Neural-Network-Based Prediction of Non-Burial Overwintering Material Covering Height for Wine Grapes

Abstract

1. Introduction

2. Materials and Methods

2.1. Test Materials

2.2. Test Treatments

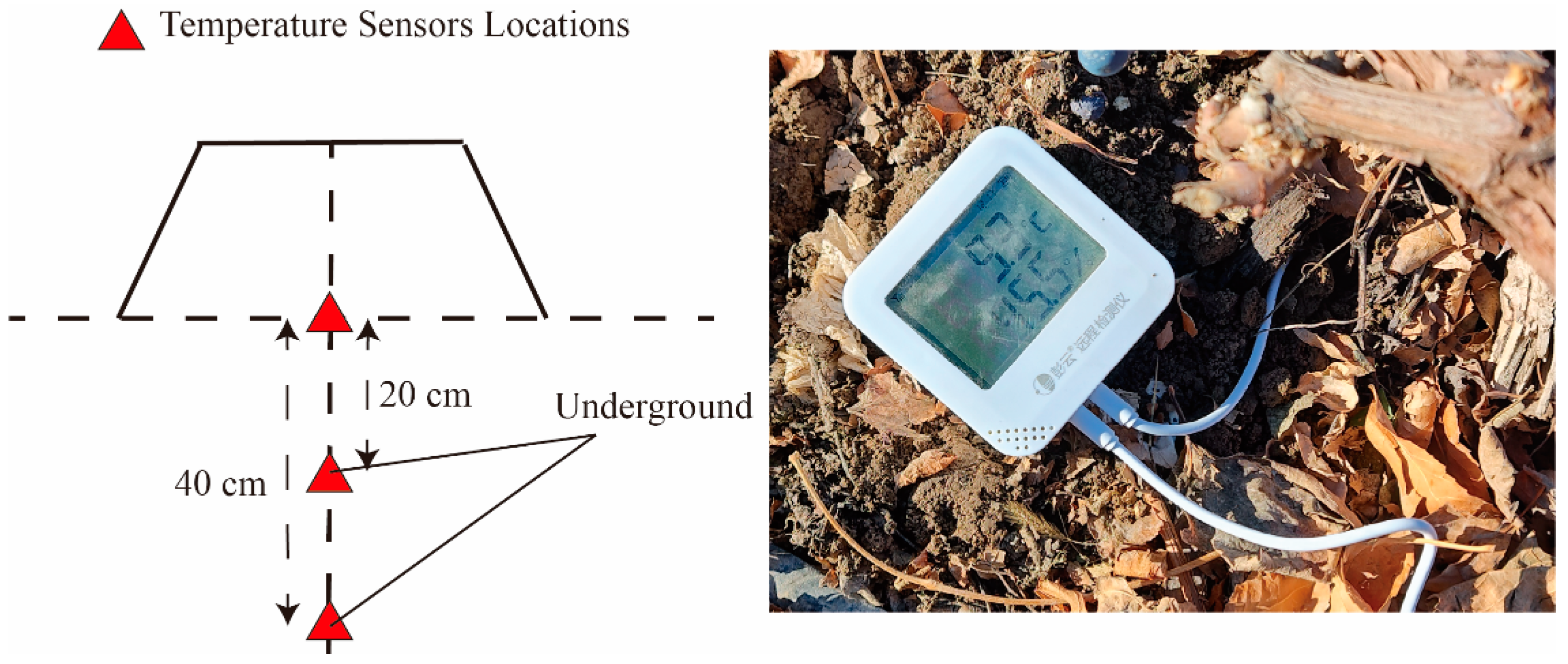

2.3. Data Observation

2.4. Data Analysis

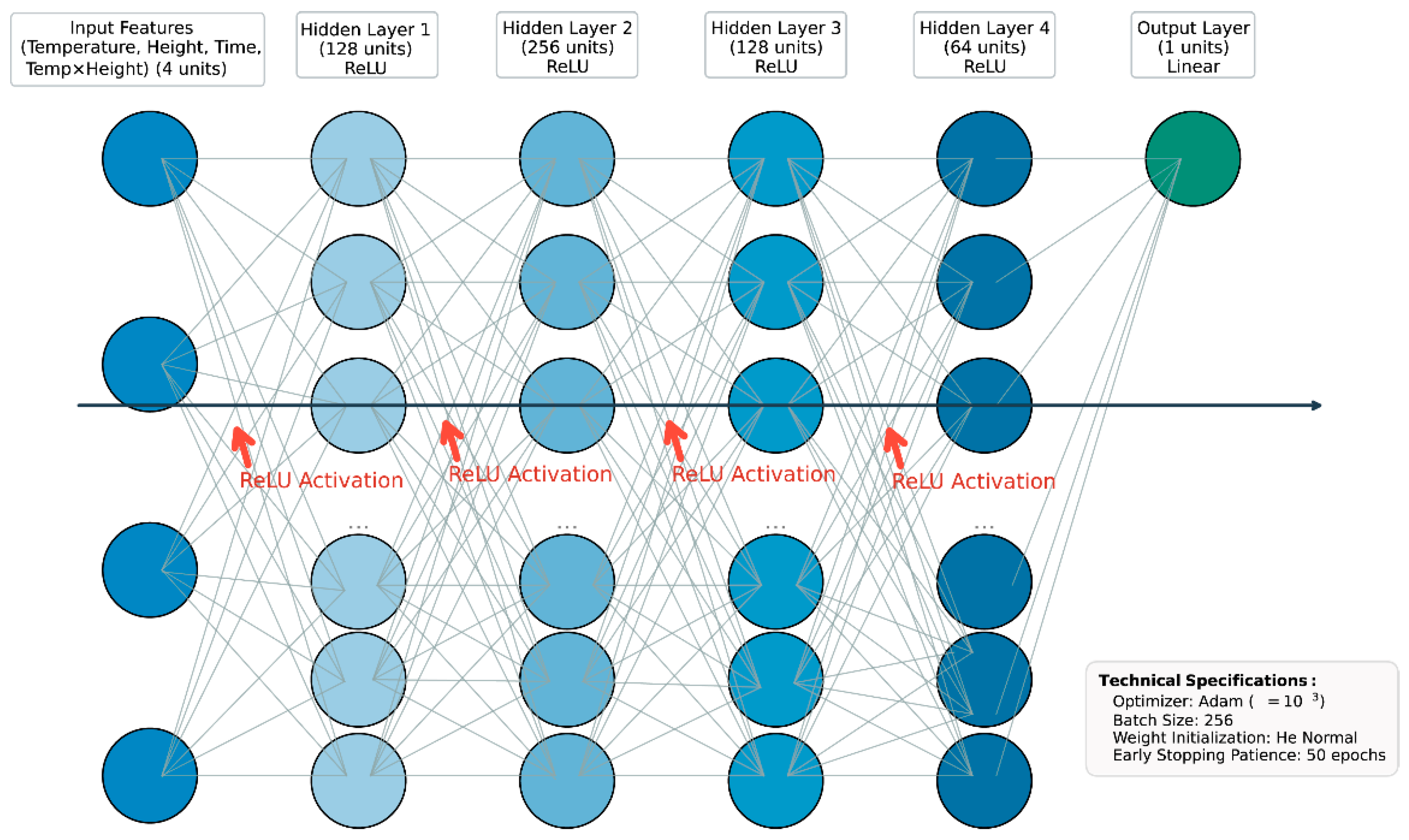

2.5. Construction of Temperature Prediction Machine Learning Model

2.5.1. Data Preprocessing

2.5.2. Model Construction and Evaluation

3. Results

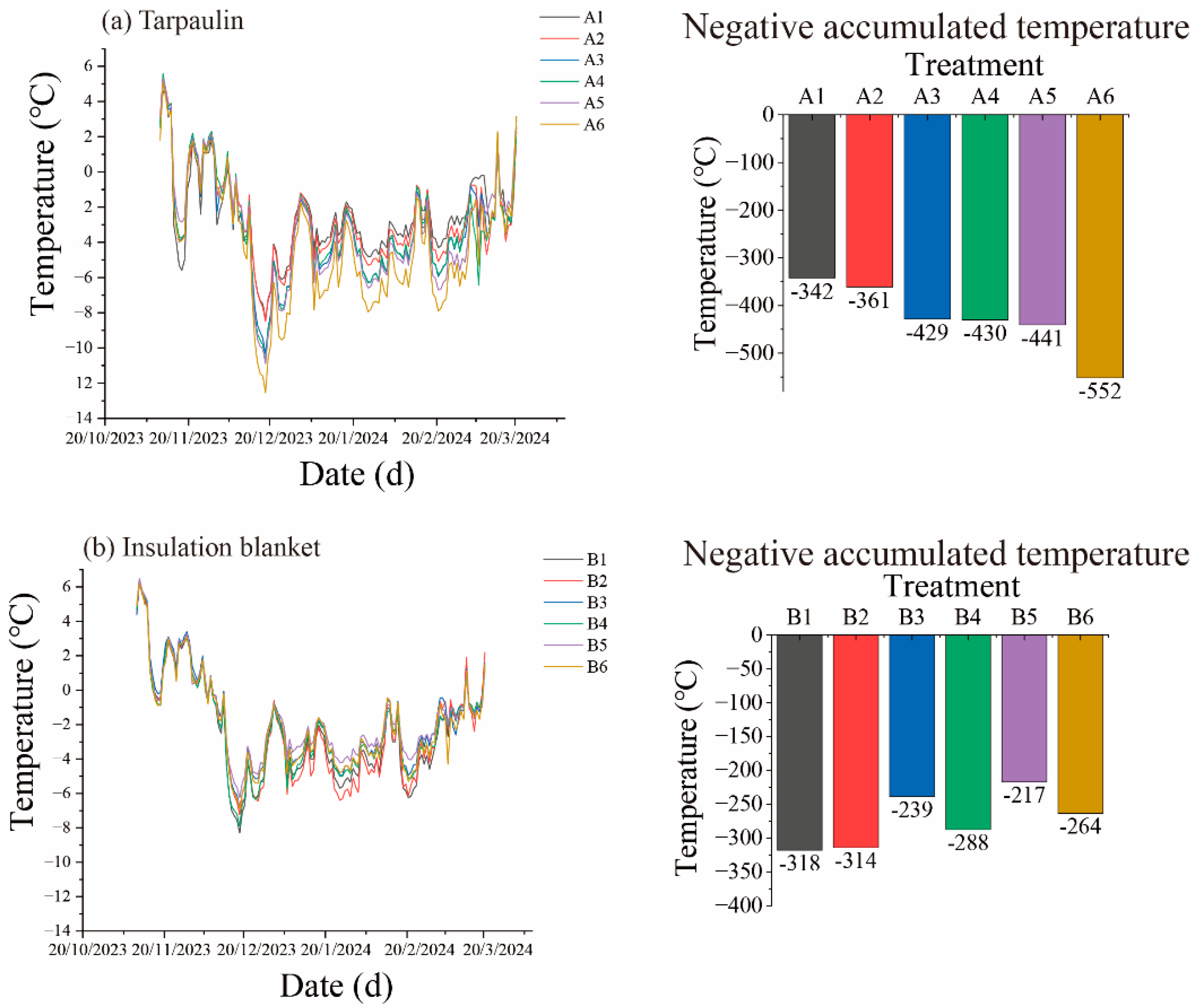

3.1. Temperature Variation Trends in Grapevine Branches During Overwintering

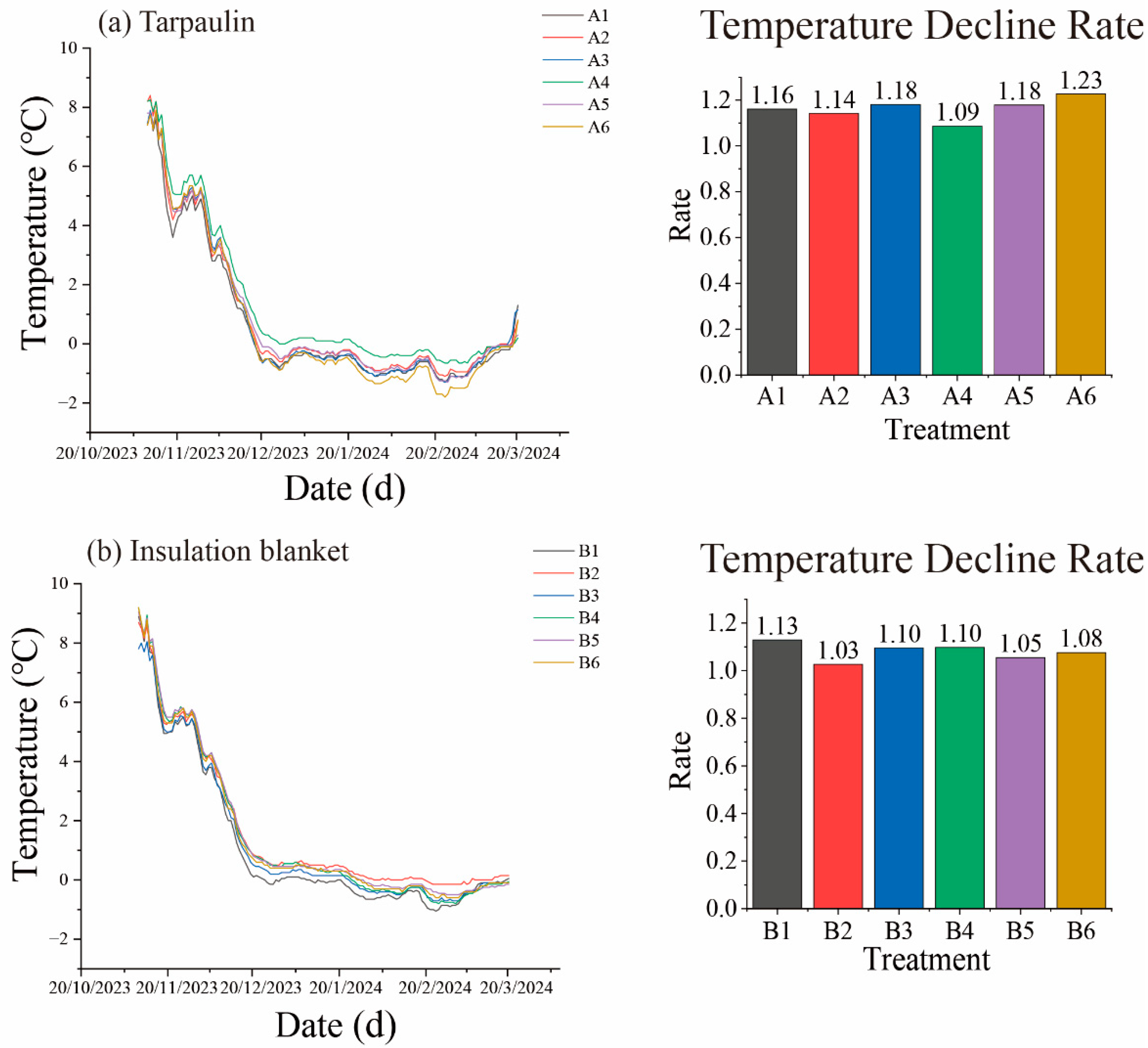

3.1.1. Temperature Variation Characteristics at Branch Sites Under Different Heights of the Same Cover Material

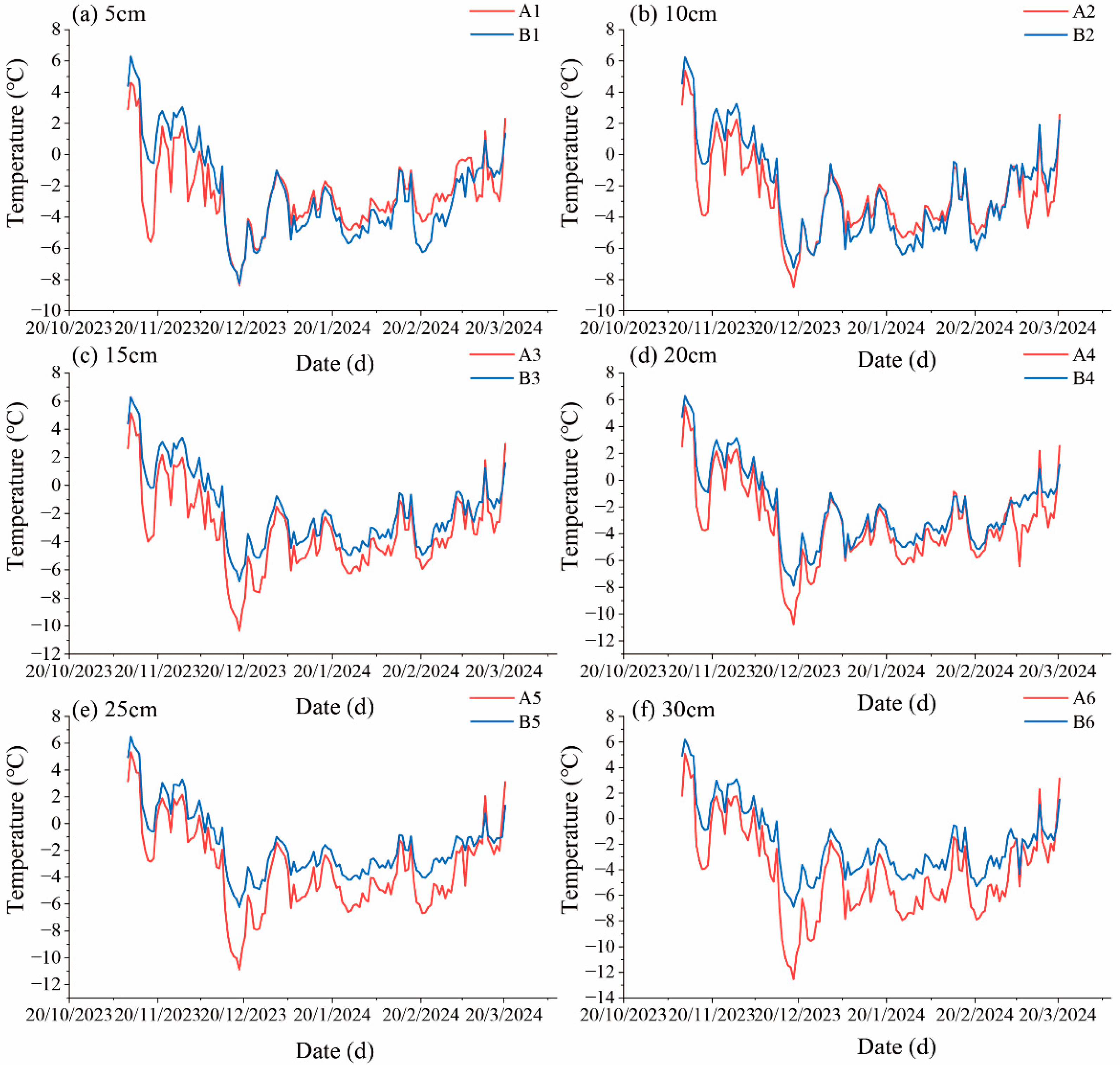

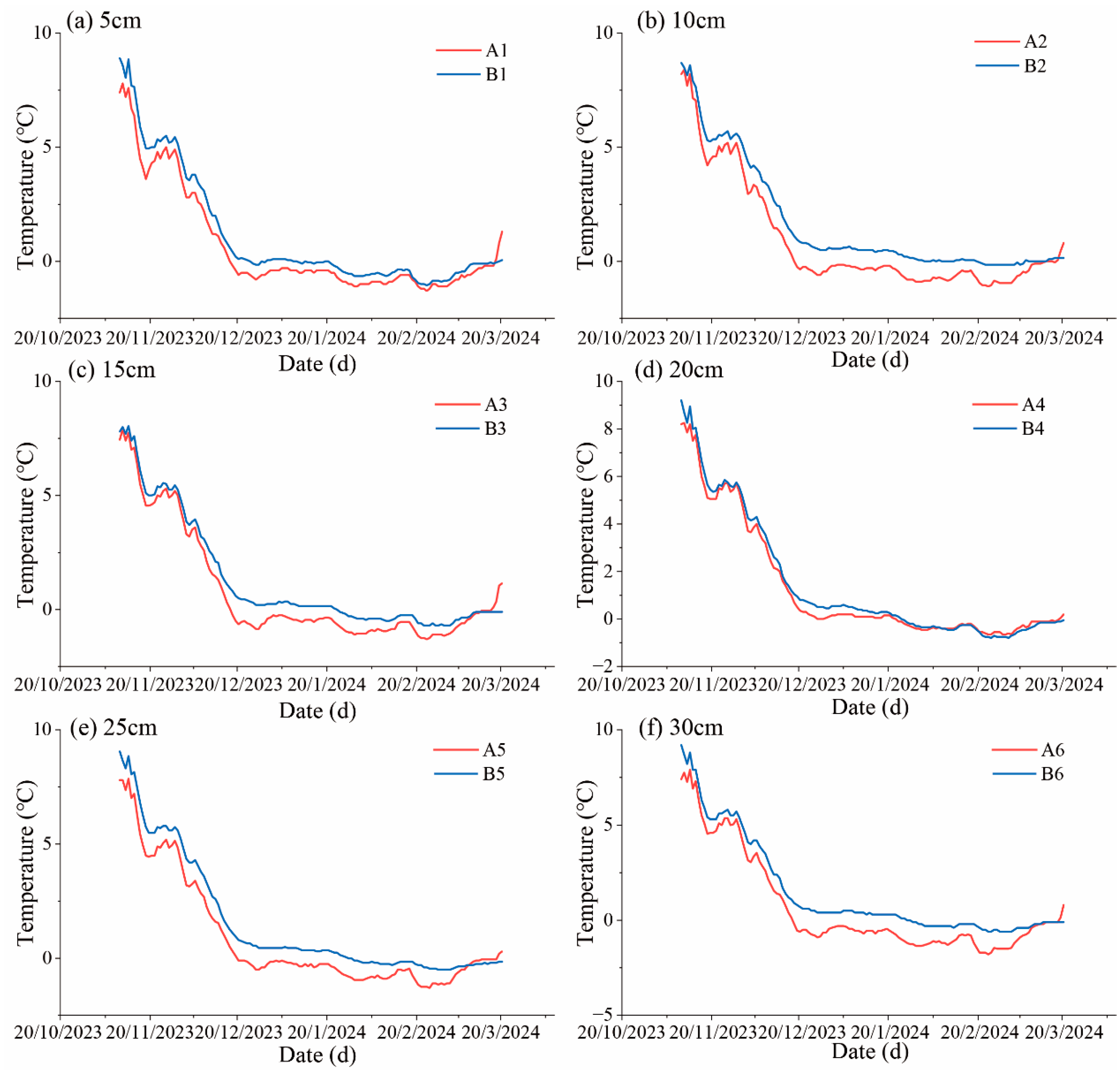

3.1.2. Temperature Variation Characteristics at Branch Sites of Different Cover Materials at the Same Height

3.2. Temperature Variation Trends in the 20 cm Subsoil Layer During Overwintering

