Effects of Different Types of Pot-Mat Trays on the Growth of Densely Sown Seedlings and Root Morphology of Machine-Transplanted Rice

Abstract

1. Introduction

2. Materials and Methods

2.1. Experimental Materials

2.2. Experimental Design

2.3. Experimental Methods

2.4. Experimental Items

2.4.1. Seedling Quality

2.4.2. Uniformity of Seedling Population

2.4.3. Root Entwining Force

2.4.4. Transplanting Quality

2.4.5. Root Morphology

2.5. Statistical Analysis

3. Results

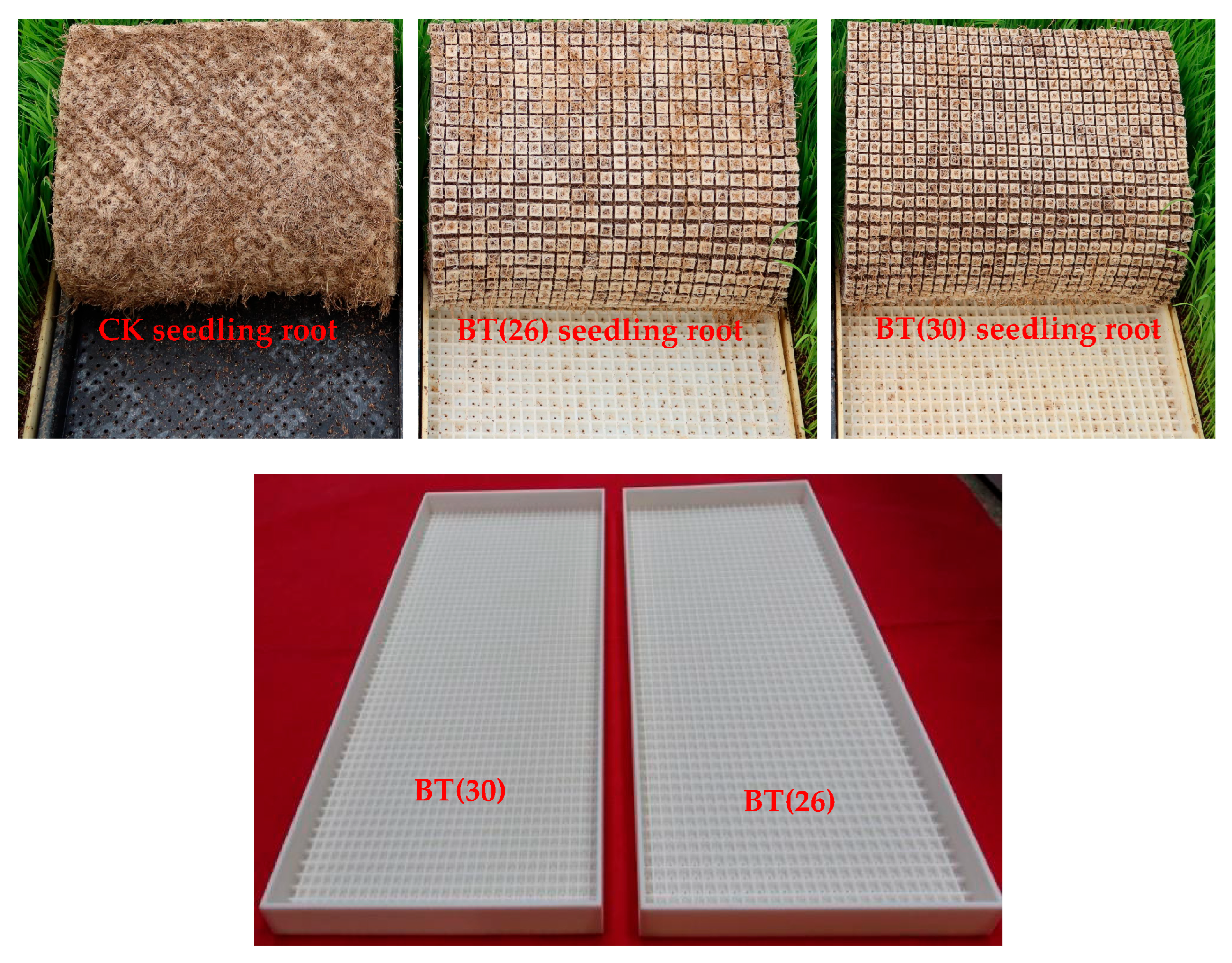

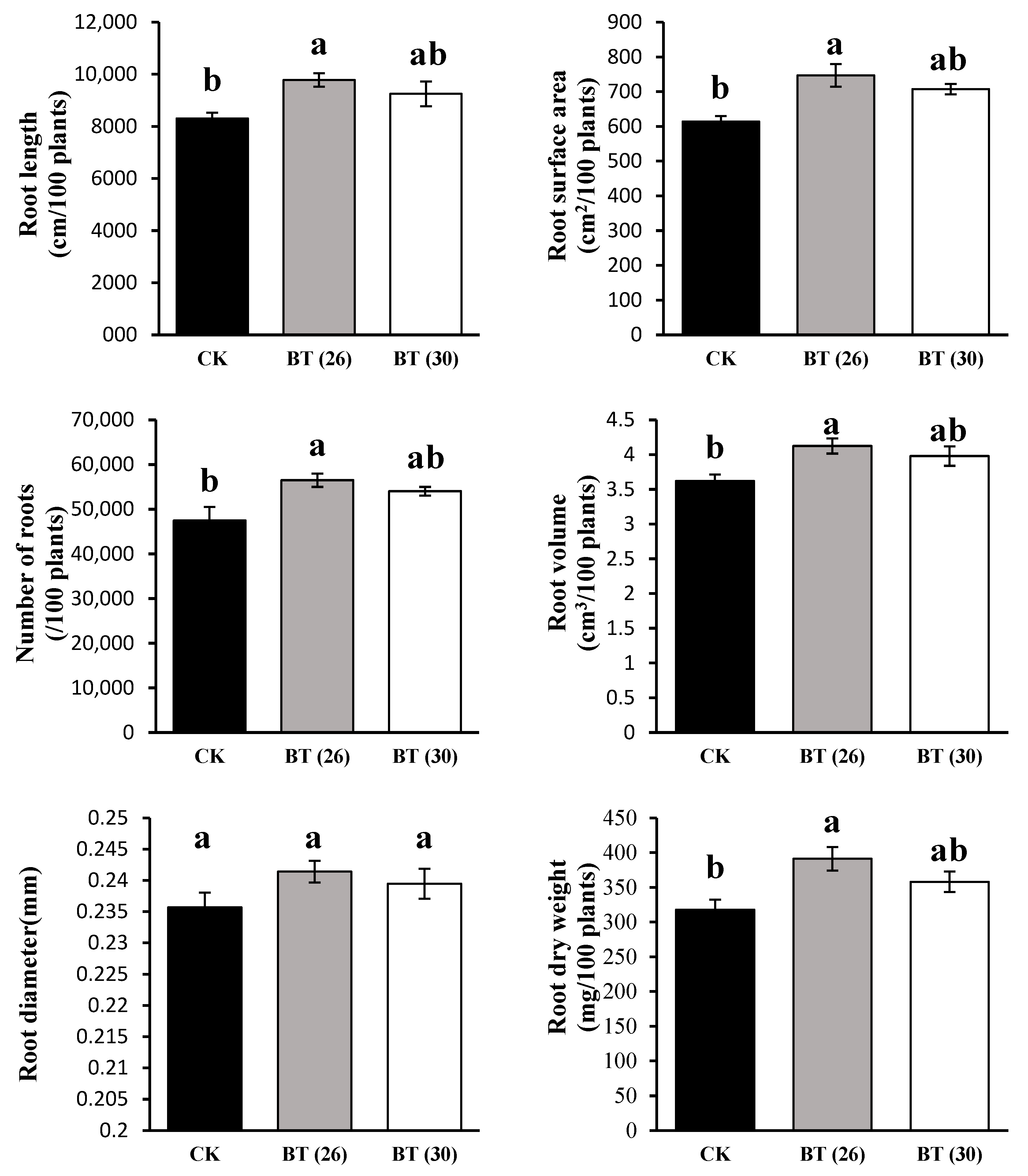

3.1. Seedling Quality and Root Morphology

3.2. Plant Height Uniformity and Root Entwining Force

3.3. Mechanical Transplantation Quality

4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| CK | Flat tray |

| BT | Pot-mat tray |

| BT(26) | Pot-mat tray (26 × 52) |

| BT(30) | Pot-mat tray (30 × 58) |

References

- Sun, T.; Li, H.J.; Wang, C.X.; Li, R.; Zhao, Z.C.; Guo, B.; Yao, L.; Gao, X.H. The Carbon Footprint and Influencing Factors of the Main Grain Crops in the North China Plain. Agronomy 2024, 14, 1720. [Google Scholar] [CrossRef]

