Selecting Optimal Hemp (Cannabis sativa L.) Varieties for Long Fibre Production in Western Europe

Abstract

1. Introduction

2. Materials and Methods

2.1. Field Trial Set Up

2.2. Plant Measurements and (Fibre) Yield Estimation

2.3. Fibre Quality Analysis

2.4. Statistical Analysis

3. Results

3.1. Effect of Site on (Fibre) Yield

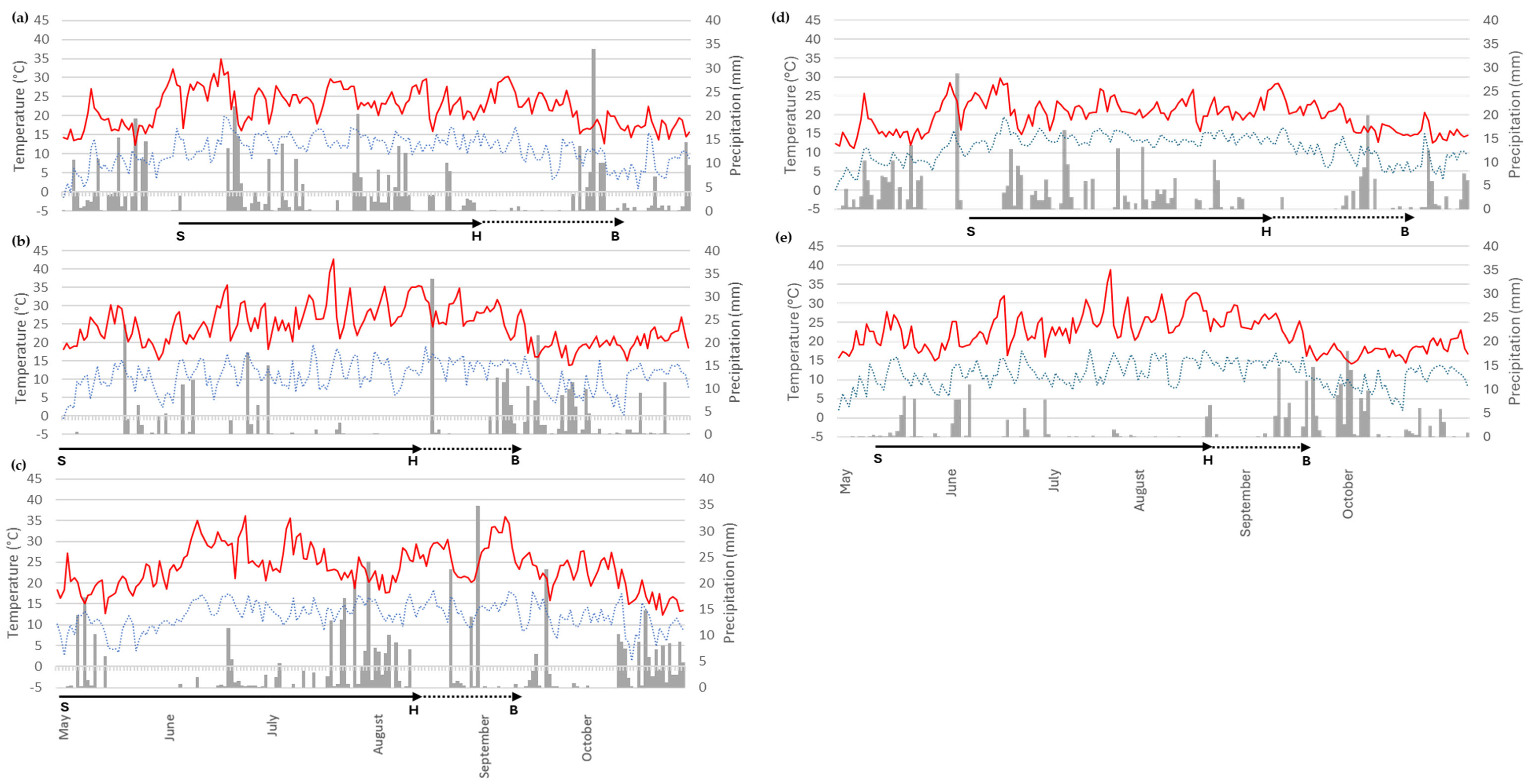

3.2. Effect of Year on (Fibre) Yield

3.3. Effect of Variety on (Fibre) Yield

3.4. Effect of Variety on Long Fibre Bundle Quality

4. Discussion

4.1. Effect of Site on (Fibre) Yield

4.2. Effect of Year on (Fibre) Yield

4.3. Effect of Variety on (Fibre) Yield

4.4. Effect of Variety on Long Fibre Bundle Quality

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Fao. FAOSTAT: Crops and Livestock Products. Available online: https://www.fao.org/faostat/en/#data/QCL (accessed on 13 November 2023).

- Zimniewska, M. Hemp Fibre Properties and Processing Target Textile: A Review. Materials 2022, 15, 1901. [Google Scholar] [CrossRef] [PubMed]

- European Commission. Hemp Production in the EU. Available online: https://agriculture.ec.europa.eu/farming/crop-productions-and-plant-based-products/hemp_en (accessed on 17 April 2025).

- Duque Schumacher, A.G.; Pequito, S.; Pazour, J. Industrial hemp fiber: A sustainable and economical alternative to cotton. J. Clean. Prod. 2020, 268, 122180. [Google Scholar] [CrossRef]

- Kaur, G.; Kander, R. The Sustainability of Industrial Hemp: A Literature Review of Its Economic, Environmental, and Social Sustainability. Sustainability 2023, 15, 6457. [Google Scholar] [CrossRef]

- Horne, M.R.L. Bast fibres. In Handbook of Natural Fibres; Elsevier: Amsterdam, The Netherlands, 2020; pp. 163–196. [Google Scholar] [CrossRef]

