Research Progress on Intelligent Variable-Rate Spray Technology for Precision Agriculture

Abstract

1. Introduction

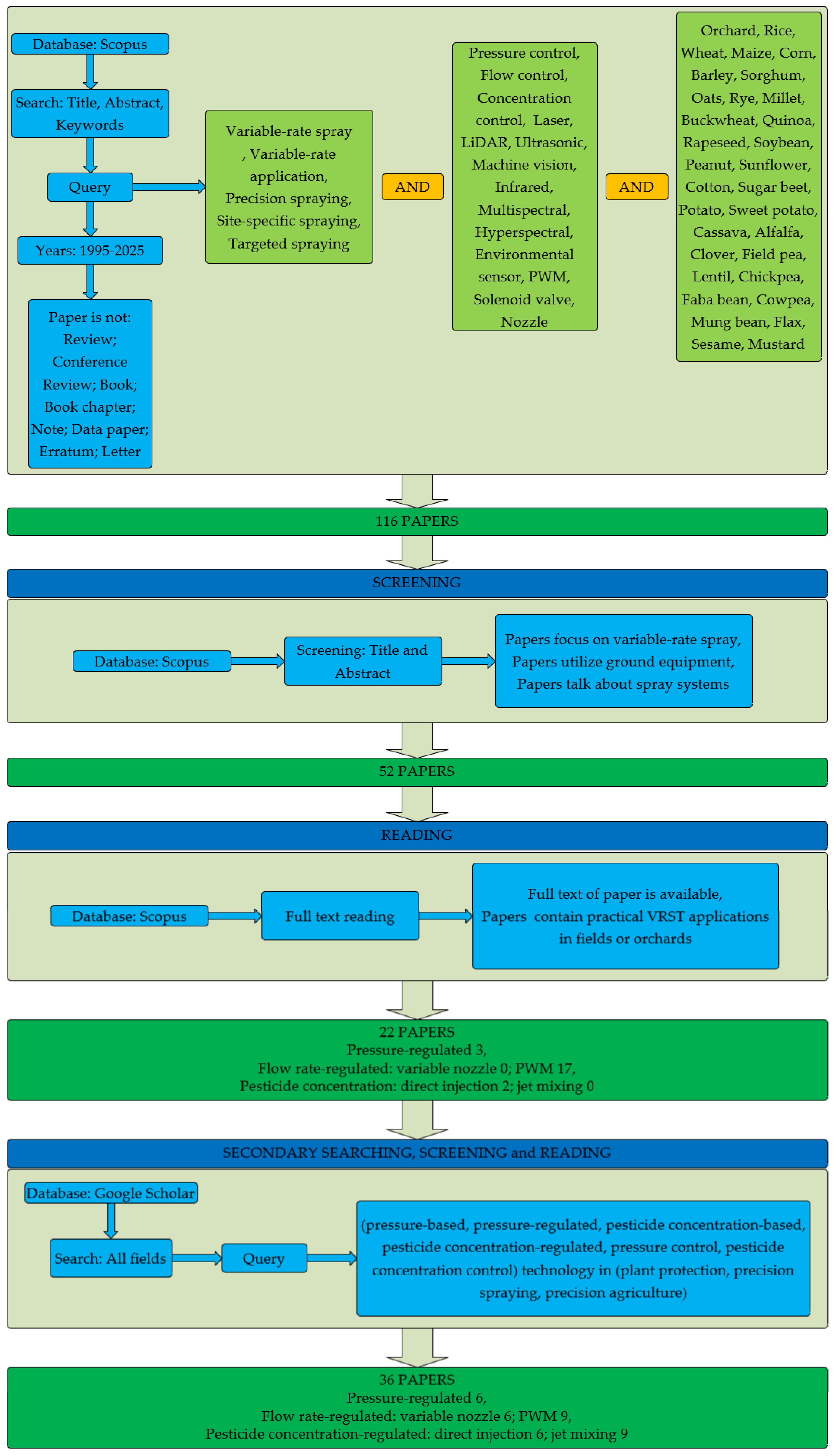

2. Materials and Methods

2.1. Identification and Search Strategy

2.2. Screening

2.3. Reading

2.4. Selecting and Summarizing

3. Pressure-Regulated Variable-Rate Spray Technology

| Reference | Year | System Components and Working Principle | Control and Spray Performance |

|---|---|---|---|

| [21] | 2003 | It consists of a liquid tank, pump, GPS positioning device, SCS750 controller, flow meter, speed sensor, butterfly valve, and flow regulator valve. It receives real-time location information through GPS to match the preset application map, and the controller adjusts the butterfly valve opening based on the feedback from the flow meter and the speed sensor to change the nozzle pressure to realize flow control. | The average application error is ±2.25%, and the pressure adjustment response time is about 1.5 s. Combined with the GPS signal delay (0.5 s) and the preset 3 s “look-ahead time” algorithm, the total delay is about 2.35 s, which can trigger changes in the application of chemicals 0.65 s in advance, basically meeting the demand for accurate application of chemicals. However, the preset fixed look-ahead time algorithm cannot fully compensate for delay changes under dynamic field conditions and cannot eliminate delay differences between nozzles due to differences in piping lengths. |

| [22] | 2004 | It consists of a liquid tank, pump, proportional relief valve, and several parallel spraying units; each spraying unit contains a proportional pressure-reducing valve, solenoid valve, pressure-type variable-rate spray nozzle, pressure sensor, and flow sensor. The proportional relief valve stabilizes the pressure of the main line, the proportional pressure-reducing valve regulates the pressure of each unit independently, the hydraulic spray nozzle changes the flow rate according to the input pressure. | MATLAB 6.5 simulation shows that its step response time is 0.2 s, frequency width is 4.5 Hz, input current and output flow rate are linear, and it can dynamically adjust the application volume according to the target characteristics and the speed of the unit and, at the same time, keep the droplet size and distribution quality stable so as to realize the precise application of medicine. The disadvantage is that the inherent frequency of the proportional pressure-reducing valve limits the ability of the high-frequency dynamic response, and the actual flow rate adjustment range is constrained by the nozzle pressure–flow characteristics. |

| [23] | 2005 | It consists of a liquid tank, centrifugal pump, RavenSCS440 controller, on-board radar, GPS positioning unit, flow meter, and ball valve. Fifteen sets of three-position nozzle bodies are mounted on the spray bar, utilizing TurboTeeJet 11002, 11003, and 11004 series nozzles. The system regulates the main medicament pipeline flow through a flow meter and quick-closing ball valve. | The system was able to achieve weed management in 7.6 m × 7.6 m grid cells by adjusting pressure and speed to vary the application rate per unit area (140–336 L/ha), with herbicide rates of 21–98% of conventional rates. However, the following limitations existed: delayed nozzle switching resulted in uneven application in the 1.5–2.8 m transition zone, fast closing valves were prone to instantaneous application spikes of 450 L/ha, and the controller deadband setting (3% deviation tolerance) left small application rate changes unresponsive. |

| [24] | 2012 | It consists of two switching solenoid valves, a proportional solenoid valve, liquid tank, double membrane pump, pressure sensor, and ATmega64 embedded controller. The system dynamically regulates the pressure through a nonlinear PI controller. | The average tracking error is less than 0.3 bar over the 2–14 bar operating range, and the controller has better resistance to pump pressure pulsation noise than a fixed-parameter PI controller (4.4 Hz low-pass filtering is required). However, the polynomial fitting of the controller parameters is only applicable to the 4–14 bar range, and the low-pressure region needs to be initialized manually; the pressure sensor noise affects control accuracy. |

| [25] | 2020 | It consists of a liquid storage container, motor pump set, overflow regulator, liquid pipeline, flow meter, and pressure gauge. Flow control is realized by adjusting the system pressure. | The flow rate adjustment range was narrow (about 2:1), and when the pressure was increased to increase the flow rate, the spray angle increased at a rate of 1.08°/%, resulting in the expansion of droplet spatial coverage; the droplet sizes (DV0.1, DV0.5, and DV0.9) decreased dramatically with increasing pressure at a rate of −1.023, −1.562, and −3.609 μm/%, respectively, resulting in a sharp decrease in droplet spectra toward small particle sizes and an increased risk of drift. |

| [26] | 2021 | It consists of a reservoir, a diaphragm pump, a 12-foot spray bar with six solenoid valve nozzle SVNs spaced 22 inches apart, and an Atmega2650-based controller. The system achieves pressure control by PWM (Pulse-Width Modulation) regulation of the diaphragm pump voltage using two control strategies, PID (Proportional Integral Derivative) and cascade feedback, and combining feedforward compensation with a polynomial model of the number of SVNs (Solenoid Valve Nozzles) activated and pressure perturbation. | The cascade control has an overshoot rate of 7.93% (19.61% for PID) at a target pressure of 16 psi, with a pressure regulation time of about 2 s, ensuring a constant flow rate (1.27–4.08 L/min) with a stable spray angle (43–120°) from a single nozzle and a reduction in pesticide use of 75%. However, the diaphragm pump’s maximum pressure of 26 psi limits the system’s flow scalability, and there is still brief pressure fluctuation when the nozzle is quickly switched (about 0.5 s to recover). |