- Li, Z.H.; Ma, X.; Li, X.H.; Chen, L.T.; Li, H.W.; Yuan, Z.C. Research Progress of Rice Transplanting Mechanization. Trans. Chin. Soc. Agric. Mach. 2018, 49, 1–20. [Google Scholar]

- Singh, G.; Zhao, B. Agricultural Mechanization Situation in Asia and the Pacific Region. Ama-Agric. Mech. Asia Afr. Lat. Am. 2016, 47, 15–25. [Google Scholar]

- Zhang, M.H.; Wang, Z.M.; Luo, X.W.; Zang, Y.; Yang, W.W.; Xing, H.; Wang, B.L.; Dai, Y.Z. Review of precision rice hill-drop drilling technology and machine for paddy. Int. J. Agric. Biol. Eng. 2018, 11, 1–11. [Google Scholar] [CrossRef]

- Dong, L.Q.; Yang, T.X.; Li, R.; Ma, L.; Feng, Y.Y.; Li, Y.D. Grain Yield, Rice Seedlings and Transplanting Quantity in Response to Decreased Sowing Rate under Precision Drill Sowing. Agriculture 2024, 14, 1745. [Google Scholar] [CrossRef]

- Li, Y.C.; Zhang, Y.W.; Wang, Y.J.; Zhou, Y.F.; Zhang, J.J. Stimulating smart automation of rice seeding in China: An exploration of planter adoption influencing factors. J. Agric. Food Res. 2024, 18, 101394. [Google Scholar] [CrossRef]

