Grain Dehydration and Grain-Filling Characteristics of Different Maize Varieties in Heilongjiang

Abstract

1. Introduction

2. Materials and Methods

2.1. Experimental Design and Site Description

2.2. Determination of Grain Dry Weight and Dehydration-Related Traits

- MC: Moisture content.

- FW: Fresh weight.

- DW: Dry weight.

- PM: Physiological maturity.

- H: Harvest.

- DR: Dehydration rate.

- t: Time interval (days).

2.3. Measurement of Grain-Filling Parameters

2.4. Yield and Quality Measurement

2.5. Statistical Analysis

3. Results

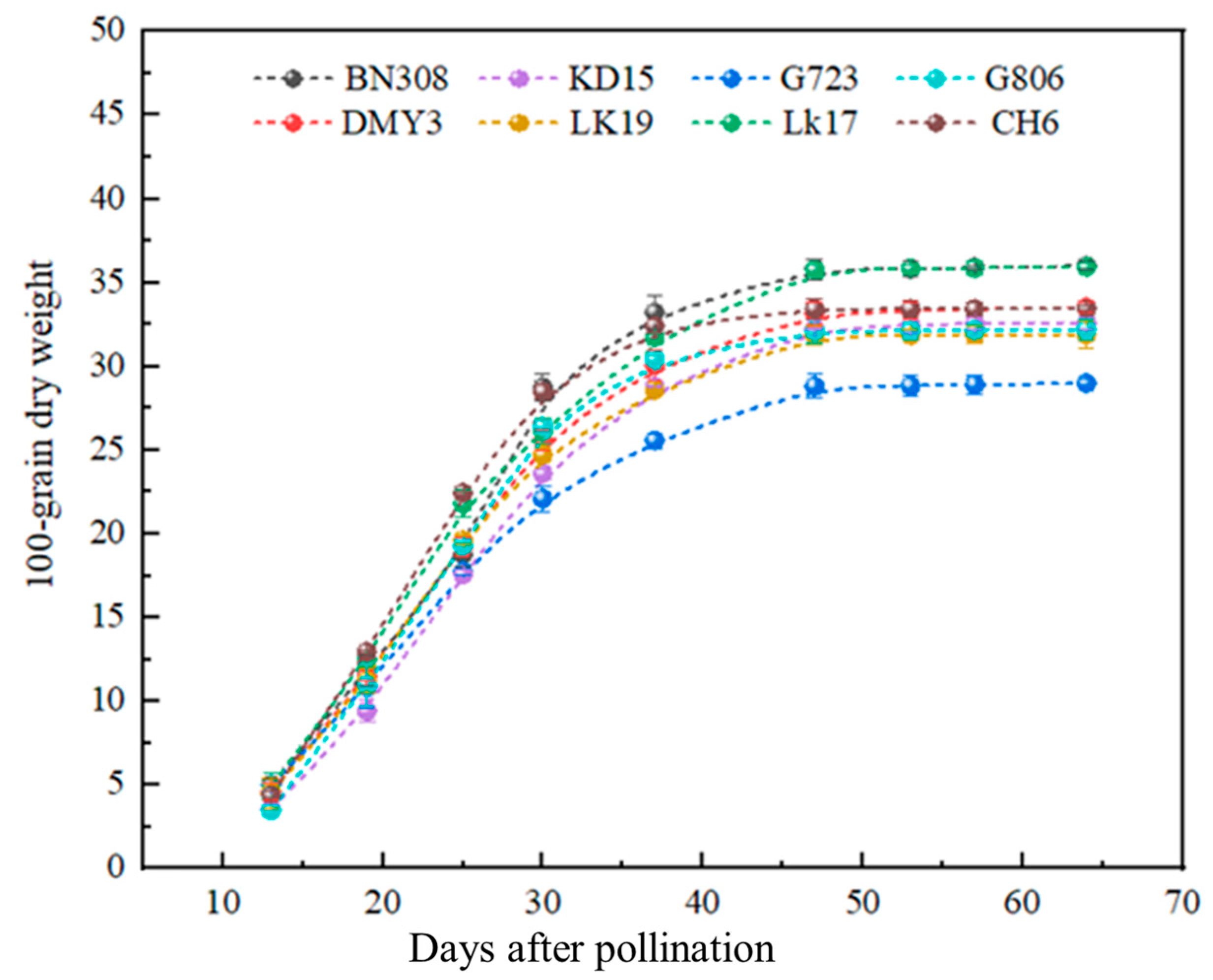

3.1. Grain Dry Weight

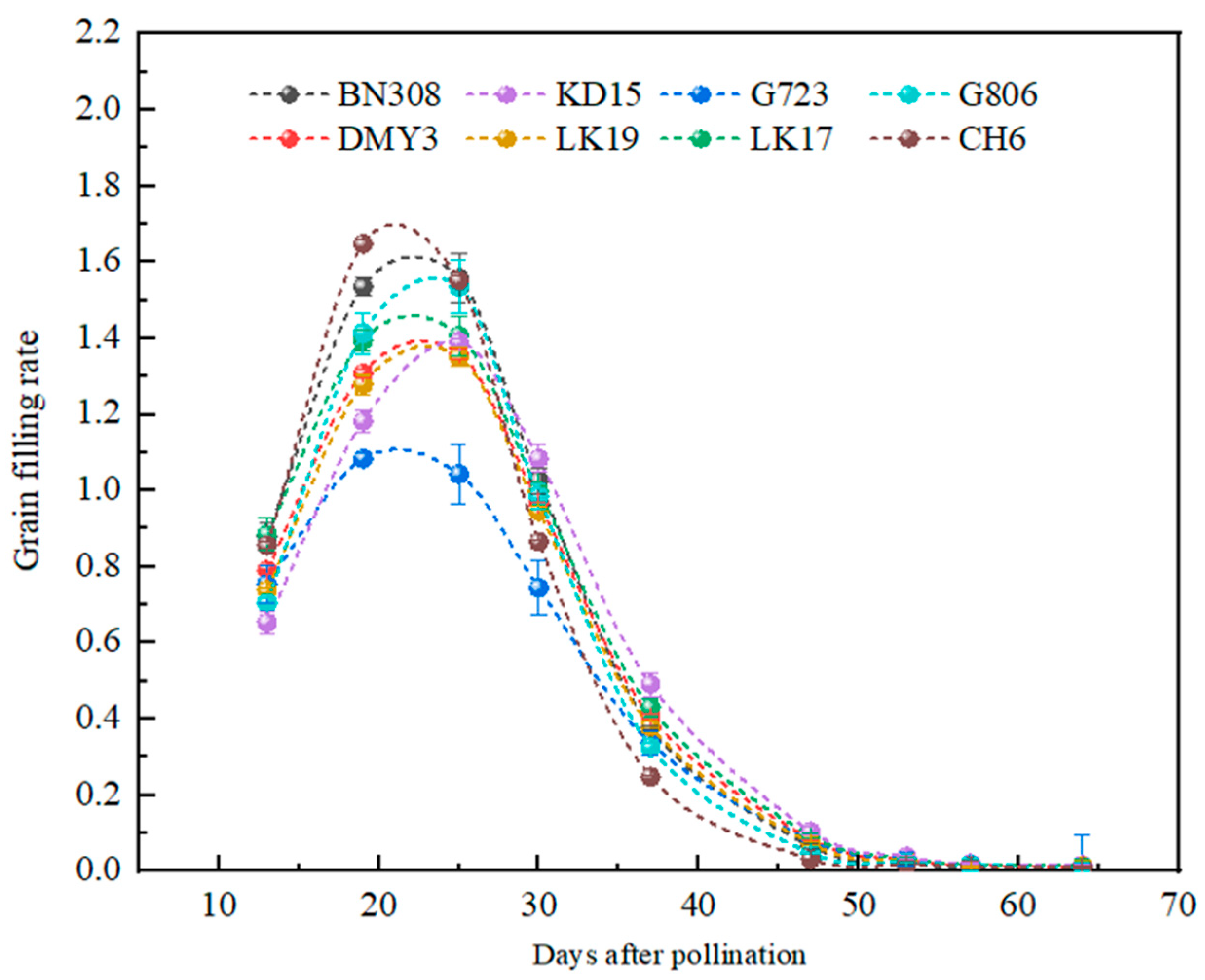

3.2. Grain-Filling Rate

3.3. Grain-Filling Parameters

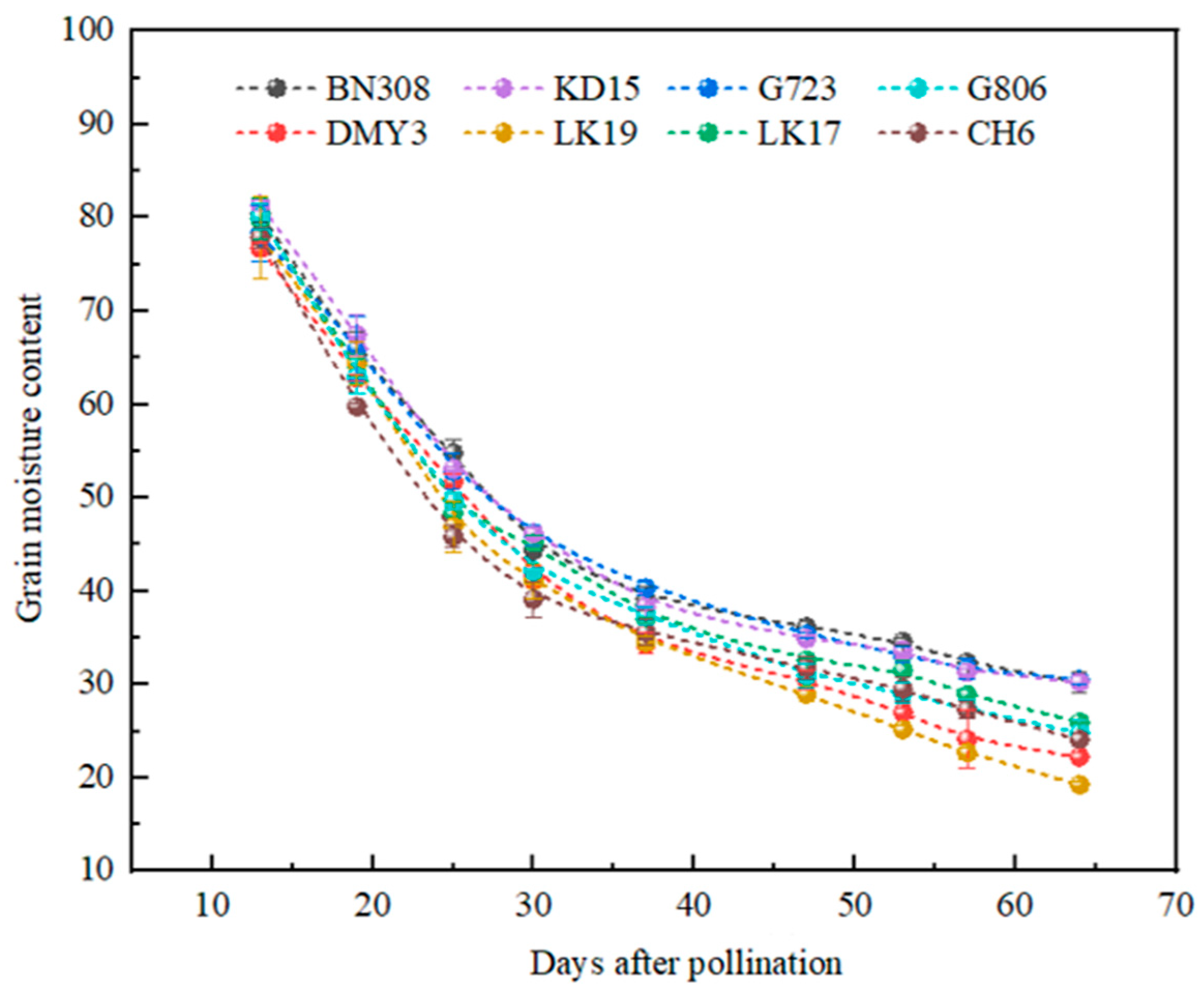

3.4. Grain Moisture Content

3.5. Post-Maturity Dehydration Rate

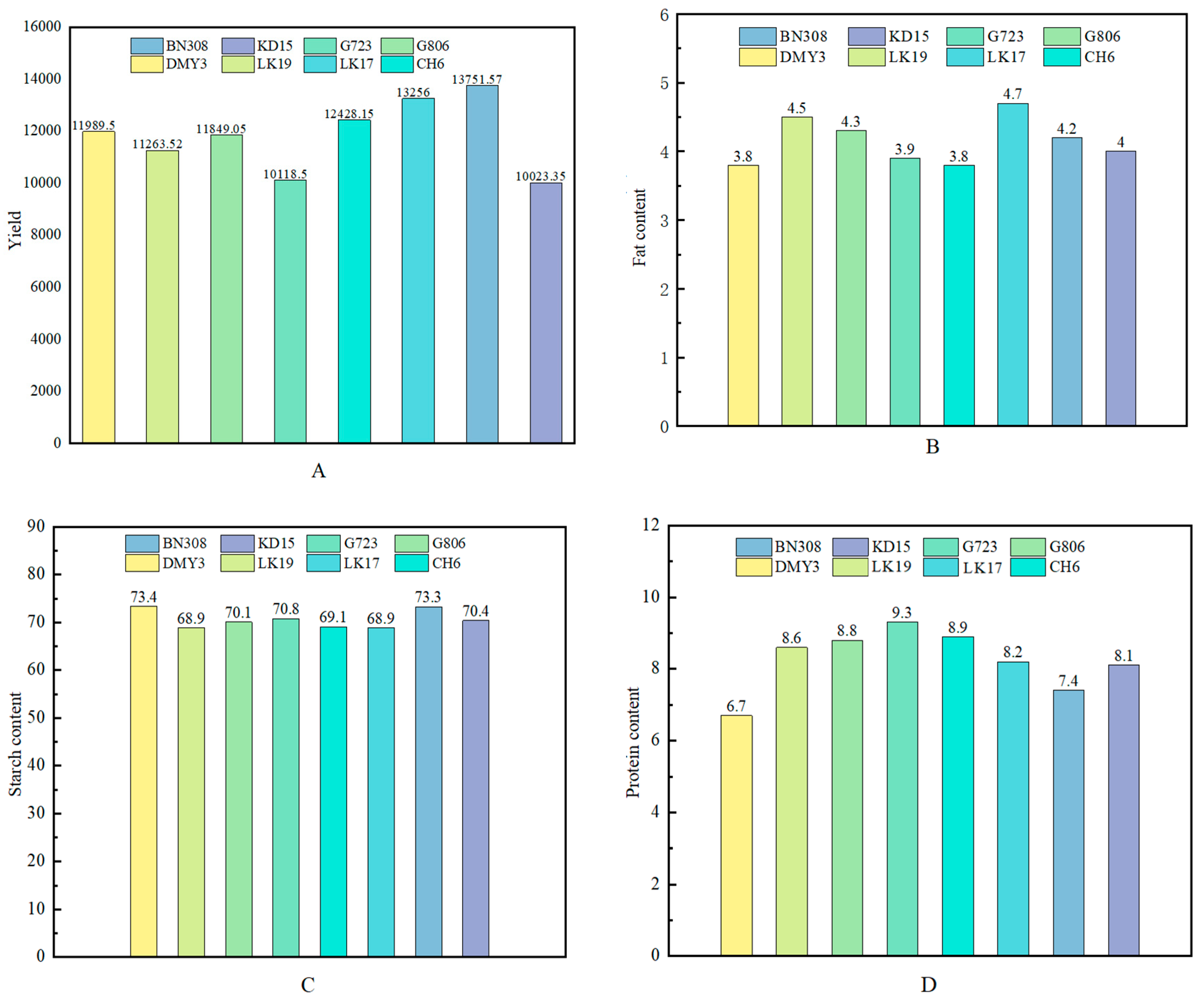

3.6. Yield and Quality

3.7. Contribution Rate

3.8. Correlation Analysis

4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Jing, Z.C.; Song, X.; Zhang, Z.H. Research on the development of China’s