1. Introduction

The partial or complete preparation of fresh vegetables for direct consumption includes operations to remove inedible parts of the plant material (e.g., peel), as well as washing, trimming, cutting, and coring. Such vegetables are very perishable during storage, transport, and distribution because tissue damage causes an increase in physiological, biochemical, and microbiological intensity. A low temperature and an altered composition of the atmosphere during storage are most often used to inhibit these changes. Various tests have been performed with different post-cutting treatments to improve the storage ability and lengthen the shelf life of fresh-cut vegetables [

1]. One of them is hot water treatment (HWT). It is a non-chemical technology that is friendly to users, consumers, and the environment [

2,

3].

HWT with simultaneous gentle brushing has been commercially used for years in Israel for whole fruits and vegetables, such as sweet corn, persimmon, sweet peppers, melon, mango, avocado, orange, grapefruit, kumquat, and organic citrus fruit [

2]. HWT with temperatures of up to 60 °C reduces respiration in many species of fruits and vegetables, reduces ethylene production, delays ripening, and reduces pathogen infestation [

4,

5,

6,

7]. A high temperature (10 °C above the normal growing temperature) also promotes the formation of new proteins (heat stress proteins—HSPs) in the place of proteins found in untreated products [

4,

8,

9]. The accumulation of HSPs provides protection against stressors, both those that cause their biosynthesis and those occurring during storage, as well as against infectious and physiological diseases [

10,

11]. Salveit [

12] reports that heat shock induces the synthesis of HSPs in the place of wound-induced enzymes of phenylpropanoid metabolism. This may be a new way to control the browning of minimally processed vegetables and fruits. The effect of HWT on freshly harvested horticultural produce depends on the temperature applied and the time of treatment. According to Fallik and Ilic [

13], factors such as the cultivation method, the cultivar, the stage of maturity at harvest, and storage conditions also affect the result of the treatment.

The cultivation and consumption of sweet peppers is growing worldwide, and much attention is being paid to both production methods and storage options. HWT technology turned out to be helpful because it was found that immersing whole bell pepper fruits for 3 min in water at 50 °C markedly reduced the damage caused by the fungi

Botrytis cinerea and

Alternaria alternata during storage [

14]. Red sweet peppers treated with hot water at 55 °C for 1 min showed less development of chilling injury, electrolyte leakage, and weight loss during 4 weeks of storage at 10 °C [

15]. Hot water rinsing and brushing (HWRB) with a temperature of 55 ± 1 °C for 12 ± 2 s effectively cleaned and disinfected peppers and contributed to maintaining better quality and improving storage life [

2]. A beneficial effect of HWRB was reported also for other products: tomatoes (52 °C–15 s), apples (55 °C for 15 s), organically grown citrus (56 or 60 °C for 10 s), litchis (55 °C for 20 s), mangoes (55 °C–15–20 s), and others [

2,

16]. According to Zong et al. [

17], the HWT of a tomato in water at 42 °C for 40 min helped reduce the development of gray mold on the fruit. However, excessive hot water treatment (55 °C for 3 or 5 min) can lead to damage to the fruit tissue [

15].

Numerous studies indicate that HWT can improve the shelf life of cut vegetables during short-term storage. Brief immersion in hot water at 53 or 55 °C essentially delayed the quality degradation of fresh-cut Chinese cabbage during storage at 0, 5, and 15 °C [

18]. In a study by Loaiza-Velarde and Saltveit [

19], crisp lettuce nerve sections treated with hot water at 50 °C for 90 s showed less browning of the tissue and the delayed loss of their green color compared to untreated pieces. Also, nerve sections of romaine lettuce treated with hot water at 45 °C for 2.5 min showed less tendency to brown during storage than untreated sections [

20]. Freshly sliced pears treated with water at 35–45 °C for a period of 40–150 min avoided surface browning and maintained better firmness [

21]. In a study by Koukonaras [

22], treating peaches with water at 50 °C for 10 min prior to cutting also delayed the browning and softening of the slices. The hot shock of spinach leaves at 40 °C delayed senescence and improved postharvest storage ability [

23]. Green bell peppers exposed to hot water (55 and 60 °C for 3 min) and cut after treatment maintained a better sensory quality during storage at 4 and 10 °C than untreated samples [

24]. Rodoni et al. [

25] recommend, for unripe cut peppers, a HWT at 45 and 60 °C for 3 min, while a treatment at 45 °C for 3 min is adequate for mature red-fruit peppers. On the other hand, treating leek pseudostems with hot water at 50–57.5 °C contributed only slightly to maintaining a better color through 9 d of storage at 4 °C [

26]. According to Salveit [

8], the application of hot water to the cut material replaces the rinsing step, and the subsequent removal of residual water is easier due to its weaker adhesion to the plant surface.

