Performance Analysis and Experimental Validation of Small-Radius Slope Steering for Mountainous Crawler Tractors

Abstract

1. Introduction

- Refines ground contact pressure models by incorporating slope-induced center-of-mass displacement effects across varying inclinations and operational scenarios;

- Formulates a small-radius steering dynamics model for deformable slopes based on enhanced pressure distributions;

- Validates the model through experimental trials conducted on the integrated “Soil-Machinery-Crop” test platform specifically designed for hilly terrain applications.

2. Materials and Methods

2.1. Kinematics Model for Small-Radius Slope Steering of MCTs

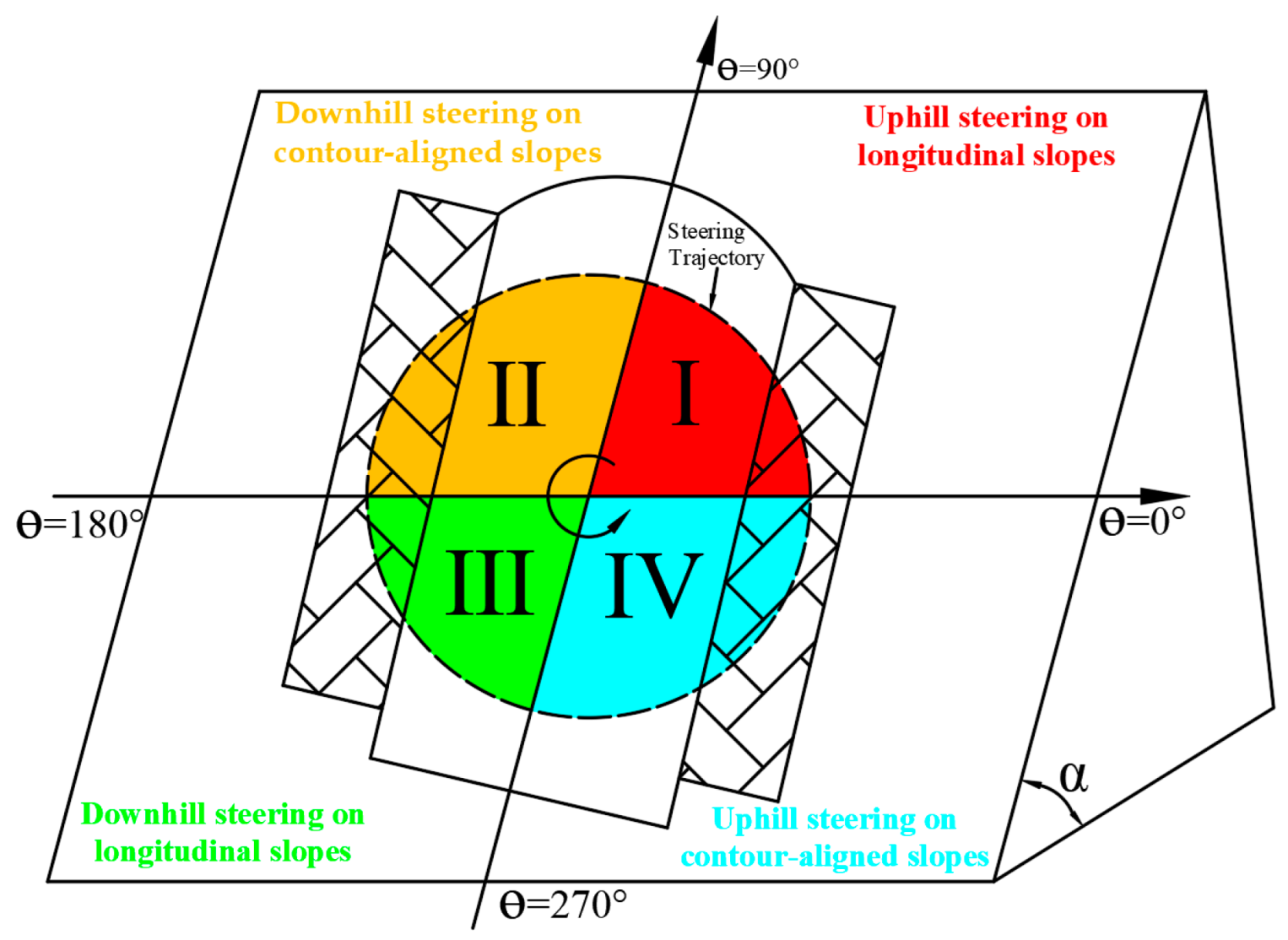

2.1.1. Definition and Classification of Typical Operational Scenarios for Small-Radius Steering

- Quadrant I (0° < θ ≤ 90°): Uphill steering on longitudinal slopes (red zone);

- Quadrant II (90° < θ ≤ 180°): Downhill steering on contour-aligned slopes (yellow zone);

- Quadrant III (180° < θ ≤ 270°): Downhill steering on longitudinal slopes (green zone);

- Quadrant IV (270° < θ ≤ 360°): Uphill steering on contour-aligned slopes (cyan zone).

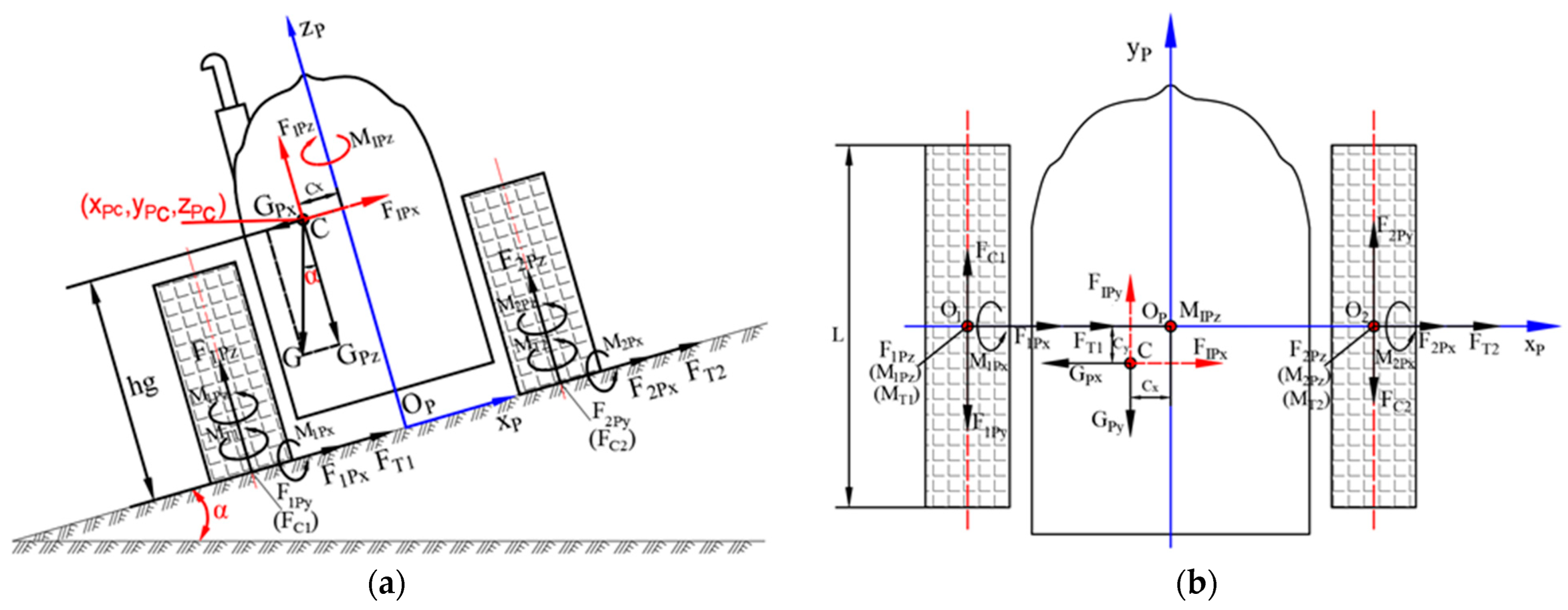

2.1.2. Fundamental Assumptions and Coordinate System Establishment

- Based on China’s Third National Land Survey, steep slopes > 25° constitute 4.2252 million hectares (63.3783 million mu), representing merely 3.31% of total cultivated area [25]. Such gradients are unsuitable for agricultural operations and continue to diminish annually. Therefore, operational slope angles are constrained to 0~25°.

- Slopes are idealized as planar surfaces with tractors performing steady-state steering.

- Variations in track tension due to grounding segment deformation are neglected.

- Pitching and rolling motions affecting steering dynamics are disregarded—vehicles rotate solely about the normal axis perpendicular to the slope surface.

- Shearing internal resistance is omitted given minimal shear displacement variations within track–soil contact regions during steering.