maize industry: A Cost-Benefit Analysis. Heilongjiang Grain 2024, 11, 107–109. [Google Scholar]

- Du, G.; Zhang, L.; Xu, X.; Wang, J. Spatial-temporal characteristics of maize production potential change under the background of climate change in Northeast China over the past 50 years. Geogr. Res. 2016, 35, 864–874. [Google Scholar]

- Yang, W.; Peng, S.; Dionisio-Sese, M.L.; Laza, R.C.; Visperas, R.A. Grain Filling Duration, a Crucial Determinant of Genotypic Variation of Grain Yield in Field-Grown Tropical Irrigated Rice. Field Crops Res. 2008, 105, 221–227. [Google Scholar] [CrossRef]

- Gasura, E.; Setimela, P.; Edema, R.; Gibson, P.T.; Okori, P.; Tarekegne, A. Exploiting Grain-Filling Rate and Effective Grain-Filling Duration to Improve Grain Yield of Early-Maturing Maize. Crop Sci. 2013, 53, 2295–2303. [Google Scholar] [CrossRef]

- Shen, L.X.; Huang, Y.K.; Li, T. Top-grain filling characteristics at an early stage of maize (Zea mays L.) with different nitrogen use efficiencies. J. Integr. Agric. 2017, 16, 626–639. [Google Scholar] [CrossRef]