- Deng, S.W.; Gao, P.L.; Wang, H.Y.; Chen, Y.L.; Wei, H.H.; Dai, Q.G. Effects of Mixed Planting on Machine Transplanting Adaptability and Grain Yield of Hybrid Rice. Agriculture 2023, 13, 384. [Google Scholar] [CrossRef]

- Huang, M.; Shan, S.L.; Xie, X.B.; Cao, F.B.; Zou, Y.B. Why high grain yield can be achieved in single seedling machine-transplanted hybrid rice under dense planting conditions? J. Integr. Agric. 2018, 17, 1299–1306. [Google Scholar] [CrossRef]

- Ying, W.J.; Wang, Y.L.; Zhu, D.F.; Huai, Y.; Zhang, Y.P.; Xiang, J.; Chen, H.Z. Research Progress of Technology in Rice Seedling Raising and Machine Transplanting. China Rice 2024, 30, 12–16. [Google Scholar]

- Sawamoto, K.; Isemura, H.; Butta, T.; Hamada, E.; Yagi, A.; Uno, F. Growth, yield, grain quality, and seedling characteristics of rice seedlings sown at a high density in nursery boxes in Ishikawa prefecture, Japan. Jpn. J. Crop Sci. 2019, 88, 27–40. [Google Scholar] [CrossRef]

