Effect of Variety and Site on the Allometry Distribution of Seed Cotton Composition

Abstract

1. Introduction

2. Data and Methods

2.1. Description of the Region

2.2. Data Sources

2.3. Data Analysis

3. Results

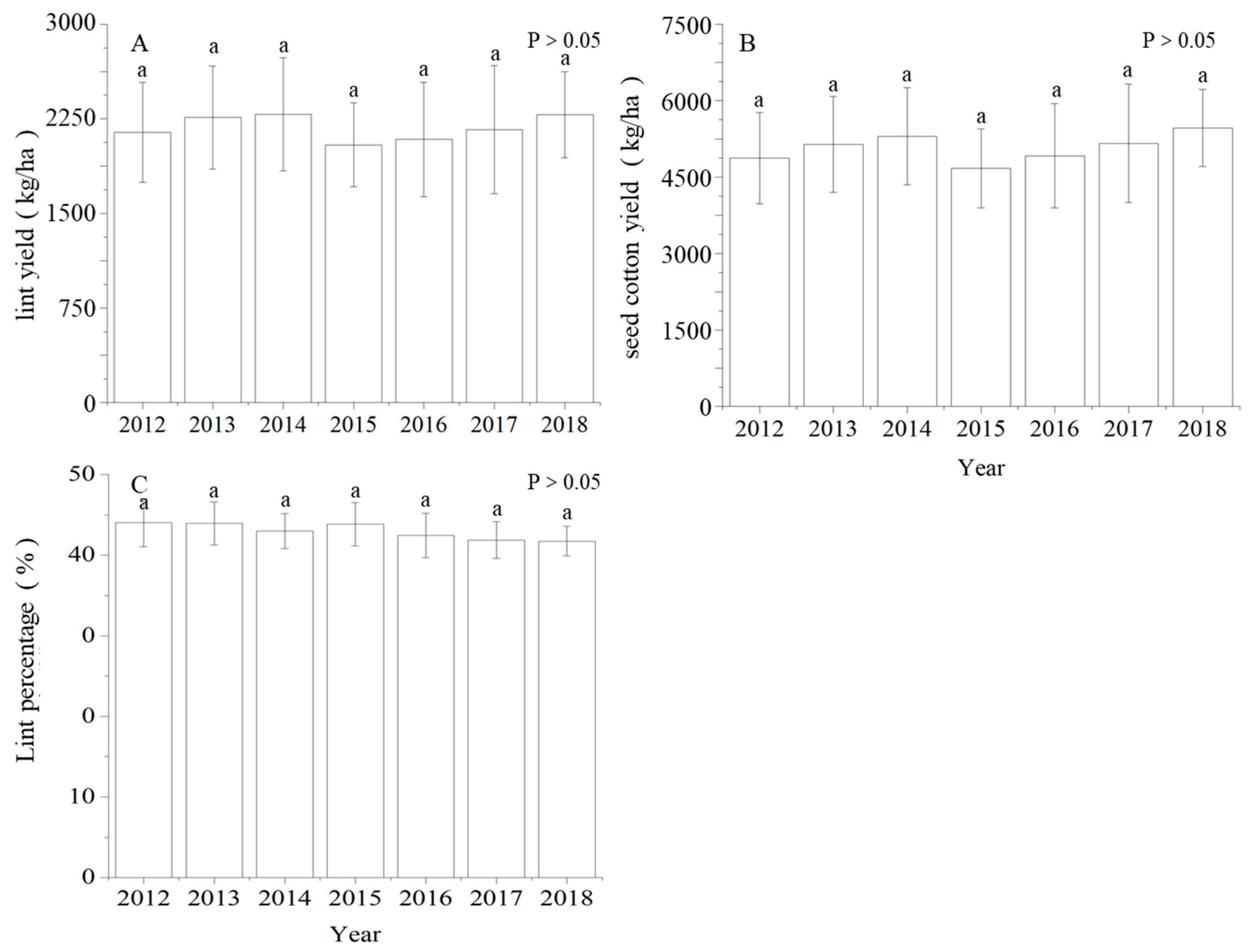

3.1. Change Pattern of Yield and Lint Percentage in the Regional Trials of Cotton Varieties from 2012 to 2018

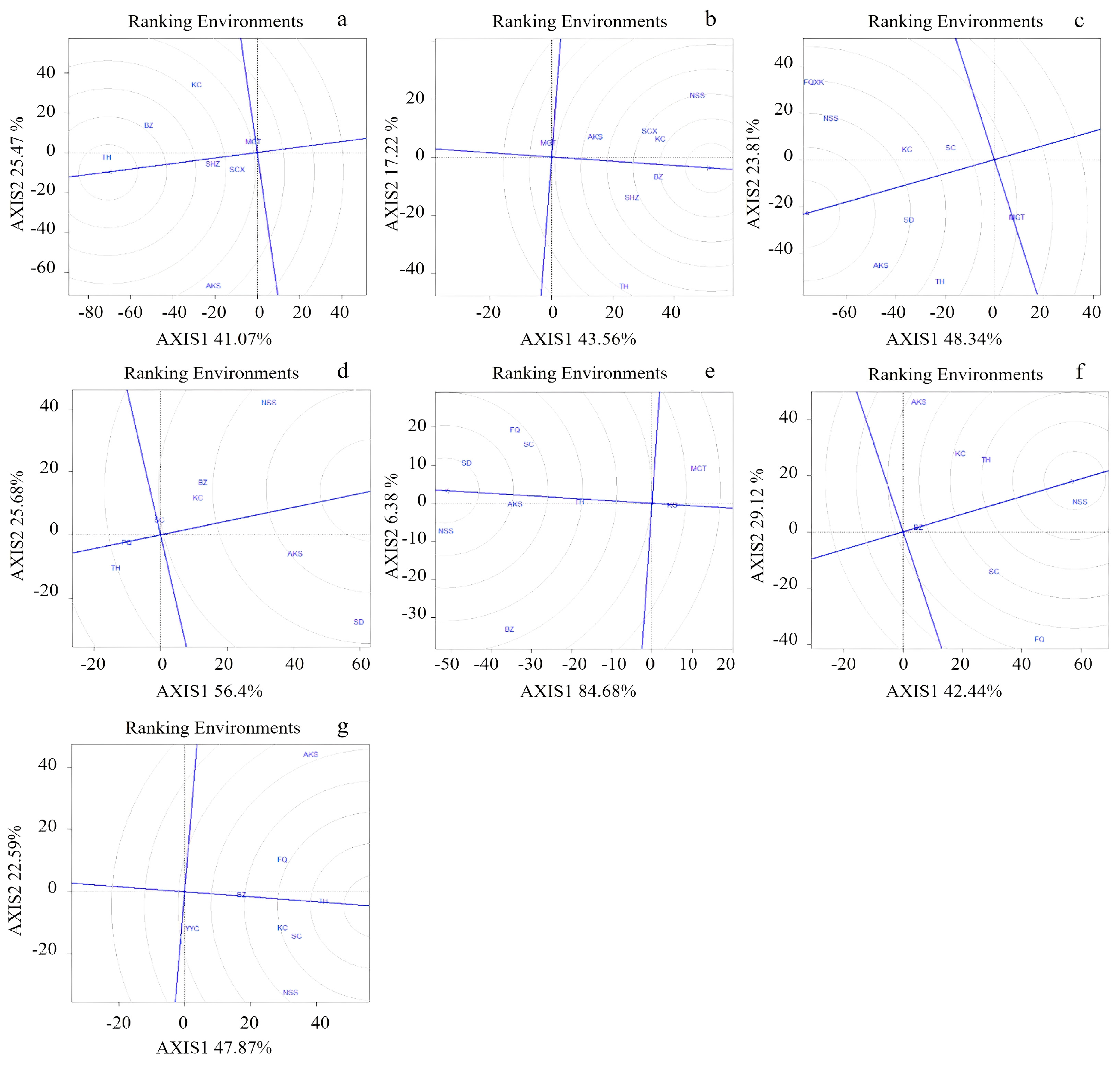

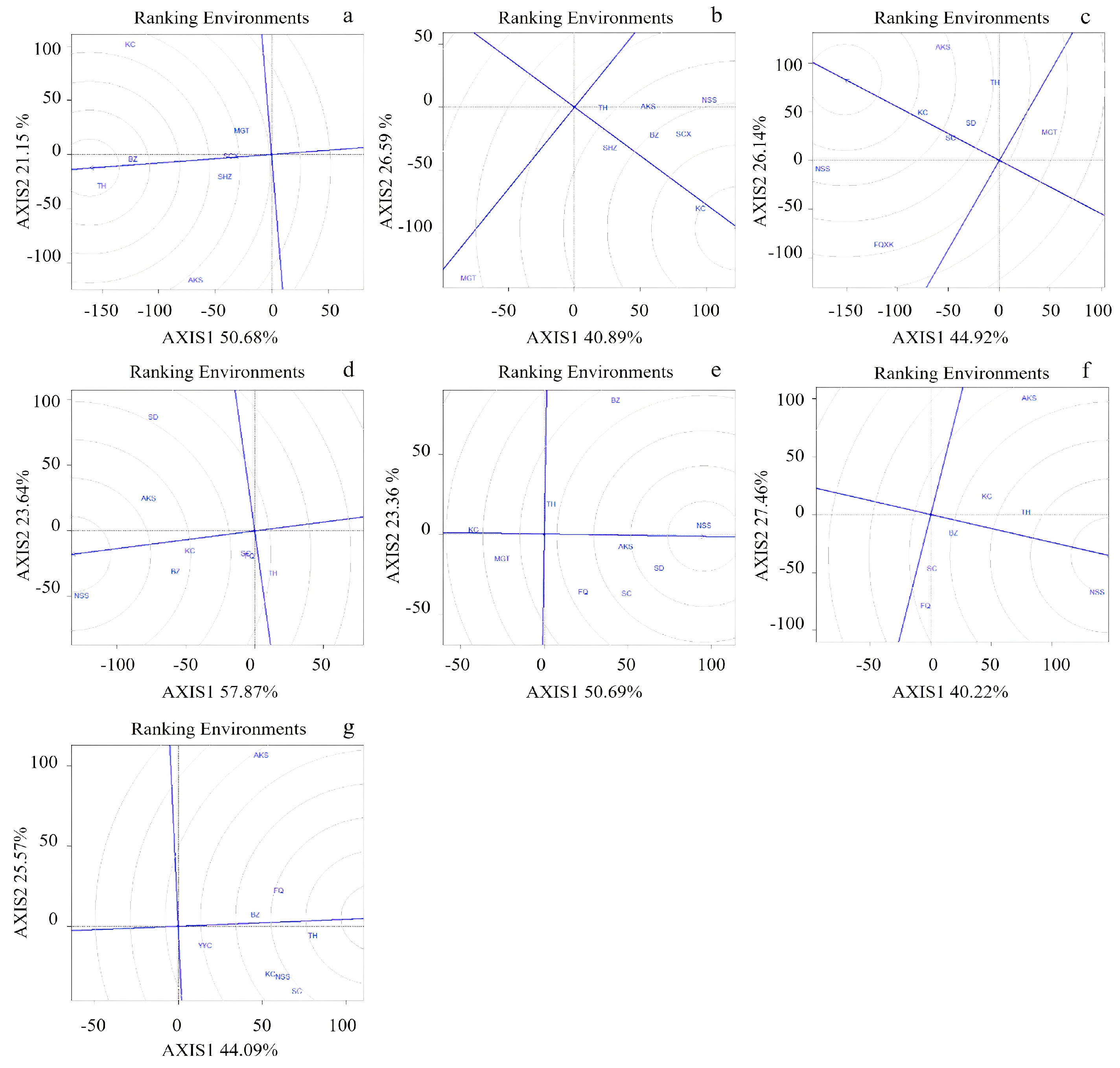

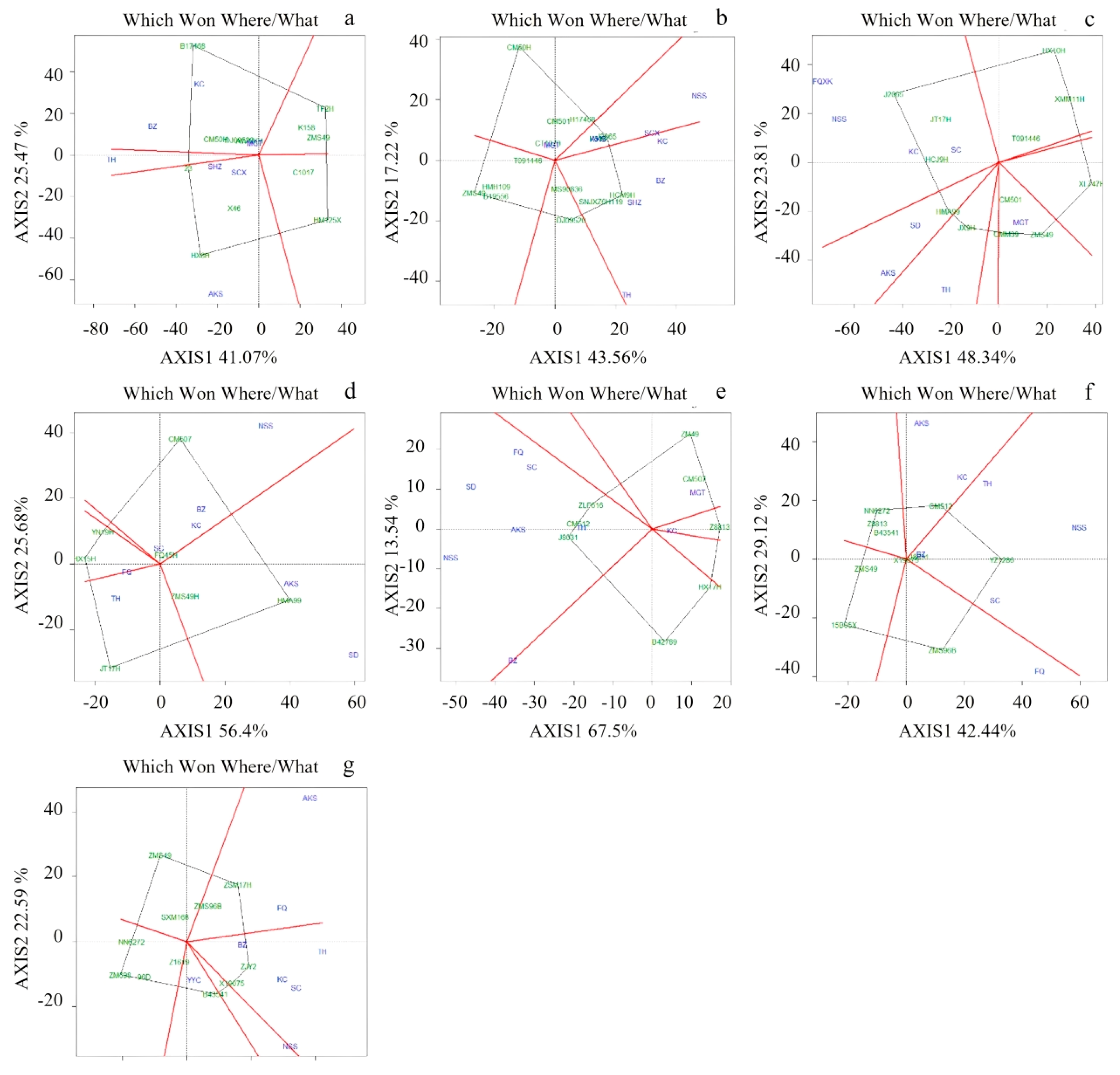

