Abstract

Maize, as a critical crop for China’s food security, is constantly challenged by weed infestations and environmental risks associated with herbicide overuse. Improving herbicide utilization efficiency through equipment optimization and intelligent control during spraying has become an essential strategy for weed management in Chinese maize fields. However, most current sprayers fail to achieve coordinated control of spray volume and nozzle parameters, and their performance is typically evaluated using single indices, such as the coefficient of variation (CV) for spray uniformity and deposition density. In this study, a split-split-plot experiment was conducted in 2022–2023 to assess the feasibility of herbicide reduction using intelligent variable-rate boom sprayers in summer maize fields on the North China Plain (NCP). The key variables included spray volume (225 vs. 180 L/ha), nozzle type (AI11003VS/LECHLER11003 in 2022; TTI11004/LECHLER11004 in 2023), and herbicide dose (recommended, −15%, and −30% reduction). Results showed that the coefficients of variation for droplet coverage and density remained below 12% for all treatments (n = 4), indicating stable spray performance. A higher spray volume (225 L/ha) significantly improved deposition uniformity (p < 0.01). In 2022, herbicide input could be reduced by 15–30% while maintaining efficacy above 90% when applied at the 3–4 leaf stage of dominant weeds. However, in 2023, efficacy dropped to 72.67% when the herbicide was applied at a 30% reduced dose with 180 L/ha and when dominant weeds had reached the 5–6 leaf stage or higher, indicating an agronomic risk. Reduced herbicide input decreased maize injury by 47–53%. Only the 30% reduced-dose treatment significantly increased maize yield by 3.05% in 2022 and 2.62% in 2023 compared to the control (both p < 0.05). Spray volume significantly influenced droplet deposition and weed control efficacy; thus, caution is warranted regarding herbicide reduction for later weed growth stages. This study demonstrates that real-time variable-rate boom sprayers, optimized for spray volume and nozzle type, can reduce herbicide use without compromising weed control efficacy or maize yield, providing both theoretical support and practical guidance for sustainable herbicide management in summer maize fields on the NCP.

1. Introduction

As one of the world’s most important staple crops, maize has the highest production yield among all cereals in China and plays a crucial role in ensuring the country’s food security [1,2]. Weeds pose a major threat to maize growth due to their early germination, rapid development, and competition for water, nutrients, and space; they can also serve as vectors for pests and diseases [3]. Effective weed control is therefore essential in maize production. Currently, chemical herbicides remain the most economical, convenient, and effective method for weed control. However, improper or excessive herbicide use often results in reduced efficacy, the development of weed resistance, crop injury, herbicide residues, environmental pollution, and poisoning risks. Consequently, scientific weed management and the promotion of reduced, efficient, and safe herbicide application are urgent issues that must be addressed.

Pesticides, crop protection equipment, and application techniques are the three critical factors influencing the effectiveness of pesticide application, pest control efficiency, and pesticide utilization [4]. In China, the average annual pesticide application intensity reached 10.95 kg/ha in 2013, approximately 2.5 times the global average. Over the past decade, the per-hectare application rate has increased by about 30%, reflecting a long-term reliance on chemical pest control in Chinese agriculture [5,6]. Nevertheless, the country’s crop protection machinery and application technologies remain relatively underdeveloped [7]. By 2021, the utilization rate of pesticides for China’s three major staple crops—rice, corn, and wheat—stood at 41.8% [8], indicating a significant gap of 15% to 25% compared to international advanced standards [9]. The issue of pesticide utilization rate in agriculture has been debated: critics argue that low utilization not only hinders effective pest control but also results in environmental pollution and residues. On the other hand, increased mechanization in plant protection has driven significant progress, with a growing number of high-efficiency plant protection machines—such as self-propelled boom sprayers, air-assisted orchard sprayers, and unmanned aerial vehicles (UAVs)—being adopted. The performance of plant protection machinery continues to improve, and the area under mechanized operations is expanding, providing technological support for pesticide reduction. These advances have greatly contributed to improved pesticide utilization and the implementation of reduction strategies, supporting agricultural disaster prevention and high yields [3].

Despite these developments, China’s plant protection machinery and application technologies still face challenges such as limited product diversification, delayed technology adoption, low specialization, insufficient integration of pesticide and equipment research, and poor adaptability of spray equipment for scientific pesticide application, especially in crop pest control [10,11]. There is a pressing need to upgrade pesticide machinery, enhance operational safety, improve the adhesion of pesticide solutions to targets, reduce spray drift, and increase application precision, all of which are key requirements for the advancement of precision agriculture [12]. The exploration and development of precision application technologies suited to national conditions remain ongoing processes [13].

In recent years, China has made significant progress in precision variable-rate spray technology and equipment. Research efforts have primarily focused on precision spray control, the optimization of intelligent spraying machinery, applications of plant protection UAVs, and anti-drift technologies. In-depth studies on variable-rate spraying control systems, intelligent algorithms, and prescription map-based spraying methods have enhanced spraying accuracy, improved pesticide utilization efficiency, and reduced environmental pollution. Concurrently, China has developed specialized equipment such as air-assisted sprayers, air-curtain boom sprayers, and recycling sprayers tailored to different operational scenarios, which optimize spray uniformity, mitigate liquid drift, and improve operational efficiency [6]. The application of plant protection UAVs in agricultural production has expanded considerably, with related research centering on droplet size control, drift prediction, and precision detection technologies to further enhance spraying accuracy and efficacy [14]. Additionally, recent studies have emphasized the environmental impacts of pesticide drift [15]. Overall, Chinese research in precision variable-rate spraying technology and equipment is progressing toward more intelligent, efficient, and eco-friendly solutions.