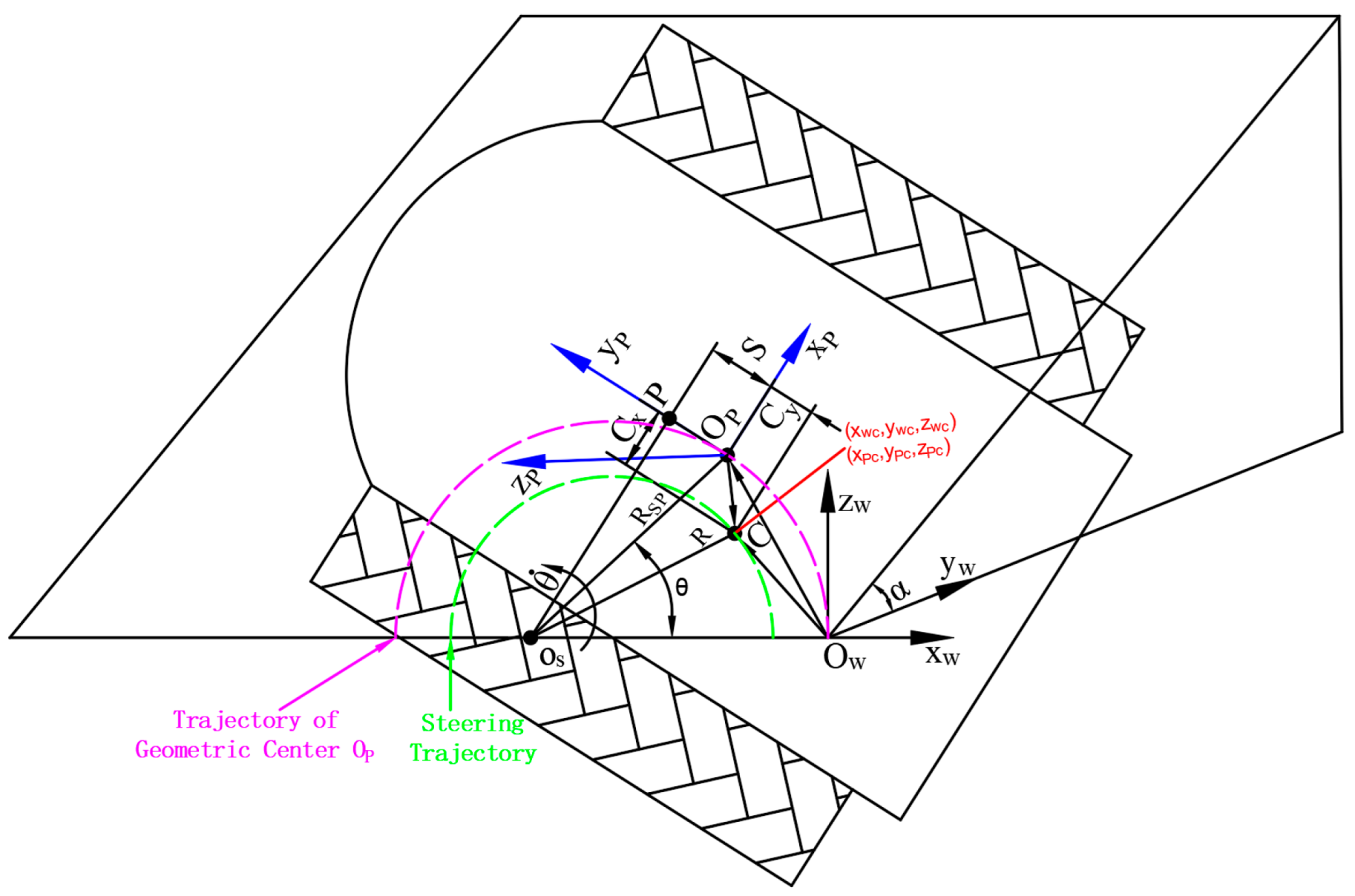

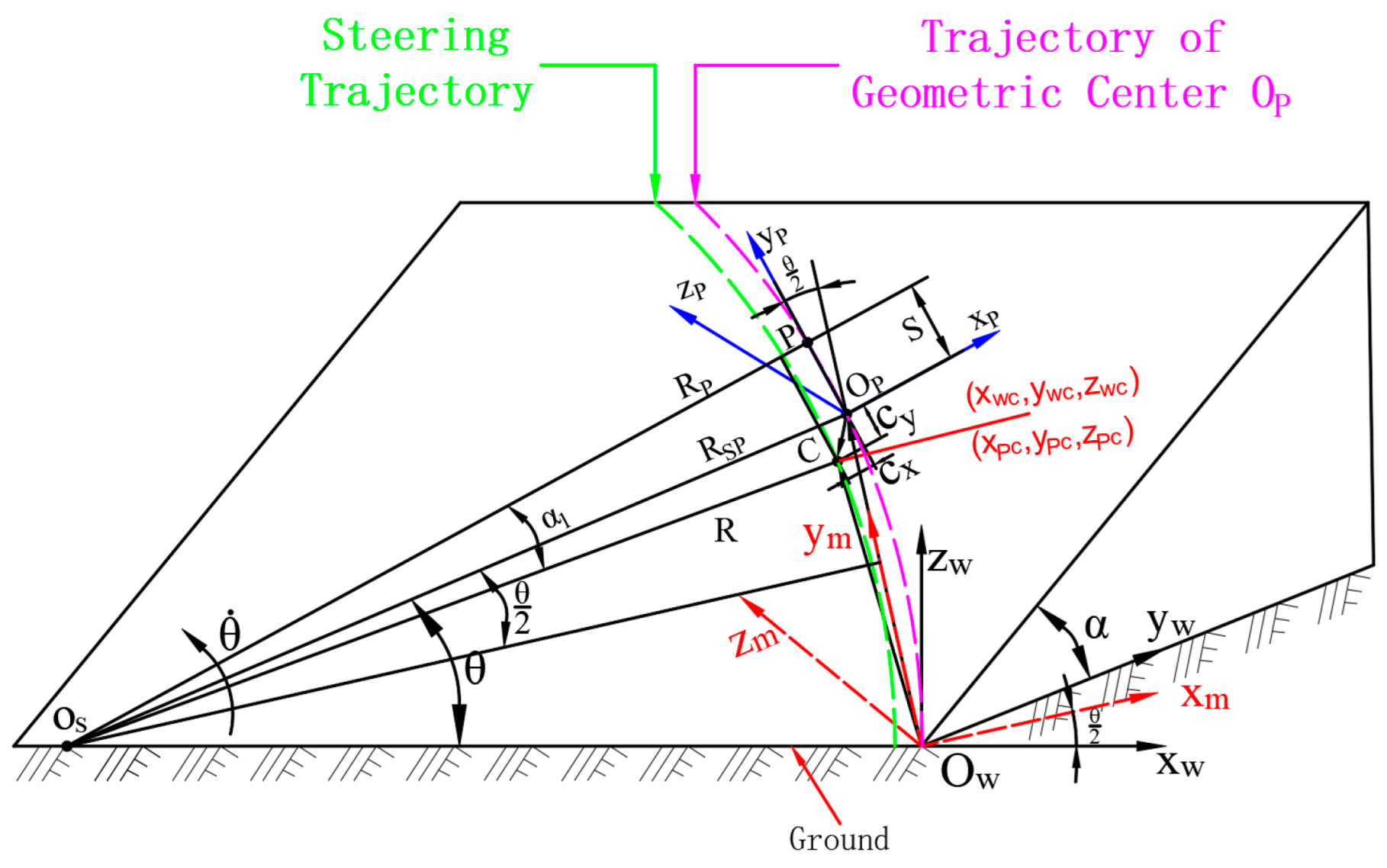

- α: Slope inclination angle;

- θ: Vehicle steering angle;

- OS: Steering center;

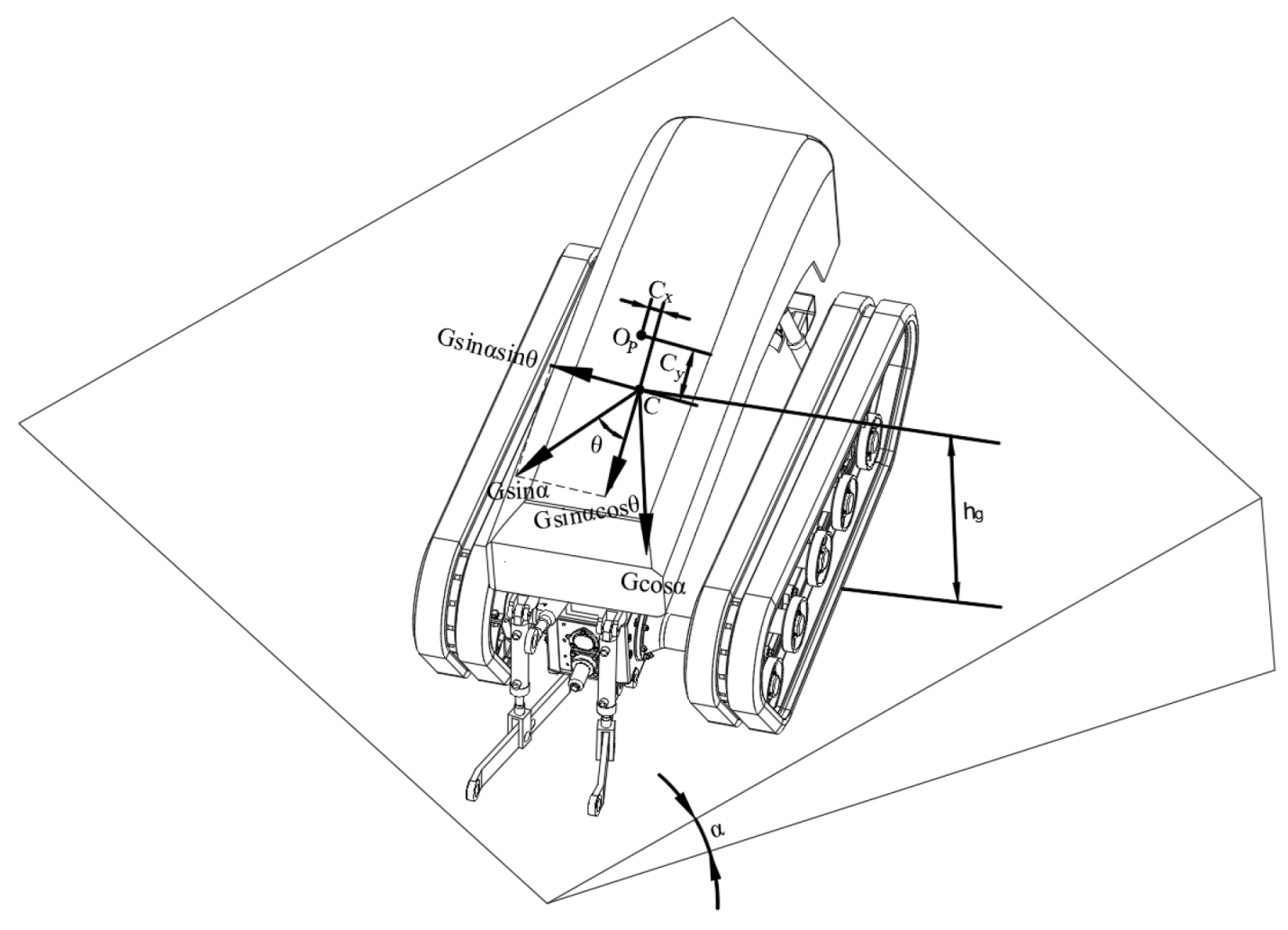

- C: Pressure center (projection of center of mass onto slope surface);

- R: Actual turning radius;

- RSP: Distance from OS to OP;

- RP: Projection of pressure center C onto OSP axis;

- : Steering angular velocity;

- Cx: Lateral deviations of pressure center relative to geometric center;

- World coordinate system Ow-xwywzw fixed to ground.

- Local coordinate system Op-xpypzp rigidly attached to the tractor, where Op denotes the geometric center of the tractor’s projection on the slope surface.

- Transition from level ground to slope: Coordinates rotate α° about the xP -axis (yP and zP axes transformation);

- Slope steering about OS: Coordinates rotate θ° about the zP -axis (xP and yP axes transformation).

