1. Introduction

The Huang-Huai-Hai wheat–maize rotation region is facing soil degradation issues due to long-term intensive cultivation. This necessitates the transformation of the cultivation system through the adoption of conservation tillage practices centered on no tillage and reduced tillage. Under the annual wheat–maize rotation system, the dense hardening of the soil surface caused by mechanical compaction and the loss of organic matter has severely limited the effectiveness of traditional no-till seeders in this region. The implementation effect of traditional no-till seeders has been restricted significantly, which is evident in difficulties with furrower penetration and uneven seedbed preparation [

1,

2,

3]. In response to these challenges, in recent years, the ridge-clearing no-tillage seeding technology has emerged. It aims to balance the carbon sequestration and soil moisture retention benefits of conservation tillage with the need for high seeding quality [

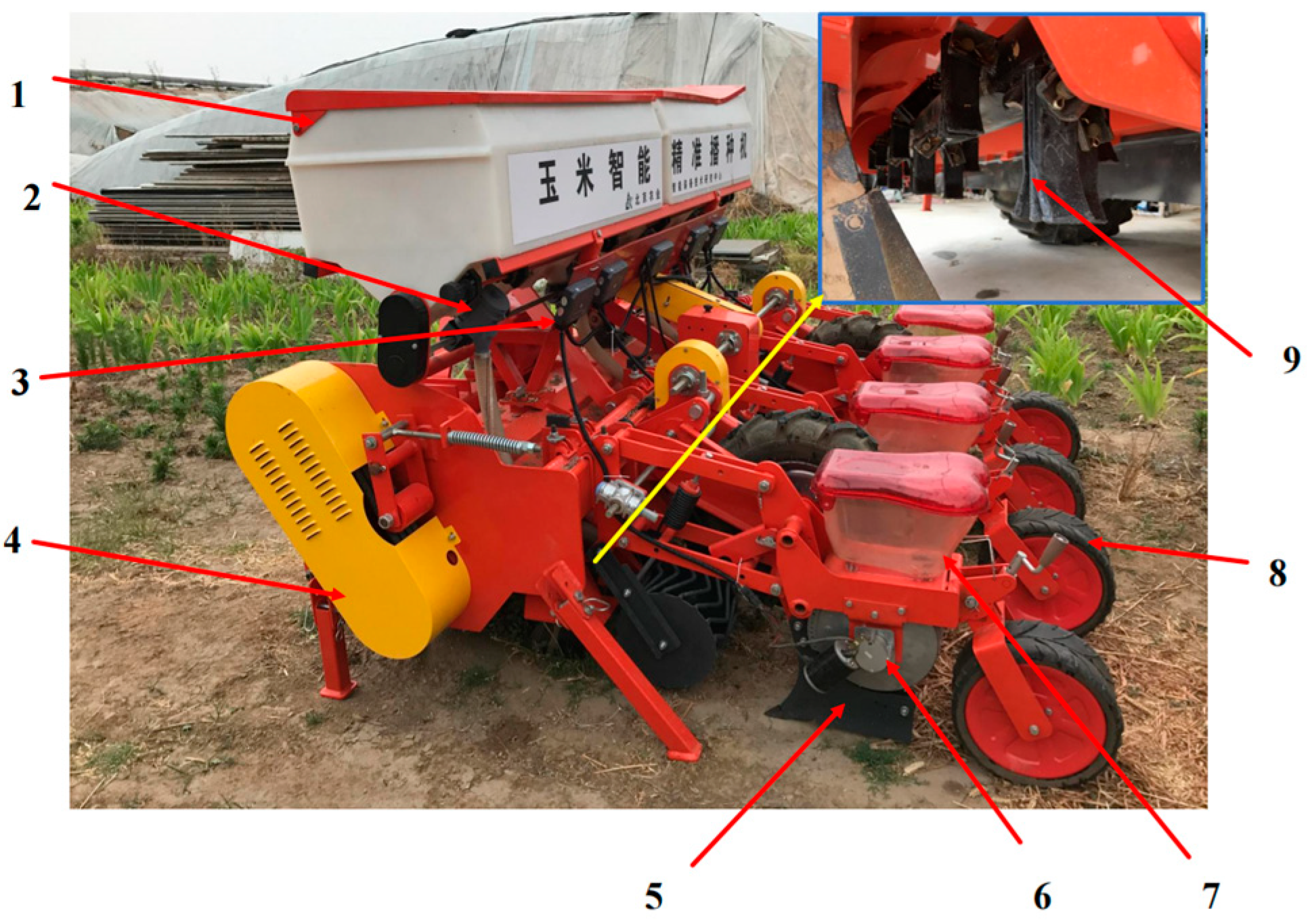

4]. This technology involves installing a stubble removal device at the front of the seeder. During operation, it preforms shallow rotary tillage in strips on the seed rows, effectively severing and shredding the straw and root remains and mixing them with the seedbed soil. This process creates a clean and loose seedbed, significantly reducing the adverse effects of stubble on seeding quality [

5]. However, practical applications have revealed that, under high-speed operations and high-torque conditions, no-till seeders experience intense mechanical vibrations [

6]. These vibrations will lead to instability in the profiling mechanisms of the seeding units [

7]. As a result, the fault-free operation time is shortened, and the work quality is diminished [

8]. Therefore, the adaptive optimization of the ridge-clearing no-till seeder has become a key focus of current research.

Previous research has shown that the operational quality of no-till seeders is affected by multiple operational parameters. On the one hand, dynamic compatibility between the forward speed and the seeding system is crucial for seed spacing uniformity. For instance, Yang et al. [

9] performed bench tests and found that, when the forward speed increased from 5 km/h to 12 km/h, the seed spacing indices of two types of electrically driven seeders—finger-clip and air-suction devices—decreased by 16.79% and 9.88%, respectively. Moreover, the miss indices were also significantly increased, by 11.62% for the finger-clip type and 9.70% for the air-suction type. In contrast, traditional no-tillage seeders, which rely on ground wheel drive, experienced increased ground wheel slippage during high-speed operations. This directly led to a significant decrease in seed spacing uniformity [

10].

On the other hand, surface stubble in conservation tillage scenarios can easily cause blockages in the operation of no-till seeders, leading to obstacles in trenching and affecting the quality of seeding [

8]. Wang et al. [