- Borrás, L.; Otegui, M.E. Maize kernel weight response to postflowering source–sink ratio. Crop Sci. 2001, 41, 1816–1822. [Google Scholar] [CrossRef]

- Guo, J.; Wang, Z.; Wei, Q.; Li, G.; Yang, H.; Lu, D. Response of waxy maize (Zea mays L. var. ceratina Kulesh) leaf photosynthesis to low temperature during the grain-filling stage. Funct. Plant Biol. 2023, 50, 335–346. [Google Scholar] [CrossRef] [PubMed]

- Wu, Y.; Zhou, G.; Song, Y.; Zhou, L. Thresholds and extent of temperature effects on maize yield differ in different grain-filling stages. Sci. Total Environ. 2024, 25, 918. [Google Scholar] [CrossRef] [PubMed]

- Zhao, F.C.; Jing, L.Q.; Yan, F.B.; Lu, D.; Wang, G.; Lu, W. The effects of high temperature stress during the filling period on sugar accumulation and sucrose metabolism-related enzyme activities in sweet corn kernels. Acta Agron. Sin. 2013, 39, 1644–1651. [Google Scholar] [CrossRef]

- Wang, X.; Wang, X.; Xu, C.; Tan, W.; Wang, P.; Meng, Q. Decreased kernel moisture in medium-maturing maize hybrids with high yield for mechanized grain harves. Crop Sci. 2019, 59, 2794–2805. [Google Scholar] [CrossRef]

- Tubbs, T.; Woloshuk, C.; Ileleji, E.K. A simple low-cost method of determining whether it is safe to store maize. AIMS Agric. Food 2017, 2, 43–55. [Google Scholar] [CrossRef]

- Li, L.; Ming, B.; Gao, S.; Wang, K.; Hou, P.; Jin, X.; Chu, Z.; Zhang, W.; Huang, Z.; Li, H.; et al. A regional analysis model of maize kernel moisture. Agron. J. 2020, 113, 1467–1479. [Google Scholar] [CrossRef]

- Li, S.K. Factors Affecting the quality of mechanical maize grain harvesting in China and development directions of grain harvesting technology. J. Shihezi Univ. (Nat. Sci.) 2017, 35, 265–272. [Google Scholar]

- Li, Y.J.; Shi, J.M.; Ju, C.M.; Zhu, J. Preliminary Report on the Correlation between Maize Kernel Moisture and Variety Traits. J. Maize Sci. 2000, 4, 37–38. [Google Scholar]

- Xu, T.J.; Lv, T.F.; Zhao, J.R.; Wang, R.H.; Xing, J.F.; Zhang, Y.; Cai, W.T.; Liu, X.E.; Liu, X.Z.; Chen, C.Y.; et al. Study on grain dehydration characteristics of summer sowing corn varieties in the Huang Huai Hai region. Agric. Sci. China 2021, 54, 708–719. [Google Scholar]

- Guo, H.; Yu, X.; Gao, J.; Ma, D.; Hu, S.; Wang, X. Grain dehydration characteristics of old and modern maize hybrids and their response to different planting densities. Agronomy 2022, 12, 1640. [Google Scholar] [CrossRef]

- Zhu, Q.S.; Cao, X.Z.; Luo, Y.Q. Growth analysis of rice grain filling. Acta Agron. Sin. 1988, 3, 182–193. [Google Scholar]

- Zhao, S.J.; Wu, H.M. Assessment of natural desiccation rate in Zea mays Kernels. J. Jiling Agric. Sci. 2002, 5, 24–26. [Google Scholar]

- Cross, Z.H. Leaf expansion rate effects on yield and yield components in early-maturing maize. Crop Sci. 1991, 31, 579–583. [Google Scholar] [CrossRef]

- Wang, Z.H.; Zhou, Z.F.; Guo, H.; Wang, J.; Jin, H.L.; Liu, H.Y.; Wang, L.F.; Shen, Y.F.; Yang, M.L.; Wang, B.T. Research analysis and germplasm improvement strategies for dehydration rate in maize kernels. J. Agric. 2015, 5, 15–18. [Google Scholar]

- Liu, G.; Bian, Q.; Fu, Y.; Liu, Y.; Wei, Y.; Zhu, J.; Wang, Z. Study on the dehydration characteristics of spring maize after physiological maturity and the suitable period of mechanical grain harvest. Wirel. Commun. Mob. Comput. 2022, 2022, 170057. [Google Scholar] [CrossRef]