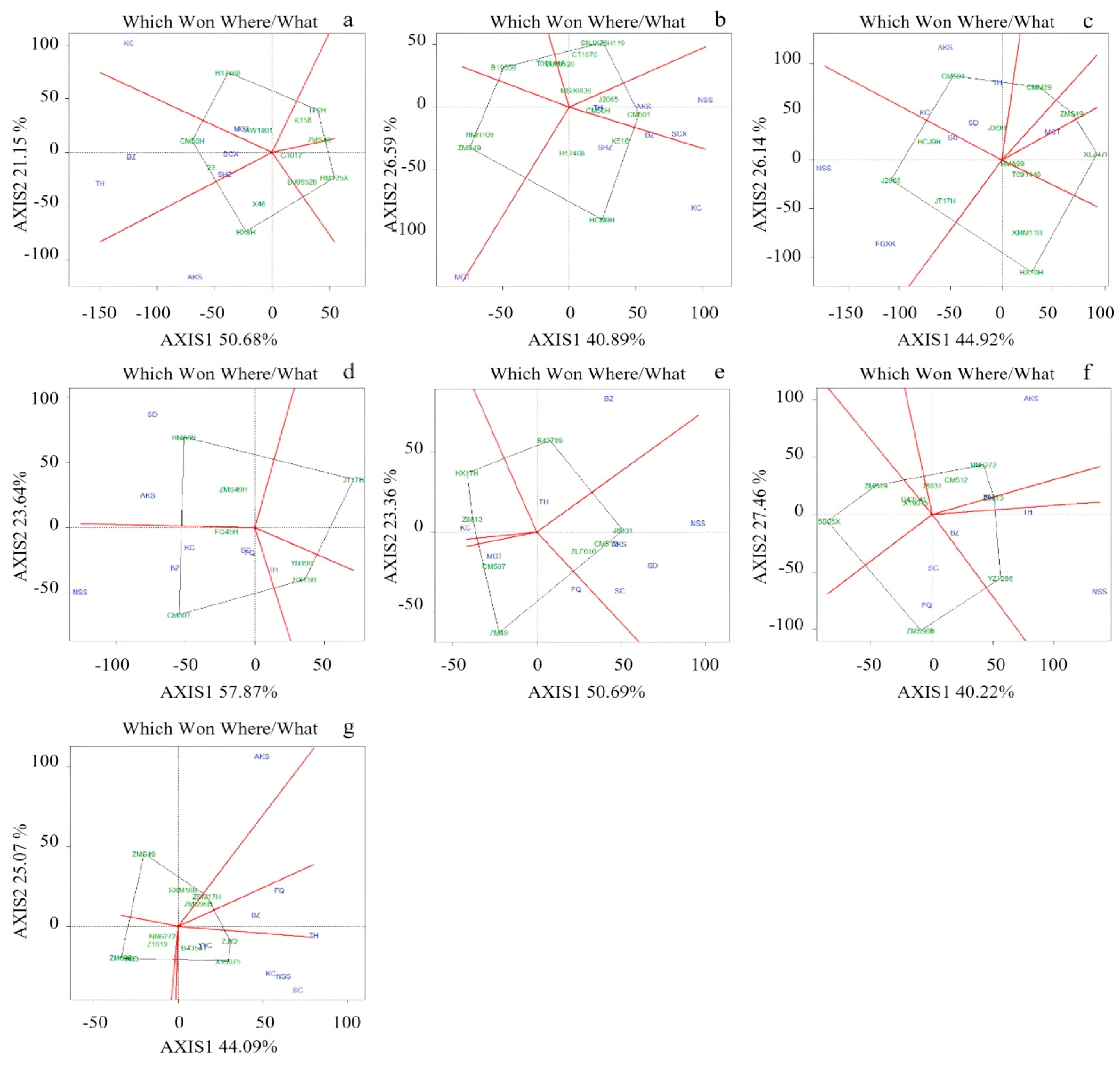

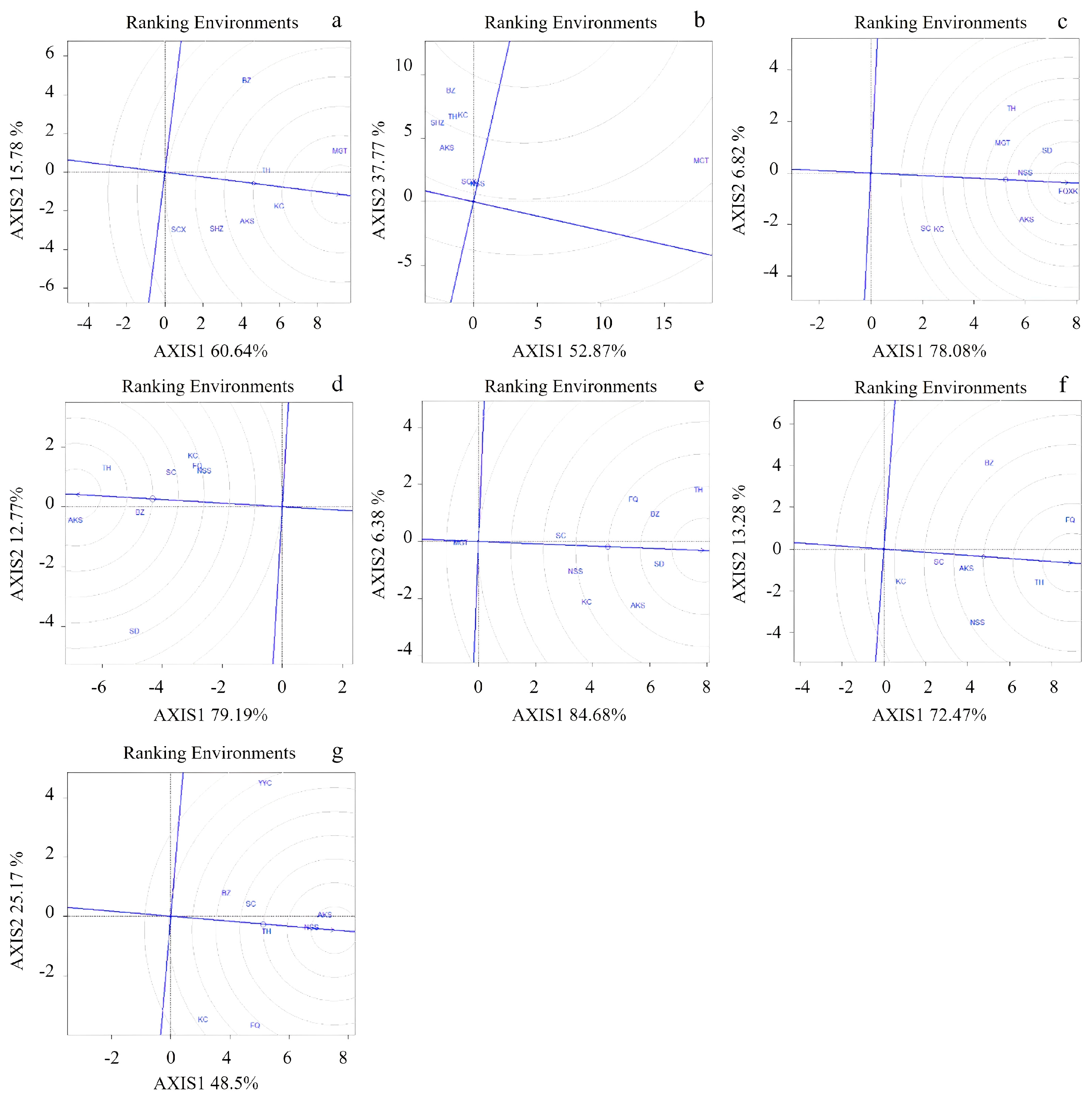

3.2. Cotton Planting Area Division Based on Yield

3.3. Division of Cotton Planting Areas Based on Lint Percentage

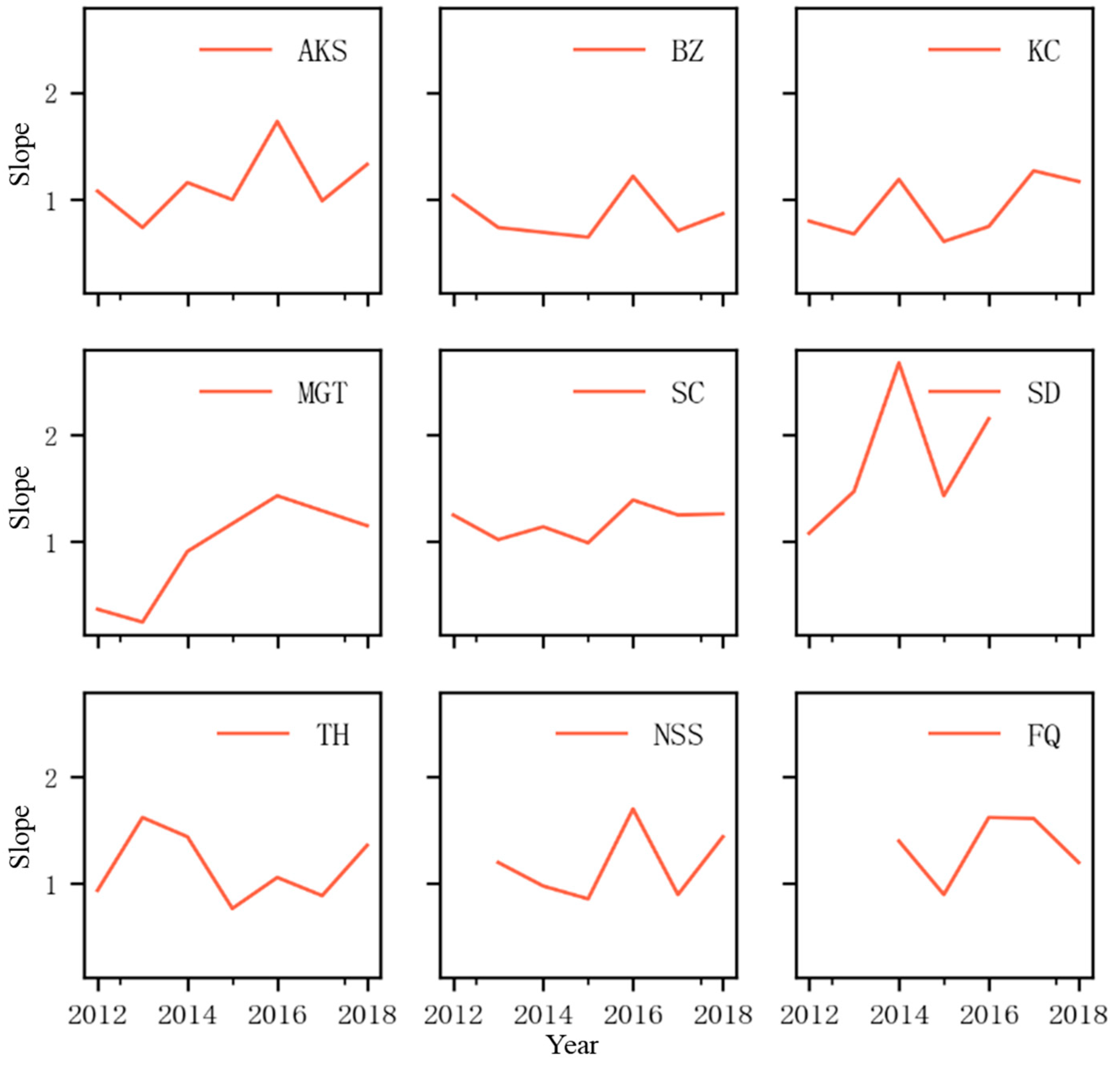

3.4. Heterozygous Growth of Seed Cotton Composition on Sites

3.5. Interannual Variation in Seed Cotton Composition of Heterozygous Growth

4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Appendix A

Appendix A.1. Site Information

Appendix A.2. GGE Analysis