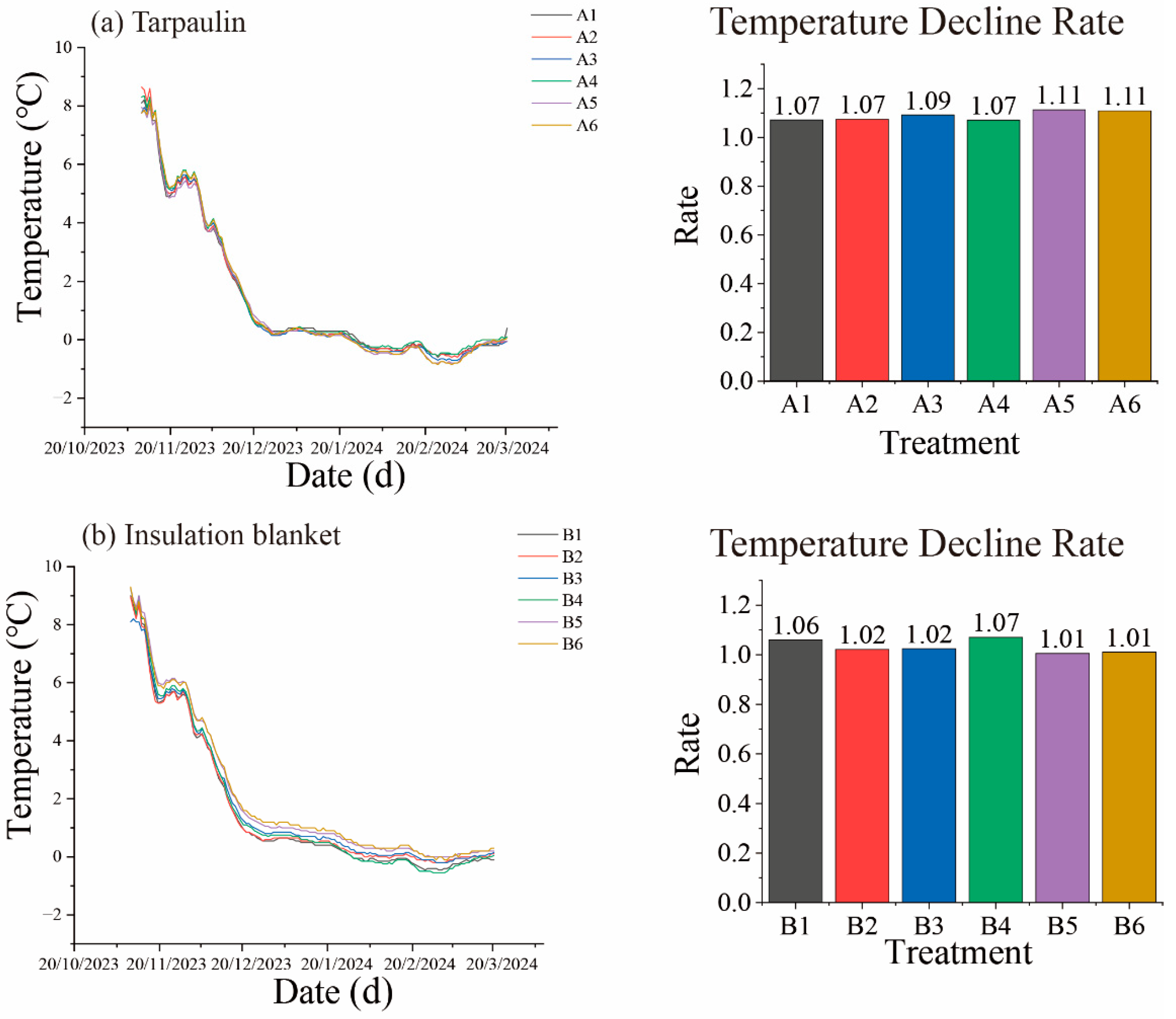

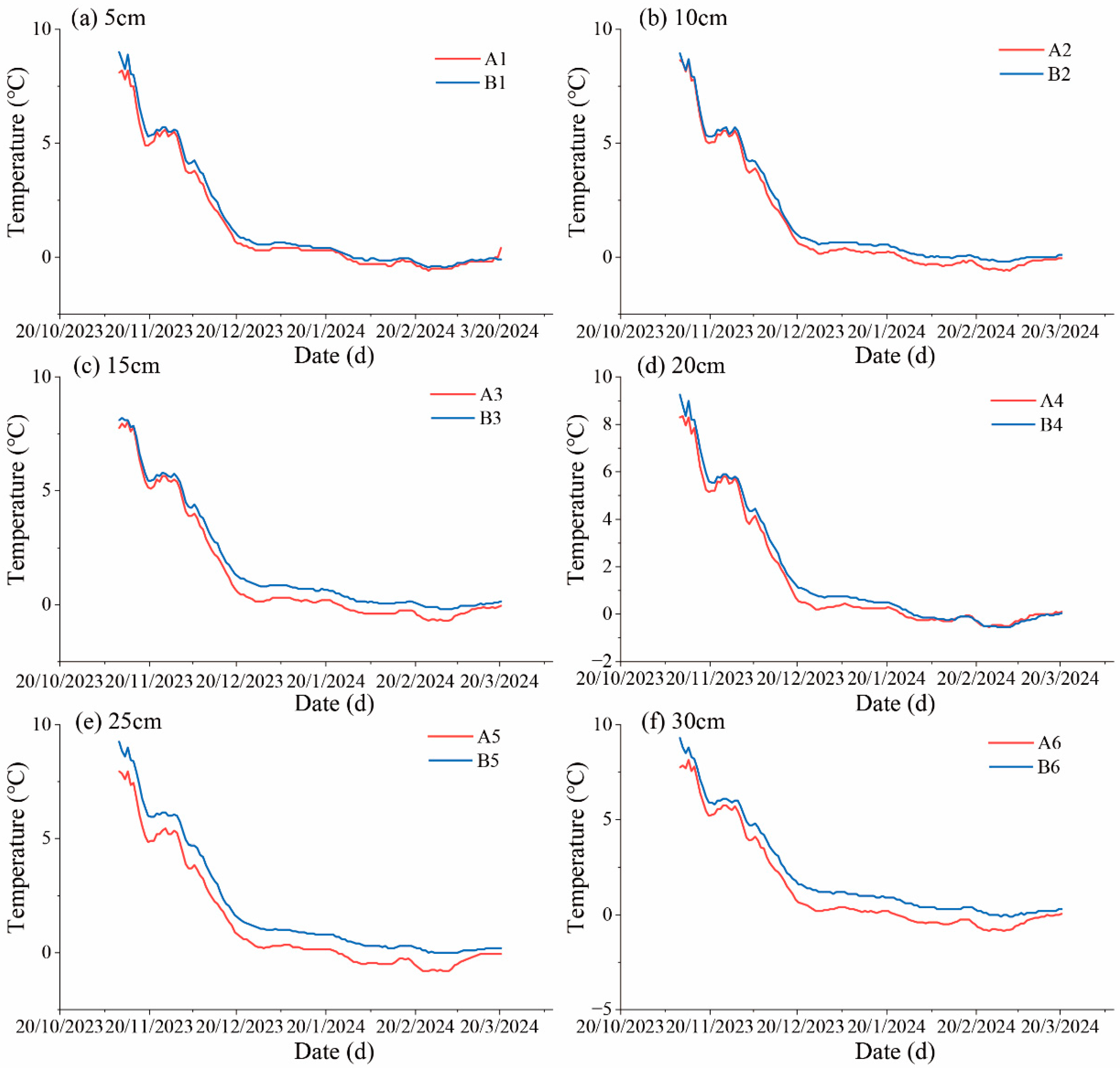

3.2.1. Comparison of Temperature in the 20 cm Subsoil Layer Under Different Heights of the Same Cover Material

3.2.2. Comparison of 20 cm Subsoil Temperature for Different Cover Materials at the Same Height

3.3. Temperature Variation Trends in the 40 cm Subsoil Layer During Overwintering

3.3.1. Comparison of 40 cm Subsoil Temperature for Different Heights of the Same Cover Material

3.3.2. Temperature Comparison at the 40 cm Subsoil Layer for Different Cover Materials at the Same Height

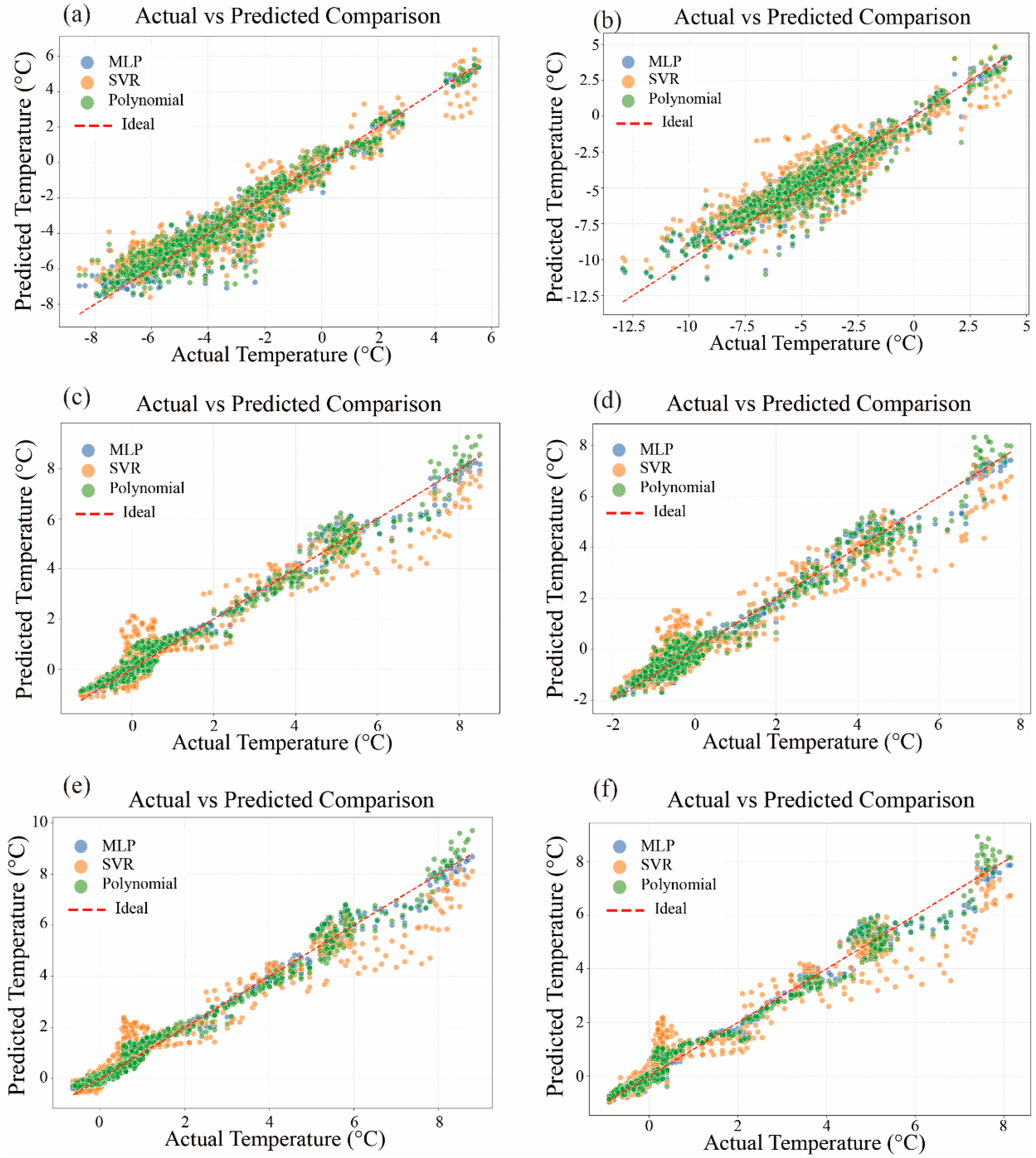

3.4. Prediction of Optimal Thermal Insulation Heights for Different Cover Materials Using Artificial Neural Networks

4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| ANN | artificial neural network |

| CFD | computational fluid dynamics |

| MLP | multilayer perceptron |

References

