Effects of Premature Harvesting on Grain Weight and Quality: A Field Study

Abstract

1. Introduction

2. Materials and Methods

2.1. Survey Study

2.2. Field Experimentation and Growth Conditions

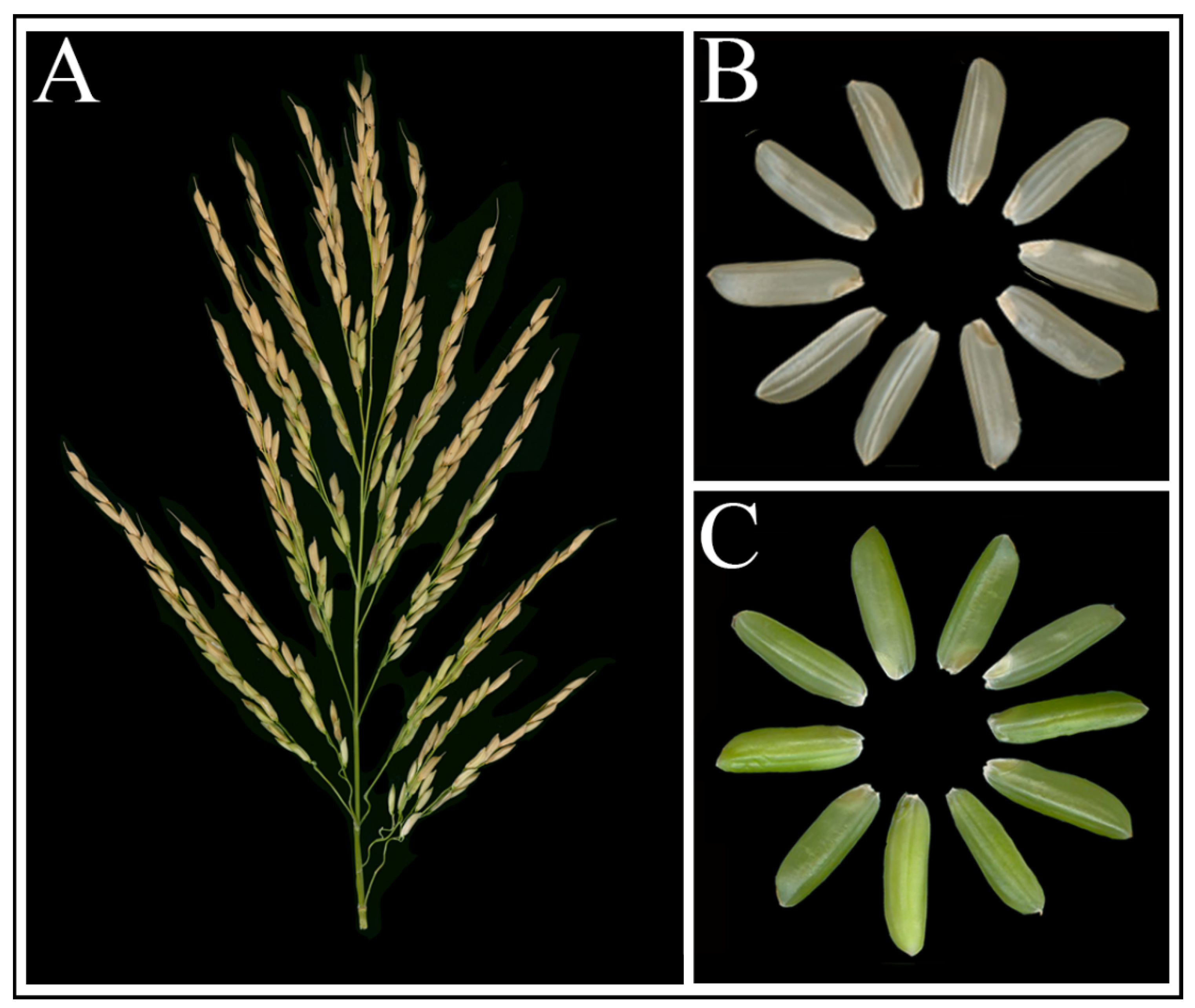

2.3. Determination of Green Rice Rate

2.4. Determination of Rice Quality

2.5. Statistical Analysis

3. Results

3.1. Premature Harvesting of Rice in Practices

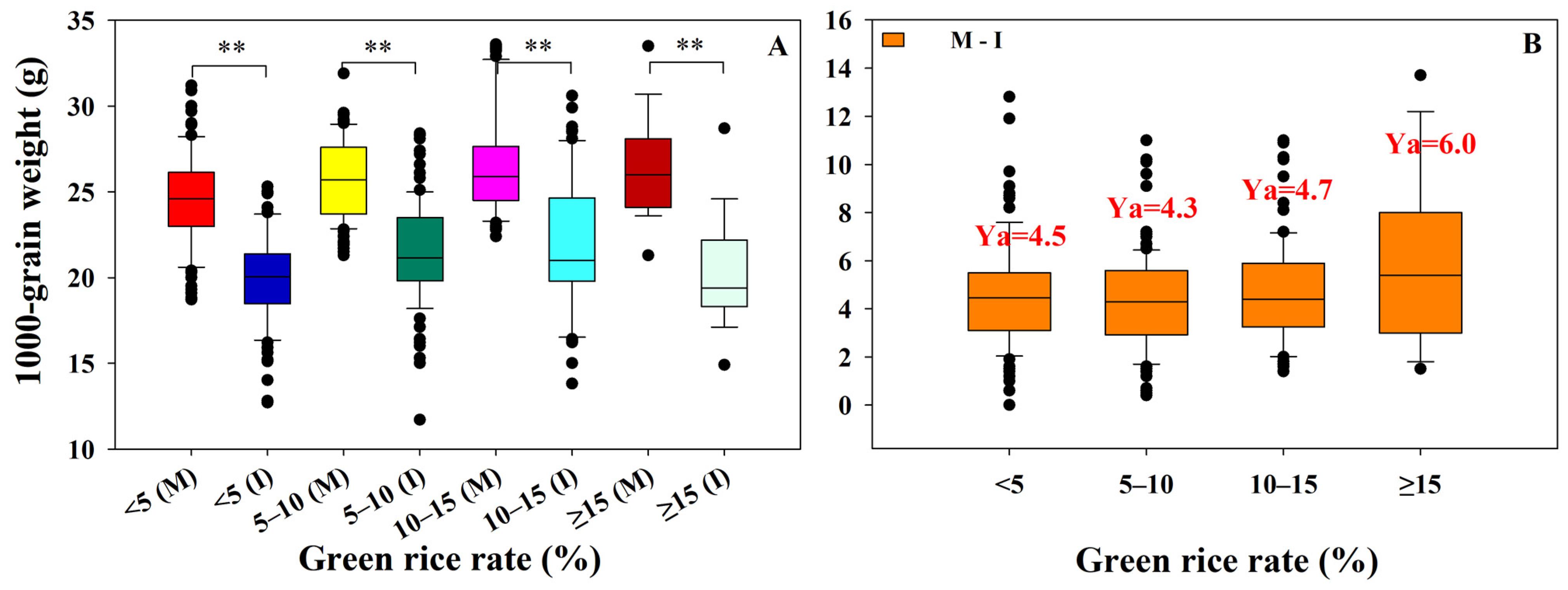

