Characteristics of the Liquid Sheet of Air-Induction Spray

Abstract

1. Introduction

2. Materials and Methods

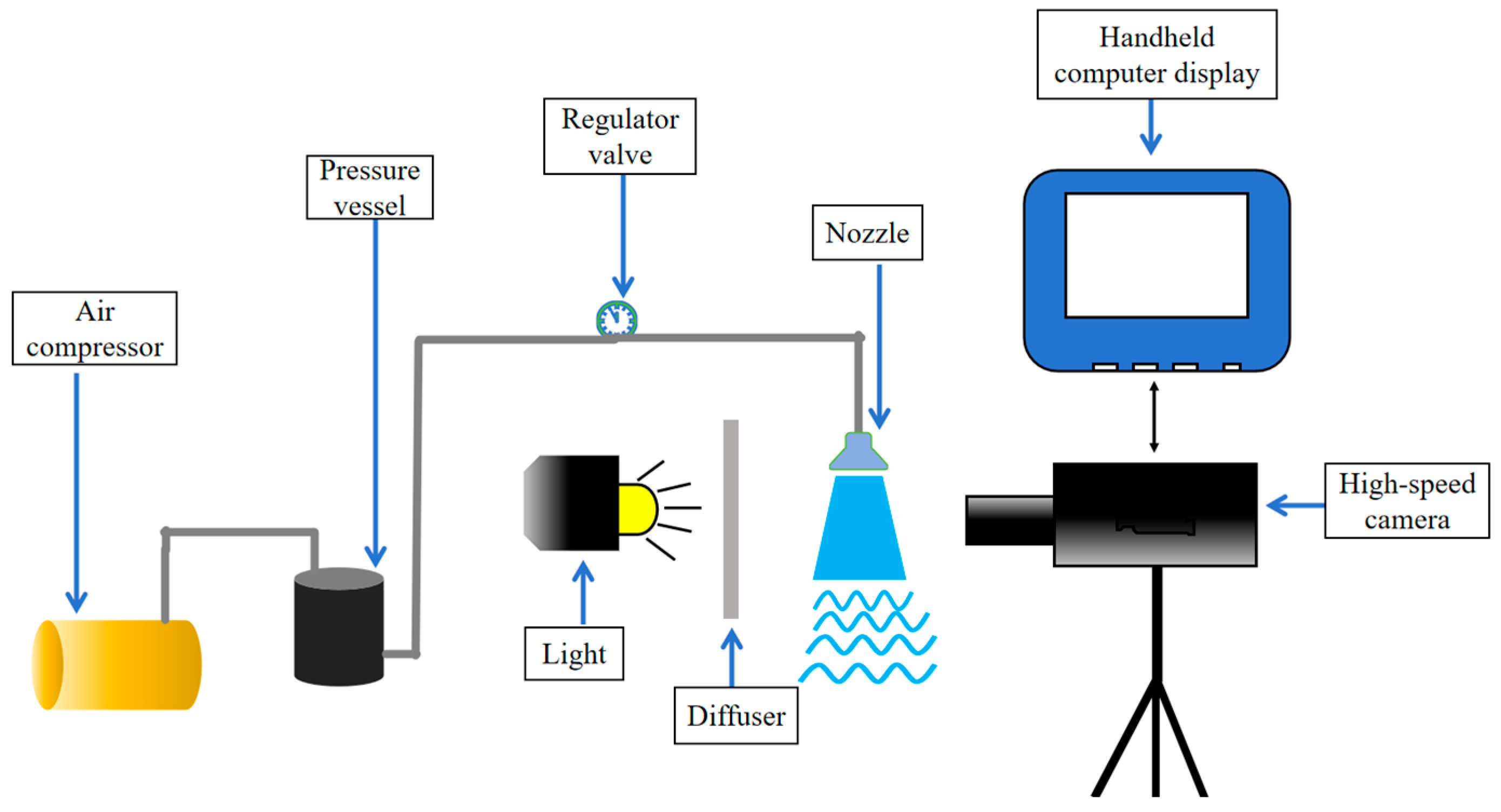

2.1. Experimental Setup

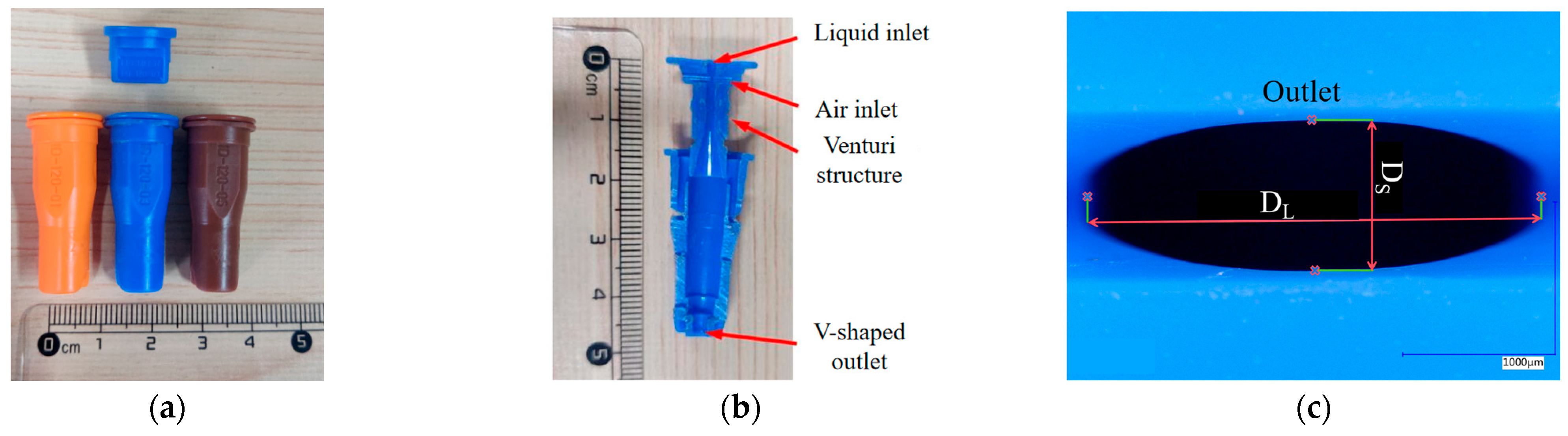

2.2. Structure of the Air-Induction Nozzle

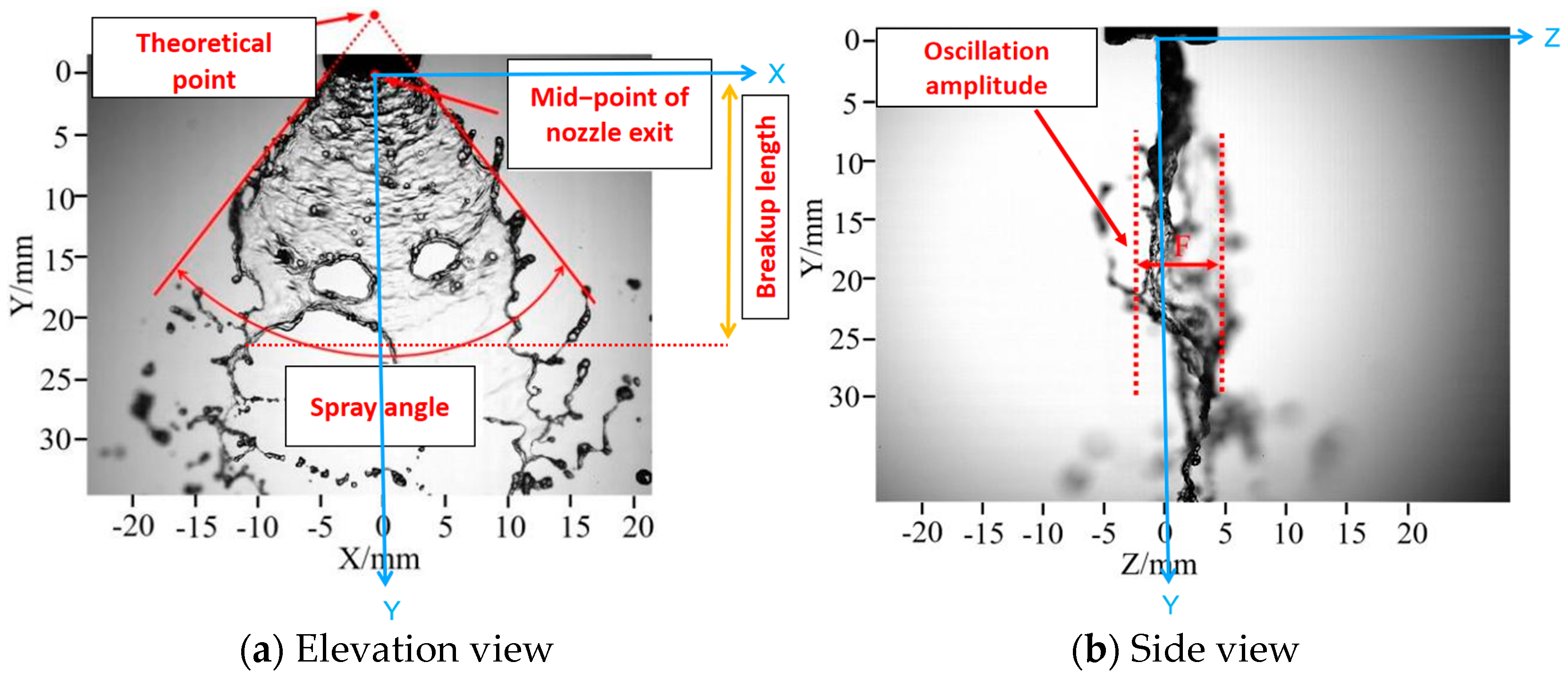