2.1.3. Solving for Vehicle Steering Motion Parameters

- Variations in vehicle motion parameters (e.g., turning radius, azimuth angle, angular velocity, angular acceleration) alter the magnitude and direction of terrain reaction forces on tracks;

- Shifts in the pressure center redistribute normal loads over the track-ground contact segment, consequently modifying the distribution of steering resistance.

2.2. Dynamics Model for Small-Radius Slope Steering of MCTs

2.2.1. Formulation of Dynamics Equations

- Gravity G;

- Inertial force FC;

- Sinkage resistance FC1, FC2 at track-terrain contact segments;

- Tractive effort F1Py and F2Py at track-terrain contact segments (acting in opposite directions during small-radius steering);

- Lateral frictional resistance F1Px, F2Px on soft terrain;

- Bulldozing resistance FT1, FT2 along track sides;

- Equivalent normal loads F1Pz, F2Pz from terrain;

- Resistance moments M1Px, M2Px in the xP- direction;

- Frictional resistance moments M1Pz, M2Pz and bulldozing resistance moments MT1, MT2 in the zP- direction.

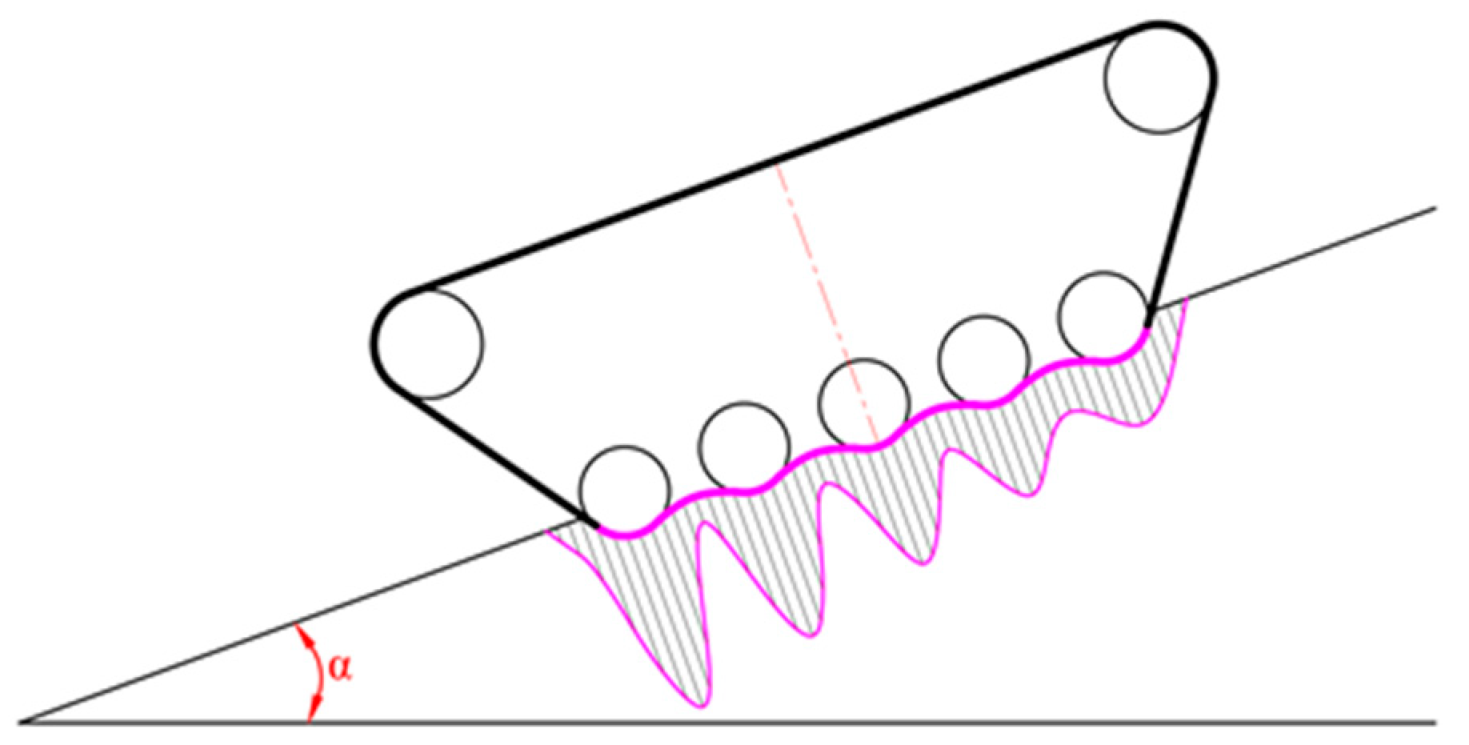

2.2.2. Track Contact Pressure Distribution

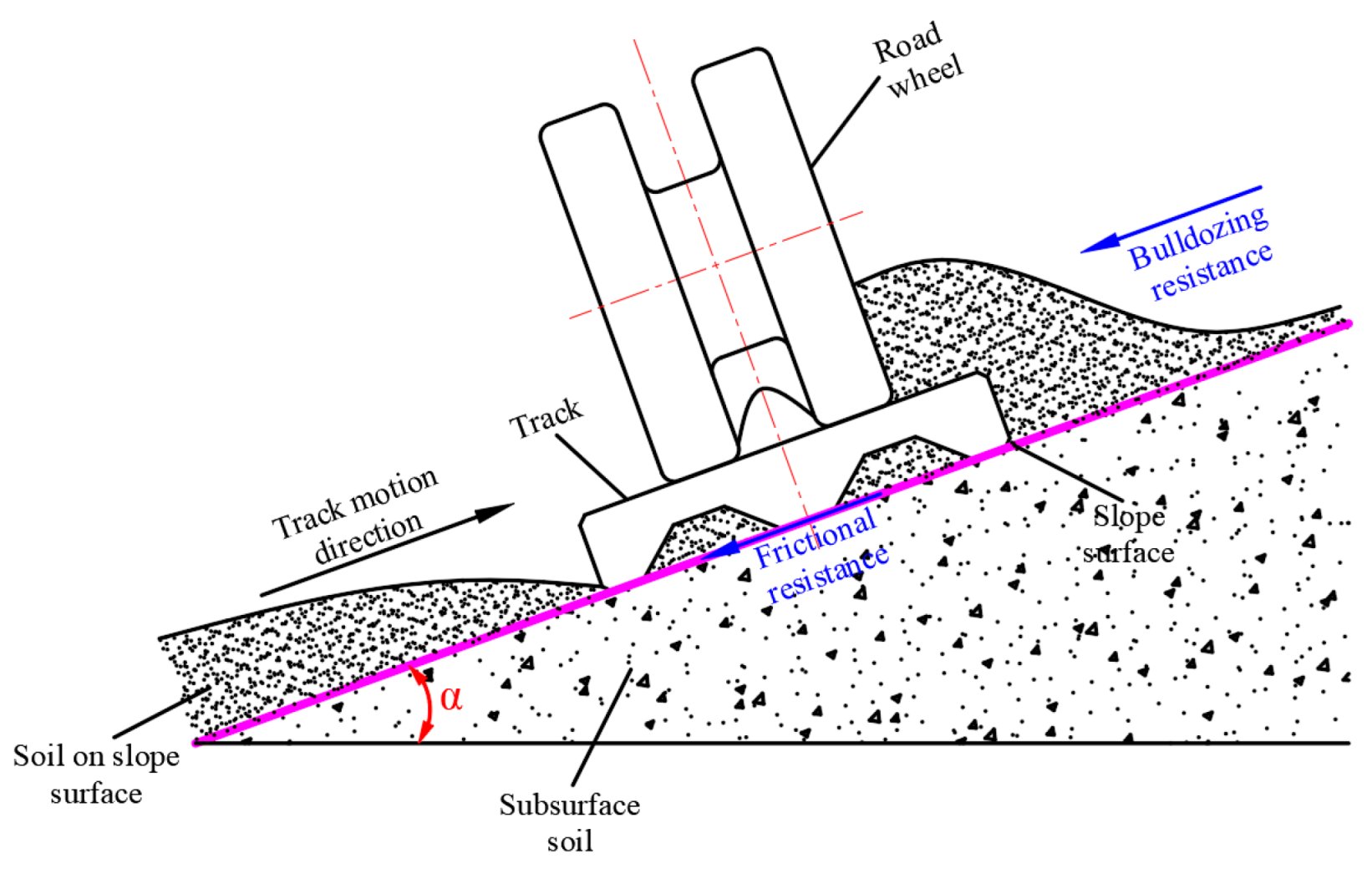

2.2.3. Lateral Resistance at the Track–Soil Interface

- (1)

- Frictional Resistance

- (2)

