Estimation of Processing Tomato Nutrient Uptake Based on the QUEFTS Model in Xinjiang

Abstract

1. Introduction

2. Materials and Methods

2.1. Data Source

2.2. Development of the QUEFTS Model

2.3. Field Validation

2.4. Statistical Analysis

3. Results

3.1. Fruit Yield and Nutrient Uptake

3.2. Characteristics of Internal Efficiency and Reciprocal Internal Efficiency

3.3. Determining the Parameters to Adapt the QUEFTS Model

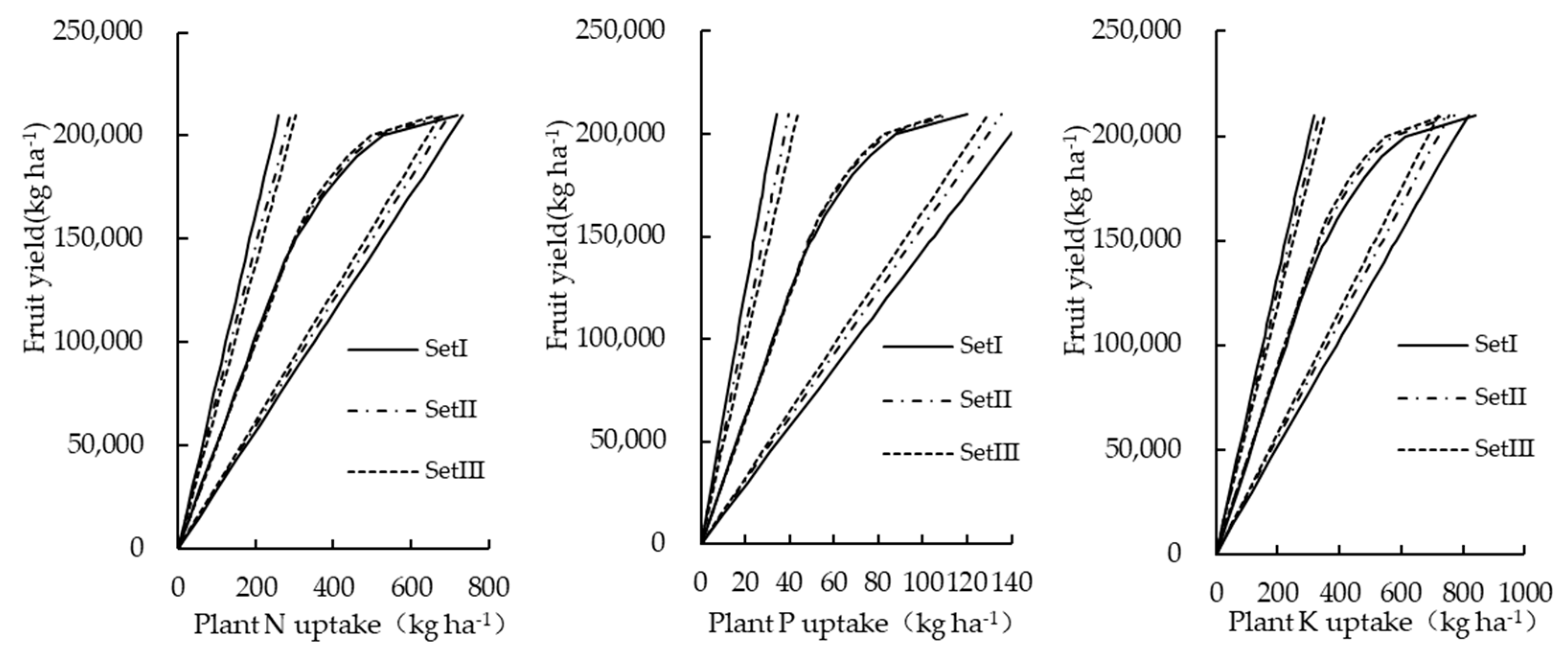

3.4. Estimation of the Optimal Nutrient Uptake

3.5. Field Validation

4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Xu, J.; Wan, W.; Zhu, X.; Zhao, Y.; Chai, Y.; Guan, S.; Diao, M. Effect of regulated deficit irrigation on the growth, yield, and irrigation water productivity of processing tomatoes under drip irrigation and mulching. Agronomy 2023, 13, 2862. [Google Scholar] [CrossRef]