- Ling, Y.F.; Liu, M.Z.; Feng, Y.; Xing, Z.P.; Gao, H.; Wei, H.Y.; Hu, Q.; Zhang, H.C. Effects of increased seeding density on seedling characteristics, mechanical transplantation quality, and yields of rice with crop straw boards for seedling cultivation. J. Integr. Agric. 2025, 24, 101–113. [Google Scholar] [CrossRef]

- Chen, Y.L.; Zhang, Y.K.; Chen, H.Z.; Xiang, J.; Wang, Y.L.; Wang, Z.G.; Xu, Y.W.; Sheng, H.S.; Tian, X.H.; Zhang, Y.P. Analysis of the Influence of New Technology of Rice Seedling Raising and Transplanting on Seedling Quality and Machine Transplanting Quality. Crop Res. 2025, 39, 167–172. [Google Scholar]

- Sasaki, R. Characteristics and seedling establishment of rice nursling seedlings. Jarq-Jpn. Agric. Res. Q. 2004, 38, 7–13. [Google Scholar] [CrossRef]

- Huang, M.; Shan, S.L.; Cao, J.L.; Fang, S.L.; Tian, A.; Liu, Y.; Cao, F.B.; Yin, X.H.; Zou, Y.B. Primary-tiller panicle number is critical to achieving high grain yields in machine-transplanted hybrid rice. Sci. Rep. 2020, 10, 2811. [Google Scholar] [CrossRef]

- Sasaki, R.; Gotoh, K. Characteristics of rooting and early growth of transplanted rice nursling seedlings with several plant ages in leaf number. Jpn. J. Crop Sci. 1999, 68, 194–198. [Google Scholar] [CrossRef]

- Xu, H.C.; He, H.B.; Yang, K.; Ren, H.J.; Zhu, T.Z.; Ke, J.; You, C.C.; Guo, S.S.; Wu, L.Q. Application of the Nitrogen Nutrition Index to Estimate the Yield of Indica Hybrid Rice Grown from Machine-Transplanted Bowl Seedlings. Agronomy 2022, 12, 742. [Google Scholar] [CrossRef]

- Liao, P.; Meng, Y.; Chen, Y.Q.; Weng, W.A.; Chen, L.; Xing, Z.P.; Guo, B.W.; Wei, H.Y.; Gao, H.; Zhang, H.C. Potted-Seedling Machine Transplantation Simultaneously Promotes Rice Yield, Grain Quality, and Lodging Resistance in China: A Meta-Analysis. Agronomy 2022, 12, 3003. [Google Scholar] [CrossRef]

- Zhou, M.L.; Wei, Z.X.; Wang, Z.L.; Sun, H.; Wang, G.B.; Yin, J.J. Design and Experimental Investigation of a Transplanting Mechanism for Super Rice Pot Seedlings. Agriculture 2023, 13, 1920. [Google Scholar] [CrossRef]

- Chen, H.Z.; Xu, Y.C.; Zhang, Y.P.; Xiang, J.; Zhang, Y.K.; Zhu, D.F. Effect of Pot-Mat Seedling on the Quality of Machined Transplanting and Yield Formation of Super Early Rice. Sci. Agric. Sin. 2019, 52, 4240–4250. [Google Scholar]

- Zhang, K.D.; Chen, Y.W.; Sun, L.H.; Chen, S.J.; Mu, J.C.; Cai, F.K.; Meng, Q.D.; Tao, B. Effects of Machine Transplanting of Bowl and Blanket Shaped Seedling and General Blanket Seedling on Rice Yield Component and Yield. J. Anhui Agric. Sci. 2014, 42, 1558–1560. [Google Scholar]

