1. Introduction

Excessive pesticide usage and drift into the environment have proven to be a challenge for agricultural spray applications, especially in specialty crops. The canopies in specialty crop orchards and vineyards have high amounts of variation between their respective shape, depth, and height, which makes targeted application difficult. In specialty crop orchards, sprays are typically delivered via air-assisted sprayers that generate a spray capable of penetrating dense foliage and provides adequate canopy coverage at the expense of resulting in excessive chemical waste [

1,

2]. Greenhouse systems often either employ handheld sprayers or boom sprayers for pesticide application. Handheld sprayers offer precise spraying, enabling operators to target individual plants or canopy zones with minimal equipment investment, though they can be labor-intensive and may result in operator fatigue, operator exposure, and inconsistent coverage [

3]. Boom sprayers provide uniform, high-throughput coverage across large bench areas and can be automated for timing and volume control, but they require greater capital investment and can increase the risk of off-target drift if the nozzle selection and operating parameters are not carefully managed [

4,

5]. Drift reduction is a critical need in both environments, as off-target deposition can damage sensitive adjacent crops or lead to regulatory noncompliance for both orchards and controlled environment settings [

6,

7]. To address the issues associated with these conventional sprayers, electrostatic sprayers have been investigated for use in agricultural pesticide applications due to their ability to reduce both pesticide usage and drift to the surrounding environment [

8,

9,

10,

11].

There are three primary methods by which an electrostatic spraying system can charge spray droplets: corona charging, conduction charging, and induction charging [

12]. In corona charging, sharp points on an electrode generate corona ions that bombard the spray droplets, which impart electrical charge upon them. Corona charging can be unreliable and typically provides a weaker charge than other spray-charging methods. Conduction charging operates by having the electrode in direct contact with the water being sprayed. This can potentially cause safety issues due to direct electrical contact, including potential short-circuits and higher operating currents. Induction charging functions by producing a strong electric field that charges the spray droplets at a relatively low current. This suggests that induction charging is the safest and most reliable method to charge spray droplets [

