Abstract

In recent years, the traditional orchard sprayer has had problems, such as waste of liquid agrochemicals, low target coverage, high manual dependence, and environmental pollution. In this study, an automatic swing-arm sprayer for orchards was developed based on the standardized pear orchard in Pinggu, Beijing. Firstly, the structural principles of a crawler-type traveling system and swing-arm sprayer were simulated using finite element software design. The combination of a diffuse reflection photoelectric sensor and Arduino single-chip microcomputer was used to realize real-time detection and dynamic spray control in the pear canopy, and the sensor delay compensation algorithm was used to optimize target recognition accuracy and improve the utilization rate of liquid agrochemicals. Through the integration of innovative structural design and intelligent control technology, a vertical droplet distribution test was carried out, and the optimal working distance of the spray was determined to be 1 m; the nozzle angle for the upper layer was 45°, that for the lower layer was 15°, and the optimal speed of the swing-arm motor was 75 r/min. Finally, a particle size test and field test of the orchard sprayer were completed, and it was concluded that the swing-arm mode increased the pear tree canopy droplet coverage by 74%, the overall droplet density by 21.4%, and the deposition amount by 23% compared with the non-swing-arm mode, which verified the practicability and reliability of the swing-arm spray and achieved the goal of on-demand pesticide application in pear orchards.

1. Introduction

Spraying for orchard plant protection is extremely important in orchard production management. During the growth period of fruit trees, they require spraying at least 8–15 times, accounting for about 30% of the total workload of tree management, which increases the difficulty and intensity of fruit tree management. At the same time, the quality of orchard plant protection affects the quality and yield of fruits, which in turn affects the economic income of fruit farmers. Orchard plant protection is a key aspect of orchard management, and its level of mechanization directly affects the economic benefits of fruit planting [1]. The traditional mode of pesticide application can cause problems, such as waste of liquid agrochemicals. In recent years, the emergence of standardized densely planted orchards has been beneficial for improving the production efficiency of orchards, protecting the environment, and enhancing fruit quality. Spraying for the control of pests and diseases in standardized orchards has also developed from manual spray control to tractor-driven pneumatic spray control [2]. In addition, in recent years, numerous research achievements have been reported in pipeline spraying technology, wind-assisted spraying technology, irrigation bar spraying technology, and circular spraying technology [3]. These methods reduce risk, lower the labor intensity of fruit farmers, and improve the production efficiency of orchards.

In recent years, researchers from various countries around the world have invested in the development of orchard sprayers. Most of the orchard spraying techniques and equipment shown in Figure 1 use fixed doses of pesticides to continuously spray fruit trees. However, the canopy structure of fruit trees in orchards is complex, and the leaf density varies greatly. The characteristics and density of the canopy, the growth stage of the trees, and the surrounding environmental conditions all have a huge impact on the effectiveness of pesticide application, and the spraying effect is relatively uneven, with poor spray deposition. In terms of research and development of orchard spraying, Jiang Honghua et al. [4] and Qiu Wei et al. [5] adopted a top-mounted fan method, using the negative pressure suction of a fan to guide the airflow within the canopy to change its direction of movement, achieving the movement of droplets from the outside to the inside and then from bottom to top, a breakthrough in overcoming the problem of stagnant airflow in a greenhouse orchard. They developed an adjustable-shaped air duct, and the droplet density inside the chamber increased from 23 drops/cm2 to 56 drops/cm2. Ru Yu et al. [6] designed an axial flow air supply system suitable for traditional orchard sprayers, optimized the guide vane parameters of the axial flow fan through CFD simulation, extended the air supply distance from 8 m to 15 m, and reduced the drift loss of liquid agrochemicals by 28%. Hanif et al. [7] established a multifactor coupling analysis model for the first time. By comparing 50 patent data items, they revealed key technical indicators such as the response speed of the cooperative microcontroller, the accuracy of the multispectral sensors, and the performance of the anti-disturbance nozzles required for unmanned aerial vehicle platforms, providing decision support for global product development. Grella et al. [8] completed the ergonomic verification of a PWM control system in a vineyard setting. Through designing a fourth-order working cycle (30~100%) and a three-speed working condition (4–8 km/h) orthogonal experiment, they innovatively proposed the theory of pulse smoothing effect, clarifying that high-frequency modulation can eliminate the blind spots in the deep cover of grape leaves, providing a new paradigm for precise pesticide application for economic crops. E. Nasir et al. [9] built a YOLOv5n lightweight model and cascade pressure control algorithm, integrated an edge computing unit (NVIDIA Jetson Nano), and created a new path for intelligent crop spraying.

Figure 1.

The main types of machinery for crop protection and spraying in orchards.

In view of the serious waste of liquid agrochemicals and low target coverage of traditional spray equipment, this research adopts the innovative structure of swing-arm spraying to develop a way to achieve pesticide spraying on demand, reduce the labor costs and health risks of fruit farmers, improve the spray coverage effect, significantly improve the uniformity of spray, play an undisputed role in promoting the research and development process of plant protection equipment, and have social significance on the development path of agricultural modernization. Therefore, the development of efficient, precise, reliable, and highly utilized orchard pesticide application machinery with an autonomous walking control system, the development of high-efficiency and low-pollution machinery, and research on pesticide application technology to create a new mode of fruit tree operation and production with reduced application and increased efficiency are of great significance for improving orchard operation efficiency, reducing labor costs, reducing pesticide use, and enhancing the core competitiveness and independent innovation capability of intelligent equipment for high-end plant protection agricultural machinery in China.

2. Materials and Methods

2.1. Design of Orchard Swing-Arm Sprayer

2.1.1. Background of Orchard Planting and Pesticide Application

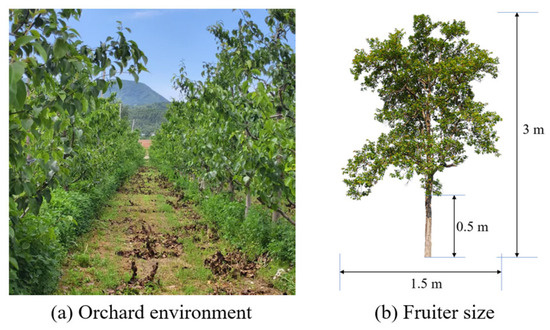

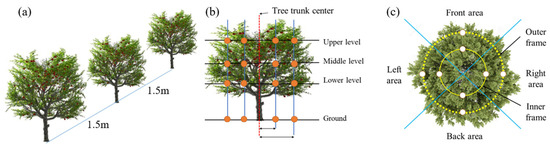

As shown in Figure 2, the standardized pear orchard is located in Xiying Village, Yukou Town, Pinggu District, Beijing, and the variety in the standardized closely planted pear orchard is Fojianxi pear, with a slender spindle-shaped tree shape, a row spacing of about 3 m, a plant spacing of about 1.5 m, a pear tree height of about 3 m, and a canopy width of about 1.5 m. Fifty pear trees in the orchard were randomly selected to measure their size and obtain the average value. The experiment, without reducing the experimental error, was conducted at 10 am in May, with normal temperature, wind speed, and humidity. The design requirements of orchard sprayers need to be comprehensively considered based on specific orchard types, planting patterns, and pest control needs [10]. Based on the field survey and literature research of the orchard, this paper determines the conditions for mechanized pesticide application in the pear orchard and presents the actual demand for the development of a swing-arm sprayer. The designed swing-arm sprayer should have the following functions: spray function, liquid agrochemical loading function, liquid agrochemical conveying function, and walking function. It needs to be able to evenly spray the liquid agrochemical to all parts of the fruit tree crown to avoid missed spraying or respraying. The spray should achieve the accurate application of pesticide, which requires high operating efficiency, rapid completion of large-scale orchard spray operations, and ability to cope with problems such as lack of agricultural personnel [11,12,13]. At the same time, the sprayer should be simple to operate, easy to learn, convenient for farmers to use, and also needs to have good safety performance to avoid accidents such as liquid agrochemical leakage and mechanical failure.

