Sustainable Valorization of Tequila Industry Vinasse: A Patent Review on Bioeconomy-Driven Technologies

Abstract

1. Introduction

2. Materials and Methods

3. Results

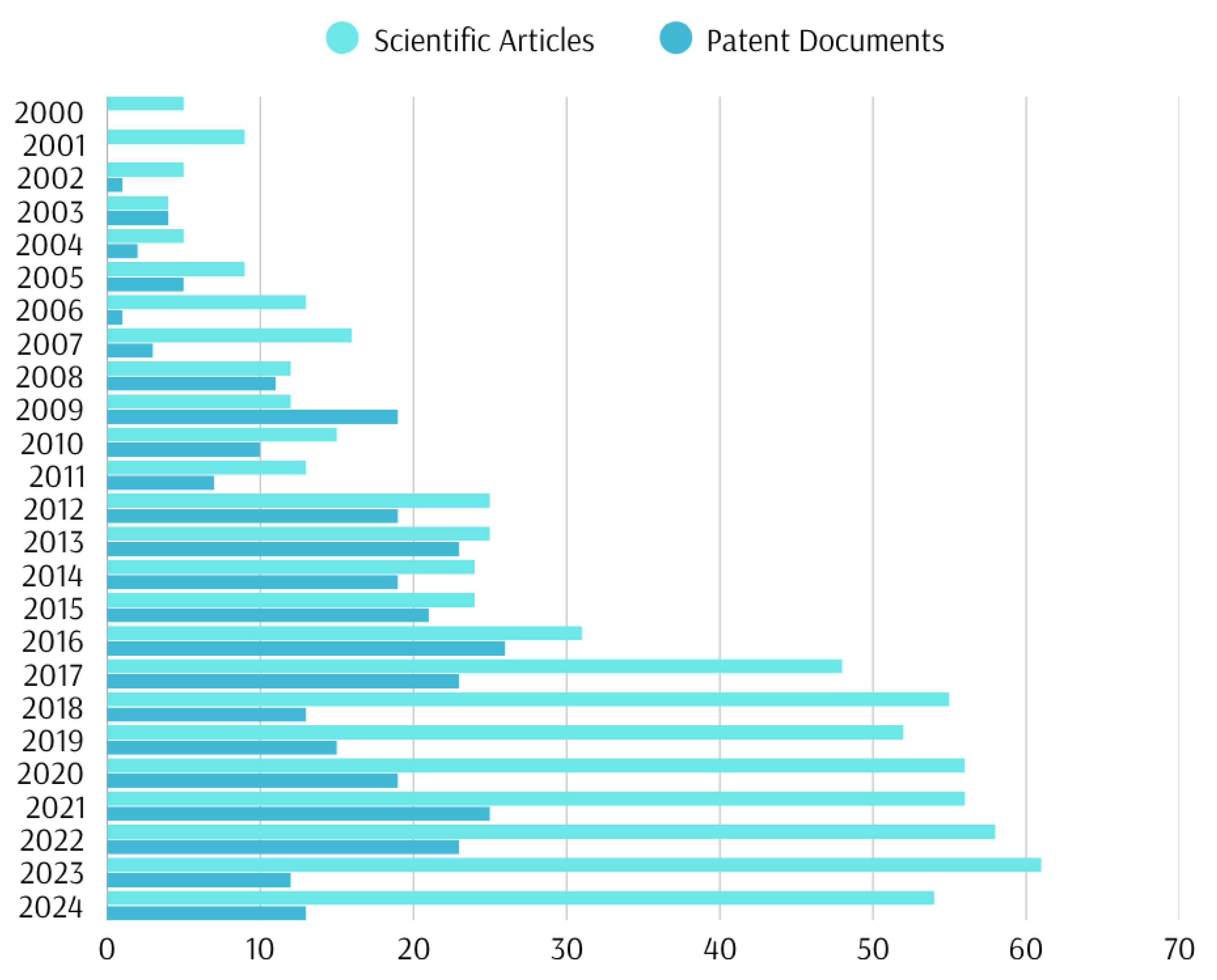

3.1. Technological and Scientific Landscape Analysis: Temporal, Technical, and Geographical Perspectives

Historical Development of Research Publications

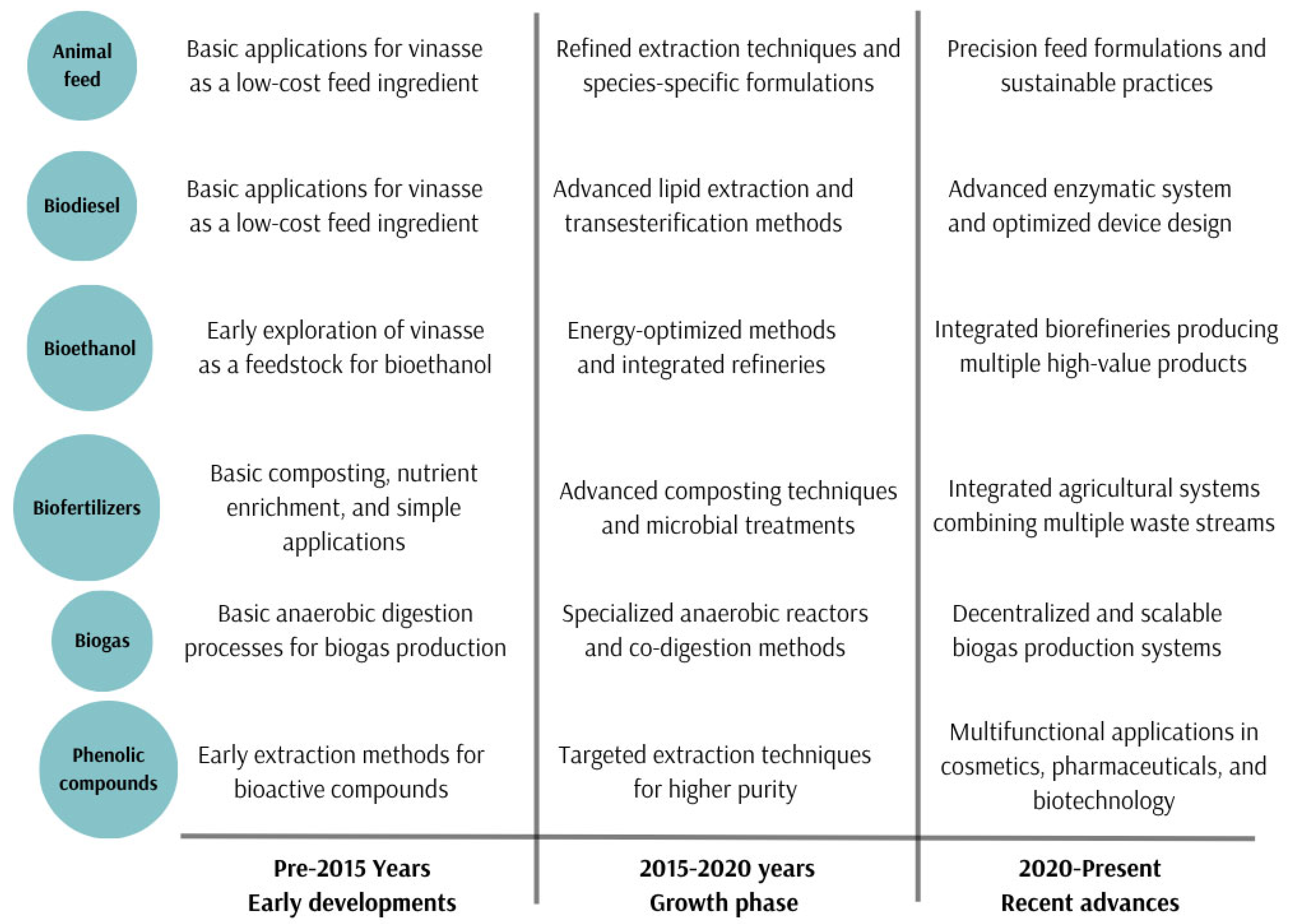

3.2. Chronological Analysis of Vinasse Byproduct Patent Documents

General Evolution of Byproduct Technology

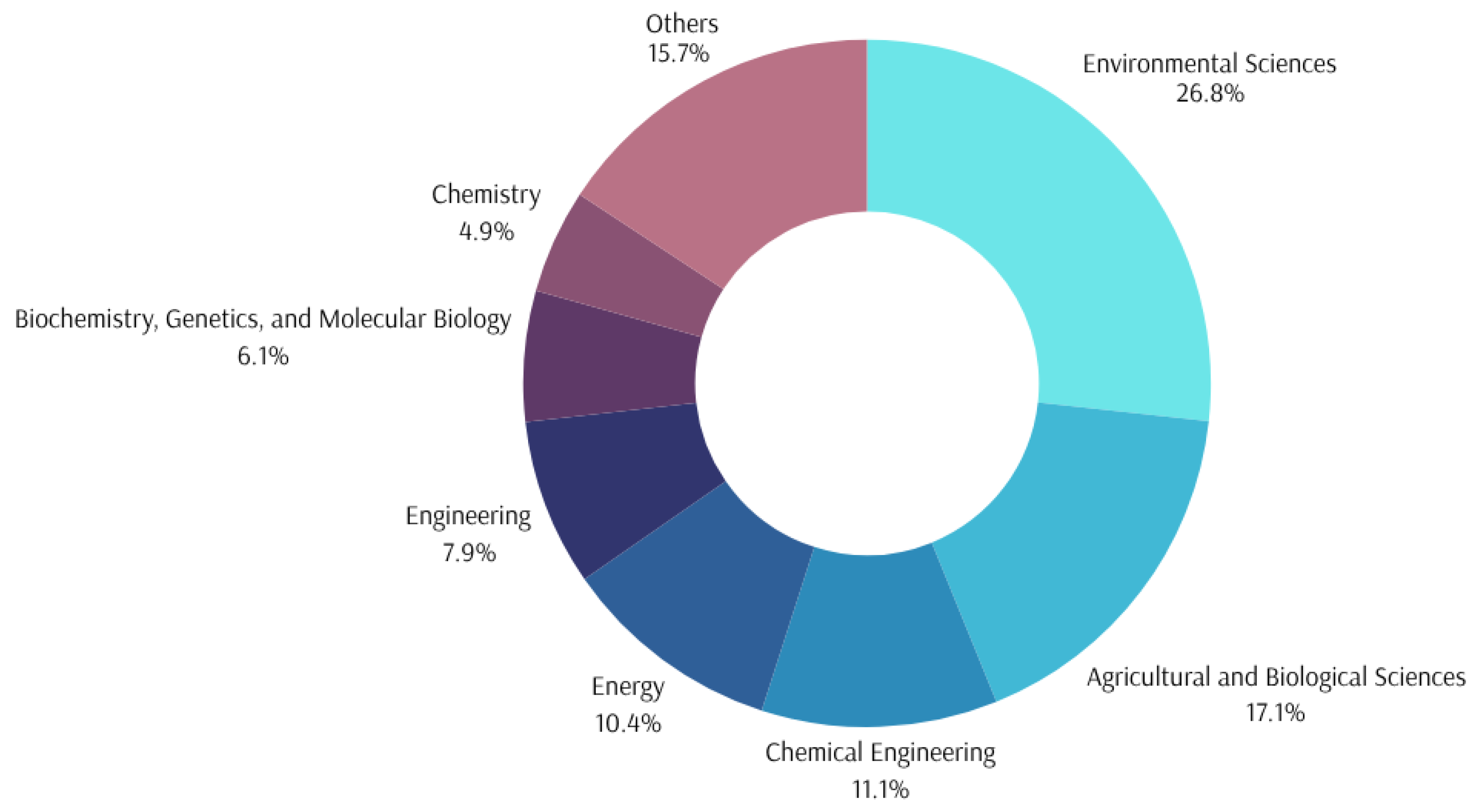

3.3. Subject Area of Scientific Articles

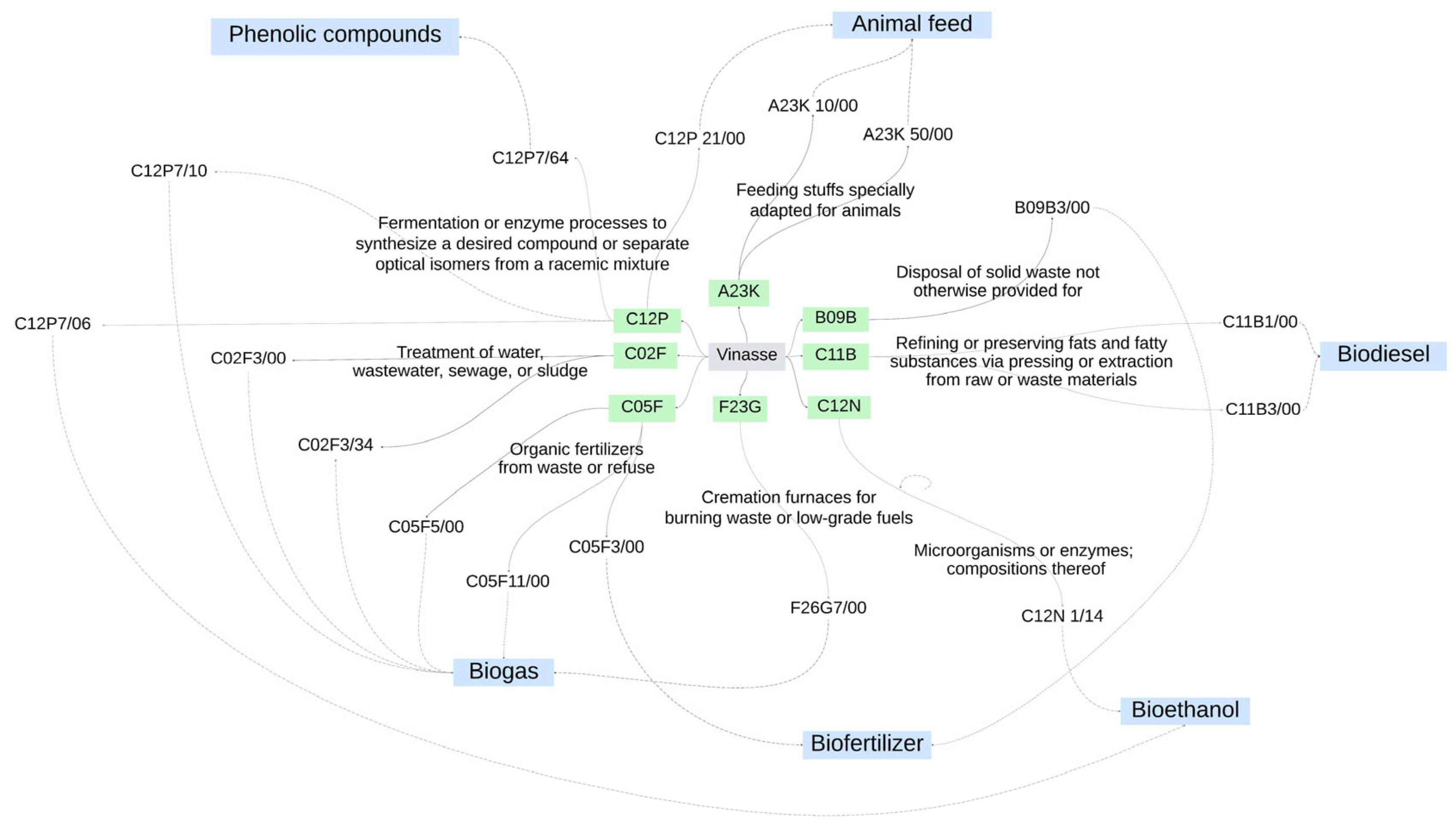

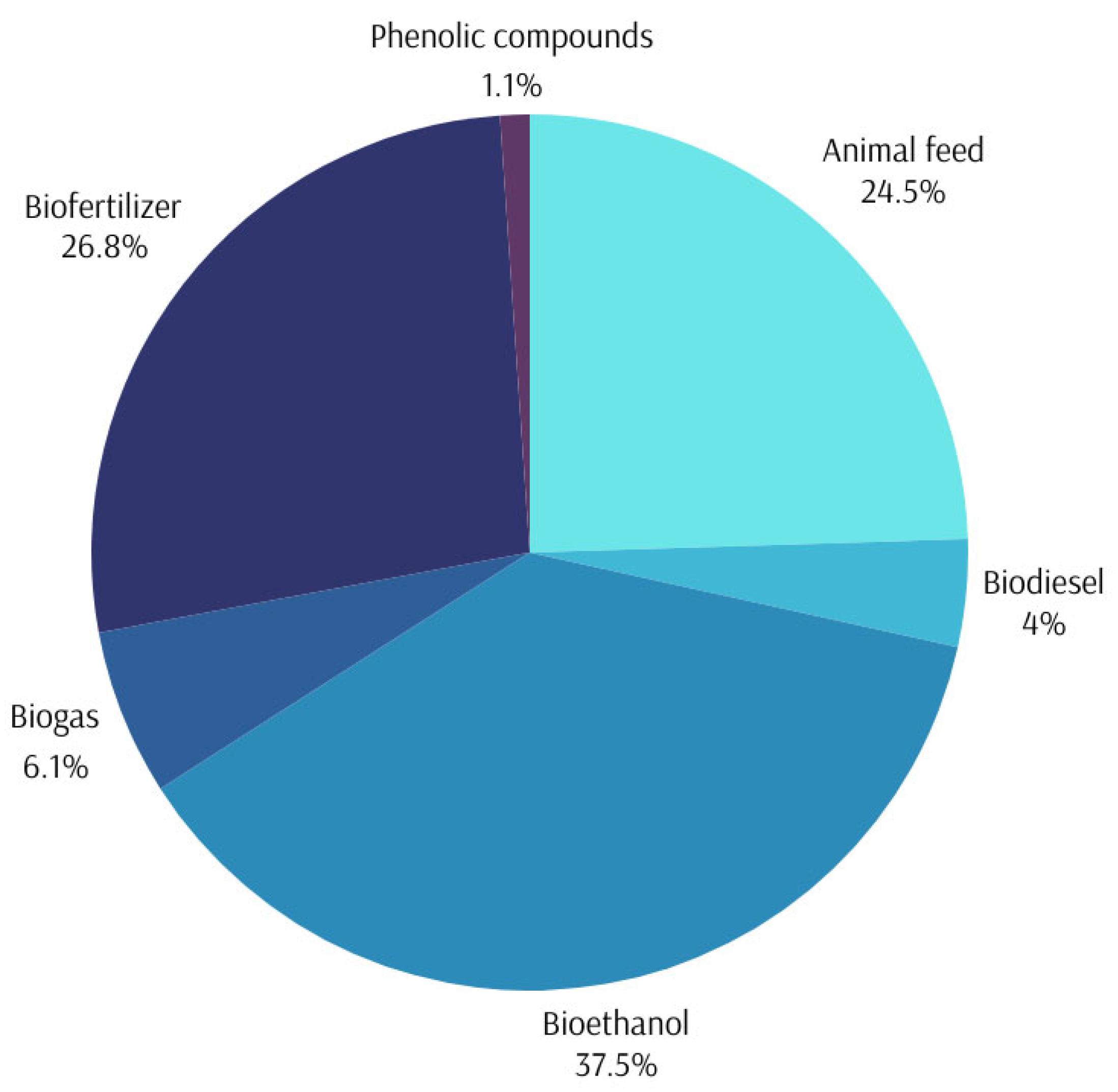

3.4. Technological Domains of Patent Documents

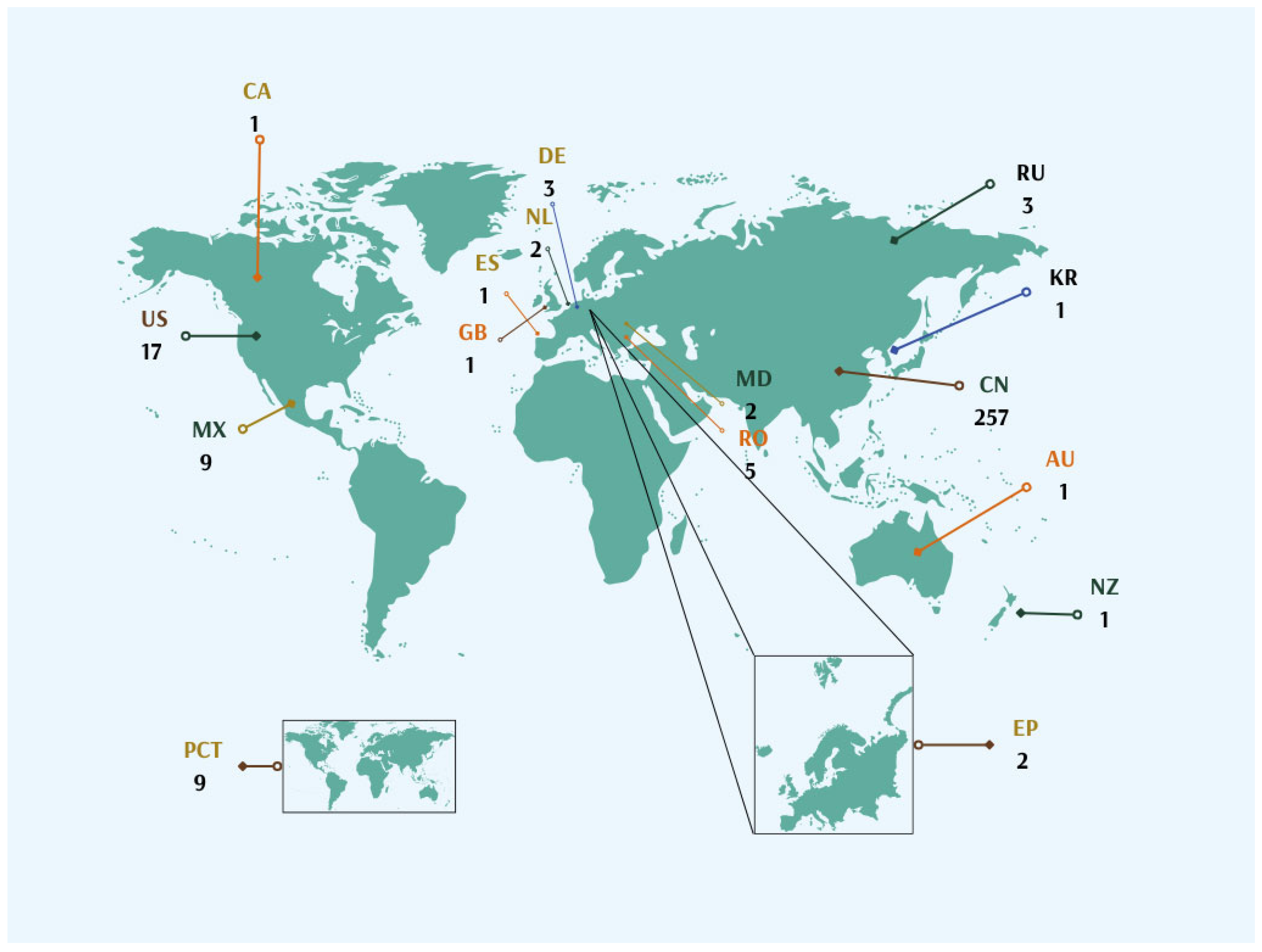

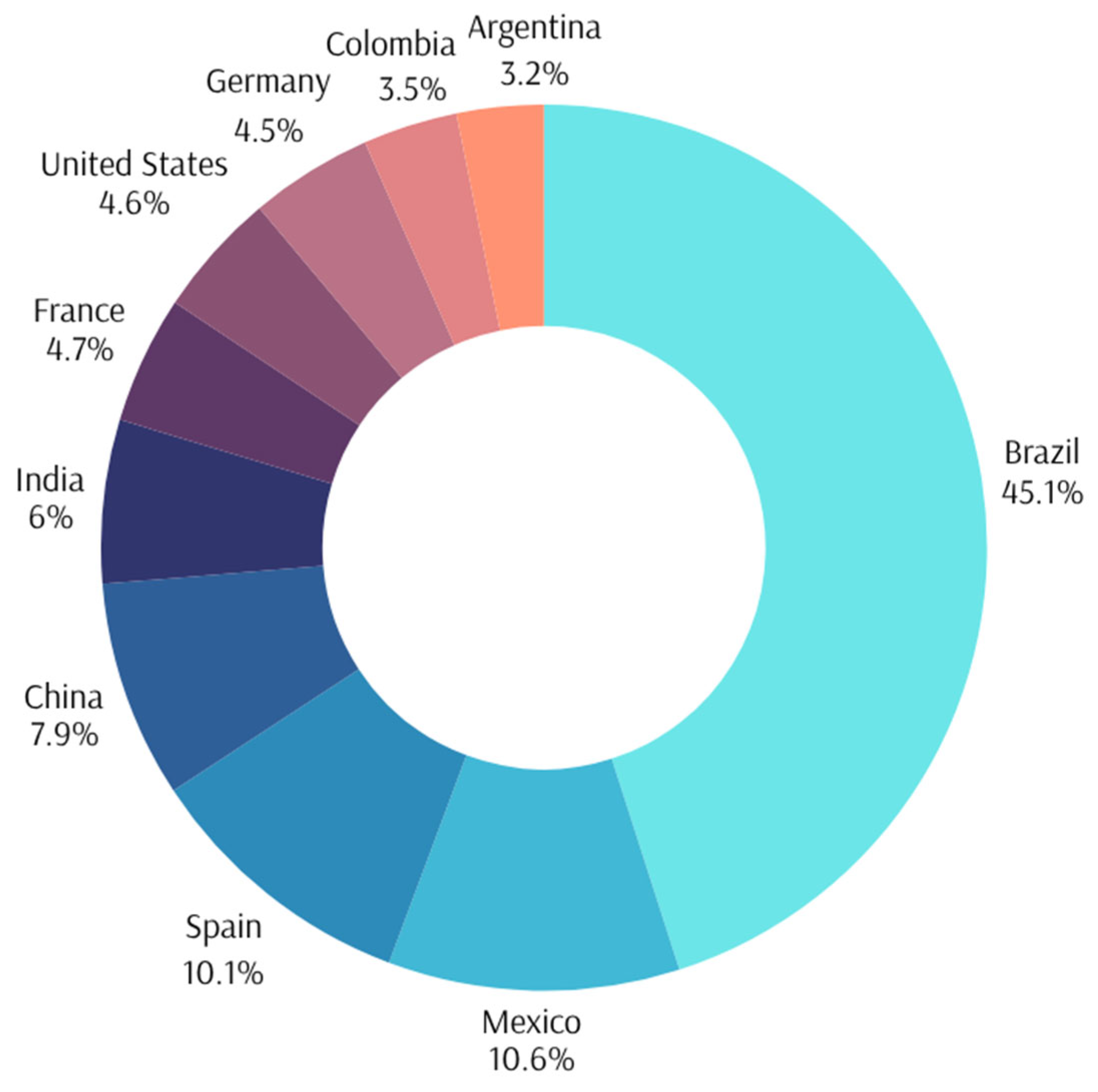