- Qian, C.R.; Wang, R.H.; Zhao, J.R.; Yv, Y.; Xv, T.J.; Hao, Y.B.; Jiang, Y.B.; Gong, X.J.; Li, L.; Ge, X.L. Characteristics of dry matter accumulation, allocation, and translocation in maize at different maturity periods. Chin. J. Ecol. 2017, 36, 2177–2183. [Google Scholar]

- Wang, L.M.; Li, S.Q.; Shao, M.A. Effects of water and nitrogen supply on the accumulation and distribution of dry matter and nitrogen in vegetative organs of the corn canopy. Sci. Agric. Sin. 2010, 43, 2697–2705. [Google Scholar]

- Ke, F.L.; Ma, X.L.; Huang, R.D.; Wang, C.H.; Xv, A.B. The influence of planting density on the grain filling characteristics of Xianyu 335 population. Corn Sci. 2011, 19, 58–62+66. [Google Scholar]

- Borrás, L.; Zinselmeier, C.; Senior, M.L.; Westgate, M.E.; Muszynski, M.G. Characterization of grain-filling patterns in diverse maize germplasm. Crop Sci. 2009, 49, 999–1009. [Google Scholar] [CrossRef]

- Wang, R.H.; Xu, T.J.; Chen, C.Y.; Wang, Y.D.; Lyu, T.F.; Liu, Y.E.; Cai, W.T.; Liu, X.Z.; Zhao, J.R. Grain filling and dehydration characteristics of different maturity types of corn varieties. Acta Agron. Sin. 2021, 47, 149–158. [Google Scholar] [CrossRef]

- Yao, D.D.; Wang, J.; Wang, W.P. Grain filling characteristics of three main spring maize varieties in the eastern Hebei regio. J. Hebei Norm. Univ. Sci. Technol. 2019, 33, 8–15. [Google Scholar]

- Wang, L. The Effect of Controlled Release Urea and Conventional Urea Combination on Starch Formation and Filling Characteristics of Spring Corn Grains. Master’s thesis, Ningxia University, Yinchuan, China, 2019. [Google Scholar]

- Cui, Y.K.; Wang, L.X.; Kong, L.J.; Zhao, W.M.; Zhang, M.J.; Chen, Y.P.; Yuan, J.H. Analysis of yield and grain filling characteristics of different glutinous corn varieties in the southern fresh corn region. Corn Sci. 2023, 31, 67–72. [Google Scholar]

- Li, S.C.; Lu, J.H.; Meng, B.M.; Dong, Z.X. The relationship between the proliferation of maize endosperm cells and the enrichment of storage capacity. Corn Sci. 2000, 4, 45–47. [Google Scholar]

| Variety | Name | Source | Maturity Days |

|---|---|---|---|

| DMY3(CK) | Demeiy3 | 9F592 × 6F576 | 113 |

| LK17 | Longken17 | kenxi15 × kenxi17 | 114 |

| BN308 | Bona308 | H3399 × H366 | 123 |

| KD15 | Kendan15 | jia34 × jia45 | 117 |

| LK19 | Longken19 | beixi114 × beixi69 | 113 |

| G806 | Doctor Jin806 | jin339 × jin386 | 123 |

| G723 | Doctor Jin723 | W113 × W445 | 114 |

| CH6 | Chenghe6 | W12-01 × ww-04 | 128 |

| Indicator | Calculation Formula |

|---|---|

| Grain-filling duration (d) | T = (ln B + 4.59512)/C |

| Active grain-filling period (d) | P = 6/C |

| Days to maximum filling rate (d) | Tmax = (ln B)/C |

| Kernel weight at max rate (g) | Wmax = A/2 |

| Maximum filling rate [g/(100 kernels × d)] | Rmax = (C × Wmax)/2 |

| Average filling rate [g/(100 kernels × d)] | Rmean = A/T |

| Source of Variation | DF | SS | F-Value | Significance |

|---|---|---|---|---|

| Variety (V) | 7 | 76.918 | 260.461 | ** |

| Days after pollination (DAP) | 8 | 2755.359 | 9330.222 | ** |

| V × DAP | 56 | 4.005 | 13.563 | ** |

| Source of Variation | DF | SS | F-Value | Significance |

|---|---|---|---|---|

| Variety (V) | 7 | 0.057 | 58.426 | ** |

| Days after pollination (DAP) | 8 | 8.119 | 8341.066 | ** |

| V × DAP | 56 | 0.025 | 25.822 | ** |

| Variety | Characteristic Parameters | Coefficient of Determination | |||||

|---|---|---|---|---|---|---|---|

| T (d) | Tmax (d) | Wmax (g) | Rmax [g/(100 kernels·d)] | P (d) | Rmean [g/(100 kernels·d)] | ||