2.3. Image Processing

3. Results and Discussion

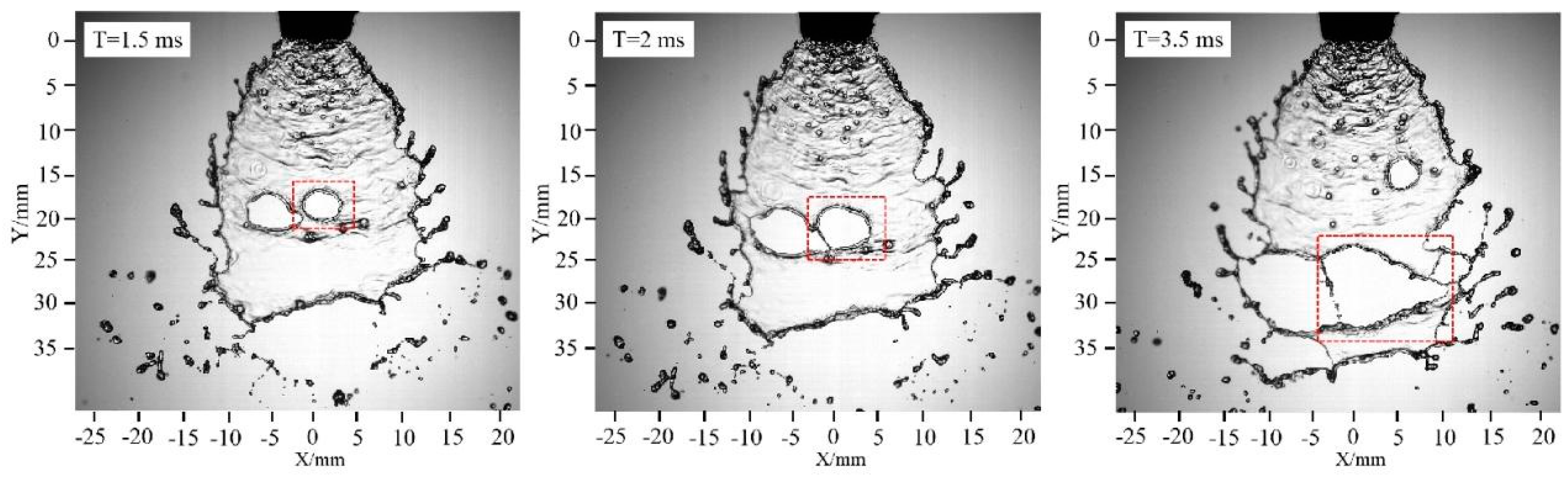

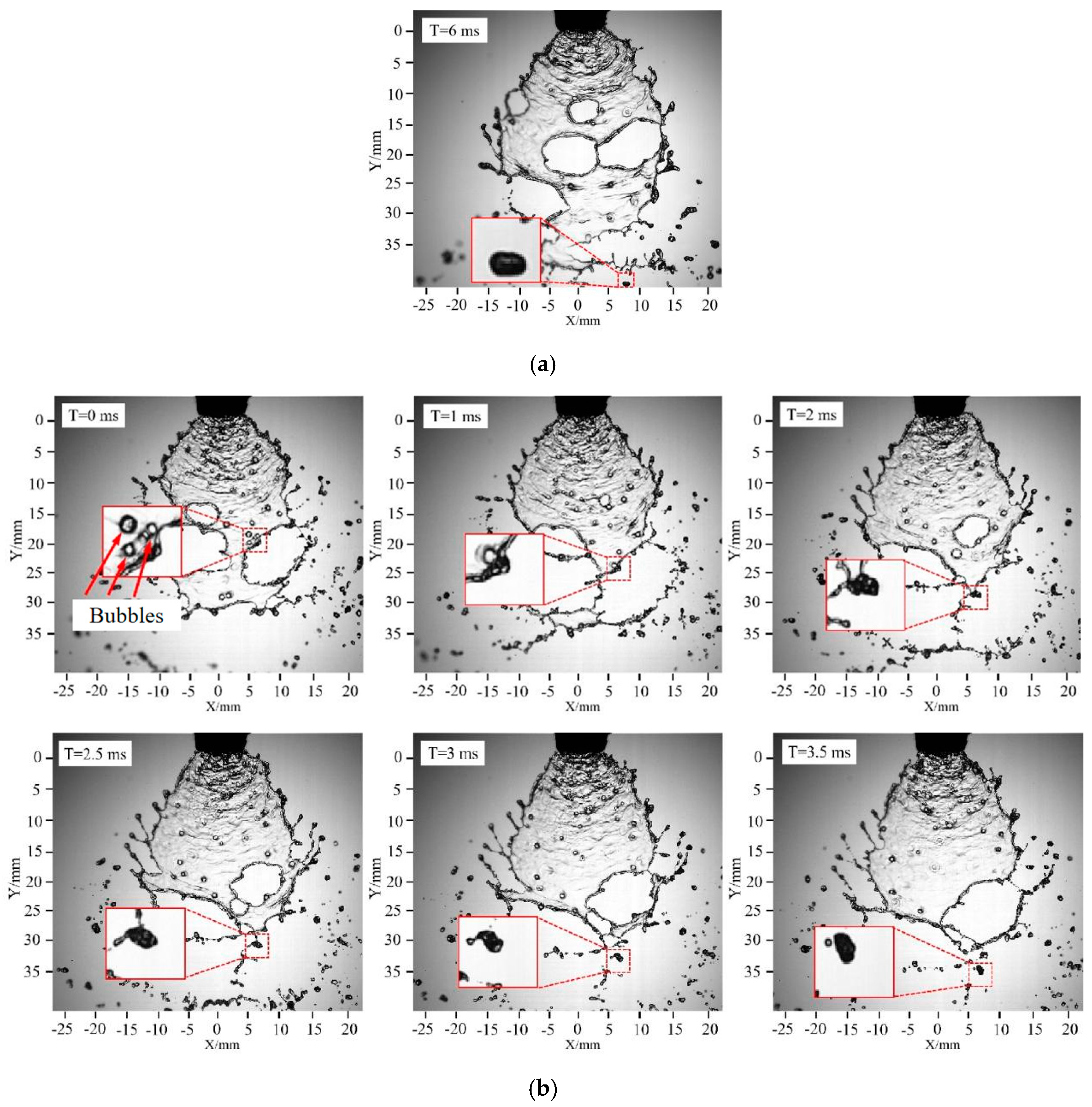

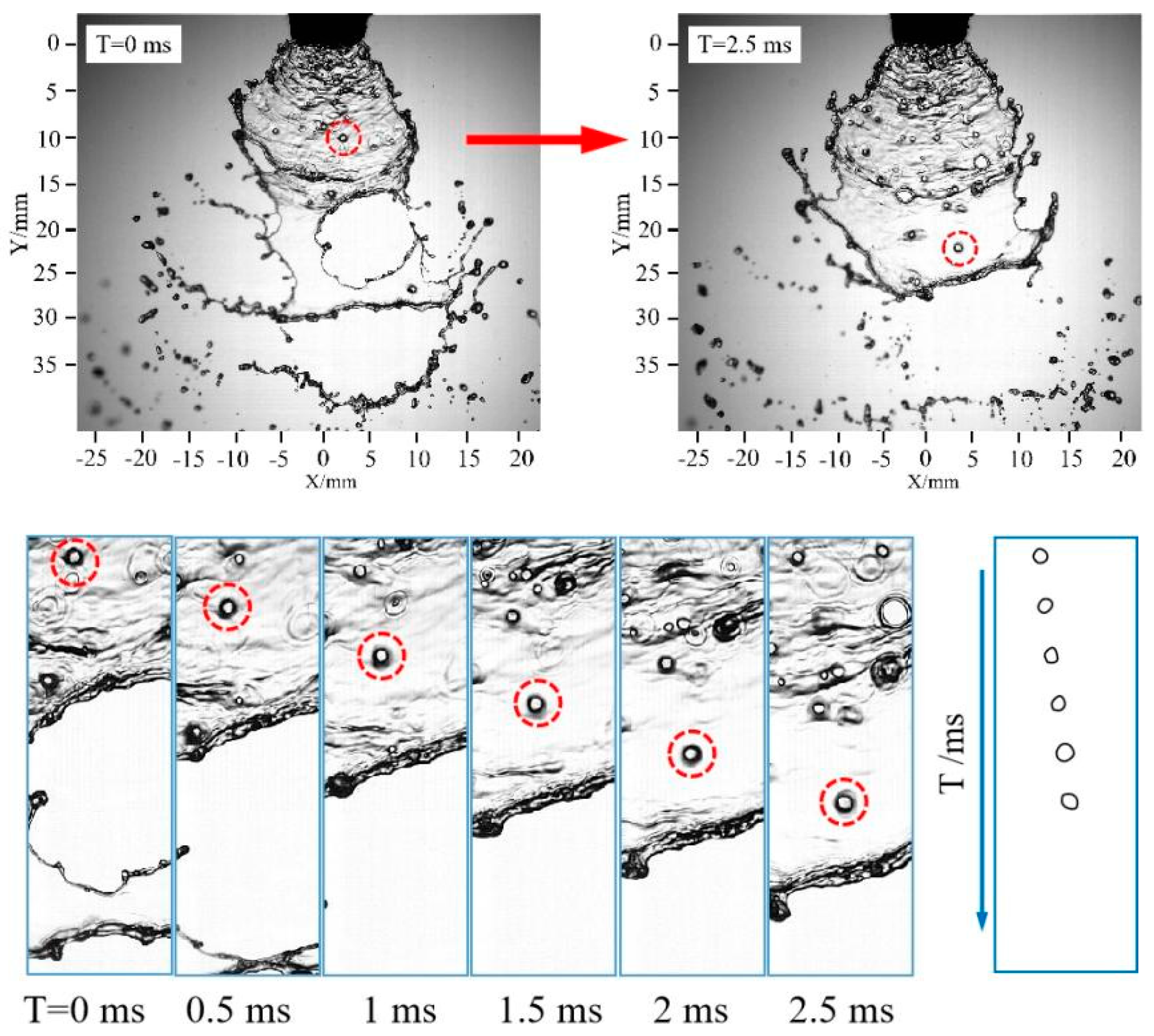

3.1. Study on Atomization and Disintegration Characteristics of Air-Induction Liquid Sheet

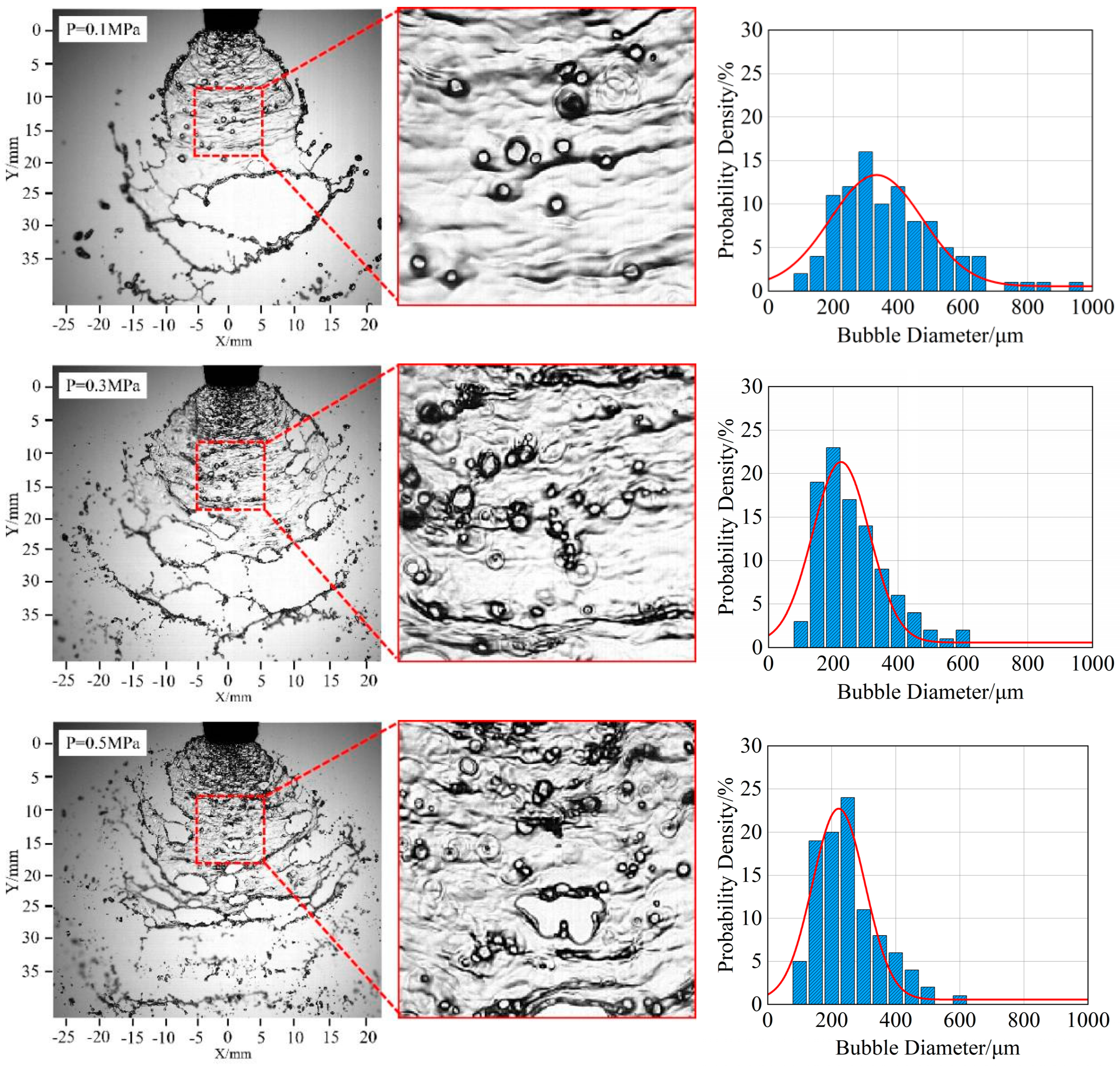