- Zhao, D.; Wang, Z.; Zhang, J.; Li, W.; Zhou, B. Improving yield and quality of processing tomato (Lycopersicon esculentum Miller) using alternate partial root-zone drip irrigation in arid northwest China. Water 2019, 11, 1503. [Google Scholar] [CrossRef]

- Li, S.; Fan, Y.; Han, J.; Liu, F.; Ding, Y.; Li, X.; Yu, E.; Wang, S.; Wang, F.; Wang, C. Foodborne pathogen and microbial community differences in fresh processing tomatoes in Xinjiang, China. Foodborne Pathog. Dis. 2024, 21, 236–247. [Google Scholar] [CrossRef] [PubMed]

- Dumas, Y.; Dadomo, M.; Di Lucca, G.; Grolier, P. Effects of environmental factors and agricultural techniques on antioxidant content of tomatoes. J. Sci. Food Agric. 2003, 83, 369–382. [Google Scholar] [CrossRef]

- Truffault, V.; Marlene, R.; Brajeul, E.; Vercambre, G.; Gautier, H. To stop nitrogen overdose in soilless tomato crops: A way to promote fruit quality without affecting fruit yield. Agronomy 2019, 9, 80. [Google Scholar] [CrossRef]

- Huang, S.W.; Tang, J.W.; Li, C.H.; Zhang, H.Z.; Yuan, S. Potential and scientific application strategies for reducing chemical fertilizer use in vegetables in China. J. Plant Nutr. Fertil. 2017, 23, 1480–1493. [Google Scholar]

- Huang, Z.C.; Liu, S.J.; Sun, H.; Hou, L.Z.; Wu, R.; Xue, W.T. Current status of vegetable fertilizer utilization rates in China and strategies for improvement. Vegetables 2021, 43, 43–50. [Google Scholar]

- Pramanick, B.; Choudhary, S.; Kumar, M.; Singh, S.K.; Jha, R.K.; Singh, S.K.; Salmen, S.H.; Ansari, M.J.; Hossain, A. Can site-specific nutrient management improve the productivity and resource use efficiency of climate-resilient finger millet in calcareous soils in India? Heliyon 2024, 10, e32774. [Google Scholar] [CrossRef]

- Farneselli, M.; Tosti, G.; Onofri, A.; Benincasa, P.; Guiducci, M.; Pannacci, E.; Tei, F. Effects of N sources and management strategies on crop growth, yield, and potential N leaching in processing tomato. Eur. J. Agron. 2018, 98, 46–54. [Google Scholar] [CrossRef]

- Hartz, T.K. The challenge of nutrition management of processing tomatoes in an era of rising yield expectations. In Proceedings of the XIV International Symposium on Processing Tomato, Santiago, Chile, 6–9 March 2016; ISHS Acta Horticulturae 1159. pp. 1–6. [Google Scholar]

- Thompson, R.B.; Voogt, W.; Incrocci, L.; Fink, M.; De Neve, S. Strategies for optimal fertiliser management of vegetable crops in Europe. Acta Hortic. 2018, 1192, 129–140. [Google Scholar] [CrossRef]

- Ravensbergen, A.P.P.; Chamberlin, J.; Craufurd, P.; Shehu, B.M.; Hijbeek, R. Adapting the QUEFTS model to predict attainable yields when training data are characterized by imperfect management. Field Crops Res. 2021, 266, 108126. [Google Scholar] [CrossRef]

- Pathak, H. Mitigating greenhouse gas and nitrogen loss with improved fertilizer management in rice: Quantification and economic assessment. Nutr. Cycl. Agroecosyst. 2010, 87, 443–454. [Google Scholar] [CrossRef]

- Darzi-Naftchali, A.; Motevali, A.; Layani, G.; Keikha, M.; Bagherian-Jelodar, M.; Nadi, M.; Firouzjaeian, A.A.; Pirdashti, H. Optimizing cropping pattern through reducing environmental issues and improving socio-economic indicators. Environ. Dev. Sustain. 2024, 26, 13041–13068. [Google Scholar] [CrossRef]

- Witt, C.; Dobermann, A.; Abdulrachman, S.; Gines, H.; Guanghuo, W.; Nagarajan, R.; Satawatananont, S.; Son, T.T.; Tan, P.S.; Van Tiem, L.; et al. Internal nutrient efficiencies of irrigated lowland rice in tropical and subtropical Asia. Field Crops Res. 1999, 63, 113–138. [Google Scholar] [CrossRef]