- Svyantek, A.; Köse, B.; Stenger, J.; Auwarter, C.; Hatterman-Valenti, H. Cold-Hardy Grape Cultivar Winter Injury and Trunk Re-Establishment Following Severe Weather Events in North Dakota. Horticulturae 2020, 6, 75. [Google Scholar] [CrossRef]

- Wan, N.; Yang, B.; Yin, D.; Ma, T.; Fang, Y.; Sun, X. Overwintering covered with soil or avoiding burial of wine grapes under cold stress: Chinese wine industry’s past and future, challenges and opportunities. Stress Biol. 2023, 3, 40. [Google Scholar] [CrossRef]

- Huang, S.; Liu, Q.; Wu, Y.; Chen, M.; Yin, H.; Zhao, J. Edible Mushroom Greenhouse Environment Prediction Model Based on Attention CNN-LSTM. Agronomy 2024, 14, 473. [Google Scholar] [CrossRef]

- Ambroise, V.; Legay, S.; Guerriero, G.; Hausman, J.-F.; Cuypers, A.; Sergeant, K. The Roots of Plant Frost Hardiness and Tolerance. Plant Cell Physiol. 2020, 61, 3–20. [Google Scholar] [CrossRef] [PubMed]

- Zhang, L.; Zhu, W.; Xu, G.; Zhang, L.; Liu, G.; Li, R.; Wang, Z.; Yang, F.; Wang, H.; Cheng, C.; et al. Effects of Winter Thermal Blanket Coverage on the Overwintering Physiological Metabolism of Grapevine Plants in the Eastern Foothills of Helan Mountain. J. China Agric. Univ. 2024, 29, 68–78. (In Chinese) [Google Scholar]

- Qin, Y.; Lu, H.; Xiao, L.; Yang, R.; Dong, C.; Hu, X. Study on Overwintering Covering of Field-Grown “Honey-Juice” Grape in Harbin Area. North. Hortic. 2019, 8, 47–52. (In Chinese) [Google Scholar]

- Davenport, J.R.; Keller, M.; Mills, L.J. How Cold Can You Go? Frost and Winter Protection for Grape. HortScience Horts 2008, 43, 1966–1969. [Google Scholar] [CrossRef]

- Li, Y.; Pan, B.; Adili, W.; Shen, L.; Fang, G.; Li, Q.; Ma, H.; Li, X. Influence of Snowfall on the North Slope of Tianshan Mountains on the Overwintering of Grapes with Different Mulching Effects. J. Arid. Zone Resour. Environ. 2015, 29, 132–137. (In Chinese) [Google Scholar] [CrossRef]