13,

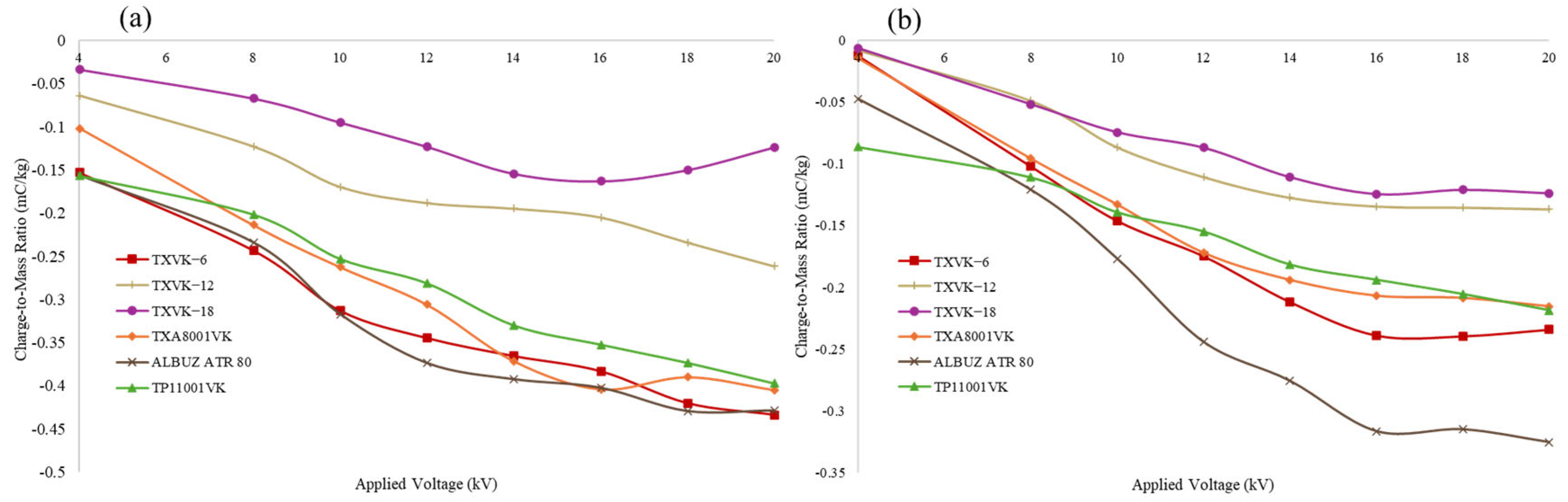

14]. The amount of charge is measured in terms of the charge-to-mass ratio (CMR), which is defined as the amount of imparted electrostatic charge in millicoulombs per kilogram of sprayed droplets. Key design parameters that impact the CMR include the applied voltage, liquid conductivity, mass flow rate, and spray pattern [

15].

While the CMR is important, there are several other key parameters that significantly impact the effectiveness of electrostatic spraying systems when delivering pesticides to targeted crop canopies. The spray droplets must be large enough to resist evaporation and drift, but also small enough that the charge can alter the trajectory when they approach the target. Therefore, careful consideration must be given to the distance between the spray nozzle and the canopy to ensure that the droplets can be adequately charged while not being lost due to drift. Additionally, the droplet must reach the target, with previous works finding that the droplet generally has to pass within approximately four centimeters of the target for electrostatic charging to be impactful [

16]. This can be problematic when spraying dense canopies since the spray will likely deposit on the first grounded object that it encounters. Additionally, the outer surface of the canopy could prevent spray from penetrating deeper into the canopy. Another factor to consider would be the space cloud effect. Since all the spray droplets would have the same charge, according to Coulomb’s law, they would repel each other. This would help the plume expand into the canopy, potentially giving the system more uniform coverage [

17]. However, it could also cause the droplets to excessively expand upwards and miss the target. The final major consideration is with regard to the shape, density, and spacing of a crop and its influence on the charged spray. Sharp points, such as the tips of leaves, can distort and concentrate the electric field generated by a charged particle. This can potentially result in an exchange of charges between the leaf tip and the spray, which could potentially neutralize or repel droplets [

18].

Canopy deposition and spray drift associated with the use of electrostatic pesticide sprayers are also strongly influenced by the distance between the spray boom and the crop canopy [

19]. As the spray distance increases, the electric field strength at the droplet’s location diminishes, reducing the effectiveness of electrostatic forces at influencing droplet motion [

20]. Furthermore, an increased travel distance allows more time for external forces, such as gravity and wind-induced drag, to alter the droplet trajectories, potentially decreasing deposition. This makes electrostatic spraying most effective at relatively short boom heights, though the spray height must still be sufficient to ensure full canopy coverage. This operational constraint makes electrostatic systems particularly well-suited to orchard sprayers, greenhouse applications, and small- to medium-scale field operations where the spray can be discharged near the canopy. The efficiency of these systems can also vary based on the chemical composition of the spray solution, including the type of pesticide and adjuvants used. Certain adjuvants, especially those with high ionic strength or surfactant properties that alter droplet conductivity, may interfere with the charge retention or modify droplet formation, thereby influencing the deposition patterns [

15,

21]. While many electrostatic systems demonstrate broad compatibility, optimizing the performance for specific pesticides or adjuvants may be necessary to achieve the maximum deposition efficiency.

Previous studies on electrostatic pesticide spraying systems have primarily focused on handheld applications, though they have also been employed with pneumatic, air-blast, and boom sprayers [

9,

22,

23]. Handheld electrostatic sprayers, while inexpensive, can suffer from limitations such as inconsistent spray coverage, operator fatigue, and difficulty in reaching higher or denser canopy areas, compromising the uniformity and effectiveness of pesticide application [

3]. The use of electrostatic pneumatic sprayers has had mixed results in field conditions and can have problems with excessive drift, making their use tenuous [

8,

24]. However, these systems have found success in controlled environment conditions to increase the droplet deposition onto roots in aeroponic systems or canopy deposition in controlled environment settings [

18,

25,

26]. Electrostatic boom sprayers can be utilized in many of the same applications as these other sprayers, such as in greenhouses, while offering the advantage of covering large areas more quickly and uniformly [

3]. However, the challenge with electrostatic boom sprayers lies in maintaining consistent electrostatic charge across extended spray widths and ensuring effective coverage in varying canopy densities and structures [

24,

27]. Much of the inconsistent performance reported in previous studies may stem from suboptimal configurations of the electrode size, voltage, and nozzle type, which directly affect the charge-to-mass ratio and droplet behavior. Therefore, identifying and implementing optimal electrostatic settings is essential to improve the spray performance, which would enable better deposition, more uniform coverage, and reduced drift potential under a variety of operating conditions.