By comparison, international research and application of precision spraying technology began earlier and has achieved broader commercial adoption. In Europe and the United States, precision agriculture has been studied for decades, resulting in notable advancements in technology integration and optimization [16]. Sensor-based intelligent spraying systems—utilizing optical, ultrasonic, and meteorological sensors to monitor crop health, soil moisture, and climate conditions in real time—have been widely implemented in these regions. These systems dynamically adjust spray volume and targeting, effectively minimizing pesticide waste [17]. Research in Europe and the U.S. places a strong emphasis on innovation in spray technology, advancing system integration, data analytics, and intelligent decision-making [16]. For example, many American agricultural enterprises have combined precision spraying systems with autonomous driving technologies to achieve fully automated and intelligent spraying operations, significantly enhancing agricultural productivity and sustainability [18].

The intelligent precision variable boom sprayer used in this study was retrofitted from conventional pesticide application machinery by equipping it with a real-time monitoring system for critical operating parameters such as precise control, enabling automatic sensor signal acquisition through a variable-rate application system and achieving variable pesticide spraying via information fusion. The development of intelligent precision variable sprayers and high-efficiency pesticide application technologies is key to reducing pesticide usage and increasing utilization efficiency. Although intelligent precision variable boom sprayers (e.g., in wheat fields [19]) have demonstrated potential for herbicide reduction, significant research gaps remain regarding their adaptability in maize fields.

Excessive pesticide application (particularly of herbicides) in maize fields has become a major challenge threatening agricultural sustainability. The high canopy density in maize results in poor pesticide penetration and low deposition rates under conventional uniform spraying, which often compels farmers to increase application rates to ensure effectiveness. This leads to a vicious cycle of excessive application → environmental pollution → herbicide-resistant weed proliferation. Existing pesticide reduction strategies for maize fields primarily focus on equipment optimization and intelligent control. In addition, integrated weed management (IWM) practices—such as crop rotation, mechanical weeding, and cultural control—also play an important role in reducing pesticide reliance.

During pesticide application, spray quality largely determines efficacy, with critical parameters such as spray volume and nozzle type directly affecting performance. However, current research mainly investigates single parameters (e.g., spray volume or general-purpose nozzle selection) and lacks in-depth exploration of optimized spray volume–nozzle type combinations. Furthermore, existing evaluation metrics for pesticide applications in maize fields primarily focus on spray uniformity, with limited research addressing herbicide reduction together with maize safety (e.g., phytotoxicity risks).

Therefore, the innovation of this study lies in its focus on optimizing spray volume–nozzle combinations for intelligent precision variable boom sprayers, while simultaneously investigating the relationship between herbicide reduction and phytotoxicity risk. In the present study, the maize varieties Shengrui 999 (2022) and Hanyu 66 (2023), both possessing moderate tolerance to common maize herbicides, were used. By addressing these issues, this research aims to enhance sprayer performance, improve weed control efficacy in maize fields, reduce herbicide inputs, mitigate environmental pollution, and evaluate the feasibility of herbicide reduction with respect to weed control and crop safety. The findings will provide important references for the practical application and technological optimization of intelligent sprayers in maize cultivation.

2. Materials and Methods

2.1. Trial Location

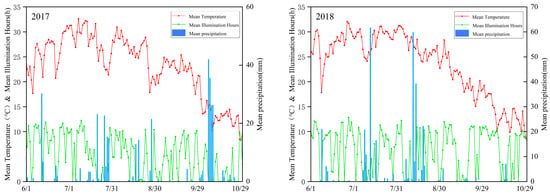

The experimental site in 2022 was located in Nanyaojia Village, Zhaozhou Town, Zhaoxian County, Shijiazhuang City, Hebei Province (37°43.358′ N, 114°48.643′ E). In 2023, the experiment was conducted in Tingzhutou Village, also in Zhaozhou Town, Zhaoxian County, Shijiazhuang City, Hebei Province (37°43.696′ N, 114°48.150′ E). Prior to the study, the experimental field had been continuously planted with maize for three years using conventional tillage and standard fertilization practices. The temperature, precipitation, and sunshine duration during the maize growing season are presented in Figure 1. The soil type at the experimental site is sandy loam, with a pH of 8.17, available phosphorus content of 19.45 mg/kg, available potassium content of 180 mg/kg, and total nitrogen content of 14.97 g/kg. Soil particle size analysis revealed that clay accounted for 3.0%, silt for 25.6%, and sand for 71.5% (data provided by the College of Resources and Environmental Sciences, China Agricultural University).

Figure 1.

Meteorological data for the experimental sites in 2022 and 2023.

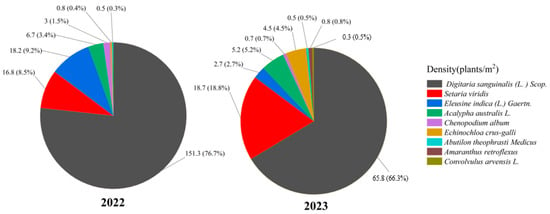

In 2022, the maize variety used was Shengrui 999 (Zhengzhou Shengruiyuan Agricultural Technology Development Co., Ltd., Henan Province, China), planted at a spacing of 60 cm × 30 cm, with herbicide application at the 4–5 leaf stage. In 2023, the variety was Hanyu 66 (Handan Academy of Agricultural Sciences, Hebei Province and Hebei Zhongxin Seed Technology Co., Ltd., Hebei Province, China), planted at 55 cm × 27 cm, with herbicide application at the 5–6 leaf stage. The composition of the weed community in both years is shown in Figure 2. Digitaria sanguinalis was the dominant species, followed by Eleusine indica and Setaria viridis, with these three species accounting for more than 94% of the total weed population. In 2022, at the time of herbicide application, Digitaria sanguinalis and Setaria viridis were both at the 3–4 leaf stage, while Eleusine indica was at the 2–3 leaf stage. In 2023, Digitaria sanguinalis and Setaria viridis were both at the 5–6 leaf stage, with some individuals exhibiting 2–3 tillers at the time of herbicide application.