3.2. Difference in Grain Weight and Quality at Different Maturities in Survey Study

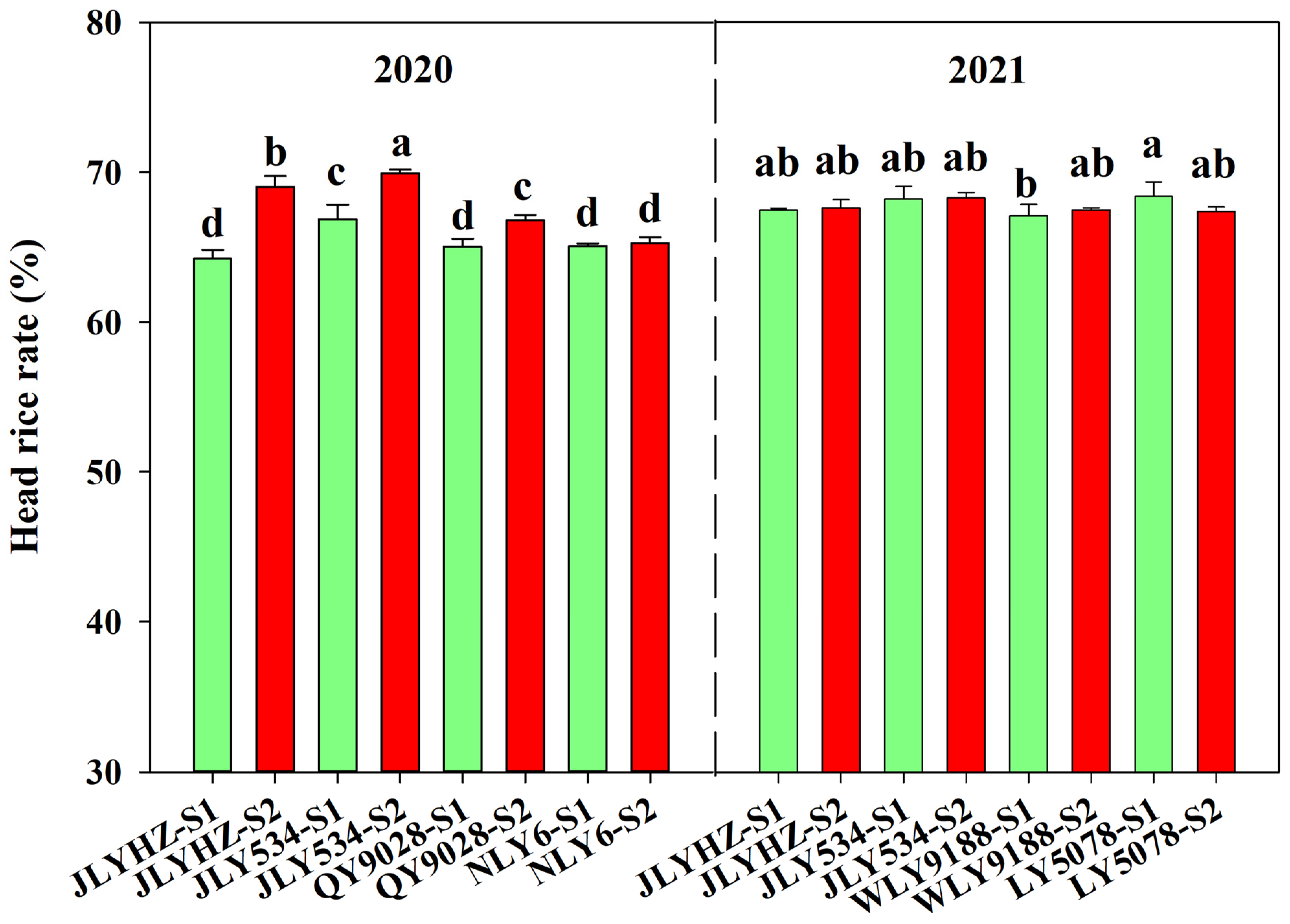

3.3. Response of Rice Quality to Different Maturities

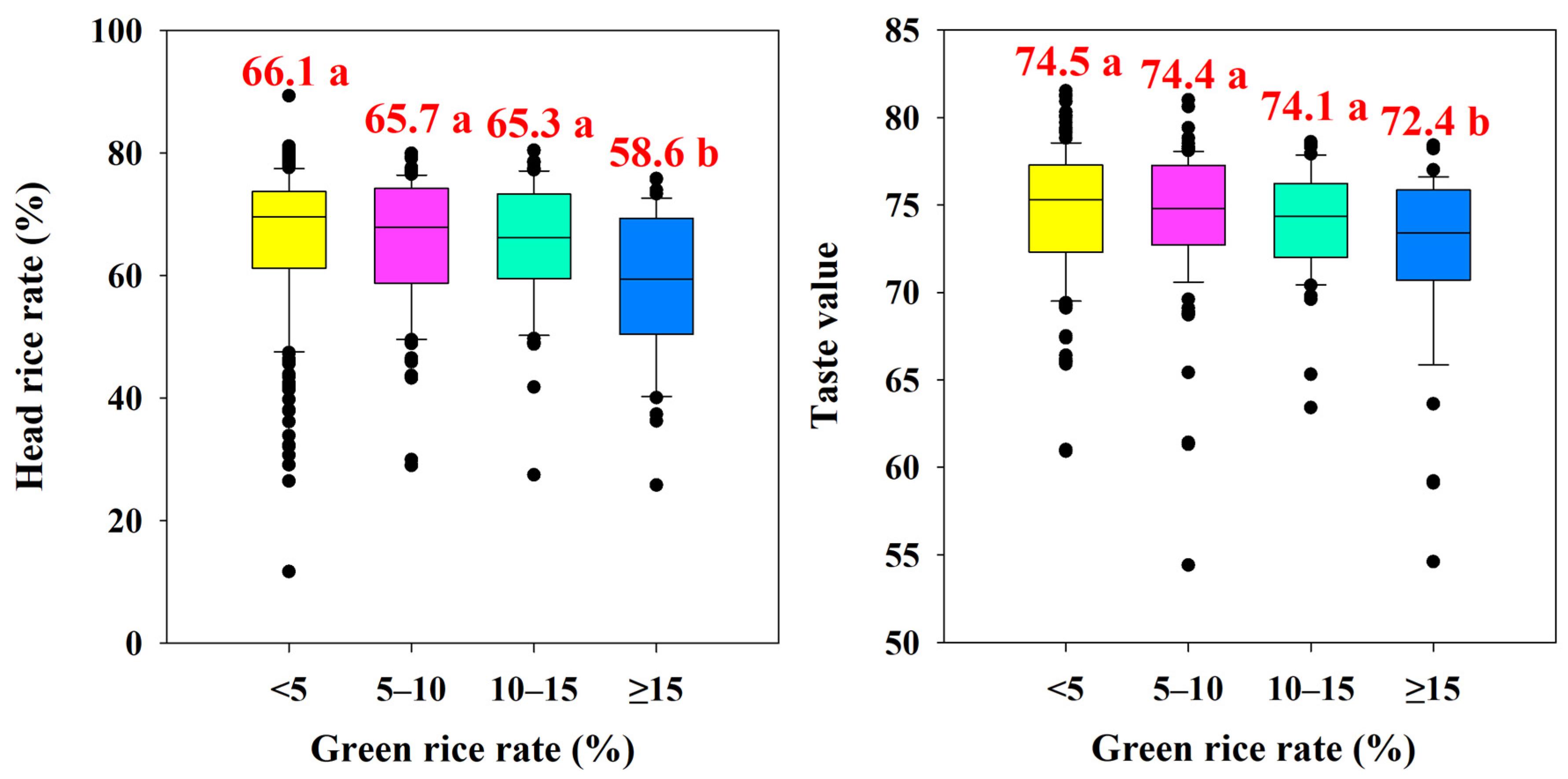

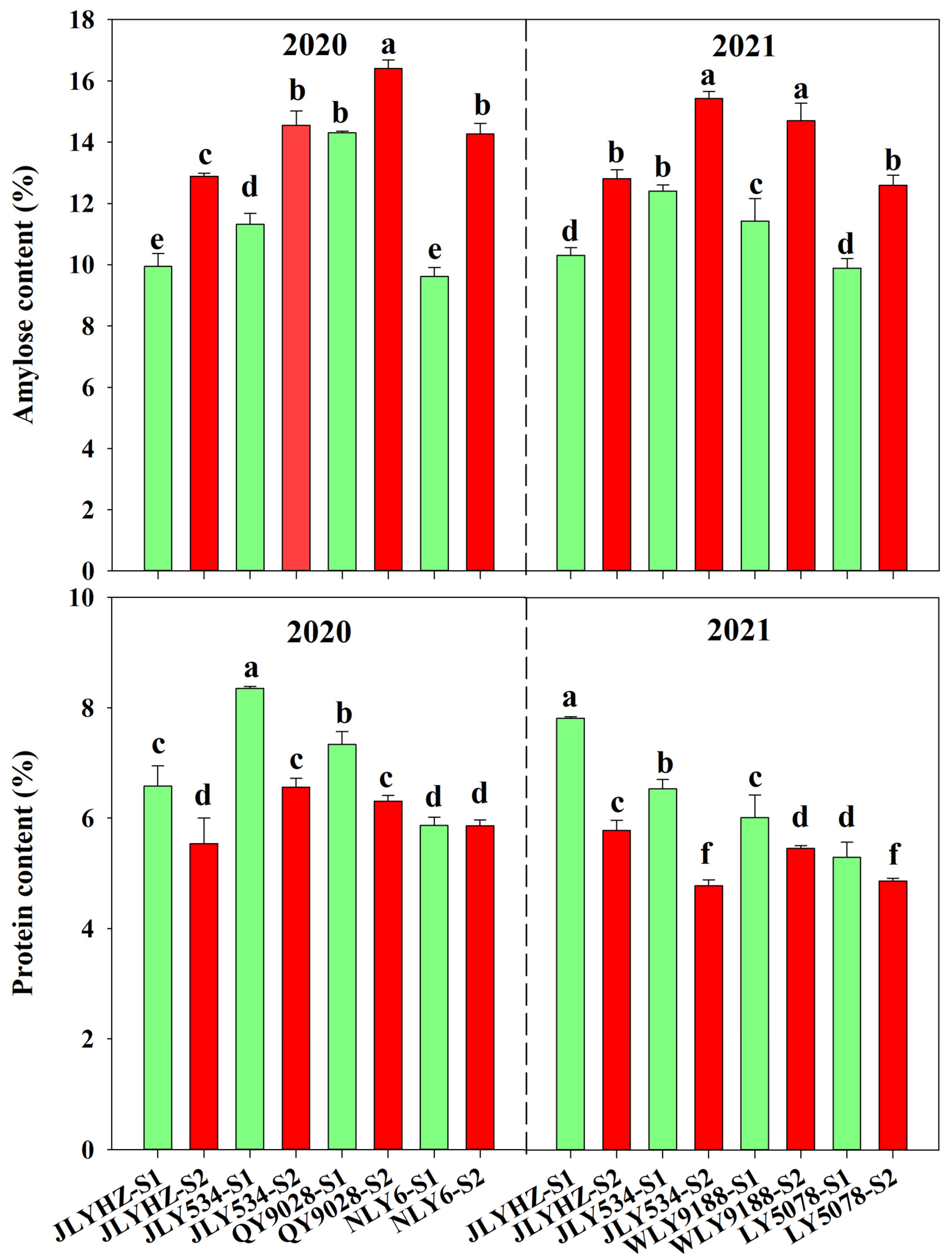

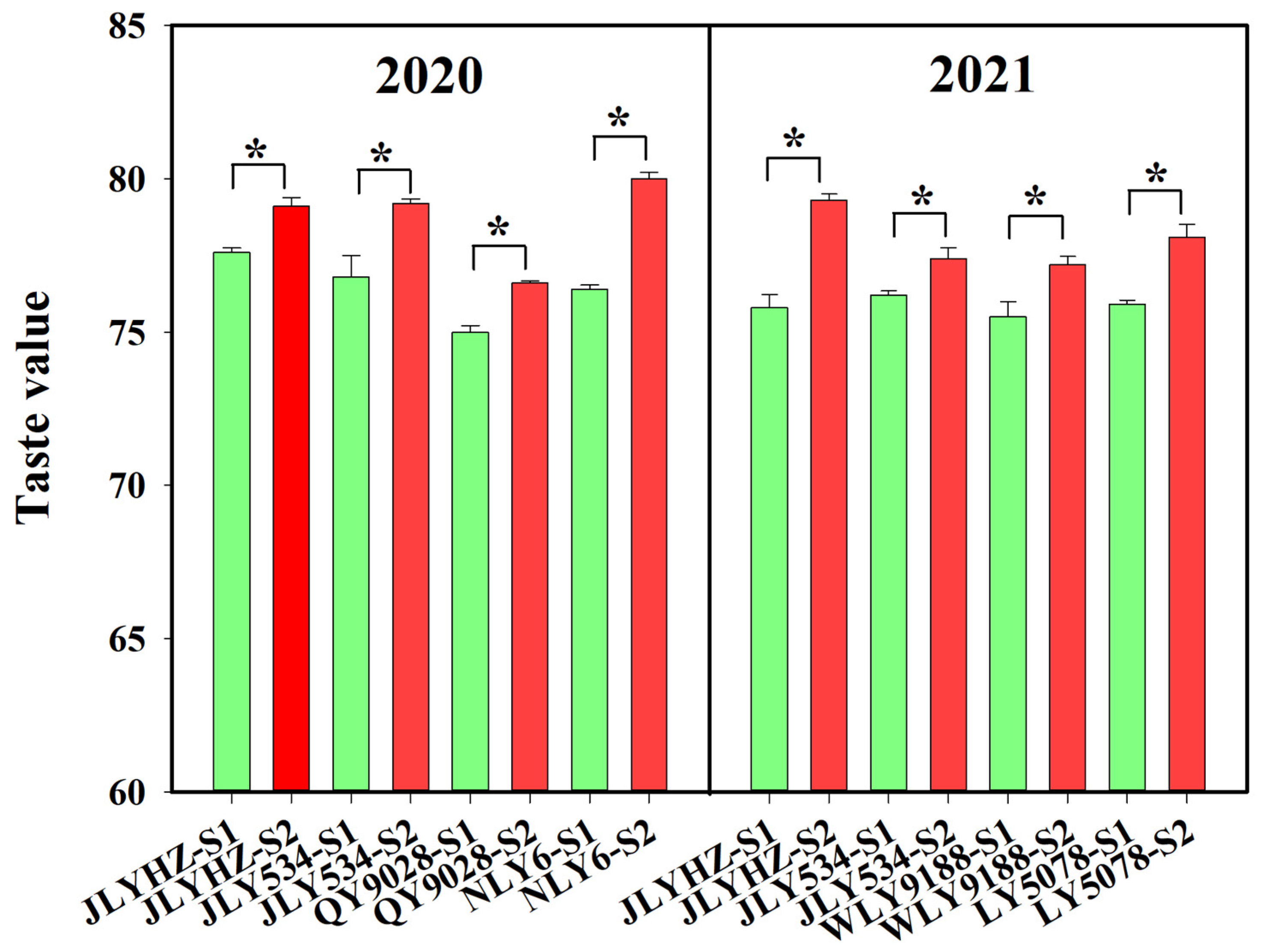

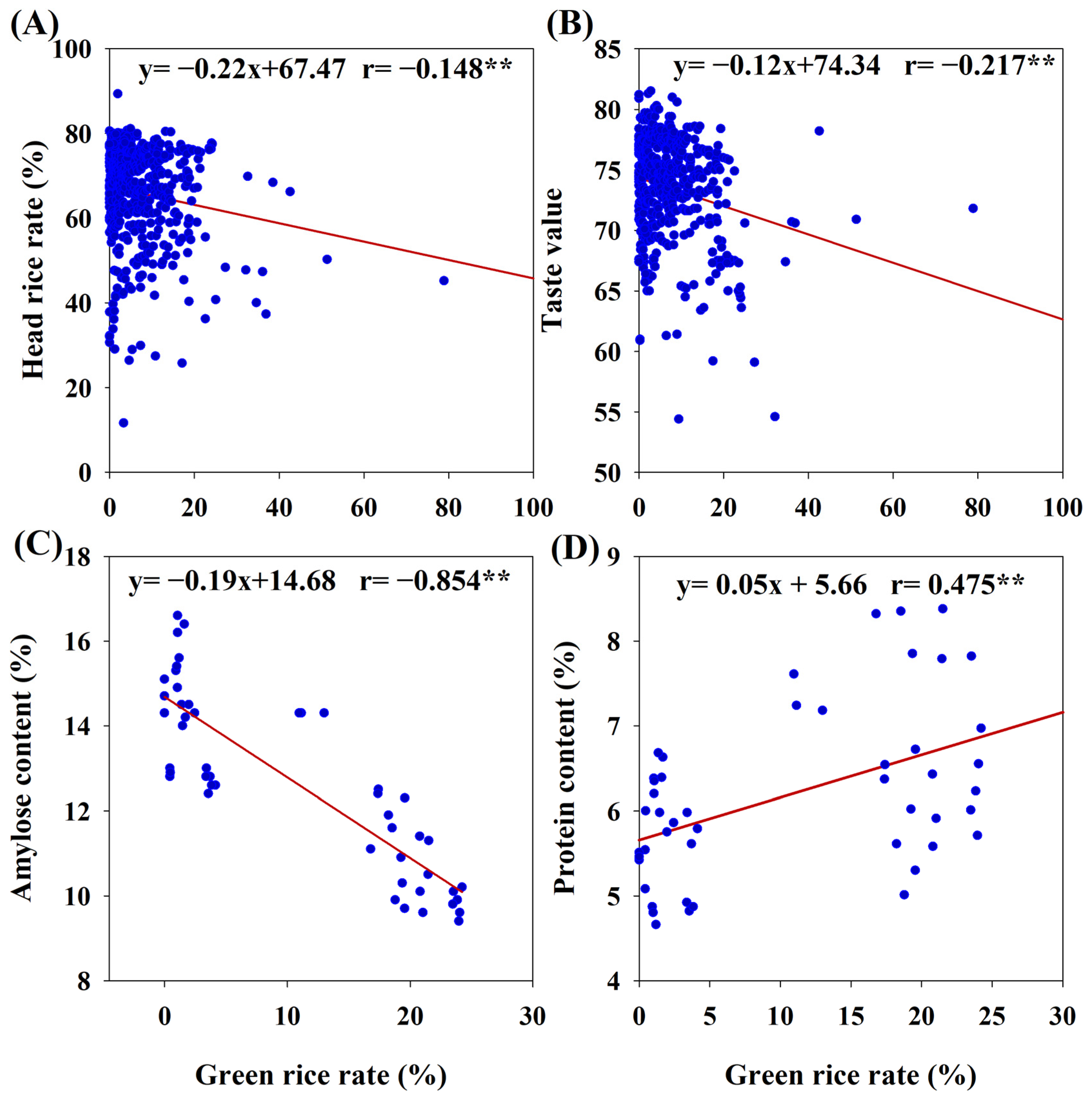

3.4. Relationship Between Green Rice Rate and Rice Quality

