Design and Tests of a Large-Opening Flexible Seedling Pick-Up Gripper with Multiple Grasping Pins

Abstract

1. Introduction

2. Materials and Methods

2.1. Overall Design and Analysis

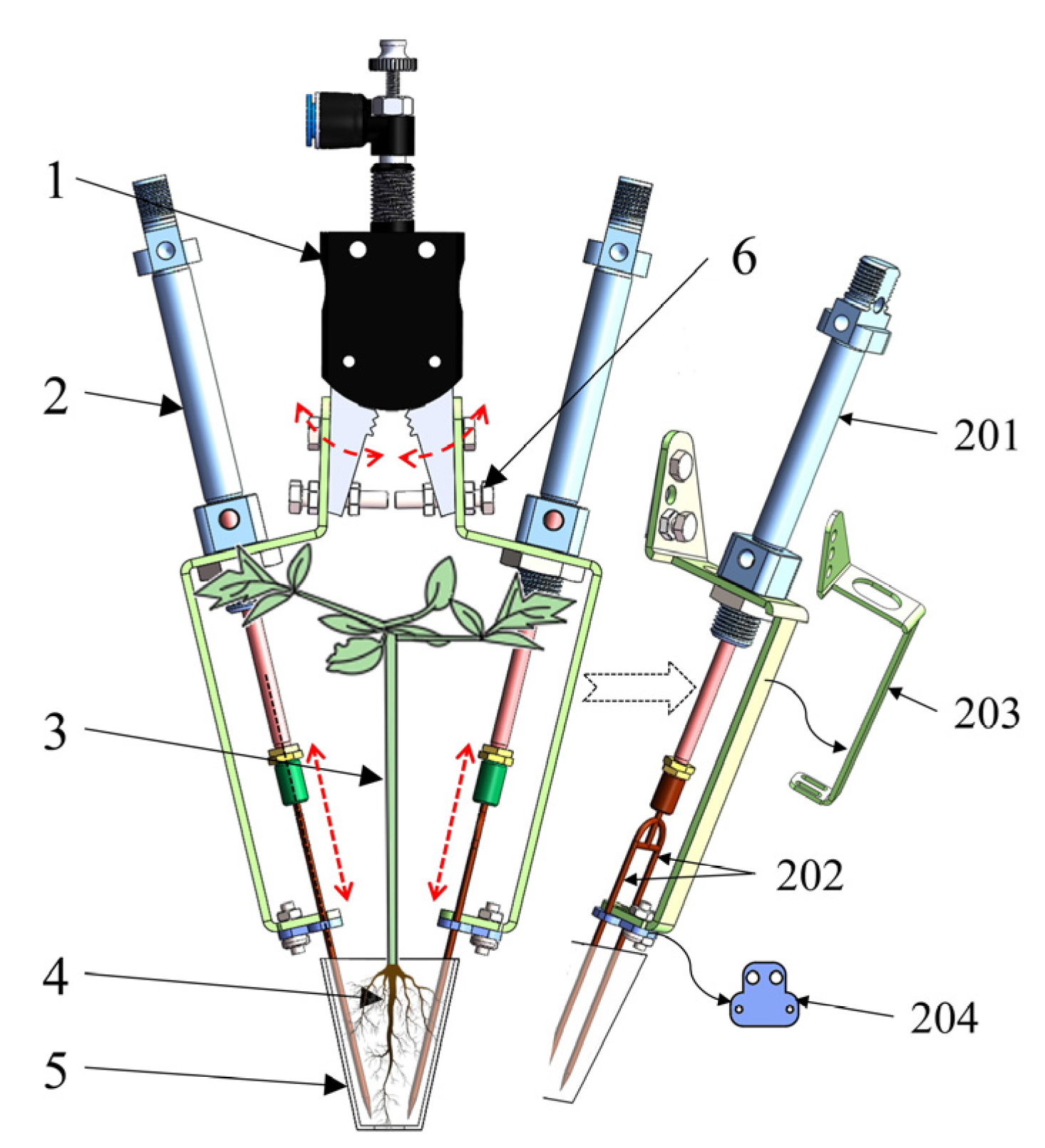

2.1.1. Mechanical Structure and Working Principle

- -

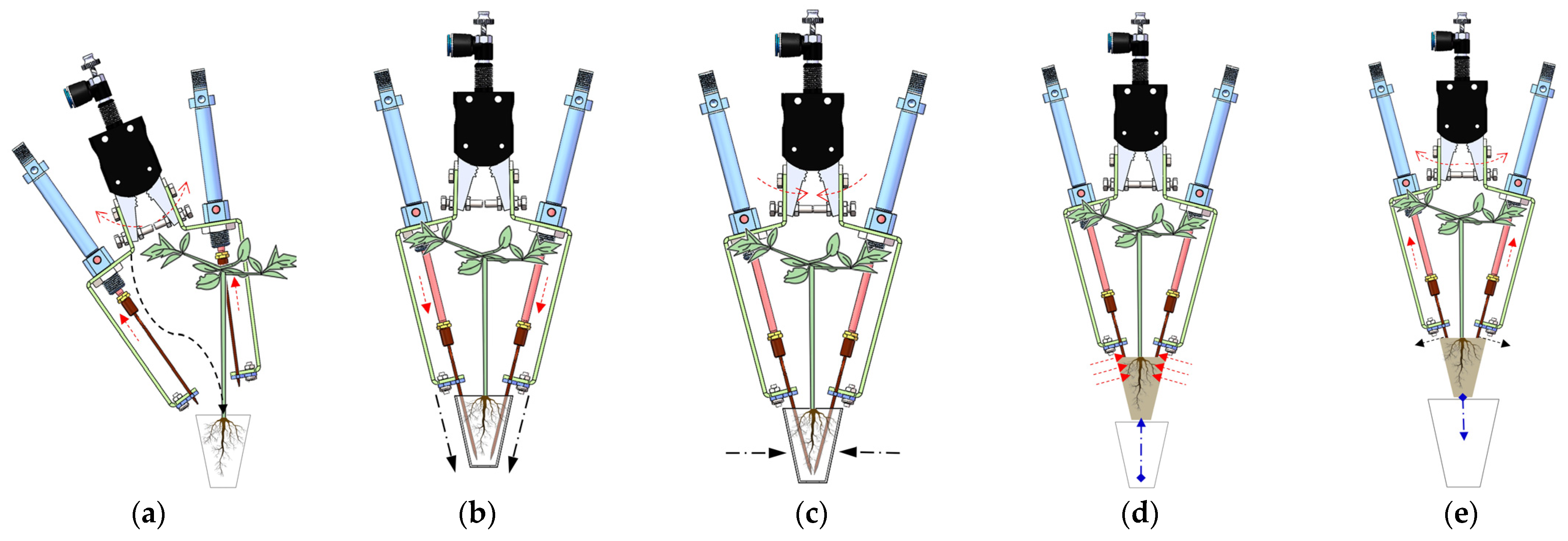

- At the beginning of a working cycle, two cylinder fingers pull their fork-type pins back. The pneumatic fixture is bounced off, causing the cylinder fingers to open. In this case, the pick-up gripper is moved by the automatic transplanting manipulator towards the seedling’s root lump with little damage to its upright plant (Figure 2a).

- -

- When the pick-up gripper is adjusted to be normal to the tray cell surface, the cylinder fingers push the fork-type pins to obliquely penetrate the root lump along both sides of the tray cell (Figure 2b). Then, the multiple pin assembly moves toward the seedlings until it can grasp the maximum number of their root lumps.

- -

- The pneumatic fixture is driven to close, causing the fork-type pins to squeeze the root lump gradually as they penetrate the tray cell (Figure 2c). With the help of this operation, the pick-up gripper applies some grasping forces to hold the seedling firmly. Finally, the pick-up gripper is moved up to extract the seedling from the tray cell (Figure 2d).

- -

- After extracting the seedling, the automatic transplanting manipulator moves the pick-up gripper to transfer the seedling to the place where it is to be transplanted. As opposed to grasping seedlings, the pick-up gripper efficiently discharges the seedling through the combined operations of opening the cylinder fingers and then retracting the fork-type pins (Figure 2e). In this way, the seedling falls with the inertia action while standing upright.