- DuanMu, X.Y.; Wang, R.; Qiu, T.; Wang, X.D.; Li, J.Y.; He, L.H.; Ren, W.J. Quality Difference of Mechanical Seeding and Seedling Raising of Indica Hybrid Rice Varieties under Different Sowing Quantity and Its Relationship with Seed Traits. J. Sichuan Agric. Univ. 2019, 37, 143–151. [Google Scholar]

- Feng, Y.; Liu, M.Z.; Wang, K.T.; Ling, Y.F.; Hu, Q.; Zhang, H.C.; Zhang, H.P. Optimal seeding rate enhances seedling quality, mechanical transplanting quality, and yield in hybrid rice. Front. Plant Sci. 2024, 15, 1427972. [Google Scholar] [CrossRef]

- Wang, W.J.; Xu, R.; Wei, R.; Wang, W.E.; Hu, X.T. Effects of different pressures and laying lengths of micro-sprinkling hose irrigation on irrigation uniformity and yield of spring wheat. Agric. Water Manag. 2023, 288, 108495. [Google Scholar] [CrossRef]

- Fang, H.; Rong, H.; Hallett, P.D.; Monney, S.J.; Zhang, W.J.; Zhou, H.; Peng, X.H. Impact of soil puddling intensity on the root system architecture of rice (Oryza sativa L.) seedlings. Soil Tillage Res. 2019, 193, 1–7. [Google Scholar] [CrossRef]

- Jia, X.; Li, Y.L.; Song, J.N.; Liu, C.L.; Cao, X.L.; Chen, L.C.; Wan, L.P.C.; Ma, X. Effects of different machine transplanting methods on the physiological and yield characteristics of late rice in China. Int. J. Agric. Biol. Eng. 2023, 16, 37–47. [Google Scholar] [CrossRef]

- Li, Y.X.; He, Z.Z.; Li, X.C.; Ding, Y.F.; Li, G.H.; Liu, Z.H.; Tang, S.; Wang, S.H. Quality and Field Growth Characteristics of Hydroponically Grown Long-Mat Seedlings. Agron. J. 2016, 108, 1581–1591. [Google Scholar] [CrossRef]

- Shaikh, N.Y.; Alam, M.A.; Kamruzzaman, M.; Mamun, M.A.A.; Islam, A.S. Effect of seeding density on mat-type seedling quality for mechanical transplanting in dry season rice. Agric. Sci. 2021, 12, 1231–1243. [Google Scholar] [CrossRef]

- Saigusa, M.; Hanaki, M.; Ito, T. Utilization of paddy nitrogen by different ages of rice seedlings. Jpn. J. Crop Sci. 1999, 68, 95–98. [Google Scholar] [CrossRef]

- Huang, M.; Fang, S.L.; Cao, F.B.; Chen, J.N.; Shan, S.L.; Liu, Y.; Lei, T.; Tian, A.L.; Tao, Z.; Zou, Y.B. Early sowing increases grain yield of machine-transplanted late-season rice under single-seed sowing. Field Crops Res. 2020, 253, 107832. [Google Scholar] [CrossRef]

- Tang, J.C.; Zhang, Z.M.; Tung, S.H.; Lu, B.L.; Yang, W.J. Plant growth regulators improve root growth of rice seedlings after mechanical transplanting and increase grain yield. Exp. Agric. 2024, 60, e8. [Google Scholar] [CrossRef]

- Gao, Y.Z.; Zhu, Y.; Zhang, Y.P.; Zhang, Y.K.; Wang, Y.L.; Wang, Z.G.; Chen, H.Z.; Zhang, Y.B.; Xiang, J. Physiological Characteristics of Root Regeneration in Rice Seedlings. Agronomy 2023, 13, 1772. [Google Scholar] [CrossRef]

- Li, H.L.; Wang, C.; Zou, H.F.; Sun, H.T.; Wang, H.X.; Yu, Z.Z.; Shi, J.W.; Liu, X.Y. Structural Design and Performance Test of Biomass-Based Nursery Trays. Sustainability 2022, 14, 9101. [Google Scholar] [CrossRef]

