Recent Advances and Applications of Imaging and Spectroscopy Technologies for Tea Quality Assessment: A Review

Abstract

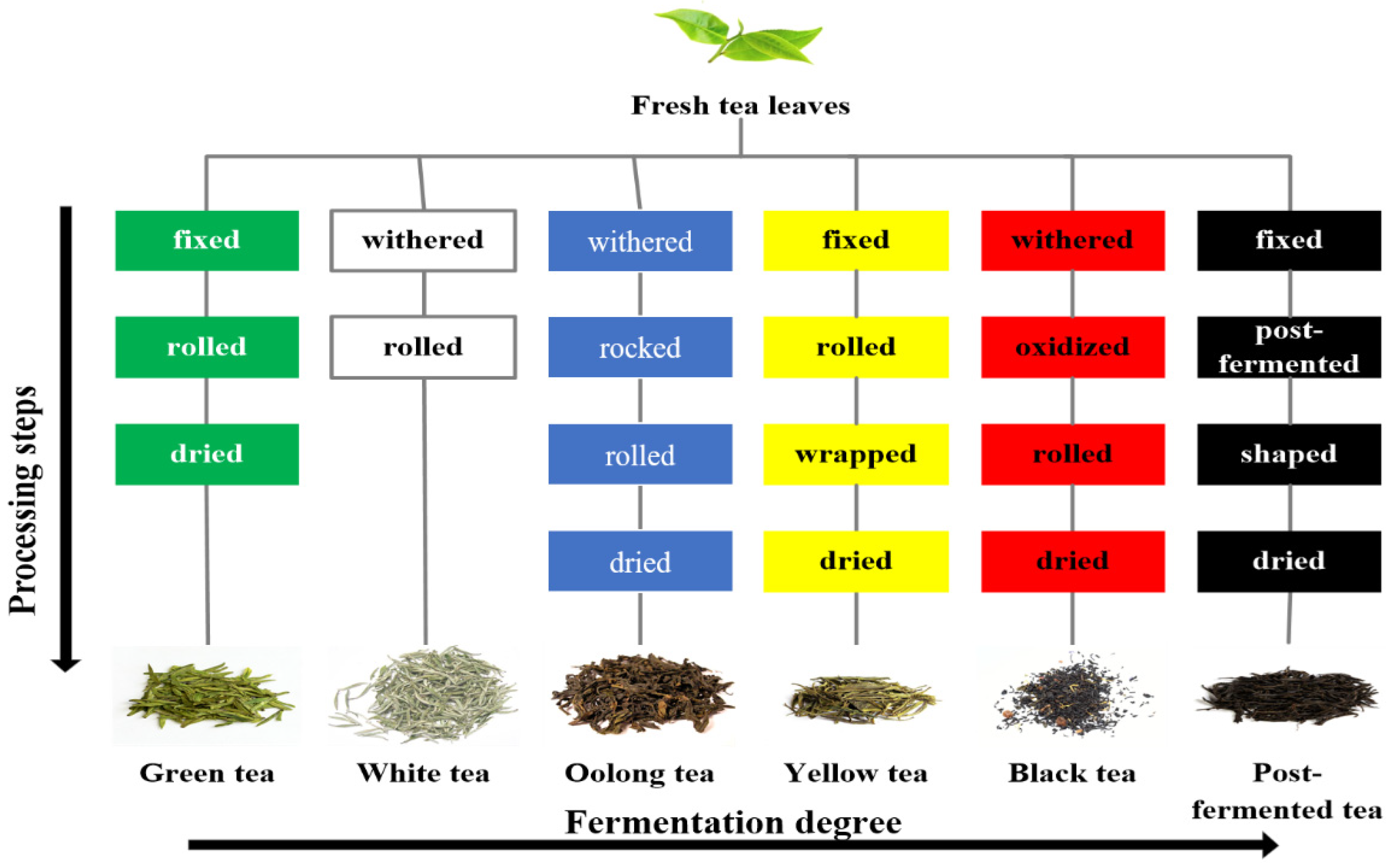

1. Introduction

2. Overview of Non-Destructive Technologies

2.1. Imaging Technologies

2.1.1. Computer Vision

2.1.2. X-Ray Imaging

2.1.3. Magnetic Resonance Imaging

2.1.4. Fluorescence Imaging

2.1.5. Raman Imaging

2.2. Spectroscopy Technology

2.3. Spectral Imaging Technologies

3. Data Processing and Analyzing Methods

3.1. Image Processing and Analysis Methods

3.1.1. Image Processing Methods

3.1.2. Image Analysis Methods

3.2. Spectral Analysis Methods

3.2.1. Spectral Preprocessing

3.2.2. Wavelength Selection

3.2.3. Calibration Models

3.2.4. Model Evaluation

4. Applications in Tea Quality Assessment

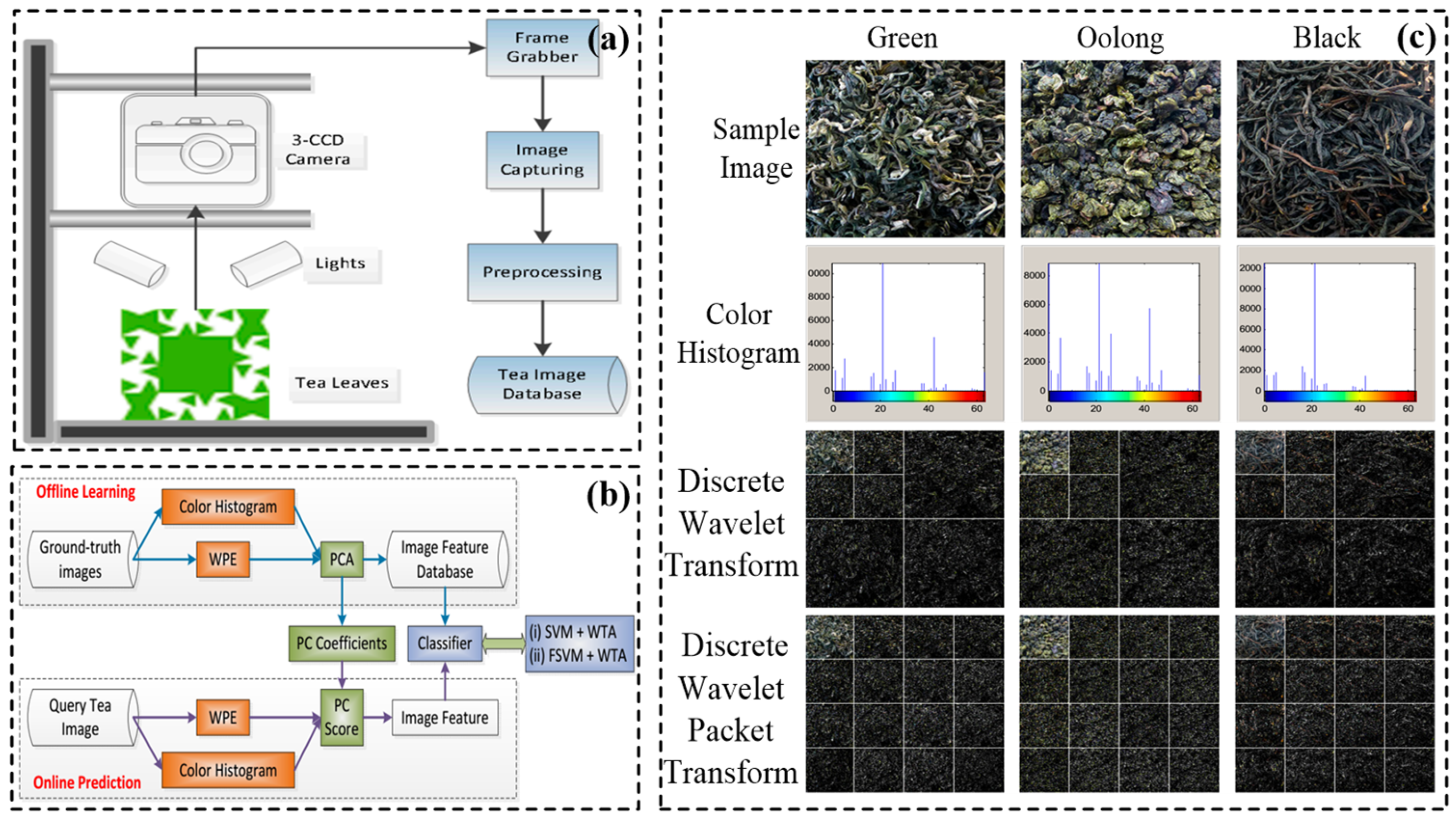

4.1. External Quality Assessment

4.1.1. Color Features

4.1.2. Texture Features

4.1.3. Shape Features

| Application | Tea Categories | Technology | Feature(s)/Spectra Region (nm) | Analysis Method (s) | Optimal Result | References |

|---|---|---|---|---|---|---|

| Identification of tea varieties | Green tea | Computer vision | Color, Texture | LDA, PCA, | 98.33% | [136] |

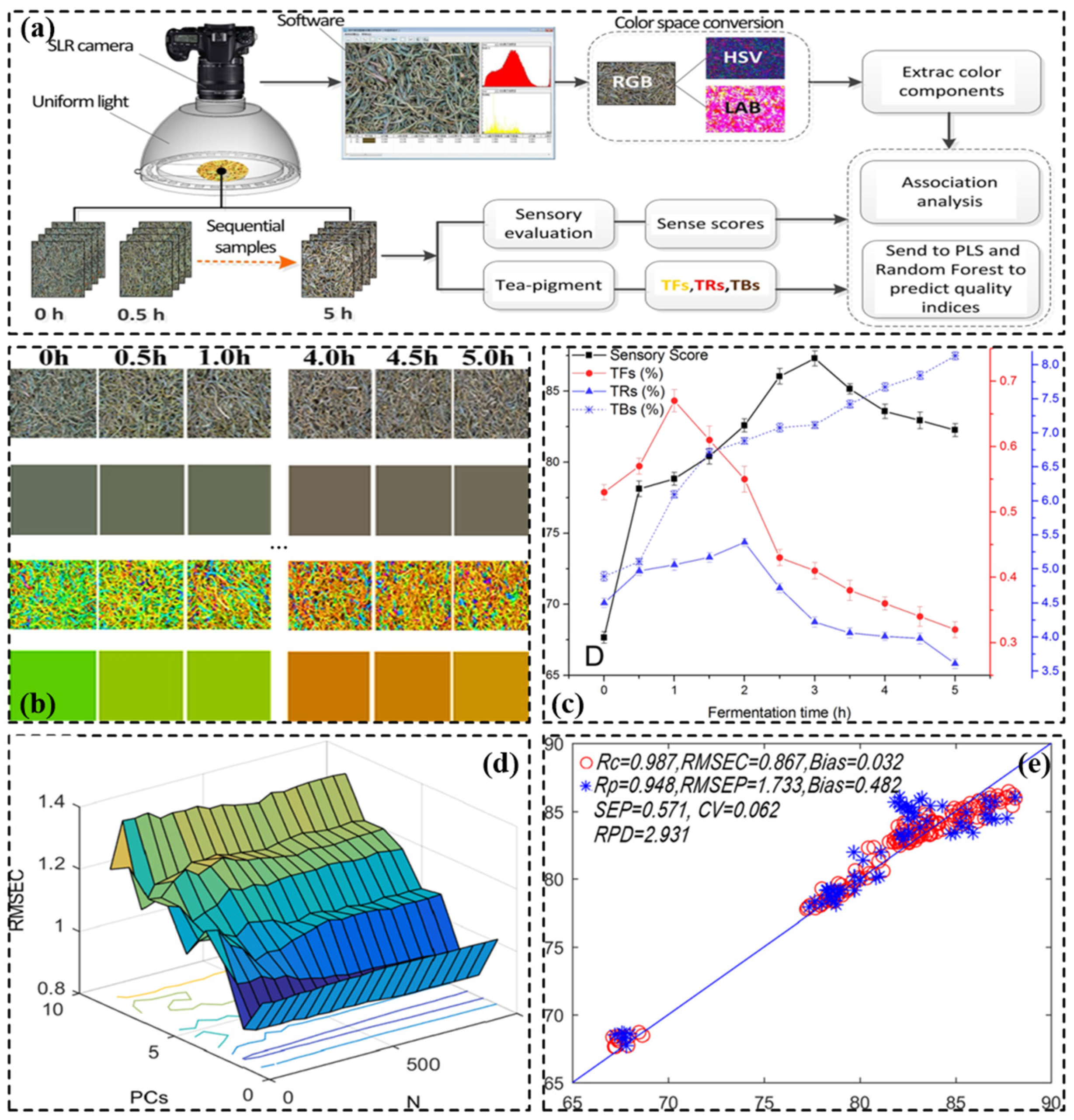

| Prediction of fermentation quality indices | Black tea | Machine vision | Color | PCA, PLS, SVM, Random forest | = 0.941, RMSEP = 1.733 | [137] |

| Evaluation of black tea fermentation quality | Black tea | Machine vision | Color | PLS | RPD = 4.13 for catechins RPD = 3.53 for theaflavins RPD = 3.39 for chlorophylls | [95] |

| Prediction of nitrogen content | Tea plants | Machine vision | Color | OLS, XGBoost, RNN-LSTM, CNN, ResNet | MA = 0.9144 for elder tea leaves in experimental strategy I MA = 0.8696 for elder tea shoots in experimental strategy I MA = 0.9148 in experimental strategy II | [121] |

| Color Measurement | Green tea | HSI | Color 380–1030 nm | CARS, SPA, PLS, MLR, LS-SVM | = 0.902 to 0.931 for ΔL* = 0.618 to 0.973 for Δa* = 0.904 to 0.944 for Δb* | [140] |

| Evaluation of tea authentication | Argentinean and Sri Lankan black teas and Argentinean green teas | Machine vision | Color | PCA, PLS, DD-SIMCA | 100% for category and geographical origin REP = 6.38% for MC REP = 9.031% for TP REP = 14.58% for caffeine | [144] |

| Monitoring green tea fixation quality | Green tea | Machine vision NIRS | Color 900–1700 nm | CARS, LS-SVM | 100% for fixation degree RPD = 6.46 for MC | [143] |

| Quantitative prediction and visualization of color physicochemical indicators | Matcha | HMI | 400–998 nm | CARS, IRF, SPA, | Rp = 0.9262 for L* Rp = 0.8826 for a* Rp = 0.8583 for b* Rp = 0.8243 for chlorophyll a Rp = 0.7518 for chlorophyll b Rp = 0.8093 for chlorophyll total | [147] |

| Tea shoots detection | Tea | Machine vision | Color | YOLOv7 | 91.12% | [153] |

| Evaluation of fermentation degree | Black tea | FT-NIR Computer vision | Color 800–2500 nm | PCA, KNN, LDA, SVM | 100% for fermentation degree | [145] |

| Monitoring withering degree | Black tea | Machine vision NIRs CSA sensors | Color 900–1700 nm Color variables | PCA, Spearman correlation analysis, SVM | 97.5% | [152] |