Appendix A.3. SMRAT Software Setup Interface

Appendix B

| Location | Mean Annual Temperature (°C) | Annual Range (°C) | Accumulated Temperature (°C) | Duration (°C) | Annual Precipitation (mm) | Annual Sunshine Time (h) |

|---|---|---|---|---|---|---|

| Aksu | 10.9 | 33.4 | 3953 | 220.1 | 65.1 | 2621.2 |

| Bazhou | 11.7 | 33.4 | 4250 | 196.6 | 57.5 | 2670.1 |

| Kuche | 11.3 | 32.4 | 4134 | 199.4 | 74.6 | 2718.4 |

| Maigaiti | 11.8 | 30.9 | 4215 | 207.7 | 64.1 | 2727.6 |

| Shache | 11.7 | 30.8 | 4183 | 205 | 53.4 | 2861.4 |

| Shihezi University | 7.4 | 40.6 | 3770 | 176.3 | 181.1 | 2713.7 |

| Tahe | 10.7 | 31.2 | 4214 | 195.3 | 55.2 | 2868.2 |

| Fuquan | 9.5 | 32.9 | 3274 | 177.4 | 42.2 | 3259.3 |

| Nongsanshi | 12.1 | 35.2 | 4596.5 | 191.2 | 53.1 | 2596 |

| Year | Region | Preceding Crop | Sowing Period | Weeding and Cultivating (Time) | Irrigation and Drainage (Time) | Pruning (Time) | Chemical Regulation (Time) | Pest Control (Time) | Topping Period |