| BN308 | 50.87 ± 0.14 a | 22.14 ± 0.33 bcd | 18.08 ± 0.19 a | 1.67 ± 0.68 b | 38.59 ± 1.62 a | 0.77 ± 0.13 a | 0.994 |

| CH6 | 50.81 ± 0.78 ab | 21.54 ± 0.70 cd | 16.71 ± 0.30 b | 1.77 ± 0.19 a | 35.15 ± 0.68 bc | 0.77 ± 0.04 a | 0.999 |

| DMY3(CK) | 49.40 ± 0.38 cd | 22.45 ± 0.43 bc | 16.73 ± 0.3 b | 1.42 ± 0.18 c | 35.23 ± 0.47 bc | 0.68 ± 0.04 c | 0.999 |

| G806 | 45.54 ± 0.64 f | 22.69 ± 0.52 b | 16.10 ± 0.55 cd | 1.62 ± 0.91 b | 32.53 ± 1.36 d | 0.71 ± 0.31 b | 0.999 |

| G723 | 47.04 ± 0.71 e | 21.35 ± 1.14 d | 14.51 ± 0.15 e | 1.13 ± 0.56 d | 29.87 ± 0.89 e | 0.57 ± 0.06 e | 0.998 |

| KD15 | 43.19 ± 0.26 g | 23.92 ± 0.46 a | 16.46 ± 0.33 bc | 1.40 ± 0.01 c | 28.30 ± 0.36 e | 0.65 ± 0.08 d | 0.999 |

| LK17 | 49.81 ± 0.64 bc | 22.09 ± 0.59 bcd | 18.01 ± 0.07 a | 1.49 ± 0.45 c | 36.24 ± 1.10 b | 0.72 ± 0.10 b | 0.995 |

| LK19 | 48.57 ± 0.76 d | 22.60 ± 0.15 b | 15.97 ± 0.10 d | 1.41 ± 0.36 c | 33.91 ± 0.85 cd | 0.66 ± 0.10 cd | 0.998 |

| Source of Variation | DF | SS | F-Value | Significance |

|---|---|---|---|---|

| Variety (V) | 7 | 199.082 | 104.755 | ** |

| Days after pollination (DAP) | 8 | 7843.240 | 4127.038 | ** |

| V × DAP | 56 | 8.874 | 4.669 | ** |

| Variety Code | Physiological Maturity Water Content (%) | Harvest Moisture Content (%) | Average Dehydration Rate After Physiological Maturity (%/d) |

|---|---|---|---|

| BN308 | 36.18 ± 0.55 a | 30.24 ± 1.03 a | 0.54 ± 0.14 bc |

| CH6 | 29.78 ± 1.179 cd | 24.73 ± 0.57 b | 0.46 ± 0.71 bc |

| DMY3 (CK) | 30.54 ± 1.03 c | 22.25 ± 0.55 c | 0.75 ± 0.13 a |

| G723 | 35.34 ± 0.28 a | 30.47 ± 0.44 a | 0.44 ± 0.61 bc |

| G806 | 30.96 ± 1.25 c | 24.85 ± 1.29 b | 0.56 ± 0.26 bc |

| KD15 | 34.93 ± 0.22 a | 30.28 ± 0.63 a | 0.42 ± 0.39 c |

| LK17 | 32.59 ± 0.28 b | 25.98 ± 0.12 b | 0.60 ± 0.34 b |

| LK19 | 28.97 ± 0.69 d | 19.25 ± 0.29 d | 0.89 ± 0.87 a |

| Index | C1 | C2 | C3 | C4 |

|---|---|---|---|---|

| Dry weight per 100 kernels | 0.952 | 0.063 | 0.192 | −0.120 |

| Seed moisture content | 0.052 | −0.888 | 0.146 | −0.155 |

| T | 0.567 | 0.290 | 0.160 | 0.725 |

| Tmax | −0.022 | 0.033 | 0.110 | −0.968 |

| Wmax | 0.946 | 0.036 | 0.189 | −0.157 |

| Rmax | 0.828 | −0.114 | −0.124 | 0.100 |

| P | 0.806 | 0.322 | 0.223 | 0.425 |

| Rmean | 0.938 | −0.054 | −0.016 | 0.136 |

| Average dehydration rate after physiological maturity | 0.038 | 0.984 | 0.125 | −0.025 |