4. Flow Rate-Regulated Variable-Rate Spray Technology

4.1. Variable Nozzle

| Reference | Year | Variable Nozzle Components and Working Principle | Control and Spray Performance |

|---|---|---|---|

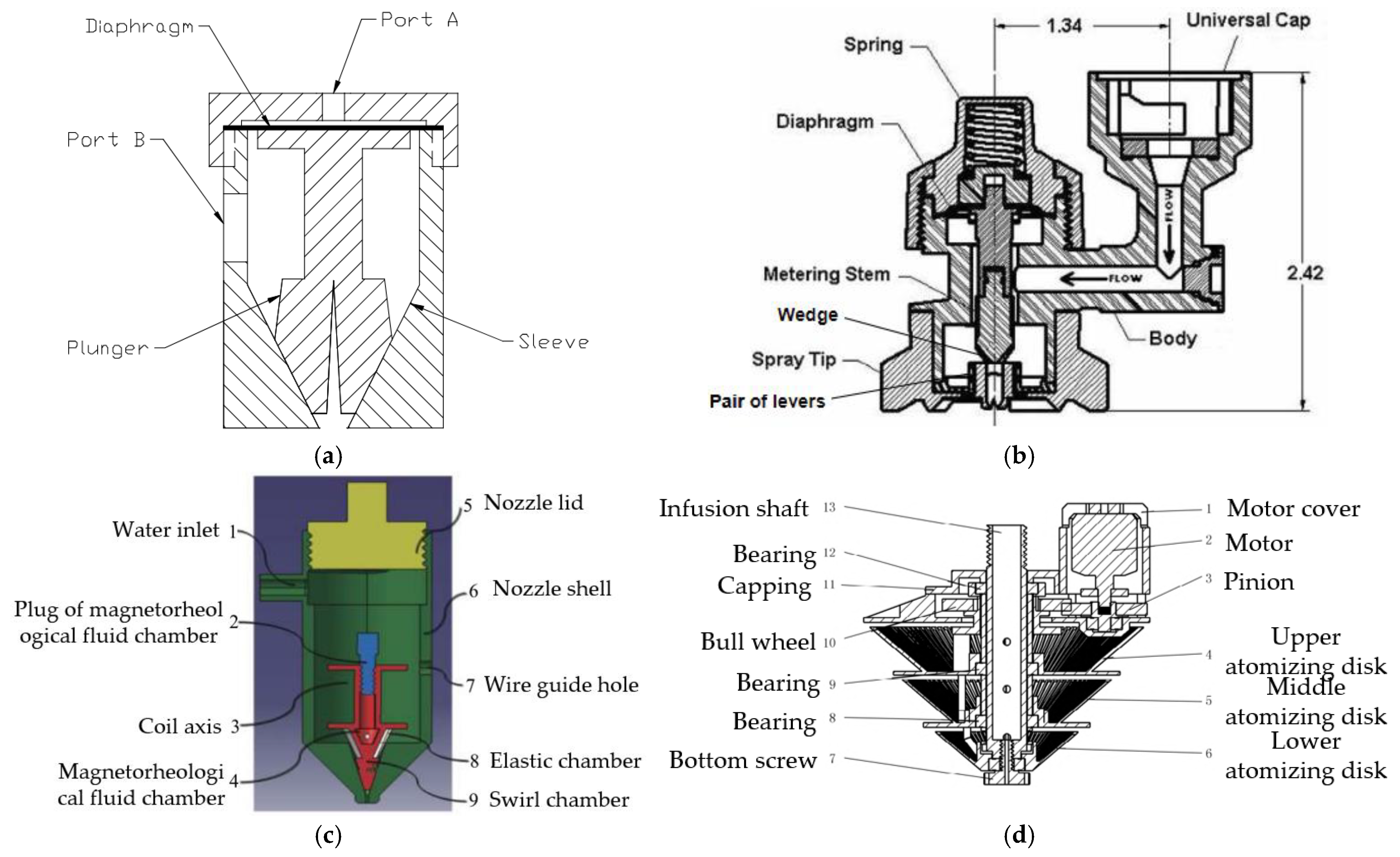

| [27,28] | 2001, 2002 | It consists of a conical nozzle body sleeve, split-end metering plunger, diaphragm actuator, and pressure control port. Its core is the longitudinal displacement adjustment of the split-end plunger within the conical sleeve, which dynamically adjusts the flow rate by changing the nozzle opening through the balance between the control pressure and the supply pressure. | The nozzle flow rate adjustment range is 0.227–3.028 L/min, and the adjustment ratio reaches 13.3:1, which can obtain a DV0.5 of 141–522 μm while maintaining spray distribution uniformity. However, the spray angle decreases significantly at low flow rates (the angle of a 90° nozzle decreases to 65° at a flow rate of 0.227 L/min), which affects the coverage width. Also, the plunger position is sensitive to pressure balance, and the spring constants and diaphragm design may cause adjustment complexity. |

| [29] | 2005 | It consists of a variable area pre-hole, a variable area spray hole, a flexible nozzle, a metering assembly (with wedge-shaped groove structure), a diaphragm, a spring, and a nozzle body. The system makes use of the dynamic balance between liquid pressure and spring force to adjust the position of the metering component and synchronously change the area of the pre-hole and spray hole. | The pre-orifice controls flow (0.15–0.80 GPM at 15–50/65 PSI pressure) and the spray orifices maintain a constant spray angle (110°) and optimized droplet size (325–425 μm for systemic pesticides VMD, 200–240 μm for contact pesticides) by lever-adjusting the V-cut angle, with a response time of <0.25 s and a coefficient of variation for uniformity of spray distribution of 8 to 13%. However, the mechanical adjustment structure is at risk of wear and tear under high-frequency use, and the ease of operation is limited by the need to change nozzles for different pesticide types. |

| [30] | 2007 | It consists of a spray tip with a variable orifice, a metering device (with adjusting lever and wedge groove), a diaphragm, a spring, and a nozzle body, which dynamically adjusts the area of the spray orifice to realize flow control through pressure changes. | The system achieves flow regulation ratios of 12:1 and 10:1 for the black and clear nozzles, respectively, over a pressure range of 10–110 psi. Field tests showed that the nozzle droplet size fluctuations were small (VMD 498–621 μm for the black nozzle and 465–599 μm for the clear nozzle) under the conditions of a 4–12 mph variable speed and a 4–12 GPA variable application rate. However, at pressures above 40 psi, the droplet size is out of the standard range, and the system relies on precise pressure control. |

| [31] | 2019 | It consists of a water inlet, magnetorheological fluid cavity, coil winding axis, elastic membrane, cyclone cavity, and outer shell, etc. Its core function is to control the viscosity and distribution pattern of magnetorheological fluid through the magnetic field generated by the coil and then adjust the inlet cross-sectional area of the nozzle to realize flow control. | By adjusting the magnetic field strength with 0–28 V, the system can achieve a 25% change in flow rate at a magnetorheological fluid injection volume of 1.5 mL with a fast and reversible response. Under the constant pressure of 0.3 MPa, the flow rate decreases by 28.57% when the magnetorheological fluid injection volume is increased from 0 to 2.5 mL, while it decreases by only 14.29% under 24 V, which shows that the magnetic field can effectively inhibit flow rate attenuation. However, the system has limitations, such as a limited flow rate adjustment range (maximum 25%), magnetic field saturation effect (the flow rate stabilizes after the voltage exceeds 24 V), and the large volume and weight of the nozzle (50 mm diameter of the casing), and the magnetorheological fluid may produce residuals that affect stability in long-term use. |

| [32] | 2023 | Composed of three layers of independent atomization disks, each layer is equipped with a liquid supply pipe, solenoid valve, and peristaltic pump, using STM32F103-embedded controller output adjustable PWM wave control peristaltic pump flow combined with the combination of an on/off solenoid valve to achieve 4 levels of flow regulation (1 level of only upper level open, 2 levels of the upper layer + middle, 3 levels of the upper layer + the bottom, 4 levels of full open). | By adjusting the motor voltage to control the rotational speed of the atomizing disk (5540–8395 r/min), the spray width was stabilized at 1.98 m, the amount of droplet deposition increased from 1183.2 mL to 2696.5 mL with the flow rate level, and the droplet particle size continued to decrease with the increase in rotational speed (187.6–113.2 μm), and the distribution of the deposition was in accordance with the normal distribution. However, the study only verified the performance of the clear water medium and did not address the effect of actual agent viscosity; the three-layer independent structure increased mechanical complexity, and there may be sealing problems in long-term use. |

4.2. Pulse-Width Modulation

5. Pesticide Concentration-Regulated Variable-Rate Spray Technology

5.1. Direct Injection

| Reference | Year | System Components and Working Principle | Control and Spray Performance |

|---|---|---|---|

| [53] | 2007 | It consists of two parts: the injection system contains pesticide delivery devices (gear pumps, diaphragm pumps, and pneumatic tanks) and injection equipment (proportional valves and PWM control valves), which control the amount of pesticide injected in real time; the transportation and mixing system uses optimized mixing chambers (including KMS, SMX, and Quadro static mixers) to achieve rapid and uniform mixing. | The system reduces the injection time to less than 80 ms with a novel control strategy (initial high-flow pulse injection to shorten the response time), combined with a CFD-optimized compact mixing chamber (diameter ratio L/D = 16) that reduces the transport mixing time to 52 ms, for a total response time of about 150 ms, to meet real-time application requirements (<0.33 s). The system achieves mixing homogeneity with a 5% concentration coefficient of variation (CoV), significantly reducing pesticide usage and environmental risks. However, the following limitations exist: mixing efficiency is significantly affected by the carrier flow rate and flow regime (laminar/turbulent), and long mixing paths are still required at low flow rates; and there is limited adaptability to highly viscous pesticides. |

| [54] | 2007 | It consists of a carrier pump, a chemical metering pump, a proportional adjustment valve, a mixer, a nozzle, and a sensor (conductivity sensor/transmittance sensor), which mix the herbicide with the carrier water at the end of the line using direct injection technology. The system realizes variable control by two injection methods: spray rod section injection injects the agent into the spray rod main pipe, and nozzle direct injection sets a metering orifice plate in front of the nozzle for local distribution. The system realizes closed-loop flow control by means of a proportional valve with Kv-value characteristics and a differential pressure flow meter. | The response time of the spray bar injection system is 2.75–8.84 s, while the lag time for direct nozzle injection can be optimized to less than 0.3 s. A flow range of 0.002–0.4 L/min can be covered but with flow calibration errors of up to 18% for high-viscosity agents (219 mPa·s). It can save 59% of herbicide dosage, but there is a mixing uniformity problem, and the coefficient of variation of concentration between nozzles is as high as 16.3–39%, which is mainly affected by the residual liquid in the pipeline (2.5 L residual liquid in the 12.7 mm pipe diameter and 300 mm pipe length), the viscosity of the agent affecting the flow rate stability (differential pressure fluctuation of ±0.2 bar due to 60 mPa·s solution), and the response delay leading to the offset of the application position (30 s delay corresponds to 66 m deviation), among other limitations. |