|---|---|---|---|---|---|---|---|---|---|

| 2012 | Aksu | Cotton | 18 April | 5 | 8 | 0 | 3 | 3 | 18 July |

| Bazhou | Cotton | 11 April | 3 | 5 | 0 | 6 | 0 | 8 July | |

| Kuche | Cotton | 14 April | 5 | 9 | 0 | 5 | 3 | 10 July | |

| Maigaiti | Cotton | 8 April | 5 | 4 | 0 | 6 | 2 | 13 July | |

| Shache | Cotton | 15 April | 3 | 4 | 0 | 3 | 4 | 3 July | |

| Shihezi | Cotton | 30 April | 3 | 8 | 4 | 3 | 12 July | ||

| Tahe | Cotton | 20 April | 5 | 11 | 0 | 7 | 5 July | ||

| 2013 | Aksu | Cotton | 18 April | 5 | 8 | 0 | 3 | 3 | 18 July |

| Bazhou | Cotton | 11 April | 3 | 5 | 0 | 6 | 0 | 8 July | |

| Kuche | Cotton | 14 April | 5 | 9 | 0 | 5 | 3 | 10 July | |

| Maigaiti | Cotton | 8 April | 5 | 4 | 0 | 6 | 2 | 13 July | |

| Shache | Cotton | 15 April | 3 | 4 | 0 | 3 | 4 | 3 July | |

| Shihezi | Cotton | 30 April | 3 | 8 | 0 | 4 | 3 | 12 July | |

| Tahe | Cotton | 17 April | N | 11 | 0 | 7 | 5 July | ||

| Nongsanshi | Cotton | 11 April | 8 | 14 | 0 | 4 | 3 | 9 July | |

| 2014 | Aksu | Cotton | 9 April | 3 | 9 | 0 | 3 | 3 | 23 July |

| Kuche | Cotton | 13 April | 2 | 9 | 0 | 5 | 3 | 20 July | |

| Maigaiti | Cotton | 8 April | 5 | 3 | 0 | 6 | 2 | 13 Dec | |

| Shache | Cotton | 10 April | 3 | 4 | 0 | 4 | 8 July | ||

| Shihezi | Cotton | 24 April | 3 | 10 | 0 | 3 | 9 | 16 July | |

| Tahe | Cotton | 11 April | N | 10 | 0 | 8 | 10 | 7 July | |

| Nongsanshi | Cotton | 15 April | 5 | 14 | 2 | 3 | 3 | 11 July | |

| Fuquan | Cotton | 18 April | 5 | 6 | 0 | 3 | 2 | 10 July | |

| 2015 | - | - | - | - | - | - | - | - | - |

| 2016 | Aksu | Cotton | 13 April | 3 | 9 | 0 | 3 | 3 | 23 July |

| Kuche | Cotton | 13 April | 4 | 9 | 0 | 5 | 4 | 12 July | |

| 2016 | Maigaiti | Cotton | 11 April | 5 | 7 | 0 | 4 | 8 | 13 July |

| Shache | Cotton | 15 April | 3 | 4 | 0 | 0 | 5 | 5 July | |

| Shihezi | Cotton | 21 April | 3 | 12 | 0 | 4 | 5 | 6 July | |

| Tahe | Cotton | 13 April | - | 9 | 2 | 6 | 12 | 2 July | |

| Nongsanshi | Cotton | 13 April | 5 | 11 | 0 | 5 | 4 | 5 July | |

| Fuquan | Cotton | 20 April | 5 | 8 | 0 | 4 | 3 | 10 July | |

| 2017 | Aksu | Cotton | 13 April | 3 | 9 | 0 | 3 | 3 | 23 July |

| Nongsanshi | Cotton | 17 April | 4 | 9 | 0 | 5 | 4 | 12 July | |

| Shache | Cotton | 12 April | 5 | 7 | 0 | 4 | 8 | 13 July | |

| Kuche | Cotton | 12 April | 3 | 4 | 0 | 0 | 5 | 5 July | |

| Tahe | Cotton | 11 April | 3 | 12 | 0 | 4 | 5 | 6 July | |

| Bazhou | Cotton | 21 April | N | 9 | 2 | 6 | 12 | 2 July | |

| Fuquan | Cotton | 19 April | 5 | 11 | 0 | 5 | 4 | 5 July | |

| 2018 | Aksu | Cotton | 6 May | 3 | 6 | 0 | 5 | 4 | 12 July |

| Bazhou | Cotton | 14 April | 3 | 11 | 0 | 7 | 12 | 9 July | |

| Fuquan | Cotton | 18 April | 5 | 8 | 0 | 3 | 2 | 10 July | |

| Kuche | Cotton | 12 April | 4 | 7 | 0 | 5 | 5 | 15 July | |

| Nongsanshi | Cotton | 10 April | 9 | 11 | 0 | 4 | 3 | 15 July | |

| Shache | Cotton | 14 April | 2 | 4 | 0 | 0 | 5 | 6 July | |

| Tahe | Cotton | 15 April | - | 11 | 0 | 6 | 12 | 5 July | |

| Maigaiti | Cotton | 20 April | 8 | 11 | 1 | 5 | 12 | 13 July |

References

- Markinos, A.T.; Gemtos, T.A.; Pateras, D.; Toulios, L.; Zerva, G.; Papaeconomou, M. The influence of cotton variety in the calibration factor of a cotton yield monitor. Oper. Res. Int. J. 2005, 5, 165–176. [Google Scholar] [CrossRef]

- Desrochers, P.; Szurmak, J. Long Distance Trade, Locational Dynamics and By-Product Development: Insights from the History of the American Cottonseed Industry. Sustainability 2017, 9, 579. [Google Scholar] [CrossRef]

- Stewart, S. A Community Crop: Cotton, Science, and Extension in Interwar Shandong, 1918–1937. Twent.-Century China 2021, 46, 199–219. [Google Scholar] [CrossRef]

- Zhu, Y.; Zheng, B.; Luo, Q.; Jiao, W.; Yang, Y. Uncovering the Drivers and Regional Variability of Cotton Yield in China. Agriculture 2023, 13, 2132. [Google Scholar] [CrossRef]

- Dai, J.; Dong, H. Intensive cotton farming technologies in China: Achievements, challenges and countermeasures. Field Crops Res. 2014, 155, 99–110. [Google Scholar] [CrossRef]

- Feng, L.; Dai, J.; Tian, L.; Zhang, H.; Li, W.; Dong, H. Review of the technology for high-yielding and efficient cotton cultivation in the northwest inland cotton-growing region of China. Field Crops Res. 2017, 208, 18–26. [Google Scholar] [CrossRef]

- Chen, W.; Hou, Z.; Wu, L.; Liang, Y.; Wei, C. Effects of salinity and nitrogen on cotton growth in arid environment. Plant Soil. 2010, 326, 61–73. [Google Scholar] [CrossRef]

- Vitale, G.S.; Aurelio, S.; Silvia, Z.; Teresa, T.; Carmelo, S.; Gaetano, P.; Sara, L.; Umberto, A.; Paolo, G. Agronomic Strategies for Sustainable Cotton Production: A Systematic Literature Review. Agriculture 2024, 14, 1597. [Google Scholar] [CrossRef]