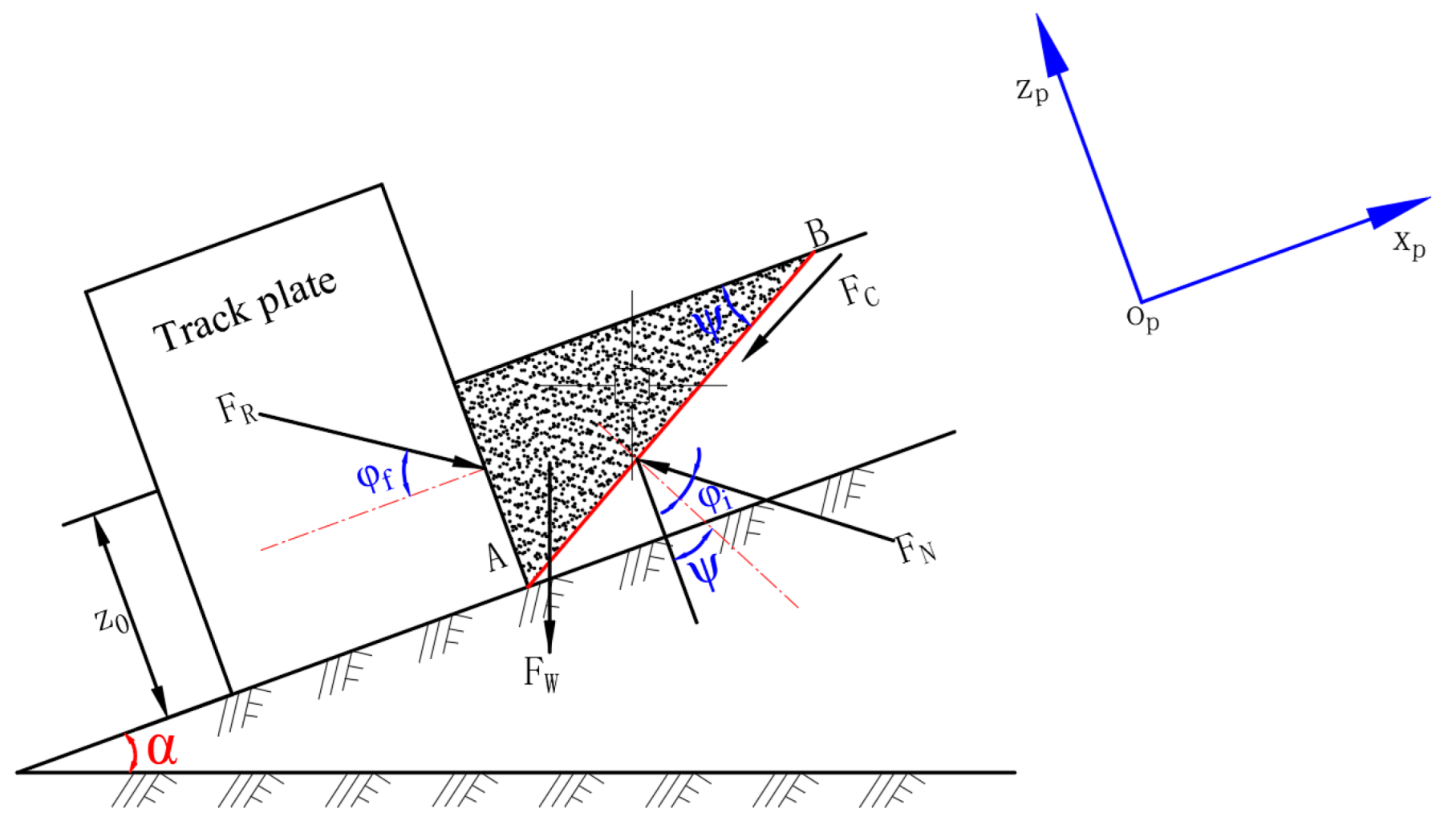

- Bulldozing Resistance

- Plane AB denotes the soil-track interaction surface;

- z represents soil sinkage perpendicular to the slope surface;

- FR is the bulldozing resistance per unit track length;

- FW denotes the gravity force of the soil wedge above plane AB per unit length;

- FN indicates the supporting force from soil beneath plane AB;

- FH signifies sliding resistance on plane AB;

- φf designates the track plate wall friction angle;

- φi represents the soil internal friction angle;

- ψ defines the inclination angle of the soil failure wedge.

- kk1 denotes the coefficient of the cot2ψ term in the numerator, expressed as

- kk2 denotes the coefficient of the cotψ term in the numerator, expressed as

- qq1 denotes the coefficient of the constant term in the numerator, expressed as

- kk4 denotes the coefficient of the cotψ term in the denominator, expressed as

- qq2 denotes the coefficient of the constant term in the denominator, expressed as

2.2.4. Sinkage Resistance of Soft Soils on Tracks

2.3. Numerical Solution and Result Analysis

3. Results

3.1. Effect of Longitudinal Offset of Instantaneous Steering Center on Steering Stability

- When S = 0, the vehicle’s instantaneous steering center coincides with the theoretical instantaneous steering center, representing an ideal steering condition;

- When S increases, the instantaneous steering center shifts toward the direction of vehicle motion;

- When S decreases, the instantaneous steering center shifts opposite to the direction of vehicle motion;

- The magnitude of S indicates the deviation from the ideal steering condition, where larger |S| signifies greater deviation;

- When −L/2 ≤ S ≤ L/2, the instantaneous steering center remains within the track contact segment, indicating stable slope steering;

- When S < −L/2 or S > L/2, the instantaneous steering center deviates beyond the track contact segment, resulting in unstable slope steering with risks of arbitrary sideslip phenomena.

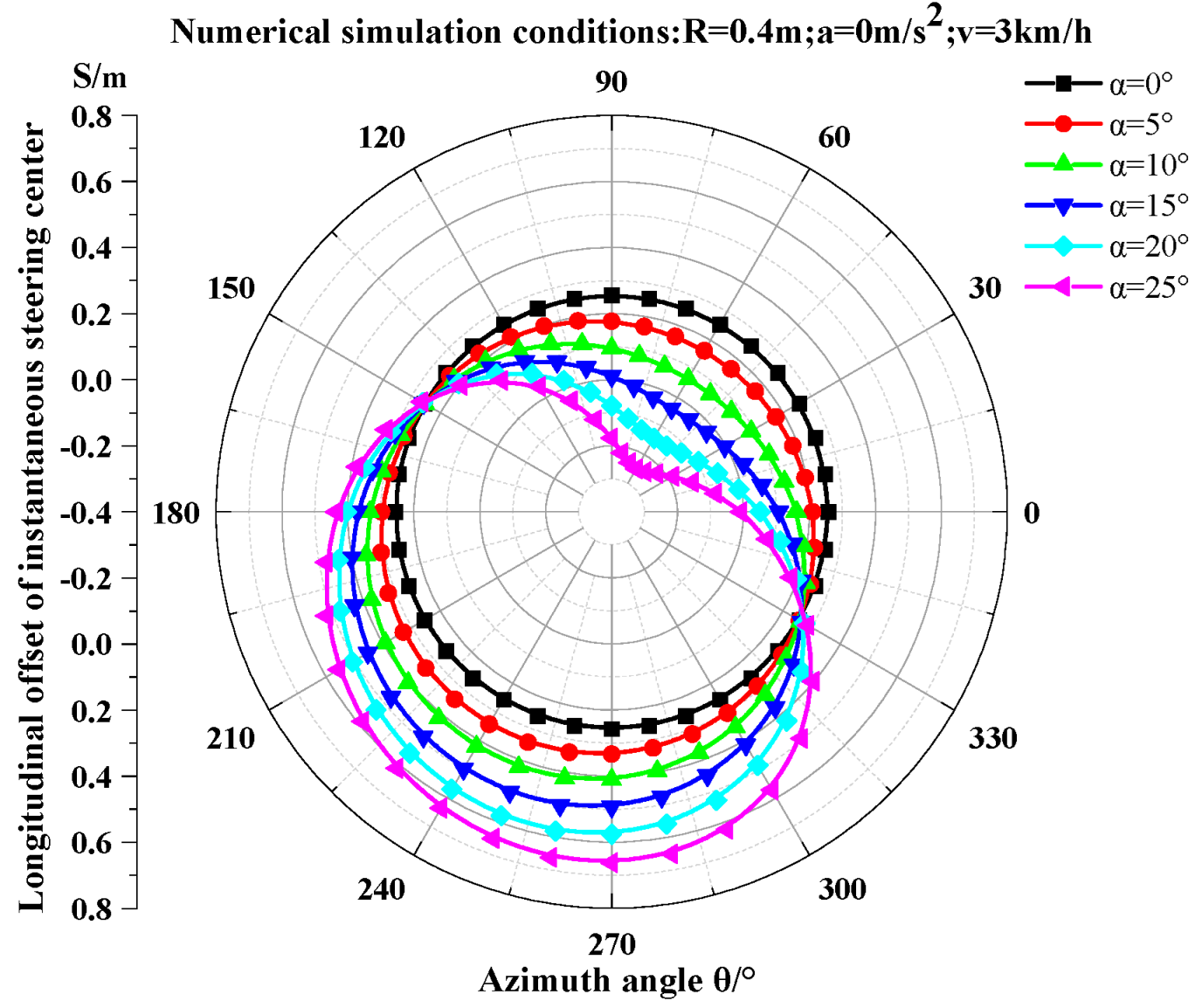

3.1.1. Offset Characteristics of Instantaneous Steering Center Under Varying Slope Angles

- 1.

- Uphill steering on longitudinal slopes (θ ∈ [0°,90°)):

- S initially decreases then increases;

- Steering center shifts backward from initial position;

- Maximum backward displacement (S ≈ −0.25 m) at θ ≈ 60°;

- Subsequently shifts forward.

- 2.

- Downhill steering on contour-aligned slopes and Downhill steering on longitudinal slopes (θ ∈ [90°,270°)):

- S monotonically increases;

- Steering center shifts continuously forward;

- Coincides with level-steering center at θ ≈ 150° and 330°;

- Maximum forward displacement (S ≈ 0.67 m) at θ ≈ 270°.

- 3.

- Uphill steering on contour-aligned slopes (θ ∈ [270°,360°)):

- S monotonically decreases;

- Steering center shifts continuously backward toward initial position.

- During uphill steering on longitudinal slopes at slope angles α > 15°, the instantaneous steering center progressively shifts toward the rear of the track contact segment as α increases. Near the azimuth angle θ ≈ 90°, this leads to oversteering conditions characterized by reduced steering radius, analogous to the “nose-in behavior” observed in understeering rear-drive passenger vehicles.

- During downhill steering on contour-aligned slopes and longitudinal slopes, the instantaneous steering center progressively shifts toward the front of the track contact segment as the slope angle increases. Near the initial position of longitudinal uphill steering (θ ≈ 270°), this leads to understeering conditions characterized by an enlarged steering radius.

- During uphill steering on contour-aligned slopes, the instantaneous steering center migrates from the front of the track contact segment toward its center as the slope angle increases, while oversteering persistently manifests.

- Under both downhill steering scenarios, understeering conditions emerge. Influenced by the gravitational component parallel to the slope and the forward-shifted instantaneous steering center, significant lateral sliding occurs at the rear of the track contact segment. This manifests as “tail-swing behavior” analogous to oversteering in rear-wheel-drive vehicles. Slope gradients amplify this phenomenon—greater slope angles intensify tail-swing severity. When lateral forces exceed the crawler tractor’s lateral adhesion capacity, the steering center exits the track contact segment, triggering whole-vehicle sideslip with rearward pendulum motion. In extreme cases, the outer track loses ground contact, precipitating rollover.

- 1.

- For α ≤ 15°:

- Rearward-to-forward shift reversal occurs at θ ≤ 60°;

- Forward-to-rearward shift reversal occurs at θ ≤ 250°.

- 2.

- For α > 15°:

- Rearward-to-forward reversal initiates at θ > 60°;

- Forward-to-rearward reversal initiates at θ > 250°.