The purpose of this study was to evaluate the quality and determine the morphological changes occurring during the short-term storage of fresh-cut red- and cream-fruit peppers treated with hot water. The evaluation was carried out through morphological observations and microscopic analyses. Preliminary tests by Grzegorzewska [

27] with fresh-cut yellow peppers, Sunny F1, showed that the use of hot water helps to inhibit softening and thus maintain better quality during short-term storage. Also, an unpublished study with fresh-cut peppers, “Yecla” and “Blondy”, packed in PE bags indicated a beneficial effect of HWT on their quality during short-term storage and shelf life.

2. Materials and Methods

2.1. Plant Material and Treatments

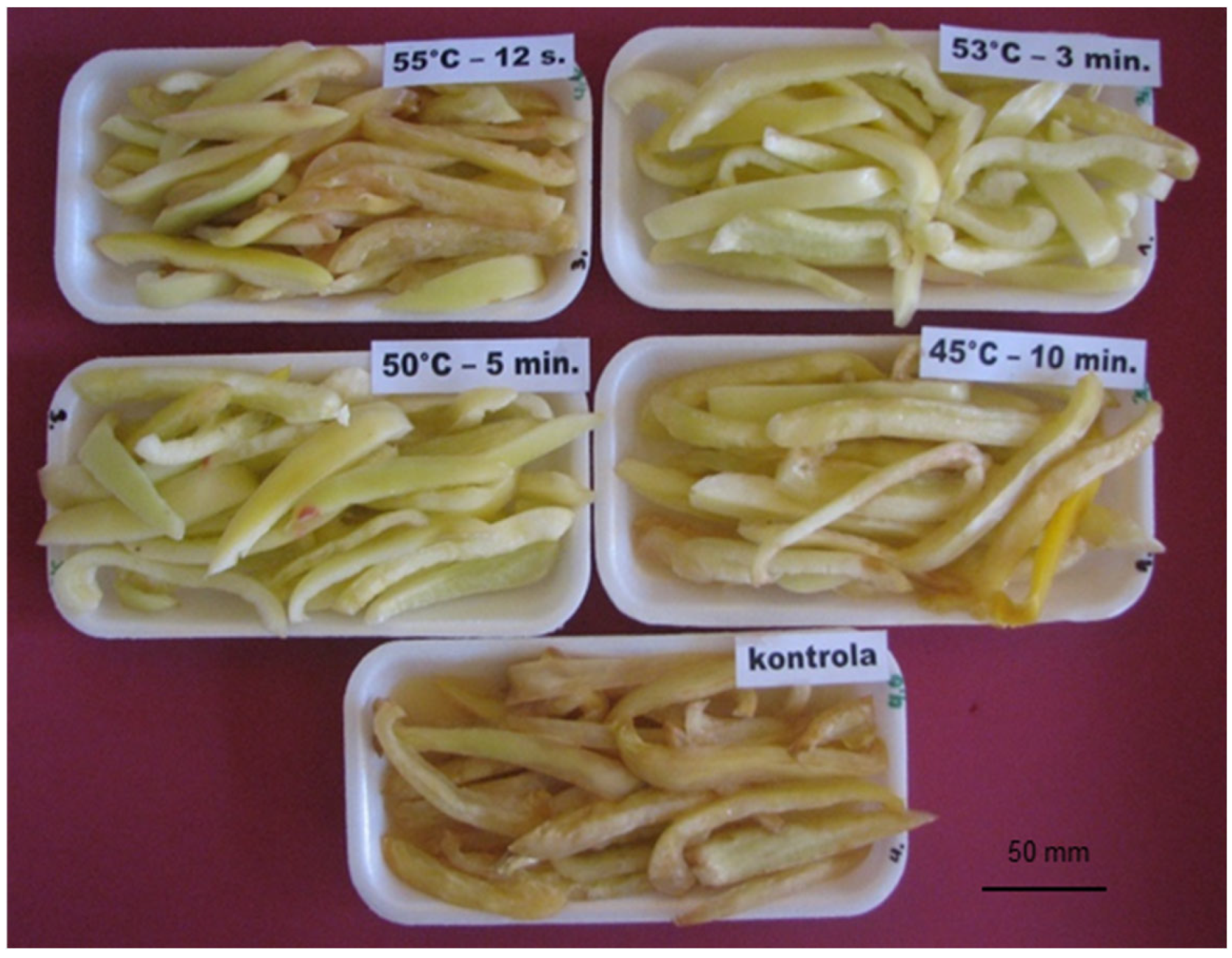

Red-fruit “Yecla F1” and cream-fruit “Blondy F1” peppers were purchased (first experiment—1 September 2014; second experiment—31 August 2015) from the largest bell pepper basin in Poland, in the Radom region (“Agropaprix” in Przystałowice Duże—Kolonia). The fruit was freshly picked, firm, and shiny. Immediately after delivery to the laboratory (which took about 1.5 h) the fruits were washed and dried. The bell pepper fruits were then cut in half and, after removing the placenta with seeds and inner sepals, were cut into strips 0.5–1.0 cm wide and as long as the length of the fruit. Immediately after the cut, the pepper sticks were treated with hot water by immersing individual batches for a defined time in hot water with one of four parameter regimens: (1) 45 °C for 10 min; (2) 50 °C for 5 min; (3) 53 °C for 3 min; (4) 55 °C for 12 s. The control group was fresh-cut peppers that were neither treated in hot nor cold water. The HW parameters were chosen based on a research report for whole pepper fruit [

5,

6,

14,

24]. Preliminary tests were also conducted, and promising results were obtained for the treatments, namely the selected HW parameters, for fresh-cut peppers.