- Amaducci, S.; Zatta, A.; Pelatti, F.; Venturi, G. Influence of agronomic factors on yield and quality of hemp (Cannabis sativa L.) fibre and implication for an innovative production system. Field Crops Res. 2008, 107, 161–169. [Google Scholar] [CrossRef]

- Mariz, J.; Guise, C.; Silva, T.; Rodrigues, L. Hemp: From Field to Fiber—A Review. Textiles 2024, 4, 165–183. [Google Scholar] [CrossRef]

- Tang, K.; Struik, P.C.; Yin, X.; Calzolari, D.; Musio, S.; Thouminot, C.; Bjelková, M.; Stramkale, V.; Magagnini, G.; Amaducci, S. A comprehensive study of planting density and nitrogen fertilization effect on dual-purpose hemp (Cannabis sativa L.) cultivation. Ind. Crops Prod. 2017, 107, 427–438. [Google Scholar] [CrossRef]

- Finnan, J.; Burke, B. Nitrogen fertilization to optimize the greenhouse gas balance of hemp crops grown for biomass. GCB Bioenergy 2013, 5, 701–712. [Google Scholar] [CrossRef]

- Struik, P.C.; Amaducci, S.; Bullard, M.J.; Stutterheim, N.C.; Venturi, G.; Cromack, H.T.H. Agronomy of fibre hemp (Cannabis sativa L.) in Europe. Ind. Crops Prod. 2000, 11, 107–118. [Google Scholar] [CrossRef]

- Westerhuis, W.; van Delden, S.H.; van Dam, J.E.G.; Pereira Marinho, J.P.; Struik, P.C.; Stomph, T.J. Plant weight determines secondary fibre development in fibre hemp (Cannabis sativa L.). Ind. Crops Prod. 2019, 139, 111493. [Google Scholar] [CrossRef]

- Mediavilla, V.; Leupin, M.; Keller, A. Influence of the growth stage of industrial hemp on the yield formation in relation to certain fibre quality traits. Ind. Crops Prod. 2001, 13, 49–56. [Google Scholar] [CrossRef]

- Vandepitte, K.; Vasile, S.; Vermeire, S.; Vanderhoeven, M.; Van der Borght, W.; Latré, J.; De Raeve, A.; Troch, V. Hemp (Cannabis sativa L.) for high-value textile applications: The effective long fiber yield and quality of different hemp varieties, processed using industrial flax equipment. Ind. Crops Prod. 2020, 158, 112969. [Google Scholar] [CrossRef]