- Abdel-Ghany, A.M.; Kozai, T. On the determination of the overall heat transmission coefficient and soil heat flux for a fog cooled, naturally ventilated greenhouse: Analysis of radiation and convection heat transfer. Energy Convers Manag. 2006, 47, 2612–2628. [Google Scholar] [CrossRef]

- Jain, D.; Tiwari, G.N. Effect of greenhouse on crop drying under natural and forced convection II. Thermal modeling and experimental validation. Energy Convers Manag. 2004, 45, 2777–2793. [Google Scholar] [CrossRef]

- Murad, R.I.; Abdel-Wahed, M.H.; Hassan, M.F.; Raslan, M.A. Performance of Low Agricultural Tunnels for Vegetables Production. Misr J. Agric. Eng. 2020, 35, 641–656. [Google Scholar] [CrossRef]

- Tian, D.; Li, Y.; Zhao, S.; Wu, Q.; Ma, C.; Song, W. An Analysis of the Influence of Construct Parameters on the Solar Radiation Input in an Insulated Plastic Greenhouse. Agronomy 2024, 14, 510. [Google Scholar] [CrossRef]

- Abid, H.; Ketata, A.; Lajnef, M.; Chiboub, H.; Driss, Z. Impact of greenhouse roof height on microclimate and agricultural practices: CFD and experimental investigations. J. Therm. Anal. Calorim. 2024, 149, 5483–5495. [Google Scholar] [CrossRef]

- El-Maghlany, W.M.; Teamah, M.A.; Tanaka, H. Optimum design and orientation of the greenhouses for maximum capture of solar energy in North Tropical Region. Energy Convers. Manag. 2015, 105, 1096–1104. [Google Scholar] [CrossRef]

- Guo, Z.Y.; Li, D.Y.; Wang, B.X. A novel concept for convective heat transfer enhancement. Int. J. Heat Mass Transf. 1998, 41, 2221–2225. [Google Scholar] [CrossRef]

- Bai, Y.; Xiong, Y.; Huang, J.; Zhou, J.; Zhang, B. Accurate prediction of soluble solid content of apples from multiple geographical regions by combining deep learning with spectral fingerprint features. Postharvest Biol. Technol. 2019, 156, 110943. [Google Scholar] [CrossRef]

- Bedi, P.; Gole, P. Plant disease detection using hybrid model based on convolutional autoencoder and convolutional neural network. Artif. Intell. Agric. 2021, 5, 90–101. [Google Scholar] [CrossRef]