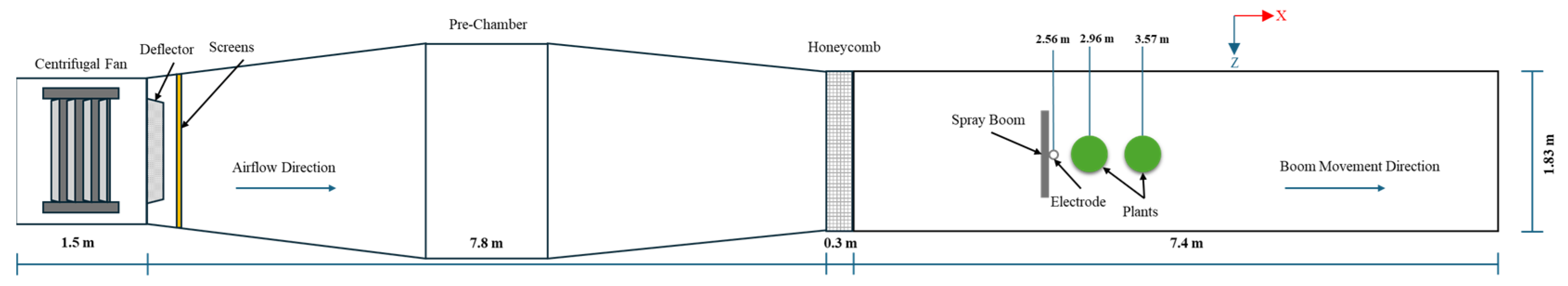

The objective of this study was to develop an optimized electrostatic pesticide nozzle for boom sprayers to enhance the spray canopy deposition and minimize the spray drift potential. The specific goals were to (1) determine the effects of the applied voltage, electrode geometry, and nozzle selection on the CMRs of spray droplets; (2) optimize the design and operation conditions of an electrostatic spraying system; and (3) evaluate the performance of the electrostatic spraying system with the optimal electrostatic settings on the spray deposition, coverage, and drift potential under wind tunnel conditions.