- Yan, F.J.; Sun, Y.J.; Xu, H.; Yin, Y.Z.; Wang, H.Y.; Wang, C.Y.; Guo, C.C.; Yang, Z.Y.; Sun, Y.Y.; Ma, J. Effects of wheat straw mulch application and nitrogen management on rice root growth, dry matter accumulation and rice quality in soils of different fertility. Paddy Water Environ. 2018, 16, 507–518. [Google Scholar] [CrossRef]

- Wang, T.J.; Xiong, W.; Kuang, F.M.; Sun, D.D.; Geng, Z.X.; Que, J.N.; Hou, R.Z.; Zhu, D.Q. Effects of seedling age and root pruning on root characteristics and dry matter accumulation dynamics in machine-transplanted rice. Plant Soil Environ. 2024, 70, 164–175. [Google Scholar] [CrossRef]

- Wu, W.E.; Tu, D.B.; Xi, M.; Xu, Y.Z.; Zhou, Y.J.; Li, Z.; Ji, Y.L.; Sun, X.Y.; Yang, Y.C.; Li, F.Y. Variations of Rice Yield and Quality in Response to Different Establishment Methods at Farmers’ Field. Agronomy 2022, 12, 3174. [Google Scholar] [CrossRef]

- Wang, T.J.; Shi, M.H.; Xi, D.D.; Sun, D.D.; Kuang, F.M.; Xiong, W.; Zhang, S.; Zhu, D.Q. Injury mechanisms in high-speed transplanting of over aged rice seedlings. Biosyst. Eng. 2024, 248, 142–155. [Google Scholar] [CrossRef]

- Yang, J.J.; Zhou, M.L.; Yin, D.Q.; Yin, J.J. Design and Development of Rice Pot-Seedling Transplanting Machinery Based on a Non-Circular Gear Mechanism. Appl. Sci. 2024, 14, 1027. [Google Scholar] [CrossRef]

- Huang, M.; Zou, Y.B. Integrating mechanization with agronomy and breeding to ensure food security in China. Field Crops Res. 2018, 224, 22–27. [Google Scholar] [CrossRef]

- Huang, M.; Fang, S.L.; Cao, F.B.; Chen, J.N.; Shan, S.L.; Liu, Y.; Lei, T.; Tian, A.L.; Tao, Z.; Zou, Y.B. Prolonging seedling age does not reduce grain yields in machine-transplanted early-season rice under precision sowing. Ann. Appl. Biol. 2020, 176, 308–313. [Google Scholar] [CrossRef]

- Liu, Q.H.; Wu, X.; Ma, J.Q.; Chen, B.C.; Xin, C.Y. Effects of Delaying Transplanting on Agronomic Traits and Grain Yield of Rice under Mechanical Transplantation Pattern. PLoS ONE 2015, 10, e0123330. [Google Scholar] [CrossRef]

| Seedling Age | Seedling Tray | Plant Height (cm) | Leaf Age | Shoot Dry Weight (mg/100 Plants) | Root Dry Weight (mg/100 Plants) |

|---|---|---|---|---|---|

| 5 d | CK | 7.74 ± 0.13 b | 1.88 ± 0.04 a | 501.83 ± 43.52 a | 280.17 ± 9.63 a |

| BT(26) | 9.30 ± 0.17 a | 1.91 ± 0.03 a | 542.50 ± 24.07 a | 293.00 ± 18.63 a | |

| BT(30) | 8.89 ± 0.22 a | 1.93 ± 0.04 a | 554.67 ± 14.27 a | 286.33 ± 11.85 a | |

| 10 d | CK | 9.23 ± 0.35 b | 2.31 ± 0.05 a | 723.50 ± 17.53 a | 322.83 ± 12.08 b |

| BT(26) | 10.31 ± 0.20 a | 2.45 ± 0.03 a | 739.50 ± 47.22 a | 387.17 ± 14.49 a | |