- Janssen, B.H.; Guiking, F.C.T.; Vander, E.D.; Smaling, E.; Wolf, J.; van Reuler, H. A system for quantitative evaluation of the fertility of tropical soils (QUEFTS). Geoderma 1990, 46, 299–318. [Google Scholar] [CrossRef]

- Remya Remesh, K.R.; Byju, G. Estimation of nutrient uptake requirements for yams in India based on QUEFTS model. J. Root Crops 2018, 44, 12–22. [Google Scholar]

- Shi, H.; Wang, M.; Zhao, J.; Zhang, Z.; Xu, X.; Liu, Z. Construction and validation of apple Nutrient Expert system based on yield response and agronomic efficiency. J. Plant Nutr. Fertil. 2023, 29, 496–510. [Google Scholar]

- Shehu, B.M.; Lawan, B.A.; Jibrin, J.M.; Kamara, A.Y.; Mohammed, I.B.; Rurinda, J.; Zingore, S.; Craufurd, P.; Vanlauwe, B.; Adam, A.M.; et al. Balanced nutrient requirements for maize in the Northern Nigerian Savanna: Parameterization and validation of QUEFTS model. Field Crops Res. 2019, 241, 107585. [Google Scholar] [CrossRef]

- Byju, G.; Nedunchezhiyan, M.; Ravindran, C.S.; Mithra, V.S.S.; Ravi, V.; Naskar, S.K. Modeling the response of cassava to fertilizers: A site-specific nutrient management approach for greater tuberous root yield. Commun. Soil Sci. Plant Anal. 2012, 43, 1149–1162. [Google Scholar] [CrossRef]

- Breure, M.S.; Van Eynde, E.; Kempen, B.; Comans, R.N.; Hoffland, E. Transfer functions for phosphorus and potassium soil tests and implications for the QUEFTS model. Geoderma 2022, 406, 115458. [Google Scholar] [CrossRef]

- Kang, F.; Wang, Z.; Xiong, H.; Li, Y.; Wang, Y.; Fan, Z.; Zhao, H.; Kuang, D.; Chen, Z.; Wang, J.; et al. Estimation of watermelon nutrient requirements based on the QUEFTS model. Agronomy 2020, 10, 1776. [Google Scholar] [CrossRef]

- Antwi, M.; Duker, A.; Fosu, M.; Abaidoo, R.C. Simulation of major soil nutrients requirement for maize production using the QUEFTS model in the Northern region of Ghana. Direct Res. J. Agric. Food Sci. 2017, 5, 133–140. [Google Scholar]

- Pampolino, M.F.; Witt, C.; Pasuquin, J.M.; Johnston, A.; Fisher, M.J. Development approach and evaluation of the Nutrient Expert software for nutrient management in cereal crops. Comput. Electron. Agric. 2012, 88, 103–110. [Google Scholar] [CrossRef]

- Jiang, W.; Liu, X.; Qi, W.; Xu, X.; Zhu, Y. Using QUEFTS model for estimating nutrient requirements of maize in the Northeast China. Plant Soil Environ. 2017, 63, 481–487. [Google Scholar] [CrossRef]

- Liu, H.L.; Yang, J.Y.; Drury, C.F.; Reynolds, W.D.; Tan, C.S.; Bai, Y.L.; He, P.; Jin, J.; Hoogenboom, G. Using the DSSAT-CERES-Maize model to simulate crop yield and nitrogen cycling in fields under long-term continuous maize production. Nutr. Cycl. Agroecosyst. 2010, 89, 313–328. [Google Scholar] [CrossRef]

- Min, Y.H.; Blackwell, M.; Rahn, C.; Chen, Q. Fertilization and catch crop strategies for improving tomato production in North China. Pedosphere 2015, 25, 364–371. [Google Scholar]

- Ronga, D.; Pentangelo, A.; Parisi, M. Optimizing N fertilization to improve yield, technological and nutritional quality of tomato grown in high fertility soil conditions. Plants 2020, 9, 575. [Google Scholar] [CrossRef]