| [55] | 2008 | It consists of a mixing chamber, static mixer (e.g., KMS type), light transmission sensor, and pesticide direct injection device. Its core innovation is to adopt the principle of the iodine–sodium thiosulphate decolorization reaction combined with light transmission sensor to monitor the mixing uniformity at the nozzle outlet in real time. | Control performance is dependent on the geometric configuration of the static mixer (e.g., 12 L/D mixer length) and optimization of the injection position (90° is optimal), which achieves a mixing time of 40.2 ms at a flow rate of 20 mL/s and a mixing homogeneity of 99.67% (with a standard deviation of 0.25%), which meets the criterion of a coefficient of variation of 5%, significantly improves pesticide uniformity of distribution, and reduces environmental residues. However, its limitations are reflected in the highly sensitive mixer configuration: low-concentration (<0.3%) or high-viscosity (600 mPa·s) pesticides need the mixer to be extended to 16 L/D to maintain the effect; injection position shift will lead to a 1/3 reduction in mixing efficiency. |

| [56] | 2011 | It consists of a hydraulic spray bar (series or parallel layout), diaphragm pump (conveying carrier liquid), and peristaltic pump (chemical agent injection) driven by a DC power supply, PID feedback controller, pressure sensor, and fluorescence concentration sensor, etc. It realizes precise control of concentrations by real-time adjustment of the ratio of the carrier flow rate to the amount of chemical agent injected. | The system uses a tandem spray bar (6 mm diameter) with 97% application uniformity and a concentration response delay of 1.5 s, while the parallel spray bar (4 mm diameter) reduces the delay to 2 s by supplying fluids through separate nozzles but with a 7–10% increase in pressure loss. The constant current-carrying strategy has a delay of 2.5 s for sudden changes in velocity (0.6→1.2 m/s), whereas the variable total flow strategy reduces the delay to 2.3 s by pressure regulation (1–3 bar). Limitations are that the operating speed variations need to be limited to 0.5 m/s2 for stability, and the parallel layout reduces delay but increases system complexity and cost. |

| [57] | 2014 | It consists of a chemical storage tank, peristaltic metering pump (equipped with motor drive, speed sensor), tractor driving speed sensor, GPS positioning module, electronic control unit (ECU), venturi mixing device, and other core components. The system operates through ECU-integrated processing, GPS geographic information, real-time driving speeds, spray pressure data, and dynamic adjustment of the metering pump speed to achieve precise application control. | The working pressure has a significant effect on the response time, with average response times of 25.8 s, 22.8 s, and 17.9 s at 3, 4, and 5 bar, respectively. The system is capable of proportioning the pesticide concentration on demand and compensating for the response time by means of an “advance trigger” algorithm. Its limitations include the following: the system does not integrate an automatic pressure adjustment module, so the spray pressure needs to be preset manually; the long response time (especially in low-pressure conditions) limits the accuracy of the dynamic adjustment; the physical distance between the mixing unit and the spray bar directly affects the response characteristics of the system, which may result in differences in the concentration of multiple nozzles. |

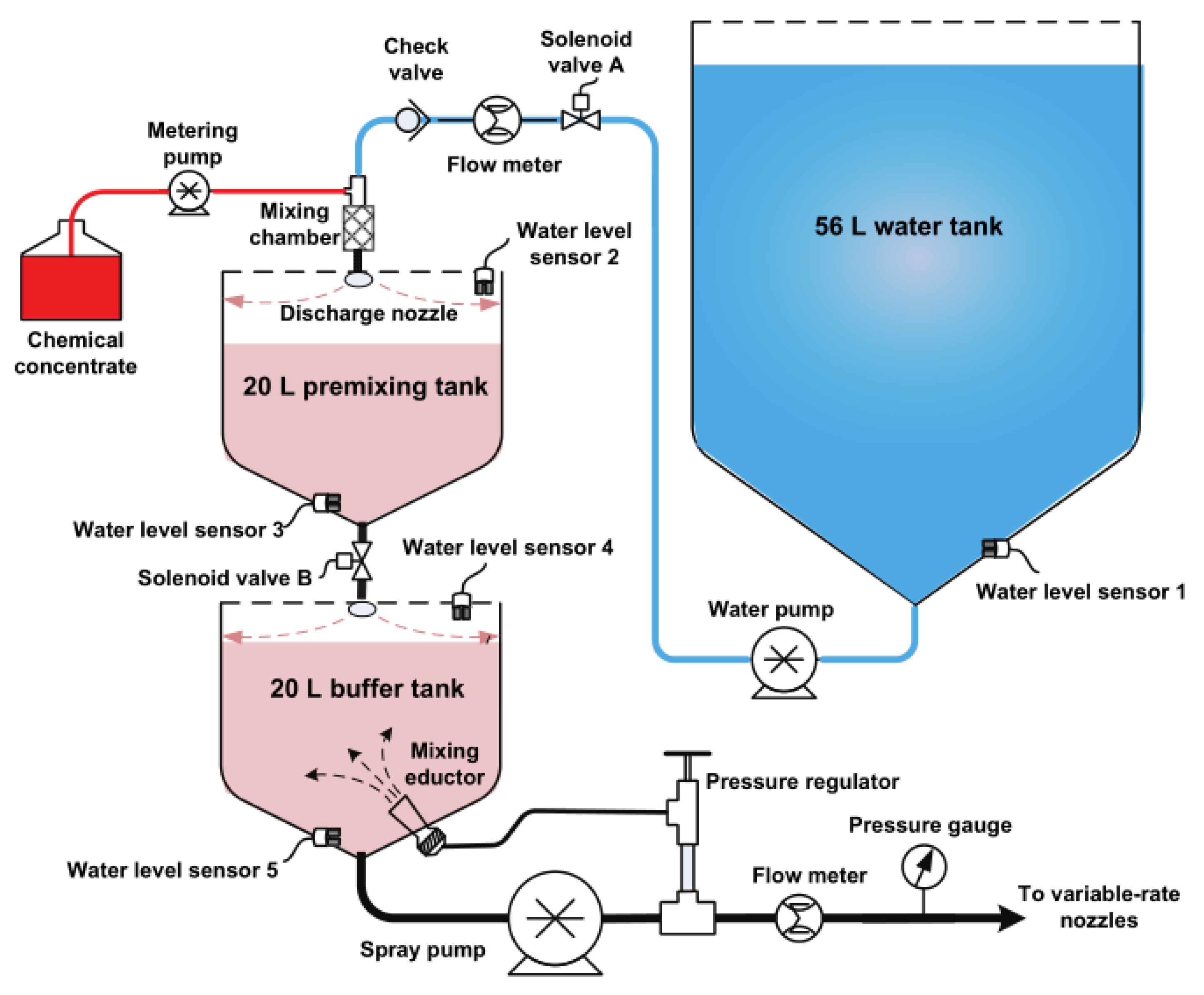

| [58] | 2014 | It consists of a ceramic piston metering pump, centrifugal water pump, diaphragm spray pump, embedded computer control unit, 56 L water tank, 5 L liquid tank, 20 L pre-mixing tank, buffer tanks and other core components. The microprocessor-controlled metering pump injects pesticide liquid (accuracy of ±0.05 mL) into the mixing chamber together with 10 L of water injected by the centrifugal pump. The hollow cone nozzle provides mandatory mixing in the pre-mixing tank, and the pesticide is ultimately transferred to the buffer tank for dynamic output from the spray pump. | The embedded computer has a touch screen, which achieves human–computer interaction, the real-time adjustment of the liquid ratio (0.1–1.0%), and a metering pump in the 50–400 rpm speed range. With viscosities of 0.9–31.3 mPa·s, the liquid flow control error is less than 0.5%, and the coefficient of variation of the mixing uniformity is less than 6.1%. The system effectively solves the problems of lag effect (response time reduced to less than 30 s), inaccurate measurement of low flow rate (minimum flow rate of 5 mL/min), and uneven concentration between nozzles that exist in traditional online mixing systems, and it reduces the waste of pesticides by more than 60%. The main limitation is that the buffer tank and pre-mixing tank each cycle up to 20 L of residual liquid, although compared with a traditional large-capacity tank, this is a significant reduction, but there is still a small amount of waste. |

| [59] | 2019 | The core components include a precision metering pump, water pump, static mixer, pre-mixing tank, and buffer tank. The system accurately controls the flow of the pesticide liquid through the metering pump, and the water delivered by the pump is initially mixed in the static mixer before entering the pre-mixing tank and is then supplied to the variable flow nozzle through the secondary mixing of the buffer tank. The Arduino control unit automatically triggers the mixing cycle based on the signal from the level sensor, and the metering pump rotational speed and running time are adjusted. | The system can achieve liquid metering accuracy with an error of <5% in the viscosity range of 0.9–32.0 mPa·s. The relative error in concentration of the mixture is up to 7.6%, with a coefficient of variation of ≤4.5%, which satisfies a coefficient of variation of <5%. The main limitations are the 2.3% attenuation of the metering pump flow when dealing with high-viscosity pesticides (32 mPa·s) and the relatively large error (5.8%) in the 2% high-concentration ratio. |

| [60] | 2019 | It consists of a water solvent-regulating pipeline and pesticide injection pipeline: the water solvent pipeline realizes the main flow rate closed-loop regulation by controlling the bypass throttling through the electric regulating valve, and the pesticide injection pipeline adopts an electromagnetic metering pump combined with a dynamic matrix control algorithm to realize precise flow rate control and is equipped with a SK static mixer to enhance mixing homogeneity. The system adopts an STM32F4 controller to realize double closed-loop control. In automatic mode, the flow instruction is generated by a prescription map or GPS positioning, and manual mode supports manual parameter input. | The system has a mixing ratio range of 10:1–270:1, a steady-state response time of about 3 s for aqueous solvent flow, a steady-state error of no more than 5% for dynamic matrix control of pesticide flow, a spatial coefficient of variation of the mixture of less than 5%, and good nozzle spray volume uniformity. The main limitations are that the system still suffers from a concentration transfer delay of about 0.8 s, and the strong dependence of the static mixer on homogeneity may increase maintenance costs. |

| [61] | 2024 | The system consists of pesticide pumps, pressure storage buffer tanks, accumulators, electric regulating valves, pumps, static mixers, photoelectric detection units, and other core components. The real-time adjustment of electric valve openings achieves precise control of pesticide flow, combined with a non-contact photoelectric detection module (based on the principle of solution transmittance) for the monitoring of the mixing ratio. | With a maximum standard deviation of 0.00145 over the mixing ratio range of 1:40 to 1:200, an average coefficient of variation of less than 3.41%, and a response time of up to 3.5 s, the system is adaptable to simulated fluids of different viscosities (1.01–34.76 mPa·s). However, the system still has technical limitations: the micro-flow sensor is susceptible to corrosion, leading to measurement errors; high-viscosity liquid (75% glycerol content) may lead to fluctuations in mixing homogeneity (maximum detection error of 5.5%) and an increase in response latency; there are fluctuations in flow rates of 8% during the charging and discharging switching process; and it needs to rely on the addition of conductive salts to realize the calibration of the concentration. |