- Cui, R.; Li, J.; Wang, Y.; Fang, S.; Yu, K.; Zhao, Y. Hyperspectral imaging coupled with dual-channel convolutional neural network for early detection of apple valsa canker. Comput. Electron. Agric. 2022, 202, 107411. [Google Scholar] [CrossRef]

- Daza, K.; Hernandez, J.; Florez, H. Hardware and software system for hydric estimation and crop irrigation scheduling. In Lecture Notes in Computer Science; Misra, S., Gervasi, O., Murgante, B., Stankova, E., Korkhov, V., Torre, C., Eds.; Springer International Publishing: Cham, Switzerland, 2019; pp. 150–165. [Google Scholar]

- Dong, C.; Zhang, Z.; Yue, J.; Zhou, L. Automatic recognition of strawberry diseases and pests using convolutional neural network. Smart Agric. Technol. 2021, 1, 100009. [Google Scholar] [CrossRef]

- Machado, R.M.A.; Oliveira, M.D.R.G. Tomato root distribution, yield and fruit quality under different subsurface drip irrigation regimes and depths. Irrig. Sci. 2005, 24, 15–24. [Google Scholar] [CrossRef]

- Ji, M.; Zhang, L.; Wu, Q. Automatic grape leaf diseases identification via UnitedModel based on multiple convolutional neural networks. Inf. Process. Agric. 2020, 7, 418–426. [Google Scholar] [CrossRef]

- Yang, M.; Xu, D.; Chen, S.; Li, H.; Shi, Z. Evaluation of machine learning approaches to predict soil organic matter and pH using vis-NIR spectra. Sensors 2019, 19, 263. [Google Scholar] [CrossRef] [PubMed]

- Sharma, A.; Jain, A.; Gupta, P.; Chowdary, V. Machine Learning Applications for Precision Agriculture: A Comprehensive Review. IEEE Access 2021, 9, 4843–4873. [Google Scholar] [CrossRef]

- Shamshirband, S.; Esmaeilbeiki, F.; Zarehaghi, D.; Neyshabouri, M.; Samadianfard, S.; Ghorbani, M.A.; Mosavi, A.; Nabipour, N.; Chau, K.-W. Comparative analysis of hybrid models of firefly optimization algorithm with support vector machines and multilayer perceptron for predicting soil temperature at different depths. Eng. Appl. Comp. Fluid 2020, 14, 939–953. [Google Scholar] [CrossRef]

- Oh, K.C.; Park, S.; Kim, S.J.; Cho, L.H.; Lee, C.G.; Kim, D.H. Data-Driven Optimization Method for Recurrent Neural Network Algorithm: Greenhouse Internal Temperature Prediction Model. Agronomy 2024, 14, 2545. [Google Scholar] [CrossRef]

- Jung, D.-H.; Kim, H.S.; Jhin, C.; Kim, H.-J.; Park, S.H. Time-serial analysis of deep neural network models for prediction of climatic conditions inside a greenhouse. Comput. Electron. Agric. 2020, 173, 105402. [Google Scholar] [CrossRef]

- Ferreira, P.M.; Faria, E.A.; Ruano, A.E. Neural network models in greenhouse air temperature prediction. Neurocomputing 2002, 43, 51–75. [Google Scholar] [CrossRef]

- Dong, W.; Li, X.; Li, X.; Zhou, Z.; Lan, L.; Qu, W.; Liang, Q. Design and Application of Thermal Insulation Systems in Multi-span Greenhouses. Agric. Eng. 2024, 14, 61–64. (In Chinese) [Google Scholar] [CrossRef]

- Mao, J.; Chen, B.; Cao, J.; Wang, L.; Wang, H.; Wang, Y. Effects of different drip irrigation modes on root distribution of wine grape ‘Cabernet Sauvignon’ in desert area of Northwest China. Ying Yong Sheng Tai Xue Bao = J. Appl. Ecol. 2013, 24, 3084–3090. (In Chinese) [Google Scholar]

- Gabriel, K.R. The biplot graphic display of matrices with application to principal component analysis. Biometrika 1971, 58, 453–467. [Google Scholar] [CrossRef]

- Lightbody, G.; Irwin, G.W. Multi-layer perceptron based modelling of nonlinear systems. Fuzzy Set Syst. 1996, 79, 93–112. [Google Scholar] [CrossRef]

- Petrakis, T.; Kavga, A.; Thomopoulos, V.; Argiriou, A.A. Neural network model for greenhouse microclimate predictions. Agriculture 2022, 12, 780. [Google Scholar] [CrossRef]

- Naskath, J.; Sivakamasundari, G.; Begum, A.A.S. A Study on Different Deep Learning Algorithms Used in Deep Neural Nets: MLP SOM and DBN. Wirel. Pers. Commun. 2023, 128, 2913–2936. [Google Scholar] [CrossRef]

- Jaihuni, M.; Basak, J.K.; Khan, F.; Okyere, F.G.; Sihalath, T.; Bhujel, A.; Park, J.; Lee, D.H.; Kim, H.T. A novel recurrent neural network approach in forecasting short term solar irradiance. ISA Trans. 2022, 121, 63–74. [Google Scholar] [CrossRef]

- Horiuchi, R.; Arakawa, K.; Kasuga, J.; Suzuki, T.; Jitsuyama, Y. Freezing resistance and behavior of winter buds and canes of wine grapes cultivated in northern Japan. Cryobiology 2021, 101, 44–51. [Google Scholar] [CrossRef]

- Li, H.; Duan, X.; Xu, H.; Yang, Y.; Zhu, N.; Yang, K.; Zhang, X.; Zhang, L. Comparison of the Effects of Overwintering Covering Cold-Protection Measures for Wine-making Grapes on Both Sides of Helan Mountain. Chin. Agric. Meteorol. 2022, 43, 575–586. (In Chinese) [Google Scholar]

- Semenov, V.; Kozlov, S.; Zhukov, A.; Ter-Zakaryan, K.; Zinovieva, E.; Fomina, E. Insulation systems for buildings and structures based on expanded polyethylene. In 6th International Scientific Conference on Integration, Partnership and Innovation in Construction Science and Education (IPICSE); Volkov, A., Pustovgar, A., Adamtsevich, A., Eds.; EDP Sciences: Les Ulis, France, 2018; Volume 251. [Google Scholar]

- Mobtaker, H.G.; Ajabshirchi, Y.; Ranjbar, S.F.; Matloobi, M. Simulation of thermal performance of solar greenhouse in north-west of Iran: An experimental validation. Renew. Energ. 2019, 135, 88–97. [Google Scholar] [CrossRef]

- Sun, Q.; Song, Y.; Yang, Z.; Liu, X.; Cui, S. Analysis of the light performance of Chinese solar greenhouse with internal insulation based on a solar radiation model. Front. Energy Res. 2023, 11, 1247153. [Google Scholar] [CrossRef]