Figure 2.

Orchard environment and fruiter size.

2.1.2. Scheme Design of the Whole Machine

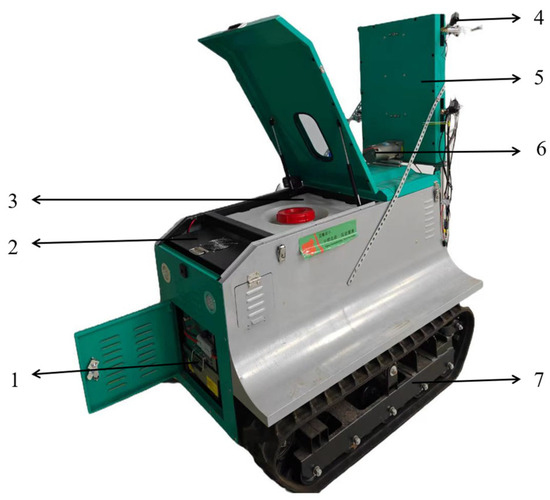

The orchard swing-arm sprayer designed in this article mainly consists of the walking system, spraying system, swing-arm mechanism, control system, and other main components, as shown in Figure 3.

Figure 3.

Structural design of a swing-arm sprayer for an orchard. 1. Walking system; 2. Battery; 3. Control system; 4. Agrochemical tank; 5. Arm swing motor; 6. Swing-arm linkage; 7. Electromagnetic valve and nozzle.

The walking system mainly includes the chassis and power system, which provides power for the sprayer to walk in orchards on different terrains. The chassis system is designed as a track-type system, mainly composed of tracks, drive wheels, guide wheels, support wheels, and a suspension system [14,15]. Its power system, designed to have an extended range, mainly includes a gasoline generator, power battery, and drive motor. The spray system mainly consists of a liquid agrochemical tank, liquid pump, pipeline, and nozzle, which can evenly spray liquid agrochemicals to all parts of the pear tree crown to achieve the most effective pest control. The swing-arm mechanism is mainly composed of a brushless motor, a linkage mechanism, a spray bar, and an eccentric wheel. It mainly plays a role in supporting and adjusting the position and angle of the spray bar so that it can adapt to the different heights and shapes of fruit tree crowns. The supporting spray rod of the linkage mechanism can rotate around the horizontal axis within a certain angle range, achieving height and angle adjustment of the spray rod. The spray nozzle is installed on the spray bar and delivers the agrochemical to the nozzle [16,17]. The motor provides power to the linkage mechanism, enabling it to achieve lifting and rotating movements. The control system mainly controls the movement of the sprayer, spraying, swing-arm, and other actions to realize the automatic operation of the sprayer, including remote control, the microcontroller drive system, speed sensor, etc. The structural frame diagram divided between the components of the spray is shown in Figure 4.

Figure 4.

The principle of the swing-arm sprayer for orchards.

The working principle of the swing-arm sprayer is based on the coordinated work of the walking system, the spray system, the swing-arm mechanism, and the control system, which can evenly spray the liquid agrochemical in the liquid tank into the pear tree canopy to achieve the prevention and control of diseases and pests. The power of the spray comes from the gasoline engine. After starting, the engine uses the generator to send electrical energy back into the power battery. The power is transmitted to the two drive motors at the front end through the circuit. The power is transmitted to the track drive wheel through the reducer to cause the track to rotate. The speed of the drive wheel is adjusted by controlling the differential to complete the steering, turning, and other actions of the sprayer, so that it can walk freely in the pear orchard. During the walking process, the liquid pump transports the pre-mixed liquid from the liquid tank to the nozzle on the spray bar through the pipeline. The liquid pump converts the mechanical energy into the pressure energy of the liquid. The nozzle atomizes the liquid agrochemical into small droplets [18,19]. The size and distribution of the droplets are controlled by adjusting the type of nozzle and the spray pressure to achieve the best coverage effect. While spraying, the swing-arm mechanism is driven by the combined structure of motor and eccentric wheel. The output shaft of the motor drives the eccentric wheel causing it to rotate, and, through the linkage mechanism, the rotational motion of the eccentric wheel is converted into the reciprocating motion of the swing-arm, achieving the lifting and angle adjustment of the spray bar. By adjusting the speed of the motor and the length of the crankshaft, the swing speed and range of the spray bar can be flexibly adjusted. The control system is the “brain” of the sprayer, responsible for coordinating the work of the various components. The operator can send command signals to the sprayer through the remote control, and the signal receiver will transmit the signals to the computer below to control the driving motor, liquid pump, and swing-arm mechanism of the walking system and complete the control of the sprayer’s walking, spraying, and swing-arm movements [20,21,22]. In addition, the swing sprayer will also integrate variable spray technology to monitor the presence of pear canopy in real time through photosensitive sensors and automatically complete the switch control of spray.

The orchard swing sprayer designed in this paper is fundamentally an oil–electric hybrid type, and the main technical parameters are shown in Table 1.

Table 1.

Technical parameters of the sprayer.

2.1.3. Design and Selection of Key Components

- (1)

- Walking system

The tracks of this sprayer are rubber tracks, and its chassis suspension is welded from 30 mm × 50 mm steel. The guide wheel and support wheel are assembled to the corresponding installation shaft of the suspension and fixed. The drive motor and reducer are connected by flanges, and the output shaft of the reducer is connected to the drive wheel by splines. The driving wheel is meshed with the rubber track to drive the rubber track to rotate, thus realizing the traveling action of the sprayer chassis. The formula for calculating the grounding length of rubber tracks is as follows:

In the formula: L—grounding length of rubber track, mm; G—full load weight of the whole machine, N; b—width of rubber track, mm; and γ—proportional coefficient.

Generally, the designed full load mass of the whole machine is m = 500 kg, and the proportional coefficient γ is generally taken as 0.18–0.22 for ordinary machinery and 0.24~0.28 for machinery used in swamps. Therefore, in this design γ = 0.20 is taken. By substituting Formula (1), the grounding length of the track is L = 1830 mm, rounded to L = 1800 mm. Therefore, the grounding length of a single rubber track is L0 = 900 mm, and the track width is b = 180 mm.