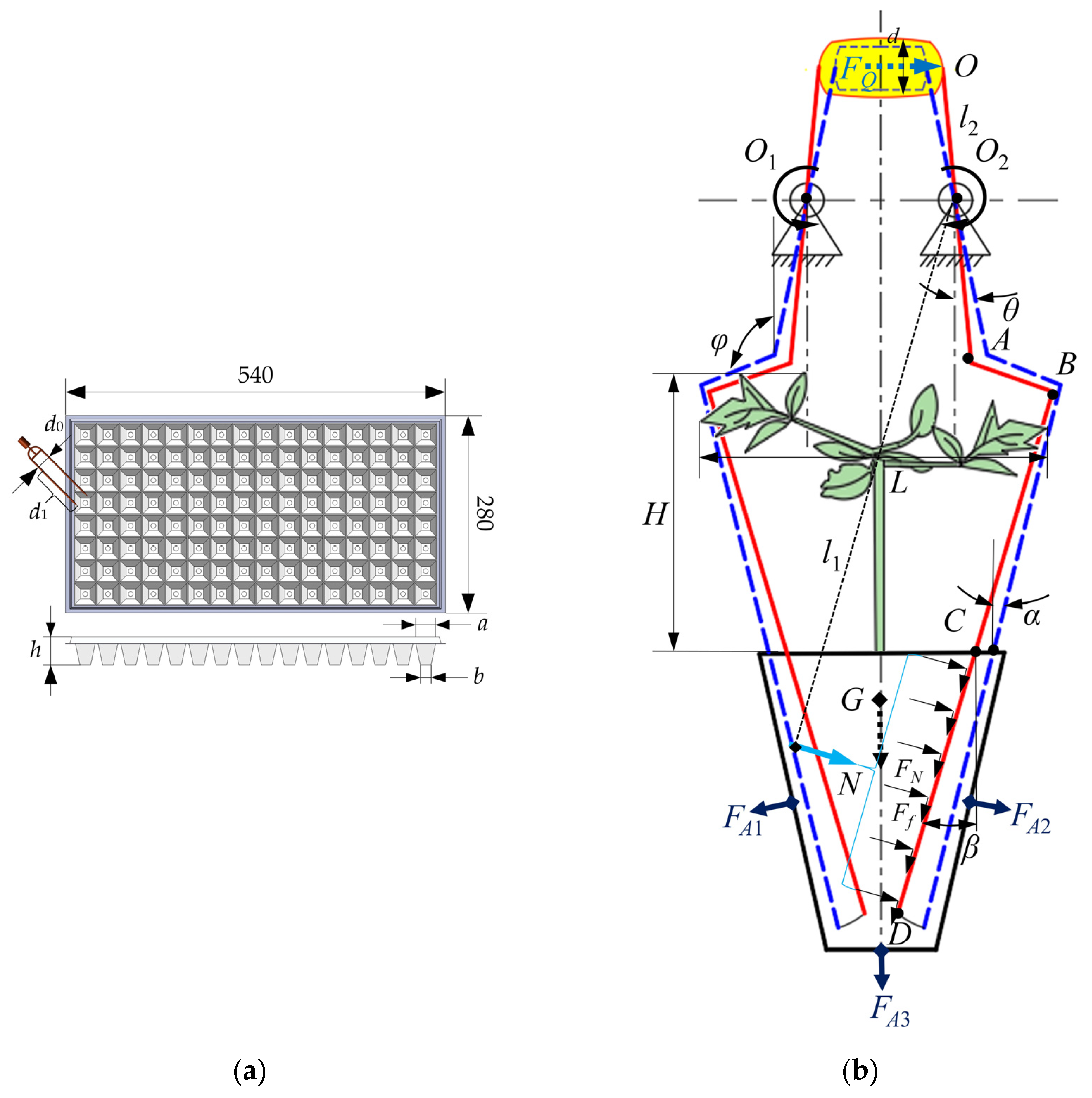

2.1.2. Dimension and Force Analysis of Key Components

2.2. Prototype Optimization and Performance Tests

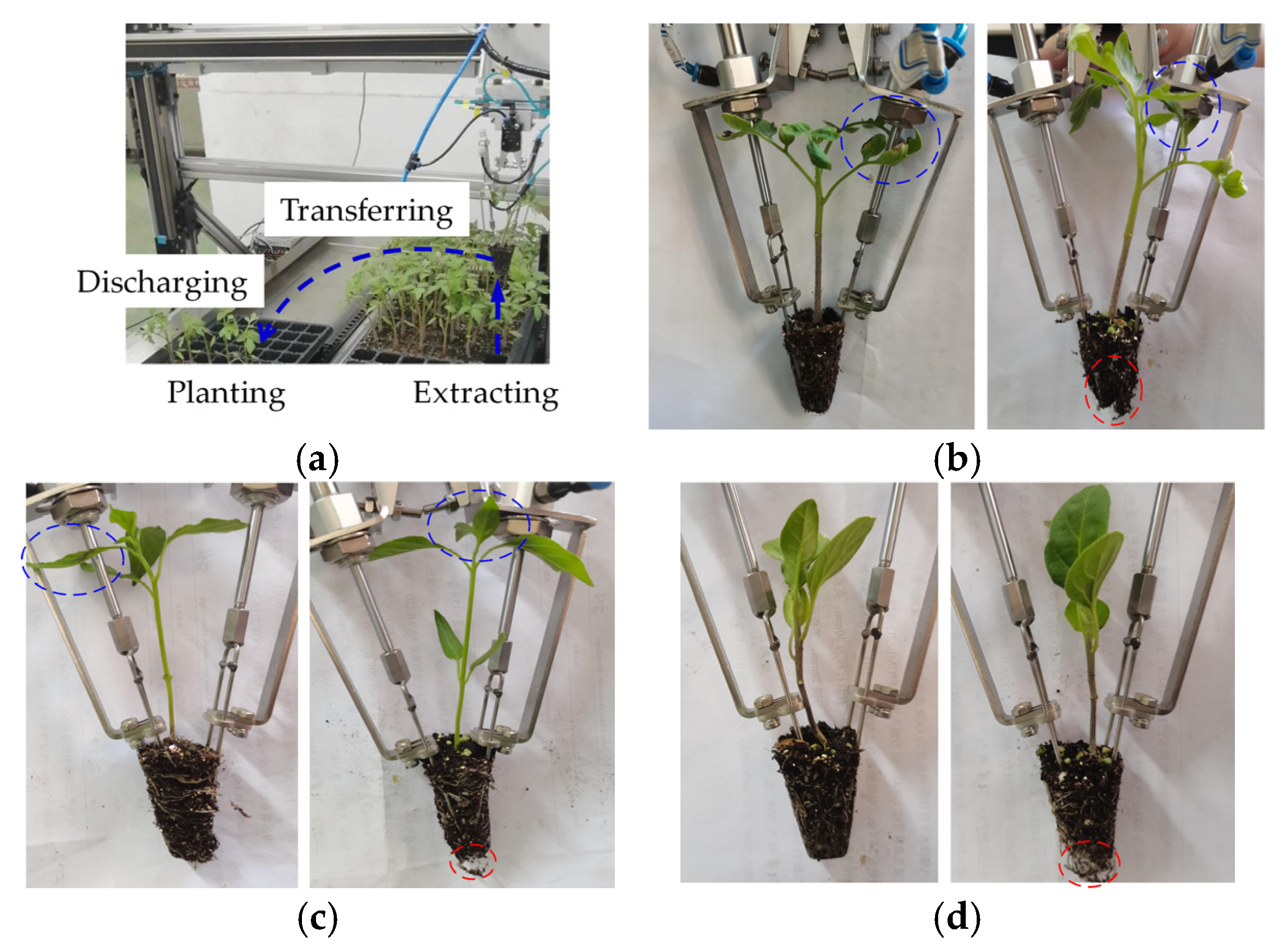

2.2.1. Prototype Construction of Testing Device

2.2.2. Optimization Tests of Grasping Parameters

2.2.3. Performance Tests Under Actual Conditions

3. Results and Discussion

3.1. Optimization Tests

3.2. Performance Tests

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Khadatkar, A.; Mathur, S.M.; Gaikwad, B.B. Automation in transplanting: A smart way of vegetable cultivation. Curr. Sci. 2018, 115, 1884–1892. [Google Scholar] [CrossRef]

- Jin, Y.; Liu, J.; Xu, Z.; Yuan, S.; Li, P.; Wang, J. Development status and trend of agricultural robot technology. Int. J. Agric. Biol. Eng. 2021, 14, 1–19. [Google Scholar] [CrossRef]

- Zhang, B.; Wen, X.; Wen, Y.; Wang, X.; Zhu, H.; Pan, Z.; Yang, Z. Design and testing of a closed multi-channel air-blowing seedling pick-up device for an automatic vegetable transplanter. Agriculture 2024, 14, 1688. [Google Scholar] [CrossRef]

- Zhang, T.; Zhou, J.; Liu, W.; Yue, R.; Yao, M.; Shi, J.; Hu, J. Seedling-yolo: High-efficiency target detection algorithm for field broccoli seedling transplanting quality based on yolov7-tiny. Agronomy 2024, 14, 931. [Google Scholar] [CrossRef]