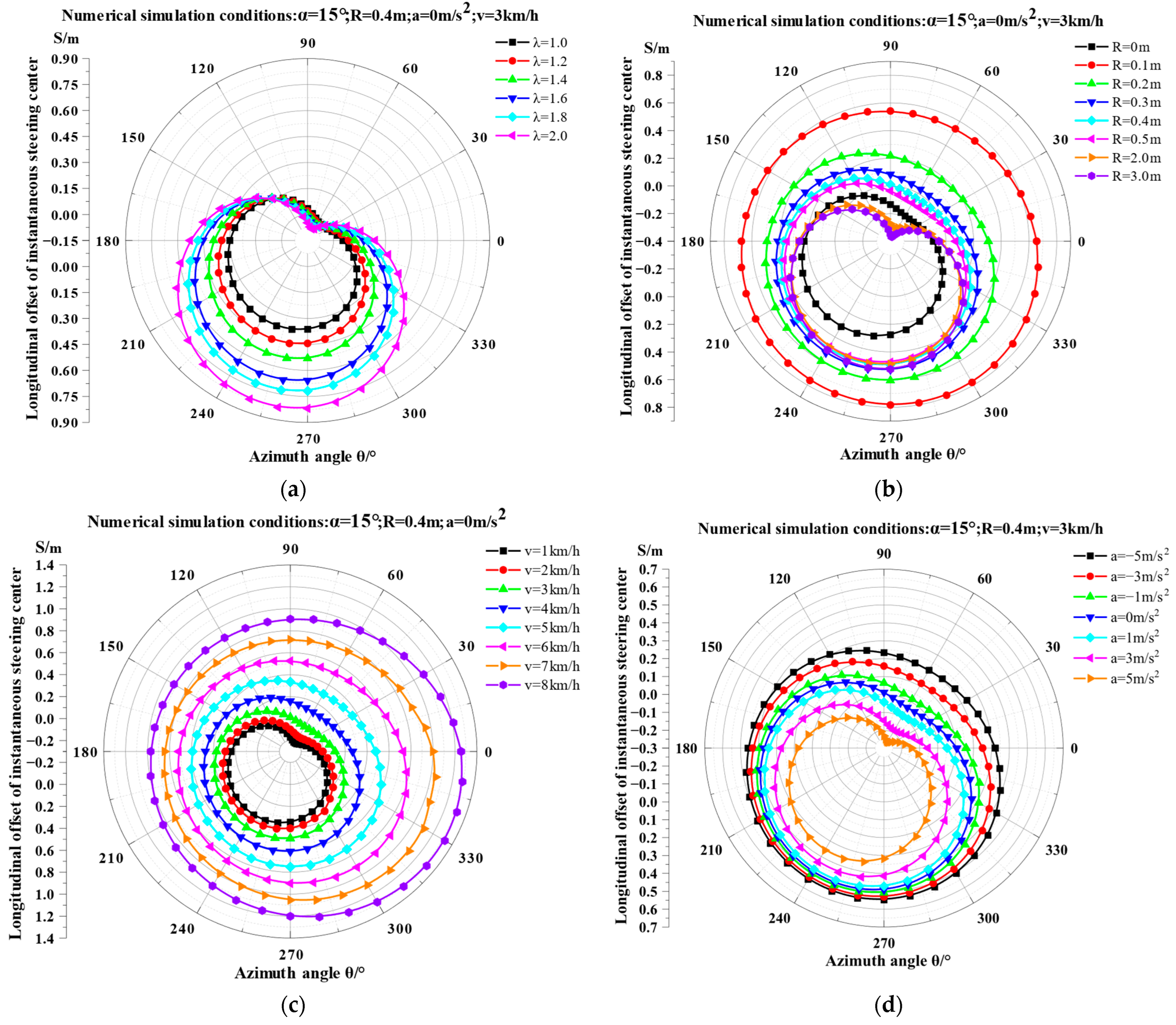

3.1.2. Analysis of Factors Influencing Instantaneous Steering Center Offset

- Reducing L diminishes steering center offset, enhancing stability during small-radius slope steering. However, this concurrently elevates ground contact pressure, intensifying soil compaction risks in agricultural fields.

- Increasing B reduces offset magnitude and augments steering torque capacity, but expands the vehicle footprint, impeding operation in confined hilly terrain.

- 1.

- Radius-dependent fluctuation:

- Excluding zero-radius steering, larger steering radii increase the range of S (i.e., amplified steering center fluctuation).

- 2.

- Small-radius zone (R < 0.525 m):

- Decreasing R (excluding R = 0) elevates the average deviation from the ideal steering center.

- 3.

- Critical thresholds:

- R ≤ 0.3 m: Steering center remains in the front section of the track contact segment, inducing persistent understeering.

- R = 0.1 m: Steering center approaches or exceeds the front edge of the contact segment, causing severe instability with significant safety hazards.

- 1.

- Speed–impact relationship:

- Rising speeds amplify forward steering center displacement.

- This suppresses “nose-in” behavior while intensifying “tail-swing” phenomena, particularly near the initial contour-uphill steering position (azimuth angle ≈ 270°).

- 2.

- Critical speed thresholds:

- Above 3 km/h near 90° azimuth:

- The steering center remains ahead of its ideal position, eliminating oversteering and inducing exclusive understeering (“tail-swing”).

- Above 6 km/h:

- 1.

- Acceleration-dependent dynamics:

- Transitioning from negative to positive acceleration amplifies fluctuations in steering center offset.

- Variation patterns remain essentially identical across acceleration levels.

- 2.

- Negative acceleration (a < 0):

- Steering center oscillates exclusively within the front section of the track contact segment.

- Oversteering is fully suppressed during all steering phases.

- 3.

- Non-negative acceleration (a ≥ 0):

- The instantaneous steering center progressively shifts from the rear portion of the track contact segment to the front portion and subsequently moves toward the geometric center of the track system.

- Severe tail-swing behavior emerges near the downhill endpoint (θ ≈ 270°), demanding critical steering state monitoring.

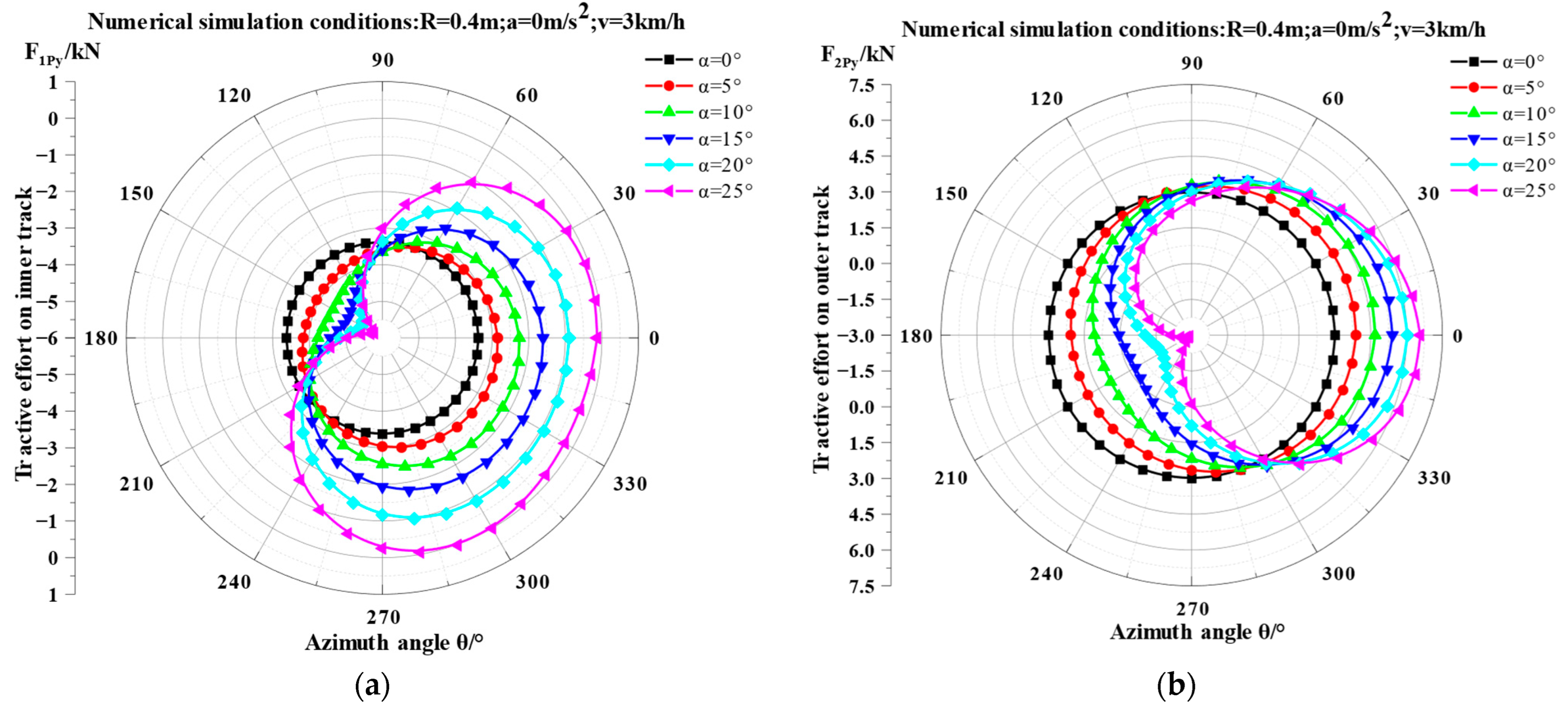

3.2. Variation Patterns of Tractive Efforts on Dual Tracks

- Uphill steering phases (θ ∈ [0°,90°] ∪ [300°,360°)):

- Required tractive effort increases with slope angle.