4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| JLYHZ | Jingliangyouhuazhan |

| JLY534 | Jingliangyou 534 |

| QY9028 | Quanyou 9028 |

| NLY6 | Nuoliangyou 6 |

| WLY9188 | Wangliangyou 9188 |

| LY5078 | Liangyou 5078 |

| ECQ | Eating and cooking quality |

| S1 | 1st sampling time, at 30 ± 3 d after grain filling stage |

| S2 | 2nd sampling time, namely harvest |

References

- Kato, K.; Suzuki, Y.; Hosaka, Y.; Takahashi, R.; Kodama, I.; Sato, K.; Kawamoto, T.; Kumamaru, T.; Fujita, N. Effect of high temperature on starch biosynthetic enzymes and starch structure in japonica rice cultivar ‘Akitakomachi’ (Oryza sativa L.) endosperm and palatability of cooked rice. J. Cereal Sci. 2019, 87, 209–214. [Google Scholar] [CrossRef]

- Tu, D.; Jiang, Y.; Zhang, L.; Cai, M.; Li, C.; Cao, C. Effect of various combinations of temperature during different phenological periods on indica rice yield and quality in the Yangtze River Basin in China. J. Integr. Agric. 2022, 21, 2900–2909. [Google Scholar] [CrossRef]

- Huang, M.; Zou, Y. Integrating mechanization with agronomy and breeding to ensure food security in China. Field Crops Res. 2018, 224, 22–27. [Google Scholar] [CrossRef]

- Zhang, C.; Zhou, L.; Lu, Y.; Yang, Y.; Feng, L.; Hao, W.; Li, Q.; Fan, X.; Zhao, D.; Liu, Q. Changes in the physicochemical properties and starch structures of rice grains upon pre-harvest sprouting. Carbohydr. Polym. 2020, 234, 115893. [Google Scholar] [CrossRef] [PubMed]

- Lyman, N.B.; Jagadish, K.S.V.; Nalley, L.L.; Dixon, B.L.; Siebenmorgen, T. Neglecting Rice Milling Yield and Quality Underestimates Economic Losses from High-Temperature Stress. PLoS ONE 2013, 8, e72157. [Google Scholar] [CrossRef] [PubMed]