Figure 2.

Weed community structure at the experimental site.

2.2. Application Machinery

The intelligent precision variable boom sprayer (Shandong Province, China) used in this trial was developed by the National Agricultural Intelligent Equipment Technology Research Center (NERCITA). This advanced plant protection machine integrates electronic control technology, a GPS positioning system, and an electronic hydraulic control system, and is equipped with pressure sensors, flow sensors, and a vehicle speed detection system. These components enable precise synchronization between the sprayer’s forward speed and spray rate, ensuring accurate application of the target rates. The sprayer features a 13 m wide boom with 26 nozzles spaced at 0.5 m intervals. Spray pressure was adjustable between 2.0 and 5.0 MPa, and the vehicle speed was maintained between 5 and 8 km/h during spraying operations.

In both years, herbicide application was carried out on 7 July, between 07:00 a.m. and 10:00 a.m. In 2022, the wind speed during spraying was 1–2 m·s−1, mainly from the southeast, with relative humidity ranging from 30% to 40% and temperatures between 23 °C and 30 °C. In 2023, wind speed ranged from 1.5 m·s−1 to 3 m·s−1, predominantly from the south, with relative humidity between 30% and 36%, and temperatures from 21 °C to 29 °C. The spraying site is shown in Figure 3.

Figure 3.

Application operation site: (a) application operation site in 2022; (b) application operation site in 2023.

2.3. Experimental Herbicide

The herbicide used in 2022 was a 30% Cyanazine + Atrazine suspension concentrate (SC), with each active ingredient accounting for 15%. It was supplied by Henan Lübao Technology Development Co., Ltd. (Henan Province, China), and the recommended application rate was 3 L/ha (formulation). In 2023, the herbicide applied was a 55% Pyrazosulfuron-ethyl + Atrazine + Ethalfluralin dispersible suspension concentrate (SC), containing 3% Pyrazosulfuron-ethyl, 26% Atrazine, and 26% Ethalfluralin. This product was supplied by Liaoning Jintian Technology Co., Ltd. (Liaoning Province, China), with a recommended application rate of 2 L/ha (formulation).

2.4. Experimental Design

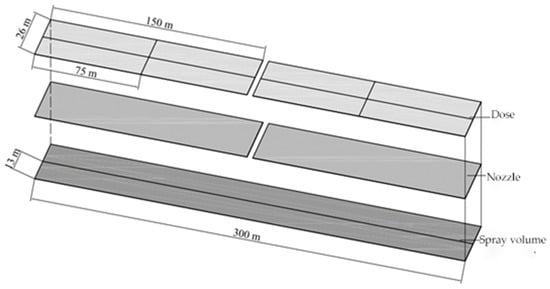

The field experiment employed a three-factor split-split-plot design. The main plot factor was spray volume (Factor A), with two levels: A1—225 L/ha and A2—180 L/ha. The subplot factor was nozzle type (Factor B), with two levels: in 2022, B1—AI11003VS (TeeJet Technologies, Springfield, IL, USA)) and B2—LECHLER11003 (TeeJet Technologies, Springfield, IL, USA); in 2023, B1—TTI11004 (Lechler GmbH, Metzingen, Germany) and B2—LECHLER11004 (Lechler GmbH, Metzingen, Germany). The sub-subplot factor was herbicide dose (Factor C), set at three levels in 2022: C1—recommended dose, C2—15% reduction, and C3—30% reduction; and two levels in 2023: C1—recommended dose and C3—30% reduction. According to ISO standard 10625:2018, the nominal flow rates for the 03 (red) and 04 (blue) nozzle types at an operating pressure of 0.3 MPa are approximately 1.19 L/min and 1.59 L/min, respectively. Prior to field application, all nozzles were pre-calibrated by collecting the spray output for one minute at the target pressure (0.3 MPa) and measuring the discharge volume. Only nozzles with flow rates within ±5% of the nominal value were used; any exceeding this deviation were replaced to ensure application accuracy.

The experiment utilized a large block design, with each unique treatment combination assigned to a separate block. There were 12 treatment combinations (2 × 2 × 3) in 2022 and 8 treatment combinations (2 × 2 × 2, see Figure 4) in 2023, with each block measuring 75 m × 13 m = 975 m2. Within each block, one 5 m × 5 m (25 m2) plot was randomly selected as a weedy control area and covered with plastic sheeting to prevent herbicide exposure. Similarly, four 5 m × 5 m plots were randomly selected in each block as weed-free controls. Buffer rows of maize (or untreated borders) were present between plots and blocks to minimize edge effects from drift or spray overlap.

Figure 4.

Schematic diagram of spraying volume, nozzle type, and herbicide dose three-factor split-split-plot experimental design.

All field applications were carried out under wind speeds below 2 m/s, measured at boom height by a handheld anemometer before each spraying event. Spraying took place in the early morning or late afternoon to avoid wind gusts and reduce spray drift risk. Additionally, the boom height was maintained at 50 cm above the crop canopy throughout the experiment to minimize off-target movement.

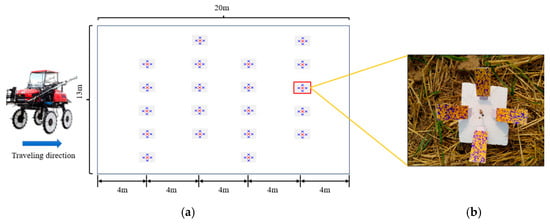

2.5. Measurement of Droplet Deposition

A 20 m × 13 m rectangular area was randomly selected at the center of each application zone along the direction of the sprayer’s travel. Within this area, four rows of droplet collection devices were arranged perpendicular to the direction of sprayer movement (i.e., parallel to the spray boom), with five collection devices placed in each row. Spacing was maintained between adjacent rows to minimize interference. The layout and setup of the droplet collection devices are shown in Figure 5.