| Protein | −0.398 | −0.233 | −0.843 | 0.239 |

| Fat | 0.387 | 0.466 | −0.498 | −0.298 |

| Starch | 0.055 | −0.136 | 0.950 | 0.063 |

| Yield | 0.916 | 0.137 | 0.109 | 0.308 |

| Eigenvalue | 5.997 | 2.245 | 1.865 | 1.728 |

| Contribution rate | 46.128 | 17.269 | 14.377 | 13.261 |

| Cumulative contribution rate | 46.128 | 63.397 | 77.774 | 91.035 |

| Characteristic | Dry Weight per 100 Kernels | Seed Moisture Content | T | Tmax | Wmax | Rmax | P | Rmean | Average Dehydration Rate After Physiological Maturity | Protein | Fat | Starch | Yield |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Dry weight per 100 kernels | 1 | ||||||||||||

| Seed moisture content | 0.076 | 1 | |||||||||||

| T | 0.532 | −0.281 | 1 | ||||||||||

| Tmax | 0.090 | 0.065 | −0.695 | 1 | |||||||||

| Wmax | 0.999 ** | 0.113 | 0.498 | 0.123 | 1 | ||||||||

| Rmax | 0.662 | −0.073 | 0.429 | −0.026 | 0.649 | 1 | |||||||

| P | 0.777 * | −0.232 | 0.894 ** | −0.409 | 0.750 * | 0.611 | 1 | ||||||

| Rmean | 0.823 * | −0.040 | 0.580 | −0.091 | 0.810 * | 0.963 ** | 0.769 * | 1 | |||||

| Average dehydration rate after physiological maturity | 0.107 | −0.853 ** | 0.306 | 0.085 | 0.082 | −0.067 | 0.370 | −0.006 | 1 | ||||

| Protein | −0.605 | 0.038 | −0.266 | −0.316 | −0.601 | −0.154 | −0.470 | −0.305 | −0.342 | 1 | |||

| Fat | 0.373 | −0.215 | 0.072 | 0.134 | 0.378 | 0.066 | 0.287 | 0.157 | 0.409 | 0.105 | 1 | ||

| Starch | 0.187 | 0.292 | 0.155 | 0.026 | 0.185 | −0.044 | 0.266 | 0.049 | 0.000 | −0.745 * | −0.454 | 1 | |

| Yield | 0.866 ** | −0.062 | 0.782 * | −0.335 | 0.845 ** | 0.711 * | 0.953 ** | 0.858 ** | 0.169 | −0.408 | 0.357 | 0.191 | 1 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, D.; Lin, Y.; Li, J.; Zheng, H.; Zhang, Y.; Zhou, Y.; Guo, X.; Wang, Y.; Zhang, J.; Zhang, J.; et al. Grain Dehydration and Grain-Filling Characteristics of Different Maize Varieties in Heilongjiang. Agronomy 2025, 15, 1356. https://doi.org/10.3390/agronomy15061356

Yang D, Lin Y, Li J, Zheng H, Zhang Y, Zhou Y, Guo X, Wang Y, Zhang J, Zhang J, et al. Grain Dehydration and Grain-Filling Characteristics of Different Maize Varieties in Heilongjiang. Agronomy. 2025; 15(6):1356. https://doi.org/10.3390/agronomy15061356

Chicago/Turabian StyleYang, Deguang, Yaxin Lin, Jingdu Li, Hao Zheng, Yumeng Zhang, Yanci Zhou, Xiaonan Guo, Yufei Wang, Jiahao Zhang, Jingwen Zhang, and et al. 2025. "Grain Dehydration and Grain-Filling Characteristics of Different Maize Varieties in Heilongjiang" Agronomy 15, no. 6: 1356. https://doi.org/10.3390/agronomy15061356

APA StyleYang, D., Lin, Y., Li, J., Zheng, H., Zhang, Y., Zhou, Y., Guo, X., Wang, Y., Zhang, J., Zhang, J., & Yang, S. (2025). Grain Dehydration and Grain-Filling Characteristics of Different Maize Varieties in Heilongjiang. Agronomy, 15(6), 1356. https://doi.org/10.3390/agronomy15061356