11] performed a simulation analysis and field experiments and found that, when the height of straw stubble exceeded the critical value, the dynamic fluctuation range of the furrower’s entry angle increased. This dynamic instability directly impaired the quality of the seedbed and compromised the stability of the seeding depth. Additionally, Wang et al. [

12] compared the performance of openers under different straw stubble coverage densities. They demonstrated that a higher stubble coverage density significantly increased both the cutting force and the implement slip rate. This subsequently led to indirect impacts on seeding depth stability.

For this reason, some scholars have proposed adopting a stubble-cleaning device to reduce stubble interference during the seeding process. For instance, by controlling the rotational speed of the power take-off (PTO) shaft, the degree of straw crushing by the stubble-cleaning device can be adjusted, which can improve the seedbed quality [

13]. Yao et al. [

14] and Fang et al. [

15] revealed that, when the PTO rotational speed was insufficient, inadequately crushed long straw segments generated under high-speed operations tended to form stubborn straw accumulations. Such stubble accumulation not only induced seed-metering system entanglement and blockage [

16] but also amplified seeding system vibrations [

17]. Ultimately, this reduced the qualified indices of seed spacing.

The above literature research confirms that the stubble height, PTO speed, and forward speed collectively influence two critical seeding quality metrics—seed spacing uniformity and seeding depth stability—by integrating agricultural machinery with agronomic practices. However, two fundamental limitations persist. One of the limitations is that previous investigations have predominantly focused on isolated parameter effects, failing to establish quantitative models for seeding quality prediction under multi-parameter coupling dynamics. The second limitation is that the adaptive interplay between key operational parameters remains undefined. Specifically, there is an absence of real-time control strategies for coordinated parameter adjustment in response to stubble variability, which is essential in maintaining consistent seeding performance.

To address the seeding quality bottleneck, which is caused by the coexistence of surface compaction layers and stubble coverage, in the Huang-Huai-Hai wheat–maize rotation region, this study aimed to achieve the high-quality and efficient operation of the ridge-clearing no-till seeder for strip tillage. The specific research objectives were set as follows:

(1) To investigate the impacts of three factors—the stubble height, forward speed, and PTO speed—on the seeding quality of a ridge-clearing no-till seeder for strip tillage through field experiments and modeling analysis;

(2) To establish a quantitative analytical model describing the relationships between the three factors and seeding quality (seeding depth stability, seed spacing uniformity) based on field test data;

(3) To optimize the parameters using the response surface methodology to identify the best combination of parameters that satisfies the requirements for high-quality seeding.