5.2. Jet Mixing

| Reference | Year | System Components and Working Principle | Control and Spray Performance |

|---|---|---|---|

| [65] | 2010 | It consists of a cylindrical fluid storage tank, circulation pump, jet mixer, replaceable nozzles (5 types of active area 11.4–53.2%), and a flow meter, which realizes fluid mixing control by adjusting the active area of the nozzles, the position of the jet, and the flow rate. | The nozzle, with 20% spray area, has the largest liquid retention rate and the best mixing effect at jet position T/1.8. The system forms a complete circulating flow path in low-viscosity liquid (water), with high mixing efficiency and low energy consumption, but for high-viscosity fluids (CMC/guar concentration > 0.3%), the injection speed needs to be greatly increased in order to maintain effective mixing, and the system has the limitations of not integrating real-time monitoring or feedback control of the concentration, relying on the static experiments of the optimization parameters of the nozzle and drastically increasing the energy consumption of high-viscosity working conditions. |

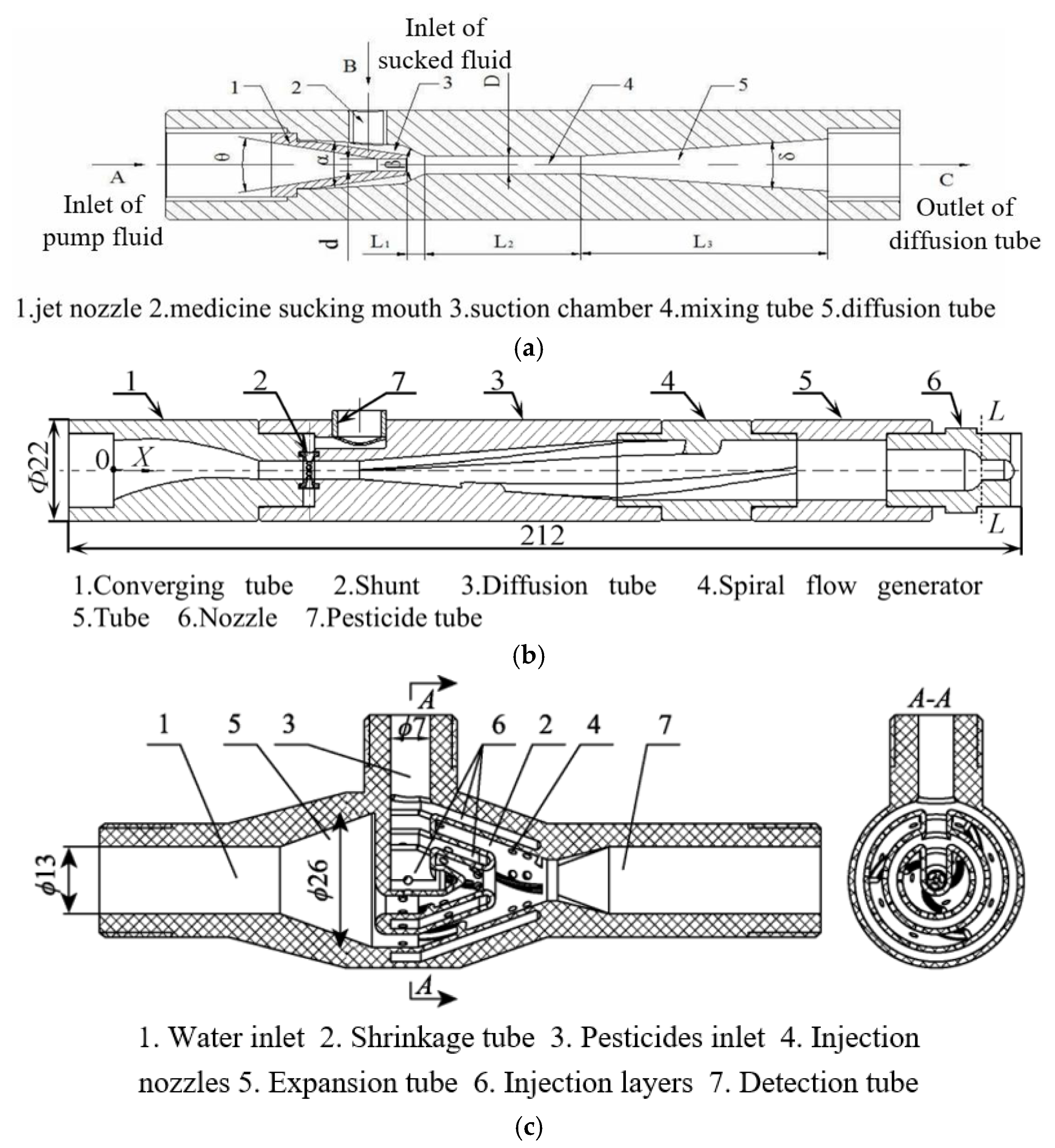

| [66] | 2014 | It consists of a jet mixing device, power liquid pump, water tank, liquid tank, spraying system (including spraying rod and 16 nozzles with 0.5 m spacing), and measuring elements (pressure gauge, flow meter, etc.). The core structure of the jet mixing device includes nozzles (adjustable diameter of 2–4 mm), a suction port, a suction chamber, and mixing and diffusion tubes, and the switching of the working state (suction, reflux, or cavitation) is realized by changing the diameter of the nozzles and the load of the system. | In the no-load bench test, the 2 mm nozzle causes bubbles in the inhalation chamber due to cavitation, which affects mixing efficiency, while in the actual spray bar spray system, the 2 mm nozzle can realize a stable suction state, and the 3 mm and above nozzle triggers a reflux state, which avoids the cavitation phenomenon. However, its limitations are as follows: 1. existing research focuses on the flow-field simulation of the jet mixing device itself, and the overall synergistic control of the spray system is insufficient; 2. the system relies on manually adjusting the nozzle diameter and other structural parameters, it lacks real-time dynamic regulation, and it is difficult to achieve accurate concentration feedback control; 3. the cavitation phenomenon will still destroy the uniformity of mixing under specific conditions, and the reflux state may result in the circulation of the liquid medicine, with efficiency decline. |

| [67] | 2014 | It consists of a jet mixing device (the core component, including jet nozzle, mixing tube, diffusion tube, and other structures), a spray bar sprayer, a liquid pump, a water tank, a liquid tank, and a flow/pressure measuring device, in which the structural parameters of the jet mixing device (such as the diameter of the jet nozzle outlet d, the diameter of the mixing tube D, and the area ratio m) can realize the online control of the concentration of the pesticide solution by adjusting the fluid dynamics characteristics. The system regulates the mixing performance by changing the structural parameters of the jet device and spray pressure (0.26–0.36 MPa). | When the diameter of the jet nozzle outlet is small (e.g., d = 2.00 mm, area ratio m = 4.00) and the resistance of the spraying system is low (e.g., F110-015 spray nozzle), the system can be stably in the suction state, and the spatial coefficient of variation (CV) of the mixing concentration is less than 5%. However, there are significant limitations of the system: first, the working state is highly dependent on the matching of the parameters of the jet device and the resistance of the spraying system, which may lead to reflux problems when the diameter of the jet nozzle is too large or the area ratio exceeds a reasonable range; second, the experimental conditions are based on the simulated liquid (cochineal) and the laboratory environment, and the differences in the physicochemical properties of the pesticide, dynamic pressure fluctuations, and complex piping conditions in the actual field applications may affect the stability of the pesticide mixing. |

| [68] | 2016 | It consists of liquid supply system (including water tank, centrifugal pump, and electric motor), pesticide supply system (including liquid tank, metering pump, and flow control module), and rotating jet mixer. The mixer adopts the structure of a spiral bending contraction tube, spinning device, and diffusion tube with a guide vane to realize the online mixing of water and fat-soluble pesticides through pressure difference, and its core innovation lies in the enhancement of mixing uniformity through fluid spinning. | Through the closed-loop adjustment of the flow rate of the electric metering pump (microcontroller control of the motor frequency to adjust the pump speed), the precise control of the pesticide flow rate can be realized (error < 0.001 kg/s). Numerical simulations and tests show that the system can achieve a uniformity index of 0.9989 for the volume fraction of pesticide in the outlet cross-section under 1 MPa working pressure, but there are the following limitations: the traditional structure of the mixing of fat-soluble pesticides exists in the phenomenon of agglomerated suspension, with a low degree of mixing uniformity; the improved rotary structure improves the mixing effect but increases flow resistance and energy loss (pressure loss of about 0.2 MPa), precision structures such as guide leaves are easily affected by changes in pesticide viscosity, and structural parameters (e.g., guide leaf height, pitch, etc.) need to be adjusted for different pesticide characteristics. |

| [69] | 2016 | It consists of a rotary jet mixer, pressure drive system, and mixing effect monitoring system. Among them, the core structure of the mixer includes a spiral contraction tube (contraction degree 0.095, pitch 128 mm, contraction angle 16°), a tangential diverter (adjustable tangential angle β), a guide vane diffuser tube (guide vane height 0–6.5 mm gradient, wrapping angle 15 °), and a relay rotator (including three 6.5 mm high, 15 ° wrapping angle guide vane), using spiral flow generation and maintenance technology to achieve the mixing of the pesticide solution. The diaphragm pump provides water pressure (0.23 MPa) and pesticide pressure (0.22 MPa), with flow meters and manometers to achieve dual-channel precision control. | The volume fraction uniformity index at the nozzle reaches 0.9995, and the maximum mixing ratio is 99.4425%, which significantly improves the dispersion uniformity of fat-soluble pesticides and effectively solves the problem of pesticide suspension in the traditional jet mixer. However, the system still has limitations: first, the structural parameters (such as diverter tangential angle, guide vane layout) need to be dynamically adjusted according to the viscosity and concentration of pesticides, which increases the complexity of the operation; second, it relies on the pesticide pump to maintain the pressure (the outlet directly connected to the spray nozzle requires 0.22 MPa pesticide pump pressure), and energy consumption and equipment costs are high. |