Figure 5.

Deposition test experimental setup: (a) sampling point layout; (b) droplet testing apparatus.

After the spray application, the droplet collection devices were allowed to dry so that spray droplets could adhere fully, after which the water-sensitive papers were collected and returned to the laboratory for analysis. The droplet traces on the water-sensitive papers were scanned and analyzed using iDASPro (Version 1.0), a droplet deposition analysis software developed by NERCITA. Droplet coverage and deposition data were used as key indicators for evaluating deposition performance. The average coverage and average deposition values were calculated to analyze the effects of spray volume (SV) and nozzle type (NT) on droplet deposition. Additionally, the coefficient of variation (CV) of the coverage and deposition measurements was calculated to assess the impact of different SV and NT on spray uniformity between nozzles at various positions along the spray boom. The calculation formula for CV is shown in Equation (1):

where S is the standard error of the droplet deposition or droplet coverage data, and is the mean value of the droplet deposition or droplet coverage data.

2.6. Evaluation of Weed Control Efficacy

Weed control efficacy was assessed four weeks after application in both years for different spray treatment combinations of the intelligent sprayer. Each large treatment block was divided into four equal sections along its length, serving as four survey subplots. Within each subplot, four sampling quadrats (0.5 m × 0.5 m = 0.25 m2 each) were randomly selected along the diagonal direction as repetitions. The aboveground biomass of all weeds within each quadrat was clipped, and the fresh weight of each weed species was recorded separately to calculate fresh weight reduction. The calculation formula is shown in Equation (2):

where FWCK is the fresh weight of weeds in the weedy control, and FWT is the fresh weight of weeds in the treated plot.

2.7. Evaluation of Corn Safety and Yield

One week after treatment application in 2022, and two weeks after treatment in 2023, the effects of each pesticide treatment combination on maize growth were assessed. Each treatment plot was divided into four equal subplots along its longer side, from which two central rows of maize were randomly selected for evaluation. Visual inspections for phytotoxicity symptoms—such as leaf discoloration or wilting—were conducted. The severity of maize injury was rated using a 0–9 scale according to the guidelines of the European Weed Research Society (EWRS), where 0 indicates no injury and 9 represents complete plant death. All visual assessments were performed by a single experienced observer to ensure consistency and minimize inter-observer variation.

The number of affected maize plants within a 25 m row was also recorded.

At harvest (both experimental years had a harvest date of October 6), each treatment plot was again divided into four equal subplots along its longer side. In each subplot, two central maize rows were randomly selected, and 20 ears of maize were randomly harvested from these rows. The ears were air-dried, then threshed and weighed (with a moisture content of approximately 11.8% for both years), and maize yield was estimated in tons per hectare (t/ha).

2.8. Data Analysis

Data were organized using Excel 2021, and three-way analysis of variance (ANOVA) was conducted with SAS 8.0 to evaluate the effects of different treatment combinations on weed control efficacy and maize safety—including seedling safety, yield, and yield components. Post hoc comparisons were performed using the least significant difference (LSD) method. Two-way ANOVA was applied to assess the effects of treatment combinations on droplet deposition. Statistical significance was determined at the α = 0.05 level. Due to a significant interaction between year and herbicide treatment, data from each year were analyzed separately.

3. Results

3.1. Droplet Deposition

As shown in Table 1, spray volume had a highly significant effect on both droplet deposition and droplet coverage (p < 0.01), whereas nozzle type did not significantly affect either parameter (p > 0.05). Moreover, the interaction between spray volume and nozzle type exhibited a highly significant effect on droplet coverage (p < 0.01). These results further confirm that spray volume is a critical factor influencing droplet deposition.

Table 1.

Effects of spray volume and nozzle type on droplet deposition.

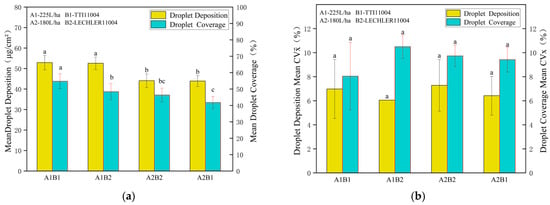

Results for droplet deposition under the interaction of spray volume and nozzle type (Figure 6a) indicate that, regardless of nozzle type, both droplet deposition and coverage were higher at a spray volume of 225 L/ha than at 180 L/ha. Furthermore, under the high spray volume condition (225 L/ha), the coverage with the TTI11004 nozzle was significantly lower than that with the LECHLER11004 nozzle, while at the low spray volume (180 L/ha), there was no significant difference in coverage between the two nozzle types. This suggests that under higher spray volume conditions, nozzle type has a more pronounced effect on coverage, whereas its impact is relatively minor under lower spray volume conditions.

Figure 6.

The droplet deposition and coverage under different combinations of spray volume and nozzle type (left panel), and the average coefficient of variation for deposition and coverage (right panel): (a) droplet deposition and coverage; (b) average coefficient of variation for droplet deposition and coverage; different letters indicate statistically significant differences at the p < 0.05 level, as determined by Duncan’s multiple range test. Error bars represent the standard deviation of the mean, calculated from three independent replicates for each treatment.

Analysis of the average coefficient of variation for droplet deposition and coverage under the various combinations of spray volume and nozzle type (Figure 6b) shows that the coefficient of variation for both parameters was less than 12% across all four treatment combinations, with no significant differences observed. This indicates good droplet deposition uniformity during spraying. Notably, under the higher spray volume (225 L/ha) condition, deposition uniformity was relatively greater, as reflected by the lower mean coefficient of variation for droplet deposition.