3. Results

3.1. Quality Analysis of Seed Spacing Uniformity in Seeder

The experimental seed spacing data are tabulated in

Table 3, with the associated range analysis detailed in

Table 4.

(1) The range analysis of the experimental data presented in

Table 4 indicated that the forward speed was the dominant factor influencing seeding quality, with the highest range contribution rate of 6.97 to the qualified index. Specifically, the qualified indices of experimental groups 2, 3, and 5 were measured at 61.16%, 59.67%, and 61.73%, all of which were much lower than the average of the other six groups. In particular, the high-speed groups, namely groups 3 and 5, recorded miss indices of 33.33% and 33.74%, which shows that high speeds can lead to a clear drop in seed spacing qualification. While group 4 achieved a qualified index of 71.49%, which was just above the required threshold, its miss index of 19.68% still exceeded the permissible limit, further underscoring the detrimental effects associated with speed-dependent operations. These results collectively indicate that higher operating speeds negatively impact seeding qualification indices while correlating with elevated miss indices.

(2) An analysis of the multiples index revealed that the stubble height is one of the key operational parameters affecting seeding uniformity. The experimental data showed that groups with lower stubble heights, such as experiments 2, 4, and 9, had higher multiples indices. Notably, that of experiment 9 reached 15.27%, indicating a greater risk of multiple seeding at low stubble heights. Combined with the range analysis results, where the range value for the stubble height was found to be 18.56, these findings confirm that the stubble height is the primary factor influencing multiple-seeding phenomena. The further comparative analysis of the experimental data from high-stubble conditions, such as between experiments 1 and 9, as well as experiments 4 and 8, showed that the qualified index could be improved by up to 22.6% under high-stubble conditions. This suggests that appropriate stubble cover possibly helps to improve seed placement and enhance seeding uniformity.

(3) Moreover, an analysis of the operationally compliant experiments revealed that, under high PTO rotational speeds, such as in experimental groups 6 and 7, the multiples index demonstrated statistically superior performance compared to other groups. This operational superiority was validated by an elevated range contribution rate of 17.77, as shown in

Table 4, confirming the PTO speed as a critical parameter governing seeding space uniformity. Conversely, at low PTO speeds, such as in experimental groups 2, 3, and 5, the qualified index decreased substantially, while the miss and multiple indices increased, demonstrating that low rotational speeds degrade seed spacing uniformity.

In summary, during no-till seeder operations, the forward speed ought to be reasonably controlled to guarantee seed spacing accuracy, thus avoiding such issues as missing and non-uniform seeding caused by excessive speeds. Moreover, an emphasis should be placed on the quality of stubble removal, with the stubble height properly regulated. This would ensure a favorable forward environment and mitigate the risk of multiple seeding. Additionally, the PTO rotational speed should be properly increased as a crucial method of guaranteeing seeding uniformity.

3.2. Quality Analysis of Seeding Depth Consistency in Seeder

To further explore the impacts of the operational parameters on the seeding depth, comparative experiments were conducted based on the test scheme outlined above. The qualified index of the seeding depth and standard deviation were used as evaluation metrics. The experiments focused on analyzing the relative contributions of the PTO speed, stubble height, and forward speed to seeding depth stability. Detailed experimental data are provided in

Table 5, and corresponding parameter ranges are presented in

Table 6.

(1) An analysis of the experimental data from

Table 5 revealed that the stubble height had the highest influence weight of 15.49, as detailed in

Table 6, on the coefficient of variation of the seeding depth. This made it the dominant parameter governing seeding depth stability. Specifically, when stubble coverage increased from the low threshold in experiment 1 to the high threshold in experiment 6, the standard deviation of the seeding depth expanded from 7.93 to 9.37. This corresponded to an increase in the coefficient of variation from 15.36 to 19.07, which revealed significant deterioration in seeding depth consistency.

(2) The influence of the forward speed on seeding quality showed a nonlinear threshold effect. High-speed experiments, such as experiments 3, 5, and 7, demonstrated increased standard deviations and coefficients of variation for the seeding depth, alongside a declining qualified index. This indicated that the uniformity of the seeding depth was significantly disturbed.