- Zhou, M.; Shan, Y.; Xue, X.; Yin, D. Theoretical analysis and development of a mechanism with punching device for transplanting potted vegetable seedlings. Int. J. Agric. Biol. Eng. 2020, 13, 85–92. [Google Scholar] [CrossRef]

- Choi, W.C.; Kim, D.C.; Ryu, I.H.; Kim, K.U. Development of a seedling pick-up device for vegetable transplanters. Trans. Amer. Soc. Agric. Eng. (Trans. ASAE) 2002, 45, 13–19. [Google Scholar]

- Kang, T.G.; Kim, S.W.; Kim, Y.K.; Lee, S.H.; Jun, H.J.; Choi, I.S.; Yang, E.Y.; Jang, K.S.; Kim, H.G. Analysis of pick-up mechanism for automatic transplanter (I). J. Agric. Life Sci. 2017, 51, 187–192. [Google Scholar] [CrossRef]

- Zhou, M.; Yang, J.; Xu, T.; Ying, J.; Wang, X. Optimal design of transplanting mechanism with differential internal engagement non-circular gear trains. J. Agric. Eng. 2022, 53, 1412. [Google Scholar] [CrossRef]

- Yue, R.; Hu, J.; Liu, Y.; Yao, M.; Zhang, T.; Shi, J. Design and working parameter optimization of pneumatic reciprocating seedling-picking device of automatic transplanter. Agriculture 2023, 12, 1989. [Google Scholar] [CrossRef]

- Zhou, M.; Sun, H.; Xu, X.; Yang, J.; Wang, G.; Wei, Z.; Xu, T.; Yin, J. Study on the method and mechanism of seedling picking for pepper (Capsicum annuum L.) plug seedlings. Agriculture 2024, 14, 11. [Google Scholar] [CrossRef]

- Yue, R.; Yao, M.; Zhang, T.; Shi, J.; Zhou, J.; Hu, J. Design and experiment of dual-row seedling pick-up device for high-speed automatic transplanting machine. Agriculture 2024, 14, 942. [Google Scholar] [CrossRef]

- Ryu, K.H.; Kim, G.; Han, J.S. Development of a robotic transplanter for bedding plants. J. Agric. Eng. Res. 2001, 78, 141–146. [Google Scholar] [CrossRef]

- Khadatkar, A.; Pandirwar, A.P.; Paradkar, V. Design, development and application of a compact robotic transplanter with automatic seedling picking mechanism for plug-type seedlings. Sci. Rep. 2023, 13, 1883. [Google Scholar] [CrossRef]

- Gao, G.; Feng, T.; Li, F. Working parameters optimization and experimental verification of inclined-inserting transplanting manipulator for plug seedling. Trans. Chin. Soc. Agric. Eng. (Trans. CSAE) 2015, 31, 16–22. [Google Scholar] [CrossRef]

- Tong, J.; Shi, H.; Wu, C.; Ding, Y.; Zhao, X.; Wang, R. Simulation and test of seedling pot grabbing by spade end-effector. Trans. Chin. Soc. Agric. Mach. (Trans. CSAM) 2019, 50, 107–116. [Google Scholar] [CrossRef]

- Tian, Z.; Ma, W.; Yang, Q.; Yao, S.; Guo, X.; Duan, F. Design and experiment of gripper for greenhouse plug seedling transplanting based on EDM. Agronomy 2022, 12, 1487. [Google Scholar] [CrossRef]

- Jin, X.; Li, D.; Ma, H.; Ji, J.; Zhao, K.; Pang, J. Development of single row automatic transplanting device for potted vegetable seedlings. Int. J. Agric. Biol. Eng. 2018, 11, 67–75. [Google Scholar] [CrossRef]

- Yang, Y.; Ting, K.C.; Giacomelli, G.A. Factors affecting performance of sliding-needles gripper during robotic transplanting of seedlings. Amer. Soc. Agric. Eng. 1991, 7, 493–498. [Google Scholar] [CrossRef]

- Han, L.; Xiang, D.; Xu, Q.; Du, X.; Ma, G.; Mao, H. Development of simplified seedling transplanting device for supporting efficient production of vegetable raw materials. Appl. Sci. 2023, 13, 10022. [Google Scholar] [CrossRef]