The treatments were performed in a vessel filled with 150 L of water. Two portions of cut peppers weighing about 2.5 kg (each portion) were immersed in hot water for each treatment. The water temperature was measured all the time with two thermometers. While the water was being heated, two plastic openwork crates measuring 600 mm × 400 mm × 135 mm (L × W × H) were placed in a vessel and heated together with the water. The portions of cut peppers were placed in one crate and covered with another crate so that the sticks were completely submerged all the time (i.e., they did not float to the surface of the water). In a large volume of water (150 L), the thermometers indicated an even temperature, and no additional water mixing was performed.

Immediately after the treatment, the sticks were spread on 900 mm × 800 mm flat sieves. After draining the water, they were spread on other dry sieves lined with tissue paper. On these sieves, they were dried in a stream of air supplied by two SEVERIN VL 8620 fans (SEVERIN, Ense, Germany), set to the lowest speed level (1—low), until dry surfaces were obtained. Next, the peppers were packed into crates, protected from desiccation by polyethylene (PE) film, and stored overnight at 8 °C. The next day, the fresh-cut peppers were packed into polystyrene foam trays of external dimensions 226 mm × 100 mm × 9 mm and placed in plastic boxes. Each box was lined with PE in such a way that the trays with peppers were also covered with this film. Each treatment had 21 samples, each representing 200 g of cut peppers (separately packed into a tray). Four replicates from each treatment were stored under cold conditions at 3, 5, or 8 °C for 6 days. The relative humidity in the storage rooms was 80%. Two replicates for each treatment from each storage temperature were used for the evaluation of shelf life. After 4 d of cold storage (3, 5, or 8 °C), these two replicates were moved to 18–20 °C (market-simulated conditions) and stored for 2 d. One replicate from each treatment and each storage temperature was subjected to microscopic observation.

2.2. Quality Assessment

Quality assessment was performed every 2 d during cold storage, i.e., after 2, 4, and 6 d. Under conditions of market simulation (18–20 °C), observations were made daily. The evaluations were performed organoleptically, based on a nine-point scale (

Table 1).

On the same days, the natural weight loss of the cut peppers was measured, expressed as a percentage representing the difference between the initial weight and the weight on a given day of observation.