- Singh, D.V.; Mukhi, S.K.; Mishra, S.N. Impact of integrated nutrient management on tomato yield under farmers field conditions. Int. J. Agric. Environ. Biotechnol. 2016, 9, 567–572. [Google Scholar] [CrossRef]

- Wei, J.; Li, S.; He, P.; Xu, X.; Tan, D.; Li, Y.; Li, G.; Guo, Y.; Cui, R. QUEFTS model-based estimation of the nutrient requirements and fertilizer recommendation for Chinese onion. HortScience 2022, 57, 297–303. [Google Scholar] [CrossRef]

- Kumar, P.; Dua, V.K.; Sharma, J.; Byju, G.; Minhas, J.S.; Chakrabarti, S.K. Site-specific nutrient requirements of NPK for potato (Solanum tuberosum L.) in Western Indo-Gangetic Plains of India based on QUEFTS. J. Plant Nutr. 2018, 41, 1988–2000. [Google Scholar] [CrossRef]

- Ezui, K.S.; Franke, A.C.; Mando, A.; Ahiabor, B.D.; Tetteh, F.M.; Sogbedji, J.; Janssen, B.H.; Giller, K.E. Fertilizer requirements for balanced nutrition of cassava across eight locations in West Africa. Field Crops Res. 2015, 185, 69–78. [Google Scholar] [CrossRef]

- Pathak, H.; Aggarwal, P.K.; Roetter, R.; Kalra, N.; Bandyopadhaya, S.; Prasad, S.; Van Keulen, H. Modelling the quantitative evaluation of soil nutrient supply, nutrient use efficiency, and fertilizer requirements of wheat in India. Nutr. Cycl. Agroecosyst. 2003, 65, 105–131. [Google Scholar] [CrossRef]

- Yimer, T.; Abera, G.; Beyene, S.; Ravensbergen, A.P.P.; Ukato, A.; Rasche, F. Optimizing fertilization schemes to narrow the maize yield gap in smallholder farming systems in southern Ethiopia. Heliyon 2024, 10, e33926. [Google Scholar] [CrossRef]

- Mohammad Nezhad, Y.; Basirat, M.; HajiAbaee, H.; Torabi, B. Determining the fertilizer requirement for irrigated wheat in Golestan Dam fields, using the QUEFTS model. J. Crops Improv. 2020, 22, 433–443. [Google Scholar]

- Pushpalatha, R.; Byju, G. QUEFTS model, a tool for site-specific nutrient management of crops: A review. Commun. Soil Sci. Plant Anal. 2022, 53, 2339–2352. [Google Scholar] [CrossRef]

| Region | Case (n) | Longitude (°E) | Latitude (°N) | pH | Organic Matter (g kg−1) | Alkali-Hydrolyzable N (mg kg−1) | Olsen-P (mg kg−1) | NH4OAc-K (mg kg−1) |

|---|---|---|---|---|---|---|---|---|

| Changji | 89 | 86.22–87.48 | 43.95–44.33 | 7.8~8.9 | 0.12~2.31 | 20.8~177.9 | 0.7~63.1 | 66.0~349.0 |

| Bozhou | 55 | 83.93–84.77 | 44.10–44.54 | 7.5~8.6 | 0.05~1.8 | 6.0~87.0 | 2.5~43.0 | 56.0~297.0 |

| Tacheng | 31 | 86.49–86.69 | 41.93–42.36 | 7.8~8.2 | 0.86~1.82 | 35.0~113.0 | 1.8~29.7 | 83.0~226.0 |

| Shixenze | 6 | 86.00 | 44.43 | 7.2~8.2 | 0.72~1.78 | 45.6~65.1 | 7.7~25.9 | 101.9~342.0 |

| Parameter | Unit | N 1 | Mean | SD 2 | Minimum | 25% Q 3 | Median | 75% Q | Maximum |

|---|---|---|---|---|---|---|---|---|---|

| Fruit yield | kg ha−1 | 1106 | 91,169 | 33,255 | 18,933 | 68,446 | 88,548 | 109,198 | 213,556 |

| Canopy yield | kg ha−1 | 1027 | 4412 | 2364 | 701 | 2790 | 3765 | 5325 | 20,177 |

| Harvest index | kg kg−1 | 1027 | 0.54 | 0.10 | 0.23 | 0.46 | 0.54 | 0.60 | 0.82 |