Table 6 also supports this trend, showing a larger range value for the forward speed’s impact on the seeding depth qualified index. This indicates reduced depth uniformity at higher forward speeds. Correspondingly, low-speed experiments, such as experiments 1, 4, and 8, exhibited smaller standard deviations, lower coefficients of variation, and higher qualified indices, confirming that appropriate speed reduction improves seeding uniformity. This trend was further validated by the substantial range value for the forward speed’s impact on seeding depth qualification, as shown in

Table 6, demonstrating compromised depth consistency at elevated operating speeds. However, at the maximum tested speed of 10 km/h, the qualification rates unexpectedly showed an increasing trend. Consequently, the influence of the forward speed on seeding depth quality does not follow a linear decline but exists within specific speed adaptation ranges.

(3) The range analysis of the experimental data showed that the PTO speed had a range contribution rate of 7.78, as indicated in

Table 6, highlighting its significance as a key parameter affecting the seeding depth qualified index. A comparative analysis between the high-PTO-speed experiments 2, 6, and 7 and low-PTO-speed experiments 1, 4, and 8 showed that higher PTO speeds led to relatively larger standard deviations and coefficients of variation for the seeding depth, along with lower qualified indices. These observations demonstrate compromised seeding depth consistency under high PTO speeds.

Based on the above analysis, the following measures should be implemented during no-tillage seeding operations: scientifically regulate the amount of crop residue retention to ensure optimal soil trenching conditions; reasonably set the operational speed to balance efficiency with seeding quality; and optimize PTO speed matching to achieve synergistic enhancements in stubble cleaning and seeding depth stability.

3.3. Establishment of Regression Equations and Response Surface Analysis

The derived nonlinear regression variance parameters are detailed in

Table 7.

For the solved Equations (12) and (13), ridge regression sacrifices coefficient unbiasedness by introducing bias, rendering the p-values for individual parameters non-indicative of significance. However, predictive stability and accuracy were ensured through equation variance analysis. The critical correlation coefficients at significance levels α = 0.05 and α = 0.01 were R(0.05)(3,5) = 0.874 and R(0.01)(3,5) = 0.937, respectively (degrees of freedom: numerator = 3, denominator = 5). All calculated R-values in the regression models exceeded 0.937, demonstrating that the established nonlinear regression equations achieved statistically significant fits to the vibration amplitude measurements across all monitoring points.

The response surface methodology addresses the limitations of conventional orthogonal experimental designs by mathematically modeling complex interactions among multiple factors. This approach enables the comprehensive exploration of experimental domains and accelerates the identification of optimal parameter combinations [

22,

23]. The matrix processing of the seeding depth and seed spacing qualification indices was performed using the Origin 2024 software. It generated response surfaces, as shown in