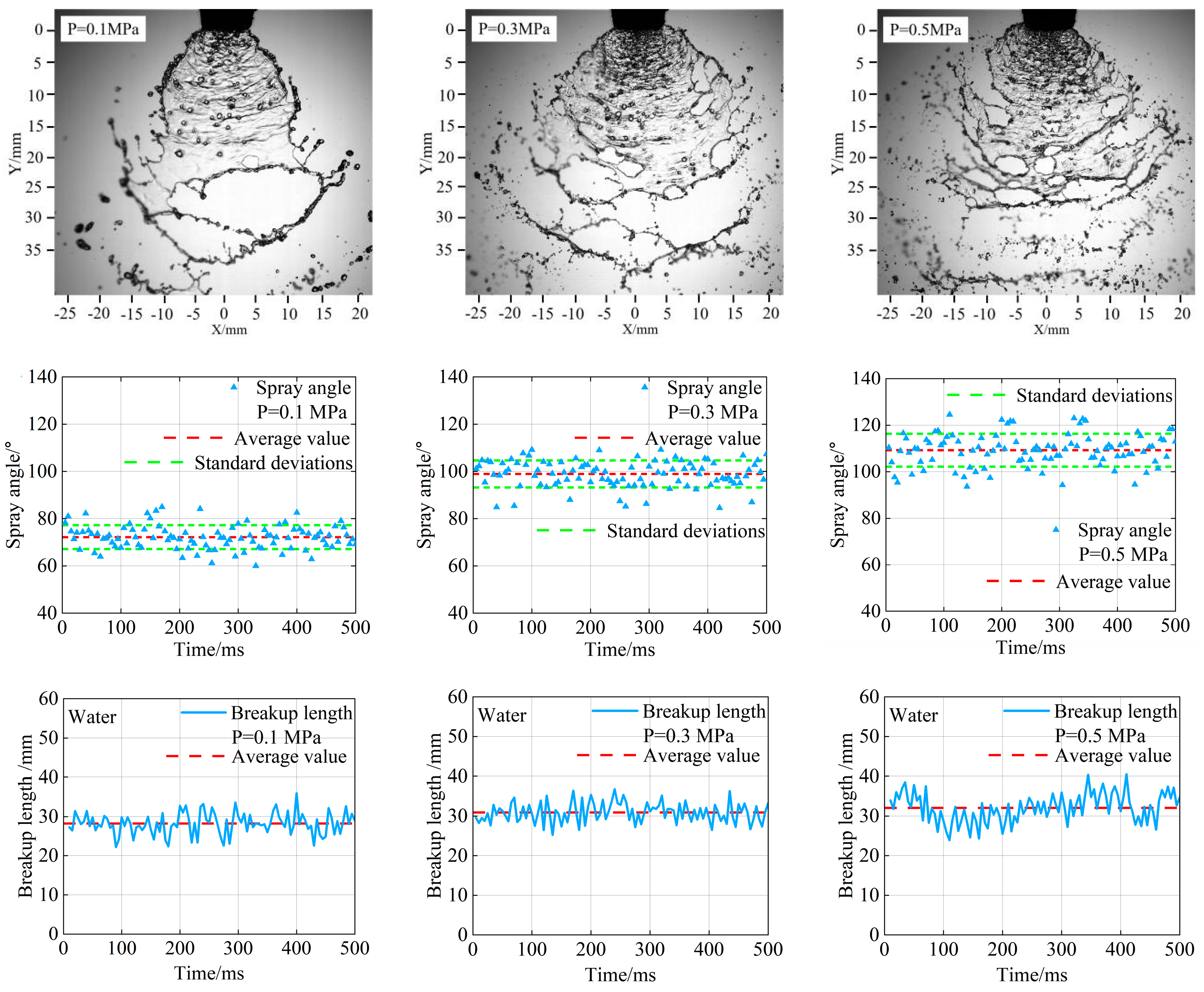

3.2. The Effect of Spray Pressure on Liquid Sheet of Air-Induction Spray

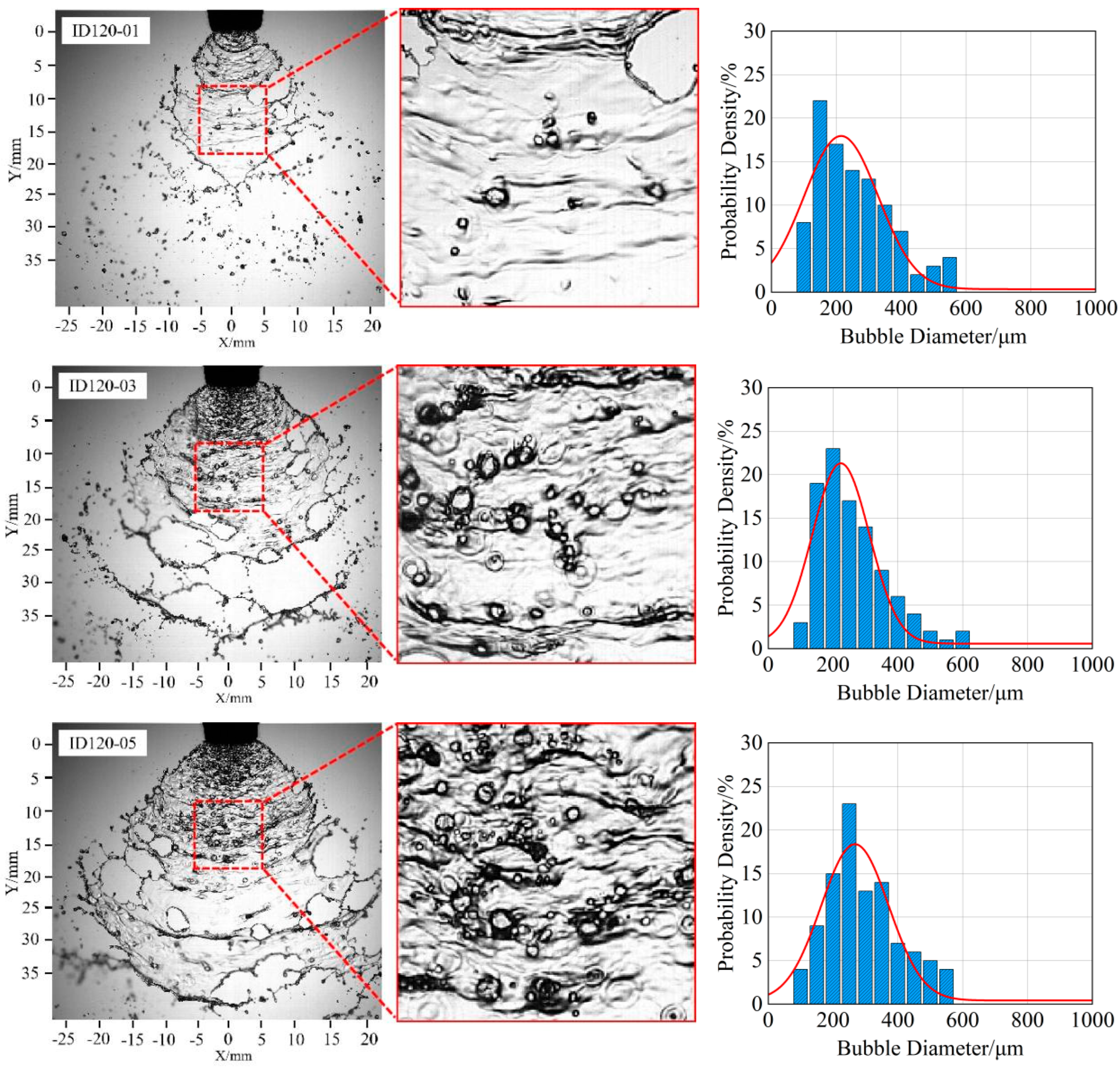

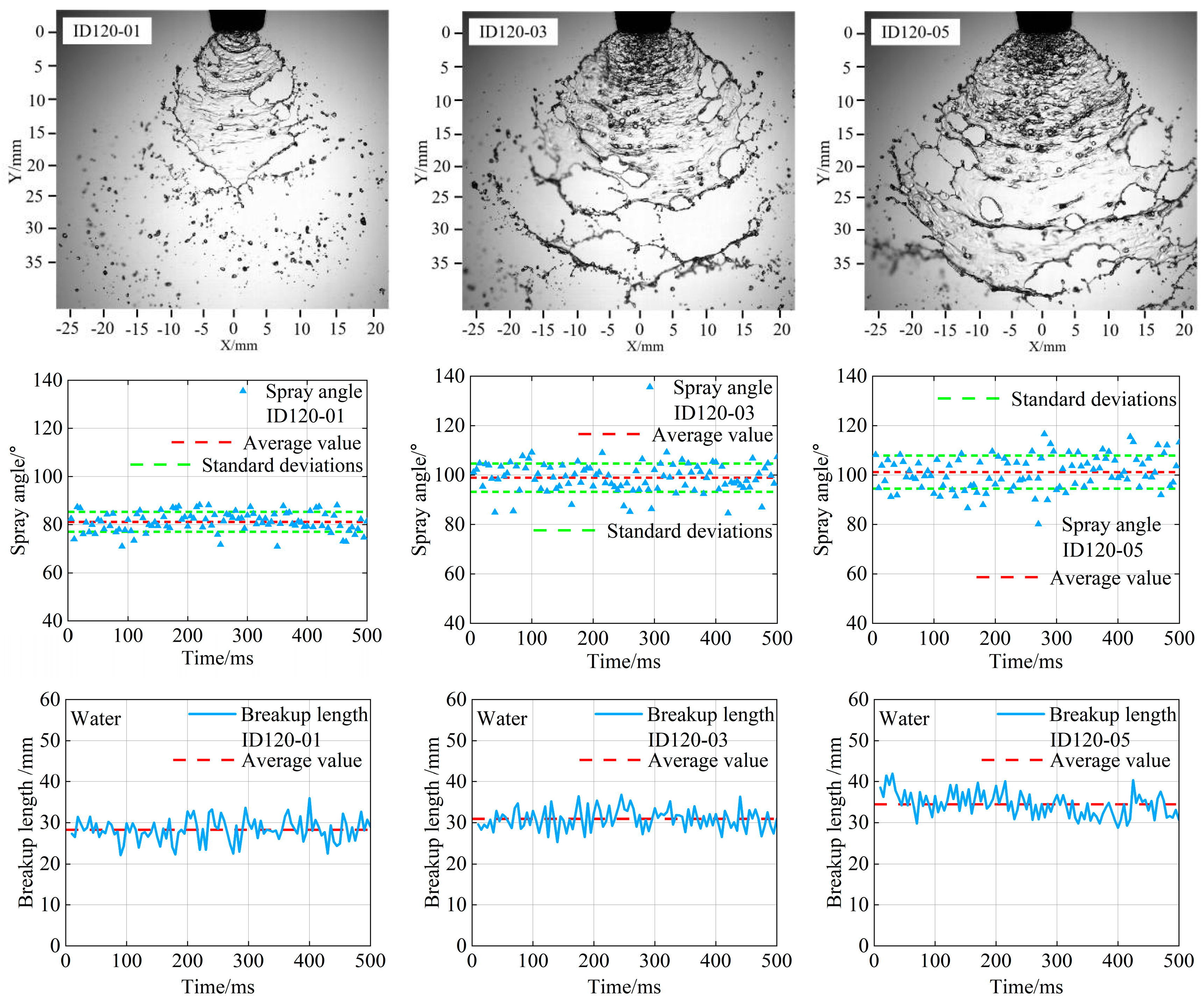

3.3. The Effect of Nozzle Structure on Liquid Sheet of Air-Induction Spray

4. Conclusions

- (1)

- Air-induction sprays have a distinct liquid sheet disintegration structure compared to standard flat-fan sprays, with significant bubble and perforation presence on the liquid sheet. Bubble rupture induces perforation, increasing the sheet’s lateral oscillation amplitude. Differences in nozzle configuration, affecting structural dimensions and liquid sheet disintegration, significantly influence the spray angle and disintegration length. Compared to standard flat-fan sprays, air-induction sprays have smaller liquid sheet spray angles and disintegration lengths, by 23.48% and 16.32%, respectively.

- (2)