The pitch, t, of the track can be calculated according to an empirical formula:

In the formula: t—track pitch, mm and m—quality of sprayer, kg.

The range of track pitch is 70 mm~82 mm, and a larger pitch can increase the strength of the chain links. Therefore, the average value t = 76 mm is taken.

The driving motor transmits power to the driving wheels through a reducer, and the driving wheels mesh with the tracks to achieve the walking of the track chassis. During the walking process, the more contact between the driving wheel teeth and the track, the more stable the walking. However, the larger the number of driving wheel teeth, the larger the diameter, which increases the weight of the driving wheel. Therefore, the number of driving wheel teeth z = 11 is selected. The pitch of the driving wheel is equal to that of the track, both being 76 mm. The diameter of the driving wheel pitch circle is calculated according to the following formula:

In the formula: D0—drive wheel pitch diameter, mm; j—drive wheel pitch, mm; and z—number of driving teeth.

Due to j = t = 76 mm and z = 11, the diameter of the driving wheel pitch circle can be calculated as D0 = 269.8 mm, which is rounded to 270 mm.

The support wheels and guide wheels are key components in the track chassis. The support wheels support the vehicle weight and maintain the tension of the track appropriately. The diameter of the support wheels and the pitch of the track are as follows:

In the formula: D1—diameter of the supporting wheel, mm and t—track wheel pitch, mm.

The diameter range of the supporting wheel D1 is 114 mm~228 mm, and the number of single-sided track supporting wheels is designed to be 3. Based on the grounding length of the track, D1 = 120 mm is taken.

The guide wheel guides the track to move correctly, adjusts the tightness of the track, and prevents the track from slipping off the track. The diameter of the guide wheel and the pitch of the track should meet the empirical formula

In the formula: D2—guide wheel diameter, mm.

The range of the diameter D2 of the guide wheel is 228 mm~380 mm, with D2 = 270 mm.

- (2)

- Spraying system

The spray system mainly includes motors, agrochemical pumps, nozzles, agrochemical tanks, and delivery pipes. The agrochemical pump is the power source which delivers the agrochemical from the agrochemical tank to the nozzle through the agrochemical delivery tube at a certain pressure and sprays it onto the surface of fruit tree leaves after atomization by the nozzle. The flow rate of a plunger pump should satisfy the following formula:

In the formula: Qb—total flow rate of the plunger pump, L/min; Qp—total flow rate of nozzle L/min; Vm—agrochemical tank volume, L; and K—hydraulic mixing coefficient.

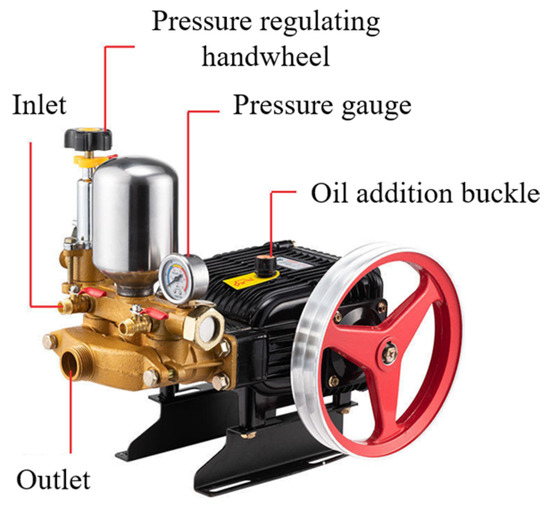

The maximum total flow of the eight nozzles of the spray is about 20 L/min, the capacity of the agrochemical tank is 150 L, and the hydraulic mixing coefficient K is 0.12, so the total flow of the plunger pump, Qb, is ≥38 L/min. The multifunctional power pump manufactured by Taizhou Road and Bridge Pioneer Electronic Technology Co., Ltd. (Taizhou, China) is selected, as shown in Figure 5.

Figure 5.

3WZB-60 plunger pump.

The motor is used to drive the power pump to rotate and extract the agrochemical, and the power of the motor should meet the following requirements:

In the formula: —represents the power of the motor, kW; —the power of the power pump, kW; and K—the safety factor, taken as 1.2.

The power of the motor should be 2.4~3.6 kW, and the speed should match the speed of the plunger pump. Therefore, a servo motor with a rated power of 2.4 kW and a rated speed of 1000 r/min is selected.

- (3)

- Swing-arm mechanism

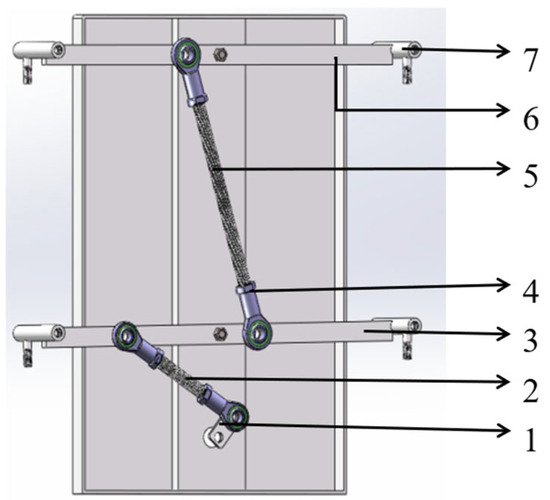

The swing-arm mechanism mainly realizes the up and down swing process of the spray bar. Commonly used mechanisms for achieving the swinging motion of the spray bar include the cam mechanism, eccentric wheel mechanism, gear mechanism, and crank connecting rod mechanism. The swing amplitude of the spray rod of this sprayer is about 0.3 m, and the transmission distance between the cam and the eccentric wheel mechanism is relatively short. Therefore, a crank connecting rod mechanism with strong load-bearing capacity and high transmission efficiency is selected. Its structure is shown in Figure 6. While spraying, the swing-arm mechanism is driven by the combined structure of the motor and eccentric wheel. The output shaft of the motor drives the eccentric wheel, causing it to rotate, and, through the linkage mechanism, the rotational motion of the eccentric wheel is converted into the reciprocating motion of the swing arm, achieving the lifting and angle adjustment of the spray bar. By adjusting the speed of the motor and the length of the crankshaft, the swing speed and range of the spray bar can be flexibly adjusted. The control system is the “brain” of the spray, which is responsible for coordinating the work of various components. The operator can send command signals to the spray through the remote controller, and the signal receiver will transmit the signals to the machine below, control the driving motor, liquid pump, and motor of the swing-arm mechanism of the walking system, and complete the control of the sprayer’s walking, spraying and swing-arm actions. In addition, the swing spray will also integrate variable spray technology to monitor the presence of pear canopy in real time through photosensitive sensors and automatically complete the switch control of the spray.

Figure 6.

Structural diagram of crank connecting rod mechanism. 1. Crankshaft; 2. Short rocker arm; 3. Lower swing arm; 4. Rod end joint bearing; 5. Long rocker arm; 6. Upper swing arm; 7. Spray bar.