3.2. Weed Control Efficacy

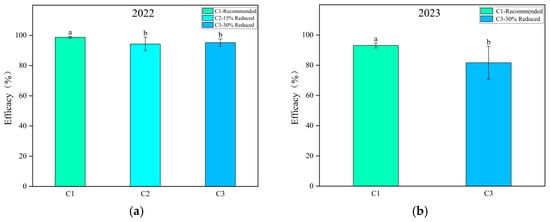

Herbicide dose was the primary factor influencing weed control efficacy, as evidenced by significant effects in both years (2022: p = 0.002; 2023: p < 0.01, Table 2). In both years’ weed control efficacy trials, reducing the application dose with the intelligent sprayer led to a significant decrease in efficacy compared to the recommended dose (Table 3). However, no significant difference in weed control efficacy was observed between the 15% and 30% reduced rates (Figure 7a). Notably, in 2022, both the 15% and 30% reduced application rates still achieved more than 90% efficacy (Figure 7a), whereas in 2023, these reduced rates resulted in significantly lower efficacy (Figure 7b).

Table 2.

Effects of spray volume, nozzle type, and herbicide dose on weed control efficacy.

Table 3.

The effect of spray volume, nozzle type, and herbicide dosage on fresh biomass efficacy in 2022 and 2023.

Figure 7.

Effect of herbicide dosage on fresh biomass efficacy in 2022 and 2023: (a) effect of herbicide dosage on fresh biomass efficacy in 2022 (n = 48); (b) effect of herbicide dosage on fresh biomass efficacy in 2023 (n = 32). (Different letters indicate statistically significant differences at the p < 0.05 level, as determined by Duncan’s multiple range test.).

Nozzle type did not significantly affect weed control efficacy, but the interaction between spray volume and herbicide dose played a pivotal role. In both 2022 and 2023, the spray volume × dose interaction had a highly significant effect on weed control efficacy (2022: p = 0.003; 2023: p < 0.01, Table 2).

3.3. Maize Safety

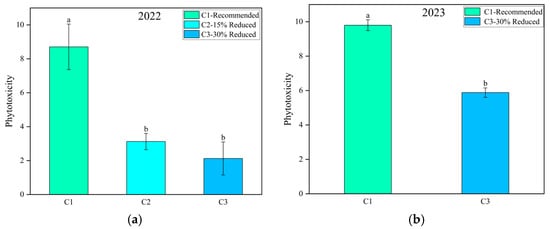

Three-way analysis of variance showed that herbicide dosage is the main factor affecting herbicide phytotoxicity in summer maize (p < 0.001 for both 2022 and 2023, Table 4), while spray volume, nozzle type, and their interactions had no significant effect on herbicide phytotoxicity in summer maize (p > 0.05). In the herbicide phytotoxicity experiments over the two years, the recommended herbicide dosage applied by the intelligent spraying machine caused significantly higher herbicide phytotoxicity in summer maize compared to the 15% and 30% reduced dosages (Figure 8). No significant difference in maize phytotoxicity was observed among the four treatments at the recommended dosage in both 2022 and 2023; similarly, no significant difference in maize phytotoxicity was observed among the four treatments at the 15% and 30% reduced dosages.

Table 4.

Three-way analysis of variance (ANOVA) of the effects of spray volume, nozzle type, and herbicide dosage on phytotoxicity in summer maize in 2022 and 2023.

Figure 8.

Effect of herbicide dosage on phytotoxicity in summer maize in 2022 and 2023: (a) phytotoxicity in summer maize in 2022; (b) phytotoxicity in summer maize in 2023. (Different letters indicate statistically significant differences at the p < 0.05 level, as determined by Duncan’s multiple range test.).

In 2022, the interaction between spray volume and herbicide dosage significantly affected maize phytotoxicity, whereas in 2023, the interaction between the two factors was not significant (Table 4).

3.4. Maize Yield

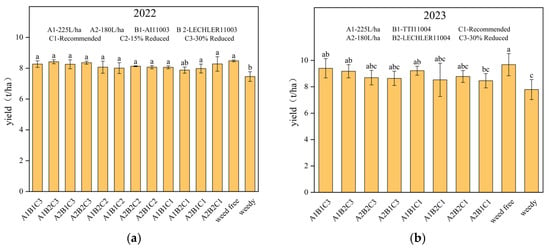

The maize yield data for the two years show that the blank control group (weedy) had significantly lower maize yield than the manual weeding group (weed-free), with a decrease of 12% in 2022 and 19.52% in 2023, respectively (Figure 9). Under both the recommended herbicide dose and reduced application treatments (15% and 30% reduction), maize yield was significantly higher than in the blank control group, but there was no significant difference compared to the manual weeding group (p > 0.05, Table 5). The effects of spray volume, nozzle type, and their interactions on maize yield were not significant (p > 0.05, Table 5).

Figure 9.

Effect of spray volume, nozzle type, and herbicide dosage on maize yield in summer maize in 2022 and 2023: (a) maize yield in summer maize in 2022; (b) maize yield in summer maize in 2023. (Different letters indicate statistically significant differences at the p < 0.05 level, as determined by Duncan’s multiple range test.).

Table 5.

Three-way analysis of variance (ANOVA) of the effects of spray volume, nozzle type, and herbicide dosage on yield in summer maize in 2022 and 2023.

In 2022, herbicide dose significantly affected maize yield (p < 0.05). Maize yield under both the recommended dose and reduced application treatments was significantly higher than in the blank control group, with no significant difference compared to the manual weeding group. Furthermore, no significant difference in yield was found between the 12 treatment groups and the manual weeding group.