- Khan, A.; Tan, D.K.Y.; Munsif, F.; Afridi, M.Z.; Shah, F.; Wei, F.; Fahad, S.; Zhou, R. Nitrogen nutrition in cotton and control strategies for greenhouse gas emissions: A review. Environ. Sci. Pollut. Res. 2017, 24, 23471–23487. [Google Scholar] [CrossRef]

- Macdonald, B.C.T.; Chang, Y.F.; Nadelko, A.; Tuomi, S.; Glover, M. Tracking fertiliser and soil nitrogen in irrigated cotton: Uptake, losses and the soil N stock. Soil. Res. 2016, 55, 264–272. [Google Scholar] [CrossRef]

- Tao, R.; Wakelin, S.A.; Liang, Y.; Chu, G. Organic Fertilization Enhances Cotton Productivity, Nitrogen Use Efficiency, and Soil Nitrogen Fertility under Drip Irrigated Field. Agron. J. 2017, 109, 2889–2897. [Google Scholar] [CrossRef]

- Boulal, H.; Gómez-Macpherson, H.; Villalobos, F.J. Permanent bed planting in irrigated Mediterranean conditions: Short-term effects on soil quality, crop yield and water use efficiency. Field Crops Res. 2012, 130, 120–127. [Google Scholar] [CrossRef]

- Ma, Z.B.; Gong, Y.F.; Han, M.; Li, L.L.; Zhu, W. The influence of different soil textures on the spatiotemporal distribution and yield of cotton boll formation. J. Henan Agric. Univ. 2011, 45, 497–501. [Google Scholar]

- Nouri, A.; Lee, J.; Yin, X.; Tyler, D.D.; Saxton, A.M. Thirty-four years of no-tillage and cover crops improve soil quality and increase cotton yield in Alfisols, Southeastern USA. Geoderma 2019, 337, 998–1008. [Google Scholar] [CrossRef]

- Moreno, P.M.; Sproul, E.; Quinn, J.C. Economic and environmental sustainability assessment of guayule bagasse to fuel pathways. Ind. Crops Prod. 2022, 178, 114644. [Google Scholar] [CrossRef]

- Shojaei, S.H.; Mostafavi, K.; Bihamta, M.R.; Omrani, A.; Mousavi, S.M.N.; Illés, Á.; Bojtor, C.; Nagy, J. Stability on Maize Hybrids Based on GGE Biplot Graphical Technique. Agronomy 2022, 12, 394. [Google Scholar] [CrossRef]

- Lee, S.Y.; Lee, H.S.; Lee, C.M.; Ha, S.K.; Park, H.; Lee, S.; Kwon, Y.; Jeung, J.U.; Mo, Y. Multi-Environment Trials and Stability Analysis for Yield-Related Traits of Commercial Rice Cultivars. Agriculture 2023, 13, 256. [Google Scholar] [CrossRef]

- Malosetti, M.; Ribaut, J.-M.; van Eeuwijk, F.A. The statistical analysis of multi-environment data: Modeling genotype-by-environment interaction and its genetic basis. Front. Physiol. 2013, 4, 44. [Google Scholar] [CrossRef]

- Wu, J.; Wang, Y.; Xiang, L.; Gu, Y.; Yan, Y.; Li, L.; Tian, X.; Jing, W.; Wang, X. Machine learning model to predict the efficacy of antiseizure medications in patients with familial genetic generalized epilepsy. Epilepsy Res. 2022, 181, 106888. [Google Scholar] [CrossRef]

- Beninde, J.; Veith, M.; Hochkirch, A. Biodiversity in cities needs space: A meta-analysis of factors determining intra-urban biodiversity variation. Ecol. Lett. 2015, 18, 581–592. [Google Scholar] [CrossRef]

- Cassman, K.G. Ecological intensification of cereal production systems: Yield potential, soil quality, and precision agriculture. Proc. Natl. Acad. Sci. USA 1999, 96, 5952–5959. [Google Scholar] [CrossRef] [PubMed]

- Isaacs, K.; Weltzien, E.; Some, H.; Diallo, A.; Diallo, B.; Sidibé, M.; vom Brocke, K.; Samake, B.; Nebié, B.; Rattunde, F.W. Increasing sorghum yields for smallholder farmers in Mali: The evolution towards a context-driven, on-farm, gender-responsive sorghum breeding program. Front. Sustain. Food Syst. 2024, 8, 1334385. [Google Scholar] [CrossRef]

- Lin, B.B. Resilience in Agriculture through Crop Diversification: Adaptive Management for Environmental Change. BioScience 2011, 61, 183–193. [Google Scholar] [CrossRef]

- Yan, W.K. GGEbiplot—A Windows Application for Graphical Analysis of Multienvironment Trial Data and Other Types of Two-Way Data. Agron. J. 2001, 93, 1111–1118. [Google Scholar] [CrossRef]

- Xu, N.Y.; Zhang, G.W.; Li, J.; Zhou, Z. Environmental evaluation of cotton regional test in Yangtze River Basin based on GGE biplot and fiber length selection. Resour. Environ. Yangtze Basin 2013, 22, 735–741. [Google Scholar] [CrossRef]

- Tang, S.R.; Xu, N.Y.; Yang, W.H.; Wei, S.; Zhou, Z. Is based on the analysis of the GGE northwest inland cotton fiber quality ecological division. J. Chin. Ecol. Agric. 2016, 24, 1674–1682. [Google Scholar] [CrossRef]

- Daemo, B.B.; Zeleke, A. Application of AMMI and GGE biplot for genotype by environment interaction and yield stability analysis in potato genotypes grown in Dawuro zone, Ethiopia. J. Agric. Food Res. 2024, 18, 101287. [Google Scholar] [CrossRef]

- Liu, Y.; Zhao, X.; Liu, W.; Feng, B.; Lv, W.; Zhang, Z.; Yang, X.; Dong, Q. Plant biomass partitioning in alpine meadows under different herbivores as influenced by soil bulk density and available nutrients. Catena 2024, 240, 108017. [Google Scholar] [CrossRef]

- Matloob, A.; Aslam, F.; Rehman, H.U.; Khaliq, A.; Ahmad, S.; Yasmeen, A.; Hussain, N. Cotton-Based Cropping Systems and Their Impacts on Production. In Cotton Production and Uses: Agronomy, Crop Protection, and Postharvest Technologies; Ahmad, S., Hasanuzzaman, M., Eds.; Springer: Singapore, 2020; pp. 283–310. [Google Scholar] [CrossRef]

- Wang, C.X.; Yuan, W.M.; Liu, J.J.; Xie, X.Y.; Ma, Q.; Jiu, J.S.; Chen, Y.Y.; Wang, N.; Feng, K.Y.; Su, J.J. Comprehensive evaluation and breeding evolution of early-maturing landrace cotton varieties in inland Northwest China. Chin. Agric. Sci. 2023, 56, 1–21. [Google Scholar]

- Thorp, K.R.; Ale, S.; Bange, M.P.; Barnes, E.M.; Hoogenboom, G.; Lascano, R.J.; McCarthy, A.C.; Nair, S.; Paz, J.O.; Rajan, N.; et al. Development and application of process-based simulation models for cotton production: A review of past, present, and future directions. J. Cotton Sci. 2014, 18, 10–47. [Google Scholar] [CrossRef]