3.5. Country of Origin of Patent Documents and Scientific Articles

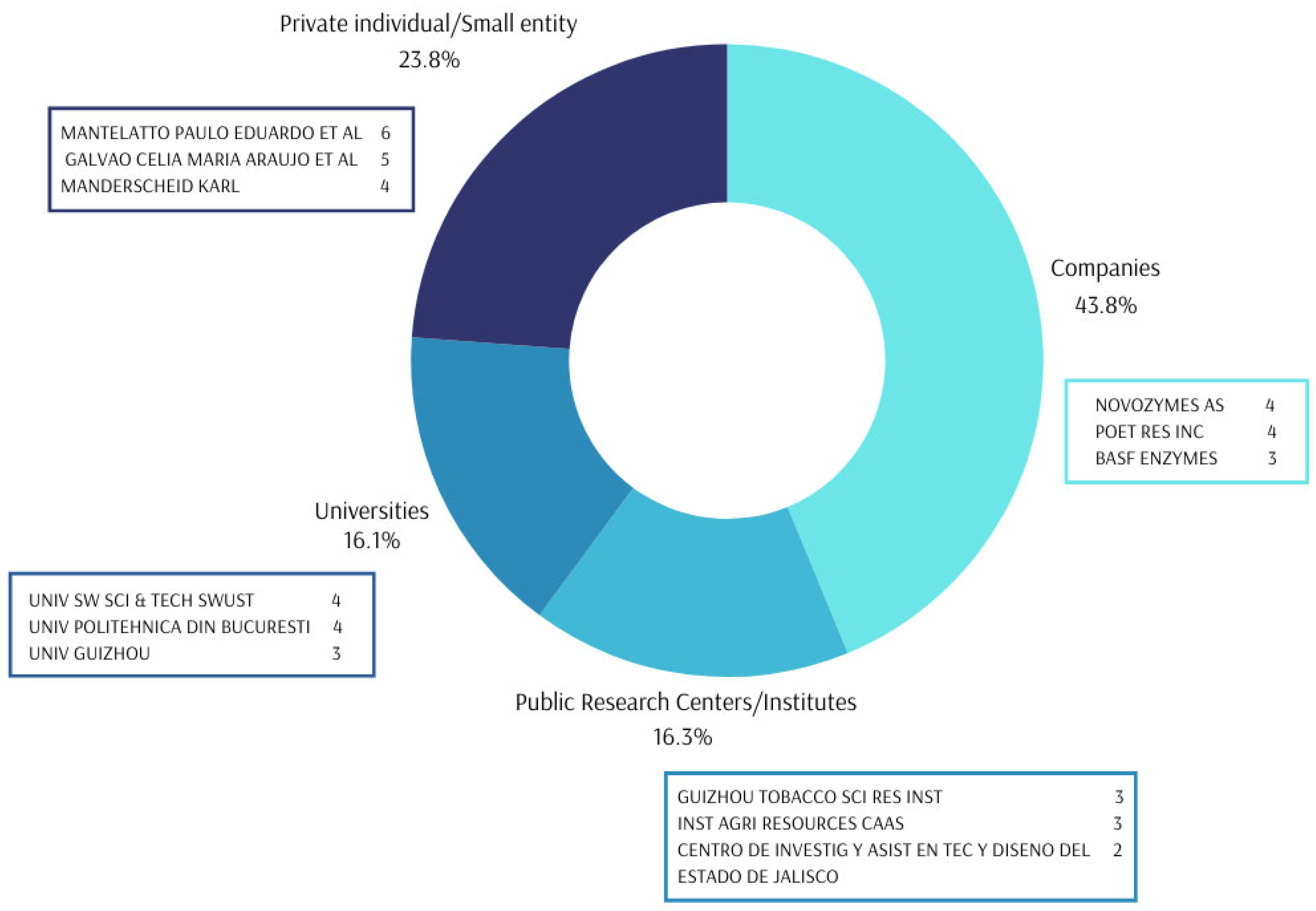

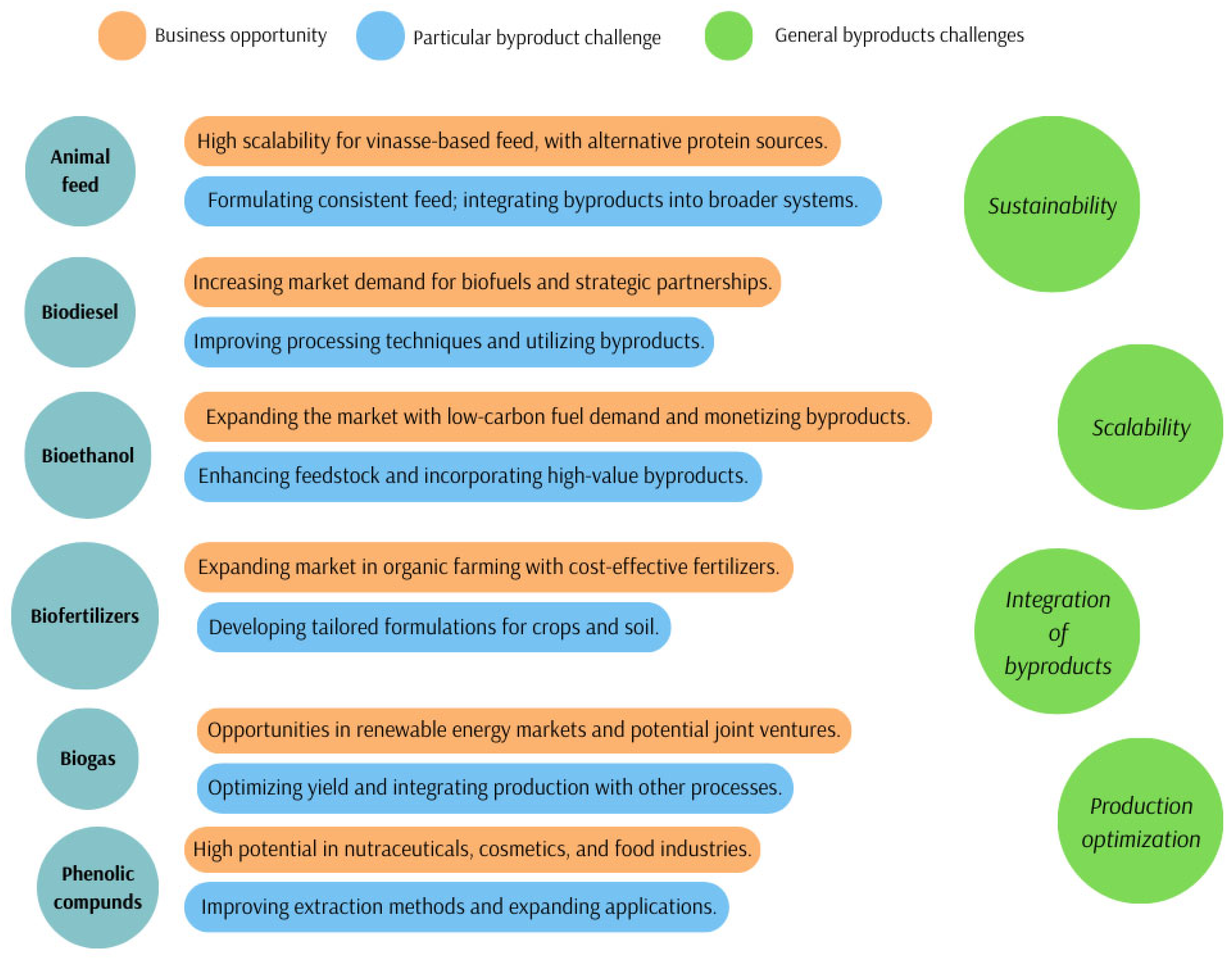

3.6. Technological Prospection

4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| CRT | Tequila Regulatory Council |

| COD | Chemical Oxygen Demand |

| COW | Cutting Oil Wastewater |

| IPC | International Patent Classification |

References

- Consejo Regulador del Tequila. Estadísticas; Consejo Regulador del Tequila: Zapopan, Mexico, 2024. [Google Scholar]

- Secretaria de Agricultura y Desarrollo Rural. Gobierno de México. 2021. Available online: https://www.gob.mx/agricultura/articulos/tequila-bebida-mexicana-por-excelencia?idiom=es (accessed on 26 May 2025).

- Cámara Nacional de la Industria Tequilera. El Tequila; Cámara Nacional de la Industria Tequilera: Guadalajara, Mexico, 2024. [Google Scholar]