| N in fruit | g kg−1 | 842 | 25.4 | 12.3 | 9.0 | 20.7 | 24.5 | 29.2 | 54.0 |

| P in fruit | g kg−1 | 776 | 4.4 | 2.3 | 1.3 | 3.6 | 4.4 | 5.3 | 9.2 |

| K in fruit | g kg−1 | 956 | 34.5 | 13.8 | 12.1 | 28.9 | 34.7 | 39.9 | 55.2 |

| N in canopy | g kg−1 | 842 | 18.9 | 9.1 | 5.5 | 15.9 | 19.1 | 21.5 | 37.7 |

| P in canopy | g kg−1 | 776 | 3.4 | 1.9 | 0.9 | 2.3 | 3.2 | 4.3 | 8.3 |

| K in canopy | g kg−1 | 956 | 15.5 | 7.3 | 4.9 | 11.5 | 14.4 | 18.6 | 36.9 |

| N uptake in fruit | kg ha−1 | 854 | 132.5 | 69.7 | 18.9 | 81.7 | 118.9 | 171.2 | 405.5 |

| P uptake in fruit | kg ha−1 | 788 | 22.8 | 12.6 | 2.6 | 13.5 | 19.8 | 30.8 | 82.2 |

| K uptake in fruit | kg ha−1 | 968 | 179.3 | 100.7 | 19.0 | 115.3 | 157.0 | 213.2 | 611.8 |

| N uptake in canopy | kg ha−1 | 854 | 91.9 | 54.1 | 7.5 | 54.4 | 77.9 | 118.1 | 414.6 |

| P uptake in canopy | kg ha−1 | 788 | 16.6 | 11.1 | 1.2 | 8.9 | 13.4 | 21.9 | 72.0 |

| K uptake in canopy | kg ha−1 | 968 | 71.5 | 46.1 | 6.1 | 37.1 | 56.0 | 98.0 | 319.6 |

| N uptake total | kg ha−1 | 882 | 224.0 | 104.8 | 27.0 | 146.0 | 208.5 | 286.5 | 584.0 |

| P uptake total | kg ha−1 | 793 | 39.3 | 20.4 | 3.8 | 23.2 | 36.2 | 52.5 | 125.3 |

| K uptake total | kg ha−1 | 968 | 250.8 | 130.5 | 30.4 | 166.5 | 215.0 | 315.0 | 810.0 |

| N-HI 4 | kg kg−1 | 854 | 0.59 | 0.11 | 0.25 | 0.51 | 0.60 | 0.66 | 0.93 |

| P-HI | kg kg−1 | 788 | 0.59 | 0.12 | 0.23 | 0.50 | 0.58 | 0.67 | 0.90 |

| K-HI | kg kg−1 | 968 | 0.71 | 0.11 | 0.30 | 0.64 | 0.73 | 0.80 | 0.93 |

| Parameter | Unit | Case (n) | Mean | SD | Minimum | 25% Q | Median | 75% Q | Maximum |

|---|---|---|---|---|---|---|---|---|---|

| IE-N | kg kg−1 | 882 | 489 | 138 | 217 | 375 | 476 | 576 | 1169 |

| IE-P | kg kg−1 | 793 | 2934 | 1246 | 1145 | 2031 | 2634 | 3474 | 9410 |

| IE-K | kg kg−1 | 968 | 429 | 107 | 185 | 354 | 411 | 493 | 906 |

| RIE-N | kg Mg−1 | 882 | 2.21 | 0.62 | 0.86 | 1.74 | 2.10 | 2.67 | 4.62 |

| RIE-P | kg Mg−1 | 793 | 0.39 | 0.14 | 0.11 | 0.29 | 0.38 | 0.49 | 0.87 |

| RIE-K | kg Mg−1 | 967 | 2.48 | 0.62 | 1.10 | 2.03 | 2.43 | 2.82 | 5.41 |

| Nutrients | Set I | Set II | Set III | |||

|---|---|---|---|---|---|---|

| a (2.5th) | d (97.5th) | a (5th) | d (95th) | a (7.5th) | d (92.5th) | |

| N | 286 | 811 | 300 | 730 | 311 | 690 |

| P | 1431 | 6189 | 1547 | 5303 | 1621 | 4812 |

| K | 257 | 663 | 278 | 627 | 292 | 597 |

| Fruit Yield (Mg ha−1) | Nutrient Uptake of Aboveground (kg ha−1) | Internal Efficiency (kg kg−1) | Nutrient Uptake of Fruit (kg ha−1) | Nutrient Harvest Index (kg kg−1) | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| N | P | K | N | P | K | N | P | K | N | P | K | |