- Barrera-Animas, A.Y.; Oyedele, L.O.; Bilal, M.; Akinosho, T.D.; Delgado, J.M.D.; Akanbi, L.A. Rainfall prediction: A comparative analysis of modern machine learning algorithms for time-series forecasting. Mach. Learn. Appl. 2022, 7, 100204. [Google Scholar] [CrossRef]

- Illston, B.G.; Fiebrich, C.A. Horizontal and vertical variability of observed soil temperatures. Geosci. Data J. 2017, 4, 40–46. [Google Scholar] [CrossRef]

- Tong, G.; Christopher, D.M.; Li, T.; Wang, T. Passive solar energy utilization: A review of cross-section building parameter selection for Chinese solar greenhouses. Renew. Sustain. Energy Rev. 2013, 26, 540–548. [Google Scholar] [CrossRef]

- Tong, G.; Christopher, D.M.; Li, B. Numerical modelling of temperature variations in a Chinese solar greenhouse. Comput. Electron. Agric. 2009, 68, 129–139. [Google Scholar] [CrossRef]

- Zhang, X.; Lv, J.; Xie, J.; Yu, J.; Zhang, J.; Tang, C.; Li, J.; He, Z.; Wang, C. Solar Radiation Allocation and Spatial Distribution in Chinese Solar Greenhouses: Model Development and Application. Energies 2020, 13, 1108. [Google Scholar] [CrossRef]

- Çakır, U.; Şahin, E. Using solar greenhouses in cold climates and evaluating optimum type according to sizing, position and location: A case study. Comput. Electron. Agric. 2015, 117, 245–257. [Google Scholar] [CrossRef]

- Ma, J.; Du, X.; Meng, S.; Ding, J.; Gu, X.; Zhang, Y.; Li, T.; Wang, R. Simulation of Thermal Performance in a Typical Chinese Solar Greenhouse. Agronomy 2022, 12, 2255. [Google Scholar] [CrossRef]

- Xu, F.; Li, S.; Ma, C.; Zhao, S.; Han, J.; Liu, Y.; Hu, B.; Wang, S. Thermal environment of chinese solar greenhouses: Analysis and simulation. Appl. Eng. Agric. 2013, 29, 991–997. [Google Scholar]

| Covering Materials | Height | |||||

|---|---|---|---|---|---|---|

| 5 cm | 10 cm | 15 cm | 20 cm | 25 cm | 30 cm | |

| Tarpaulin | A1 | A2 | A3 | A4 | A5 | A6 |

| Insulation Blanket | B1 | B2 | B3 | B4 | B5 | B6 |

| Variable Description | Sensor Type | Unit | Spatial Location | Raw Data Range | Total Observations | |

|---|---|---|---|---|---|---|

| Tarpaulin-covered system (5 to 30 cm) | Air temperature | Pengyun 21A | °C | Aboveground (branch level) | 32.7 to −12.95 | 57,456 |

| Soil temperature (20 cm depth) | Pengyun 21A | °C | Subsoil | 9.1 to −2 | 57,456 | |

| Soil temperature (40 cm depth) | Pengyun 21A | °C | Subsoil | 11.2 to −0.9 | 57,456 | |

| Insulation-blanket-covered system (5 to 30 cm) | Air temperature | Pengyun 21A | °C | Aboveground (branch level) | 25.75 to −8.55 | 57,456 |

| Soil temperature (20 cm depth) | Pengyun 21A | °C | Subsoil | 9.1 to −0.25 | 57,456 | |

| Soil temperature (40 cm depth) | Pengyun 21A | °C | Subsoil | 9.25 to −0.2 | 57,456 | |

| External environment | Ambient temperature | Pengyun 21A | °C | Aboveground (open field) | 25.7 to −32.5 | 57,456 |

| Cumulative days since overwintering | Pengyun 21A | d | - | 0 to 133 | 133 | |

| Insulation height | Manual measurement | cm | Aboveground | 5 to 30 | 6 | |

| Interaction term (Temp × Height) | Derived | - | - | 102 to −978 | 788 | |

| Insulation System | Measurement Position | Model Type | R2 | MAE (°C) | RMSE (°C) |

|---|---|---|---|---|---|

| Tarpaulin | Branch level | MLP | 0.92 | 0.62 | 0.87 |

| SVR | 0.90 | 0.77 | 1.00 | ||

| Polynomial regression | 0.91 | 0.66 | 0.92 | ||

| Subsoil (20 cm depth) | MLP | 0.99 | 0.20 | 0.31 | |

| SVR | 0.92 | 0.48 | 0.71 | ||

| Polynomial regression | 0.97 | 0.31 | 0.40 | ||

| Subsoil (40 cm depth) | MLP | 0.99 | 0.17 | 0.26 | |

| SVR | 0.93 | 0.42 | 0.65 | ||

| Polynomial regression | 0.98 | 0.25 | 0.34 | ||

| Insulation blanket | Branch level | MLP | 0.89 | 0.70 | 0.99 |

| SVR | 0.85 | 0.90 | 1.17 | ||

| Polynomial regression | 0.88 | 0.75 | 1.05 | ||

| Subsoil (20 cm depth) | MLP | 0.98 | 0.23 | 0.35 | |

| SVR | 0.91 | 0.49 | 0.71 | ||

| Polynomial regression | 0.97 | 0.32 | 0.43 | ||

| Subsoil (40 cm depth) | MLP | 0.99 | 0.18 | 0.28 | |

| SVR | 0.93 | 0.41 | 0.66 | ||

| Polynomial regression | 0.98 | 0.26 | 0.37 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ma, Y.; Yang, J.; Chen, Y.; Wang, P.; Sun, Q. Neural-Network-Based Prediction of Non-Burial Overwintering Material Covering Height for Wine Grapes. Agronomy 2025, 15, 1060. https://doi.org/10.3390/agronomy15051060

Ma Y, Yang J, Chen Y, Wang P, Sun Q. Neural-Network-Based Prediction of Non-Burial Overwintering Material Covering Height for Wine Grapes. Agronomy. 2025; 15(5):1060. https://doi.org/10.3390/agronomy15051060

Chicago/Turabian StyleMa, Yunlong, Jinyue Yang, Yibo Chen, Ping Wang, and Qinming Sun. 2025. "Neural-Network-Based Prediction of Non-Burial Overwintering Material Covering Height for Wine Grapes" Agronomy 15, no. 5: 1060. https://doi.org/10.3390/agronomy15051060

APA StyleMa, Y., Yang, J., Chen, Y., Wang, P., & Sun, Q. (2025). Neural-Network-Based Prediction of Non-Burial Overwintering Material Covering Height for Wine Grapes. Agronomy, 15(5), 1060. https://doi.org/10.3390/agronomy15051060