| Evaluation of fermentation degree | Pu-erh tea | Machine vision NIRS | Color, texture 900–1700 nm | SNV, PLS-DA, GAL, CARS, SPA, PLS, LS-SVM | 99.3% for fermentation degree RPD = 4.76 for TC RPD = 2.36 for GA/TC RPD = 4.76 for R-TI RPD = 4.76 for G-TI | [148] |

| Classification of tea varieties | Oolong tea | Machine vision | Color, texture | SVM, CNN | >93% | [174] |

| Classification of tea samples | Black tea and green tea | Machine vision | Color, texture | DT | 92.917% for Black tea 95% for green tea | [167] |

| Evaluation of fermentation degree | Black tea | Machine vision | Mathematical values, color, text, texture strength, histogram gradients, and flexible discrete wavelet | KNN, SRC, SVM | 98.75% | [168] |

| Detection of tea impurity | Pu-erh tea | MSI | 713, 736, 759, 782, 805, 828, 851, 874, 897, and 920 nm, Color | SVM | 93% | [146] |

| Evaluation of the appearance modality | Black tea | Machine Vision HSI | Color, texture, shape | SVM, RF, LS-SVM | 100% | [150] |

| Identification of tea categories | Green, black, oolong tea | Computer vision | Color, texture | PCA, SVM | 97.9% | [141] |

| Identification of tea categories | Green tea | Computer vision | Color, texture | LS-SVM | 96.33% | [161] |

| Classification of tea | Fresh tea leaves | Computer vision | Texture | BP-NN | 94.0%, 92.0% and 100% | [162] |

| Discrimination between various grades of tea | Black tea | Computer vision | Texture | MLP | 80–82.33% | [156] |

| Sorting of tea categories | Green tea | MSI | Texture 580, 680, and 800 nm | GA, PCA, LS-SVM, | Up to 100% | [163] |

| Monitoring the quality parameters of fresh tea leaves | Fresh tea leaves | Multi-spectral camera | Texture | PLS, SVR, RFR | R2 = 0.85 for total sugar | [164] |

| Discrimination of eight grades of tea | Black tea | Computer vision | Texture | MLP, LVQ | 74.67% and 80% for MLP and LVQ | [156] |

| Recognition of tea categories | Green tea | MSI | Texture | LS-SVM | 100%, 100%, 75%, and 100% for four kinds of teas | [166] |

| Identification of tea categories | Green, black, oolong tea | Computer vision | Color, texture | Fuzzy SVM | 97.77% | [5] |

| Evaluation of appearance quality | Black tea | Computer vision | Color, texture | RF, SVR, BPNN | RPD = 3.207 for appearance quality | [16] |

| Evaluation of tea quality | Black tea | HSI | Texture 900–1700 nm | DT | 93.13% | [169] |

| Evaluation of fermentation degree | Black tea | HSI and CSA sensors | Color, texture 400–1000 nm | SFLA, CARS, VCAP-IRIV, PCA, SVM | 97.5% | [117] |

| Detection of moisture content | Fresh tea leaves | Computer vision | Color and texture | LDA, PCA, GA, PSO, BPNN | R2 = 0.94 | [139] |

| Evaluation of tea quality | Black tea | HSI | 900–1750 nm texture | GLCM, GLPCM, IRIV, ISFLA, LS-SVM | 99.57% | [149] |

| Recognition of different Longjing fresh tea varieties | Fresh tea leaves | HSI | 370–1042 nm Color, texture | SVM, BPNN | 100% | [173] |

| Detection of drying quality | Black tea | NIRS Computer vision | 900–1700 nm Color, texture | LS-SVR | Rp = 0.9696 for MC | [171] |

| Evaluation of tea grade | Black tea | NIRS, E-eye, E-tongue, and E-nose | 3600–12,500 cm−1, color, texture, shape, optical and electronic signal | CARS, IRIV, VCPA, VCPA-IRIV, CNN | 0.86% for misclassification rate | [170] |

| Grading and testing of different teas | Green tea | Computer vision | Color, shape | GNN | – | [175] |

| Recognition of tea sprout | Green tea | Computer vision | Color, shape | – | 94% | [176] |

| Recognition of tea disease | Tea plant | HSI | Color, texture, shape | PCA, Fischer | 95% for non-disease 90% for disease | [178] |

| Assessment of the severity of tea Disease | Tea plant | Machine vision | Color, texture, shape | U-Net, SVM, metric learning model (MLM) | 82% | [180] |

| Recognition and positioning of fresh tea buds | Fresh tea buds | Machine vision | Color, shape | YOLOv4 | 87.10% | [179] |

| Grade evaluation of teas | Black tea | Machine vision NIRS CSA sensors | Color, shape 900–1700 nm RGB response values | SVM, LS-SVM, PLS-DA, ELM | 98.75% | [181] |

| Automatic sorting of fresh tea leaves | Fresh tea leaves | Machine vision | Shape | SVM | 94% | [178] |

| Grade evaluation of teas | Black tea | Machine vision | Shape | SVM, LS-SVM | 100% | [182] |

| Grade evaluation of teas | Black tea | Machine vision NIRS | Shape 900–1700 nm | ANN | 100% | [183] |

4.2. Internal Quality Assessment

4.2.1. Total Polyphenols Content

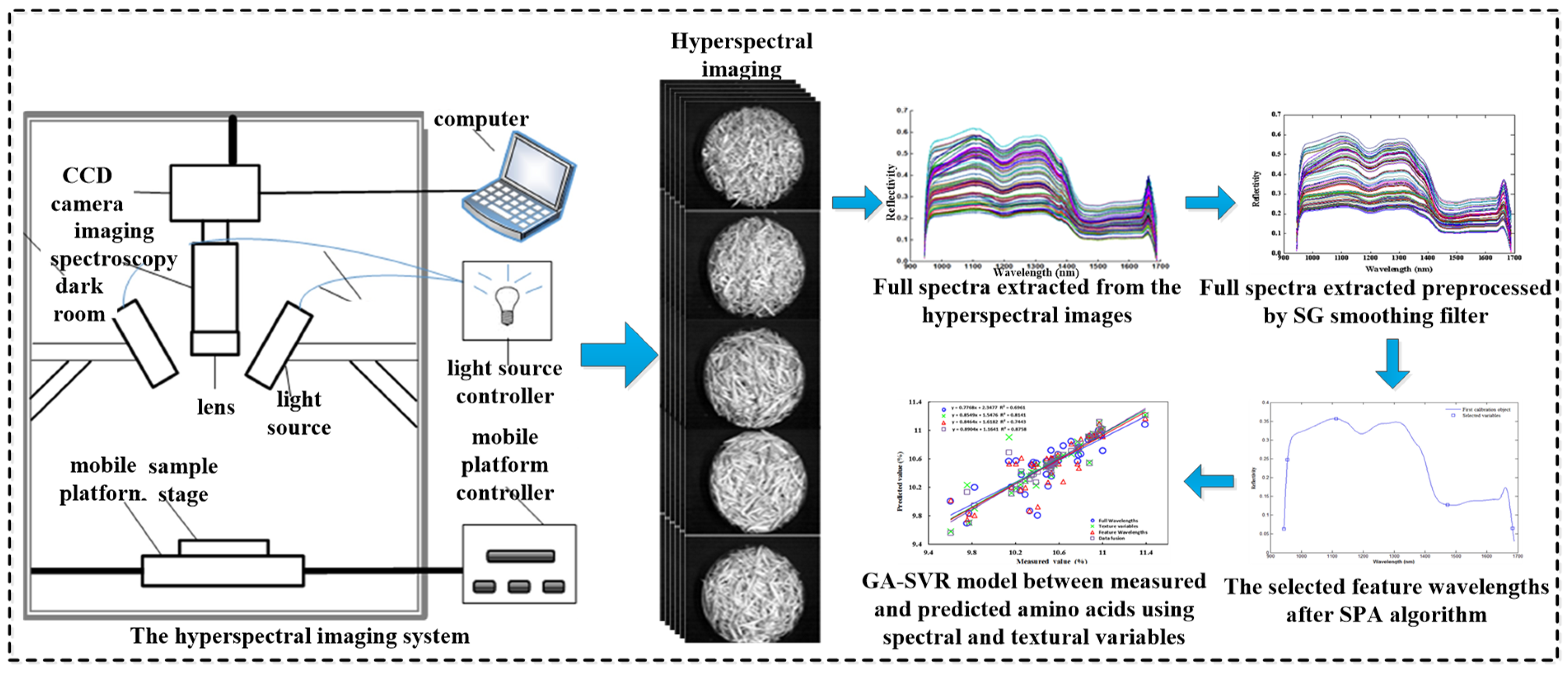

4.2.2. Amino Acids Content

4.2.3. Caffeine Content

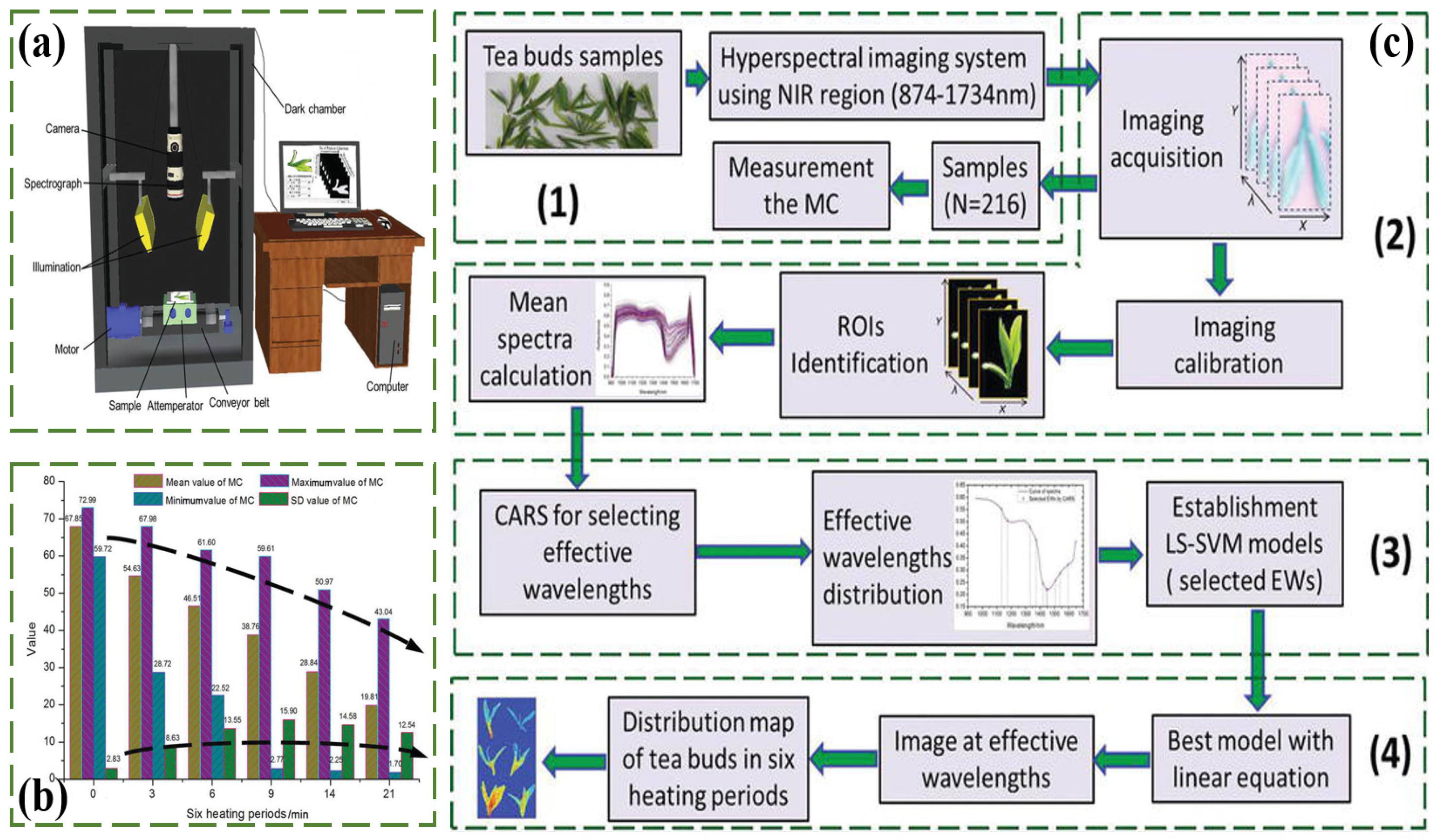

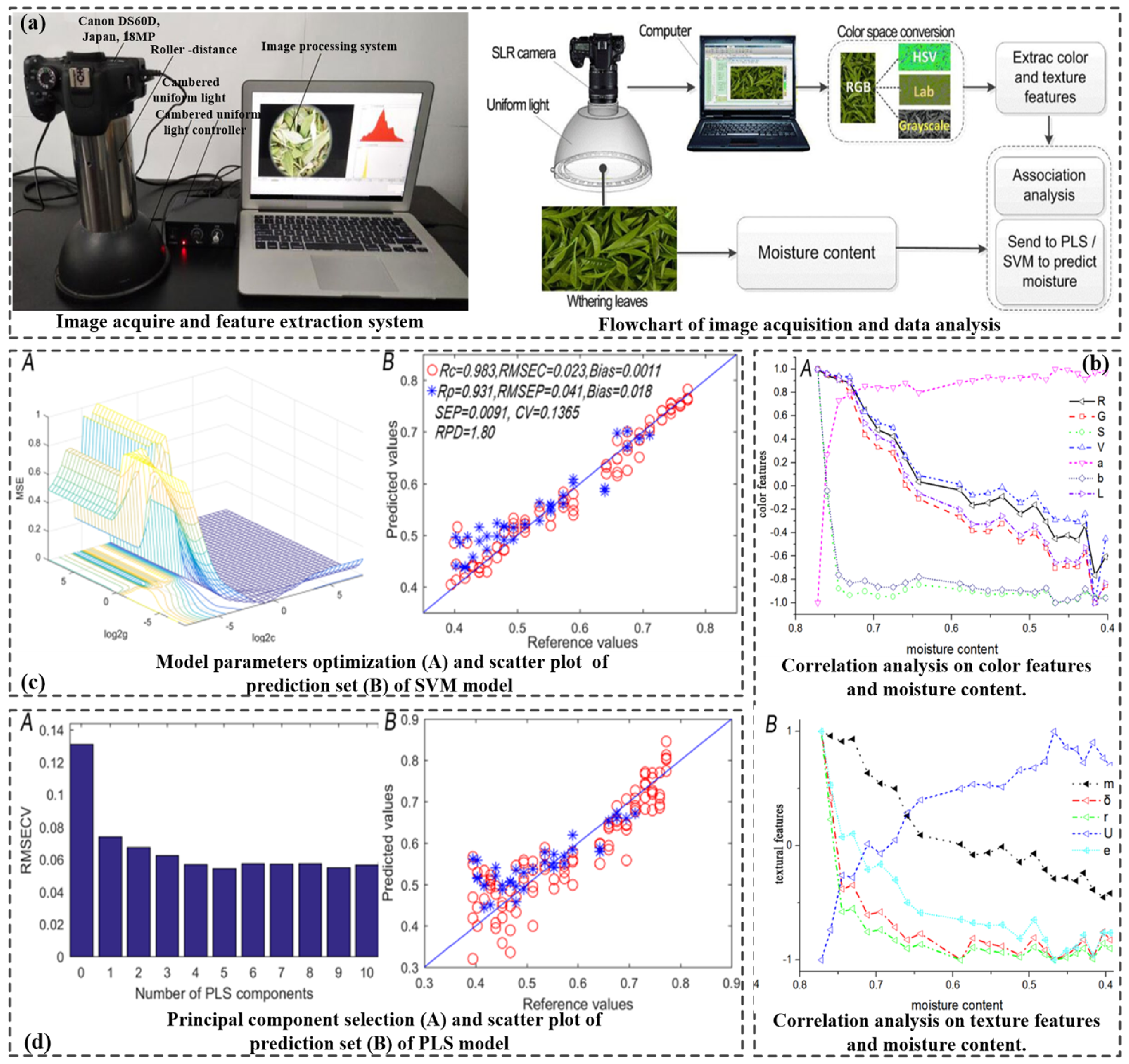

4.2.4. Moisture Content

| Quality Indices | Tea Categories | Method | Feature(s)/Spectra Region | Data Analysis | Optimal Result | References |