- de Jesús Rodríguez-Romero, J.; Aceves-Lara, C.A.; Silva, C.F.; Gschaedler, A.; Amaya-Delgado, L.; Arrizon, J. 2-Phenylethanol and 2-phenylethylacetate production by nonconventional yeasts using tequila vinasses as a substrate. Biotechnol. Rep. 2020, 25, e00420. [Google Scholar] [CrossRef] [PubMed]

- Díaz-Vázquez, D.; Garibay, M.V.; Fernández del Castillo, A.; Orozco-Nunnelly, D.A.; Senés-Guerrero, C.; Gradilla-Hernández, M.S. Yeast community composition impacts on tequila industry waste treatment for pollution control and waste-to-product synthesis. Front. Chem. Eng. 2022, 4, 1013873. [Google Scholar] [CrossRef]

- Ramírez-Ramírez, A.A.; Lozano-Álvarez, J.A.; Gutiérrez-Lomelí, M.; Zurita, F. Tequila Vinasse Treatment in Two Types of Vertical Downflow Treatment Wetlands (with Emergent Vegetation and Ligninolytic Fungi). Water 2024, 16, 1778. [Google Scholar] [CrossRef]

- Díaz-Vázquez, D.; Orozco-Nunnelly, D.A.; Yebra-Montes, C.; Senés-Guerrero, C.; Gradilla-Hernández, M.S. Using yeast cultures to valorize tequila vinasse waste: An example of a circular bioeconomy approach in the agro-industrial sector. Biomass Bioenergy 2022, 161, 106471. [Google Scholar] [CrossRef]

- Najar-Almanzor, C.E.; Velasco-Iglesias, K.D.; Nunez-Ramos, R.; Uribe-Velázquez, T.; Solis-Bañuelos, M.; Fuentes-Carrasco, O.J.; Chairez, I.; García-Cayuela, T.; Carrillo-Nieves, D. Microalgae-assisted green bioremediation of food-processing wastewater: A sustainable approach toward a circular economy concept. J. Environ. Manag. 2023, 345, 118774. [Google Scholar] [CrossRef]