2.2. Design of Spray System

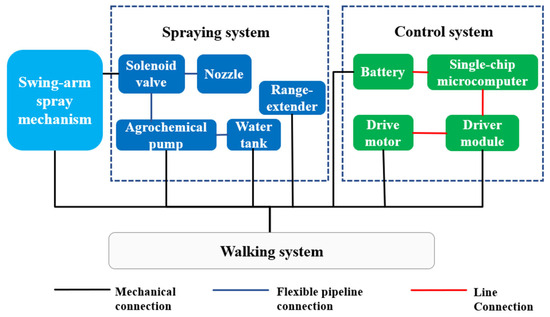

2.2.1. Overall Architecture

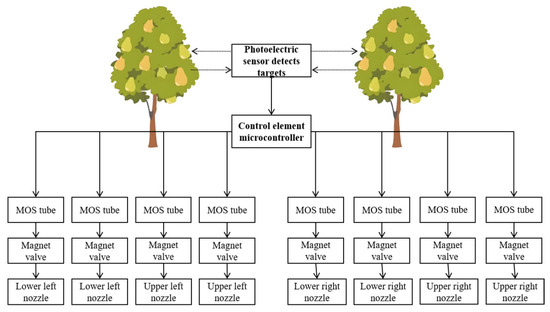

Whether the spray can accurately complete the spraying work mainly depends on the control module of the spray system stably and accurately collecting signals and issuing spray instructions [23,24]. The spray system mainly includes hardware modules and software programs which can detect the location information of pear trees and control the amount of spraying. Firstly, the photoelectric sensor senses the target information of the pear tree canopy on both sides, transmits the speed of the equipment to the control module, and controls the opening and closing of the solenoid valve to achieve the pesticide application operation. The overall design of the spray system is shown in Figure 7.

Figure 7.

Framework of the spray system.

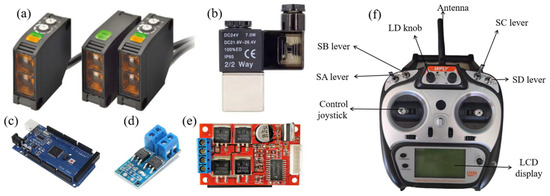

2.2.2. Hardware Design

The hardware of the spray system of the swing-arm spray machine is mainly composed of a photoelectric sensor, speed sensor, solenoid valve, MCU, driving module, depressurization module, and communication module [25,26]. As shown in Figure 8, the row spacing for pear tree planting in this article is about 3 m. The photoelectric sensor should be waterproof. An E3JK-DR11-C (Omron Corporation, Shanghai, China) diffuse reflection photoelectric sensor is selected, and the PNP connection method is used. Therefore, a two-position, two-way direct-acting normally closed solenoid valve is selected, with a rated power of 7 W, a rated voltage of 24 V, and a maximum withstand voltage of 2.0 Mpa. As a core component, the control unit should have the ability to quickly process data, evaluate decisions, and adjust spray status in real time. Its multiple communication interfaces and powerful expansion capability are widely used in robot control, multisensor systems, and other fields; The output voltage of the microcontroller output terminal is 3.3 V DC output and 5 V DC output. The solenoid valve drive module needs to amplify the output voltage of the microcontroller to drive the solenoid valve to work. It adopts original imported dual-MOS parallel active output, with lower internal resistance, higher current, and strong power. The motor voltage of the swing-arm system is 24 V and cannot be directly driven by the control unit, so a DC motor drive board is required, which can be controlled by three wires for speed regulation and forward and reverse rotation. The remote controller contains eight signal channels, and two rockers are used to control the forward, backward, left and right turns of the spray, which has the advantages of long transmission distance and low power consumption.

Figure 8.

Main hardware diagram of the spray system. (a) E3JK-DR11-C photoelectric sensor; (b) 2V025-08-type solenoid valve (Chint Group Co., Ltd., Zhejiang, China); (c) Arduino microcontroller; (d) High-power MOS; (e) Sunbond motor drive board; (f) Remote control.

2.2.3. Software Design

The spray control system program is mainly used for detecting pear tree target information and processing spray information [27]. The program is designed using Arduino IDE development environment. and C language is used as the programming language. Two sets of single-chip computers and sensors are used to control and drive the opening and closing of the solenoid valves of the left and right pipelines of the spray, respectively, and to send a high-level signal to the motor drive board at the same time to make the swing-arm structure perform the swing-arm action. When the photoelectric sensor is working, it will detect the target within the detection range. The microcontroller polls the transmission information with the sensor. When the photoelectric sensor detects the presence or absence of target information, the microcontroller controls the opening and closing of the solenoid valve. The sampling frequency of the photoelectric sensor is 500 Hz, and the sampling speed is fast. Due to the gaps between the branches and leaves of fruit trees, as well as between fruit trees, the digital signals collected by the photoelectric sensor are relatively chaotic and need to be processed. Therefore, it is necessary to optimize the target detection program. Firstly, in terms of hardware, it is necessary to add an RC low-pass filter (R = 1 kΩ, C = 3.3 nF) with a cutoff frequency of 250 Hz to the circuit. The RC filter circuit can suppress high-frequency noise and provide anti-aliasing protection. Secondly, it is necessary to adjust the installation angle of the photoelectric sensor from 90° vertically to 60° obliquely to reduce light leakage between branches and leaves. In terms of program algorithms, firstly, it is necessary to enhance the detection logic by processing the binary data collected by the photoelectric sensor in the microcontroller, dividing every 10 data points into groups. It is required that in a group of data samples, if more than 3 samples are high, it can be determined that there is a target object within the detection range of the photoelectric sensor.

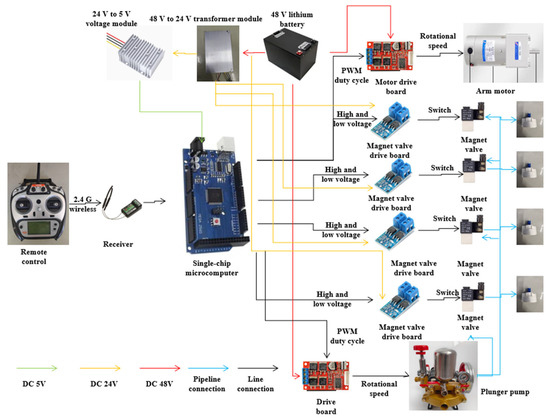

Figure 9 shows the software and hardware composition diagram of the spray system in four parts: remote control, control unit, power supply, and actuator. The power supply is powered by a 48 V lithium battery, and the motor drive board is directly powered by the lithium battery. The voltage reduction module reduces the 48 V DC voltage to 24 V DC voltage to supply power to the photoelectric sensor and solenoid valve. The remote controller sends PWM code commands through the 2.4 GHz frequency band, and the receiver demodulates the pulse width, which is analyzed by the single-chip microcomputer, and maps the signals into control parameters, thus controlling the swing-arm action of the swing-arm spray machine.

Figure 9.

Software and hardware connection diagram of the spray system.