|---|---|---|---|---|---|---|

| TP | Green tea | NIR | 1000–2500 nm | MSC, SNV, PLS, iPLS, siPLS | = 0.9583, RMSEP = 0.7327 | [136] |

| TP | Black, green, oolong, Kamairi, Pu’er, Houji, and Sunrouge teas, tea extracts. | VIS-NIRS | 400–2498 nm | SNV, PLS, SG-2D | R = 0.96 | [204] |

| TP, antioxidant activity (AA) | Black tea, oolong tea, green tea, and green tea powder (matcha) | Synchronous fluorescence spectroscopy (SFS) | 350–750 nm | PLS | R2 > 0.86 | [200] |

| TP | Green tea beverages | paper-based colorimetric biosensor | Color | scanometric method | RSD = 3.11% | [201] |

| TP | Green tea | MIR | 1282–28571 nm | MSC, SNV, iPLS, biPLS, RF, PLS | = 0.9059, RMSEP = 1.0277 | [193] |

| TP | Green tea | UV-Vis spectroscopy, NIR | 200–800 nm, 1000–2500 nm | SNV, RF, PCA, PLS | = 0.9983, RMSEP = 0.2693 | [5] |

| TP, MC | Black tea | Vis, NIR | 350–2500 nm | SNV, FD, PLS | = 0.89, RMSEP = 0.54 for TP; = 0.96, RMSEP = 0.11 for MC | [194] |

| TP, caffeine, FAA | Post-fermented tea, black tea, oolong tea, green tea | NIR | 1000–2500 nm | S-G smoothing, MSC, RF, CARS, PLS, | = 0.997, RMSEP = 0.595 for TP; = 0.99, RMSEP = 0.07 for caffeine; = 0.996, RMSEP = 0.063 for FAA | [195] |

| TP | White tea | HSI | 350–2500 nm | SPA, PLS, ANN | = 0.91, RMSEP = 0.004 | [197] |

| TP, FAA, etc. | Green tea | NIR | 1000–2500 nm | MSC, Centering, PLS, PCA, siPLS | = 0.90, RMSEP = 0.242% | [196] |

| TP | Oolong tea | MSI | 800–2500 nm | SNV, LS-SVM, BPNN, PCA | = 0.96, RMSEP = 0.27 for tea power; = 0.90, RMSEP = 0.54 for tea power; total classification accuracy = 97.5% | [189] |

| TP | Green tea | Vis, NIR | 347–2506 nm | S-G smoothing, PCA, MLR, PLS | = 0.90, RMSEP = 1.39 | [192] |

| TP | Pu-erh tea | NIRS | 900–1700 nm | SNV, CARS, PLS | RPD = 2.372 | [203] |

| TP, catechin | Black tea | Computer vision NIRS | Color 900–1700 nm | CARS, Pearson correlation analysis, PLS | RPD = 5.41 for TP RPD = 4.03 for catechin | [188] |

| TP | Green, white, yellow, oolong, black, and dark tea | HSI | 900–1700 nm | PLS | RPD = 3.34 for TP | [205] |

| TP | Green tea | Computer vision Color sensitive sensor | Color | ACO, ELM | Rp = 0.8035 for TP | [202] |

| TP, AAC, TP/ACC | Postharvest fresh tea leaves | NIRS | 900–1700 nm | SNV, 1D, 2D, GA, CARS, IVSO, PLS | RPD = 2.24 for TP RPD = 2.43 for AAC RPD = 2.42 for TP/AAC | [216] |

| TP, FAA, TP/FAA | Matcha | NIRS | 4000 to 10,000 cm−1 | SNV, MSC, 1D, 2D, S-G-M, SPA, GA, SA, Si-PLS | Rp > 0.97 for TP Rp > 0.98 for FAA Rp > 0.98 for TP/FAA | [211] |

| TP, FAA | Dark tea | HSI | 387–1035 nm | SG, MSC, SNV, PCA, Adaboost, GBDT, SVM | 100% for tea grade RPD = 3.646 for TP RPD = 2.813 for FAA | [212] |

| TP, MC, caffeine, tea polysaccharides | Instant tea | NIRS | 10,000–4000 cm−1 | SVR, PLS, BPSO | Rp = 0.9678 for MC Rp = 0.9757 for caffeine Rp = 0.7569 for TP Rp = 0.8185 for tea polysaccharides | [199] |

| Total catechin, FAA, and chlorophyll a, | Dark tea | HSI | 400–1000 nm | LS-SVM | 98.63% RPD = 11.26 for total catechin RPD = 4.34 for FAA RPD = 3.89 for chlorophyll a | [147] |

| TP, FAA, caffeine, and total sugar | Fresh tea leaves | VIS-NIRS | 400–2400 nm | CWT, VCPA-IRIV, BOSS, VISSA, GA, PLS | Rp = 0.6891 for TP Rp = 0.8385 for FAA Rp = 6810 for caffeine Rp = 0638 for total sugar | [151] |

| AAC | Green tea | NIR | 1000–2500 nm | SNV, MSC, FD, SD, BP-NN, PLS | = 0.958, RMSEP = 0.246 | [209] |

| TP, AAC | Green tea | NIR | 1000–2500 nm | SNV, siPLS, PLS | = 0.87, RMSEP = 0.316 | [100] |

| TP, AAC, etc. | White tea, etc. | Vis, NIR | 350–2500 nm | PLS | = 0.94, 0.90 for TP, AAC at powder level; = 0.90, 0.87 for TP, AAC at leaf level; = 0.91, 0.88 for TP, AAC at canopy level; | [197] |

| AAC | Yellow tea | HSI | Texture/908–1735 nm | S-G smoothing, SPA, GA, SVM, | = 0.83, RMSEP = 0.188 | [211] |

| TP, caffeine | Green tea | NIR | 909–2632 nm | SNV, FD, SD, PLS, | = 0.9299, RMSEP = 1.1138% for TP, = 0.9688, RMSEP = 0.0836% for caffeine | [217] |

| N, TP, AAC | Tea canopy | MSI | 450, 555, 660, 720, 750 and 840 nm | PLS, SVM | R2 = 0.7583 for N R2 = 0.7533 for TP R2 = 0.7597 for AAC | [211] |

| TP, caffeine, FAA, TP/FAA, chlorophyll | Matcha | HSI | 400–1000 nm | SNV, BOSS, CARS, PLS | Rp = 0.8077 for caffeine Rp = 0.7098 for TP Rp = 0.7942 for FAA Rp = 0.8314 for TP/FAA Rp = 0.8473 for chlorophyll | [68] |

| FAA, caffeine | Matcha | NIRS | Si-PLS, CARS, BOSS | Rp = 0.8920 for FAA Rp = 0.8992 for caffeine | [228] | |

| TP, FAA, caffeine | Black tea | HSI | 391–1010 nm | SPA, CARS, UVE, SVM, PLS, RF | Rp = 0.91 for TP Rp = 0.88 for FAA Rp = 0.81 for caffeine | [214] |

| Caffeine, AAC, MC, TP | Black tea | FT-NIR | 800–2500 nm | SNV, MSC, min/max normalization, PLS | = 0.983, 0.977, 0.975, 0.943 for caffeine, MC, TP, AAC; RMSEP = 0.102%, 0.654%, 0.552%, 0.248% for caffeine, MC, TP, AAC | [220] |

| Caffeine | Green tea | Vis, NIR | 400–2500 nm | SNV, MSC, PLS, | = 0.98, RMSEP = 1.538 | [216] |

| AAC, caffeine, MC, | Black tea | FT-NIR | 1000–2500 nm | MSC, SNV, siPLS, PLS, GA, CARS, biPLS, | = 0.9232, 0.9498, 0.8785 for caffeine, AAC, MC; RMSEP = 0.209, 0.214, 1.47 for caffeine, AAC, MC | [215] |

| TP, caffeine, AAC | Green, black tea | NIR | 1100–2500 nm | MLR, PLS | – | [222] |

| Caffeine | Green tea | NIR | 1100–2500 nm | SNV, FD, SD, PLS | = 0.96 for the whole leaves; = 0.93 for the ground leaves | [214] |

| Caffeine | Green tea | 1H-NMR spectroscopy | – | PCA, | – | [211] |

| caffeine | Green tea | UV, FT-NIR | 833–2500 nm | FD, SD, PLS | the recovery of caffeine in instant tea: 101.2–103.9% (UV), 98.3–99.8% (FT-NIR); the recovery of caffeine in tea granules: 101.8–104.2% (UV), 97.9–101.1% (FT-NIR); | [221] |

| Caffeine, etc. | Green tea | 1H-NMR spectroscopy | – | – | = 0.9995 | [212] |

| Theafuscin, thearubigin, catechin, caffeine, soluble sugar, theaffavin and TP/FAA | Black tea | HSI | 400–1000 nm | Z-score, MSC, Smooth, 2D, Min-Max, Center, PCA, SPA, VCPA-IRIV, SFLA, CARS, VISSA, MCUVE, VCPA-GA, PLS, SVR, RF | RPD = 3.4 for theafuscin RPD = 2.21 for thearubigin RPD = 5.71 for catechin RPD = 1.46 for caffeine RPD = 2.89 for soluble sugar RPD = 3.78 for theaffavin RPD = 2.91 for TP/FAA | [210] |

| Total catechins, soluble sugar and caffeine | Black tea | HSI and electrical properties | 400–1000 nm 0.02–1000 kHz | CARS, BOSS, MASS, PLS, SVR, RF | Rp = 0.9978 for total catechins Rp = 0.9973 for soluble sugar Rp = 0.9560 for caffeine | [226] |

| Sensory score, catechins, and caffeine | Green tea | FT-NIRS Colorimeter | 3800–12,000 cm−1 Color | S-G, SNV, MSC, CARS BOSS, SPA, PCA, SVR | RPD = 2.8 for Sensory score RPD = 1.6 for catechins RPD = 2.6 for caffeine | [198] |

| Sensory score, catechins, and caffeine | Green tea | NIRS | 900–1700 nm | PCA, CARS, RF, SVR, VCPA-IRIV | RPD = 2.485 for Sensory score RPD = 2.584 for catechins RPD = 2.873 for caffeine | [229] |

| TP, caffeine | Green tea, Black tea | Fluorescence, medium (MIR), and near (NIR) infrared spectroscopy | 260–600 nm 4000 to 650 cm−1 8300–4000 cm−1 | PSCM | RMSE < 5.82 for TP RMSE < 1.79 for caffeine | [227] |

| Caffeine, catechins, bitterness, astringency | Pu-erh ripen tea | NIRS | 1000–1800 nm | PLSR | RPD > 2.5 | [153] |

| Caffeine, catechins | Green and Black tea | NIRS | 900–1700 nm | SNV, PSO, SVR | RPD = 9.83 for catechins RPD = 2.71 for caffeine | [231] |

| Bitterness score, astringency score, caffeine, EGCG | Black tea | NIRS | 900–1700 nm | CARS, SPA, PLS | RPD = 3.07 for bitterness score RPD = 2.28 for astringency score RPD = 3.29 for caffeine RPD = 2.91 for EGCG | [206] |

| Caffeine, EGCG, MC | Green tea | FT-NIR | 4000 to 10,000 cm−1 | MSC, SD, SG, FD, ND, NS, PLS | p > 0.5 | [233] |

| Polyphenol and caffeine | Green tea | VIS-NIRS | 400–2498 nm | PCA, SPA, PLS, MLR | Rp2 > 0.834 | [221] |

| Catechin polyphenols, caffeine | Fresh tea leaves | VIS-NIRS | 400–2498 nm | PLS, MLR, CARS, SPA | R2 > 0.89 | [228] |

| TP, caffeine, MC | Argentinean and Sri Lankan black teas and Argentinean green teas | Machine vision | Color | PCA, PLS, DD-SIMCA | REP = 6.38% for MC REP = 9.031% for TP REP = 14.58% for caffeine | [144] |

| Caffeine, total ashes, MC | Yerba mate | NIRS | 1100–2500 nm | PLS | REP < 6.97% | [243] |

| MC | Green tea | Computer vision | – | ANN, RBF | = 0.905 | [7] |

| MC | Green tea | Vis, NIR | 325–1075 nm | WT, PCA, LS-SVM, MLR, PLS | = 0.86, RMSEP = 0.046 | [239] |

| TP, MC | Unknown | NIR | 1111–2631 nm | SNV, MSC, SPA, PLS | = 0.966, RMSEP = 0.599 mg/kg for TP; = 0.970, RMSEP = 0.32 mg/kg for TP; | [233] |

| MC | Green tea | FT-NIR | 1111–2631 nm | FD, PLS | – | [221] |

| MC | Fresh tea leaves | Computer vision | Color, texture | PLS, SVM, Random Forest | = 0.9314, RMSEP = 0.0411 | [236] |

| MC | Green tea | HSI | Texture/874.41–1733.91 nm | SPA, PCA, PLS | = 0.9855, RMSEP = 0.0988 | [230] |

| MC | Fresh tea leaves | HSI | 380–1030 nm | SPA, PLS, MSC, | = 0.973, RMSEP = 0.052 | [140] |

| MC | Green tea | HSI | 874–1734 nm | CARS, PLS, LS-SVM | = 0.946, RMSEP = 0.0507 | [89] |

| MC | Tea leaves | MSI and depth images | 679, 693, 719, 732, 745, 758, 771, 784, 796, 808, 827, 839, 849, 860, 871, 880, 889, 898, 915, 922, 931, 937, 944, 951, 956 nm | LDA, LS-SVR, | Rp2 = 0.77 for front surface Rp2 = 0.68 for back surface | [246] |

| MC | Tea leaves | Vis-NIR | 350–2500 nm | 0–2 D, PLS, PCR | 0.4 or 0.6 D displayed best performance | [247] |

| MC | Tea leaves | Vis-NIR | 220–1100 nm | PLS, MSC, PCA, DS | Rp2 > 0.85 | [240] |

| MC | Black tea | micro-NIRS | 900–1700 nm | ENN, PCA | RPD = 11.8108 | [244] |

| MC | Green tea | HSI NIR | 908.15–1735.68 nm 950–1750 nm | DS, PLS, SNV | RPD = 2.76 | [172] |

| MC | Black tea | HSI | 400–1000 nm | SPA, SFLA, PLS, ELM | RPD = 1.6 for local region | [106] |

| MC | Green tea | Machine vision NIRS | Color, texture 900–1700 nm | CARS, PLSR, SVR | RPD = 4.5 | [242] |

| MC | Tea leaves | VIS-NIRS | 400–1000 nm | SPRS, SNV-based Aug-TrAdaBoost.R2, S/B, PLS | R2 = 0.9895 | [241] |

| MC | Black tea | Machine vision | Color, texture Image | PLS, SVR, CNN | RPD = 9.5781 | [238] |

| MC | Black tea | NIRS | 833–2630 nm | DWT, BOSS, GA, PLS | R2p = 0.951 | [248] |

| MC | Black tea | NIRS Machine vision | 900–1700 nm Color, texture | SFLA, SVR, PCA | RPD = 5.5596 | [239] |

| MC, total nitrogen, crude fiber, quality index | Fresh leaves | HSI | 328–1115 nm | SPA, PLS, MLR, CARS | RPD = 4.0 for MC RPD = 2.56 for total nitrogen RPD = 2.31 for crude fiber RPD = 3.51 for quality index | [245] |

| MC, roduct quality | Pu-erh tea | Machine vision | Image, Environmental parameters (EP) | CNN, NCA | RPD > 13 for MC in each batch of tea RPD > 4 for final quality score | [239] |

| MC | Black tea | HSI | 400–1000 nm | SNV, Si-PLS, CARS, ELM | RPD = 13.0907 | [237] |