- Downhill-dominated range (θ ∈ [0°,300°]):

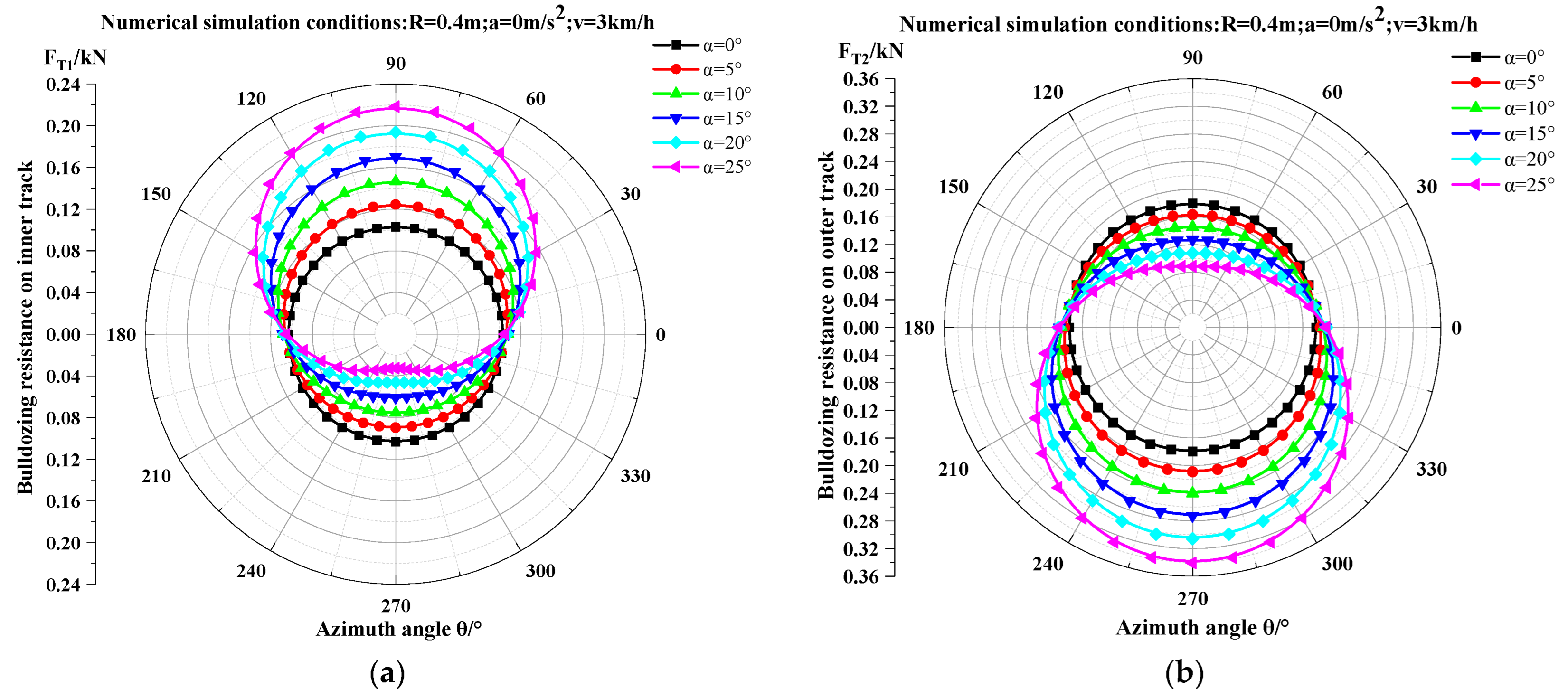

3.3. Variation Patterns of Bulldozing Resistance on Dual Tracks

- 1.

- Phase 1: Uphill steering on longitudinal slopes (0° ≤ θ < 90°)

- Inner track resistance increases with rising azimuth angle, reaching its peak at 90°.

- Outer track resistance decreases with rising azimuth angle, hitting its lowest point at 90°.

- 2.

- Phase 2: Downhill Steering (90° ≤ θ < 270°)

- Combines contour-aligned and longitudinal downhill steering.

- Inner track resistance continuously declines, bottoming out at 270°.

- Outer track resistance rises progressively, peaking at 270°.

- 3.

- Phase 3: Uphill steering on contour-aligned slopes (270° ≤ θ < 360°)

- Inner track resistance increases as the azimuth angle advances.

- Outer track resistance decreases as the azimuth angle advances.

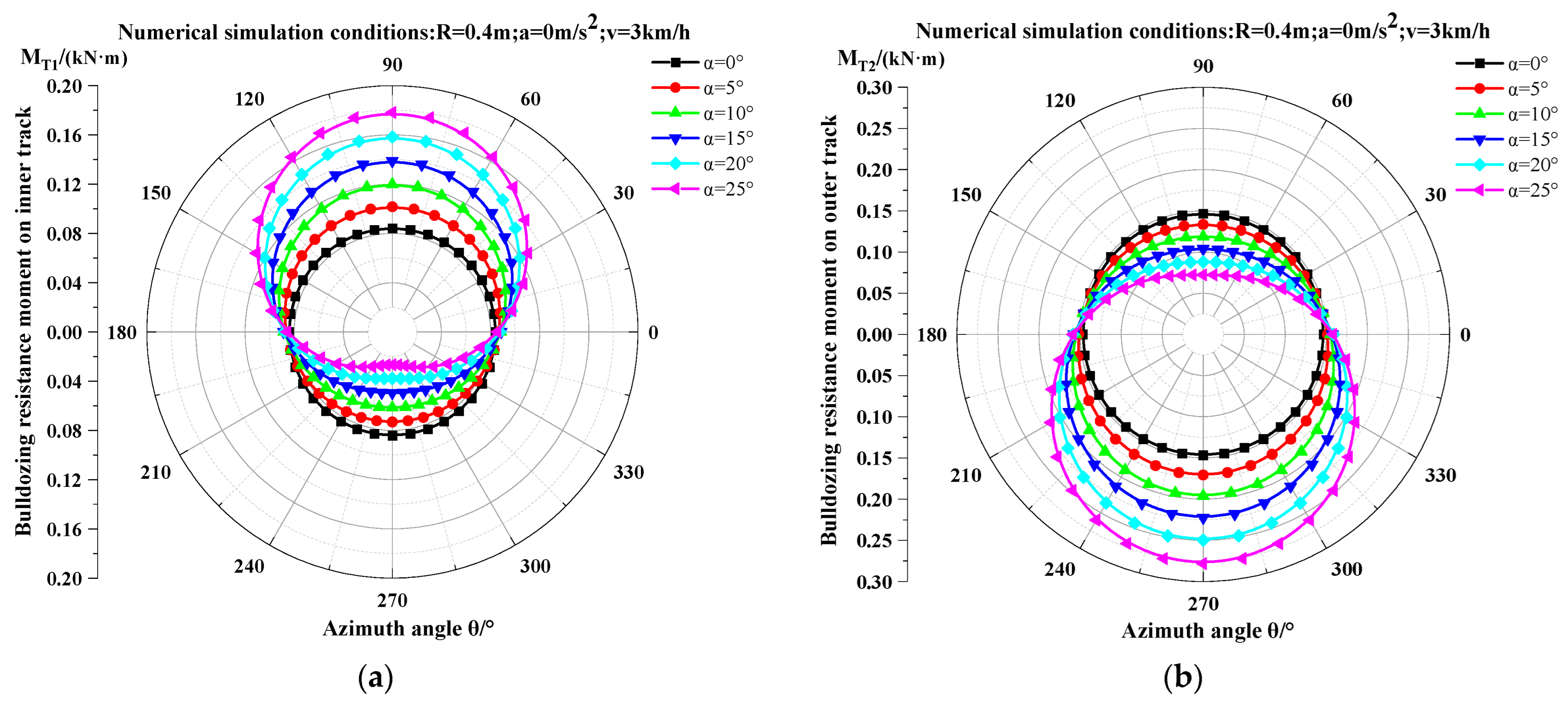

3.4. Variation in Steering Bulldozing Resistance Moments of Dual Tracks

- 1.

- Uphill steering on longitudinal slopes (0° ≤ θ < 90°)

- Inner track moment MT1 increases with θ;

- Outer track moment MT2 decreases with θ.

- 2.

- Downhill Steering (90° ≤ θ < 270°)

- Inner track moment MT1 decreases with θ;

- Outer track moment MT2 increases with θ.

- 3.

- Uphill steering on contour-aligned slopes (270° ≤ θ < 360°)

- Inner track moment MT1 increases with θ;

- Outer track moment MT2 decreases with θ.