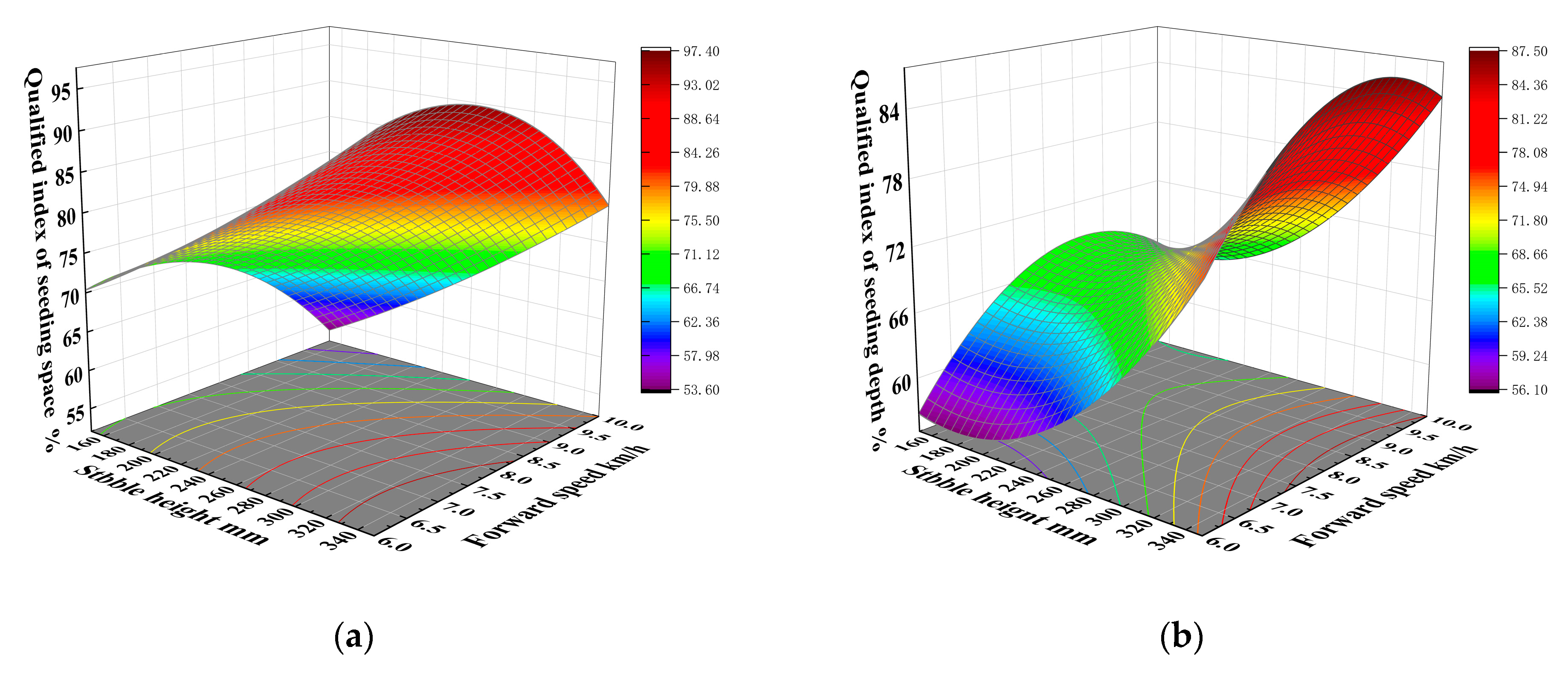

Figure 5. These surfaces were used to analyze the effects of the experimental parameters on both metrics.

For the qualified index of seed spacing, when the PTO speed was 540 r/min, the interaction response surface between the stubble height and forward speed was as shown in

Figure 5a. It could be seen that, when the operational speed was fixed, the qualified index increased with increasing stubble heights. When the stubble height was fixed, the qualified index of seed spacing initially increased and then decreased with the forward speed.

For the qualified index of the seeding depth of the electrically driven seeder, the interaction between the stubble height and forward speed was as shown in

Figure 5b. When the forward speed was constant, the qualified index of the seeding depth showed a nonlinear response, first decreasing and then increasing with changes in stubble height. When the stubble height remained constant, the qualified index of the seeding depth initially increased and then decreased with rising forward speeds.

The multifactorial interaction analysis delineated distinct optimization zones for seeding parameters, as illustrated in

Figure 5 and detailed in

Table 4 and

Table 6. For the qualified index of seed spacing, the maximum values occurred within the interaction range of 8–9 km/h for the forward speed and 280–330 mm for the stubble height. The dominant factor analysis revealed that the stubble height exhibited a significantly higher range contribution rate of 5.55 compared to seed spacing than other parameters. For seeding depth stability, peak values were observed within the interaction domain of 300–350 mm for the stubble height and 7.5–9 km/h for the forward speed. Among them, the dominant factor analysis revealed that the forward speed exhibited a significantly higher range contribution rate of 7.78 compared to the seeding depth than other parameters.

Comprehensively, by identifying the overlap zone between the maximum-value intervals of the two qualification indices, it was determined that, at a PTO speed of 540 r/min, within the stubble height range of 300–330 mm and the forward speed range of 8–9 km/h, both the seed spacing qualification index and seeding depth qualification index reached relatively high values. The solution was derived by incorporating 10 mm stepwise increments in the stubble height within this constrained interval. The constraint conditions for the experimental factors are follows:

Based on

Table 8, when the stubble height was maintained within the 300–330 mm range and the forward speed was within 8–9 km/h, the qualified seeding depth rate exceeded 94%, while the qualified seed spacing rate reached or surpassed approximately 80%. Both metrics exceeded the industry-standard thresholds. These results verify the validity of the optimized operational interval derived through the response surface methodology.