- Alemán-Nava, G.S.; Gatti, I.A.; Parra-Saldivar, R.; Dallemand, J.-F.; Rittmann, B.E.; Iqbal, H.M. Biotechnological revalorization of Tequila waste and by-product streams for cleaner production–A review from bio-refinery perspective. J. Clean. Prod. 2018, 172, 3713–3720. [Google Scholar] [CrossRef]

- Kumar, G.; Kim, S.-H.; Lay, C.-H.; Ponnusamy, V.K. Recent developments on alternative fuels, energy and environment for sustainability. Bioresour. Technol. 2020, 317, 124010. [Google Scholar] [CrossRef]

- Teymennet-Ramírez, K.V.; García-Morales, S.; Hernández-Fernández, O.; Barrera-Martínez, I. Detoxification of tequila vinasse by Trametes sanguineus: A biotechnological approach to laccase production and water reuse in seedling growth. Environ. Sci. Pollut. Res. 2025, 1–12. [Google Scholar] [CrossRef]

- Ferral-Pérez, H.; Torres Bustillos, L.; Méndez, H.; Rodríguez-Santillan, J.; Chairez, I. Sequential treatment of tequila industry vinasses by biopolymer-based coagulation/flocculation and catalytic ozonation. Ozone Sci. Eng. 2016, 38, 279–290. [Google Scholar] [CrossRef]

- The World Intellectual Property Organization. What Is Intellectual Property? WIPO: Geneva, Switzerland, 2003. [Google Scholar]

- Czajkowski, A. Using and Exploiting Patent Information; World Intellectual Property Organization: Geneva, Switzerland, 2014; pp. 1–60. [Google Scholar]

- Nascimento, L.L.; Pereira, M.S.; de Almeida, L.S.; da Silveira Ferreira, L.; de Moura Pita, B.L.; de Souza, C.O.; Ribeiro, C.D.F.; Fricks, A.T. Innovation in cocoa fermentation: Evidence from patent documents and scientific articles. Fermentation 2024, 10, 251. [Google Scholar] [CrossRef]

