; Wang, J.J.; Pavuluri, K.; Darapuneni, M.; Dattamudi, S.; Maharjan, B.; Kharel, G. Biochar impacts on soil water dynamics: Knowns, unknowns, and research directions. Biochar 2024, 6, 34. [Google Scholar] [CrossRef]

- Kukowska, S.; Szewczuk-Karpisz, K. Management of the soil environment using biochar and zeolite in various combinations: Impact on soil condition and economical aspects. J. Soils Sediments 2025, 25, 77–102. [Google Scholar] [CrossRef]

- Sohi, S.P.; Krull, E.; Lopez-Capel, E.; Bol, R. A review of biochar and its use and function in soil. Adv. Agron. 2010, 105, 47–82. [Google Scholar]

- Liu, Z.; Dugan, B.; Masiello, C.A.; Barnes, R.T.; Gallagher, M.E.; Gonnermann, H. Impacts of biochar concentration and particle size on hydraulic conductivity and DOC leaching of biochar–sand mixtures. J. Hydrol. 2016, 533, 461–472. [Google Scholar] [CrossRef]

- Lehmann, J.; Rillig, M.C.; Thies, J.; Masiello, C.A.; Hockaday, W.C.; Crowley, D. Biochar effects on soil biota: A review. Soil Biol. Biochem. 2011, 43, 1812–1836. [Google Scholar] [CrossRef]

- Toková, L.; Igaz, D.; Horák, J.; Aydın, E. Can application of biochar improve the soil water characteristics of silty loam soil? J. Soils Sediments 2023, 23, 2832–2847. [Google Scholar] [CrossRef]

- Daraei, E.; Bayat, H.; Gregory, A.S. Impact of natural biochar on soil water retention capacity and quinoa plant growth in different soil textures. Soil Tillage Res. 2024, 244, 106281. [Google Scholar] [CrossRef]

- Kim, D.; Han, M.; Kim, N.; Kim, J.; Jung, S.P. Waste Plastic Pyrolysis Industry: Current Status and Prospects. J. Korean Soc. Environ. Eng. 2024, 46, 395–407. [Google Scholar] [CrossRef]

- Sembiring, F.; Purnomo, C.W.; Purwono, S. Catalytic Pyrolysis of Waste Plastic Mixture. IOP Conf. Ser. Mater. Sci. Eng. 2018, 316, 012020. [Google Scholar] [CrossRef]

- Kartika, A.A.; Chun, L.S.; Ismail, S. Life Cycle Assessment (LCA) and Environmental Impacts Towards Plastic Waste by Using Pyrolysis. Int. J. Appl. Nanotechnol. Sci. Eng. Res. 2024, 3, 1175. [Google Scholar] [CrossRef]

| Acronym | Description | Doses (% p/p) | Size Particle (µm) |

|---|---|---|---|

| Control | Alfisol | 100 | - |

| B-1%-small | 100% hazel biomass | 1 | <25 |

| B-1%-large | 100% hazel biomass | 1 | 25–2000 |

| B-5%-small | 100% hazel biomass | 5 | <25 |

| B-5%-large | 100% hazel biomass | 5 | 25–2000 |

| P-1%-small | 90% biomass + 10% polyethylene | 1 | <25 |

| P-1%-large | 90% biomass + 10% polyethylene | 1 | 25–2000 |

| P-5%-small | 90% biomass + 10% polyethylene | 5 | <25 |

| P-5%-large | 90% biomass + 10% polyethylene | 5 | 25–2000 |

| Parameter | Unit | 1 B | 1 P |

|---|---|---|---|

| Ashes | % | 5.28 | 6.52 |

| pH | - | 9.86 | 9.8 |

| EC | dS m−1 | 0.98 | 0.88 |

| 2 VM | % | 12.8 | 13.1 |

| N | % | <2 | <2 |

| C | % | 78.19 | 61.08 |

| H | % | 2.64 | 2.49 |

| S | % | <2 | <2 |

| O | % | 12.62 | 31.13 |

| Treatments | 1/10 Atm | 1/3 Atm | 3 Atm | 5 Atm | 15 Atm | WA 1 |

|---|---|---|---|---|---|---|

| Control | 21.49 ± 0.52 e | 18.43 ± 0.83 d | 14.14 ± 0.39 e | 12.03 ± 0.31 d | 10.35 ± 0.42 e | 8.08 ± 0.58 b |

| B-1%-large | 25.03 ± 0.82 cd | 21.87 ± 0.27 bc | 16.88 ± 0.43 d | 15.00 ± 0.11 c | 13.37 ± 0.61 c | 8.50 ± 0.40 ab |