4. Discussion

This study selected the stubble height, forward speed, and residue-chopping device rotational speed (PTO speed) as experimental factors. Field experiments quantitatively revealed the effects of these operational parameters on seeding depth stability and seed spacing uniformity. In contrast to prior studies focusing on single-parameter impacts on ridge-clearing no-till seeding quality, this work further validated the multi-parameter interactive effects and established an operational parameter–seeding quality coupling model. These findings have practical implications for the optimization of seeder parameter selection in Huang-Huai-Hai wheat–maize rotation systems.

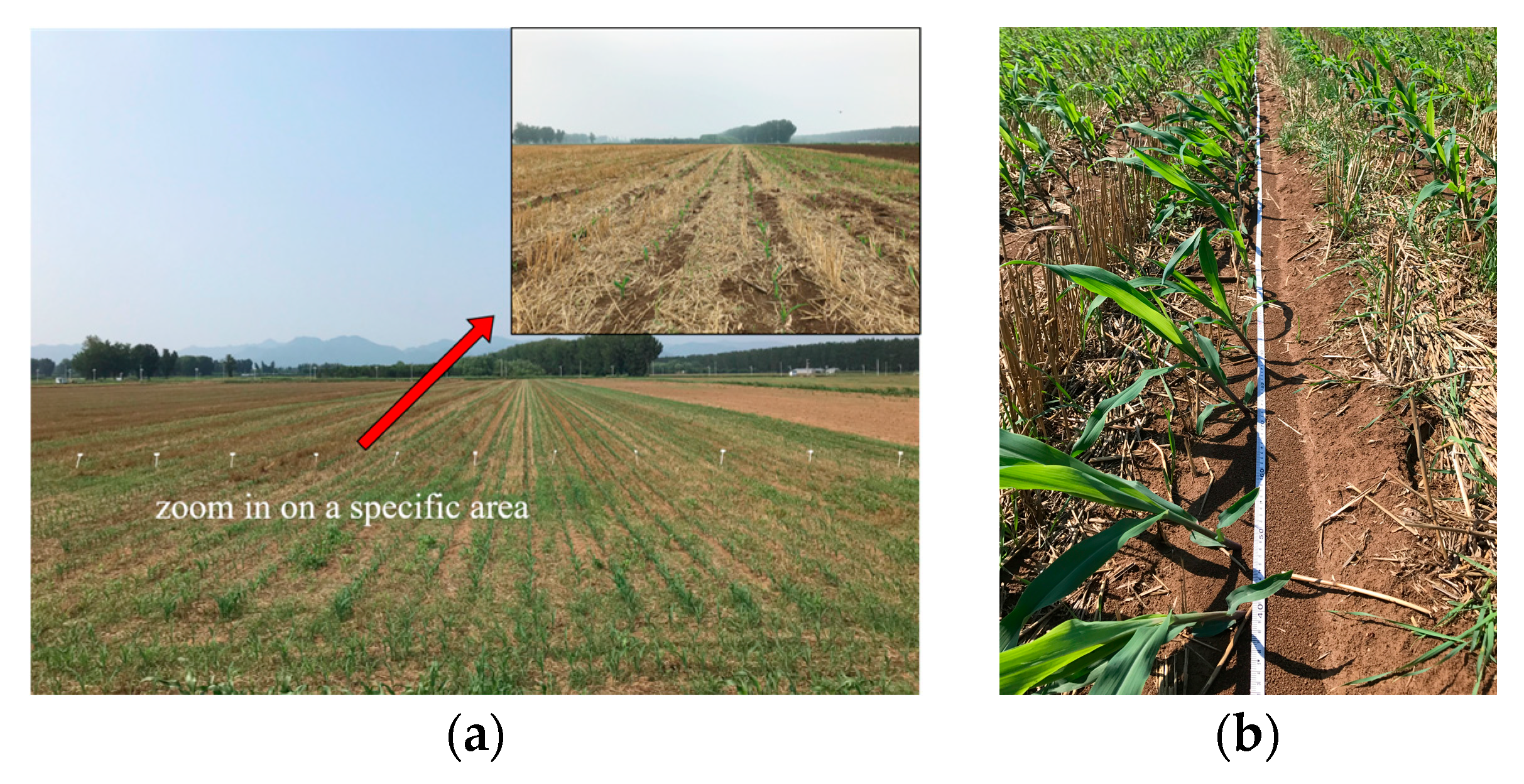

Field experiments demonstrated that stubble coverage manifests dual effects: vibration absorption and resistance interference. Specifically, a moderate stubble height enhanced the seed spacing qualification indices through suppressing mechanical vibrations [