In 2023, the significant effect of herbicide dose on maize yield disappeared (p > 0.05). At the same time, the manual weeding group had significantly higher yield than the blank control group and the A2B2C1 treatment (spray volume 180 L/ha, LICHENG11004 VP nozzle, recommended dose), with no significant difference compared to other treatments (Figure 9b), and there were no significant yield differences among the eight treatment groups.

Further analysis of the effect of herbicide dose on maize yield showed that in 2022, maize yield under both the recommended dose and reduced application treatments was significantly higher than in the blank control group, but there was no significant difference between the different doses. In 2023, no significant difference in yield was found between the recommended dose (C1) and the 30% reduced dose (C3), but both were also significantly higher than that of the weedy treatment.

4. Discussion

This study systematically evaluated the application potential of intelligently controlled variable-rate boom sprayers for herbicide reduction in summer maize fields. The equipment demonstrated stable droplet deposition performance across differing spray volumes (225 L/ha and 180 L/ha) and nozzle types, with average coefficients of variation (CV) for both deposition density and coverage remaining below 12%. Notably, higher spray volumes (225 L/ha) significantly enhanced spray quality compared to the lower volume (180 L/ha), a result consistent with previous research on precision spraying systems [20,21].

As expected, nozzle type had no significant effect on fresh weight-based weed control efficacy, while herbicide dosage showed a positive correlation with efficacy. Across two years of field trials, reduced herbicide doses led to decreased weed control efficacy compared to the recommended rates. In 2022, when weeds were at the 3–4 leaf stage, efficacy remained above 90% even with reduced doses. However, in 2023, when weeds were older (5–6 leaf stage) and some had begun to tiller, control efficacy dropped below 80%. The lowest efficacy (72.67%) was observed in 2023 under the 180 L/ha spray volume with a 30% dose reduction, which falls below the generally accepted agronomic safety threshold and presents a significant practical risk. These results align with previous findings that greater weed age substantially reduces control efficacy [22,23]. Further analysis revealed that spray volume had limited influence during the early weed growth stage (3–4 leaves), but became critical for controlling older weeds (5–6 leaves), in agreement with existing literature [24,25,26,27,28].

Regarding maize safety, herbicide dosage was the principal factor affecting phytotoxicity within 1–2 weeks after application. Dose reductions of 15–30% notably decreased crop injury rates compared to the standard rate, lowering phytotoxicity by 75.54% in 2022 and by 40% in 2023. Both spray volume and nozzle type had minimal effects on maize phytotoxicity at equivalent dosages, reinforcing that dosage selection is key.

Yield analysis validated the yield-protective benefits of weed management. Herbicide-treated plots yielded significantly more than untreated controls (p < 0.01), consistent with prior studies [29,30,31]. Untreated plots experienced average yield losses of 12.02% in 2022 and 19.52% in 2023. Both recommended and reduced-dose treatments (15–30% reductions) outperformed controls, and interestingly, yield increases were observed under reduced-dose regimes: +0.25% (15% reduction) and +3.05% (30% reduction) in 2022; +2.62% (30% reduction) in 2023. This demonstrates that precision sprayers can facilitate herbicide reduction while sustaining high yields. No significant effects of spray volume or nozzle type on maize yield were detected.

The significant effect of herbicide dosage on maize yield may be mediated by crop growth stage and environmental conditions. In 2022, dosage significantly impacted yield, possibly because the maize was younger (4–5 leaf stage) and thus more sensitive. In 2023, with maize at the 6–7 leaf stage, increased crop resilience may have lessened the impact of dosage [32,33,34,35]. Meteorological data (Figure 1) showed similar average daily temperature and sunshine duration for both years, but a notable difference in rainfall: 165.02 mm in 2022 versus 283.83 mm in 2023 (from application to harvest). The higher rainfall in 2023 may have promoted yield recovery [36,37,38,39], mitigating the adverse effect of herbicide phytotoxicity.

This study was conducted in flat, sandy loam summer maize fields on the North China Plain, and thus, its applicability to sloped terrains and other regions requires further validation. The optimal herbicide application window also needs to be verified through long-term, site-specific trials under changing climatic conditions. Additionally, efficacy and injury assessments in this study were partly based on visual observation. Future research should incorporate multi-sensor data (e.g., NDVI, thermal, or hyperspectral imaging) and machine learning algorithms (such as neural networks, SVMs, or decision trees) to improve the accuracy and automation of intelligent spraying system evaluation.

5. Conclusions

Based on a two-year field study, this research elucidated the potential of intelligent precision variable-rate boom sprayers for reducing herbicide use in summer maize fields. The findings demonstrated that the equipment maintained stable spraying performance at both 225 L/ha and 180 L/ha spray volumes, with average coefficients of variation (CV) for droplet deposition and coverage below 12%. Nozzle type did not significantly impact spray uniformity. Weed control efficacy under 15–30% herbicide reduction was closely related to weed age and density. When weeds were at early growth stages (3–4 leaves) and low density, reduced-dose treatments achieved control efficacies above 90%. However, when weeds were older (5–6 leaves) and denser, reduced herbicide application at lower spray volume (180 L/ha) led to a notable decrease in control efficacy (minimum: 72.67%), indicating the risk of inadequate control.

Maize safety assessments revealed that reduced-dose treatments resulted in significantly lower herbicide-induced phytotoxicity—by 47% ± 3.02% for the 15% reduction and 53% ± 4.33% for the 30% reduction (p < 0.001)—compared to the recommended rate. Specifically, the average phytotoxicity scores were 2.4 ± 0.31 (recommended rate), 0.8 ± 0.16 (15% reduction), and 0.7 ± 0.27 (30% reduction). Meanwhile, maize yield improved by 0.25–3.05%. Integrative analysis indicates that by optimizing nozzle and spray volume combinations, it is feasible to achieve consistent herbicide savings of 15–20% without compromising yield. Application strategies should be tailored according to weed growth stage: for weeds at or below the 4 leaf stage, 180 L/ha with TTI nozzles is recommended to minimize drift; for weeds at or beyond the 5 leaf stage, 225 L/ha with LECHLER nozzles is suggested to enhance deposition efficiency.