- Ma, G.; Mao, H.; Bu, Q.; Han, L.; Shabbir, A.; Gao, F. Effect of compound biochar substrate on the root growth of cucumber plug seedlings. Agronomy 2020, 9, 1080. [Google Scholar] [CrossRef]

- Mao, H.; Han, L.; Hu, J.; Kumi, F. Development of a pincette-type pick-up device for automatic transplanting of greenhouse seedlings. Appl. Eng. Agric. 2014, 30, 547–556. [Google Scholar] [CrossRef]

- Gurera, D.; Bhushan, B.; Kumar, N. Lessons from mosquitoes’ painless piercing. J. Mech. Behav. Biomed. 2018, 84, 178–187. [Google Scholar] [CrossRef] [PubMed]

- Li, A.D.R.; Putra, K.B.; Chen, L.; Montgomery, J.S.; Shih, A. Mosquito proboscis inspired needle insertion to reduce tissue deformation and organ displacement. Sci. Rep. 2020, 10, 12248. [Google Scholar] [CrossRef] [PubMed]

- Lim, J.H.; Park, S.; Chae, W.B.; Kim, S.K.; Choi, S.K.; Yang, E.Y.; Lee, M.J.; Park, G.B.; Jang, Y.; Seo, M.H.; et al. Seedling conditions for kimchi cabbage, head lettuce, cabbage and broccoli for a riding-type transplanter. J. Bio. Eng. 2017, 42, 104–111. [Google Scholar] [CrossRef]

- Shaw, L. Changes needed to facilitate automatic field transplanting. HortTechnology 1993, 3, 418–420. [Google Scholar] [CrossRef]

- Ndikumana, J.N.; Lee, Y.H.; Yeoung, Y.R. Development of a functional plug tray for producing high-quality strawberry transplants. Hortic. Sci. Technol. 2019, 37, 345–353. [Google Scholar] [CrossRef]

- Takahiro, F.; Hiroshi, Y.; Fumio, S. Effects of mophological and physical properties of cabbage plug seedlings on working precision of automatic transplanter. Jpn. J. Farm Work. Res. 1999, 34, 77–84. [Google Scholar]

- Liu, Z.; Shi, L.; Liu, Z.; Xing, J.; Hu, C.; Wang, X.; Wang, L. Design and testing of a seedling pick-up device for a facility tomato automatic transplanting machine. Sensors 2024, 24, 6700. [Google Scholar] [CrossRef]

- Tong, J.; Yu, J.; Wu, C.; Yu, G.; Du, X.; Shi, H. Health information acquisition and position calculation of plug seedling in greenhouse seedling bed. Comput. Electron. Agr. 2021, 185, 106146. [Google Scholar] [CrossRef]