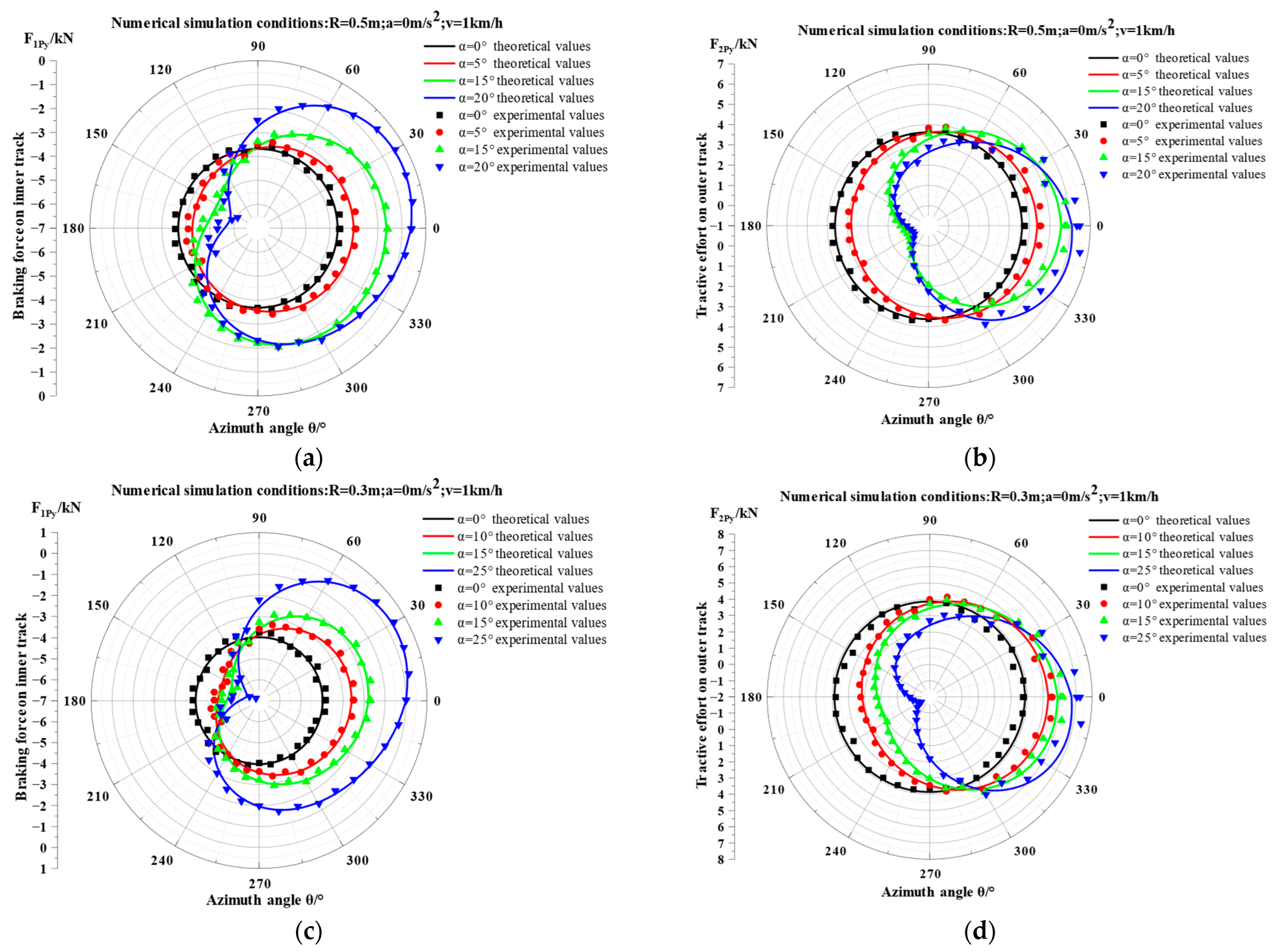

3.5. Experimental Validation and Analysis

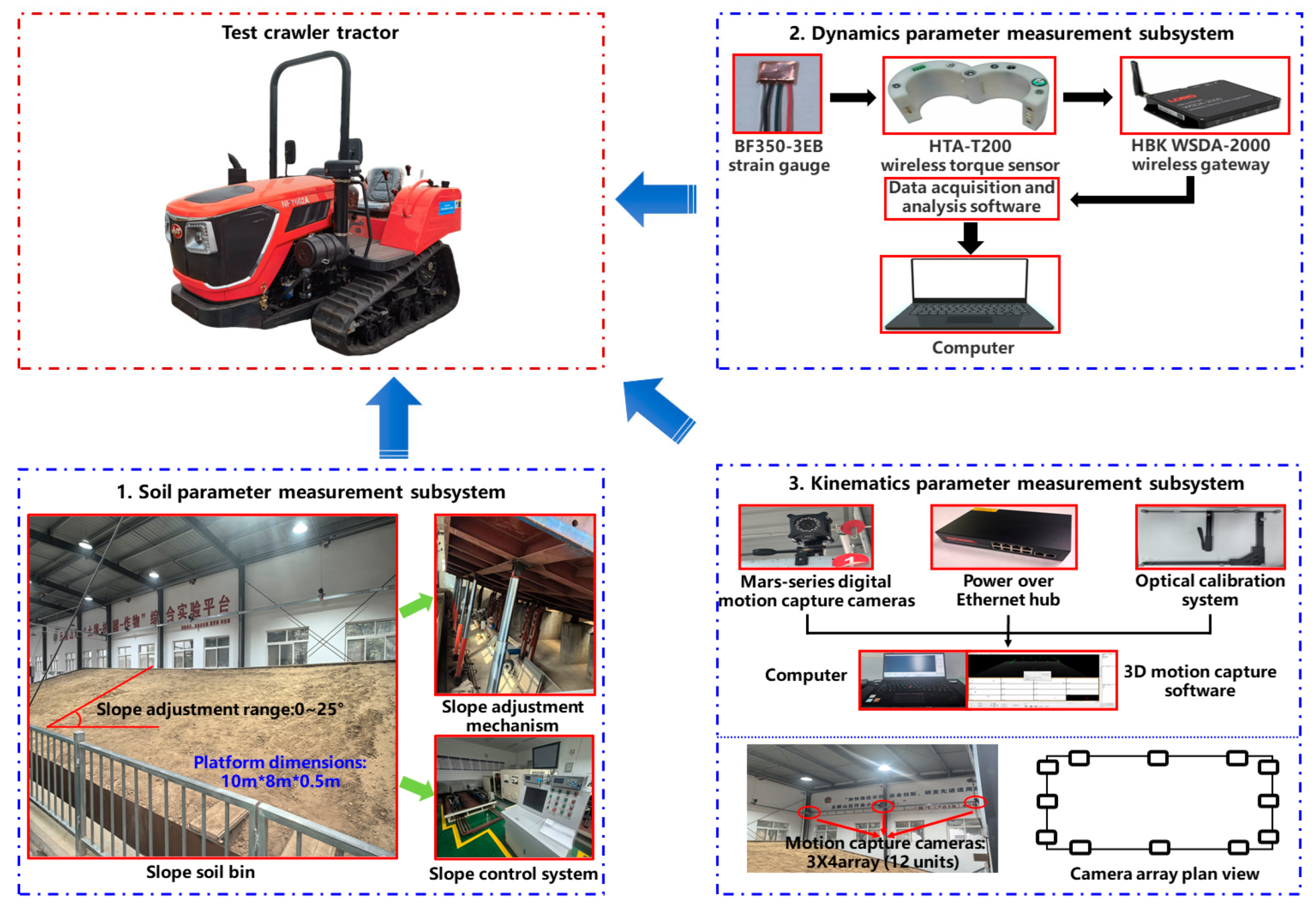

- The soil parameter measurement subsystem comprises the comprehensive experimental platform, primarily designed for real-time slope angle measurement.

- The dynamics parameter measurement subsystem utilizes HTA-200 wireless torque sensors installed on both transmission output half-shafts to indirectly measure the output torque of the drive wheels.

- The kinematics parameter measurement subsystem was constructed using the NOKOV optical 3D motion capture system from Beijing Measure Technology Co., Ltd. (Beijing, China). It primarily acquires the following parameters during vehicle steering maneuvers: three-dimensional coordinates, azimuth angle, steering trajectory, displacement, linear velocity, linear acceleration, angular velocity, and angular acceleration.

- Outer track tractive effort error: <9.5%;

- Inner track braking force error: <8.5%;

- Average tractive effort error (both tracks): <6.5%.

- Outer track tractive effort error: <11.5%;

- Inner track braking force error: <10.5%;

- Average tractive effort error (both tracks): <8%.

4. Discussion

- 1.

- Level-ground small-radius steering [32]:

- Control outer motor to output tractive effort;

- Control inner motor to deliver braking force.

- 2.

- Slope small-radius steering:

- Dynamically regulate motor torque on both sides based on real-time slope angle and azimuth;

- Critical intervention: During downhill operations on slopes exceeding 15°, the outer motor must apply braking torque to maintain vehicle stability during small-radius steering on steep gradients, thereby preventing severe sideslip or rollover.

- Control strategies should adjust inner/outer track torque distribution dynamically based on real-time slope angle and azimuth. Actively employ outer-track braking on steep slopes to improve steering stability.

- Strictly limit steering speed to mitigate rollover and tail-swing risks caused by increased centrifugal forces and rapid normal load transfer.

- Vehicle design should optimize the center-of-mass position [15] and track steering ratio (L/B) to enhance load distribution uniformity during slope steering, simultaneously reduce instantaneous steering center offset, and ensure accurate trajectory tracking.

- Idealized soil assumption—Actual soil properties are complex and variable, potentially compromising accuracy;

- Planar slope simplification—Real terrain exhibits undulations rather than idealized planes;

- Neglected tension effects—Track tension influence on driving torque was disregarded.

5. Conclusions

- Within azimuth angles θ ∈ [0°, 60°], the steering center shifts rearward, reaching its maximum rearward displacement (S = −0.25 m) near θ = 60°, which induces oversteering (“nose-in”).

- Within azimuth angles θ ∈ [60°, 270°), the steering center shifts forward, achieving its maximum forward displacement (S = 0.67 m) near θ = 270°, resulting in understeering (“tail-swing”).

- Within azimuth angles θ ∈ [270°, 360°), the steering center shifts rearward and moves toward the initial position.

- Increased steering ratio causes significant growth in steering center offset distance.

- Thus, during tractor design, rational selection of track contact length and track gauge is essential to ensure slope steering stability while meeting passability and ground contact pressure requirements.

- Smaller steering radii amplify fluctuations in steering center offset because reduced radii increase steering resistance coefficients, lateral resistance, and centrifugal forces.

- High-speed steering intensifies instability during small-radius slope maneuvers while elevating tail-swing and rollover risks. Consequently, travel speed must be appropriately reduced to enhance safety and stability.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

Appendix A.1

References

- Liu, Y. Conjecture on Agricultural Machinery in 2024 (VIII): Breakthrough in Mechanization for Hilly and Mountainous Areas [EB/OL]. 2024. Available online: http://www.amic.agri.cn/secondLevelPage/info/5/173379 (accessed on 14 February 2025).

- Sun, J.B.; Zeng, L.K.; Ying, J.; Sun, Q.; Zheng, H.; Sun, Q.; Meng, X.Z. Research Status and Prospects of Key Technologies for Agricultural Crawler Chassis. Trans. Chin. Soc. Agric. Mach. 2024, 55, 202–220. [Google Scholar] [CrossRef]

- Pan, G.T.; Yang, F.Z.; Sun, J.B.; Liu, Z.J. Analysis and Test of Obstacle Negotiation Performance of Small Hillside Crawler Tractor during Climbing Process. Trans. Chin. Soc. Agric. Mach. 2020, 51, 374–383. [Google Scholar] [CrossRef]

- Liu, Q. Research of Manoeuvrability Performance for Mountain Tracked Chassis on Slopes Under Non-linear Ground Pressure. Master’s Thesis, Northwest A&F Universitatis, Yangling, China, 2024. [Google Scholar] [CrossRef]

- Hu, J.B.; Li, X.Y.; Wei, C. Driving Principles of Armored Vehicles, 1st ed.; Beijing Institute of Technology Press: Beijing, China, 2020; pp. 140–146. [Google Scholar]

- Uberti, S.; Beltrami, D.; Ferrari, M.; Iora, P. Agricultural tractor bogie axle adoption: Market opportunities and traction and ground pressure improvements through mobility metrics and simulations. J. Terramechanics 2025, 117, 101013. [Google Scholar] [CrossRef]

- Esch, H.J.; Bashford, L.L.; Von Bargen, K.; Ekstrom, R.E. Tractive performance comparisons between a rubber belt track and a four-wheel-drive tractor. Trans. ASAE 1990, 33, 1109–1115. [Google Scholar] [CrossRef]

- Zhang, R.; Zhou, W.; Liu, H.; Gong, J.; Chen, H.; Khajepour, A. Similarities between wheels and tracks: A “tire model” for tracked vehicles. IEEE Trans. Veh. Technol. 2024, 73, 16416–16431. [Google Scholar] [CrossRef]

- Zeng, G.; Wang, W.D.; Gai, J.T.; Ma, C.J.; Li, X.M.; Li, H.H. Steering on Ramp Control Strategy of Double Motor Coupling Drive Transmission for Tracked Vehicle. Acta Armamentarii 2021, 42, 2189–2195. [Google Scholar] [CrossRef]

- Sun, F.C.; Shi, Q.L. Study on Grounding Pressure of Tracked Vehicles Steering on Ramp. Trans. Chin. Soc. Agric. Mach. 2006, 37, 14–18. [Google Scholar]