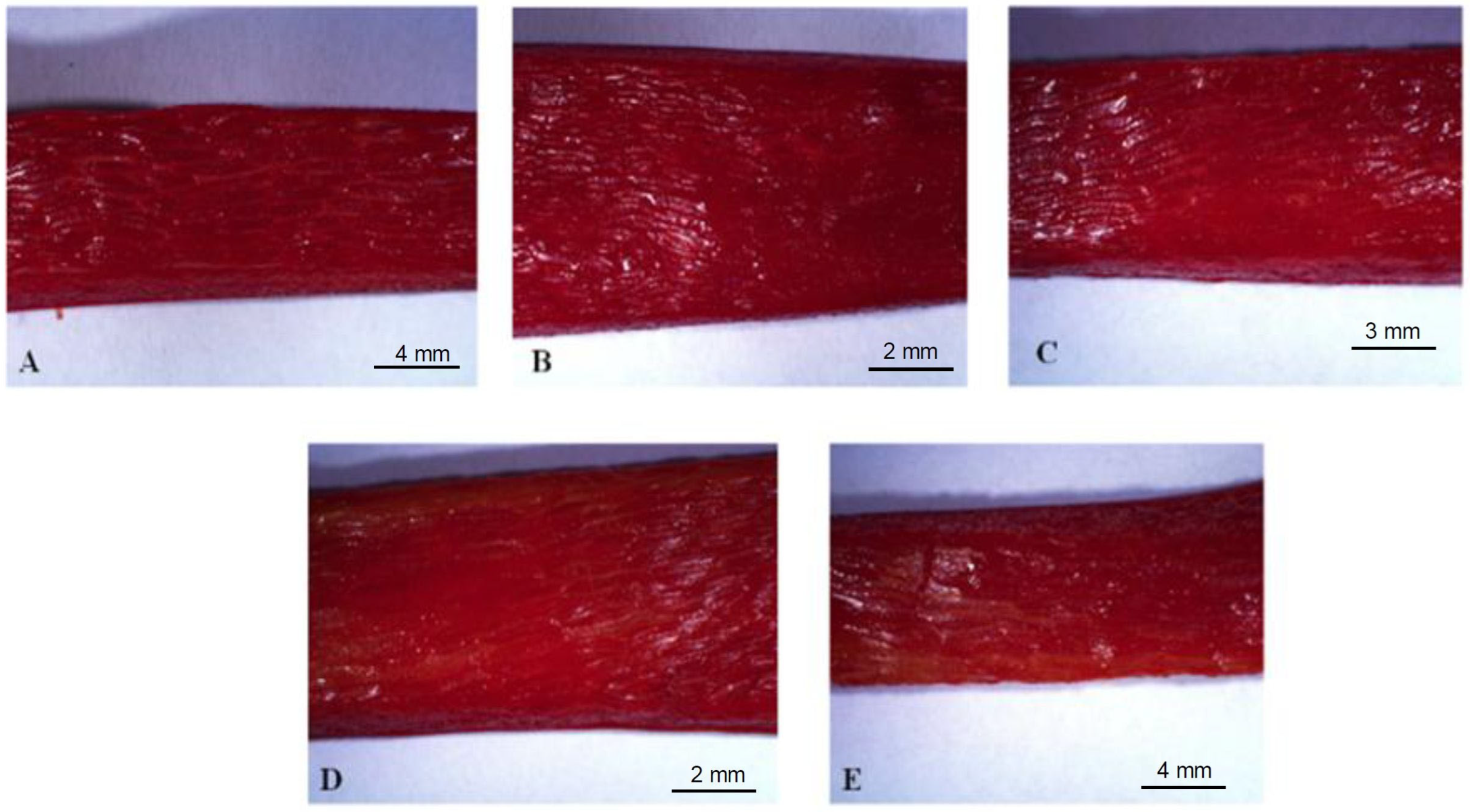

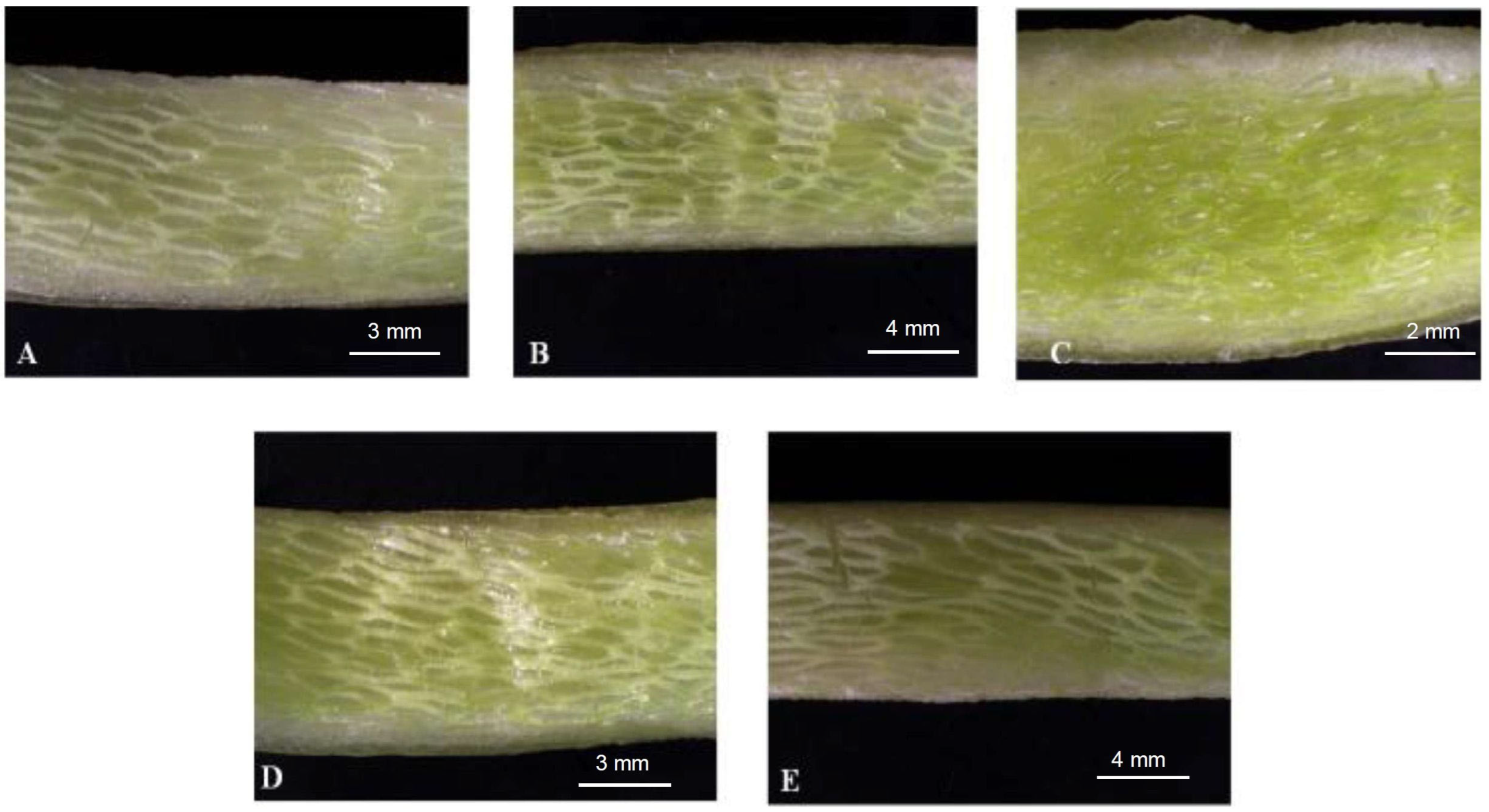

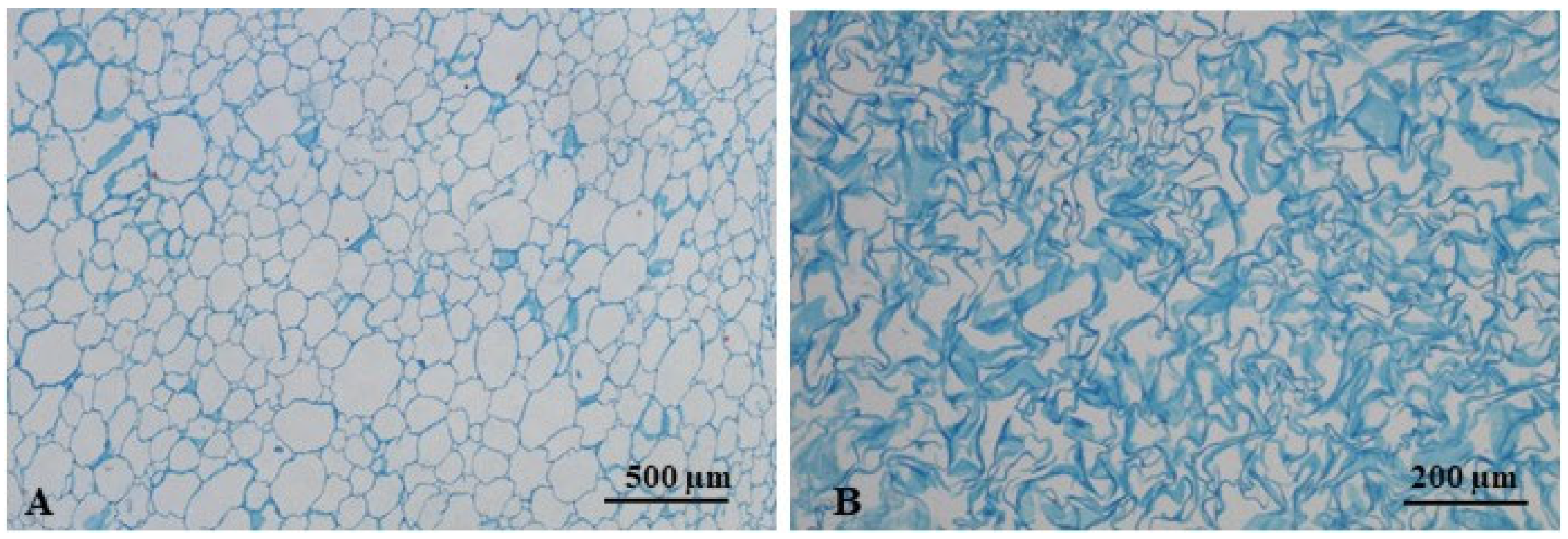

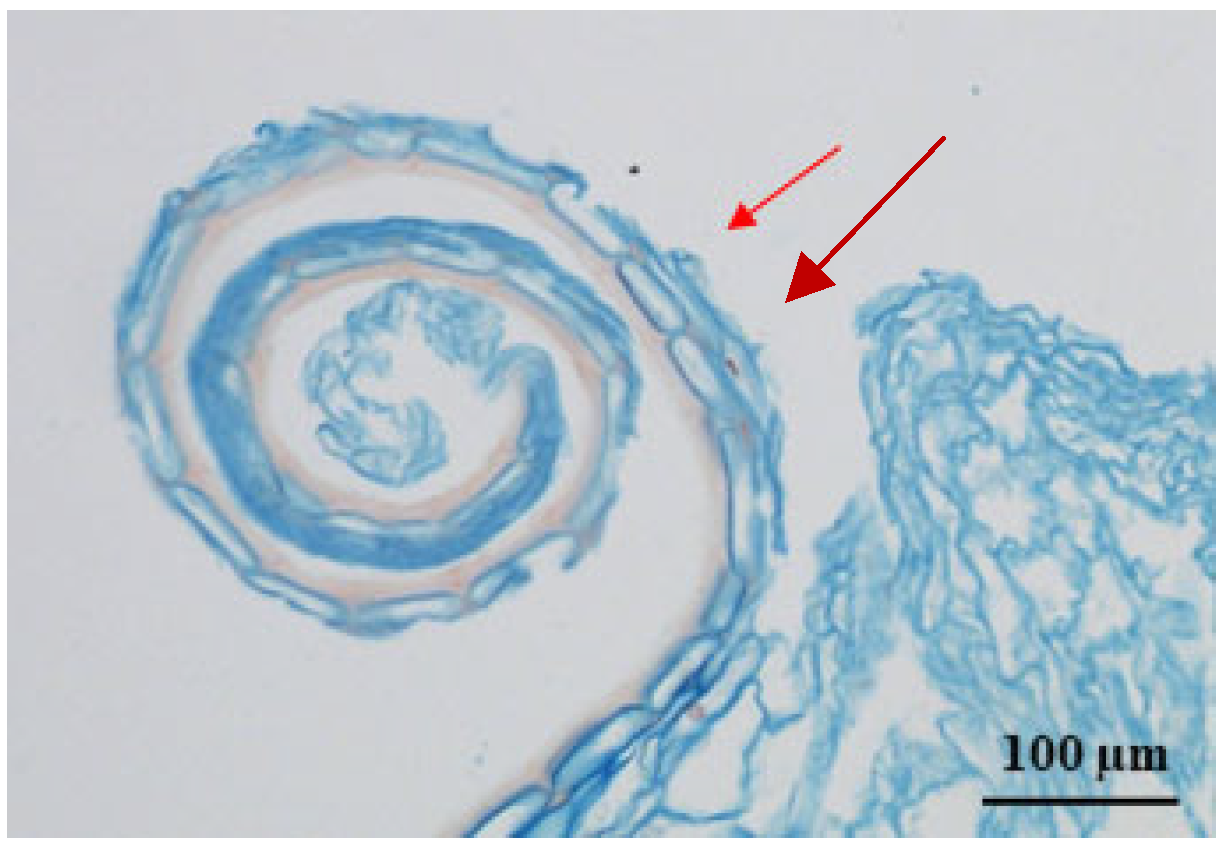

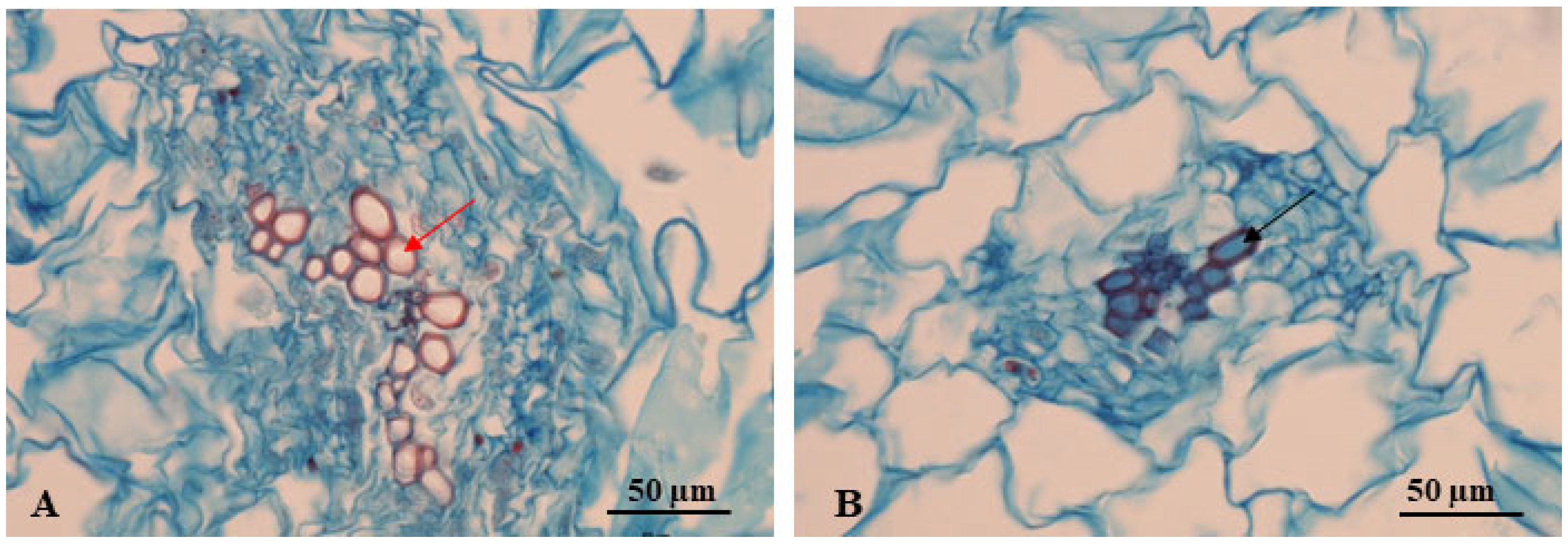

2.3. Microscopic Evaluation

The morphological features of the pepper fragments were evaluated using a stereoscopic microscope, Olympus SZX 16 (Olympus Corporation, Tokyo, Japan), with cellSens version 1.12 imaging software. For the histological analysis, the samples were fixed in a solution of chromic acid, acetic acid, and formalin for 48 h, dehydrated through an alcohol series, embedded in paraffin, and sectioned to 15 μm on a rotary microtome. The cut material, after staining with safranin and fast green, was enclosed in Canada balsam [

28,

29] and examined by conventional light microscopy with a Nikon Eclipse 80i (Nikon Corporation, Tokyo, Japan), with the imaging software NIS-Elements Br 4.00 used for photo-documentation.

2.4. Data Analysis