5. Challenges and Future Trends

6. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Achudume, A.C.; Owoeye, D. Quantitative assessment of heavy metals in some tea marketed in Nigeria—Bioaccumulation of heavy metals in tea. Health 2010, 2, 1097–1100. [Google Scholar] [CrossRef]

- Bhattacharya, U.; Halder, B.; Mukhopadhyay, S.; Giri, A.K. Role of oxidation-triggered activation of JNK and p38 MAPK in black tea polyphenols induced apoptotic death of A375 cells. Cancer Sci. 2010, 100, 1971–1978. [Google Scholar] [CrossRef] [PubMed]

- Halder, B.; Bhattacharya, U.; Mukhopadhyay, S.; Giri, A.K. Molecular mechanism of black tea polyphenols induced apoptosis in human skin cancer cells: Involvement of Bax translocation and mitochondria mediated death cascade. Carcinogenesis 2008, 29, 129–138. [Google Scholar] [CrossRef]

- Yang, Z.; Tu, Y.; Xia, H.; Jie, G.; Chen, X.; He, P. Suppression of free-radicals and protection against H2O2-induced oxidative damage in HPF-1 cell by oxidized phenolic compounds present in black tea. Food Chem. 2007, 105, 1349–1356. [Google Scholar] [CrossRef]

- Wang, X.; Huang, J.; Fan, W.; Lu, H. Identification of green tea varieties and fast quantification of total polyphenols by near-infrared spectroscopy and ultraviolet-visible spectroscopy with chemometric algorithms. Anal. Methods 2015, 7, 787–792. [Google Scholar] [CrossRef]

- Sarımehmet, B.; Pınarbaşı, M.; Alakaş, H.M.; Eren, T. Harvest optimization for sustainable agriculture: The case of tea harvest scheduling. Artif. Intell. Agric. 2023, 10, 35–45. [Google Scholar] [CrossRef]

- Zhu, H.; Ye, Y.; He, H.; Dong, C. Evaluation of green tea sensory quality via process characteristics and image information. Food Bioprod. Process. 2017, 102, 116–122. [Google Scholar] [CrossRef]

- Sultana, N.; Arayne, M.S.; Ali, S.S.; Sajid, S. Simultaneous determination of olmesartan medoxomil and irbesartan and hydrochlorothiazide in pharmaceutical formulations and human serum using high performance liquid chromatography. Chin. J. Chromatogr. 2008, 26, 544–549. [Google Scholar] [CrossRef]

- Wang, L.; Xu, R.; Hu, B.; Li, W.; Sun, Y.; Tu, Y.; Zeng, X. Analysis of free amino acids in Chinese teas and flower of tea plant by high performance liquid chromatography combined with solid-phase extraction. Food Chem. 2010, 123, 1259–1266. [Google Scholar] [CrossRef]

- Jumtee, K.; Komura, H.; Bamba, T.; Fukusaki, E. Predication of Japanese green tea (Sen-cha) ranking by volatile profiling using gas chromatography mass spectrometry and multivariate analysis. J. Biosci. Bioeng. 2011, 112, 252–255. [Google Scholar] [CrossRef]

- Yang, Y.Q.; Qian, M.C.; Deng, Y.L.; Yuan, H.B.; Jiang, Y.W. Insight into aroma dynamic changes during the whole manufacturing process of chestnut-like aroma green tea by combining GC-E-Nose, GC-IMS, and GC x GC-TOFMS. Food Chem. 2022, 387, 132813. [Google Scholar] [CrossRef] [PubMed]

- Izquierdo, P.F.; Delagado, L.C.; Benavides, F.O. An artificial neuronal network coupled with a genetic algorithm to optimise the production of unsaturated fatty acids in Parachlorella kessleri. Artif. Intell. Agric. 2024, 13, 32–44. [Google Scholar]

- Baldwin, E.A.; Jinhe, B.; Anne, P.; Sharon, D. Electronic noses and tongues: Applications for the food and pharmaceutical industries. Sensors 2011, 11, 4744–4766. [Google Scholar] [CrossRef] [PubMed]

- An, T.; Huang, W.Q.; Tian, X.; Fan, S.X.; Duan, D.D.; Dong, C.W.; Zhao, C.J.; Li, G.L. Hyperspectral imaging technology coupled with human sensory information to evaluate the fermentation degree of black tea. Sens. Actuators B-Chem. 2022, 366, 131994. [Google Scholar] [CrossRef]

- Brosnan, T.; Sun, D.W. Inspection and grading of agricultural and food products by computer vision systems—A review. Comput. Electron. Agric. 2002, 36, 193–213. [Google Scholar] [CrossRef]

- Yu, X.L.; Sun, D.W.; He, Y. Emerging techniques for determining the quality and safety of tea products: A review. Compr. Rev. Food Sci. Food Saf. 2020, 19, 2613–2638. [Google Scholar] [CrossRef]

- Song, F.H.; Lu, X.L.; Lin, Y.Q.; Zhou, Q.Y.; Li, Z.F.; Ling, C.J.; Song, C.F. Evaluation of black tea appearance quality using a segmentation-based feature extraction method. Food Biosci. 2024, 58, 103644. [Google Scholar] [CrossRef]

- Sachithra, V.; Subhashini, L. How artificial intelligence uses to achieve the agriculture sustainability: Systematic review. Artif. Intell. Agric. 2023, 8, 46–59. [Google Scholar] [CrossRef]

- Rizzo, M.; Marcuzzo, M.; Zangari, A.; Gasparetto, A.; Albarelli, A. Fruit ripeness classification: A survey. Artif. Intell. Agric. 2023, 7, 44–57. [Google Scholar] [CrossRef]

- Haralick, R.M.; Shapiro, L.G. Computer and Robot Vision; Addison-Wesley: Reading, MA, USA, 1992; Volume 1. [Google Scholar]

- Patel, K.K.; Kar, A.; Jha, S.; Khan, M. Machine vision system: A tool for quality inspection of food and agricultural products. J. Food Sci. Technol. 2012, 49, 123–141. [Google Scholar] [CrossRef]

- Elango, V.; Karunamoorthy, L. Effect of lighting conditions in the study of surface roughness by machine vision—An experimental design approach. Int. J. Adv. Manuf. Technol. 2008, 37, 92–103. [Google Scholar] [CrossRef]

- Brosnan, T.; Sun, D.W. Improving quality inspection of food products by computer vision—A review. J. Food Eng. 2004, 61, 3–16. [Google Scholar] [CrossRef]

- Zhou, J.C.; Li, L.F.; Qadir, A.; Li, H.X.; Lv, J.H.; Shehzad, K.; Xu, X.Y.; Liu, L.X.; Tian, F.; Liu, W.; et al. Charge Sampling Photodetector Based on van der Waals Heterostructures. Adv. Opt. Mater. 2022, 10, 2201442. [Google Scholar] [CrossRef]

- Zhu, H.; Yang, L.; Wang, Y.; Wang, Y.; Hou, W.; Rao, Y.; Liu, L. Enhanced detection algorithm for apple bruises using structured light imaging. Artif. Intell. Agric. 2024, 11, 50–60. [Google Scholar] [CrossRef]

- Bigas, M.; Cabruja, E.; Forest, J.; Salvi, J. Review of CMOS image sensors. Microelectron. J. 2006, 37, 433–451. [Google Scholar] [CrossRef]

- Xiong, Z.; Sun, D.W.; Zeng, X.A.; Xie, A. Recent developments of hyperspectral imaging systems and their applications in detecting quality attributes of red meats: A review. J. Food Eng. 2014, 132, 1–13. [Google Scholar] [CrossRef]

- Kotwaliwale, N.; Singh, K.; Kalne, A.; Jha, S.N.; Seth, N.; Kar, A. X-ray imaging methods for internal quality evaluation of agricultural produce. J. Food Sci. Technol. 2014, 51, 1–15. [Google Scholar] [CrossRef]

- Xiong, Z.; Sun, D.W.; Pu, H.; Gao, W.; Dai, Q. Applications of emerging imaging techniques for meat quality and safety detection and evaluation: A review. Crit. Rev. Food Sci. Nutr. 2017, 57, 755–768. [Google Scholar] [CrossRef]

- Khazem, S.; Richard, A.; Fix, J.; Pradalier, C. Deep learning for the detection of semantic features in tree X-ray CT scans. Artif. Intell. Agric. 2023, 7, 13–26. [Google Scholar] [CrossRef]

- Navajas, E.A.; Lambe, N.R.; Mclean, K.A.; Glasbey, C.A.; Fisher, A.V.; Charteris, A.J.L.; Bünger, L.; Simm, G. Accuracy of in vivo muscularity indices measured by computed tomography and their association with carcass quality in lambs. Meat Sci. 2007, 75, 533–542. [Google Scholar] [CrossRef]

- Mathiassen, J.R.; Misimi, E.; Bondø, M.; Veliyulin, E.; Østvik, S.O. Trends in application of imaging technologies to inspection of fish and fish products. Trends Food Sci. Technol. 2011, 22, 257–275. [Google Scholar] [CrossRef]

- Antequera, T.; Caballero, D.; Grassi, S.; Uttaro, B.; Perez-Palacios, T. Evaluation of fresh meat quality by Hyperspectral Imaging (HSI), Nuclear Magnetic Resonance (NMR) and Magnetic Resonance Imaging (MRI): A review. Meat Sci. 2021, 172, 108340. [Google Scholar] [CrossRef] [PubMed]

- Bushong, S.C.; Clarke, G. Magnetic Resonance Imaging-E-Book: Physical and Biological Principles; Elsevier Health Sciences: Amsterdam, The Netherlands, 2013. [Google Scholar]

- Abbasi, R.; Martinez, P.; Ahmad, R. Estimation of morphological traits of foliage and effective plant spacing in NFT-based aquaponics system. Artif. Intell. Agric. 2023, 9, 76–88. [Google Scholar] [CrossRef]

- Abbasi, R.; Martinez, P.; Ahmad, R. Crop diagnostic system: A robust disease detection and management system for leafy green crops grown in an aquaponics facility. Artif. Intell. Agric. 2023, 10, 1–12. [Google Scholar] [CrossRef]

- Thybo, A.K.; Szczypiński, P.M.; Karlsson, A.H.; Dønstrup, S.; Stødkilde-Jørgensen, H.S.; Andersen, H.J. Prediction of sensory texture quality attributes of cooked potatoes by NMR-imaging (MRI) of raw potatoes in combination with different image analysis methods. J. Food Eng. 2004, 61, 91–100. [Google Scholar] [CrossRef]

- Shaarani, S.M.; Cardenas-Blanco, A.; Amin, M.G.; Soon, N.G.; Hall, L.D. Monitoring Development and Ripeness of Oil Palm Fruit (Elaeis guneensis) by MRI and Bulk NMR. Int. J. Agric. Biol. 2010, 12, 1560–8530. [Google Scholar]

- Ozel, B.; Oztop, M.H. A quick look to the use of time domain nuclear magnetic resonance relaxometry and magnetic resonance imaging for food quality applications. Curr. Opin. Food Sci. 2021, 41, 122–129. [Google Scholar] [CrossRef]

- Qiu, Z.J.; Bian, Y.L.; Wang, F.Y.; Huang, T.; Wang, Z.P. A novel method for detection of internal quality of walnut kernels using low-field magnetic resonance imaging. Comput. Electron. Agric. 2024, 217, 108546. [Google Scholar] [CrossRef]

- Juwono, F.H.; Wong, W.; Verma, S.; Shekhawat, N.; Lease, B.A.; Apriono, C. Machine learning for weed–plant discrimination in agriculture 5.0: An in-depth review. Artif. Intell. Agric. 2023, 10, 13–25. [Google Scholar] [CrossRef]

- Ives, J.; Warach, S.; Schmitt, F.; Edelman, R.; Schomer, D. Monitoring the patient’s EEG during echo planar MRI. Electroencephalogr. Clin. Neurophysiol. 1993, 87, 417–420. [Google Scholar] [CrossRef]

- Clark, C.J.; Hockings, P.D.; Joyce, D.C.; Mazucco, R.A. Application of magnetic resonance imaging to pre- and post-harvest studies of fruits and vegetables. Postharvest Biol. Technol. 1997, 11, 1–21. [Google Scholar] [CrossRef]

- Schmidt, S.J.; Sun, X.; Litchfield, J.B. Applications of magnetic resonance imaging in food science. Crit. Rev. Food Sci. Nutr. 1996, 36, 29. [Google Scholar] [CrossRef] [PubMed]

- Zeng, F.Y.; Shao, W.D.; Kang, J.M.; Yang, J.X.; Zhang, X.; Liu, Y.; Wang, H.H. Detection of moisture content in salted sea cucumbers by hyperspectral and low field nuclear magnetic resonance based on deep learning network framework. Food Res. Int. 2022, 156, 111174. [Google Scholar] [CrossRef] [PubMed]

- Adhinata, F.D.; Sumiharto, R. A comprehensive survey on weed and crop classification using machine learning and deep learning. Artif. Intell. Agric. 2024, 13, 45–63. [Google Scholar] [CrossRef]

- Cheng, J.-H.; Dai, Q.; Sun, D.-W.; Zeng, X.-A.; Liu, D.; Pu, H.-B. Applications of non-destructive spectroscopic techniques for fish quality and safety evaluation and inspection. Trends Food Sci. Technol. 2013, 34, 18–31. [Google Scholar] [CrossRef]

- Karoui, R.; Blecker, C. Fluorescence Spectroscopy Measurement for Quality Assessment of Food Systems—A Review. Food Bioprocess Technol. 2011, 4, 364–386. [Google Scholar] [CrossRef]