| [70] | 2019 | The core structure consists of a jet mixer (e.g., ordinary jet mixer A and improved sandwich orifice tube mixer B), a pesticide supply device (e.g., volumetric metering pump or pulse-width modulated solenoid valve), and an online mixing and detection system (with high-speed camera and fluorescent tracer technology). The system optimizes the control performance by adjusting the carrier flow rate (800–2000 mL/min) and the mixing ratio (4:100–10:100), wherein the sandwich orifice tube mixer B attenuates the injection pulsation through the multi-orifice plate structure, which significantly improves the dynamic concentration consistency. | The average dynamic concentration inconsistency index (CV value) under the test conditions was reduced from 0.039 to 0.011 for mixer A and met the stringent criterion of CV < 0.020 at an injection frequency of >5.10 Hz or a mixing ratio of >5:100. Mixer B achieved an instantaneous homogeneity index (D-value) of about 13.00 for homogeneous mixing at high carrier flow rates (>1400 mL/min) and mixing ratios (>9:100), but its limitation is that the homogeneity of the common jet mixer A decreases due to a single-point injection at high mixing ratios (up to a maximum of D-value of 21.13), and the dynamic homogeneity of mixer B at low flow rates or low mixing ratios still has fluctuations (e.g., CV increased to 0.018 at Qc = 2000 mL/min), and transient uniformity is not sufficiently optimized (D-value vs. CV correlation was only 0.684). |

6. Discussion

7. Prospects

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Giles, D.K.; Akesson, N.B.; Yates, W.E. Pesticide application technology: Research and development and the growth of the industry. Trans. ASABE 2008, 51, 397–403. [Google Scholar] [CrossRef]

- Moss, S. Integrated weed management (IWM): Why are farmers reluctant to adopt non-chemical alternatives to herbicides? Pest Manag. Sci. 2019, 75, 1205–1211. [Google Scholar] [CrossRef] [PubMed]

- Liu, Z.; Wang, H.; Wang, J.; Lv, J.; Xie, B.; Luo, S.; Yu, J. Physical, chemical, and biological control of black rot of brassicaceae vegetables: A review. Front. Microbiol. 2022, 13, 1023826. [Google Scholar] [CrossRef] [PubMed]

- Bai, Y.; Wang, L.; Yuan, X. Pesticide control, physical control, or biological control? How to manage forest pests and diseases more effectively. Front. Ecol. Evol. 2023, 11, 1200268. [Google Scholar] [CrossRef]

- Deguine, J.P.; Aubertot, J.N.; Flor, R.J.; Lescourret, F.; Wyckhuys, K.A.; Ratnadass, A. Integrated pest management: Good intentions, hard realities. A review. Agron. Sustain. Dev. 2021, 41, 38. [Google Scholar] [CrossRef]

- Yadav, S.K. Pesticide applications-threat to ecosystems. J. Hum. Ecol. 2010, 32, 37–45. [Google Scholar] [CrossRef]

- Dhananjayan, V.; Jayakumar, S.; Ravichandran, B. Conventional methods of pesticide application in agricultural field and fate of the pesticides in the environment and human health. In Controlled Release of PESTICIDES for Sustainable Agriculture; Springer International Publishing: Cham, Switzerland, 2019; pp. 1–39. [Google Scholar]

- Shimada, B.S.; Simon, M.V. Use of chemical control in agriculture. Colloq. Agrar. 2022, 18, 60–71. [Google Scholar] [CrossRef]

- Zanin, A.R.A.; Neves, D.C.; Teodoro, L.P.R.; da Silva Júnior, C.A.; da Silva, S.P.; Teodoro, P.E.; Baio, F.H.R. Reduction of pesticide application via real-time precision spraying. Sci. Rep. 2022, 12, 5638. [Google Scholar] [CrossRef]

- Virk, S.S.; Prostko, E.P. Survey of pesticide application practices and technologies in Georgia agronomic crops. Weed. Technol. 2022, 36, 616–628. [Google Scholar] [CrossRef]

- Zheng, J.; Xu, Y. A review: Development of plant protection methods and advances in pesticide application technology in agro-forestry production. Agriculture 2023, 13, 2165. [Google Scholar] [CrossRef]

- Gebbers, R.; Adamchuk, V.I. Precision agriculture and food security. Science 2010, 327, 828–831. [Google Scholar] [CrossRef] [PubMed]

- Karunathilake, E.M.B.M.; Le, A.T.; Heo, S.; Chung, Y.S.; Mansoor, S. The path to smart farming: Innovations and opportunities in precision agriculture. Agriculture 2023, 13, 1593. [Google Scholar] [CrossRef]

- Guan, Y.; Chen, D.; He, K.; Liu, Y.; Li, L. Review on research and application of variable rate spray in agriculture. In Proceedings of the IEEE 10th Conference on Industrial Electronics and Applications (ICIEA), Auckland, New Zealand, 15–17 June 2015; IEEE: New York, NY, USA, 2015; pp. 1575–1580. [Google Scholar]

- Song, Y.; Sun, H.; Li, M.; Zhang, Q. Technology application of smart spray in agriculture: A review. Intell. Autom. Soft Comput. 2015, 21, 319–333. [Google Scholar] [CrossRef]

- Dou, H.; Zhang, C.; Li, L.; Hao, G.; Ding, B.; Gong, W.; Huang, P. Application of variable spray technology in agriculture. In IOP Conference Series: Earth and Environmental Science; IOP Publishing: Bristol, UK, 2018; Volume 186, p. 012007. [Google Scholar]

- He, L. Variable rate technologies for precision agriculture. In Encyclopedia of Digital Agricultural Technologies; Springer International Publishing: Cham, Switzerland, 2023; pp. 1533–1542. [Google Scholar]

- Hong, S.; Minzan, L.; Qin, Z. Detection system of smart sprayers: Status, challenges, and perspectives. Int. J. Agr. Biol. Eng. 2012, 5, 10–23. [Google Scholar]

- Petrović, D.; Jurišić, M.; Tadić, V.; Plaščak, I.; Barač, Ž. Different sensor systems for the application of variable rate technology in permanent crops. Teh. Glas. 2018, 12, 188–195. [Google Scholar] [CrossRef]

- Zhang, Z.; Wang, X.; Lai, Q.; Zhang, Z. Review of variable-rate sprayer applications based on real-time sensor technologies. In Automation in Agriculture-Securing Food Supplies for Future Generations; BoD—Books on Demand: Budapest, Hungary, 2018; Volume 13. [Google Scholar]

- Anglund, E.A.; Ayers, P.D. Field evaluation of response times for a variable rate (pressure–based and injection) liquid chemical applicators. Appl. Eng. Agric. 2003, 19, 273. [Google Scholar] [CrossRef]

- Shi, Y.; Qi, L.; Fu, Z.; Tan, Y.; Zhang, X. Model development and simulation of variable-rate of pressure spray. Trans. Chin. Soc. Agric. Eng. 2004, 5, 118–121. (In Chinese) [Google Scholar]

- Vogel, J.W.; Wolf, R.E.; Dille, J.A. Evaluation of a variable rate application system for site-specific weed management. In Proceedings of the ASAE Annual Meeting, Tampa, FL, USA, 17–20 July 2005; American Society of Agricultural and Biological Engineers: St. Joseph, MI, USA, 2005; p. 1. [Google Scholar]

- Gonzalez, R.; Pawlowski, A.; Rodriguez, C.; Guzman, J.L.; Sanchez-Hermosilla, J. Design and implementation of an automatic pressure-control system for a mobile sprayer for greenhouse applications. Span. J. Agric. Res. 2012, 10, 939–949. [Google Scholar] [CrossRef]

- Deng, W.; Zhao, C.; Zhou, J. Comparison and evaluation of spray characteristics of three types of variable-rate spray. In Proceedings of the Virtual ICPA–International Conference on Precision Agriculture—2020, Virtual, 30 June 2020. [Google Scholar]

- Nasir, F.E.; Alam, M.S.; Tufail, M.; Khan, M.T. A novel pressure and flow control technique for variable-rate precision agricultural sprayer. In Proceedings of the 2021 International Conference on Robotics and Automation in Industry (ICRAI), Rawalpindi, Pakistan, 26–27 October 2021; IEEE: New York, NY, USA, 2021; pp. 1–6. [Google Scholar]

- Womac, A.R.; Bui, Q.D. Development of a variable flow rate fan spray nozzle for precision chemical application. In Proceedings of the 2001 ASAE Annual Meeting, Sacramento, CA, USA, 30 July–1 August 2001; American Society of Agricultural and Biological Engineers: St. Joseph, MI, USA, 1998; p. 1. [Google Scholar]

- Womac, A.R.; Bui, Q.D. Design and tests of a variable–flow fan nozzle. Trans. ASAE 2002, 45, 287. [Google Scholar] [CrossRef]

- Bui, Q.D. VariTarget–A new nozzle with variable flow rate and droplet optimization. In Proceedings of the 2005 ASAE Annual Meeting, Tampa, FL, USA, 17–20 July; American Society of Agricultural and Biological Engineers: St. Joseph, MI, USA, 2005; p. 1. [Google Scholar]

- Daggupati, N.P. Assessment of the Varitarget Nozzle for Variable Rate Application of Liquid Crop Protection Products. Master’s Thesis, Kansas State University, Manhattan, KS, USA, 2007. [Google Scholar]

- Huang, X.; Lan, Y.; Yin, X. Design and test of an agricultural variable nozzle based on magnetorheological fluid. J. S. China Agric. Univ. 2019, 4, 92–99. (In Chinese) [Google Scholar]