4. Conclusions

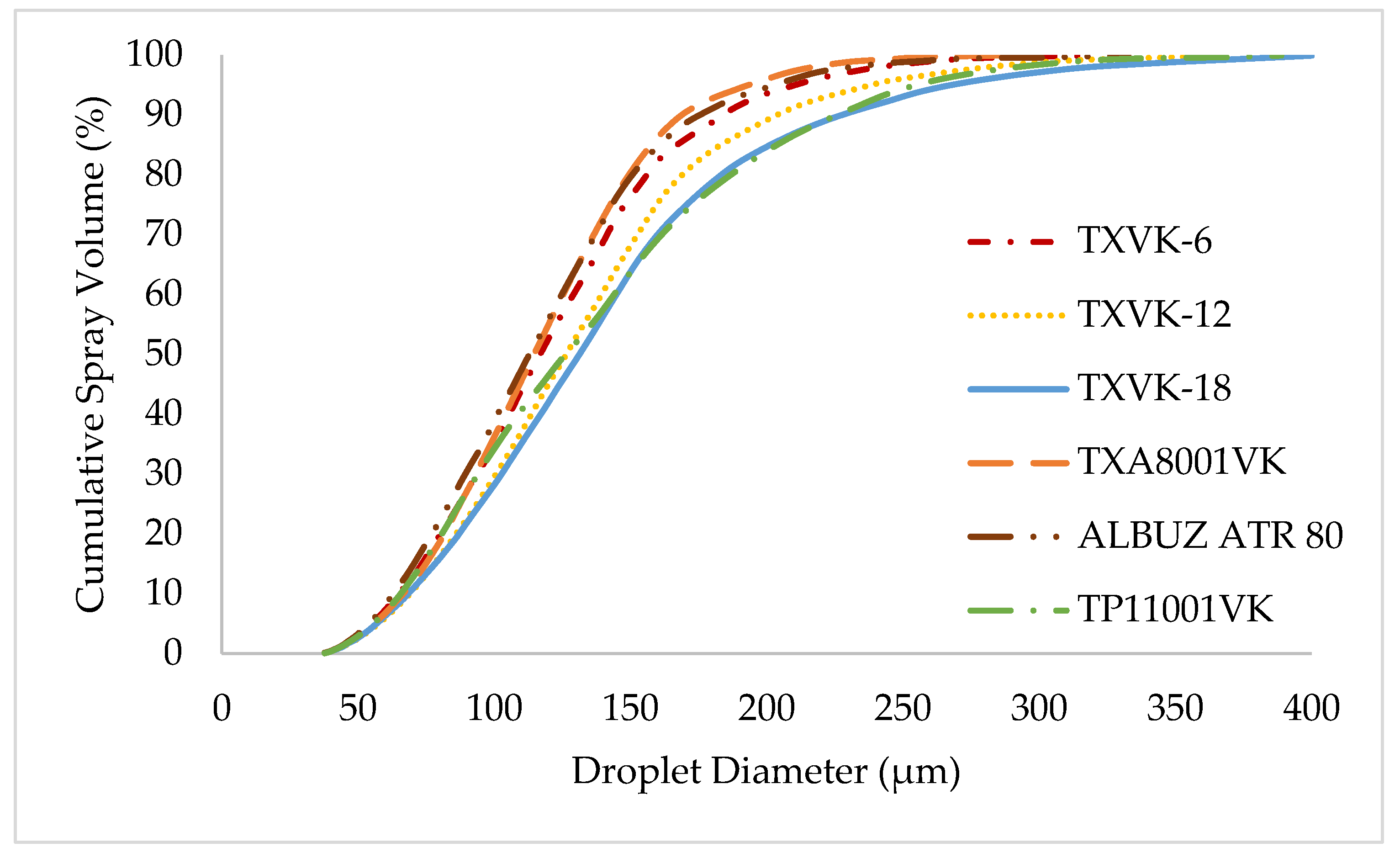

The nozzle selection, charging voltage, and wind speed significantly affected the effectiveness of an electrostatic spraying system. The droplet diameter distribution, CMR, canopy deposition, canopy coverage, and downwind drift were compared for six different spray nozzles under various test conditions. The optimized designs with electrode 1 charged to 20 kV with the ALBUZ ATR 80 and TXVK-6 nozzles yielded the highest CMRs of −0.429 and −0.434 mC kg−1, respectively. The ALBUZ ATR 80 coupled with the electrode ring 1 charged to 20 kV demonstrated the highest canopy deposition and coverage throughout the plants at 0 m s−1 wind speed, where they averaged 2.59 µg cm−2 and 15.6%, respectively. While only having a CMR of −0.402 mC kg−1, the TP11001VK nozzle performed better than the TXVK-6 nozzle, where the canopy deposition and coverage averaged 2.58 µg cm−2 and 11.8%. At a wind speed of 2.24 m s−1, the TXVK-18 nozzle emerged as the best-performing nozzle, where it delivered the highest average deposition and coverage of 1.27 µg cm−2 and 14.9%, respectively. The electrostatic system significantly enhanced the canopy deposition, where it achieved average relative increases that ranged from 74.2% to 239.5% and 21.4% to 183.9% at wind speeds of 0 and 2.24 m s−1, respectively. The canopy coverage had a similar trend by increasing the coverage by 24.6% to 56.5% and 6.9% to 34.4% in the same tested conditions. Therefore, electrostatic spraying systems can improve spray deposition for spray boom applications.

Future research should investigate the integration of air-assisted sprayers to further improve canopy penetration and mitigate the decrease in charging potential that could occur due to electrode wetting during prolonged use. Additionally, field experiments should be conducted in environments where electrostatic spraying systems could be viable, such as a greenhouse.