| B-1%-small | 26.23 ± 0.54 b | 22.51 ± 0.29 b | 16.57 ± 0.44 d | 15.00 ± 0.29 c | 13.88 ± 0.29 c | 8.63 ± 0.38 ab |

| B-5%-large | 26.37 ± 0.6 b | 22.72 ± 0.36 b | 18.00 ± 0.3 c | 15.15 ± 0.26 c | 13.89 ± 0.44 c | 8.83 ± 0.59 ab |

| B-5%-small | 27.77 ± 0.26 a | 24.56 ± 0.41 a | 18.98 ± 0.81 b | 16.00 ± 0.36 b | 14.89 ± 0.13 b | 9.66 ± 0.44 a |

| P-1%-large | 25.62 ± 0.55 bc | 21.97 ± 0.72 b | 17.00 ± 0.77 d | 15.00 ± 0.73 c | 13.36 ± 0.36 c | 8.61 ± 1.02 ab |

| P-1%-small | 24.24 ± 0.57 d | 21.01 ± 0.53 c | 17.37 ± 0.32 cd | 15.01 ± 0.12 c | 12.12 ± 0.49 d | 8.89 ± 0.96 ab |

| P-5%-large | 28.56 ± 0.65 a | 25.14 ± 0.27 a | 20.12 ± 0.79 a | 17.55 ± 0.68 a | 15.33 ± 1.09 ab | 9.80 ± 1.13 a |

| P-5%-small | 28.39 ± 0.82 a | 25.25 ± 0.79 a | 20.00 ± 0.52 a | 18.00 ± 0.63 a | 15.64 ± 0.8 a | 9.61 ± 1.29 a |

| CV (%) | 2.37 | 2.39 | 3.19 | 2.9 | 4.24 | 9.23 |

| p value | <0.05 | <0.05 | <0.05 | <0.05 | <0.05 | <0.05 |

| RETC Calculated | Θr (cm3 cm−3) | θs (cm3 cm−3) | α (cm−1) | N | Ks (cm d−1) |

|---|---|---|---|---|---|

| Predicted Alfisol | 0.0483 | 0.457 | 0.0336 | 4.85 | 65.5 |

| Treatments | PT | AC | PFD | PAW |

|---|---|---|---|---|

| % by volume ± SD | ||||

| Control | 41.55 | 16.47 ± 1.20 | 3.91 ± 1.24 | 10.85 ± 1.39 |

| B-1%-large | 41.55 | 11.89 ± 0.39 ** | 4.06 ± 0.81 | 11.68 ± 0.55 |

| B-1%-small | 41.55 | 11.42 ± 0.46 ** | 5.35 ± 0.29 | 11.83 ± 0.43 |

| B-5%-large | 41.55 | 10.58 ± 0.29 ** | 4.52 ± 1.04 | 12.31 ± 0.78 |

| B-5%-small | 41.55 | 8.40 ± 0.69 ** | 4.47 ± 1.15 | 13.48 ± 0.67 * |

| P-1%-large | 41.55 | 11.63 ± 1.11 ** | 4.55 ± 1.14 | 11.90 ± 1.40 |

| P-1%-small | 41.55 | 12.09 ± 0.55 ** | 2.68 ± 1.03 * | 12.61 ± 1.34 |

| P-5%-large | 41.55 | 7.10 ± 0.63 ** | 3.83 ± 1.53 | 13.73 ± 1.96 * |

| P-5%-small | 41.55 | 7.34 ± 0.87 ** | 4.08 ± 1.83 | 13.12 ± 1.82 * |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Henríquez-Arevalo, J.; Muñoz, C.; Sandoval, M.; Espejo, W. Evaluation of Plant-Available Water in Degraded Alfisol Using Biomass Copyrolyzed with Plastic. Agronomy 2025, 15, 1985. https://doi.org/10.3390/agronomy15081985

Henríquez-Arevalo J, Muñoz C, Sandoval M, Espejo W. Evaluation of Plant-Available Water in Degraded Alfisol Using Biomass Copyrolyzed with Plastic. Agronomy. 2025; 15(8):1985. https://doi.org/10.3390/agronomy15081985

Chicago/Turabian StyleHenríquez-Arevalo, Jonathan, Cristina Muñoz, Marco Sandoval, and Winfred Espejo. 2025. "Evaluation of Plant-Available Water in Degraded Alfisol Using Biomass Copyrolyzed with Plastic" Agronomy 15, no. 8: 1985. https://doi.org/10.3390/agronomy15081985

APA StyleHenríquez-Arevalo, J., Muñoz, C., Sandoval, M., & Espejo, W. (2025). Evaluation of Plant-Available Water in Degraded Alfisol Using Biomass Copyrolyzed with Plastic. Agronomy, 15(8), 1985. https://doi.org/10.3390/agronomy15081985