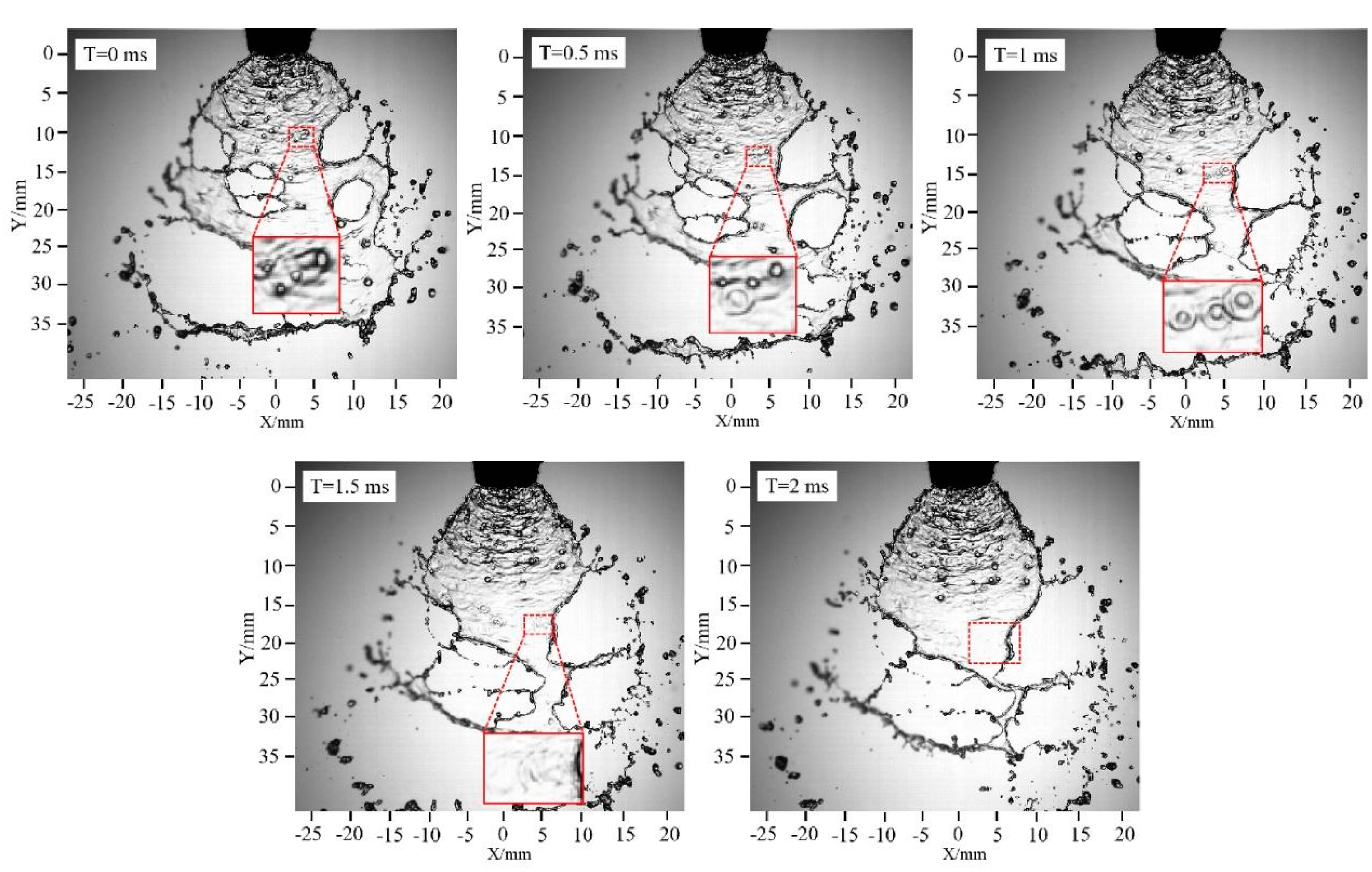

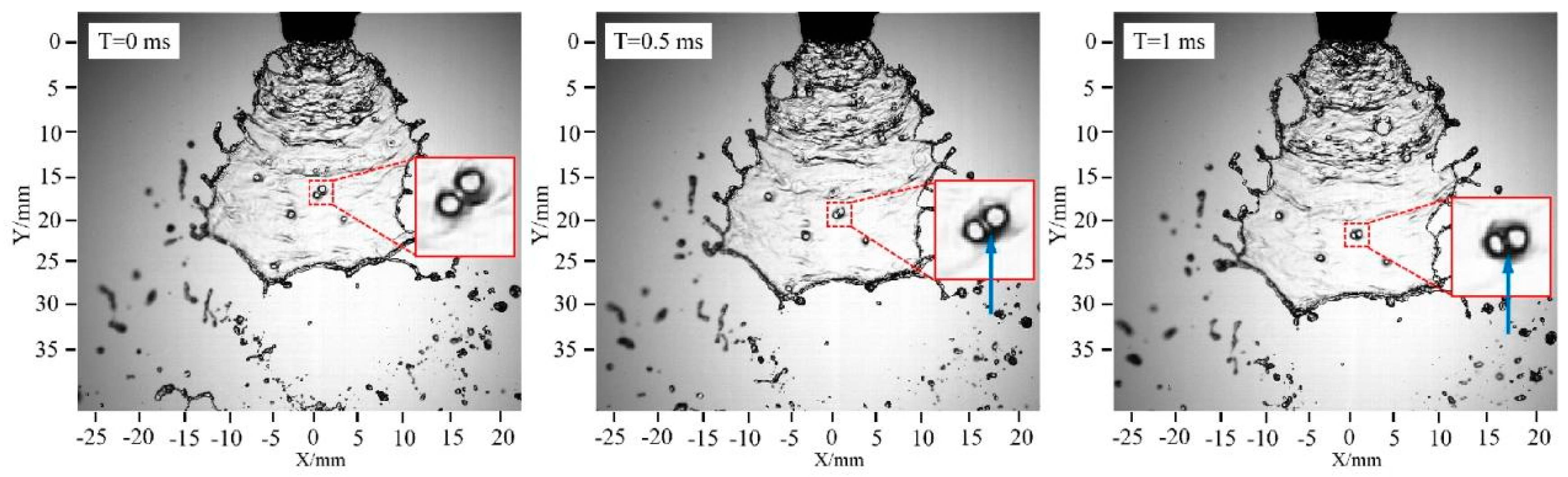

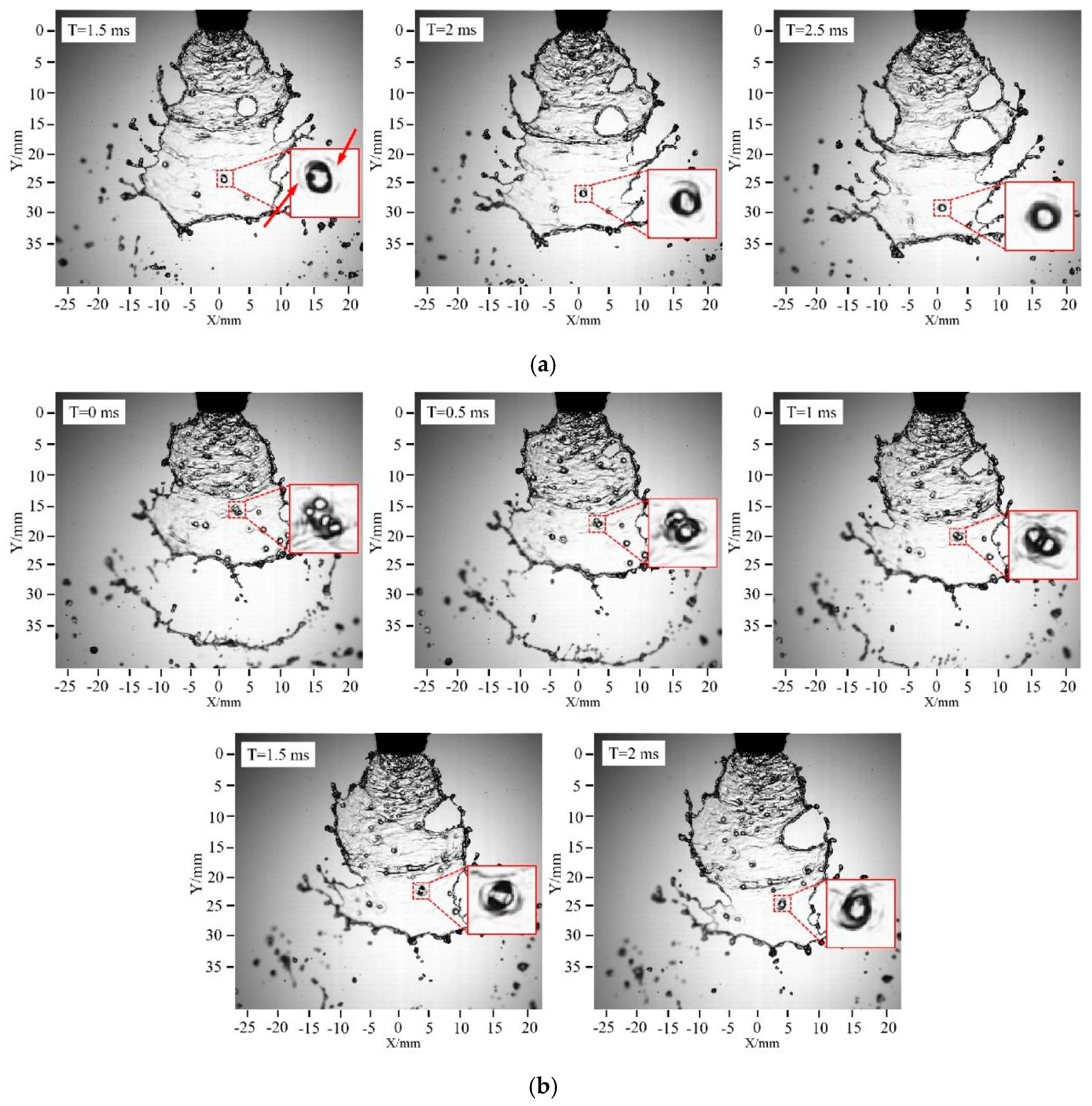

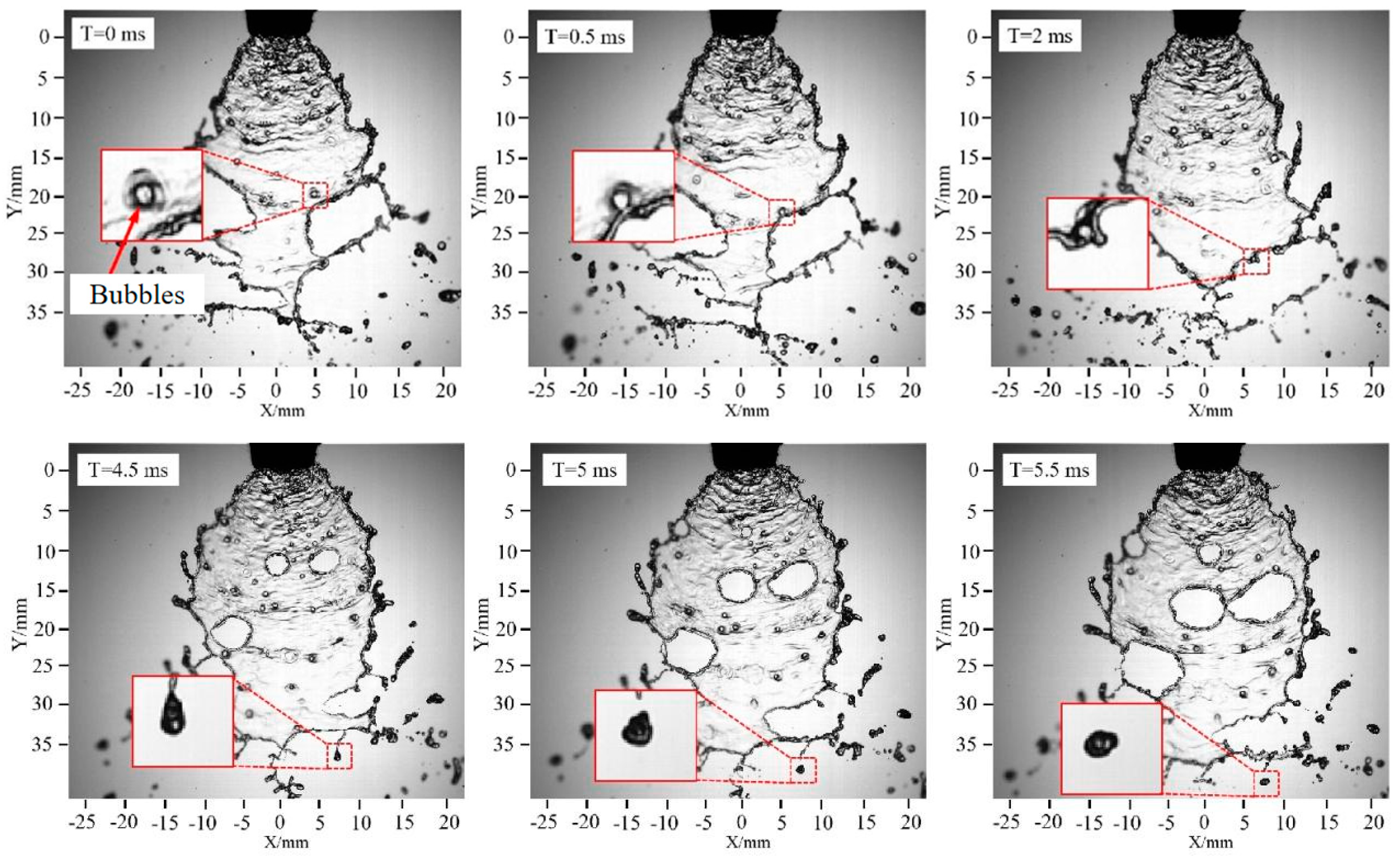

- High-speed photography captured spray images, visually illustrating the evolution of bubble flow on the liquid sheet. Observed behaviors include direct perforation from bubble rupture, perforation induced by bubble rupture, ripple formation from bubble rupture, bubble coalescence leading to reduced bubble count and increased size, and the formation process of bubble-containing droplets.

- (3)

- Increased spray pressure decreases the average bubble size but increases bubble count on the liquid sheet. Bubble size distributions at different spray pressures fit normal distributions. At 0.1 MPa, the bubble size distribution is widest with the fewest small bubbles; at 0.5 MPa, it narrows with more small bubbles. Higher spray pressure also intensifies liquid sheet disintegration, increasing the spray angle and disintegration length. Larger nozzle models (ID120-01 to ID120-05) increase both average bubble size and count. Bubble size distributions for different nozzles also fit normal distributions. Larger nozzles result in bigger spray angles and disintegration lengths. The ID120-01 nozzle, with the smallest primary dimensions, produces the smallest spray angle and disintegration length.

- (4)

- The spray liquid sheet from an air-induction nozzle contains bubbles, complicating the sheet’s characteristics. This study only explores the characteristics of the spray liquid sheet from an air-induction nozzle under pure water conditions. Further research is needed on the characteristics of the spray liquid sheet from an air-induction nozzle with more complex medicinal solutions.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Ma, J.; Liu, K.; Dong, X.; Huang, X.; Ahmad, F.; Qiu, B. Force and motion behaviour of crop leaves during spraying. Biosyst. Eng. 2023, 235, 83–99. [Google Scholar] [CrossRef]