- Ranalli, P.; Venturi, G. Hemp as a raw material for industrial applications. Euphytica 2004, 140, 1–6. [Google Scholar] [CrossRef]

- Pinsard, L.; Revol, N.; Pomikal, H.; De Luycker, E.; Ouagne, P. Production of Long Hemp Fibers Using the Flax Value Chain. Fibers 2023, 11, 38. [Google Scholar] [CrossRef]

- Pinsard, L. From Cultivars to Textile Application: Insight Into the Textile Hemp Value Chain; Institut National Polytechnique de Toulouse—INPT: Toulouse, France, 2023. [Google Scholar]

- Angulu, M.; Gusovius, H.-J. Retting of Bast Fiber Crops Like Hemp and Flax—A Review for Classification of Procedures. Fibers 2024, 12, 28. [Google Scholar] [CrossRef]

- Grégoire, M.; Bar, M.; De Luycker, E.; Musio, S.; Amaducci, S.; Gabrion, X.; Placet, V.; Ouagne, P. Comparing flax and hemp fibres yield and mechanical properties after scutching/hackling processing. Ind. Crops Prod. 2021, 172, 114045. [Google Scholar] [CrossRef]

- Gabrion, X.; Koolen, G.; Grégoire, M.; Musio, S.; Bar, M.; Botturi, D.; Rondi, G.; de Luycker, E.; Amaducci, S.; Ouagne, P.; et al. Influence of industrial processing parameters on the effective properties of long aligned European hemp fibres in composite materials. Compos. Part A Appl. Sci. Manuf. 2022, 157, 106915. [Google Scholar] [CrossRef]

- Tsaliki, E.; Moysiadis, T.; Kalivas, A.; Panoras, I.; Grigoriadis, I. Multi-Year Insights into Industrial Hemp Growth in a Mediterranean Climate. Agronomy 2024, 14, 1946. [Google Scholar] [CrossRef]

- van der Werf, H. Crop Physiology of Fibre Hemp (Cannabis sativa L.); Wageningen University and Research: Wageningen, The Netherlands, 1994. [Google Scholar]

- Amaducci, S.; Scordia, D.; Liu, F.H.; Zhang, Q.; Guo, H.; Testa, G.; Cosentino, S.L. Key cultivation techniques for hemp in Europe and China. Ind. Crops Prod. 2015, 68, 2–16. [Google Scholar] [CrossRef]

- Tang, K.; Struik, P.C.; Yin, X.; Thouminot, C.; Bjelková, M.; Stramkale, V.; Amaducci, S. Comparing hemp (Cannabis sativa L.) cultivars for dual-purpose production under contrasting environments. Ind. Crops Prod. 2016, 87, 33–44. [Google Scholar] [CrossRef]

- European Commission. EUPVP—COMMON CATALOGUE. Available online: https://ec.europa.eu/food/plant-variety-portal/index.xhtml (accessed on 17 April 2025).

- ISO 5079; Textile Fibres—Determination of Breaking Force and Elongation at Break of Individual Fibres. International Organization of Standardization: Geneva, Switzerland, 2020.

- ISO 1973; Textile Fibres—Determination of Linear Density—Gravimetric Method and Vibroscope Method. International Organization for Standardization: Geneva, Switzerland, 2021.

- Adesina, I.; Bhowmik, A.; Sharma, H.; Shahbazi, A. A Review on the Current State of Knowledge of Growing Conditions, Agronomic Soil Health Practices and Utilities of Hemp in the United States. Agriculture 2020, 10, 129. [Google Scholar] [CrossRef]

- Vessel, J.; Black, C.A. Soil Type and Soil Management Factors in Hemp Production; Agricultural Experiment Station, Iowa State College of Agriculture and Mechanic Arts: Ames, IA, USA, 1947. [Google Scholar]

- Amaducci, S.; Federica, P.; Bonatti, P.M. Fibre Development in Hemp (Cannabis sativa L.) as Affected by Agrotechnique. J. Ind. Hemp 2005, 10, 31–48. [Google Scholar] [CrossRef]