- Miao, L.M.; Ren, K.Y.; Feng, J.L.; Dong, H.X.; Wang, H.; Tong, X.H.; Jiang, L.Z. Effects of fibrillation combined with glycation by different chain length sugars on structural and functional properties of soybean protein. Food Hydrocoll. 2024, 153, 110026. [Google Scholar] [CrossRef]

- Sasic, S.; Ozaki, Y. Raman, Infrared, and Near-Infrared Chemical Imaging; John Wiley & Sons: Hoboken, NJ, USA, 2011. [Google Scholar]

- Qu, C.; Li, Y.Z.; Du, S.S.; Geng, Y.C.; Su, M.K.; Liu, H.L. Raman spectroscopy for rapid fingerprint analysis of meat quality and security: Principles, progress and prospects. Food Res. Int. 2022, 161, 111805. [Google Scholar] [CrossRef]

- Liu, H.; Ren, Y.; Chu, H.; Shan, H.; Wong, K.W. A fuzzy risk assessment model used for assessing the introduction of African swine fever into Australia from overseas. Artif. Intell. Agric. 2023, 7, 27–34. [Google Scholar] [CrossRef]

- Houetohossou, S.C.A.; Houndji, V.R.; Hounmenou, C.G.; Sikirou, R.; Kakaï, R.L.G. Deep learning methods for biotic and abiotic stresses detection and classification in fruits and vegetables: State of the art and perspectives. Artif. Intell. Agric. 2023, 9, 46–60. [Google Scholar] [CrossRef]

- Ditcharoen, S.; Sirisomboon, P.; Saengprachatanarug, K.; Phuphaphud, A.; Rittiron, R.; Terdwongworakul, A.; Malai, C.; Saenphon, C.; Panduangnate, L.; Posom, J. Improving the non-destructive maturity classification model for durian fruit using near-infrared spectroscopy. Artif. Intell. Agric. 2023, 7, 35–43. [Google Scholar] [CrossRef]

- Yaseen, T.; Sun, D.W.; Cheng, J.H. Raman imaging for food quality and safety evaluation: Fundamentals and applications. Trends Food Sci. Technol. 2017, 62, 177–189. [Google Scholar] [CrossRef]

- Silva, R.; Melo-Pinto, P. t-SNE: A study on reducing the dimensionality of hyperspectral data for the regression problem of estimating oenological parameters. Artif. Intell. Agric. 2023, 7, 58–68. [Google Scholar] [CrossRef]

- Razavi, M.A.; Nejadhashemi, A.P.; Majidi, B.; Razavi, H.S.; Kpodo, J.; Eeswaran, R.; Ciampitti, I.; Prasad, P.V. Enhancing crop yield prediction in Senegal using advanced machine learning techniques and synthetic data. Artif. Intell. Agric. 2024, 14, 99–114. [Google Scholar] [CrossRef]

- He, H.J.; Sun, D.W. Hyperspectral imaging technology for rapid detection of various microbial contaminants in agricultural and food products. Trends Food Sci. Technol. 2015, 46, 99–109. [Google Scholar] [CrossRef]

- Suárez, P.L.; Velesaca, H.O.; Carpio, D.; Sappa, A.D. Corn kernel classification from few training samples. Artif. Intell. Agric. 2023, 9, 89–99. [Google Scholar] [CrossRef]

- Herrero, A.M. Raman spectroscopy for monitoring protein structure in muscle food systems. Crit. Rev. Food Sci. Nutr. 2008, 48, 512–523. [Google Scholar] [CrossRef]

- Wang, Y.J.; Liu, Y.; Chen, Y.Y.; Cui, Q.Q.; Li, L.Q.; Ning, J.M.; Zhang, Z.Z. Spatial distribution of total polyphenols in multi-type of tea using near-infrared hyperspectral imaging. LWT-Food Sci. Technol. 2021, 148, 111737. [Google Scholar] [CrossRef]

- Huang, L.; Zhao, J.; Chen, Q.; Zhang, Y. Nondestructive measurement of total volatile basic nitrogen (TVB-N) in pork meat by integrating near infrared spectroscopy, computer vision and electronic nose techniques. Food Chem. 2014, 145, 228–236. [Google Scholar] [CrossRef]

- Badaró, A.T.; Tavares, J.; Blasco, J.; Aleixos-Borrás, N.; Barbin, D.F. Near infrared techniques applied to analysis of wheat-based products: Recent advances and future trends. Food Control 2022, 140, 109115. [Google Scholar] [CrossRef]

- Zhang, L.H.; Zhang, M.; Mujumdar, A.S. Technological innovations or advancement in detecting frozen and thawed meat quality: A review. Crit. Rev. Food Sci. Nutr. 2023, 63, 1483–1499. [Google Scholar] [CrossRef] [PubMed]

- Tkachenko, N.V. Optical Spectroscopy Methods and Instrumentations; Elsevier: Amsterdam, The Netherlands, 2006. [Google Scholar]

- Esslinger, S.; Riedl, J.; Fauhl-Hassek, C. Potential and limitations of non-targeted fingerprinting for authentication of food in official control. Food Res. Int. 2014, 60, 189–204. [Google Scholar] [CrossRef]

- Jin, S.; Li, M.J.; Liu, Z.Q.; Liu, R.H.; Li, Y.C.; Zhu, Y.Y.; Yuan, Y.W.; Li, P.C.; Li, P.M.; Chen, C.M.; et al. Study on the correlation between color and taste of beauty tea infusion and the pivotal contributing compounds based on UV-visible spectroscopy, taste equivalent quantification and metabolite analysis. Food Chem.-X 2024, 21, 101192. [Google Scholar] [CrossRef]

- Zhang, H.L.; Zhan, B.S.; Pan, F.; Luo, W. Determination of soluble solids content in oranges using visible and near infrared full transmittance hyperspectral imaging with comparative analysis of models. Postharvest Biol. Technol. 2020, 163, 111148. [Google Scholar] [CrossRef]

- Ouyang, Q.; Wang, L.; Park, B.; Kang, R.; Chen, Q.S. Simultaneous quantification of chemical constituents in matcha with visible-near infrared hyperspectral imaging technology. Food Chem. 2021, 350, 129141. [Google Scholar] [CrossRef]

- Barbin, D.F.; Elmasry, G.; Sun, D.W.; Allen, P.; Morsy, N. Non-destructive assessment of microbial contamination in porcine meat using NIR hyperspectral imaging. Innov. Food Sci. Emerg. Technol. 2013, 17, 180–191. [Google Scholar] [CrossRef]

- Hansson, M.; Nordberg, Å.; Mathisen, B. On-line NIR monitoring during anaerobic treatment of municipal solid waste. Water Sci. Technol. 2003, 48, 9–13. [Google Scholar] [CrossRef]

- Fakhlaei, R.; Babadi, A.A.; Sun, C.J.; Ariffin, N.M.; Khatib, A.; Selamat, J.; Xiaobo, Z. Application, challenges and future prospects of recent nondestructive techniques based on the electromagnetic spectrum in food quality and safety. Food Chem. 2024, 441, 138402. [Google Scholar] [CrossRef]

- Wang, S.; Yang, X.; Zhang, Y.; Phillips, P.; Yang, J.; Yuan, T.-F. Identification of green, oolong and black teas in China via wavelet packet entropy and fuzzy support vector machine. Entropy 2015, 17, 6663–6682. [Google Scholar] [CrossRef]

- Sankaran, J.; Manna, M.; Guo, L.; Kraut, R.; Wohland, T. Diffusion, Transport, and Cell Membrane Organization Investigated by Imaging Fluorescence Cross-Correlation Spectroscopy. Biophys. J. 2009, 97, 2630–2639. [Google Scholar] [CrossRef]

- Dankowska, A.; Kowalewski, W. Tea types classification with data fusion of UV–Vis, synchronous fluorescence and NIR spectroscopies and chemometric analysis. Spectrochim. Acta Part A Mol. Biomol. Spectrosc. 2019, 211, 195–202. [Google Scholar] [CrossRef] [PubMed]

- Zhang, B.; Huang, W.; Li, J.; Zhao, C.; Fan, S.; Wu, J.; Liu, C. Principles, developments and applications of computer vision for external quality inspection of fruits and vegetables: A review. Food Res. Int. 2014, 62, 326–343. [Google Scholar] [CrossRef]

- Qin, J.; Chao, K.; Kim, M.S.; Lu, R.; Burks, T.F. Hyperspectral and multispectral imaging for evaluating food safety and quality. J. Food Eng. 2013, 118, 157–171. [Google Scholar] [CrossRef]

- Wu, D.; Sun, D.W. Advanced applications of hyperspectral imaging technology for food quality and safety analysis and assessment: A review—Part II: Applications. Innov. Food Sci. Emerg. Technol. 2013, 19, 1–14. [Google Scholar] [CrossRef]

- An, T.; Wang, Z.L.; Li, G.L.; Fan, S.X.; Huang, W.Q.; Duan, D.D.; Zhao, C.J.; Tian, X.; Dong, C.W. Monitoring the major taste components during black tea fermentation using multielement fusion information in decision level. Food Chem.-X 2023, 18, 100718. [Google Scholar] [CrossRef]

- Goetz, A.F.; Vane, G.; Solomon, J.E.; Rock, B.N. Imaging spectrometry for Earth remote sensing. Science 1985, 228, 1147–1153. [Google Scholar] [CrossRef]

- Unoa, Y.; Prashera, S.O.; Lacroixb, R.; Goela, P.K.; Karimia, Y.; Viauc, A.; Patela, R.M. Artificial neural networks to predict corn yield from Compact Airborne Spectrographic Imager data. Comput. Electron. Agric. 2005, 47, 149–161. [Google Scholar] [CrossRef]

- Smail, V.W.; Fritz, A.K.; Wetzel, D.L. Chemical imaging of intact seeds with NIR focal plane array assists plant breeding. Vib. Spectrosc. 2006, 42, 215–221. [Google Scholar] [CrossRef]

- Monteiro, S.T.; Minekawa, Y.; Kosugi, Y.; Akazawa, T.; Oda, K. Prediction of sweetness and amino acid content in soybean crops from hyperspectral imagery. ISPRS J. Photogramm. Remote Sens. 2007, 62, 2–12. [Google Scholar] [CrossRef]

- Barbedo, J.G.A. A review on the combination of deep learning techniques with proximal hyperspectral images in agriculture. Comput. Electron. Agric. 2023, 210, 107920. [Google Scholar] [CrossRef]

- Kang, Y.S.; Ryu, C.; Suguri, M.; Park, S.B.; Kishino, S.; Onoyama, H. Estimating the catechin concentrations of new shoots in green tea fields using ground-based hyperspectral imagery. Food Chem. 2022, 370, 130987. [Google Scholar] [CrossRef] [PubMed]

- Xie, Y.T.; Plett, D.; Evans, M.; Garrard, T.; Butt, M.; Clarke, K.; Liu, H.J. Hyperspectral imaging detects biological stress of wheat for early diagnosis of crown rot disease. Comput. Electron. Agric. 2024, 217, 108571. [Google Scholar] [CrossRef]

- Grahn, H.; Geladi, P. Techniques and Applications of Hyperspectral Image Analysis; John Wiley & Sons: Hoboken, NJ, USA, 2007. [Google Scholar]

- Dai, F.S.; Shi, J.; Yang, C.S.; Li, Y.; Zhao, Y.; Liu, Z.Y.; An, T.; Li, X.L.; Yan, P.; Dong, C.W. Detection of anthocyanin content in fresh Zijuan tea leaves based on hyperspectral imaging. Food Control 2023, 152, 109839. [Google Scholar] [CrossRef]

- Yu, K.; Zhao, Y.; Li, X.; He, Y. NIR Hyperspectral Imaging for Mapping of Moisture Content Distribution in Tea Buds During Dehydration. In Processing and Analysis of Hyperspectral Data; IntechOpen: London, UK, 2019. [Google Scholar]

- Kim, M.S.; Mcmurtrey, J.E.; Mulchi, C.L.; Daughtry, C.S.; Chappelle, E.W.; Chen, Y.R. Steady-state multispectral fluorescence imaging system for plant leaves. Appl. Opt. 2001, 40, 157–166. [Google Scholar] [CrossRef]

- Park, B.; Lawrence, K.C.; Windham, W.R.; Smith, D.P. Multispectral imaging system for fecal and ingesta detection on poultry carcasses. J. Food Process Eng. 2004, 27, 311–327. [Google Scholar] [CrossRef]

- Orlando, S.; Minacapilli, M.; Sarno, M.; Carrubba, A.; Motisi, A. A low-cost multispectral imaging system for the characterisation of soil and small vegetation properties using visible and near-infrared reflectance. Comput. Electron. Agric. 2022, 202, 107359. [Google Scholar] [CrossRef]

- Jian-Liang, L.U.; Liang, Y.R.; Gong, S.Y.; Zhi-Lei, G.U.; Zhang, L.Y.; Yue-Rong, X.U. Studies on Relationship between Liquor Chromaticity and Organoleptic Quality of Tea. J. Tea Sci. 2002, 22, 57–61. [Google Scholar]

- Sharma, O.; Mioc, D.; Anton, F. Polygon feature extraction from satellite imagery based on colour image segmentation and medial axis. Int. Arch. Photogramm. Remote Sens. Spat. Inf. Sci. 2008, 37, 235–240. [Google Scholar]

- Wang, F.R.; Xie, B.M.; Lue, E.L.; Zeng, Z.X.; Mei, S.; Ma, C.Y.; Guo, J.M. Design of a Moisture Content Detection System for Yinghong No. 9 Tea Leaves Based on Machine Vision. Appl. Sci. 2023, 13, 1806. [Google Scholar] [CrossRef]

- Chen, C.; Zhang, W.; Shan, Z.; Zhang, C.; Dong, T.; Feng, Z.; Wang, C. Moisture contents and product quality prediction of Pu-erh tea in sun-drying process with image information and environmental parameters. Food Sci. Nutr. 2022, 10, 1021–1038. [Google Scholar] [CrossRef]

- Aharonov, R.; Goldschmidt, Y.; Ozery-Flato, M.; Yanover, C. Modular Memoization, Tracking and Train-Data Management of Feature Extraction. U.S. Patent No. 10,572,822, 25 February 2020. [Google Scholar]

- Krutz, G.W.; Gibson, H.G.; Cassens, D.L.; Zhang, M. Colour vision in forest and wood engineering. Landwards 2000, 55, 2–9. [Google Scholar]

- García-Pérez, P.; Becchi, P.P.; Zhang, L.L.; Rocchetti, G.; Lucini, L. Metabolomics and chemometrics: The next-generation analytical toolkit for the evaluation of food quality and authenticity. Trends Food Sci. Technol. 2024, 147, 104481. [Google Scholar] [CrossRef]

- Ai, S.R.; Wu, R.M.; Yan, L.Y.; Wu, Y.H. Measurement of the Ratio of Tea Polyphenols to Amino Acids in Green Tea Infusion Based on near Infrared Spectroscopy. Adv. Mater. Res. 2011, 301–303, 1093–1097. [Google Scholar] [CrossRef]

- Kumari, M.; Soni, S. A Review of Classification in Web Usage Mining using K-Nearest Neighbor. Adv. Comput. Sci. Technol. 2017, 10, 1405–1416. [Google Scholar]