- Qin, W.-C.; Qiu, B.-J.; Xue, X.-Y.; Chen, C.; Xu, Z.-F.; Zhou, Q.-Q. Droplet deposition and control effect of insecticides sprayed with an unmanned aerial vehicle against plant hoppers. Crop Prot. 2016, 85, 79–88. [Google Scholar] [CrossRef]

- Shen, Y.; Zhu, H.; Liu, H.; Chen, Y.; Ozkan, E. Development of a Laser-Guided, Embedded-Computer-Controlled, Air-Assisted Precision Sprayer. Trans. Asabe 2017, 60, 1827–1838. [Google Scholar] [CrossRef]

- Ahmad, F.; Zhang, S.; Qiu, B.; Ma, J.; Xin, H.; Qiu, W.; Ahmed, S.; Chandio, F.A.; Khaliq, A. Comparison of Water Sensitive Paper and Glass Strip Sampling Approaches to Access Spray Deposit by UAV Sprayers. Agronomy 2022, 12, 1302. [Google Scholar] [CrossRef]

- Li, J.; Nie, Z.; Chen, Y.; Ge, D.; Li, M. Development of Boom Posture Adjustment and Control System for Wide Spray Boom. Agriculture 2023, 13, 2162. [Google Scholar] [CrossRef]

- Zhang, C.; Zhai, C.; Zhang, M.; Zhang, C.; Zou, W.; Zhao, C. Staggered-Phase Spray Control: A Method for Eliminating the Inhomogeneity of Deposition in Low-Frequency Pulse-Width Modulation (PWM) Variable Spray. Agriculture 2024, 14, 465. [Google Scholar] [CrossRef]

- Shi, Q.; Mao, H.; Guan, X. Numerical Simulation and Experimental Verification of the Deposition Concentration of an Unmanned Aerial Vehicle. Appl. Eng. Agric. 2019, 35, 367–376. [Google Scholar] [CrossRef]

- Ferguson, J.C.; Chechetto, R.G.; Adkins, S.W.; Hewitt, A.J.; Chauhan, B.S.; Kruger, G.R.; O’Donnell, C.C. Effect of spray droplet size on herbicide efficacy on four winter annual grasses. Crop Prot. 2018, 112, 118–124. [Google Scholar] [CrossRef]