- van der Werf, H.M.G.; Harsveld van der Veen, J.E.; Bouma, A.T.M.; ten Cate, M. Quality of hemp (Cannabis sativa L.) stems as a raw material for paper. Ind. Crops Prod. 1994, 2, 219–227. [Google Scholar] [CrossRef]

- Silska, G.; Górecki, T. Fiber Content of the Flax Germplasm (Linum usitatissimum L.) Originating from Different Parts of the World. J. Nat. Fibers 2023, 20, 2164108. [Google Scholar] [CrossRef]

- Cosentino, S.L.; Riggi, E.; Testa, G.; Scordia, D.; Copani, V. Evaluation of European developed fibre hemp genotypes (Cannabis sativa L.) in semi-arid Mediterranean environment. Ind. Crops Prod. 2013, 50, 312–324. [Google Scholar] [CrossRef]

- Gill, A.R.; Loveys, B.R.; Cowley, J.M.; Hall, T.; Cavagnaro, T.R.; Burton, R.A. Physiological and morphological responses of industrial hemp (Cannabis sativa L.) to water deficit. Ind. Crops Prod. 2022, 187, 115331. [Google Scholar] [CrossRef]

- Herppich, W.B.; Gusovius, H.-J.; Flemming, I.; Drastig, K. Effects of Drought and Heat on Photosynthetic Performance, Water Use and Yield of Two Selected Fiber Hemp Cultivars at a Poor-Soil Site in Brandenburg (Germany). Agronomy 2020, 10, 1361. [Google Scholar] [CrossRef]

- Angelini, L.G.; Tavarini, S.; Di Candilo, M. Performance of New and Traditional Fiber Hemp (Cannabis sativa L.) Cultivars for Novel Applications: Stem, Bark, and Core Yield and Chemical Composition. J. Nat. Fibers 2016, 13, 238–252. [Google Scholar] [CrossRef]

- Karimzadeh Soureshjani, H.; Bahador, M.; Tadayon, M.; Ghorbani Dehkordi, A. Modelling seed germination and seedling emergence of flax and sesame as affected by temperature, soil bulk density, and sowing depth. Ind. Crops Prod. 2019, 141, 111770. [Google Scholar] [CrossRef]

- Westerhuis, W.; Amaducci, S.; Struik, P.C.; Zatta, A.; Dam, V.J.E.G.; Stomph, T.J. Sowing density and harvest time affect fibre content in hemp (Cannabis sativa L.) through their effects on stem weight. Ann. Appl. Biol. 2009, 155, 225–244. [Google Scholar] [CrossRef]

- Kwiatkowska, E.; Zimniewska, M.; Różańska, W.; Puchalski, M.; Przybylska, P. Assessing the Impact of Drought Stress on Hemp (Cannabis sativa L.) Fibers. Materials 2024, 17, 4198. [Google Scholar] [CrossRef]

- Decker, A.; Tritter, A.; Sarazin, V.; Drean, J.-Y.; Harzallah, O. Effect of the Cultivar on the Development Hemp Stem and Textile Fiber in the East of France; Springer Nature Singapore: Singapore, 2024; pp. 97–106. [Google Scholar] [CrossRef]

- Amarasinghe, P.; Pierre, C.; Moussavi, M.; Geremew, A.; Woldesenbet, S.; Weerasooriya, A. The morphological and anatomical variability of the stems of an industrial hemp collection and the properties of its fibres. Heliyon 2022, 8, e09276. [Google Scholar] [CrossRef] [PubMed]

- Sankari, H.S. Comparison of bast fibre yield and mechanical fibre properties of hemp (Cannabis sativa L.) cultivars. Ind. Crops Prod. 2000, 11, 73–84. [Google Scholar] [CrossRef]