The experiment was conducted twice, each time following the same protocols, in a two-factor system of five treatments and three storage temperatures. The results were statistically analyzed with a two-factor analysis of variance. The averages for storage temperatures were analyzed as a one-factor analysis of variance. To compare means, the Tukey test was used, with the statistical significance set at p < 0.05. Calculations were made using STATISTICA 13 software (Dell Inc.) (Round Rock, TX, USA).

4. Discussion

Currently, the demand for fresh vegetables and fruits prepared for direct consumption is developing intensively. However, producers and traders have a problem with poor shelf life and, consequently, large losses. HWT is a non-chemical method to improve the storage life of whole vegetables and fruits. The use of this method appeared to be effective for improving the shelf life of fresh-cut red-fruit and cream-fruit peppers. The response of the tested cultivars to HWT differed significantly. The “Yecla” peppers showed an inhibition of stick softening, while the “Blondy” peppers showed a reduction in both stick softening and browning. Both disorders severely limit commercial marketing and increase losses [

25,

30]. The reasons for the softening may be a change in the osmotic state of the tissue and the decomposition of the cell wall structure [

1,

31]. The discoloration of the “Yecla” peppers was not apparent during cold storage, nor during shelf life under market-simulated conditions, which may have been a result of the predominance of red pigments masking other pigments in the pepper tissue. According to other researchers [

32,

33], the reason is the weak expression of genes affecting membrane lipid metabolism, which can limit the browning process. Our finding contradicts the results of Rodoni et al. [

25], who found that the heat treatment of red peppers at 45 °C for 3 min led to color changes during storage at 4 °C, in addition to softening and rotting. The cultivars we tested also reacted variably to the different combinations of HWTs. The inhibition of the softening of the “Yecla” strips occurred as a result of all the HWTs, but there was a tendency to maintain the best firmness and quality during short-term storage after the HWT of 55 °C for 12 s. The “Blondy” peppers treated with water at 53 °C for 3 min or water at 50 °C for 5 min retained the best color and quality. This is strong evidence that the reaction of fresh-cut vegetables to HWT is dependent on the type of plant material. The specific genetic and structural characteristics of the fruit can influence the direction of changes in the synthesis of HSPs and determine the morphological response in the tissue. The HSPs can delay the maturation and senescence processes to which the inhibition of polygalacturonase and exo- and endocellulase activity contribute [