- Liao, J.; Hewitt, A.J.; Wang, P.; Luo, X.; Zang, Y.; Zhou, Z.; Lan, Y.; O’Donnell, C. Development of droplet characteristics prediction models for air induction nozzles based on wind tunnel tests. Int. J. Agric. Biol. Eng. 2019, 12, 1–6. [Google Scholar] [CrossRef]

- Liao, J.; Luo, X.; Wang, P.; Zhou, Z.; O’Donnell, C.C.; Zang, Y.; Hewitt, A.J. Analysis of the Influence of Different Parameters on Droplet Characteristics and Droplet Size Classification Categories for Air Induction Nozzle. Agronomy 2020, 10, 256. [Google Scholar] [CrossRef]

- Wang, C.; Zeng, A.; He, X.; Song, J.; Herbst, A.; Gao, W. Spray drift characteristics test of unmanned aerial vehicle spray unit under wind tunnel conditions. Int. J. Agric. Biol. Eng. 2020, 13, 13–21. [Google Scholar] [CrossRef]

- Gong, C.; Li, D.; Yan, S.; Kang, C.; Ding, K. Relation between bubble behaviors in spray sheet and bubbly flow inside an air-induction fan nozzle: A visualization study. Phys. Fluids 2024, 36, 103362. [Google Scholar] [CrossRef]

- Abdelmotalib, H.M.; Dafsari, R.A.; Seung-Hwa, Y.; Lee, J. Computational study of internal flow characteristics of the air induction nozzle. Int. J. Mech. Sci. 2021, 204, 106578. [Google Scholar] [CrossRef]

- Butts, T.R.; Luck, J.D.; Fritz, B.K.; Hoffmann, W.C.; Kruger, G.R. Evaluation of spray pattern uniformity using three unique analyses as impacted by nozzle, pressure, and pulse-width modulation duty cycle. Pest Manag. Sci. 2019, 75, 1875–1886. [Google Scholar] [CrossRef] [PubMed]

- Post, S.L.; Hewitt, A.J. Flat-Fan Spray Atomization Model. Trans. Asabe 2018, 61, 1249–1256. [Google Scholar] [CrossRef]

- Post, S.L. Drift of Droplets from Air-Induction Nozzles. Trans. Asabe 2019, 62, 1683–1687. [Google Scholar] [CrossRef]

- Dafsari, R.A.; Yu, S.; Choi, Y.; Lee, J. Effect of geometrical parameters of air-induction nozzles on droplet characteristics and behaviour. Biosyst. Eng. 2021, 209, 14–29. [Google Scholar] [CrossRef]

- McArtney, S.J.; Obermiller, J.D. Comparative performance of air-induction and conventional nozzles on an axial fan sprayer in medium density apple orchards. Horttechnology 2008, 18, 365–371. [Google Scholar] [CrossRef]

- Vallet, A.; Tinet, C. Characteristics of droplets from single and twin jet air induction nozzles: A preliminary investigation. Crop Prot. 2013, 48, 63–68. [Google Scholar] [CrossRef]

- Cryer, S.A.; Altieri, A.L. Role of large inhomogeneities in initiating liquid sheet breakup in agricultural atomisation. Biosyst. Eng. 2017, 163, 103–115. [Google Scholar] [CrossRef]

- Cryer, S.A.; Altieri, A.L.; Schmucker, A.L.; Day, K.M. Minimising atomisation drift potential by exploring the break-up of liquid sheets using multiphase methylated soybean and silicon oil emulsions. Biosyst. Eng. 2021, 202, 142–151. [Google Scholar] [CrossRef]

- Miller, P.C.H.; Ellis, M.C.B. Effects of formulation on spray nozzle performance for applications from ground-based boom sprayers. Crop Prot. 2000, 19, 609–615. [Google Scholar] [CrossRef]

- Altieri, A.L.; Cryer, S.A. Break-up of sprayed emulsions from flat-fan nozzles using a hole kinematics model. Biosyst. Eng. 2018, 169, 104–114. [Google Scholar] [CrossRef]

- Vernay, C. Destabilisation of Liquid Sheets of Dilute Emulsions; Université Montpellier: Montpellier, France, 2015. [Google Scholar]

- Chen, G.; Dongyang, L.; Can, K. Visualisation of the evolution of bubbles in the spray sheet discharged from the air-induction nozzle. Pest Manag. Sci. 2022, 78, 1850–1860. [Google Scholar]

- Hu, J.; Liu, C.; Wang, Z.; Li, Y.; Song, J.; Liu, Y.; Chu, X. Motion model for describing the quantity of air in droplets through changing the structure of air induction nozzle. Int. J. Agric. Biol. Eng. 2021, 14, 35–40. [Google Scholar] [CrossRef]

- Brackbill, J.U.; Kothe, D.B.; Zemach, C. A continuum method for modeling surface tension. J. Comput. Phys. 1992, 100, 335–354. [Google Scholar] [CrossRef]

- Duangsuwan, W.; Tuzun, U.; Sermon, P.A. The Dynamics of Single Air Bubbles and Alcohol Drops in Sunflower Oil at Various Temperatures. Aiche J. 2011, 57, 897–910. [Google Scholar] [CrossRef]

- Glover, G.M.C.; Generalis, S.C. The modelling of buoyancy driven flow in bubble columns. Chem. Eng. Process.-Process Intensif. 2004, 43, 101–115. [Google Scholar] [CrossRef]

- Ghosh, P. A comparative study of the film-drainage models for coalescence of drops and bubbles at flat interface. Chem. Eng. Technol. 2004, 27, 1200–1205. [Google Scholar] [CrossRef]

- Harris, P.J. An investigation into the use of the boundary integral method to model the motion of a single gas or vapour bubble in a liquid. Eng. Anal. Bound. Elem. 2004, 28, 325–332. [Google Scholar] [CrossRef]

- Ohta, M.; Imura, T.; Yoshida, Y.; Sussman, M. A computational study of the effect of initial bubble conditions on the motion of a gas bubble rising in viscous liquids. Int. J. Multiph. Flow 2005, 31, 223–237. [Google Scholar] [CrossRef]

| Nozzle Type | Liquid Inlet Diameter Dl/mm | Air Inlet Diameter Da/mm | V-Notch Angle a/° | Long Axis Diameter of Nozzle Outlet DL/mm | Short Axis Diameter of Nozzle Outlet DS/mm |

|---|---|---|---|---|---|

| LU120-03 | - | - | 16 | 2.47 | 0.44 |

| ID120-01 | 0.72 | 1.41 | 26 | 2.10 | 0.50 |

| ID120-03 | 1.29 | 1.54 | 31 | 2.98 | 0.99 |

| ID120-05 | 1.73 | 1.96 | 34 | 4.12 | 1.19 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yan, M.; Chen, F.; Gong, C.; Kang, C. Characteristics of the Liquid Sheet of Air-Induction Spray. Agronomy 2025, 15, 1270. https://doi.org/10.3390/agronomy15061270

Yan M, Chen F, Gong C, Kang C. Characteristics of the Liquid Sheet of Air-Induction Spray. Agronomy. 2025; 15(6):1270. https://doi.org/10.3390/agronomy15061270

Chicago/Turabian StyleYan, Mingzhi, Fujun Chen, Chen Gong, and Can Kang. 2025. "Characteristics of the Liquid Sheet of Air-Induction Spray" Agronomy 15, no. 6: 1270. https://doi.org/10.3390/agronomy15061270

APA StyleYan, M., Chen, F., Gong, C., & Kang, C. (2025). Characteristics of the Liquid Sheet of Air-Induction Spray. Agronomy, 15(6), 1270. https://doi.org/10.3390/agronomy15061270