- Yang, G.; Lan, Y.; Geng, L.; Zhang, B.; Yi, L.; Han, X. Experimental Research on Three-layer Intelligent Centrifugal Variable Sprinkler. J. Agric. Mech. Res. 2023, 8, 155–160. (In Chinese) [Google Scholar]

- Wang, X. Advances in Pulse Width Modulation Techniques. Master’s Thesis, McGill University, Montréal, QC, Canada, 1993. [Google Scholar]

- Bora, G.C.; Schrock, M.D.; Oard, D.L.; Grimm, J.J.; Kolb, T.C. Performance of a stacked valve multipoint pulse width modulation (PWM) manifold for variable rate anhydrous ammonia application. Agric. Eng. Int. CIGR J. 2005, 7, 1–12. [Google Scholar]

- Deng, W.; Ding, W.; He, X. Spray Characteristics of PWM-based Intermittent Pulse Variable-rate spray. Trans. Chin. Soc. Agric. Mach. 2009, 1, 74–78. (In Chinese) [Google Scholar]

- Zhang, R.; Li, L.; Fu, W.; Chen, L.; Yi, T.; Tang, Q.; Hewitt, A.J. Spraying atomization performance by pulse width modulated variable and droplet deposition characteristics in wind tunnel. Trans. Chin. Soc. Agric. Eng. 2019, 3, 42–51. (In Chinese) [Google Scholar]

- Butts, T.R.; Luck, J.D.; Fritz, B.K.; Hoffmann, W.C.; Kruger, G.R. Evaluation of spray pattern uniformity using three unique analyses as impacted by nozzle, pressure, and pulse-width modulation duty cycle. Pest Manag. Sci. 2019, 75, 1875–1886. [Google Scholar] [CrossRef]

- Zhang, C.; Zhai, C.; Zhang, M.; Zhang, C.; Zou, W.; Zhao, C. Staggered-phase spray control: A method for eliminating the inhomogeneity of deposition in low-frequency pulse-width modulation (PWM) variable spray. Agriculture 2024, 14, 465. [Google Scholar] [CrossRef]

- Zhang, C.; Zhai, C.; Zhao, X.; Zou, W.; Zhang, M.; Zhao, C. Experimental study on the pressure fluctuation characteristics of target spray system. Trans. Chin. Soc. Agric. Eng. 2022, 18, 31–39. (In Chinese) [Google Scholar]

- Zhang, M.; Zhang, C.; Zhao, X.; Yang, S.; Li, S.; Zhai, C. Research progress on pressure fluctuation characteristics and elimination methods of variable-rate spraying system. J. Chin. Agric. Mech. 2024, 11, 60–68. (In Chinese) [Google Scholar]

- Ken Giles, D.; Henderson, G.W.; Funk, K. Digital control of flow rate and spray droplet size from agricultural nozzles for precision chemical application. In Proceedings of the Third International Conference on Precision Agriculture, Madison, WI, USA, 23–26 June 1996; American Society of Agronomy, Crop Science Society of America, Soil Science Society of America: Madison, WI, USA, 1996; pp. 729–738. [Google Scholar]

- Deng, W.; He, X.; Ding, W. Droplet size and spray pattern characteristics of PWM-based continuously variable spray. Int. J. Agr. Biol. Eng. 2009, 2, 8–18. [Google Scholar]

- Needham, D.L.; Holtz, A.J.; Giles, D.K. Actuator system for individual nozzle control of flow rate and spray droplet size. Trans. ASABE 2012, 55, 379–386. [Google Scholar] [CrossRef]

- Jiang, H.; Zhou, M.; Tong, J.; Liu, Y. PWM Variable Spray Control Based on Kalman Filter. Trans. Chin. Soc. Agric. Mach. 2014, 10, 60–65. (In Chinese) [Google Scholar]

- Silva, J.E.; Zhu, H.; da Cunha, J.P.A.R. Spray outputs from a variable-rate sprayer manipulated with PWM solenoid valves. Appl. Eng. Agric. 2018, 34, 527–534. [Google Scholar] [CrossRef]

- Grella, M.; Gioelli, F.; Marucco, P.; Zwertvaegher, I.; Mozzanini, E.; Mylonas, N.; Balsari, P. Field assessment of a pulse width modulation (PWM) spray system applying different spray volumes: Duty cycle and forward speed effects on vines spray coverage. Precis. Agric. 2022, 23, 219–252. [Google Scholar] [CrossRef]

- Yin, X.; Wang, Y.; Du, J.; An, G.; Jin, C.; Wang, Y. Design and performance test of electronic control precision nozzle body based on PWM. Trans. Chin. Soc. Agric. Eng. 2022, S1, 18–26. (In Chinese) [Google Scholar]

- Wang, Y.; Yin, X.; Yang, S.; Yao, H.; Ma, W.; Jin, C. Design and experiment of electronically controlled precision spray control system based on PWM. J. Chin. Agric. Mech. 2023, 5, 81–88. (In Chinese) [Google Scholar]

- Yuan, C.; Zhang, L.; Han, H.; He, X.; Liu, Y. The PWM Spray Characteristic Test of the Asynchronous Opening and Closing of Solenoid Valve. J. Agric. Mech. Res. 2024, 2, 139–144. (In Chinese) [Google Scholar]

- Vondricka, J.; Lammers, P.S. Evaluation of a carrier control valve for a direct nozzle injection system. Biosyst. Eng. 2009, 103, 43–48. [Google Scholar] [CrossRef]

- Dai, X.; Xu, Y.; Song, H.; Chen, J.; Kuang, L.; Ma, L. Mixing Uniformity Analysis Methods and In-line Mixing Experiments of Mixer under Variable Working Conditions. Trans. Chin. Soc. Agric. Mach. 2018, 10, 172–179. (In Chinese) [Google Scholar]

- Dai, X.; Xu, Y.; Zheng, J.; Song, H. Analysis of the variability of pesticide concentration downstream of inline mixers for direct nozzle injection systems. Biosyst. Eng. 2019, 180, 59–69. [Google Scholar] [CrossRef]

- Vondricka, J.; Hloben, P.; Lammers, P.S. Optimization of direct nozzle injection system for site-specific herbicide application. In Proceedings of the 2007 ASAE Annual Meeting, Chicago, IL, USA, 10–13 August 2007; American Society of Agricultural and Biological Engineers: Madison, WI, USA, 2007; p. 1. [Google Scholar]

- Hlobeň, P. Study on the Response Time of Direct Injection Systems for Variable Rate Application of Herbicides. Ph.D. Thesis, Rheinische Friedrich-Wilhelms-Universität Bonn, Bonn, Germany, 2008. [Google Scholar]

- Vondricka, J.; Lammers, P.S. Measurement of mixture homogeneity in direct injection systems. Trans. ASABE 2009, 52, 61–66. [Google Scholar] [CrossRef]

- Aissaoui, A.E.; Lebeau, F.; El Bahir, L.; Destain, M.F.; Houmy, K. A Feasibility Study of Developing Direct Injection Spraying Technology for Small Scale Farms. In Synergy in the Technical Development of Agriculture and Food Industry (Synergy 2011); Szent István University, Faculty of Mechanical Engineering: Gödöllő, Hungary, 2011. [Google Scholar]

- Alamouti, M.Y.; Hosseini, M.S. Response time of a direct injection type-variable-rate sprayer. Agric. Eng. Int. CIGR J. 2014, 16, 70–76. [Google Scholar]

- Shen, Y.; Zhu, H. Embedded computer-controlled premixing inline injection system for air-assisted variable-rate sprayers. Trans. ASABE 2015, 58, 39–46. [Google Scholar]

- Zhang, Z.; Zhu, H.; Guler, H.; Shen, Y. Improved premixing in-line injection system for variable-rate orchard sprayers with Arduino platform. Comput. Electron. Agr. 2019, 162, 389–396. [Google Scholar] [CrossRef]

- Jiang, X.; Wang, Z.; Bai, X.; Xiong, F.; Li, D. Design and Experiment of injection-type Intelligent Online Mixing Pesticide Control System. In Proceedings of the 2019 IEEE 2nd International Conference on Automation, Electronics and Electrical Engineering (AUTEEE), Shenyang, China, 22–24 November 2019; IEEE: New York, NY, USA, 2019; pp. 379–384. [Google Scholar]

- Chen, Y.; Chen, Y.; Guo, P.; Zhang, S.; Jin, H.; Adilet, S.; Chen, J. Design and experimentation of direct injection in-line mixing control system for sprayers. Comput. Electron. Agr. 2024, 226, 109304. [Google Scholar] [CrossRef]

- Ou, M.; Jia, W.; Qiu, B.; Guan, X.; Sheng, Y. Experiment and Numerical Analysis of Flow Field in Jet Mixing Device under Variable Working Conditions. Trans. Chin. Soc. Agric. Mach. 2015, 9, 107–111. (In Chinese) [Google Scholar]

- Sun, D.; Liu, W.; Li, Z.; Zhan, X.; Dai, Q.; Xue, X.; Song, S. Numerical experiment and optimized design of pipeline spraying on-line pesticide mixing apparatus based on CFD orthogonal experiment. Agronomy 2022, 12, 1059. [Google Scholar] [CrossRef]

- Chen, Z.; Wang, P. Experimental study on double-stage on-line jet mixing apparatus. Int. J. Model. Simul. Sci. Comput. 2022, 13, 2142001. [Google Scholar] [CrossRef]

- Saravanan, K.; Sundaramoorthy, N.; Mohankumar, G.; Subramanian, N. Studies on some aspects of jet mixers I: Hydrodynamics. Mod. Appl. Sci. 2010, 4, 51. [Google Scholar]

- Ma, J.; Qiu, B.J.; Yan, R.; Zhu, B.F. Study on the working state of Jet-mixing Apparatus. Appl. Mech. Mater. 2014, 563, 219–223. [Google Scholar] [CrossRef]

- Qiu, B.; Ma, J.; Deng, B.; Ou, M.; Dong, X. Experiment on mixing performance of on-line mixing spray system. Trans. Chin. Soc. Agric. Eng. 2014, 17, 78–85. (In Chinese) [Google Scholar]