- de Souza, R.P.; Girardi, F.; Santana, V.S.; Fernandes-Machado, N.R.C.; Gimenes, M.L. Vinasse treatment using a vegetable-tannin coagulant and photocatalysis. Acta Sci. Technol. 2013, 35, 89–95. [Google Scholar] [CrossRef]

- Christofoletti, C.A.; Escher, J.P.; Correia, J.E.; Marinho, J.F.U.; Fontanetti, C.S. Sugarcane vinasse: Environmental implications of its use. Waste Manag. 2013, 33, 2752–2761. [Google Scholar] [CrossRef] [PubMed]

- Mota, V.T.; Santos, F.S.; Amaral, M.C. Two-stage anaerobic membrane bioreactor for the treatment of sugarcane vinasse: Assessment on biological activity and filtration performance. Bioresour. Technol. 2013, 146, 494–503. [Google Scholar] [CrossRef] [PubMed]

- Adarme, O.F.H.; Baêta, B.E.L.; Gabriel Filho, J.B.; Gurgel, L.V.A.; de Aquino, S.F. Use of anaerobic co-digestion as an alternative to add value to sugarcane biorefinery wastes. Bioresour. Technol. 2019, 287, 121443. [Google Scholar] [CrossRef]

- Perez, M.; Rodriguez-Cano, R.; Romero, L.; Sales, D. Anaerobic thermophilic digestion of cutting oil wastewater: Effect of co-substrate. Biochem. Eng. J. 2006, 29, 250–257. [Google Scholar] [CrossRef]

- Beltran de Heredia, J.; Torregrosa, J.; Dominguez, J.; Partido, E. Distillery wastewaters treatment-Degradation of wine distillery wastewaters by the combination of aerobic biological treatment with chemical oxidation by Fenton’s reagent. Water Sci. Technol. 2005, 51, 167–174. [Google Scholar] [CrossRef]

- España-Gamboa, E.; Vicent, T.; Font, X.; Dominguez-Maldonado, J.; Canto-Canché, B.; Alzate-Gaviria, L. Pretreatment of vinasse from the sugar refinery industry under non-sterile conditions by Trametes versicolor in a fluidized bed bioreactor and its effect when coupled to an UASB reactor. J. Biol. Eng. 2017, 11, 6. [Google Scholar] [CrossRef]

- Molina-Cortés, A.; Sánchez-Motta, T.; Tobar-Tosse, F.; Quimbaya, M. Spectrophotometric estimation of total phenolic content and antioxidant capacity of molasses and vinasses generated from the sugarcane industry. Waste Biomass Valorization 2020, 11, 3453–3463. [Google Scholar] [CrossRef]

- Silva, V.; Rabelo, C.A.; Camargo, F.P.; Sakamoto, I.K.; Silva, E.L.; Varesche, M.B.A. Optimization of key factors affecting hydrogen and ethanol production from xylose by Thermoanaerobacterium calidifontis VCS1 isolated from vinasse treatment sludge. Waste Biomass Valorization 2022, 13, 1897–1912. [Google Scholar] [CrossRef]

- Carpanez, T.; Moreira, V.; Assis, I.; Amaral, M. Sugarcane vinasse as organo-mineral fertilizers feedstock: Opportunities and environmental risks. Sci. Total Environ. 2022, 832, 154998. [Google Scholar] [CrossRef]

- Friedmann, H. Apparatus and Process for the Conversion into Biogas of Fermentation Stillage Arising as a Waste Product of Ethanol Production. CA2646377A, 12 December 2008. [Google Scholar]

- Mahler, J. Method for the Production of Bioethanol and for the Coproduction of Energy from a Starchy Plant Starting Material. CA2653059A1, 10 January 2008. [Google Scholar]

- Pollert, G.; Luedtke, O.; Fitcher, E.; Bettien, K.-D. Energy-Optimized Method for Operating a Bioethanol Production Plant. WO2010139699A2, 1 June 2010. [Google Scholar]

- Carthery Arnoldo, L.J.; Bonkoski, W.; Vallero Guerini, M.V.; Lima Barata, F.C.; Zabeu, C.; Arntsen, B. Vinasse Treatment for Water Reuse, Fertilizer and Biogas Production. WO2014098874A1, 20 December 2012. [Google Scholar]

- Li, C.; Zhang, B.; Gao, L. Distillate Spirit Vinasse Spot Comprehensive Utilization Method. CN102921700A, 13 February 2013. [Google Scholar]

- Xin, Y.; Cui, D.; Ma, D.; Wang, B.; Jin, S. Method for Preparing Fuel Gas and Biogas Manures by Using Beer Brewing Wastes. CN103008323A, 3 April 2013. [Google Scholar]

- Liu, W. Comprehensive Utilization Method of Vinasse. CN103849414A, 14 May 2013. [Google Scholar]

- Vuori, A. Method for Reducing Potassium Content in Vinasse, Its Use, Precipitate and Process Solution. WO2013087969A1, 20 June 2013. [Google Scholar]

- Wu, Z.; Sun, Y.; Zhao, Y. Method for Producing Biodiesel and Feed by Use of Acorn Vinasse. CN104531366A, 5 December 2014. [Google Scholar]

- Zhen, F.; Zhu, H.; Yue, R.; Xu, F.; Zhang, Y. Animal Feed and Preparation Method Thereof. CN105285324A, 20 November 2015. [Google Scholar]

- Xu, H.; Xu, Z. Method for Extracting Organic Phenolic Ester Alcohol and Saccharide Fermentation Enzyme Natural Organic Vitamin from Piper Spicatum Fruits. CN104291884A, 21 January 2015. [Google Scholar]

- Wu, Z.; Sun, Y.; Zhao, Y. The Device of Biofuel and Feed Prepared by a Kind of Acorn Nut Vinasse. CN204369842U, 3 June 2015. [Google Scholar]

- Chen, S.; Xiao, L.; Qin, S.; Wang, J.; Liu, X.; Lin, L. Bio-Refinery Integrated Process for Separating and Classifying Whole-Plant Corn Component. CN104630307A, 2 May 2015. [Google Scholar]

- Lu, X. Earthworm Feed Utilizing Cassava Vinasse. CN106562007A, 11 November 2016. [Google Scholar]

- Hu, A. Breeding Farm Waste Gas Recycling Method. CN105779504A, 14 March 2016. [Google Scholar]

- Qi, F. System for Recycling Waste Resources Generated by Brewing White Spirits. CN105562426A, 24 February 2016. [Google Scholar]

- Lei, C. Application of the Green Feed Additive in Eupolyphoge Sinensis Cultivation. CN109673825A, 18 October 2017. [Google Scholar]

- Gao, H. The Preparation Method of Fertilizer. CN107915518A, 17 April 2018. [Google Scholar]

- Covaliov, V.; Covaliova, O.; Nenno, V. Combined Process for Obtaining Methane. MD20190055A2, 8 July 2019. [Google Scholar]