| BT(30) | 10.37 ± 0.20 a | 2.43 ± 0.09 a | 725.50 ± 3.67 a | 369.33 ± 13.82 a | |

| 15 d | CK | 11.03 ± 0.26 b | 2.85 ± 0.04 a | 889.34 ± 33.28 a | 334.00 ± 12.27 b |

| BT(26) | 11.75 ± 0.26 ab | 2.77 ± 0.05 a | 981.50 ± 36.72 a | 426.17 ± 15.95 a | |

| BT(30) | 12.08 ± 0.24 a | 2.77 ± 0.07 a | 929.50 ± 34.78 a | 376.15 ± 14.07 b |

| Seedling Tray | Root Length (cm/100 Plants) | Root Surface Area (cm2/100 Plants) | Number of Roots | Root Volume (cm3/100 Plants) | Root Diameter (mm) | Root Dry Weight (mg/100 Plants) |

|---|---|---|---|---|---|---|

| CK | 1633.79 ± 128.23 b | 126.86 ± 11.72 b | 8289.41 ± 679.48 b | 0.78 ± 0.08 b | 0.25 ± 0.01 b | 46.96 ± 4.60 b |

| BT(26) | 2048.85 ± 65.22 ab | 170.47 ± 4.20 a | 9814.19 ± 731.43 ab | 1.13 ± 0.02 a | 0.26 ± 0.01 ab | 58.54 ± 4.21 ab |

| BT(30) | 2279.82 ± 164.29 a | 192.61 ± 12.01 a | 13,026.56 ± 1153.91 a | 1.30 ± 0.08 a | 0.27 ± 0.01 a | 69.12 ± 1.50 a |

| Seedling Tray | Root Length (%) | Root Surface Area (%) | Root Volume (%) |

|---|---|---|---|

| CK | 80.39 ± 1.03 a | 79.36 ± 1.77 a | 78.42 ± 1.88 a |

| BT(26) | 79.01 ± 1.03 a | 77.08 ± 1.36 ab | 72.58 ± 0.97 ab |

| BT(30) | 75.28 ± 1.85 a | 72.80 ± 1.24 b | 67.20 ± 3.01 b |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shang, Y.; Zhang, P.; Ma, X.; Wu, X.; Chen, Y.; Chen, H.; Zhang, Y.; Xiang, J.; Wang, Y.; Wang, Z.; et al. Effects of Different Types of Pot-Mat Trays on the Growth of Densely Sown Seedlings and Root Morphology of Machine-Transplanted Rice. Agronomy 2025, 15, 1616. https://doi.org/10.3390/agronomy15071616

Shang Y, Zhang P, Ma X, Wu X, Chen Y, Chen H, Zhang Y, Xiang J, Wang Y, Wang Z, et al. Effects of Different Types of Pot-Mat Trays on the Growth of Densely Sown Seedlings and Root Morphology of Machine-Transplanted Rice. Agronomy. 2025; 15(7):1616. https://doi.org/10.3390/agronomy15071616

Chicago/Turabian StyleShang, Yuhang, Peng Zhang, Xinling Ma, Xiang Wu, Yulin Chen, Huizhe Chen, Yuping Zhang, Jing Xiang, Yaliang Wang, Zhigang Wang, and et al. 2025. "Effects of Different Types of Pot-Mat Trays on the Growth of Densely Sown Seedlings and Root Morphology of Machine-Transplanted Rice" Agronomy 15, no. 7: 1616. https://doi.org/10.3390/agronomy15071616

APA StyleShang, Y., Zhang, P., Ma, X., Wu, X., Chen, Y., Chen, H., Zhang, Y., Xiang, J., Wang, Y., Wang, Z., Xu, Y., Zhang, X., & Zhang, Y. (2025). Effects of Different Types of Pot-Mat Trays on the Growth of Densely Sown Seedlings and Root Morphology of Machine-Transplanted Rice. Agronomy, 15(7), 1616. https://doi.org/10.3390/agronomy15071616