2.3. Parameter Optimization of Swing-Arm Mechanism

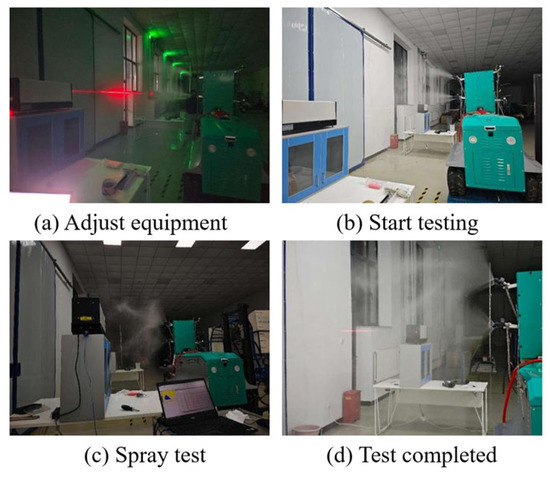

2.3.1. Apparatus and Design

To obtain the best operating parameters of the swing-arm mechanism in spray operation, an indoor swing-arm spray performance test device was designed and built, which mainly includes the swing-arm spray machine, DC motor speed regulator, 48 V power supply, tape measure, and BV-20-400 vertical droplet distribution meter (Beijing Leixina Company, Beijing, China). The vertical fog droplet distribution instrument consists of a driving platform, a steel triangular base, guide rails, and a stainless steel collector. The drive platform reciprocates on the guide rail and adjusts the speed. The collector is 4.5 m high and installed on a steel triangle base. There are 20 collecting trays connected to a 100 mL measuring cylinder every 20 cm, which can accurately measure the distribution of spray droplets in the vertical direction. Trays are collected below 4 m from the measuring instrument, numbered from low to high, and the driving platform rotated back and forth five times. Three sets of test data were measured and the average value taken.

The spray conditions of the measuring spray were compared at different distances in the modes of no arm swing and arm swing, and the distance between the spray and the measuring instrument was set at 1 m and 1.5 m in turn. At the optimal spray distance, the angle of the upper and lower two layers of nozzles was adjusted, and tests were conducted. The nozzles were adjusted upward in the positive direction. The test scheme is shown in Table 2. The droplet distribution and the advantages and disadvantages of the two modes were analyzed.

Table 2.

Installation angle scheme for the double layer of nozzles.

To determine the optimal swing-arm speed of the swing-arm spray, the optimal distance between the spray and the measuring instrument and the optimal speed of the driving platform were selected. The motor speed was set to 30 r/min, 45 r/min, 60 r/min, 75 r/min, and 90 r/min, and the collected data were compared and analyzed to obtain the optimal speed of the motor, that is, the optimal swing-arm speed of the swing-arm structure.

2.3.2. Process and Evaluation

Firstly, install the vertical droplet distribution measuring instrument on open ground and mark it with identification tape at positions 1 m, 1.5 m, and 2 m away from the measuring instrument. Then, turn on the swing-arm sprayer to the 1 m mark and adjust the plunger pump pressure to 1 MPa. Start the swing-arm spray, close the swing-arm mode, adjust the swing-arm to the horizontal plane, and after the spray is stable, start the driving platform of the measuring instrument. Test the spray machine five times, record the measurement data, and repeat three times. Then, turn on the swing-arm mode of the sprayer, record the measurement data, and conduct the experiment in sequence. Use a DC motor speed regulator to adjust the speed of the swing-arm motor for sequential testing, and collect measurement data. The experimental process is shown in Figure 10.

Figure 10.

Process diagram of the vertical droplet distribution test.

To evaluate the spray effect, the factors in the test are coded. The swing of the swing-arm mechanism is recorded as Y, and the non-swing is recorded as N; the distance factor between the spray machine and the measuring instrument is recorded as A; the test repetition groups are recorded as T1, T2, and T3, respectively. The effective coverage range of fog droplets in the vertical direction is defined as VCR, and the boundary height (upper and lower limits) of the area with fog droplet volume ≥ 5 mL is determined. The volume of droplets per unit area is the droplet deposition density, denoted as DDD. The coefficient of variation (CV) of vertical droplet density is used to reflect the uniformity of droplet distribution.

where SD represents the standard deviation of droplet density and MN represents the average droplet density.

2.4. Performance Test of Orchard Swing-Arm Sprayer

2.4.1. Spray Particle Size Test

As shown in Figure 11, the spray particle size test was conducted in the Agricultural UAV System Research Institute of China Agricultural University in November 2024. The swing-arm sprayer can well realize uniform spraying from top to bottom during the operation [28,29,30]. Considering the speed and angle of the swing-arm, the LU-120-03 nozzle is selected based on the previous literature research and pre-experiment, and the droplet size test experiment is carried out. The OMAX spray laser particle size analyzer is used to collect light signals from different angles in combination with the detector array. The test range is 1–1500 μm, and the repeatability error is less than 3%.

Figure 11.

Spray particle size test.

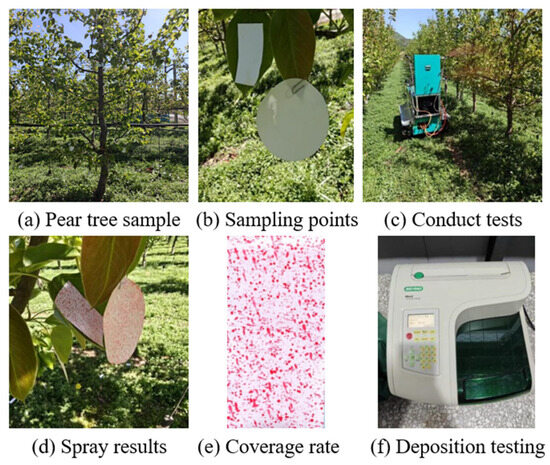

2.4.2. Field Trial

The field experiment was conducted in April 2025 at the Smart Pear Garden in Xiying Village, Yukou Town, Pinggu District, Beijing. The main focus was on planting spindle- shaped pear trees, which had an elliptical canopy with narrow upper and lower canopies and wide middle canopy [31,32]. The experimental materials included an LU-120-03 nozzle, photo paper (sampling paper), neutral filter paper, carmine dye, self-sealing bag, etc. When the test was conducted in the swing-arm mode, the spray adopted the optimal swing-arm speed, the optimal travel speed of the machine, which was 0.8 m/s, and the four nozzles on one side were opened for spraying. The distance between the nozzle and the center of the pear tree was about 1.1 m. Each mode test was repeated three times. Two groups of pear trees were selected for the spray experiment in the swing-arm mode and non-swing-arm mode. Each group of pear trees contained one sampled pear tree, and five pear trees separated the two groups of pear trees. As shown in Figure 12, the pear tree was divided into upper, middle, and lower layers, and on each layer five pieces of sampling test paper were arranged. Taking the travel direction of the spray machine as the front, the pear tree was divided into front, back, left, and right, and one sampling point was selected from the center. Sampling paper and filter paper were stuck on both sides of the leaves at each sampling point.

Figure 12.

Schematic diagram of field experiment test paper sampling. (a) Spacing between fruit trees; (b) Front view; (c) Top view.