24], whereas excessive heights increased the seeding depth coefficient of variation by 15.36–19.07%. Mechanistically speaking, high stubble disrupted soil structural continuity by serving as a physical barrier, thereby causing fluctuating furrower penetration resistance. Concurrently, dynamic straw–furrower interactions amplified system vibrations. This dual effect underscores that appropriate stubble coverage optimizes seed embedment via vibration-buffering effects, while insufficient coverage compromises collaborative furrower–seed tube compatibility. Consequently, reduced kinetic energy for seed guidance leads to shallow-layer seed accumulation [

25]. Conversely, low-stubble scenarios further induce localized seed accumulation in furrows due to compromised seed drop stability, ultimately elevating multiple seeding indices.

Medium–low forward speeds facilitated seeding depth consistency and improved seed spacing qualification rates, while high speeds increased the missing rates and depth fluctuations [

26]. Trials 2, 3, and 5 (

Table 3) exhibited missing indices of 33.33–33.74%, with the qualification indices declining to 59.67–61.73%. This indicates that, when the operational speed increased, seed metering motor rotation failed to synchronize with the travel speed, causing a seed supply–demand mismatch and untimely seed delivery. Concurrently, high-speed operations reduced placement stability, exacerbating seeding errors [

27]. Although group 4 (

Table 3) achieved a qualified depth index of 71.49%, its missing index of 19.68% still exceeded the permissible limits, further evidencing the adverse effects of excessive speeds.

Under low-PTO-speed conditions, seeding depth consistency was maintained, whereas higher PTO speeds enhanced the residue pulverization effectiveness [

13], which reduced the interference with seed spacing and significantly improved the multiples index (range contribution rate: 17.77; see

Table 5). However, higher PTO speeds also induced minor implement disturbances that compromised the furrowing stability, increasing the seeding depth’s standard deviation and coefficient of variation [

28]. Low-PTO operations minimized vibrations, but insufficient residue clearance obstructed seed trajectories, reducing the qualification rates while elevating the missing and multiples index values.

The response surface analysis demonstrated significant interactive effects between the stubble height and forward speed on seeding quality. As depicted in

Figure 5a, the seed spacing qualification index increased with higher stubble heights. This phenomenon arose from insufficient stubble coverage at low stubble levels corresponding to reduced qualification indices, where exposed compacted soil surfaces amplified seed rebound and rolling deviations due to direct mechanical impact during seed–soil contact. Elevated stubble heights, on the other hand, mitigated seeder vibration through enhanced energy absorption and accordingly improved the seeding uniformity and consistency. Meanwhile, uniform stubble distribution created a physical baffle that stabilized seed trajectories. This helped to guide directional seeding. Meanwhile, as shown in

Figure 5a, the seed spacing qualification index initially increased then decreased with rising forward speeds. This was because the seeder had sufficient time for precise seed placement at low forward speeds, resulting in a higher qualified index. Lower vibration levels and optimal synchronization between the seeding apparatus’ speed and the forward speed ensured uniform seed distribution. As the forward speed increased, the seeder’s operational efficiency improved, and the qualified index reached its peak due to well-matched vibration levels and seeding apparatus speeds. However, when the forward speed increased further, the intensified seeder vibrations and the potential mismatch between the seeding apparatus’ speed and the forward speed led to imprecise seed placement. This caused the qualified index to decline.

As shown in

Figure 5b, the seeding depth qualification index first decreased and then increased with rising stubble heights. This was because, at excessively low stubble heights, the uneven distribution of crushed straw created alternating areas of stubble accumulation and bare soil. Accumulation areas caused furrower blockage and stubble entanglement, which intensified mechanical vibrations and led to shallower seeding depths. In contrast, bare soil areas increased soil compaction, raised furrower penetration resistance, and caused the seeding depths to exceed the standards. When the stubble height reached 300–350 mm with a uniform distribution, the continuous surface cover layer effectively buffered the mechanical vibration energy. This improved the seeding depth control precision by enhancing the dynamic stability of the furrower–soil system. Additionally,