- Song, H.; Xu, Y.; Zheng, J.; Zhu, H. Swirling Jet Mixture Mechanism of Fat-soluble Pesticides and Numerical Simulation of Mixer Field. Trans. Chin. Soc. Agric. Mach. 2016, 9, 79–84. (In Chinese) [Google Scholar]

- Song, H.; Xu, Y.; Zheng, J.; Wang, X.; Zhang, M. Structural analysis and mixing uniformity experiments of swirling jet mixer for applying fat-soluble pesticides. Trans. Chin. Soc. Agric. Eng. 2016, 23, 86–92. (In Chinese) [Google Scholar]

- Dai, X.; Xu, Y.; Chen, J.; Zheng, J.; Song, H.; Ma, L. Improved jet mixer injection nozzle enhancing pesticide mixing uniformity and dynamic concentration consistency. Trans. Chin. Soc. Agric. Eng. 2019, 8, 65–74. (In Chinese) [Google Scholar]

- Patil, S.; Patil, Y.; Patil, S. Review on automatic variable-rate spraying systems based on orchard canopy characterization. Inform. Autom. 2023, 22, 57–86. [Google Scholar] [CrossRef]

- Mao, Z.; Xue, X.; Sun, Z.; Xu, Y.; Zhou, Q.; Jiao, Y.; Zhou, H.; Ding, S. Design and Testing of a PLC-Controlled Pressure Stabilization System for Targeted Spraying on Heading Vegetables. Agriculture 2025, 15, 452. [Google Scholar] [CrossRef]

- Xue, S.; Xi, X.; Lan, Z.; Wen, R.; Ma, X. Longitudinal drift behaviors and spatial transport efficiency for spraying pesticide droplets. Int. J. Heat Mass. Tran. 2021, 177, 121516. [Google Scholar] [CrossRef]

- Xun, L. Towards a Sustainable Use of Plant Protection Products in Orchards: Implementation of Canopy-Adapted Spray Technology and New Developments for Spray Efficiency Evaluation. Doctoral’s Thesis, Universitat Politècnica de Catalunya, Barcelona, Spain, 2024. [Google Scholar]

- Nuyttens, D.; Baetens, K.; De Schampheleire, M.; Sonck, B. Effect of nozzle type, size and pressure on spray droplet characteristics. Biosyst. Eng. 2007, 97, 333–345. [Google Scholar] [CrossRef]

- Creech, C.F.; Henry, R.S.; Fritz, B.K.; Kruger, G.R. Influence of herbicide active ingredient, nozzle type, orifice size, spray pressure, and carrier volume rate on spray droplet size characteristics. Weed. Technol. 2015, 29, 298–310. [Google Scholar] [CrossRef]

- Mashhadi, H.; Raeini, M.G.N.; Asoodar, M.A.; Mehdizadeh, S.A. Effect of pressure and nozzle diameter on spray quality and droplet size in handheld gun sprayers. Results Eng. 2025, 26, 104709. [Google Scholar] [CrossRef]

- Liu, H.; Zhu, H.; Shen, Y.; Chen, Y.; Ozkan, H.E. Development of digital flow control system for multi-channel variable-rate sprayers. Trans. ASABE 2014, 57, 273–281. [Google Scholar]

- Khot, L.; Hoheisel, G.A.; Osroosh, Y.A.S.I.N.; Ehsani, R.E.Z.A. Precision technologies for pest and disease management. In Automation in Tree Fruit Production: Principles And practice; CABI: Wallingford, UK, 2018; pp. 112–133. [Google Scholar]

- Sun, D.; Liu, W.; Luo, R.; Zhan, X.; Chen, Z.; Wei, T.; Wang, X.; Xue, X.; Li, Z.; Song, S. Monocular vision for variable spray control system. Int. J. Agr. Biol. Eng. 2022, 15, 206–215. [Google Scholar] [CrossRef]

- Wei, Z.; Xue, X.; Salcedo, R.; Zhang, Z.; Gil, E.; Sun, Y.; Li, Q.; Shen, J.; He, Q.; Dou, Q.; et al. Key technologies for an orchard variable-rate sprayer: Current status and future prospects. Agronomy 2022, 13, 59. [Google Scholar] [CrossRef]

- Infanta, S.C.; Selvakumar, T.; Ragavan, T.; Sheela, K.S.; Bharathi, C. Cultivating change: A review of progressive technologies in weed detection and management. Emir. J. Food Agr. 2024, 36, 1–11. [Google Scholar] [CrossRef]

- Qing, H.; Chi, Y.; Hong, Y.; Zhao, Y.; Qi, F.; Li, Y.; Yin, J. Fully 3D-printed miniature soft hydraulic actuators with shape memory effect for morphing and manipulation. Adv. Mater. 2024, 36, 2402517. [Google Scholar] [CrossRef]

- Islam, R.; Maparathne, S.; Chinwangso, P.; Lee, T.R. Review of Shape-Memory Polymer Nanocomposites and Their Applications. Appl. Sci. 2025, 15, 2419. [Google Scholar] [CrossRef]

- Shan, Y.; Zhang, L.; Ma, X.; Hu, X.; Hu, Z.; Li, H.; Du, C.; Meng, Z. Application of the modified fuzzy-PID-Smith predictive compensation algorithm in a pH-controlled liquid fertilizer system. Processes 2021, 9, 1506. [Google Scholar] [CrossRef]

- Ferraz, R.S.C.; Mello, T.P.; Borges Filho, M.N.; Borges, R.F.O.; Magalhães Filho, S.C.; Scheid, C.M.; Meleiro, L.A.C.; Calçada, L.A. An experimental and theoretical approach on real-time control and monitoring of the apparent viscosity by fuzzy-based control. J. Pet. Sci. Eng. 2022, 217, 110896. [Google Scholar] [CrossRef]

- Yang, Z.; Yu, J.; Duan, J.; Xu, X.; Huang, G. Optimization-design and atomization-performance study of aerial dual-atomization centrifugal atomizer. Agriculture 2023, 13, 430. [Google Scholar] [CrossRef]

- Baio, F.H.R.; Oliveira, J.T.D.; Alves, M.E.M.; Teodoro, L.P.R.; Cunha, F.F.D.; Teodoro, P.E. Characterization of the Droplet Population Generated by Centrifugal Atomization Nozzles of UAV Sprayers. AgriEngineering 2025, 7, 15. [Google Scholar] [CrossRef]

- Wang, J.; Lv, X.; Wang, B.; Lan, X.; Yan, Y.; Chen, S.; Lan, Y. Numerical simulation and analysis of droplet drift motion under different wind speed environments of single-rotor plant protection UAVs. Drones 2023, 7, 128. [Google Scholar] [CrossRef]

- Qin, W.C.; Chen, P.Y. Analysis of the research progress on the deposition and drift of spray droplets by plant protection UAVs. Sci. Rep. 2023, 13, 14935. [Google Scholar]

- Zhu, H.; Lan, Y.; Wu, W.; Hoffmann, W.C.; Huang, Y.; Xue, X.; Liang, J.; Fritz, B. Development of a PWM precision spraying controller for unmanned aerial vehicles. J. Bionic. Eng. 2010, 7, 276–283. [Google Scholar] [CrossRef]

- Wen, S.; Zhang, Q.; Deng, J.; Lan, Y.; Yin, X.; Shan, J. Design and experiment of a variable spray system for unmanned aerial vehicles based on PID and PWM control. Appl. Sci. 2018, 8, 2482. [Google Scholar] [CrossRef]

- Luo, S.; Wen, S.; Zhang, L.; Lan, Y.; Chen, X. Extraction of crop canopy features and decision-making for variable spraying based on unmanned aerial vehicle LiDAR data. Comput. Electron. Agr. 2024, 224, 109197. [Google Scholar] [CrossRef]

- Jeon, D.; Jung, H.J.; Lee, K.D.; Han, J.; Park, C.; Han, S.; Kim, H. A Study of Spray Volume Prediction Techniques for Variable Rate Pesticide Application using Unmanned Aerial Vehicles. J. Biosyst. Eng. 2025, 50, 21–32. [Google Scholar] [CrossRef]

- Hanif, A.S.; Han, X.; Yu, S.H. Independent control spraying system for UAV-based precise variable sprayer: A review. Drones 2022, 6, 383. [Google Scholar] [CrossRef]

- Delavarpour, N.; Koparan, C.; Zhang, Y.; Steele, D.D.; Betitame, K.; Bajwa, S.G.; Sun, X. A review of the current unmanned aerial vehicle sprayer applications in precision agriculture. J. ASABE 2023, 66, 703–721. [Google Scholar] [CrossRef]

- Taseer, A.; Han, X. Advancements in variable rate spraying for precise spray requirements in precision agriculture using Unmanned aerial spraying Systems: A review. Comput. Electron. Agr. 2024, 219, 108841. [Google Scholar] [CrossRef]

- Bharad, N.B.; Vagadia, V.R.; Lakhani, A.L.; Khanpara, B.M.; Dulawat, M.S. A comprehensive review of Unmanned Aerial Vehicle (UAV) sprayer used in modern agriculture. J. Sci. Res. Rep. 2024, 30, 573–585. [Google Scholar] [CrossRef]