- Westgeest, A.J.; Vasseur, F.; Enquist, B.J.; Milla, R.; Gómez-Fernández, A.; Pot, D.; Vile, D.; Violle, C. An allometry perspective on crops. New Phytol. 2024, 244, 1223–1237. [Google Scholar] [CrossRef]

- Hardin, R.G.; Barnes, E.M.; Delhom, C.D.; Wanjura, J.D.; Ward, J.K. Internet of things: Cotton harvesting and processing. Comput. Electron. Agric. 2022, 202, 107294. [Google Scholar] [CrossRef]

- Sun, Q.; Chen, S.; Sun, L.; Qiao, C.; Li, X.; Wang, L. Calculation and evaluation of cotton lint carbon footprint based on different cotton straw treatment methods: A case study of Northwest China. J. Clean. Prod. 2024, 484, 144374. [Google Scholar] [CrossRef]

- Tlatlaa, J.S.; Tryphone, G.M.; Nassary, E.K. Unexplored agronomic, socioeconomic and policy domains for sustainable cotton production on small landholdings: A systematic review. Front. Agron. 2023, 5, 1281043. [Google Scholar] [CrossRef]

- Scarpin, G.J.; Dileo, P.N.; Winkler, H.M.; Cereijo, A.E.; Lorenzini, F.G.; Roeschlin, R.A.; Muchut, R.J.; Acuña, C.; Paytas, M. Genetic progress in cotton lint and yield components in Argentina. Field Crops Res. 2022, 275, 108322. [Google Scholar] [CrossRef]

- Zhang, Q.H.; He, W.Z.; Pei, M.Y. Analysis of yield and related traits of spring cotton varieties approved by the state in the Yellow River Basin from 2011 to 2020. China Cotton 2023, 50, 17–21. [Google Scholar] [CrossRef]

- Mao, S.C.; Cheng, S.X.; Ma, X.Y.; Wei, S.J.; Tang, S.R.; Wang, W.K.; Wang, Z.B. Quality Changes of Main Cotton Varieties in Xinjiang from 2018 to 2020 and Suggestions for Selection and Promotion of High Quality Cotton Varieties. China Cotton 2021, 48, 1–7. [Google Scholar]

- Benaragama, D.; Rossnagel, B.G.; Shirtliffe, S.J. Breeding for Competitive and High-Yielding Crop Cultivars. Crop Sci. 2014, 54, 1015–1025. [Google Scholar] [CrossRef]

- Joshi, K.D.; Musa, A.M.; Johansen, C.; Gyawali, S.; Harris, D.; Witcombe, J.R. Highly client-oriented breeding, using local preferences and selection, produces widely adapted rice varieties. Field Crops Res. 2007, 100, 107–116. [Google Scholar] [CrossRef]

| Region | Abbreviation | Year | Altitude | Longitude | Latitude |

|---|---|---|---|---|---|

| Aksu | AKS | 2012–2018 | 1028 | 80°45′ | 40°37′ |

| Bazhou | BZ | 2012–2013, 2015–2018 | 1500 | 86°70′ | 41°44′ |

| Kuche | KC | 2012–2018 | 1099 | 82°54′ | 41°21′ |

| Maigaiti | MGT | 2012–2014, 2016, 2018 | 1180 | 77°70′ | 38°90′ |

| Shache | SC | 2012–2018 | 1236 | 77°20′ | 38°40′ |

| Shihezi University | SD | 2012–2016, 2018 | 443 | 86°20′ | 44°20′ |

| Tahe | TH | 2013–2018 | 917 | 73°10′ | 34°55′ |

| Fuquan | FQ | 2014–2018 | 800 | 88°10′ | 45°00′ |

| Nongsanshi | NSS | 2013–2018 | 1050 | 86°07′ | 40°31′ |

| Year | Variety |

|---|---|

| 2012 | ChuanMian 50 (XM50), Xin 46 (X46), 2–3, Kl58, B17468, DJ09-520, TianFeng 2 (TF2), AwlOOl, HuiXiang 8 (HX8), HuaiMian 125 (HM125), Cl017, ZhongMianSuo 49 (ZMS49) |

| 2013 | J206-5, ChuanMian 501 (CM501), HeMianH l09 (HMH109), ChengTian10-70 (CT1070), Ta 09-1446 (T091446), MS90836, K516, B17468, DJ09-520, ChuanMian 50 (CM50), ShengNong JXZ6H119 (SNJXZ6H119), HuaCuiMian 9 (HCM9), Ba 19556 (B19556), ZhongMianSuo 49 (ZMS49) |

| 2014 | XinLuZhong 47 (XLZ47), ZhongMianSuo 49 (ZMS49), Ta 09-1446 (T091446), HuiXiang 10 (HX10), HeMianA 9-9 (HMA99), JiTian 17 (JT17), XinMuMian 11 (XMM11), JinXin 9 (JX9), ChuanJinMian 39 (CJM39), ChuanMian 501 (CM501), 206-5, HuaCuiMian 9 (HCM9) |

| 2015 | HeMianA 9-9 (CMA99), HuiXiang15 (HX15), JiTian 17 (JT17), ChuanMian 507 (CM507), YouNong 19 (YN19), FuQuan 45 (FQ45), ZhongMianSuo 49 (ZMS49) |

| 2016 | ZLF 616, ChuanMian 507 (CM507), Zhong 8813 (Z8813), ChuanMian 512 (CM512), Ba 42789 (B42789), HuiXiang 17 (HX17), J8031, ZhongMian 49 (ZM49) |

| 2017 | ZhongMianSuo 49 (ZMS49), ZhongMianSuo 96B (ZMS96B), Zhong 8813 (Z8813), 15B05X\ChuanMian 512 (CM512), Ba 43541 (B53541), X 19075, YouZhi 1286 (YZ1286), J8031, Nanjing Agri. 6272 (NN6272) |

| 2018 | ZhongShengMian 17 (ZSM17), Nanjing Agri. 6272 (NN6272), Zhong 1619 (Z1619), Ba 43541 (B43541), SuxinMian 168 (SXM168), X 19075, ZhongMian 698 (ZM698), 96D, ZhongMianSuo 49, Zhejiang Jin Yan-2 (ZJY-2), ZhongMianSuo 96B (ZMS96B) |