- Pisupati, A.; Willaert, L.; Goethals, F.; Uyttendaele, W.; Park, C.H. Variety and growing condition effect on the yield and tensile strength of flax fibers. Ind. Crops Prod. 2021, 170, 113736. [Google Scholar] [CrossRef]

| Year | pH | Organic Matter (%) | NO3−N (kg N/ha) | P (mg/kg) | K (mg/kg) | Mg (mg/kg) | Ca (mg/kg) | Na (mg/kg) |

|---|---|---|---|---|---|---|---|---|

| BOTT | ||||||||

| 2021 | 6.0 | 1.05 | 15 | 340 | 230 | 180 | 1430 | 12 |

| 2022 | 6.0 | 1.33 | 13 | 300 | 210 | 170 | 1270 | 15 |

| 2023 | 5.7 | 0.75 | 21 | 320 | 200 | 120 | 730 | 9 |

| BEIT | ||||||||

| 2021 | 6.7 | 1.02 | 9 | 250 | 160 | 210 | 1460 | 20 |

| 2022 | 5.7 | 0.76 | 68 | 230 | 120 | 170 | 1060 | 20 |

| Year | |||||

|---|---|---|---|---|---|

| Variety (Abbreviation) | Origin | Time of Flowering | 2021 | 2022 | 2023 |

| USO 31 (USO) | Ukraine | Early | X | X | X |

| Santhica 27 (S27) | France | Mid-Late | X | X | X |

| Bialobrzeskie (BIA) | Poland | Mid-Late | X | X | X |

| Santhica 70 (S70) | France | Late | X | X | X |

| Fibror 79 (FIB) | France | Late | X | X | X |

| Muka 76 (MUK) | France | Late | X | X | |

| Year | Site | Sowing | Harvest (DAS) | Storing (DAH) | ||

|---|---|---|---|---|---|---|

| Early | Late | Early | Late | |||

| 2021 | Bottelare | 10/06 | 25/08 (D77) | 02/09 (D85) | 11/10 (D47) | 11/10 (D39) |

| Beitem | 11/06 | 26/08 (D77) | 8/09 (D90) | 11/10 (D46) | 11/10 (D33) | |

| 2022 | Bottelare | 05/05 | 04/08 (D92) | 24/08 (D112) | 13/09 (D40) | 22/09 (D29) |

| Beitem | 09/05 | 08/08 (D92) | 23/08 (D106) | 12/09 (D35) | 21/09 (D29) | |

| 2023 | Bottelare | 04/05 | 01/08 (D90) | 21/08 (D110) | 11/09 (D41) | 26/09 (D36) |

| Site | Emergence (%) | Diameter (mm) | Plant Height (cm) | YDM (t ha−1) | BFC (%) | LFC (%) | YLF (t ha−1) |

|---|---|---|---|---|---|---|---|

| BOTT | 66 ± 5 a | 7.2 ± 0.9 b | 213 ± 5 a | 12.4 ± 0.9 a | 36.4 ± 0.3 a | 24.1 ± 0.5 a 1 | 2 ± 0.2 a1 |

| BEIT | 19 ± 5 b | 10.2 ± 1.0 a | 215 ± 6 a | 8.4 ± 1.0 b | 33.7 ± 0.4 b | 13.5 ± 1.0 b 2 | 0.7 ± 0.3 b2 |

| Year | Bottelare | Beitem | ||||

|---|---|---|---|---|---|---|

| Precipitation (mm) | Growth Period (Days) | Dry Days (%) | Precipitation (mm) | Growth Period (Days) | Dry Days (%) | |

| 2021 | 255 | 77/85 | 40/41 | 186 | 77/90 | 36/43 |

| 2022 | 154 | 92/112 | 73/74 | 90 | 91/106 | 57/59 |

| 2023 | 245 | 90/110 | 51/52 | N.A. | N.A. | N.A. |

| Site | Year | Emergence (%) | Diameter (mm) | Height (cm) | YDM (t ha−1) | BFC (%) | YBAST (t ha−1) | LFC (%) | YLF (t ha−1) |

|---|---|---|---|---|---|---|---|---|---|

| BOTT | 2021 | 55 ± 3 c | 8.4 ± 0.2 a | 215 ± 3 a | 10.7 ± 0.5 b | 35.8 ± 0.4 a | 3.9 ± 0.2 b | N.A. | N.A. |