- Squillacciotti, S. Prediction Oriented Classification in PLS Path Modeling. In Handbook of Partial Least Squares: Concepts, Methods and Applications; Springer: Berlin/Heidelberg, Germany, 2010. [Google Scholar]

- Temel, F.A.; Yolcu, O.C.; Turan, N.G. Artificial intelligence and machine learning approaches in composting process: A review. Bioresour. Technol. 2023, 370, 128539. [Google Scholar]

- Shuai, M.Y.; Peng, C.Y.; Niu, H.L.; Shao, D.L.; Hou, R.Y.; Cai, H.M. Recent techniques for the authentication of the geographical origin of tea leaves from camellia sinensis: A review. Food Chem. 2022, 374, 131713. [Google Scholar] [CrossRef]

- Barker, M.; Rayens, W. Partial least squares for discrimination. J. Chemom. J. Chemom. Soc. 2003, 17, 166–173. [Google Scholar] [CrossRef]

- An, T.; Li, Y.; Tian, X.; Fan, S.; Duan, D.; Zhao, C.; Huang, W.; Dong, C. Evaluation of aroma quality using multidimensional olfactory information during black tea fermentation. Sens. Actuators B-Chem. 2022, 371, 132518. [Google Scholar] [CrossRef]

- Magwaza, L.S.; Opara, U.L.; Cronje, P.J.R.; Saeys, W.; Nicolaï, B. NIR Spectroscopy Applications for Internal and External Quality Analysis of Citrus Fruit—A Review. Food Bioprocess Technol. 2012, 5, 425–444. [Google Scholar] [CrossRef]

- Wang, H.P.; Chen, P.; Dai, J.W.; Liu, D.; Li, J.Y.; Xu, Y.P.; Chu, X.L. Recent advances of chemometric calibration methods in modern spectroscopy: Algorithms, strategy, and related issues. TRAC-Trends Anal. Chem. 2022, 153, 116648. [Google Scholar] [CrossRef]

- Wang, W.; Yan, Y.; Liu, D.; Chen, Z.; Su, C.; Liu, F.; Geng, L.; Chen, L.; Du, J. Calibration and Data Processing for a Chinese Spectral Radioheliograph in the Decimeter Wave Range. Publ.-Astron. Soc. Jpn. 2013, 65, 2226–2237. [Google Scholar] [CrossRef]

- Rinnan, Å.; Berg, F.V.D.; Engelsen, S.B. Review of the most common pre-processing techniques for near-infrared spectra. Trends Anal. Chem. 2009, 28, 1201–1222. [Google Scholar] [CrossRef]

- Liu, Y.; Liu, Y.L.; Chen, Y.Y.; Zhang, Y.; Shi, T.Z.; Wang, J.J.; Hong, Y.S.; Fei, T.; Zhang, Y. The Influence of Spectral Pretreatment on the Selection of Representative Calibration Samples for Soil Organic Matter Estimation Using Vis-NIR Reflectance Spectroscopy. Remote Sens. 2019, 11, 450. [Google Scholar] [CrossRef]

- Nicolaï, B.M.; Beullens, K.; Bobelyn, E.; Peirs, A.; Saeys, W.; Theron, K.I.; Lammertyn, J. Nondestructive measurement of fruit and vegetable quality by means of NIR spectroscopy: A review. Postharvest Biol. Technol. 2007, 46, 99–118. [Google Scholar] [CrossRef]

- Li, X.; Li, R.; Wang, M.; Liu, Y.; Zhang, B.; Zhou, J. Hyperspectral Imaging and Their Applications in the Nondestructive Quality Assessment of Fruits and Vegetables. In Hyperspectral Imaging in Agriculture, Food and Environment; IntechOpen: London, UK, 2018; p. 27. [Google Scholar]

- Barclay, V.J.; Bonner, R.F. Application of Wavelet Transforms to Experimental Spectra: Smoothing, Denoising, and Data Set Compression. Anal. Chem. 1997, 69, 78–90. [Google Scholar] [CrossRef]

- Sun, X.D.; Zhang, H.L.; Liu, Y.D. Nondestructive assessment of quality of Nanfeng mandarin fruit by a portable near infrared spectroscopy. Int. J. Agric. Biol. Eng. 2009, 2, 65–71. [Google Scholar]

- Liu, D.; Sun, D.W.; Zeng, X.A. Recent Advances in Wavelength Selection Techniques for Hyperspectral Image Processing in the Food Industry. Food Bioprocess Technol. 2014, 7, 307–323. [Google Scholar] [CrossRef]

- An, T.; Yu, S.Y.; Huang, W.Q.; Li, G.L.; Tian, X.; Fan, S.X.; Dong, C.W.; Zhao, C.J. Robustness and accuracy evaluation of moisture prediction model for black tea withering process using hyperspectral imaging. Spectrochim. Acta Part A-Mol. Biomol. Spectrosc. 2022, 269, 120791. [Google Scholar] [CrossRef]

- Han, G.M.; Dai, L.M.; Sun, Y.H.; Li, C.; Ruan, S.L.; Li, J.M.; Xu, Y. Determination of the age of dry red wine by multivariate techniques using color parameters and pigments. Food Control 2021, 129, 108253. [Google Scholar] [CrossRef]

- Zhou, J.C.; Wang, D.; Kheirollah, S.N.; Maroufpoor, S.; Band, S.S. Sensitivity analysis of wheat yield based on growing degree days in different growth stages: Application of machine learning approach enhanced by grey systems theory. Comput. Electron. Agric. 2023, 210, 107876. [Google Scholar] [CrossRef]

- Guo, J.M.; Huang, H.; He, X.L.; Cai, J.W.; Zeng, Z.X.; Ma, C.Y.; Lue, E.L.; Shen, Q.Y.; Liu, Y.H. Improving the detection accuracy of the nitrogen content of fresh tea leaves by combining FT-NIR with moisture removal method. Food Chem. 2023, 405, 134905. [Google Scholar] [CrossRef]

- Wang, F.; Cao, Q.; Zhao, C.J.; Duan, D.D.; Chen, L.Y.; Meng, X.Y. Non-destructive determination of taste-related substances in fresh tea using NIR spectra. J. Food Meas. Charact. 2023, 17, 5874–5885. [Google Scholar] [CrossRef]

- Zhu, A.F.; Xu, Y.; Ali, S.; Ouyang, Q.; Chen, Q.S. Au@Ag nanoflowers based SERS coupled chemometric algorithms for determination of organochlorine pesticides in milk. LWT-Food Sci. Technol. 2021, 150, 111978. [Google Scholar] [CrossRef]

- Mehmood, T.; Warringer, J.; Snipen, L.; Sæbø, S. Improving stability and understandability of genotype-phenotype mapping in Saccharomyces using regularized variable selection in L-PLS regression. BMC Bioinform. 2012, 13, 3693. [Google Scholar] [CrossRef]

- Lorente, D.; Aleixos, N.; Gómez-Sanchis, J.; Cubero, S.; García-Navarrete, O.L.; Blasco, J. Recent Advances and Applications of Hyperspectral Imaging for Fruit and Vegetable Quality Assessment. Neuroimage 2012, 5, 1121–1142. [Google Scholar] [CrossRef]

- Zhang, Y.Y.; Gao, W.J.; Cui, C.J.; Zhang, Z.Z.; He, L.L.; Zheng, J.K.; Hou, R.Y. Development of a method to evaluate the tenderness of fresh tea leaves based on rapid, in-situ Raman spectroscopy scanning for carotenoids. Food Chem. 2020, 308, 125648. [Google Scholar] [CrossRef]

- Zhang, Z.X.; Liu, H.L.; Chen, D.Y.; Zhang, J.H.; Li, H.; Shen, M.S.; Pu, Y.G.; Zhang, Z.J.; Zhao, J.; Hu, J. SMOTE-based method for balanced spectral nondestructive detection of moldy apple core. Food Control 2022, 141, 109100. [Google Scholar] [CrossRef]

- Suykens, J.A.; Vandewalle, J. Multiclass least squares support vector machines. In Proceedings of the IJCNN’99. International Joint Conference on Neural Networks. Proceedings (Cat. No.99CH36339), Washington, DC, USA, 10–16 July 1999; p. 900. [Google Scholar]

- Wu, Q.; Liu, S.-y.; Du, Z. Fuzzy least square support vector machines for regression. J. Xidian Univ. 2007, 34, 773–778. [Google Scholar]

- Balabin, R.M.; Lomakina, E.I.; Safieva, R.Z. Neural network (ANN) approach to biodiesel analysis: Analysis of biodiesel density, kinematic viscosity, methanol and water contents using near infrared (NIR) spectroscopy. Fuel 2011, 90, 2007–2015. [Google Scholar] [CrossRef]

- Li, J.; Huang, W.; Zhao, C.; Zhang, B. A comparative study for the quantitative determination of soluble solids content, pH and firmness of pears by Vis/NIR spectroscopy. J. Food Eng. 2013, 116, 324–332. [Google Scholar] [CrossRef]

- Liang, Y.; Lu, J.; Zhang, L.; Wu, S.; Wu, Y. Estimation of black tea quality by analysis of chemical composition and colour difference of tea infusions. Food Chem. 2003, 80, 283–290. [Google Scholar] [CrossRef]

- Singh, G.; Kamal, N. Machine vision system for tea quality determination-Tea Quality Index (TQI). IOSR J. Eng. 2013, 3, 46–50. [Google Scholar] [CrossRef]

- Borah, S.; Bhuyan, M. Non-destructive testing of tea fermentation using image processing. Insight-Non-Destr. Test. Cond. Monit. 2003, 45, 55–58. [Google Scholar] [CrossRef]

- Gejima, Y.; Nagata, M. Basic study on Kamairicha tea leaves quality judgment system. In Proceedings of the ASAE Annual International Meeting, Milwaukee, WI, USA, 9–12 July 2000. [Google Scholar]

- Wu, D.; Sun, D.-W. Colour measurements by computer vision for food quality control–A review. Trends Food Sci. Technol. 2013, 29, 5–20. [Google Scholar] [CrossRef]

- Chen, Q.; Zhao, J.; Cai, J. Identification of Tea Varieties Using Computer Vision. Trans. Asabe 2008, 51, 623–628. [Google Scholar] [CrossRef]

- Dong, C.; Liang, G.; Hu, B.; Yuan, H.; Jiang, Y.; Zhu, H.; Qi, J. Prediction of Congou Black Tea Fermentation Quality Indices from Color Features Using Non-Linear Regression Methods. Sci. Rep. 2018, 8, 10535. [Google Scholar] [CrossRef]

- Wang, H.J.; Gu, J.A.; Wang, M.N. A review on the application of computer vision and machine learning in the tea industry. Front. Sustain. Food Syst. 2023, 7, 1172543. [Google Scholar] [CrossRef]

- Wang, Y.N.; Huang, C.; Lu, F.; Ye, X.F.; Ma, H.L. In-situ and real-time monitoring of two-stage enzymatic preparation of ACE inhibitory peptides from Cordyceps militaris medium residues by ultrasonic-assisted pretreatment. Food Chem. 2023, 418, 135886. [Google Scholar] [CrossRef]

- Xie, C.; Li, X.; Shao, Y.; He, Y. Color measurement of tea leaves at different drying periods using hyperspectral imaging technique. PLoS ONE 2014, 9, e113422. [Google Scholar] [CrossRef]

- Wang, S.; Phillips, P.; Liu, A.; Du, S. Tea category identification using computer vision and generalized eigenvalue proximal svm. Fundam. Inform. 2017, 151, 325–339. [Google Scholar] [CrossRef]

- Gill, G.S.; Kumar, A.; Agarwal, R. Monitoring and grading of tea by computer vision—A review. J. Food Eng. 2011, 106, 13–19. [Google Scholar] [CrossRef]

- Chen, Y.Y.; Wu, H.T.; Liu, Y.; Wang, Y.J.; Lu, C.Y.; Li, T.H.; Wei, Y.M.; Ning, J.M. Monitoring green tea fixation quality by intelligent sensors: Comparison of image and spectral information. J. Sci. Food Agric. 2023, 103, 3093–3101. [Google Scholar] [CrossRef] [PubMed]

- Fernandes, J.S.; Fernandes, D.D.D.; Pistonesi, M.F.; Diniz, P. Tea authentication and determination of chemical constituents using digital image-based fingerprint signatures and chemometrics. Food Chem. 2023, 421, 136164. [Google Scholar] [CrossRef] [PubMed]

- Jin, G.; Wang, Y.J.; Li, L.Q.; Shen, S.S.; Deng, W.W.; Zhang, Z.Z.; Ning, J.M. Intelligent evaluation of black tea fermentation degree by FT-NIR and computer vision based on data fusion strategy. LWT-Food Sci. Technol. 2020, 125, 109216. [Google Scholar] [CrossRef]

- Kuang, Z.K.; Yu, X.Y.; Guo, Y.C.; Cai, Y.F.; Hong, W.B. Design of a Multimodal Detection System Tested on Tea Impurity Detection. Remote Sens. 2024, 16, 1590. [Google Scholar] [CrossRef]

- Li, T.; Lu, C.; Wei, Y.; Zhang, J.; Shao, A.; Li, L.; Wang, Y.; Ning, J. Chemical imaging for determining the distributions of quality components during the piling fermentation of Pu-erh tea. Food Control 2024, 158, 110234. [Google Scholar] [CrossRef]

- Li, T.H.; Lu, C.Y.; Huang, J.L.; Chen, Y.Y.; Zhang, J.X.; Wei, Y.M.; Wang, Y.J.; Ning, J.M. Qualitative and quantitative analysis of the pile fermentation degree of Pu-erh tea. LWT-Food Sci. Technol. 2023, 173, 114327. [Google Scholar] [CrossRef]

- Ren, G.X.; Gan, N.; Song, Y.; Ning, J.M.; Zhang, Z.Z. Evaluating Congou black tea quality using a lab-made computer vision system coupled with morphological features and chemometrics. Microchem. J. 2021, 160, 105600. [Google Scholar] [CrossRef]

- Ren, G.X.; Wu, R.; Yin, L.L.; Zhang, Z.Z.; Ning, J.M. Description of tea quality using deep learning and multi-sensor feature fusion. J. Food Compos. Anal. 2024, 126, 105924. [Google Scholar] [CrossRef]

- Wang, S.M.; Ma, J.H.; Zhao, Z.M.; Yang, H.Z.Y.; Xuan, Y.M.; Ouyang, J.X.; Fan, D.M.; Yu, J.F.; Wang, X.C. Pixel-class prediction for nitrogen content of tea plants based on unmanned aerial vehicle images using machine learning and deep learning. Expert Syst. Appl. 2023, 227, 120351. [Google Scholar] [CrossRef]

- Wang, Y.J.; Li, L.Q.; Liu, Y.; Cui, Q.Q.; Ning, J.M.; Zhang, Z.Z. Enhanced quality monitoring during black tea processing by the fusion of NIRS and computer vision. J. Food Eng. 2021, 304, 110599. [Google Scholar] [CrossRef]