Overall, these findings verify that intelligent variable-rate boom sprayers, synergistically optimized with appropriate spray volume and nozzle parameters, can reduce herbicide use while maintaining high maize yields. This provides both theoretical and practical guidance for implementing herbicide reduction strategies in summer maize production systems of the North China Plain.

Author Contributions

Methodology, J.Z.; Investigation, J.Z.; Resources, J.Z.; Data curation, C.Q., X.F., H.Z., M.Y. and Z.Z.; Writing—original draft, C.Q.; Writing—review & editing, C.W.; Funding acquisition, X.H. All authors have read and agreed to the published version of the manuscript.

Funding

This study was funded by the National Key R&D Program of China (Grant No. 2022YFD1700505; subproject PI: Changling Wang), and the 2115 Talent Development Program of China Agricultural University (no grant/award number; PIs: Xiongkui He and Changling Wang).

Data Availability Statement

The authors do not have permission to share data.

Acknowledgments

All members of the Centre for Chemical Application and Technology and the College of Agricultural Unmanned Systems, China Agricultural University are acknowledged for their great contribution to this research.

Conflicts of Interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

References

- Cheng, Y.; Wang, Q.; Xiang, Y. Analysis on the status, superiority and self-sufficiency ratio of maize in China. Chin. J. Agric. Resour. Reg. Plan. 2019, 40, 7–16. [Google Scholar]

- Liu, Y.; XU, T.; Cai, W.; Lu, T.; Zhang, Y.; Xue, H.; Wang, R.; Zhao, J. Current status and prospects of maize super high yield research in China. Biotechnol. Bull. 2023, 39, 52–61. [Google Scholar]

- Feng, F.; Liu, J.; Shen, X.; Fei, G.; Li, H.; Li, Y.; Wang, H.; Yang, Q.; Dong, X.; Wu, W.; et al. Species of weeds in rice and corn fields with different planting patterns in Yuxi, Yunnan. China Plant Prot. 2023, 43, 31–38+56. [Google Scholar]

- He, X. Research and development of efficient plant protection equipment and precision spraying technology in China: A review. Acta Phytophylacica Sin. 2022, 49, 389–397. [Google Scholar]

- Zhou, H.; Yang, B.; Yan, H.; Yang, X. Application status and development prospects of effective plant protection machinery. Agric. Eng. 2014, 4, 4–6. [Google Scholar]

- He, X. Research progress and developmental recommendations on precision spraying technology and equipment in China. Smart Agric. 2020, 2, 133–146. [Google Scholar]

- Jia, W.; Zhang, L.; Yan, M.; Xue, X. Current situation and development trend of boom sprayer. J. Chin. Agric. Mech. 2013, 34, 19–22. [Google Scholar]

- Chen, X.; Hu, Y.; Huang, J.; Li, Y.; Cui, Z.; Zhang, W. China’s agriculture green development: From concept to actions. Front. Agric. Sci. Eng. 2024, 11, 20–34. [Google Scholar] [CrossRef]

- Zhuang, L.; Li, G.; Qin, W. Development status of plant protection machinery in China. Agric. Eng. 2021, 11, 9–13. [Google Scholar]

- Zheng, W.; Ying, X. Study on actuality and problems with measure of plant protection machinery and spray techniques of agricultural chemicals in China. J. Agric. Mech. Res. 2008, 5, 219–221. [Google Scholar] [CrossRef]

- Zou, X.; Zang, X.; Wang, X. Status and development measures of plant protection machinery and pesticide application technique. Agric. Sci. Technol. Equip. 2014, 49–50. [Google Scholar] [CrossRef]

- Fu, Z.; Qi, L.; Wang, J. Developmental tendency and strategies of precision pesticide application techniques. Trans. Chin. Soc. Agric. Mach. 2007, 38, 189–192. [Google Scholar]

- Zhang, B.; Zhai, C.; Li, H.; Yang, S. Development status analysis of precision pesticide application techniques and equipments. J. Agric. Mech. Res. 2016, 38, 1–5+28. [Google Scholar]

- Deng, W.; Chen, L.; Zhang, R.; Tang, Q.; Xu, G.; Li, L.; Xu, M. Review on key technologies for UAV precision agro-chemical application. Agric. Eng. 2020, 10, 1–10. [Google Scholar]

- Wang, G.; Zhang, X.; Chen, X.; Liu, D.; Gong, Y. Current research status and prospects of precision pesticide application technology and device. J. Chin. Agric. Mech. 2023, 44, 68–73. [Google Scholar] [CrossRef]

- Taseer, A.; Han, X. Advancements in variable rate spraying for precise spray requirements in precision agriculture using unmanned aerial spraying systems: A review. Comput. Electron. Agric. 2024, 219, 108841. [Google Scholar] [CrossRef]

- Abbas, I.; Liu, J.; Faheem, M.; Noor, R.S.; Shaikh, S.A.; Solangi, K.A.; Raza, S.M. Different sensor based intelligent spraying systems in agriculture. Sens. Actuators A Phys. 2020, 316, 112265. [Google Scholar] [CrossRef]

- Lochan, K.; Khan, A.; Elsayed, I.; Suthar, B.; Seneviratne, L.; Hussain, I. Advancements in precision spraying of agricultural robots: A comprehensive review. IEEE Access 2024, 12, 129447–129483. [Google Scholar] [CrossRef]