| 2022 | 77 ± 3 a | 6.2 ± 0.2 c | 211 ± 3 a | 14.5 ± 0.4 a | 36.7 ± 0.4 a | 5.3 ± 0.2 a | 23.7 ± 0.6 a | 2.4 ± 0.1 a | |

| 2023 | 65 ± 3 b | 6.9 ± 0.2 b | 211± 3 a | 11.8 ± 0.4 b | 36.6 ± 0.4 a | 4.3 ± 0.2 b | 24.5 ± 0.6 a | 1.9 ± 0.1 b | |

| BEIT | 2021 | 14 ± 3 b | 12.4 ± 0.5 a | 231 ± 4 a | 7.8 ± 0.4 b | 33.8 ± 0.4 a | 2.6 ± 0.2 b | N.A. | N.A. |

| 2022 | 25 ± 3 a | 8.3 ± 0.4 b | 202 ± 4 b | 9.6 ± 0.3 a | 33.6 ± 0.4 a | 3.3 ± 0.1 a | 13.5 ± 0.7 | 0.9 ± 0.1 |

| Site | Variety | Flowering | Emergence (%) | Plant Density (Plants/m2) | Diameter (mm) | Height (cm) |

|---|---|---|---|---|---|---|

| BOTT | USO | Early | 66 ± 6 ab | 242 ± 30 ab | 7.1 ± 0.7 b | 200 ± 4 c |

| Bia | Mid-late | 59 ± 6 b | 211 ± 30 b | 7.2 ± 0.7 b | 209 ± 4 bc | |

| S27 | Mid-late | 73 ± 6 a | 257 ± 30 a | 6.8 ± 0.7 b | 209 ± 4 bc | |

| S70 | Late | 67 ± 6 ab | 243 ± 30 ab | 6.8 ± 0.7 b | 217 ± 4 ab | |

| Fib | Late | 57 ± 6 b | 224 ± 30 ab | 8.1± 0.7 a | 219 ± 4 ab | |

| Muk 1 | Late | 79 ± 7 a | 273 ± 31 a | 6.7 ± 0.7 b | 225 ± 4 a | |

| BEIT | USO | Early | 15 ± 6 a | 71 ± 28 a | 10.0 ± 2.2 a | 206 ± 17 a |

| Bia | Mid-late | 20 ± 6 a | 72 ± 28 a | 8.7 ± 2.2 a | 218 ± 17 a | |

| S27 | Mid-late | 23 ± 6 a | 97 ± 29 a | 10.0 ± 2.2 a | 214 ± 17 a | |

| S70 | Late | 23 ± 6 a | 91 ± 29 a | 11.7 ± 2.2 a | 226 ± 17 a | |

| Fib | Late | 15 ± 6 a | 78 ± 28 a | 11.6 ± 2.2 a | 213 ± 17 a | |

| Muk 2 | Late | 28 ± 8 a | 93 ± 33 a | 10.4 ± 2.3 a | 234 ± 18 a |

| Site | Variety | Flowering | YDM (t ha−1) | BFC (%) | YBAST (t ha−1) |

|---|---|---|---|---|---|

| BOTT | USO | Early | 10.9 ± 1.1 c | 34.7 ± 0.5 b | 3.9 ± 0.4 c |

| Bia | Mid-late | 11.4 ± 1.1 c | 37.6 ± 0.6 a | 4.2 ± 0.4 bc | |

| S27 | Mid-late | 11.6 ± 1.1 bc | 37.6 ± 0.5 a | 4.3 ± 0.4 bc | |

| S70 | Late | 13.5 ± 1.1 ab | 36.3 ± 0.5 ab | 4.9 ± 0.4 ab | |

| Fib | Late | 12.8 ± 1.1 bc | 36.4 ± 0.5 ab | 4.7 ± 0.4 ab | |

| Muk 1 | Late | 15 ± 1.1 a | 36.3 ± 0.7 ab | 5.4 ± 0.4 a | |

| BEIT | USO | Early | 7.7 ± 0.9 b | 31.6 ± 0.5 b | 2.5 ± 0.3 b |

| Bia | Mid-late | 8.5 ± 0.9 ab | 34.6 ± 0.6 a | 2.9 ± 0.3 ab | |

| S27 | Mid-late | 8.4 ± 1.0 ab | 33.5 ± 0.5 ab | 2.8 ± 0.3 ab | |

| S70 | Late | 10.3 ± 1.0 a | 34.5 ± 0.6 a | 3.5 ± 0.3 a | |

| Fib | Late | 8.4 ± 1.1 ab | 33.7 ± 0.5 ab | 2.8 ± 0.3 ab | |

| Muk 2 | Late | 9.3 ± 1.1 ab | 35.2 ± 0.9 a | 3.3 ± 0.4 ab |