2,

16]. In this way, HSPs also have an effect on delaying tissue softening, which occurred in the fresh-cut “Yecla” peppers. The beneficial HSPs can affect the activity of polyphenolic oxidative enzymes and contribute to reducing the browning of the cut surface of vegetables [

9]. This discoloration was inhibited after two HWTs, namely of 50 or 53 °C, in “Blondy” peppers. The browning is caused by the oxidation of polyphenolic compounds under the influence of polyphenol oxidase (PPO). Also, there is evidence that peroxidase (POD) and phenylalanine ammonia lyase (PAL) may be involved in the tissue browning of fresh-cut plant material [

1,

9,

34,

35]. Tissue browning may also be due to nonenzymatic polyphenol autooxidation [

34]. Preventing browning requires deactivating the enzymes in this process [

8]. Enzymes were not evaluated in our study, but numerous research reports indicate that treating horticultural products with high temperatures results in the inhibition of oxidative enzyme activity and reduces the browning of cut vegetables. According to Lurie et al. [

36], the short-term immersion of plant products in water at 40–55 °C can reduce the activity of oxidative enzymes (e.g., POD and PPO), which reduces tissue darkening. Heat shock treatment in the minimal processing of celery petioles at 50 °C for 90 s reduced PAL and subsequent browning [

37]. Cut lettuce reacted similarly to the same shock treatment [

38]. HWRB inhibits PPO activity, which reduces the browning of litchi peel [

2]. Also, HWT was an effective inhibitor of the browning of fresh-cut eggplants, and the storage time was extended from 4 to 8 d after HWT at 45 °C for 30 min [

39]. The browning of potato slices was inhibited only if the whole tubers were first stored for one day at 20 °C and, before cutting, were immersed in water at 55 °C for 10–20 min [

40].

The use of clean water (of food-grade quality) should not be a threat to the sanitary safety of fresh-cut peppers. Microbiological analyses conducted in preliminary studies (results not published) showed that after both 1 and 4 days of storage, treated and untreated samples were not contaminated with Esherichia coli bacteria. As for other microorganisms, after 1 day of storage, the control samples contained the most total bacteria, yeast, and mold, but after 4 days, there were no longer significant differences between the treatments.

The differences in the fresh-cut pepper quality between cold storage at 3 °C and 5 °C were insignificant in our study. Some authors recommend no more than 5 °C as the ideal storage temperature for fresh-cut fruit and vegetables [

1,

41]. Higher storage temperatures encourage microbial growth, which can lead to the rotting and maceration of the tissues [

42].

The storage time of the fresh-cut pepper was short, so even at low temperatures, chilling injuries did not develop. The development of other damage (softening, discoloration, and rotting) terminated the storage of the fresh-cut peppers. Generally, the chilling damage of fresh-cut, cold-sensitive horticultural species is not a problem during storage, as it develops more slowly than damage caused by enzymatic and microbial activity. Therefore, a low storage temperature is used for most cut vegetables, even for chilling-sensitive commodities [

1,

43]. The weight losses of the pepper sticks were low, but it was surprising to see a slightly higher percentage of loss in the first days of storage at 3 or 5 °C than at 8 °C. Covering the samples with PE film protected them from excessive drying. However, turning on the cooling equipment more often in the chamber with a temperature of 3 °C than in the one at 8 °C resulted in more intensive air circulation and a slight increase in the loss of fresh-cut pepper weight.

Microscopic observations immediately after the treatments indicated that the HWTs in our study did not cause changes to the cellular structure of the pepper tissue. The temperatures of the hot water used were within the range suggested for fresh vegetables and fruits [

4,

5,

6]. If the temperature is too high or the exposure too long, then it could damage the integrity of the cells [

44], leading to the leakage of cell contents, the loss of firmness, and faster spoilage. The HWT affected other changes of a biochemical and physiological nature. During storage, the structural changes led to the quality degradation of the fresh-cut peppers. This is in line with Foncesa et al. [

31], who claimed that cell separation and cell breakage are involved in tissue softening during the storage of fresh-cut vegetables.

HWT is a technology that is safe for the environment and human health and has the potential to improve the storage life of cut vegetables, including fresh-cut peppers. However, it is necessary to strictly follow the recommended rules, especially the water temperature and treatment duration. The ability to store fresh-cut peppers under refrigeration for extended periods of time should help significantly reduce the losses of both commodities prepared for trade and those for use in mass catering facilities: schools, hospitals, military units, and others. For products with a longer shelf life, their individual delivery volumes can be enlarged in favor of reducing the delivery frequency, which also means savings on transportation. On the other hand, it becomes possible to transport the products over longer distances, and in this way, the market can be expanded. The ability to store products for longer at 18–20 °C is important for retail sales. The goods can maintain good quality for longer, both on store shelves and in consumers’ homes.