Figure 5b shows that the seeding depth qualification index initially increased and then decreased with rising forward speeds. During the initial increase phase, higher forward speeds enhanced the furrower’s dynamic downward pressure, which enabled the seeder to penetrate through the soil surface hardening layer effectively. Concurrently, at lower speeds, reduced seeder vibration allowed the furrower to maintain stable operation, thereby improving depth uniformity. However, at elevated speeds, the qualified index declined due to a shortened furrower–soil contact duration. The partial absorption of downward pressure by the stubble resulted in insufficient furrower penetration through the stubble layer and ultimately inadequate seeding depths. This indicates its primary influence through dual “vibration absorption–resistance interference” effects. A moderate stubble height improved the spacing uniformity by reducing mechanical vibrations, while excessive stubble heights increased the seeding depth variability due to fluctuating furrower resistance. The forward speed dominated, with a range response value of 7.78. This indicates that, in the interaction between the forward speed and stubble height, lower forward speeds favored improved depth control, whereas higher forward speeds exacerbated vibration-induced seeding errors, including missed seeds and spacing deviations.

The response surface analysis revealed significant interaction effects between the stubble height and forward speed on the seeding quality [

13]. In summary, the seed spacing qualification index peaked within a forward speed of 8–9 km/h and stubble height of 280–330 mm, with the stubble height being the dominant factor (contribution value: 5.55) Meanwhile, the seeding depth qualification index peaked at a stubble height of 300–350 mm and forward speed of 7.5–8.5 km/h, where the forward speed dominated (response value: 7.78). Lower forward speeds favored depth control, while higher forward speeds induced higher missing rates and spacing deviations. The optimal parameter combination at a fixed 540 r/min PTO speed was a stubble height of 300–330 mm and forward speed of 8–9 km/h, which simultaneously enhanced both qualification indices.

The innovations of this study are as follows. First, multi-objective parameter optimization equations for the seeding depth and seed spacing were constructed, and the effectiveness of the response surface methodology in parameter matching for no-till seeders was verified. Second, the interactive compensation mechanism between stubble coverage and the operational speed was revealed, which provides parameter benchmarks for intelligent seeder control in the Huang-Huai-Hai region. These findings offer critical guidance for the advancement of adaptive seeding technologies and present a quantitative basis for the optimization of the operational speed and stubble height under different stubble coverage conditions. Future studies should integrate soil compaction and moisture measurements to quantitatively disentangle their interactions with the stubble height in governing furrower resistance dynamics.

5. Conclusions

Through field orthogonal experiments analyzing the effects of the stubble height, forward speed, and PTO speed on the maize seeding depth and seed spacing, the data analysis demonstrated that a low forward speed facilitates seeding uniformity and depth control, while high speeds increase the missing rates and spacing deviations. However, under moderate stubble height and ridge-clearing power settings, medium-to-high-speed operations achieved the optimal seed spacing performance. The stubble height exhibited regulatory effects on surface soil disturbances. An appropriate stubble height improved the seed spacing qualification rates, whereas excessive heights induced furrowing resistance fluctuations, reducing the seeding depth consistency. The PTO speed demonstrated complex impacts on the seeding system: higher PTO speeds enhanced the stubble pulverization effectiveness, thereby reducing the multiples rate and seed spacing deviations, but concurrently compromised the seeding depth precision. Forward speed–PTO speed coordination exhibited critical thresholds: the low forward speed and low PTO speed combination reduced the missing rates, while a high forward speed required high-PTO matching to strengthen residue shredding and minimize reseeding occurrences.

This study established nonlinear regression equations based on the seeding depth and seed spacing qualification rates under varying operational parameters to identify the optimal combinations for ridge-clearing no-till seeders. The response surface analysis revealed that the stubble height dominated seed spacing consistency enhancement, while the forward speed primarily controlled seeding depth stability. For the seed spacing qualification index, peak values were concentrated within the overlap zone of 8–9 km/h for the forward speed and 280–330 mm for the stubble height. For the seeding depth qualification index, peak values occurred in the overlap zone combining a 300–350 mm stubble height with a 7.5–9 km/h forward speed. Under integrated optimization with the PTO rotation speed maintained at 540 r/min, when the stubble height ranged between 300 and 330 mm and the forward speed was configured between 8 and 9 km/h, the qualified seeding depth rate exceeded 94%, while the qualified seed spacing rate reached 80%, both surpassing industry-standard requirements.