- Tang, Z. Commercial Wormcast Organic Fertilizer. CN112194510A, 14 October 2020. [Google Scholar]

- Zhao, J.; Guo, Y.; Li, X.; Qu, Y. A Cellulase System Capable of Improving the Conversion Rate of Corn Cellulose to Prepare Saccharified Liquid and Its Application. CN113061597A, 16 April 2021. [Google Scholar]

- Yu, J.; Liu, S.; Chen, D.; Ren, W.; Xu, M. Ecological Breeding Method Integrating Pig Breeding and Earthworm Breeding. CN112868600A, 28 January 2021. [Google Scholar]

- Liu, J.; Dai, P.; Chen, S.; Yuan, S.; Zhen, J. Formula and Method for Preparing Medicinal and Edible Dual-Purpose Insect Breeding Soil with Discarded Grains as Main Raw Material. CN115886162A, 7 December 2022. [Google Scholar]

- Zhang, Z.; He, R.; Ran, Y.; Yang, Q.; Song, D.G. Maotai-Flavor Vinasse Biogas Slurry Application Method. CN115735508A, 2 November 2022. [Google Scholar]

- Chen, J. Distributed Environment-Friendly Organic Solid Waste Treatment Method. CN115213193A, 7 June 2022. [Google Scholar]

- Lei, X.; Xiong, Y.; Deng, B.; Huo, D.; Hou, C.; Zeng, S.; Li, J. Treatment Method and System for Vinasse. CN116851407A, 26 July 2023. [Google Scholar]

- Anjun, L.; Hongkui, H.; Huawei, Z.; Runjie, C.; Jintong, M.; Jingxin, L.; Liming, Q.; Manli, M.; Renzhi, W. Selenium-rich vinasse feed as well as preparation method and application thereof. CN11761735A, 18 December 2023. [Google Scholar]

- Natalicchio, A.; Mora, L.; Ardito, L.; Messeni Petruzzelli, A. Evidence-informed decision-making in Smart Specialisation Strategies: A patent-based approach for discovering regional technological capabilities. Reg. Stud. 2022, 56, 1442–1453. [Google Scholar] [CrossRef]

- Zhang, X.; Zhao, C.; Shao, M.W.; Chen, Y.L.; Liu, P.; Chen, G.Q. The roadmap of bioeconomy in China. Eng. Biol. 2022, 6, 71–81. [Google Scholar] [CrossRef] [PubMed]

- Fit, C.G.; Clauser, N.M.; Felissia, F.E.; Area, M.C. Biorefinery design from agroindustrial by-products and its scaling-up analysis. Bioresour. Technol. Rep. 2025, 31, 102175. [Google Scholar] [CrossRef]

- Montiel-Rosales, A.; Montalvo-Romero, N.; Garcia-Santamaria, L.E.; Sandoval-Herazo, L.C.; Bautista-Santos, H.; Fernández-Lambert, G. Post-industrial use of sugarcane ethanol vinasse: A systematic review. Sustainability 2022, 14, 11635. [Google Scholar] [CrossRef]

| Criterion | Inclusion | Exclusion |

|---|---|---|

| Patent content (abstract description) |

|

|

| Byproduct category |

|

|

| Vinasse use/transformation |

|

|

| Technical feasibility and depth |

|

|

| Patent quality |

|

|

| Title | Main Objective | Findings |

|---|---|---|

| Use of Anaerobic Co-digestion for Sugarcane Biorefinery Wastes [19] | Evaluate how different combinations of sugarcane byproducts affect methane production in anaerobic digestion | Optimal conditions for biogas were identified with good methane yields. Sugarcane bagasse fly ash enhanced biogas production. |

| Anaerobic Thermophilic Digestion of Cutting Oil Wastewater [20] | Investigate the effect of cutting oil wastewater (COW) when co-digested with vinasse in a thermophilic anaerobic reactor | Vinasse alone showed good biogas production, but COW reduced methane production and COD removal. Further research is needed for COW degradation. |

| Degradation of Wine Distillery Wastewaters Using Aerobic Treatment and Fenton’s Reagent [21] | Examine the combined effects of aerobic treatment and Fenton’s reagent on wine distillery wastewater | The aerobic treatment effectively degraded COD, biomass, and aromatic compounds. The use of Fenton’s reagent further degraded contaminants, and a kinetic model was developed to optimize the process. |

| Start-up Phase of Anaerobic Co-digestion from Food Waste and Vinasse [22] | Investigate the start-up phase of anaerobic co-digestion with food waste and vinasse to optimize hydrogen and methane production | The study demonstrated significant reduction in total solids, peak hydrogen production at 76.5%, and high methane production with over 300 mL of biogas per g of volatile solids. |

| Pretreatment of Vinasse Using Trametes Versicolor and UASB Reactor [23] | Assess the effectiveness of Trametes versicolor for pretreating vinasse in a fluidized bed bioreactor coupled with an Upflow Anaerobic Sludge Blanket reactor | The pretreatment removed phenolic compounds and COD, improving methane production. The system showed potential for industrial application. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Suárez-Sánchez, M.; Merritt, H.; Oyoque-Salcedo, G.; Estrella-Santiago, D.P.; Oregel-Zamudio, E.; Arias-Martínez, S. Sustainable Valorization of Tequila Industry Vinasse: A Patent Review on Bioeconomy-Driven Technologies. Agronomy 2025, 15, 1567. https://doi.org/10.3390/agronomy15071567

Suárez-Sánchez M, Merritt H, Oyoque-Salcedo G, Estrella-Santiago DP, Oregel-Zamudio E, Arias-Martínez S. Sustainable Valorization of Tequila Industry Vinasse: A Patent Review on Bioeconomy-Driven Technologies. Agronomy. 2025; 15(7):1567. https://doi.org/10.3390/agronomy15071567

Chicago/Turabian StyleSuárez-Sánchez, Mauricio, Humberto Merritt, Guadalupe Oyoque-Salcedo, Diana Priscila Estrella-Santiago, Ernesto Oregel-Zamudio, and Sergio Arias-Martínez. 2025. "Sustainable Valorization of Tequila Industry Vinasse: A Patent Review on Bioeconomy-Driven Technologies" Agronomy 15, no. 7: 1567. https://doi.org/10.3390/agronomy15071567

APA StyleSuárez-Sánchez, M., Merritt, H., Oyoque-Salcedo, G., Estrella-Santiago, D. P., Oregel-Zamudio, E., & Arias-Martínez, S. (2025). Sustainable Valorization of Tequila Industry Vinasse: A Patent Review on Bioeconomy-Driven Technologies. Agronomy, 15(7), 1567. https://doi.org/10.3390/agronomy15071567