- Shi, Q.L.; Sun, F.C. Study on Steering Stability of Tracked Vehicles on Ramp. Trans. Chin. Soc. Agric. Mach. 2007, 38, 22–26. [Google Scholar]

- Sun, F.C.; Shi, Q.L.; Guo, F.; Zhai, L. Characteristics of Dynamics of Tracked Vehicles Steering on Ramp. Chin. Mech. Eng. 2007, 18, 2766–2771. [Google Scholar]

- Zhang, Y.; Qiu, M.; Liu, X.; Li, J.; Song, H.; Zhai, Y.; Hu, H. Research on Characteristics of Tracked Vehicle Steering on Slope. Math. Probl. Eng. 2021, 2021, 1–18. [Google Scholar] [CrossRef]

- Wong, J.Y.; Chiang, C.F. A general theory for skid steering of tracked vehicles on firm ground. Automob. Eng. 2001, 215, 343–355. [Google Scholar] [CrossRef]

- Dong, C.; Cheng, K.; Hu, K.L.; Hu, W.Q. Dynamic modeling study on the slope steering performance of articulated tracked vehicles. Adv. Mech. Eng. 2017, 9, 1–26. [Google Scholar] [CrossRef]

- Jia, X.; Xie, N.; Ding, X.B.; Liu, L.H.; Liu, Y. Establishment and Verification of Steady-State Steering Model for Mountain Tracked Vehicle on Soft Slope Road. J. Agric. Sci. Technol. 2022, 24, 97–111. [Google Scholar] [CrossRef]

- Pan, G.T.; Yu, L.F.; Yang, F.Z. Analysis and Simulation on Steering Stability of a Hilly Farmland Information Collection Vehicle on Slopes. J. Agric. Mach. Res. 2015, 37, 6–12. [Google Scholar] [CrossRef]

- Luo, H.; Wang, J.D. Kinematic analysis of slope steering on soft ground of tracked vehicle. Agric. Equip. Veh. Eng. 2023, 61, 21–27. [Google Scholar] [CrossRef]

- Elsharkawy, A.F.; Kamel, M.A.; Salem, A.M.; Abdelshafy, M.H. Dynamics of Tracked Vehicles during Nonuniform Turning on Level Terrain and on Slopes. Discov. Appl. Sci. 2024, 6, 547. [Google Scholar] [CrossRef]

- Zhang, Y.; Liu, X.X.; Chen, H.Q.; Qiu, M.H.; Zhao, Y.; Zhang, X.D. Slope-Steering Motion Planning for Unmanned Tracked Vehicles Based on SSTP-RRT. IEEE Access 2024, 12, 27267–27278. [Google Scholar] [CrossRef]

- Yang, F.; Liu, Q.; Ji, Y.; Chu, H.; Duan, L.; Lin, Z.; Shou, Y.; Liu, Z. Development and Validation of Sloped Ground Pressure Pre-diction Model for a Tracked Tractor in Hilly and Mountainous Environments. Soil Tillage Res. 2024, 241, 106135. [Google Scholar] [CrossRef]

- Zhao, Z.H.; Mu, X.H.; Guo, H.L.; Lv, K.; Du, F.P. Test and modeling on static ground pressure of rubber track conversion system. Trans. Chin. Soc. Agric. Eng. 2018, 34, 72–79. [Google Scholar] [CrossRef]

- Tang, S.; Yuan, S.; Hu, J.; Li, X.; Zhou, J.; Guo, J. Modeling of Steady-State Performance of Skid-Steering for High-Speed Tracked Vehicles. J. Terramechanics 2017, 73, 25–35. [Google Scholar] [CrossRef]

- Zhang, R.Z.; Gong, J.W.; Chen, H.Y.; Liu, H.O.; Lu, J.X. Turning Model for Tracked Vehicles on Hard Ground: Analysis and Verification. Acta Armamentarii 2023, 44, 233–246. [Google Scholar] [CrossRef]

- Chen, Y.J.; Yi, X.Y.; Yi, C.B.; Liu, S. Strengthening Farmland Quality Improvement to Promote High-Quality Agricultural Development. Chin. Agric. Compr. Dev. 2021, 10, 22–24. [Google Scholar]

- Song, H.J.; Gao, L.H.; Cheng, J.W. Research on the Steering of Tracked Vehicles with Zero Turning Radius. J. Acad. Armor. For. Eng. 2007, 21, 55–58. [Google Scholar]

- Duan, L.; Kang, K.; Chen, S.; Du, Z.; Zhang, L.; Liu, Z.; Yang, F.; Wang, Z. Analysis and Verification of a Slope Steering Model of TRVs in Hilly and Mountainous Environments. Agronomy 2025, 15, 147. [Google Scholar] [CrossRef]

- Bekker, M.G. Introduction to Terrain-Vehicle System, 1st ed.; University of Michigan Press: Ann Arbor, MI, USA, 1969; pp. 4–6. [Google Scholar]

- Merhof, W.; Hackbarth, E.M. Terramechanics of Crawler Vehicles, 1st ed.; National Defense Industry Press: Beijing, China, 1989; pp. 65–66. [Google Scholar]

- Wong, J.Y. Theory of Ground Vehicles, 5th ed.; John Wiley & Sons, Inc.: Ottawa, Canada, 2022; pp. 139–141. [Google Scholar]

- Chen, B.C.; Fan, Y.C.; Ren, L.Q. Relationship Between Track Thrust and Soil Parameters Under Dynamic Variation of Ground Pressure. J. Jilin Univ. (Eng. Technol. Ed.) 1984, 1, 67–84. [Google Scholar] [CrossRef]

- Huang, H.; Zhai, L.; Wang, Z. A power coupling system for electric tracked vehicles during high-speed steering with optimization-based torque distribution control. Energies 2018, 11, 1538. [Google Scholar] [CrossRef]

- Pang, G.T.; Sun, J.B.; Wang, X.L.; Yang, F.Z.; Liu, Z.J. Construction and experimental verification of sloped terrain soil pressure-sinkage model. Agriculture 2021, 11, 243. [Google Scholar] [CrossRef]

| Primary Structural Parameters | Value | Unit |

|---|---|---|

| Engine power (P) | 44.1 | kw |

| Engine rated speed (nz) | 2400 | r/min |

| Gross vehicle mass (m) | 2000 | kg |

| Overall dimensions (L×W×H) | 3400 × 1430 × 2180 | mm |

| Track ground contact length (L) | 1200 | mm |

| Track shoe width (b) | 350 | mm |

| Track gauge (B) | 1080 | mm |

| Sprocket pitch radius (r) | 180 | mm |

| Number of road wheels per side (N) | 5 | - |

| Minimum ground clearance (Hd) | 260 | mm |

| Center of mass coordinates (xPC, yPC, zPC) | (−20,228,422) | mm |

| Soil Parameters | Value | Unit |

|---|---|---|

| Soil moisture content (MC) | 13.5% | / |

| Cohesive modulus of soil deformation (kc) | 15.9 | kN/mn+1 |

| Frictional modulus of soil deformation (kϕ) | 1179 | kN/mn+2 |

| Soil deformation index (n) | 0.597 | / |

| Soil cohesion (c) | 12 | kPa |

| Unit weight of soil (γs) | 1210 | kg/m3 |

| Soil internal friction angle (φi) | 20 | ° |

| Track plate wall friction angle (φf) | 12 | ° |

| Steering Variables | Braking Force on Inner Track | Tractive Effort on Outer Track | ||||||

|---|---|---|---|---|---|---|---|---|

| Maximum Relative Error | Mean Relative Error | R2 | RMSE | Maximum Relative Error | Mean Relative Error | R2 | RMSE | |

| v = 1 km/h, R = 0.5 m, α = 0° | 4.29% | 2.8% | 0.865 | 111.9 | 4.75% | 3.1% | 0.882 | 122.99 |

| v = 1 km/h, R = 0.5 m, α = 5° | 5.51% | 3.6% | 0.893 | 142.53 | 5.97% | 3.9% | 0.919 | 155.52 |

| v = 1 km/h, R = 0.5 m, α = 10° | 5.82% | 3.8% | 0.987 | 137.44 | 7.05% | 4.6% | 0.992 | 177.90 |

| v = 1 km/h, R = 0.5 m, α = 20° | 8.12% | 5.3% | 0.988 | 193.66 | 9.34% | 6.1% | 0.987 | 246.58 |

| v = 1 km/h, R = 0.3 m, α = 0° | 4.90% | 3.2% | 0.953 | 138.08 | 6.28% | 4.1% | 0.943 | 129.54 |

| v = 1 km/h, R = 0.3 m, α = 10° | 5.67% | 3.7% | 0.967 | 154.83 | 6.89% | 4.5% | 0.971 | 191.86 |

| v = 1 km/h, R = 0.3 m, α = 15° | 7.05% | 4.6% | 0.979 | 186.52 | 8.12% | 5.3% | 0.982 | 226.27 |

| v = 1 km/h, R = 0.3 m, α = 25° | 10.41% | 6.8% | 0.986 | 257.6 | 11.49% | 7.5% | 0.986 | 326.06 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Duan, L.; Zhang, L.; Kang, K.; Ji, Y.; Mu, X.; Wang, H.; Zhou, J.; Liu, Z.; Yang, F. Performance Analysis and Experimental Validation of Small-Radius Slope Steering for Mountainous Crawler Tractors. Agronomy 2025, 15, 1956. https://doi.org/10.3390/agronomy15081956

Duan L, Zhang L, Kang K, Ji Y, Mu X, Wang H, Zhou J, Liu Z, Yang F. Performance Analysis and Experimental Validation of Small-Radius Slope Steering for Mountainous Crawler Tractors. Agronomy. 2025; 15(8):1956. https://doi.org/10.3390/agronomy15081956

Chicago/Turabian StyleDuan, Luojia, Longhai Zhang, Kaibo Kang, Yuxuan Ji, Xiaodong Mu, Hansong Wang, Junrui Zhou, Zhijie Liu, and Fuzeng Yang. 2025. "Performance Analysis and Experimental Validation of Small-Radius Slope Steering for Mountainous Crawler Tractors" Agronomy 15, no. 8: 1956. https://doi.org/10.3390/agronomy15081956

APA StyleDuan, L., Zhang, L., Kang, K., Ji, Y., Mu, X., Wang, H., Zhou, J., Liu, Z., & Yang, F. (2025). Performance Analysis and Experimental Validation of Small-Radius Slope Steering for Mountainous Crawler Tractors. Agronomy, 15(8), 1956. https://doi.org/10.3390/agronomy15081956