| Factor | Symbol | Level | |||

|---|---|---|---|---|---|

| 1 | 2 | 3 | 4 | ||

| Pin diameter/mm | A | 1.0 | 1.2 | 1.4 | 1.6 |

| Penetration depth/mm | B | 25 | 30 | 35 | 40 |

| Grasping force/MPa | C | 0.2 | 0.3 | 0.4 | 0.5 |

| Extraction speed/(mm/s) | D | 600 | 900 | 1200 | 1500 |

| No. | Factor (Levels) | Y/% | ||||

|---|---|---|---|---|---|---|

| A | B | C | D | E (Error) | ||

| 1 | 1 (1.0 mm) | 1 (25 mm) | 1 (0.2 MPa) | 1 (600 mm/s) | 1 | 83.78 |

| 2 | 1 | 2 (30 mm) | 2 (0.3 MPa) | 2 (900 mm/s) | 2 | 85.63 |

| 3 | 1 | 3 (35 mm) | 3 (0.4 MPa) | 3 (1200 mm/s) | 3 | 87.09 |

| 4 | 1 | 4 (40 mm) | 4 (0.5 MPa) | 4 (1500 mm/s) | 4 | 83.65 |

| 5 | 2 (1.2 mm) | 1 | 2 | 3 | 4 | 88.44 |

| 6 | 2 | 2 | 1 | 4 | 3 | 86.91 |

| 7 | 2 | 3 | 4 | 1 | 2 | 93.57 |

| 8 | 2 | 4 | 3 | 2 | 1 | 95.64 |

| 9 | 3 (1.4 mm) | 1 | 3 | 4 | 2 | 85.87 |

| 10 | 3 | 2 | 4 | 3 | 1 | 89.35 |

| 11 | 3 | 3 | 1 | 2 | 4 | 87.43 |

| 12 | 3 | 4 | 2 | 1 | 3 | 89.41 |

| 13 | 4 (1.6 mm) | 1 | 4 | 2 | 3 | 87.05 |

| 14 | 4 | 2 | 3 | 1 | 4 | 88.95 |

| 15 | 4 | 3 | 2 | 4 | 1 | 84.26 |

| 16 | 4 | 4 | 1 | 3 | 2 | 88.13 |

| K1 | 85.04 | 86.29 | 86.56 | 88.93 | 88.26 | |

| K2 | 91.14 | 87.71 | 86.94 | 88.94 | 88.30 | |

| K3 | 88.02 | 88.09 | 89.39 | 88.25 | 87.62 | |

| K4 | 87.10 | 89.21 | 88.41 | 85.17 | 87.12 | |

| R | 6.10 | 2.92 | 2.83 | 3.77 | 1.18 | |

| S | A2 | B4 | C3 | D2 | ||

| Source | Sum | DOF | Mean Square | F Value | p Value | Significant Test |

|---|---|---|---|---|---|---|

| A: Pin diameter | 77.30 | 3 | 25.77 | 20.19 | 0.02 | * |

| B: Penetration depth | 17.46 | 3 | 5.82 | 4.56 | 0.12 | ns |

| C: Grasping force | 20.66 | 3 | 6.89 | 5.39 | 0.10 | ns |

| D: Extraction speed | 38.69 | 3 | 12.90 | 10.10 | 0.04 | * |

| Deviation | 3.83 | 3 | 1.28 | |||

| Sum | 157.93 |

| Seedling | No. of Seedlings Fed | No. of Extraction Failures | No. of Substrate Breakages | No. of Seedlings Damaged | No. of Planting Failures | Success Rate in Transplanting/% | Average Success Rate/% |

|---|---|---|---|---|---|---|---|

| Tomato | 128 | 2 | 2 | 0 | 2 | 95.31 | 94.22 ± 1.62 |

| 128 | 3 | 3 | 2 | 2 | 92.19 | ||

| 128 | 1 | 2 | 1 | 1 | 96.09 | ||

| 128 | 3 | 4 | 1 | 1 | 92.97 | ||

| 128 | 1 | 2 | 2 | 2 | 94.53 | ||

| Pepper | 128 | 2 | 1 | 2 | 1 | 95.31 | 95.16 ± 1.39 |

| 128 | 2 | 2 | 3 | 2 | 92.97 | ||

| 128 | 1 | 2 | 2 | 1 | 95.31 | ||

| 128 | 2 | 1 | 1 | 0 | 96.88 | ||

| 128 | 1 | 1 | 3 | 1 | 95.31 | ||

| Cabbage | 128 | 2 | 2 | 0 | 1 | 96.09 | 96.41 ± 1.18 |

| 128 | 1 | 3 | 1 | 1 | 95.31 | ||

| 128 | 1 | 3 | 0 | 1 | 96.09 | ||

| 128 | 0 | 2 | 0 | 0 | 98.44 | ||

| 128 | 1 | 2 | 1 | 1 | 96.09 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Han, L.; Zhang, M.; Wang, Y.; Ma, G.; Yang, Q.; Liu, Y. Design and Tests of a Large-Opening Flexible Seedling Pick-Up Gripper with Multiple Grasping Pins. Agronomy 2025, 15, 1634. https://doi.org/10.3390/agronomy15071634

Han L, Zhang M, Wang Y, Ma G, Yang Q, Liu Y. Design and Tests of a Large-Opening Flexible Seedling Pick-Up Gripper with Multiple Grasping Pins. Agronomy. 2025; 15(7):1634. https://doi.org/10.3390/agronomy15071634

Chicago/Turabian StyleHan, Luhua, Meijia Zhang, Yan Wang, Guoxin Ma, Qizhi Yang, and Yang Liu. 2025. "Design and Tests of a Large-Opening Flexible Seedling Pick-Up Gripper with Multiple Grasping Pins" Agronomy 15, no. 7: 1634. https://doi.org/10.3390/agronomy15071634

APA StyleHan, L., Zhang, M., Wang, Y., Ma, G., Yang, Q., & Liu, Y. (2025). Design and Tests of a Large-Opening Flexible Seedling Pick-Up Gripper with Multiple Grasping Pins. Agronomy, 15(7), 1634. https://doi.org/10.3390/agronomy15071634