- Chen, H.; Chen, D.; He, L.; Wang, T.; Lu, H.; Yang, F.; Deng, F.; Chen, Y.; Tao, Y.; Li, M.; et al. Correlation of taste values with chemical compositions and Rapid Visco Analyser profiles of 36 indica rice (Oryza sativa L.) varieties. Food Chem. 2021, 349, 129176. [Google Scholar] [CrossRef]

- Fernandes, D.D.S.; dos Santos, T.P.R.; Fernandes, A.M.; Leonel, M. Harvest time optimization leads to the production of native cassava starches with different properties. Int. J. Biol. Macromol. 2019, 132, 710–721. [Google Scholar] [CrossRef]

- Cheng, C.; Lei, K.; Wang, S.; Zhu, B.; Lu, Z.; Gao, B.; Wang, B.; Shi, Q.; Zeng, Y. Effects of Water Irrigation Cut off and Harvest Date on the Grain Yield and Quality of High-quality Japonica Rice during the Late-rice Cropping Season in Southern China. Crop Res. 2020, 34, 1–7. [Google Scholar]

- Jeong, O.Y.; Baek, M.K.; Bombay, M.; Ancheta, M.B.; Lee, J.-H. Evaluation of the optimal harvest time of rice (Oryza sativa L.) with different grain shapes grown in the Philippines. J. Crop Sci. Biotechnol. 2020, 23, 405–412. [Google Scholar] [CrossRef]

- McClung, A.M. Chapter 2: The Rice Plant: Growth, Development, And Genetic Improvement. In Rice: Chemistry and Technology; American Association of Cereal Chemists, Inc.: St. Paul, MN, USA, 2004; pp. 25–48. [Google Scholar]

- Siebenmorgen, T.J.; Grigg, B.C.; Lanning, S.B. Impacts of Preharvest factors during kernel development on rice quality and functionality. Annu. Rev. Food Sci. Technol. 2013, 4, 101–115. [Google Scholar] [CrossRef]

- Chen, Z.; Li, P.; Du, Y.; Jiang, Y.; Cai, M.; Cao, C. Dry cultivation and cultivar affect starch synthesis and traits to define rice grain quality in various panicle parts. Carbohydr. Polym. 2021, 269, 118336. [Google Scholar] [PubMed]

- Deng, F.; Wang, L.; Pu, S.L.; Mei, X.F.; Li, S.X.; Li, Q.P.; Ren, W.J. Shading stress increases chalkiness by postponing caryopsis development and disturbing starch characteristics of rice grains. Agric. For. Meteorol. 2018, 263, 49–58. [Google Scholar] [CrossRef]

- Chen, Y.; Teng, Z.; Yuan, Y.; Yi, Z.; Zheng, Q.; Yu, H.; Lv, J.; Wang, Y.; Duan, M.; Zhang, J.; et al. Excessive nitrogen in field-grown rice suppresses grain filling of inferior spikelets by reducing the accumulation of cytokinin and auxin. Field Crops Res. 2022, 28, 108542. [Google Scholar]

- Tu, D.; Jiang, Y.; Salah, A.; Cai, M.; Peng, W.; Zhang, L.; Li, C.; Cao, C. Response of Source-Sink Characteristics and Rice Quality to High Natural Field Temperature During Reproductive Stage in Irrigated Rice System. Front. Plant Sci. 2022, 13, 911181. [Google Scholar]

- Díaz, E.O.; Kawamura, S.; Koseki, S. Effect of thickness and maturity on protein content of Japonica brown rice collected during postharvest processing. Biosyst. Eng. 2019, 183, 160–169. [Google Scholar] [CrossRef]

- NBSC. National Bureau of Statistics of China. 2023. Available online: http://www.stats.gov.cn (accessed on 10 September 2024).

- Chen, C.; van Groenigen, K.J.; Yang, H.; Hungate, B.A.; Yang, B.; Tian, Y.; Chen, J.; Dong, W.; Huang, S.; Deng, A.; et al. Global warming and shifts in cropping systems together reduce China’s rice production. Glob. Food Secur. 2020, 24, 100359. [Google Scholar] [CrossRef]

- Deng, N.; Ling, X.; Sun, Y.; Zhang, C.; Fahad, S.; Peng, S.; Cui, K.; Nie, L.; Huang, J. Influence of temperature and solar radiation on grain yield and quality in irrigated rice system. Eur. J. Agron. 2015, 64, 37–46. [Google Scholar] [CrossRef]

- Zhang, C.; Zhou, L.; Zhu, Z.; Lu, H.; Zhou, X.; Qian, Y.; Li, Q.; Lu, Y.; Gu, M.; Liu, Q. Characterization of Grain Quality and Starch Fine Structure of Two Japonica Rice (Oryza sativa) Cultivars with Good Sensory Properties at Different Temperatures during the Filling Stage. J. Agric. Food Chem. 2016, 64, 4048–4057. [Google Scholar] [CrossRef]