| Year | Group | Slope | 95%CI | Interc | 95%CI | R2 | p |

|---|---|---|---|---|---|---|---|

| 2012 | AKS | 1.08 | 0.82~1.42 | 0.28 | 0.92~0.37 | 0.85 | <0.01 |

| BZ | 1.04 | 0.66~1.64 | 0.19 | 1.32~0.94 | 0.55 | <0.01 | |

| KC | 0.8 | 0.56~1.14 | 0.34 | 0.33~1.01 | 0.73 | <0.01 | |

| MGT | 0.37 | 0.2~0.68 | 1.33 | 0.8~1.87 | 0.12 | 0.27 | |

| SC | 1.25 | 0.86~1.83 | 0.77 | −1.88~0.35 | 0.7 | <0.01 | |

| SHZ | 1.08 | 0.66~1.78 | −0.23 | −1.44~0.98 | 0.46 | <0.05 | |

| TH | 0.94 | 0.66~1.34 | 0.04 | −0.75~0.84 | 0.74 | <0.01 | |

| 2013 | AKS | 0.74 | 0.5~1.09 | 0.46 | −0.19~1.11 | 0.6 | <0.01 |

| BZ | 0.74 | 0.43~1.27 | 0.53 | −0.42~1.48 | 0.17 | 0.15 | |

| KC | 0.68 | 0.45~1.02 | 0.63 | −0.03~1.29 | 0.54 | <0.01 | |

| MGT | 0.25 | 0.14~0.45 | 1.63 | 1.28~1.99 | 0.01 | 0.8 | |

| NSS | 1.2 | 0.87~1.67 | −0.59 | −1.55~0.37 | 0.72 | <0.01 | |

| SC | 1.02 | 0.8~1.31 | −0.17 | −0.75~0.4 | 0.84 | <0.01 | |

| SHZ | 1.47 | 0.92~2.33 | −1.11 | −2.63~0.42 | 0.42 | <0.01 | |

| TH | 1.62 | 0.93~2.81 | −1.58 | −3.78~0.62 | 0.15 | 0.17 | |

| 2014 | AKS | 1.16 | 0.81~1.65 | −0.51 | −1.46~0.44 | 0.74 | <0.01 |

| FQ | 1.4 | 0.9~2.18 | −1.05 | −2.56~0.47 | 0.57 | <0.01 | |

| KC | 1.19 | 0.88~1.62 | −0.58 | −1.42~0.27 | 0.8 | <0.01 | |

| MGT | 0.91 | 0.53~1.55 | 0.13 | −1.08~1.34 | 0.36 | <0.05 | |

| NSS | 0.98 | 0.64~1.49 | −0.09 | −1.1~0.93 | 0.62 | <0.01 | |

| SC | 1.14 | 0.83~1.58 | −0.45 | −1.3~0.39 | 0.78 | <0.01 | |

| SD | 2.67 | 1.61~4.42 | −3.82 | −6.94~−0.7 | 0.45 | <0.05 | |

| TH | 1.44 | 1~2.07 | −1.1 | −2.3~0.1 | 0.72 | <0.01 | |

| 2015 | AKS | 1 | 0.45~2.23 | −0.14 | −2.1~1.82 | 0.4 | 0.13 |

| BZ | 0.65 | 0.37~1.14 | 0.7 | −0.14~1.55 | 0.74 | <0.01 | |

| FQ | 0.9 | 0.36~2.28 | 0.12 | −2.08~2.32 | 0.14 | 0.41 | |

| KC | 0.61 | 0.32~1.16 | 0.79 | −0.13~1.71 | 0.65 | <0.05 | |

| NSS | 0.86 | 0.61~1.21 | 0.2 | −0.5~0.9 | 0.91 | <0.01 | |

| SC | 0.99 | 0.39~2.48 | −0.12 | −2.44~2.19 | 0.15 | 0.39 | |

| SD | 1.43 | 0.9~2.3 | −1 | −2.49~0.5 | 0.82 | <0.01 | |

| TH | 0.77 | 0.3~1.96 | 0.41 | −1.52~2.34 | 0.11 | 0.47 | |

| 2016 | AKS | 1.73 | 0.8~3.75 | −1.82 | −5.15~1.5 | 0.27 | 0.19 |

| BZ | 1.22 | 0.64~2.33 | −0.62 | −2.56~1.31 | 0.52 | <0.05 | |

| FQ | 1.62 | 0.68~3.86 | −1.58 | −5.39~2.22 | 0.03 | 0.67 | |

| KC | 0.75 | 0.37~1.5 | 0.45 | −0.85~1.76 | 0.44 | 0.08 | |

| MGT | 1.43 | 0.95~2.15 | −1.07 | −2.42~0.28 | 0.82 | <0.01 | |

| NSS | 1.7 | 1.2~2.4 | −1.84 | −3.27~−0.42 | 0.88 | <0.01 | |

| SC | 1.39 | 0.9~2.16 | −1.06 | −2.48~0.36 | 0.8 | <0.01 | |

| SD | 2.15 | 1.32~3.5 | −2.59 | −4.93~−0.24 | 0.74 | <0.01 | |

| TH | 1.06 | 0.45~2.51 | −0.21 | −2.38~1.97 | 0.04 | 0.62 | |

| 2017 | AKS | 0.99 | 0.75~1.3 | −0.14 | −0.73~0.45 | 0.88 | <0.01 |

| BZ | 0.71 | 0.35~1.45 | 0.53 | −0.69~1.75 | 0.09 | 0.39 | |

| FQ | 1.61 | 0.78~3.29 | −1.58 | −4.55~1.38 | 0.08 | 0.43 | |

| KC | 1.27 | 0.9~1.79 | −0.74 | −1.75~0.27 | 0.81 | <0.01 | |

| NSS | 0.9 | 0.56~1.45 | 0.11 | −0.97~1.19 | 0.63 | <0.01 | |

| SC | 1.25 | 0.93~1.66 | −0.72 | −1.54~0.11 | 0.87 | <0.01 | |

| TH | 0.89 | 0.47~1.7 | 0.11 | −1.34~1.56 | 0.29 | 0.11 | |

| 2018 | AKS | 1.33 | 0.8~2.21 | −0.95 | −2.63~0.73 | 0.5 | <0.05 |

| BZ | 0.87 | 0.57~1.33 | 0.16 | −0.7~1.01 | 0.67 | <0.01 | |

| FQ | 1.2 | 0.73~1.96 | −0.59 | −1.98~0.79 | 0.54 | <0.01 | |

| KC | 1.17 | 0.69~1.97 | −0.54 | −2.05~0.97 | 0.47 | <0.05 | |

| NSS | 1.44 | 0.82~2.52 | −1.2 | −3.22~0.82 | 0.39 | <0.05 | |

| SC | 1.26 | 0.98~1.63 | −0.76 | −1.5~−0.03 | 0.88 | <0.01 | |

| TH | 1.36 | 0.88~2.12 | −0.98 | −2.44~0.48 | 0.64 | <0.01 | |

| MGT | 1.15 | 0.6~2.2 | −0.48 | −2.33~1.38 | 0.15 | 0.23 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shi, L.; Sun, Z.; He, L.; Liu, G.; Liang, C. Effect of Variety and Site on the Allometry Distribution of Seed Cotton Composition. Agronomy 2025, 15, 989. https://doi.org/10.3390/agronomy15040989

Shi L, Sun Z, He L, Liu G, Liang C. Effect of Variety and Site on the Allometry Distribution of Seed Cotton Composition. Agronomy. 2025; 15(4):989. https://doi.org/10.3390/agronomy15040989

Chicago/Turabian StyleShi, Lei, Zenghui Sun, Lirong He, Guobin Liu, and Chutao Liang. 2025. "Effect of Variety and Site on the Allometry Distribution of Seed Cotton Composition" Agronomy 15, no. 4: 989. https://doi.org/10.3390/agronomy15040989

APA StyleShi, L., Sun, Z., He, L., Liu, G., & Liang, C. (2025). Effect of Variety and Site on the Allometry Distribution of Seed Cotton Composition. Agronomy, 15(4), 989. https://doi.org/10.3390/agronomy15040989