A 3 g/L carmine solution was used as the indicator solution of spray. The amount of spray per mu was adjusted to 45 L/a, the spray switch was turned on, and spraying was conducted without arm swing after the spray was stable [33]. Subsequently, spraying was adjusted to the swing-arm spray mode, and the spray operation was performed at the same speed. After the experiment was completed, we waited for the sample to air-dry before collecting. The experiment steps were repeated twice, as shown in Figure 13. After the experiment, ImageJ 2023 image analysis software was used to statistically calculate and analyze the coverage and density of fog droplets. A microplate reader was used to detect absorbance and calculate the amount of droplet deposition. SPSS 27 software and Origin 2024 were used to create charts of experimental results.

Figure 13.

Sample arrangement, spray process, and results treatment of the field test.

3. Results and Discussion

3.1. Optimization of Spray Parameters of Swing-Arm Mechanism

3.1.1. Determination of Swing-Arm Angle

The No. 1 collecting plate of the droplet vertical distribution meter was 0.5 m from the ground, and the distance between each two collecting plates was 0.2 m. The VCR of each installation angle combination is shown in Table 3. Combining the orchard environment and spray conditions, the spray distance was determined to be 1 m. The DDD was calculated by using the average value of the experiment results of three repeated tests of each test scheme, and the difference between the swing-arm mode and the non-swing-arm mode when the spray was 1 m away was compared. In angles 2, 3, and 4, the VCR of the spray in the swing-arm mode of the spray was about 0.2 m higher than that of the spray in the non-swing-arm mode. It can be seen that the swing-arm structure can increase the VCR under certain conditions. By comparing angles 3, 4, and 5, it can be seen that the VCR of spray when sprayed at a distance of 1.5 m is larger than that of spray from a distance of 1 m within a certain angle. However, when sprayed at a distance of 1 m, more droplets reach the collecting plate, that is, when actually operational, more liquid agrochemical will reach the pear canopy. When spraying at a distance of 1.5 m, the VCR will increase by 20–40 cm, but the number of droplets reaching the collection plate will sharply decrease, and more droplets will fall to the ground. In actual operation, the number of droplets reaching the pear canopy will be relatively small, and the utilization rate of the liquid will be greatly reduced. Considering the above VCR and CV comprehensively, the combination of angle 4 is selected as the best nozzle installation angle of the spray, that is, the installation angle of the upper nozzle is 45°, and the installation angle of the lower nozzle is 15°.

Table 3.

Vertical coverage range of fog droplets at installation angles of 1 m and 1.5 m.

3.1.2. Determination of Motor Speed

The distance between the spray and the vertical droplet distribution meter was adjusted to 1 m. The VCR of the spray at different swing-arm speeds is shown in Table 4. Table 4 shows the VCR of spray at different rotating speeds of the motor with the swing-arm structure, that is, at different swing-arm speeds. In the table, the coverage of rotating speeds 1, 2, and 3 is 2.3 m, and the rotating speed gradually increases to 4 and 5; the coverage does not change after it increases to 2.5 m. With the increase of swing-arm speed, the DDD increases within a certain range. With the increase of rotating speed, namely, the increase of swing-arm speed, CV will decrease; that is, the distribution of spray droplets will be more uniform, and the spraying effect will be better. However, as the rotational speed increases, the wear of the swing-arm mechanism increases dramatically, the service life decreases, and its stability also decreases. Taking into account factors such as DDD, CV, and wear life at various speeds, the optimal swing-arm speed was ultimately chosen as the 4th speed scheme, which is the swing-arm structure motor speed of 75 r/min.

Table 4.

Experimental parameters and variables.

3.2. Results of Swing-Arm Sprayer Performance

3.2.1. Spray Particle Size

The average particle size values of D10, D50, D90 and span for the LU-120-03 nozzle in the swing-arm and non-swing-arm mode are shown in Table 5. It can be seen that the median particle size (D50) of the droplets at different heights during spray operation does not change significantly, indicating that the droplet size is relatively uniform in the vertical direction, and is less affected by the environment, which verifies the reliability and stability of the spray mechanism. In addition, at the same position of spray operation, the particle sizes D10, D50, and D90 of the swing-arm are slightly larger than those in the non-swing-arm mode, which may be due to the change of the initial velocity of the droplets in the swing-arm mode, which will cross-collide and coalesce during the deposition process. In the swing-arm mode, the D50 of the LU-120-03 model nozzle increased from 171.84 μm to 181.07 μm (an increase of 5.4%) and from 156.09 μm to 174.96 μm (an increase of 12.1%), respectively; D10 increased from 71.62 μm to 80.65 μm and from 73.44 μm to 80.93 μm, respectively; D90 increased from 271.59 μm to 280.88 μm and from 258.06 μm to 274.54 μm, respectively. The span values decreased from 1.17 to 1.11 and from 1.20 to 1.11, respectively. The span value was 1.20 in non-swing-arm mode and 1.11 in swing-arm mode, indicating a decrease in span value. More than 50% of the droplets had a diameter of more than 150 μm, and 90% of the droplets had a diameter of less than 300 μm. This shows that the swing-arm motion optimizes the concentration of the droplet size distribution and the spray effect.

Table 5.

Particle size parameters of the LU-120-03 model nozzle.

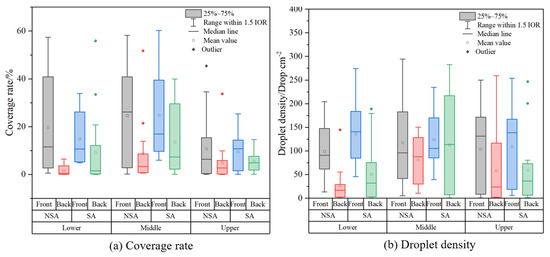

3.2.2. Coverage and Deposit

The coverage and droplet density was compared under the two modes, as shown in Figure 14. Under the same speed and spraying pressure, the movement of the swing-arm causes changes in the direction, trajectory, and initial velocity of the droplets, improving their penetration. Compared with the non-swing-arm mode, the swing-arm mode increased droplet coverage on the front of the leaf by 36.6%, on the back of the leaf by 207%, and overall by 74%. For droplet density, the swing-arm mode increased droplet density on the front of the blade by 15.1% and on the back of the blade by 33.6% compared to the non-swing-arm mode, resulting in an overall droplet density increase of 21.4%. The industry standard for droplet density is 25 droplets/cm2. The experimental results for this sprayer showed that the droplet density was higher than the standard value, which meets the requirements of plant protection operations. Therefore, the spray swing-arm mode has higher canopy droplet coverage and droplet density, and the spray effect is better.

Figure 14.

Average coverage and sedimentation density results under the two spray modes. Note: SA is swing-arm mode, NSA is non-swing-arm mode.