- Lin, G.; Yang, Y.; Chen, X.; Yu, X.; Wu, Y.; Xiong, F. Effects of high temperature during two growth stages on caryopsis development and physicochemical properties of starch in rice. Int. J. Biol. Macromol. 2020, 145, 301–310. [Google Scholar]

- Jongkaewwattana, S.; Geng, S. Non-Uniformity of Grain Characteristics and Milling Quality of California Rice (Oryza sativa L.) of Different Maturities. J. Agron. Crop Sci. 2002, 188, 161–167. [Google Scholar]

- Yao, D.; Wu, J.; Luo, Q.; Li, J.; Zhuang, W.; Xiao, G.; Deng, Q.; Lei, D.; Bai, B. Influence of high natural field temperature during grain filling stage on the morphological structure and physicochemical properties of rice (Oryza sativa L.) starch. Food Chem. 2020, 310, 125817. [Google Scholar] [PubMed]

- Cai, J.; Man, J.; Huang, J.; Liu, Q.; Wei, W.; Wei, C. Relationship between structure and functional properties of normal rice starches with different amylose contents. Carbohydr. Polym. 2015, 125, 35–44. [Google Scholar] [PubMed]

- Zhu, D.; Fang, C.; Qian, Z.; Guo, B.; Huo, Z. Differences in starch structure, physicochemical properties and texture characteristics in superior and inferior grains of rice varieties with different amylose contents. Food Hydrocoll. 2021, 110, 106170. [Google Scholar]

- Yang, J.; Zhang, J. Grain-filling problem in ‘super’ rice. J. Exp. Bot. 2010, 61, 1–5. [Google Scholar]

- Qiao, J.; Liu, Z.; Deng, S.; Ning, H.; Yang, X.; Lin, Z.; Li, G.; Wang, Q.; Wang, S.; Ding, Y. Occurrence of perfect and imperfect grains of six japonica rice cultivars as affected by nitrogen fertilization. Plant Soil 2011, 349, 191–202. [Google Scholar]

| North Latitude (°) | East Longitude (°) | Total Number of Sampled Paddy Plot | |

|---|---|---|---|

| Anqing | 30.3 | 117.0 | 60 |

| Chizhou | 30.7 | 117.5 | 42 |

| Chuzhou | 31.5 | 119.1 | 56 |

| Fuyang | 32.3 | 114.9 | 20 |

| Hefei | 31.5 | 117.2 | 54 |

| Huainan | 33.0 | 117.0 | 50 |

| Huangshan | 29.4 | 119.3 | 28 |

| Lu’an | 31.8 | 116.5 | 46 |

| Maanshan | 31.2 | 118.5 | 36 |

| Wuhu | 31.0 | 118.0 | 18 |

| Xuanchen | 30.6 | 118.5 | 56 |

| Year | Green Rice Rate (%) | |||

|---|---|---|---|---|

| 1st Sampling (S1) | 2nd Sampling (S2) | S2−S1 | ||

| JLYHZ | 2020 | 24.0 ± 0.19 | 0.4 ± 0.01 | 23.6 |

| JLY534 | 18.9 ± 2.39 | 1.4 ± 0.32 | 17.5 | |

| QY9028 | 11.7 ± 1.12 | 1.2 ± 0.31 | 10.5 | |

| NLY6 | 22.8 ± 1.57 | 2.0 ± 0.49 | 20.8 | |

| JLYHZ | 2021 | 21.4 ± 2.08 | 3.8 ± 0.36 | 17.6 |

| JLY534 | 18.1 ± 1.26 | 1.0 ± 0.14 | 17.1 | |

| WLY9188 | 19.4 ± 1.29 | 0 | 19.4 | |

| LY5078 | 19.7 ± 1.03 | 3.6 ± 0.23 | 16.1 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, X.; Yang, L.; Li, Z.; Tu, D. Effects of Premature Harvesting on Grain Weight and Quality: A Field Study. Agronomy 2025, 15, 846. https://doi.org/10.3390/agronomy15040846

Zhang X, Yang L, Li Z, Tu D. Effects of Premature Harvesting on Grain Weight and Quality: A Field Study. Agronomy. 2025; 15(4):846. https://doi.org/10.3390/agronomy15040846

Chicago/Turabian StyleZhang, Xiao, Linsheng Yang, Zhong Li, and Debao Tu. 2025. "Effects of Premature Harvesting on Grain Weight and Quality: A Field Study" Agronomy 15, no. 4: 846. https://doi.org/10.3390/agronomy15040846

APA StyleZhang, X., Yang, L., Li, Z., & Tu, D. (2025). Effects of Premature Harvesting on Grain Weight and Quality: A Field Study. Agronomy, 15(4), 846. https://doi.org/10.3390/agronomy15040846