- Wu, Z.D.; Li, C.H.; Liu, H.C.; Lin, T.; Yi, L.Z.; Ren, D.B.; Gu, Y.; Wang, S. Quantification of caffeine and catechins and evaluation of bitterness and astringency of Pu-erh ripen tea based on portable near-infrared spectroscopy. J. Food Compos. Anal. 2024, 125, 105793. [Google Scholar] [CrossRef]

- Tamura, H.; Mori, S.; Yamawaki, T. Textural features corresponding to visual perception. IEEE Trans. Syst. Man Cybern. 1978, 8, 460–473. [Google Scholar] [CrossRef]

- Borah, S.; Hines, E.; Bhuyan, M. Wavelet transform based image texture analysis for size estimation applied to the sorting of tea granules. J. Food Eng. 2007, 79, 629–639. [Google Scholar] [CrossRef]

- Gill, G.S.; Kumar, A.; Agarwal, R. Nondestructive grading of black tea based on physical parameters by texture analysis. Biosyst. Eng. 2013, 116, 198–204. [Google Scholar] [CrossRef]

- Bharati, M.H.; Liu, J.J.; Macgregor, J.F. Image texture analysis: Methods and comparisons. Chemom. Intell. Lab. Syst. 2004, 72, 57–71. [Google Scholar] [CrossRef]

- Haralick, R.M.; Shanmugam, K. Textural features for image classification. IEEE Trans. Syst. Man Cybern. 1973, SMC-3, 610–621. [Google Scholar] [CrossRef]

- Zheng, C.; Sun, D.W.; Zheng, L. Recent applications of image texture for evaluation of food qualities—A review. Trends Food Sci. Technol. 2006, 17, 113–128. [Google Scholar] [CrossRef]

- Gunasekaran, S. Nondestructive Food Evaluation: Techniques to Analyze Properties and Quality; CRC Press: Boca Raton, FL, USA, 2000. [Google Scholar]

- Yu, X.J.; Liu, K.S.; He, Y.; Wu, D. Color and Texture Classification of Green Tea Using Least Squares Support Vector Machine (LSSVM). Key Eng. Mater. 2011, 460–461, 774–779. [Google Scholar] [CrossRef]

- Tang, D.; Qin, B.; Feng, X.; Liu, T. Effective LSTMs for Target-Dependent Sentiment Classification. arXiv 2015. [Google Scholar] [CrossRef]

- Wu, D.; Yang, H.; Chen, X.; He, Y.; Li, X. Application of image texture for the sorting of tea categories using multi-spectral imaging technique and support vector machine. J. Food Eng. 2008, 88, 474–483. [Google Scholar] [CrossRef]

- Chen, L.Y.; Xu, B.; Zhao, C.J.; Duan, D.D.; Cao, Q.; Wang, F. Application of Multispectral Camera in Monitoring the Quality Parameters of Fresh Tea Leaves. Remote Sens. 2021, 13, 3719. [Google Scholar] [CrossRef]

- Tuceryan, M.; Jain, A.K. Texture segmentation using Vornoi polygons. IEEE Trans. Pattern Anal. Mach. Intell. 1990, 12, 211–216. [Google Scholar] [CrossRef]

- Li, X.; Nie, P.; Qiu, Z.J.; Yong, H. Using wavelet transform and multi-class least square support vector machine in multi-spectral imaging classification of Chinese famous tea. Expert Syst. Appl. 2011, 38, 11149–11159. [Google Scholar] [CrossRef]

- Bakhshipour, A.; Zareiforoush, H.; Bagheri, I. Application of decision trees and fuzzy inference system for quality classification and modeling of black and green tea based on visual features. J. Food Meas. Charact. 2020, 14, 1402–1416. [Google Scholar] [CrossRef]

- Bhargava, A.; Bansal, A.; Goyal, V.; Shukla, A. Machine learning & computer vision-based optimum black tea fermentation detection. Multimed. Tools Appl. 2023, 82, 43335–43347. [Google Scholar]

- Ren, G.X.; Wang, Y.J.; Ning, J.M.; Zhang, Z.Z. Using near-infrared hyperspectral imaging with multiple decision tree methods to delineate black tea quality. Spectrochim. Acta Part A-Mol. Biomol. Spectrosc. 2020, 237, 118407. [Google Scholar] [CrossRef]

- Ren, G.X.; Wu, R.; Yin, L.L.; Zhang, Z.Z. Intelligent Evaluation of the Appearance Modality of Black Tea Based on Machine Vision and Hyperspectral Imaging. Anal. Lett. 2024, 57, 176–189. [Google Scholar] [CrossRef]

- Sheng, X.F.; Zan, J.Z.; Jiang, Y.W.; Shen, S.; Li, L.; Yuan, H.B. Data fusion strategy for rapid prediction of moisture content during drying of black tea based on micro-NIR spectroscopy and machine vision. Optik 2023, 276, 170645. [Google Scholar] [CrossRef]

- Wang, Y.J.; Ren, Z.Y.; Chen, Y.Y.; Lu, C.Y.; Deng, W.W.; Zhang, Z.Z.; Ning, J.M. Visualizing chemical indicators: Spatial and temporal quality formation and distribution during black tea fermentation. Food Chem. 2023, 401, 134090. [Google Scholar] [CrossRef]

- Yan, L.; Pang, L.; Wang, H.; Xiao, J. Recognition of different Longjing fresh tea varieties using hyperspectral imaging technology and chemometrics. J. Food Process Eng. 2020, 43, e13378. [Google Scholar] [CrossRef]

- Zhu, Y.W.; Chen, S.Y.; Yin, H.Z.; Han, X.H.; Xu, M.H.; Wang, W.L.; Zhang, Y.; Feng, X.X.; Liu, Y. Classification of oolong tea varieties based on computer vision and convolutional neural networks. J. Sci. Food Agric. 2024, 104, 1630–1637. [Google Scholar] [CrossRef] [PubMed]

- Jian, W.; Xianyin, Z.; Shiping, D. Identification and Grading of Tea Using Computer Vision. Appl. Eng. Agric. 2010, 26, 639–645. [Google Scholar] [CrossRef]

- Yang, F.; Yang, L.; Tian, Y.; Yang, Q. Recognition of the Tea Sprout Based on Color and Shape Features. Trans. Chin. Soc. Agric. Mach. 2009, 40, 19–123. [Google Scholar]

- Chen, J.; He, Q. Tea disease spot recognition based on image feature points extraction and matching. Glob. Nest J. 2020, 22, 492–501. [Google Scholar]

- Chen, Z.W.; He, L.Y.; Ye, Y.; Chen, J.N.; Sun, L.; Wu, C.Y.; Chen, L.; Wang, R.Y. Automatic sorting of fresh tea leaves using vision-based recognition method. J. Food Process Eng. 2020, 43, e13474. [Google Scholar] [CrossRef]

- Guo, S.D.; Yoon, S.C.; Li, L.; Wang, W.; Zhuang, H.; Wei, C.J.; Liu, Y.; Li, Y.W. Recognition and Positioning of Fresh Tea Buds Using YOLOv4-lighted. Agriculture 2023, 13, 518. [Google Scholar] [CrossRef]

- Hu, G.S.; Wei, K.; Zhang, Y.; Bao, W.X.; Liang, D. Estimation of tea leaf blight severity in natural scene images. Precis. Agric. 2021, 22, 1239–1262. [Google Scholar] [CrossRef]

- Li, L.Q.; Chen, Y.R.; Dong, S.; Shen, J.F.; Cao, S.C.; Cui, Q.Q.; Song, Y.; Ning, J.M. Rapid and comprehensive grade evaluation of Keemun black tea using efficient multidimensional data fusion. Food Chem.-X 2023, 20, 100924. [Google Scholar] [CrossRef]

- Ren, G.X.; Wang, Y.J.; Ning, J.M.; Zhang, Z.Z. Evaluation of Dianhongblack tea quality using near-infrared hyperspectral imaging technology. J. Sci. Food Agric. 2021, 101, 2135–2142. [Google Scholar] [CrossRef]

- Song, Y.; Wang, X.Z.; Xie, H.L.; Li, L.Q.; Ning, J.M.; Zhang, Z.Z. Quality evaluation of Keemun black tea by fusing data obtained from near-infrared reflectance spectroscopy and computer vision sensors. Spectrochim. Acta Part A-Mol. Biomol. Spectrosc. 2021, 252, 119522. [Google Scholar] [CrossRef] [PubMed]

- Chen, Y.; Guo, M.; Chen, K.; Jiang, X.; Ding, Z.; Zhang, H.; Lu, M.; Qi, D.; Dong, C. Predictive models for sensory score and physicochemical composition of Yuezhou Longjing tea using near-infrared spectroscopy and data fusion. Talanta 2024, 273, 125892. [Google Scholar] [CrossRef] [PubMed]

- Fodor, M.; Matkovits, A.; Benes, E.L.; Jókai, Z. The role of near-infrared spectroscopy in food quality assurance: A review of the past two decades. Foods 2024, 13, 3501. [Google Scholar] [CrossRef] [PubMed]

- Fu, Y.; Ren, Y.; Sun, D.-W. Novel analysis of food processes by terahertz spectral imaging: A review of recent research findings. Trends Food Sci. Technol. 2024, 147, 104463. [Google Scholar] [CrossRef]

- Owuor, P.O.; Othieno, C.O.; Howard, G.E.; Robinson, J.M.; Cooke, R.D. Flavanol Composition and Caffeine Content of Green Leaf as Quality Potential Indicators of Kenyan Black Teas. J. Sci. Food Agric. 2015, 74, 209–215. [Google Scholar]

- Xiong, C.W.; Liu, C.H.; Pan, W.J.; Ma, F.; Xiong, C.; Qi, L.; Chen, F.; Lu, X.Z.; Yang, J.B.; Zheng, L. Non-destructive determination of total polyphenols content and classification of storage periods of Iron Buddha tea using multispectral imaging system. Food Chem. 2015, 176, 130–136. [Google Scholar] [CrossRef]

- Wang, Y.J.; Li, T.H.; Li, L.Q.; Ning, J.M.; Zhang, Z.Z. Evaluating taste-related attributes of black tea by micro-NIRS. J. Food Eng. 2021, 290, 110181. [Google Scholar] [CrossRef]

- Han, C.; Qu, F.; Wang, X.; Zhai, X.; Li, J.; Yu, K.; Zhao, Y. Terahertz spectroscopy and imaging techniques for herbal medicinal plants detection: A comprehensive review. Crit. Rev. Anal. Chem. 2024, 54, 2485–2499. [Google Scholar] [CrossRef]

- He, Y.; Zhang, Q.; Inostroza, A.C.; Kierszniowska, S.; Liu, L.; Li, Y.; Ruan, J. Application of metabolic fingerprinting in tea quality evaluation. Food Control 2024, 160, 110361. [Google Scholar] [CrossRef]

- Chen, Q.; Zhao, J.; Liu, M.; Cai, J.; Liu, J. Determination of total polyphenols content in green tea using FT-NIR spectroscopy and different PLS algorithms. J. Pharm. Biomed. Anal. 2008, 46, 568–573. [Google Scholar] [CrossRef]

- Li, X.; Sun, C.; Luo, L.; Yong, H. Determination of tea polyphenols content by infrared spectroscopy coupled with iPLS and random frog techniques. Comput. Electron. Agric. 2015, 112, 28–35. [Google Scholar] [CrossRef]

- Panigrahi, N.; Bhol, C.S.; Das, B.S. Rapid assessment of black tea quality using diffuse reflectance spectroscopy. J. Food Eng. 2016, 190, 101–108. [Google Scholar] [CrossRef]

- Wang, J.; Wang, Y.; Cheng, J.; Wang, J.; Sun, X.; Shuang, S.; Zhang, Z. Enhanced cross-category models for predicting the total polyphenols, caffeine and free amino acids contents in Chinese tea using NIR spectroscopy. LWT 2018, 96, 90–97. [Google Scholar] [CrossRef]

- Chunlin, L.; Haowei, G.; Bangzheng, Z.; Puming, H.; Fangyuan, F.; Shuying, G. Rapid and non-destructive discrimination of special-grade flat green tea using Near-infrared spectroscopy. Spectrochim. Acta Part A Mol. Biomol. Spectrosc. 2019, 206, 254–262. [Google Scholar]

- Bian, M.; Skidmore, A.K.; Schlerf, M.; Liu, Y.; Wang, T. Estimating Biochemical Parameters of Tea (Camellia sinensis (L.)) Using Hyperspectral Techniques. ISPRS-Int. Arch. Photogramm. Remote Sens. Spat. Inf. Sci. 2012, 39, 237–241. [Google Scholar] [CrossRef]

- Dutta, D.; Das, P.K.; Bhunia, U.K.; Singh, U.; Singh, S.; Sharma, J.R.; Dadhwal, V.K. Retrieval of tea polyphenol at leaf level using spectral transformation and multi-variate statistical approach. Int. J. Appl. Earth Obs. Geoinf. 2015, 36, 22–29. [Google Scholar] [CrossRef]

- Bai, X.L.; Zhang, L.; Kang, C.Y.; Quan, B.Y.; Zheng, Y.; Zhang, X.L.; Song, J.; Xia, T.; Wang, M. Near-infrared spectroscopy and machine learning-based technique to predict quality-related parameters in instant tea. Sci. Rep. 2022, 12, 3833. [Google Scholar] [CrossRef]

- Bilge, G.; Özdemir, K.S. Synchronous fluorescence spectroscopy combined with chemometrics for determination of total phenolic content and antioxidant activity in different tea types. J. Sci. Food Agric. 2020, 100, 3741–3747. [Google Scholar] [CrossRef]

- Hidayat, M.A.; Maharani, D.A.; Purwanto, D.A.; Kuswandi, B.; Yuwono, M. Simple and Sensitive Paper-based Colorimetric Biosensor for Determining Total Polyphenol Content of the Green Tea Beverages. Biotechnol. Bioprocess Eng. 2020, 25, 255–263. [Google Scholar] [CrossRef]

- Liu, M.; Wang, R.X.; Shi, D.L.; Cao, R.Y. Non-destructive prediction of tea polyphenols during Pu-erh tea fermentation using NIR coupled with chemometrics methods. J. Food Compos. Anal. 2024, 131, 106247. [Google Scholar] [CrossRef]

- Jiang, H.; Xu, W.D.; Chen, Q.S. Determination of tea polyphenols in green tea by homemade color sensitive sensor combined with multivariate analysis. Food Chem. 2020, 319, 126584. [Google Scholar] [CrossRef] [PubMed]

- Ranatunga, M.; Uwadaira, Y.; Ikehata, A.; Ito, H. NIR Spectroscopic Determination of Polyphenol Content in Teas and Tea Extract at 2142 nm. Sens. Mater. 2021, 33, 4135–4145. [Google Scholar] [CrossRef]

- Wang, K.Q.; Li, Z.L.; Li, J.J.; Lin, H. Raman spectroscopic techniques for nondestructive analysis of agri-foods: A state-of-the-art review. Trends Food Sci. Technol. 2021, 118, 490–504. [Google Scholar] [CrossRef]

- Wang, Y.; Liu, Y.; Cui, Q.; Li, L.; Ning, J.; Zhang, Z. Monitoring the withering condition of leaves during black tea processing via the fusion of electronic eye (E-eye), colorimetric sensing array (CSA), and micro-near-infrared spectroscopy (NIRS). J. Food Eng. 2021, 300, 110534. [Google Scholar] [CrossRef]