- Zhang, J.; Liu, L.; Xie, Y.; Yuan, W.; Liu, Y.; Ni, H. Effect of methylated soybean oil on efficacy of topramezone under different spray volumes. Weed Sci. 2014, 32, 83–86. [Google Scholar]

- Sijs, R.; Bonn, D. The effect of adjuvants on spray droplet size from hydraulic nozzles. Pest Manag. Sci. 2020, 76, 3487–3494. [Google Scholar] [CrossRef] [PubMed]

- Zhou, Q.; Xue, X.; Chen, C.; Cai, C.; Jiao, Y. Canopy deposition characteristics of different orchard pesticide dose models. Int. J. Agric. Biol. Eng. 2023, 16, 1–6. [Google Scholar] [CrossRef]

- Barros, J.F.C.; Basch, G.; de Carvalho, M. Effect of reduced doses of a post-emergence herbicide to control grass and broad-leaved weeds in no-till wheat under Mediterranean conditions. Crop Prot. 2007, 26, 1538–1545. [Google Scholar] [CrossRef]

- Javaid, M.M.; Mahmood, A.; Bhatti, M.I.N.; Waheed, H.; Attia, K.; Aziz, A.; Nadeem, M.A.; Khan, N.; Al-Doss, A.A.; Fiaz, S.; et al. Efficacy of metribuzin doses on physiological, growth, and yield characteristics of wheat and its associated weeds. Front. Plant Sci. 2022, 13, 866793. [Google Scholar] [CrossRef]

- Wan, Y.; Jin, Y.; Liu, S.; Zhao, X.; Wang, Y.; Bi, Y. Herbicidal characteristics and field control efficacy evaluation of tembotrione in maize field. Chin. J. Pestic. Sci. 2023, 25, 1303–1311. [Google Scholar]

- Bolat, A. Control of common purslane (Portulaca oleracea L.) in second-crop maize with band and broadcast spray application methods. Fresenius Environ. Bull. 2019, 28, 9843–9848. [Google Scholar]

- Creech, C.F.; Henry, R.S.; Werle, R.; Sandell, L.D.; Hewitt, A.J.; Kruger, G.R. Performance of postemergence herbicides applied at different carrier volume rates. Weed Technol. 2015, 29, 611–624. [Google Scholar] [CrossRef]

- Kouame, K.B.-J.; Butts, T.R.; Norsworthy, J.K.; Davis, J.; Piveta, L.B. Palmer amaranth (Amaranthus palmeri) control affected by weed size and herbicide spray solution with nozzle type pairings. Weed Technol. 2024, 38, e17. [Google Scholar] [CrossRef]

- Meyer, C.J.; Norsworthy, J.K.; Kruger, G.R.; Barber, T.L. Effect of nozzle selection and spray volume on droplet size and efficacy of Engenia tank-mix combinations. Weed Technol. 2016, 30, 377–390. [Google Scholar] [CrossRef]

- De Carvalho, S.J.P.; Uzuele, E.L.; Soares, D.J.; Ovejero, R.F.L.; Christoffoleti, P.J. Control of glyphosate-resistant volunteer maize using ACCase inhibiting herbicides. Rev. Caatinga 2019, 32, 575–580. [Google Scholar] [CrossRef]

- Gitsopoulos, T.K.; Melidis, V.; Evgenidis, G. Response of maize (Zea mays L.) to post-emergence applications of topramezone. Crop Prot. 2010, 29, 1091–1093. [Google Scholar] [CrossRef]

- Landau, C.A.; Bernards, M.L.; Hager, A.G.; Williams, M.M. Significance of application timing, formulation, and cytochrome P450 genotypic class on sweet corn response to dicamba. Weed Sci. 2022, 70, 167–173. [Google Scholar] [CrossRef]

- Tursun, N.; Datta, A.; Sakinmaz, M.S.; Kantarci, Z.; Knezevic, S.Z.; Chauhan, B.S. The critical period for weed control in three corn (Zea mays L.) types. Crop Prot. 2016, 90, 59–65. [Google Scholar] [CrossRef]

- Alptekin, H.; Ozkan, A.; Gurbuz, R.; Kulak, M. Management of weeds in maize by sequential or individual applications of pre- and post-emergence herbicides. Agriculture 2023, 13, 421. [Google Scholar] [CrossRef]

- Pannacci, E.; Tei, F. Effects of mechanical and chemical methods on weed control, weed seed rain and crop yield in maize, sunflower and soyabean. Crop Prot. 2014, 64, 51–59. [Google Scholar] [CrossRef]

- Simic, M.; Dragicevic, V.; Babic, M.; Brankov, M.; Filipovic, M. Integrated effects of nitrogen form, row spacing, and herbicide treatment on maize. Agron. J. 2020, 112, 748–757. [Google Scholar] [CrossRef]

- Gadédjisso-Tossou, A.; Avellán, T.; Schütze, N. Potential of deficit and supplemental irrigation under climate variability in northern Togo, West Africa. Water 2018, 10, 1803. [Google Scholar] [CrossRef]

- Hao, B.Z.; Xue, Q.W.; Marek, T.H.; Jessup, K.E.; Hou, X.B.; Xu, W.W.; Bynum, E.D.; Bean, B.W. Soil water extraction, water use, and grain yield by drought-tolerant maize on the Texas High Plains. Agric. Water Manag. 2015, 155, 11–21. [Google Scholar] [CrossRef]

- Irmak, S.; Djaman, K.; Rudnick, D.R. Effect of full and limited irrigation amount and frequency on subsurface drip-irrigated maize evapotranspiration, yield, water use efficiency and yield response factors. Irrig. Sci. 2016, 34, 271–286. [Google Scholar] [CrossRef]

- Varanasi, A.; Prasad, P.V.V.; Jugulam, M. Impact of climate change factors on weeds and herbicide efficacy. Adv. Agron. 2016, 137, 107–146. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).