- Nahiyoon, S.A.; Ren, Z.; Wei, P.; Li, X.; Li, X.; Xu, J.; Yan, X.; Yuan, H. Recent development trends in plant protection UAVs: A journey from conventional practices to cutting-edge technologies—A comprehensive Review. Drones 2024, 8, 457. [Google Scholar] [CrossRef]

| Reference | Year | System Components and Working Principle | Control and Spray Performance |

|---|---|---|---|

| [41] | 1996 | Consisting of a solenoid valve (mounted upstream of the nozzle), an electronic interface unit (generates a PWM signal with a phase difference of 180° in order to reduce the deposition gap), a closed-loop pressure control loop (regulates droplet size), and a GPS positioning module, it can be integrated into existing spray controllers to enable retrofitting. | The flow rate can be adjusted up to 10:1 at fixed pressure (30:1 in combination with pressure adjustment) with a dynamic response speed of more than 5 Hz. The coefficient of variation for lateral deposition uniformity for PWM intermittent sprays ranges from 15 to 23%. Major limitations include intermittent spraying results in poorer deposition uniformity compared with continuous spraying systems, and it relies on nozzle overlap compensation; high system complexity involving the integration of multiple modules (pressure control, PWM signal generation, GPS interface) and retrofitting to existing equipment. |

| [42] | 2009 | It consists of a proportional adjustment solenoid valve, 24 kHz high-frequency PWM drive circuit, liquid supply system, and typical nozzles (fan, hollow cone, solid cone). The core function of the system is to control solenoid valve opening to realize the continuous adjustment of the flow rate by adjusting the duty cycle (100–40%) through a DRV101 chip. | At 0.3 MPa pressure, the fan, hollow cone, and solid cone nozzle have a flow regulation ratio of 7.14:1, 3.57:1, and 3.70:1, respectively; the spray angle and flow rate decrease linearly (sensitivity 0.83–0.58 degrees/%), with a maximum drop of the droplet median diameter only 9.9%. At lower flow rates, the droplets are finer (facilitating deposition), and the distribution is concentrated directly below the nozzle. However, at low flow rates (duty cycle < 40%), the spray pattern is severely distorted, leading to measurement failures. The hollow and solid cone nozzles have a limited range of adjustment, and a significant reduction in edge coverage may lead to non-uniform application. |

| [43] | 2012 | It consists of a solenoid valve, a driving circuit, and a state–space modeling algorithm. The system regulates the solenoid valve coil current to control spool displacement through high-frequency PWM (10 kHz) to accurately regulate the valve pressure drop and nozzle inlet pressure to realize the dynamic control of the spray droplet size spectrum; at the same time, the low-frequency PWM (10 Hz) regulates the time-averaged flow rate by cyclically opening/closing the valve (100 ms cycle) to form the two-tier hierarchical control architecture. The drive circuit integrates a microcontroller, current feedback module, and pressure sensor, combined with a control algorithm to dynamically calculate the coil charging time and duty cycle. | After triggering the low-frequency PWM signal, the pressure turn-on and turn-off time averages about 8 ms, and the outlet pressure reaches a steady state after about 15 ms. The average flow rate is highly linear with respect to the low-frequency duty cycle (R2 > 0.99) and possesses robustness to voltage fluctuations (12–13.8 V) and inlet pressure variations (4.14–6.21 bar). However, the system’s steady-state pressure control suffers from deviations (maximum error of 32% between measured pressure and target value), which requires improvement of the algorithm’s accuracy; the mechanical balance of the valve spool is affected by the coupling of the spring preload and the fluid force, which leads to a nonlinear response. |

| [44] | 2014 | It consists of a pressure supply and stabilization unit (including medicine box, plunger pump, accumulator), flow regulation unit (high-speed solenoid valve and pressure sensor), signal acquisition unit (oscilloscope and sampling resistor), and PWM control unit (STC80C52 microcontroller and driving circuit), and the instantaneous flow rate is deduced through the Kalman filter algorithm by processing the data from the pressure sensor. | A high-precision model of PWM duty cycle and spray flow rate (coefficient of determination R2 > 0.995) was established. The system can realize ±6% flow rate control error in the pressure range of 0.2–0.4 MPa, which can effectively reduce the amount of liquid used and have less influence on the droplet size, but its limitations are that the small flow rate control accuracy is significantly affected by pressure fluctuations (error of −5.4%), and the lower limit of the duty cycle adjustment of the PWM signal is higher (≥4% is needed to trigger the solenoid valve action). |

| [45] | 2018 | It consists of 40 XR8004 fan nozzles equipped with individual PWM solenoid valves, a microcontroller unit, and a pressure regulator. The nozzles are connected to eight sets of five-port pneumatic manifolds via polyethylene tubing, and the solenoid valves are driven by a 10 Hz synchronization signal to achieve precise control of the duty cycle (10–100%). | Flow control linearity was good at constant pressure (242 kPa) (slope increased 51–103% with increasing number of nozzles). The system reduces pesticide use by more than 50% and deposits better than a constant spray, but there are significant limitations: at unregulated pressure, an increase in the number of nozzles (1→40) or duty cycle (10%→100%) results in a sudden drop in line pressure from 345 kPa to 104 kPa, causing a flow deviation of up to 27.6%; the PWM control shows flow nonlinearities at both low (<20%) and high (>90%) duty cycles (<20%) and at high (>90%) pressure. During PWM control at low duty cycles (<20%) and high duty cycles (>90%), there is a nonlinear fluctuation in flow rate, and the prediction error of a single nozzle at a 30% duty cycle is 207.9%; the system relies on artificial pressure compensation, and there is a lack of closed-loop feedback control, and the difference between the measured flow rate and the theoretical value under extreme conditions (40 nozzles + 90% duty cycle) is 27.6%. |

| [46] | 2021 | Equipped with the DynaJet® Flex7140 PWM control system and XR8002VS fan nozzle, flow control is achieved by adjusting the duty cycle (30–100%) and forward speed (4–8 km/h) while maintaining a constant pressure (0.4 MPa) to maintain droplet spectrum stability. The system utilizes a 180 mm spaced array of solenoid valves on the vertical spray bar for precise flow regulation, combined with an axial fan directional airflow to enhance droplet canopy penetration. | The system was effective in reducing the spray coverage coefficient of variation (CV% < 25%) at duty cycles ≥50%, and the spray uniformity index (Iu ≈ 0.8) was better than that of the laboratory simulations under field conditions, with optimal deposition densities achieved at application rates of 200–250 L/ha (insecticides) and 300–370 L/ha (fungicides). However, the system suffers from the following limitations: frequent opening and closing of the solenoid valve at low duty cycles (30%) resulted in significant inhomogeneity of spray coverage in both vertical and traveling directions (CV% up to 35%); the effect of PWM on the spray angle (a 40% reduction in duty cycles may result in a 49.8% reduction in spray angle) may affect deposition uniformity in complex canopy environments. |

| [47] | 2022 | It consists of an electromagnetic suction mechanism, two-way water valve, spray body, standard fan nozzle, and other core components. The electromagnetic suction mechanism, through a coil-energized electromagnetic force-driven spool, achieves high-frequency reciprocating motion (frequency 0–40 Hz). Combined with the opening and closing of the two-way water valve, it controls the water flow channel and uses PWM signals to regulate the duty cycle of a single cycle of water channel opening (duty cycle of 7–96%). | Under the conditions of 20 Hz frequency and 0.3 MPa pressure, the system has an average relative error of 3.1% and a maximum error of 13.1% in the spray time of a single cycle in the range of 20–96%. Its limitations are mainly reflected in the low duty cycle interval (7–19%), control stability is poor (average error of 7.5%, the maximum error of 55.1%), and the system pressure exceeds a 0.5 MPa spool reset force, which is insufficient to lead to delayed closure, while the selection of the PWM frequency needs to be dynamically adjusted according to the operating speed (critical frequency of 1–26 Hz corresponds to the speed of 1–10 km/h), and spray uniformity is speed-dependent. |

| [48] | 2023 | The system consists of a host computer (HMI serial screen), spray controller (with PIC18F258 microcontroller as the core), electronic switch, and solenoid electronically controlled nozzle body, and data communication is realized through CAN bus. The system receives the parameters of pesticide application through the host computer, and the spray controller calculates the corresponding PWM duty cycle and outputs multiple independent signals, which control the nozzle solenoid valve on/off time through the MOS electronic switch to realize flow adjustment of a single nozzle. | Under a pressure of 0.3–0.5 MPa and frequency of 10 Hz, the flow rate of the nozzle is highly linear with the duty cycle (R2 > 0.95), the maximum response time is 0.179 s, the on/off time RMS error is ≤2.54 ms, and the relative error is ≤6.8%, which provides accurate control of the application of pesticides. However, there is a linear deviation phenomenon that slows down the flow growth rate after the duty cycle exceeds 80%, and the relative error is higher (up to 6.8%) in low duty cycle intervals (30–50%). |

| [49] | 2024 | It consists of a liquid tank, diaphragm pump, pressure stabilizing tank, PWM controller, solenoid valve, and pressure gauge, etc. The delayed opening and closing of the solenoid valve is controlled by an STM32F103 microcontroller, which realizes the asynchronous working mode of multiple nozzles. | Asynchronous opening and closing can significantly reduce the pipeline pressure pulse, it has a 50% duty cycle pressure peak reduction of up to 14%, the coefficient of variation of pressure fluctuates with the increase and decrease in PWM frequency, the nozzle flow rate and duty cycle have a good linear relationship (R2 ≥ 0.90), the ST03 nozzle flow rate has an adjustable range of 0.28–1.22 L/min, asynchronous PWM spray deposition distribution has a frequency of 20 Hz, and the coefficient of variation (CV) of uniformity is less than 15%. However, the solenoid valve responds abnormally at low duty cycles (20%) under high-frequency conditions (e.g., 20 Hz), resulting in pressure peaks that cannot be effectively controlled. Asynchronous mode reduces pressure fluctuations, but pressure pulsation still affects the accuracy of flow regulation (maximum error 12–15%). |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jiao, Y.; Zhang, S.; Jin, Y.; Cui, L.; Chang, C.; Ding, S.; Sun, Z.; Xue, X. Research Progress on Intelligent Variable-Rate Spray Technology for Precision Agriculture. Agronomy 2025, 15, 1431. https://doi.org/10.3390/agronomy15061431

Jiao Y, Zhang S, Jin Y, Cui L, Chang C, Ding S, Sun Z, Xue X. Research Progress on Intelligent Variable-Rate Spray Technology for Precision Agriculture. Agronomy. 2025; 15(6):1431. https://doi.org/10.3390/agronomy15061431

Chicago/Turabian StyleJiao, Yuxuan, Songchao Zhang, Yongkui Jin, Longfei Cui, Chun Chang, Suming Ding, Zhu Sun, and Xinyu Xue. 2025. "Research Progress on Intelligent Variable-Rate Spray Technology for Precision Agriculture" Agronomy 15, no. 6: 1431. https://doi.org/10.3390/agronomy15061431

APA StyleJiao, Y., Zhang, S., Jin, Y., Cui, L., Chang, C., Ding, S., Sun, Z., & Xue, X. (2025). Research Progress on Intelligent Variable-Rate Spray Technology for Precision Agriculture. Agronomy, 15(6), 1431. https://doi.org/10.3390/agronomy15061431