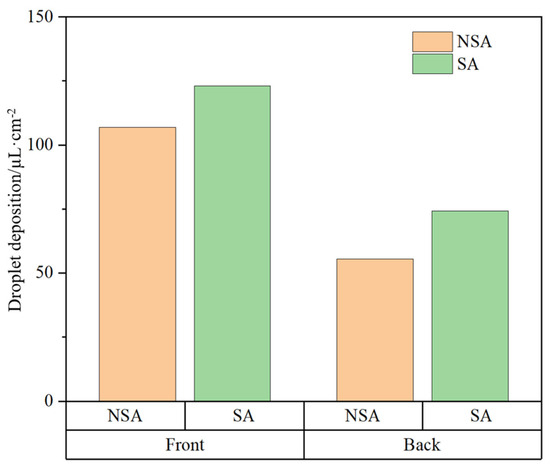

The obtained filter paper samples are processed according to different experimental groups and canopy layers. The droplet deposition amount is calculated, as shown in Figure 15. The relationship between sedimentation and absorbance is as follows:

Figure 15.

Results of average deposition under the two spray modes.

In the formula: V—the amount of droplet deposition on the surface of the filter paper per unit area, μL/cm2; Ve—volume of eluent added, mL; Fe—absorbance value of filter paper eluent; N—dilution ratio of mother liquor; Fα—absorbance value of the mother liquor; and S—area of filter paper, cm2.

4. Conclusions

Aiming at the problems of uneven spray, low target coverage, and waste of liquid agrochemicals in standardized orchard spraying, a swing-arm spray machine for orchards was developed. Through the integration of innovative structural design and intelligent control technology, the structure and application parameters of the spray were optimized by means of experiments to achieve the goal of on-demand application of pesticide in pear orchards. The main research contents and achievements are as follows:

(1) Structure design of swing-arm spray. The crawler-type walking system, spray system, and swing-arm mechanism are designed in accordance with the planting environment and operational principles. The reliability and stability of the swing-arm structure were verified through ADAMS dynamic simulation. (2) The spray system design. Through the combination of a diffuse reflection photoelectric sensor and Arduino MCU, and through the sensor delay compensation algorithm to optimize recognition accuracy, real-time detection of the pear canopy and dynamic spray control are realized. The adaptability in dense pear orchard is very high, greatly improving the utilization rate of liquid agrochemicals by 20%, reducing the waste of liquid agrochemicals, and bringing high environmental benefits. (3) Optimization of the operational parameters of the swing-arm mechanism. Through the vertical droplet distribution test, the optimal working distance of the spray was determined to be 1 m. The optimal installation angle of the sprayer was 45° for the upper layer and 15° for the lower layer, and the optimal rotational speed of the swing-arm motor was 75 r/min. At this time, the vertical coverage of the droplets was 2.5 m, and the coefficient of variation (CV) of the droplet density was reduced to 67%, which was 30% higher than in the fixed spray bar mode. (4) Particle size testing and field trials of swing-arm sprayers. The droplet size distribution of the LU-120-03 nozzle is concentrated in the ideal range of 150~300 μm for plant protection spray, and the D50 is 174.96 μm in the swing-arm mode. Compared with the non-swing-arm mode, the swing-arm movement reduces the span value to 1.11 to meet the needs of plant protection, while inhibiting span value to improve the uniformity of droplet size and optimize the spray effect. Field experiments showed that compared with the non-swing-arm mode, the swing-arm mode increased pear tree canopy droplet coverage by 74%, overall droplet density by 21.4%, and overall deposition by 23%, which verified the practicability and reliability of the spray. (5) In the future, more accurate canopy recognition can be combined with AI vision to optimize multi-terrain adaptability.

Author Contributions

Conceptualization, X.H. and H.Z.; methodology, X.H., K.Z. and Z.Y.; analysis, X.M. and Z.Y.; investigation, M.G. and Z.Y.; resources, X.H., M.G., M.G. and Z.Y.; data curation, K.Z. and Z.Y.; writing—original draft preparation, Z.Y.; writing—review and editing, X.H. and Z.Y.; visualization, Z.Y.; supervision, M.G.; project administration, X.H.; funding acquisition, X.H. All authors have read and agreed to the published version of the manuscript.

Funding

This work was supported by the 2115 talent development program of China Agricultural University (No. 2115-89052) and the earmarked fund for China Agriculture Research System (No. CARS-28).

Data Availability Statement

The original contributions presented in the study are included in the article. Further inquiries can be directed to the corresponding author.

Acknowledgments

The authors would like to thank all other staff of CCAT and CAUS, China Agricultural University, and Zhejiang Longhao Agriculture and Forestry Technology Co., Ltd. for their great contributions to this work.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Li, S.; Li, J.; Yu, S.; Wang, P.; Liu, H.; Yang, X. Anti-Drift Technology Progress of Plant Protection Applied to Orchards: A Review. Agronomy 2023, 13, 2679. [Google Scholar] [CrossRef]

- Patil, Y.M.; Patil, S.B.; Powar, R.V. A Comparative Analysis of Plant Canopy Detection Performance in a Variable-Rate Spraying System Using Deep Learning. J. Inst. Eng. (India) Ser. A 2024, 105, 487–497. [Google Scholar] [CrossRef]

- Saikumar, A.; Sahal, A.; Mansuri, S.M.; Hussain, A.; Junaid, P.M.; Nickhil, C.; Badwaik, L.S.; Kumar, S. Assessment of physicochemical attributes and variation in mass-volume of Himalayan pears: Computer vision-based modeling. J. Food Compos. Anal. 2025, 137, 106955. [Google Scholar] [CrossRef]

- Jiang, H.; Niu, C.; Liu, L.; Wang, D.; Wang, J.; Mao, W. Design and Experiment of Air Volume Control System of Orchard Multi-pipe Air Sprayer. Trans. Chin. Soc. Agric. Mach. 2020, 51, 298–307. [Google Scholar]

- Qiu, W.; Zhang, K.; Lyu, Q.; Huang, X.; Deng, Y.; Zhou, L.; Shi, Y. Design and test of goose-neck long-range air-assisted sprayer for nursery. Trans. Chin. Soc. Agric. Eng. 2024, 40, 46–53. [Google Scholar]

- Ru, Y.; Chen, X.; Liu, B.; Wang, S.; Lin, M. Optimized Design and Performance Test of Axial Flow Orchard Sprayer Air Delivery System. Trans. Chin. Soc. Agric. Mach. 2022, 53, 147–157. [Google Scholar]

- Hanif, A.S.; Han, X.; Yu, S.H. Independent Control Spraying System for UAV-Based Precise Variable Sprayer: A Review. Drones 2022, 6, 383. [Google Scholar] [CrossRef]

- Grella, M.; Gioelli, F.; Marucco, P.; Zwertvaegher, I.; Mozzanini, E.; Mylonas, N.; Nuyttens, D.; Balsari, P. Field assessment of a pulse width modulation (PWM) spray system applying different spray volumes: Duty cycle and forward speed effects on vines spray coverage. Precis. Agric. 2022, 23, 219–252. [Google Scholar] [CrossRef]

- Nasir, F.E.; Tufail, M.; Haris, M.; Iqbal, J.; Khan, S.; Khan, M.T. Precision agricultural robotic sprayer with real-time Tobacco recognition and spraying system based on deep learning. PLoS ONE 2023, 18, e0283801. [Google Scholar] [CrossRef]

- Kang, C.; He, L.; Zhu, H. Assessment of spray patterns and efficiency of an unmanned sprayer used in planar growing systems. Precis. Agric. 2024, 25, 2271–2291. [Google Scholar] [CrossRef]