| 15 | 29.3 | 4.9 | 34.2 | 512.3 | 3076.4 | 439.1 | 19.7 | 3.2 | 25.6 | 0.67 | 0.66 | 0.75 |

| 30 | 58.6 | 9.8 | 68.3 | 512.3 | 3076.4 | 439.1 | 39.4 | 6.4 | 51.2 | 0.67 | 0.66 | 0.75 |

| 45 | 87.8 | 14.6 | 102.5 | 512.3 | 3076.4 | 439.1 | 59.1 | 9.6 | 76.8 | 0.67 | 0.66 | 0.75 |

| 60 | 117.1 | 19.5 | 136.6 | 512.3 | 3076.4 | 439.1 | 78.8 | 12.8 | 102.3 | 0.67 | 0.66 | 0.75 |

| 75 | 146.4 | 24.4 | 170.8 | 512.3 | 3076.4 | 439.1 | 98.5 | 16.0 | 127.9 | 0.67 | 0.66 | 0.75 |

| 90 | 175.7 | 29.3 | 205.0 | 512.3 | 3076.4 | 439.1 | 118.2 | 19.2 | 153.5 | 0.67 | 0.66 | 0.75 |

| 105 | 205.0 | 34.1 | 239.1 | 512.3 | 3076.4 | 439.1 | 137.9 | 22.4 | 179.1 | 0.67 | 0.66 | 0.75 |

| 120 | 234.2 | 39.0 | 273.3 | 512.3 | 3076.4 | 439.1 | 157.6 | 25.6 | 204.7 | 0.67 | 0.66 | 0.75 |

| 135 | 264.0 | 44.0 | 308.0 | 511.4 | 3071.0 | 438.3 | 179.9 | 29.2 | 233.6 | 0.68 | 0.66 | 0.76 |

| 150 | 304.2 | 50.6 | 354.9 | 493.2 | 2961.5 | 422.7 | 208.8 | 33.9 | 271.2 | 0.69 | 0.67 | 0.76 |

| 165 | 352.4 | 58.7 | 411.2 | 468.2 | 2811.5 | 401.3 | 242.2 | 39.3 | 314.5 | 0.69 | 0.67 | 0.76 |

| 180 | 410.9 | 68.4 | 479.4 | 438.0 | 2630.5 | 375.4 | 282.7 | 45.9 | 367.2 | 0.69 | 0.67 | 0.77 |

| 195 | 490.4 | 81.7 | 572.1 | 397.6 | 2387.9 | 340.8 | 338.0 | 54.9 | 438.9 | 0.69 | 0.67 | 0.77 |

| 210 | 719.5 | 119.8 | 839.5 | 291.9 | 1752.7 | 250.2 | 523.8 | 85.1 | 680.1 | 0.73 | 0.71 | 0.81 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yibati, H.; Gao, J.; Zhang, Y.; Li, Q.; Xu, X.; He, P.; Yin, X. Estimation of Processing Tomato Nutrient Uptake Based on the QUEFTS Model in Xinjiang. Agronomy 2025, 15, 274. https://doi.org/10.3390/agronomy15020274

Yibati H, Gao J, Zhang Y, Li Q, Xu X, He P, Yin X. Estimation of Processing Tomato Nutrient Uptake Based on the QUEFTS Model in Xinjiang. Agronomy. 2025; 15(2):274. https://doi.org/10.3390/agronomy15020274

Chicago/Turabian StyleYibati, Halihashi, Jie Gao, Yan Zhang, Qingjun Li, Xinpeng Xu, Ping He, and Xinhua Yin. 2025. "Estimation of Processing Tomato Nutrient Uptake Based on the QUEFTS Model in Xinjiang" Agronomy 15, no. 2: 274. https://doi.org/10.3390/agronomy15020274

APA StyleYibati, H., Gao, J., Zhang, Y., Li, Q., Xu, X., He, P., & Yin, X. (2025). Estimation of Processing Tomato Nutrient Uptake Based on the QUEFTS Model in Xinjiang. Agronomy, 15(2), 274. https://doi.org/10.3390/agronomy15020274