- Hu, Y.; Chen, W.; Gouda, M.; Yao, H.; Zuo, X.; Yu, H.; Zhang, Y.; Ding, L.; Zhu, F.; Wang, Y. Fungal fermentation of Fuzhuan brick tea: A comprehensive evaluation of sensory properties using chemometrics, visible near-infrared spectroscopy, and electronic nose. Food Res. Int. 2024, 186, 114401. [Google Scholar] [CrossRef]

- Li, D.; Park, B.; Kang, R.; Chen, Q.; Ouyang, Q. Quantitative prediction and visualization of matcha color physicochemical indicators using hyperspectral microscope imaging technology. Food Control 2024, 163, 110531. [Google Scholar] [CrossRef]

- Guo, Z. Nondestructive estimation of total free amino acid in green tea by near infrared spectroscopy and artificial neural networks. Spectronic Instrum. Anal. 2011, 369, 43–53. [Google Scholar]

- Yang, C.; Zhao, Y.; An, T.; Liu, Z.; Jiang, Y.; Li, Y.; Dong, C. Quantitative prediction and visualization of key physical and chemical components in black tea fermentation using hyperspectral imaging. LWT-Food Sci. Technol. 2021, 141, 110975. [Google Scholar] [CrossRef]

- Guo, Z.M.; Barimah, A.O.; Yin, L.M.; Chen, Q.S.; Shi, J.Y.; El-Seedi, H.R.; Zou, X.B. Intelligent evaluation of taste constituents and polyphenols-to-amino acids ratio in matcha tea powder using near infrared spectroscopy. Food Chem. 2021, 353, 129372. [Google Scholar] [CrossRef]

- Hu, Y.; Huang, P.; Wang, Y.C.; Sun, J.; Wu, Y.L.; Kang, Z.L. Determination of Tibetan tea quality by hyperspectral imaging technology and multivariate analysis. J. Food Compos. Anal. 2023, 117, 105136. [Google Scholar] [CrossRef]

- Luo, D.N.; Gao, Y.; Wang, Y.; Shi, Y.J.; Chen, S.Z.; Ding, Z.T.; Fan, K. Using UAV image data to monitor the effects of different nitrogen application rates on tea quality. J. Sci. Food Agric. 2022, 102, 1540–1549. [Google Scholar] [CrossRef] [PubMed]

- Mao, Y.L.; Li, H.; Wang, Y.; Fan, K.; Song, Y.J.; Han, X.; Zhang, J.; Ding, S.B.; Song, D.P.; Wang, H.; et al. Prediction of Tea Polyphenols, Free Amino Acids and Caffeine Content in Tea Leaves during Wilting and Fermentation Using Hyperspectral Imaging. Foods 2022, 11, 2537. [Google Scholar] [CrossRef]

- Wang, Y.J.; Ren, Z.Y.; Li, M.Y.; Lu, C.Y.; Deng, W.W.; Zhang, Z.Z.; Ning, J.M. From lab to factory: A calibration transfer strategy from HSI to online NIR optimized for quality control of green tea fixation. J. Food Eng. 2023, 339, 111284. [Google Scholar] [CrossRef]

- Wang, Y.J.; Cui, Q.Q.; Jin, S.S.; Zhuo, C.; Luo, Y.H.; Yu, Y.L.; Ning, J.M.; Zhang, Z.Z. Tea Analyzer: A low-cost and portable tool for quality quantification of postharvest fresh tea leaves. LWT-Food Sci. Technol. 2022, 159, 113248. [Google Scholar] [CrossRef]

- Long, P.; Li, Y.; Han, Z.; Zhu, M.; Zhai, X.; Jiang, Z.; Wen, M.; Ho, C.-T.; Zhang, L. Discovery of color compounds: Integrated multispectral omics on exploring critical colorant compounds of black tea infusion. Food Chem. 2024, 432, 137185. [Google Scholar] [CrossRef]

- Pan, Y.; Zhang, H.; Chen, Y.; Gong, X.; Yan, J.; Zhang, H. Applications of hyperspectral imaging technology combined with machine learning in quality control of traditional Chinese medicine from the perspective of artificial intelligence: A review. Crit. Rev. Anal. Chem. 2024, 54, 2850–2864. [Google Scholar] [CrossRef]

- Chen, Q.; Zhao, J.; Huang, X.; Zhang, H.; Liu, M. Simultaneous determination of total polyphenols and caffeine contents of green tea by near-infrared reflectance spectroscopy. Microchem. J. 2006, 83, 42–47. [Google Scholar] [CrossRef]

- Ren, G.; Wang, S.; Ning, J.; Xu, R.; Wang, Y.; Xing, Z.; Wan, X.; Zhang, Z. Quantitative analysis and geographical traceability of black tea using Fourier transform near-infrared spectroscopy (FT-NIRS). Food Res. Int. 2013, 53, 822–826. [Google Scholar] [CrossRef]

- Sanaeifar, A.; Huang, X.Y.; Chen, M.Y.; Zhao, Z.F.; Ji, Y.F.; Li, X.L.; He, Y.; Zhu, Y.; Chen, X.; Yu, X.X. Nondestructive monitoring of polyphenols and caffeine during green tea processing using Vis-NIR spectroscopy. Food Sci. Nutr. 2020, 8, 5860–5874. [Google Scholar] [CrossRef]

- Yang, T.; Zhu, Y.; Shao, C.; Zhang, Y.; Shi, J.; Lv, H.-p.; Lin, Z. Enantiomeric analysis of linalool in teas using headspace solid-phase microextraction with chiral gas chromatography. Ind. Crops Prod. 2016, 83, 17–23. [Google Scholar] [CrossRef]

- Chen, Y.-G.; Song, Y.-L.; Wang, Y.; Yuan, Y.-F.; Huang, X.-J.; Ye, W.-C.; Wang, Y.-T.; Zhang, Q.-W. Metabolic differentiations of Pueraria lobata and Pueraria thomsonii using 1H NMR spectroscopy and multivariate statistical analysis. J. Pharm. Biomed. Anal. 2014, 93, 51–58. [Google Scholar] [CrossRef] [PubMed]

- Le Gall, G.; Colquhoun, I.J.; Defernez, M. Metabolite profiling using 1H NMR spectroscopy for quality assessment of green tea, Camellia sinensis (L.). J. Agric. Food Chem. 2004, 52, 692–700. [Google Scholar] [CrossRef] [PubMed]

- Yuan, Y.; Song, Y.; Jing, W.; Wang, Y.; Yang, X.; Liu, D. Simultaneous determination of caffeine, gallic acid, theanine,(−)-epigallocatechin and (−)-epigallocatechin-3-gallate in green tea using quantitative 1 H-NMR spectroscopy. Anal. Methods 2014, 6, 907–914. [Google Scholar] [CrossRef]

- An, T.; Yang, C.; Zhang, J.; Wang, Z.; Fan, Y.; Fan, S.; Huang, W.; Qi, D.; Tian, X.; Yuan, C.; et al. Evaluation of the Black Tea Taste Quality during Fermentation Process Using Image and Spectral Fusion Features. Fermentation 2023, 9, 896. [Google Scholar] [CrossRef]

- Carvalho, D.G.; Ranzan, L.; Jacques, R.A.; Trierweiler, L.F.; Trierweiler, J.O. Analysis of total phenolic compounds and caffeine in teas using variable selection approach with two-dimensional fluorescence and infrared spectroscopy. Microchem. J. 2021, 169, 106570. [Google Scholar] [CrossRef]

- Huang, Y.F.; Dong, W.T.; Sanaeifar, A.; Wang, X.M.; Luo, W.; Zhan, B.S.; Liu, X.M.; Li, R.L.; Zhang, H.L.; Li, X.L. Development of simple identification models for four main catechins and caffeine in fresh green tea leaf based on visible and near-infrared spectroscopy. Comput. Electron. Agric. 2020, 173, 105388. [Google Scholar] [CrossRef]

- Jia, J.M.; Zhou, X.F.; Li, Y.; Wang, M.; Liu, Z.Y.; Dong, C.W. Establishment of a rapid detection model for the sensory quality and components of Yuezhou Longjing tea using near-infrared spectroscopy. LWT-Food Sci. Technol. 2022, 164, 113625. [Google Scholar] [CrossRef]

- Ouyang, Q.; Liu, L.H.; Wang, L.; Zareef, M.; Wang, Z.; Li, H.Q.; Yin, J.; Chen, Q.S. Rapid determination of free amino acids and caffeine in matcha using near-infrared spectroscopy: A comparison of portable and benchtop systems. J. Food Compos. Anal. 2023, 115, 104868. [Google Scholar] [CrossRef]

- Wang, Y.J.; Li, L.Q.; Shen, S.S.; Liu, Y.; Ning, J.M.; Zhang, Z.Z. Rapid detection of quality index of postharvest fresh tea leaves using hyperspectral imaging. J. Sci. Food Agric. 2020, 100, 3803–3811. [Google Scholar] [CrossRef]

- Wu, Y.X.; Chen, J.N.; Wu, S.K.; Li, H.; He, L.Y.; Zhao, R.M.; Wu, C.Y. An improved YOLOv7 network using RGB-D multi-modal feature fusion for tea shoots detection. Comput. Electron. Agric. 2024, 216, 108541. [Google Scholar] [CrossRef]

- Zhang, S.S.; Zuo, Y.M.; Wu, Q.; Wang, J.; Ban, L.; Yang, H.L.; Bai, Z.W. Development and Validation of Near-Infrared Methods for the Quantitation of Caffeine, Epigallocatechin-3-gallate, and Moisture in Green Tea Production. J. Anal. Methods Chem. 2021, 2021, 9563162. [Google Scholar] [CrossRef] [PubMed]

- Rodrigues, S.S.; Dias, L.G.; Teixeira, A. Emerging methods for the evaluation of sensory quality of food: Technology at service. Curr. Food Sci. Technol. Rep. 2024, 2, 77–90. [Google Scholar] [CrossRef]

- Li, X.; Xie, C.; He, Y.; Qiu, Z.; Zhang, Y. Characterizing the moisture content of tea with diffuse reflectance spectroscopy using wavelet transform and multivariate analysis. Sensors 2012, 12, 9847–9861. [Google Scholar] [CrossRef] [PubMed]

- Liang, G.; Dong, C.; Hu, B.; Zhu, H.; Yuan, H.; Jiang, Y.; Hao, G. Prediction of Moisture Content for Congou Black Tea Withering Leaves Using Image Features and Nonlinear Method. Sci. Rep. 2018, 8, 7854. [Google Scholar] [CrossRef]

- Dong, C.W.; An, T.; Yang, M.; Yang, C.S.; Liu, Z.Y.; Li, Y.; Duan, D.D.; Fan, S.X. Quantitative prediction and visual detection of the moisture content of withering leaves in black tea (Camellia sinensis) with hyperspectral image. Infrared Phys. Technol. 2022, 123, 104118. [Google Scholar] [CrossRef]

- An, T.; Yu, H.; Yang, C.; Liang, G.; Dong, C. Black tea withering moisture detection method based on convolution neural network confidence. J. Food Process Eng. 2020, 43, e13428. [Google Scholar] [CrossRef]

- Chen, C.L.; Lu, J.Z.; Zhou, M.C.; Yi, J.; Liao, M.; Gao, Z.M. A YOLOv3-based computer vision system for identification of tea buds and the picking point. Comput. Electron. Agric. 2022, 198, 107116. [Google Scholar] [CrossRef]

- Huang, Z.X.; Sanaeifar, A.; Tian, Y.; Liu, L.; Zhang, D.Y.; Wang, H.; Ye, D.P.; Li, X.L. Improved generalization of spectral models associated with Vis-NIR spectroscopy for determining the moisture content of different tea leaves. J. Food Eng. 2021, 293, 110374. [Google Scholar] [CrossRef]

- Li, X.; Li, Z.; Yang, X.; He, Y. Boosting the generalization ability of Vis-NIR-spectroscopy-based regression models through dimension reduction and transfer learning. Comput. Electron. Agric. 2021, 186, 106157. [Google Scholar] [CrossRef]

- Liu, Z.Y.; Zhang, R.T.; Yang, C.S.; Hu, B.; Luo, X.; Li, Y.; Dong, C.W. Research on moisture content detection method during green tea processing based on machine vision and near-infrared spectroscopy technology. Spectrochim. Acta Part A-Mol. Biomol. Spectrosc. 2022, 271, 120921. [Google Scholar] [CrossRef]

- Rossi, G.B.; Lozano, V.A. Simultaneous determination of quality parameters in yerba mate (Ilex paraguariensis) samples by application of near-infrared (NIR) spectroscopy and partial least squares (PLS). LWT-Food Sci. Technol. 2020, 126, 109290. [Google Scholar] [CrossRef]

- Shen, S.; Hua, J.J.; Zhu, H.K.; Yang, Y.Q.; Deng, Y.L.; Li, J.; Yuan, H.B.; Wang, J.J.; Zhu, J.Y.; Jiang, Y.W. Rapid and real-time detection of moisture in black tea during withering using micro-near-infrared spectroscopy. LWT-Food Sci. Technol. 2022, 155, 112970. [Google Scholar] [CrossRef]

- Wang, Y.J.; Li, T.H.; Li, L.Q.; Ning, J.M.; Zhang, Z.Z. Micro-NIR spectrometer for quality assessment of tea: Comparison of local and global models. Spectrochim. Acta Part A-Mol. Biomol. Spectrosc. 2020, 237, 118403. [Google Scholar] [CrossRef] [PubMed]

- Wei, Y.Z.; Li, X.L.; He, Y. Generalisation of tea moisture content models based on VNIR spectra subjected to fractional differential treatment. Biosyst. Eng. 2021, 205, 174–186. [Google Scholar] [CrossRef]

- Wei, Y.Z.; He, Y.; Li, X.L. Tea moisture content detection with multispectral and depth images. Comput. Electron. Agric. 2021, 183, 106082. [Google Scholar] [CrossRef]

- Zhang, M.; Guo, J.; Ma, C.; Qiu, G.; Lü, E. An Effective Prediction Approach for Moisture Content of Tea Leaves Based on Discrete Wavelet Transforms and Bootstrap Soft Shrinkage Algorithm. Appl. Sci. 2020, 10, 4839. [Google Scholar] [CrossRef]

- Rong, Y.; Riaz, T.; Lin, H.; Wang, Z.; Chen, Q.; Ouyang, Q. Application of visible near-infrared spectroscopy combined with colorimetric sensor array for the aroma quality evaluation in tencha drying process. Spectrochim. Acta Part A Mol. Biomol. Spectrosc. 2024, 304, 123385. [Google Scholar] [CrossRef]

- Singh, R.; Nisha, R.; Naik, R.; Upendar, K.; Nickhil, C.; Deka, S.C. Sensor fusion techniques in deep learning for multimodal fruit and vegetable quality assessment: A comprehensive review. J. Food Meas. Charact. 2024, 18, 8088–8109. [Google Scholar] [CrossRef]

- GB/T 23776-2018; Methodology for Sensory Evaluation of Tea. Standardization Administration of China (SAC): Beijing, China, 2018.