- Wang, S.; Wang, W.; Lei, X.; Wang, S.; Li, X.; Norton, T. Canopy Segmentation Method for Determining the Spray Deposition Rate in Orchards. Agronomy 2022, 12, 1195. [Google Scholar] [CrossRef]

- Zhu, Y.; Guo, Q.; Tang, Y.; Zhu, X.; He, Y.; Huang, H.; Luo, S. CFD simulation and measurement of the downwash airflow of a quadrotor plant protection UAV during operation. Comput. Electron. Agric. 2022, 201, 107286. [Google Scholar] [CrossRef]

- Zhang, J.; Chen, Q.; Zhou, H.; Zhang, C.; Jiang, X.; Lv, X. CFD analysis and RSM-based design optimization of axial air-assisted sprayer deflectors for orchards. Crop. Prot. 2024, 184, 106794. [Google Scholar] [CrossRef]

- Sharda, A.; Karkee, M.; Hoheisel, G.; Zhang, Q.; Mangus, D. Design and Evaluation of Solid Set Canopy Delivery System for Spray Application in High-density Apple Orchards. Appl. Eng. Agric. 2019, 35, 751–757. [Google Scholar] [CrossRef]

- Wang, S.; Song, J.; Qi, P.; Yuan, C.; Wu, H.; Zhang, L.; Liu, W.; Liu, Y.; He, X. Design and development of orchard autonomous navigation spray system. Front. Plant Sci. 2022, 13, 960686. [Google Scholar] [CrossRef]

- Wang, Y.; Zhang, H.; Fu, M.; Fu, W.; Wang, J.; Zhang, B.; Fu, Y.; Zeng, T. Design and experimental evaluation of a variable pesticide application control system for the air—assisted rubber tree powder sprayer. Pest. Manag. Sci. 2024, 80, 5186–5199. [Google Scholar] [CrossRef]

- Wen, S.; Zhang, Q.; Deng, J.; Lan, Y.; Yin, X.; Shan, J. Design and Experiment of a Variable Spray System for Unmanned Aerial Vehicles Based on PID and PWM Control. Appl. Sci. 2018, 8, 2482. [Google Scholar] [CrossRef]

- Ou, M.; Zhang, J.; Du, W.; Wu, M.; Gao, T.; Jia, W.; Dong, X.; Zhang, T.; Ding, S. Design and experimental research of air-assisted nozzle for pesticide application in orchard. Front. Plant Sci. 2024, 15, 1405530. [Google Scholar] [CrossRef]

- Yue, B.; Zhang, Z.; Zhang, W.; Luo, X.; Zhang, G.; Huang, H.; Wu, X.; Bao, K.; Peng, M. Design of an Automatic Navigation and Operation System for a Crawler-Based Orchard Sprayer Using GNSS Positioning. Agronomy 2024, 14, 271. [Google Scholar] [CrossRef]

- Asaei, H.; Jafari, A.; Loghavi, M. Development and evaluation of a targeted orchard sprayer using machine vision technology. J. Agric. Mach. 2016, 6, 362–375. [Google Scholar]

- Salas, B.; Salcedo, R.; Garcia-Ruiz, F. Design, implementation and validation of a sensor-based precise airblast sprayer to improve pesticide applications in orchards. Precis. Agric. 2023, 25, 865–888. [Google Scholar] [CrossRef]

- Liu, H.; Du, Z.; Shen, Y.; Du, W.; Zhang, X. Development and evaluation of an intelligent multivariable spraying robot for orchards and nurseries. Comput. Electron. Agric. 2024, 222, 109056. [Google Scholar] [CrossRef]

- Wei, Z.; Zhu, H.; Zhang, Z.; Salcedo, R.; Duan, D. Droplet Size Spectrum, Activation Pressure, and Flow Rate Discharged from PWM Flat-Fan Nozzles. Trans. ASABE 2021, 64, 313–325. [Google Scholar] [CrossRef]

- Shen, Y.; Zhu, H.; Liu, H.; Chen, Y.; Ozkan, E. Development of a Laser-Guided, Embedded-Computer-Controlled, Air-Assisted Precision Sprayer. Trans. ASABE 2017, 60, 1827–1838. [Google Scholar] [CrossRef]

- Siefen, N.; McCormick, R.J.; Vogel, A.M.; Biegert, K. Effects of laser scanner quality and tractor speed to characterise apple tree canopies. Smart Agric. Technol. 2023, 4, 100173. [Google Scholar] [CrossRef]

- Dai, S.; Ou, M.; Du, W.; Yang, X.; Dong, X.; Jiang, L.; Zhang, T.; Ding, S.; Jia, W. Effects of sprayer speed, spray distance, and nozzle arrangement angle on low-flow air-assisted spray deposition. Front. Plant Sci. 2023, 14, 1184244. [Google Scholar] [CrossRef] [PubMed]

- Yan, C.; Xu, L.; Ma, S.; Tan, H.; Shen, C.; Ma, J.; Zhou, H. Enhancing spray deposition in grape canopies through the development of new prototype air-disturbance sprayers. Biosyst. Eng. 2024, 244, 1–15. [Google Scholar] [CrossRef]

- Salcedo, R.; Zhu, H.; Zhang, Z.; Wei, Z.; Chen, L.; Ozkan, E.; Falchieri, D. Foliar deposition and coverage on young apple trees with PWM-controlled spray systems. Electron. Agric. 2020, 178, 105794. [Google Scholar] [CrossRef]

- Jiang, S.; Li, W.; Yang, S.; Zheng, Y.; Tan, Y.; Xu, J. Factors Affecting Droplet Loss behind Canopies with Air-Assisted Sprayers Used for Fruit Trees. Agronomy 2023, 13, 375. [Google Scholar] [CrossRef]

- Li, T.; Qi, P.; Wang, Z.; Xu, S.; Huang, Z.; Han, L.; He, X. Evaluation of the Effects of Airflow Distribution Patterns on Deposit Coverage and Spray Penetration in Multi-Unit Air-Assisted Sprayer. Agronomy 2022, 12, 944. [Google Scholar] [CrossRef]

- Michael, C.; Gil, E.; Gallart, M.; Stavrinides, M.C. Influence of Spray Technology and Application Rate on Leaf Deposit and Ground Losses in Mountain Viticulture. Agriculture 2020, 10, 615. [Google Scholar] [CrossRef]

- Wei, Z.; Xue, X.; Salcedo, R.; Zhang, Z.; Gil, E.; Sun, Y.; LI, Q.; Shen, J.; He, Q.; Dou, Q.; et al. Key Technologies for an Orchard Variable-Rate Sprayer: Current Status and Future Prospects. Agronomy 2022, 13, 59. [Google Scholar] [CrossRef]

- Sun, D.; Liu, W.; Li, Z.; Zhan, X.; Dai, Q.; Xue, X.; Song, S. Numerical Experiment and Optimized Design of Pipeline Spraying On-Line Pesticide Mixing Apparatus Based on CFD Orthogonal Experiment. Agronomy 2022, 12, 1059. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).