| Variety | Flowering | Bottelare 2022 | |||||

|---|---|---|---|---|---|---|---|

| Fibre Length (mm) | Mass (mg) | Force (N) | Elongation at Break (%) | Linear Density (tex) | Tenacity (cN/tex) | ||

| Flax (2022) | 181 | 1.14 | 1.24 | 3.05 | 37.55 | ||

| USO | Early | 164 ± 23 a | 3.44 ± 0.75 a | 1.50 ± 0.19 a | 1.43 ± 0.1 a | 2.92 ± 0.21 a | 49.72 ± 1.38 a |

| BIA | Mid-Late | 138 ± 19 a | 2.25 ± 0.54 a | 0.93 ± 0.19 b | 1.71 ± 0.44 a | 2.33 ± 0.43 a | 40.36 ± 3.67 b |

| S27 | Mid-Late | 173 ± 10 a | 3.91 ± 1.06 a | 1.53 ± 0.27 a | 2.18 ± 0.17 a | 3.19 ± 0.70 a | 48.73 ± 5.86 ab |

| S70 | Late | 152 ± 6 a | 3.29 ± 0.39 a | 1.40 ± 0.12 ab | 1.48 ± 0.16 a | 3.10 ± 0.29 a | 45.07 ± 2.11 ab |

| Fib | Late | 160 ± 5 a | 3.81 ± 0.32 a | 1.52 ± 0.19 a | 1.80 ± 0.06 a | 3.40 ± 0.30 a | 44.33 ± 2.54 ab |

| Muk | Late | 164 ± 25 a | 3.54 ± 0.76 a | 1.33 ± 0.16 ab | 1.86 ± 0.48 a | 3.10 ± 0.52 a | 43.67 ± 2.08 ab |

| Mean (N = 18) | 158 ± 4 | 3.37 ± 0.17 | 1.37 ± 0.05 | 1.74 ± 0.07 | 3.01 ± 0.11 | 45.31 ± 0.78 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pappaert, H.; Waegebaert, S.; Vandepitte, K.; Latré, J.; Thienpondt, S.; Vermeire, S.; De Raeve, A.; De Gelder, L.; Troch, V. Selecting Optimal Hemp (Cannabis sativa L.) Varieties for Long Fibre Production in Western Europe. Agronomy 2025, 15, 1521. https://doi.org/10.3390/agronomy15071521

Pappaert H, Waegebaert S, Vandepitte K, Latré J, Thienpondt S, Vermeire S, De Raeve A, De Gelder L, Troch V. Selecting Optimal Hemp (Cannabis sativa L.) Varieties for Long Fibre Production in Western Europe. Agronomy. 2025; 15(7):1521. https://doi.org/10.3390/agronomy15071521

Chicago/Turabian StylePappaert, Hanne, Sophie Waegebaert, Katrien Vandepitte, Joos Latré, Svea Thienpondt, Sofie Vermeire, Alexandra De Raeve, Leen De Gelder, and Veronique Troch. 2025. "Selecting Optimal Hemp (Cannabis sativa L.) Varieties for Long Fibre Production in Western Europe" Agronomy 15, no. 7: 1521. https://doi.org/10.3390/agronomy15071521

APA StylePappaert, H., Waegebaert, S., Vandepitte, K., Latré, J., Thienpondt, S., Vermeire, S., De Raeve, A., De Gelder, L., & Troch, V. (2025). Selecting Optimal Hemp (Cannabis sativa L.) Varieties for Long Fibre Production in Western Europe. Agronomy, 15(7), 1521. https://doi.org/10.3390/agronomy15071521