Nanostructured Ge-Based Glass Coatings for Sustainable Greenhouse Production: Balancing Light Transmission, Energy Harvesting, and Crop Performance

Abstract

1. Introduction

2. Materials and Methods

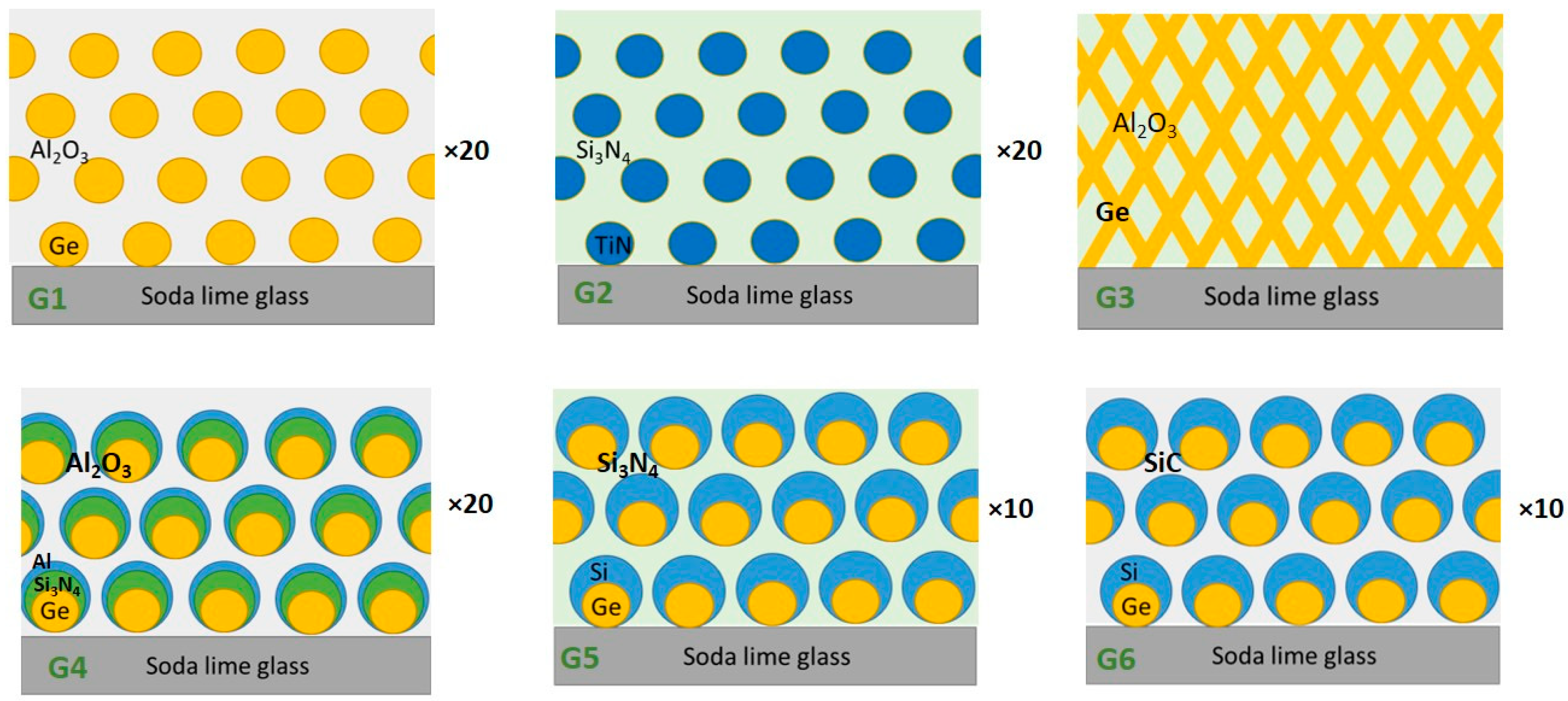

2.1. Preparation of Coatings

2.2. Optical Characterization

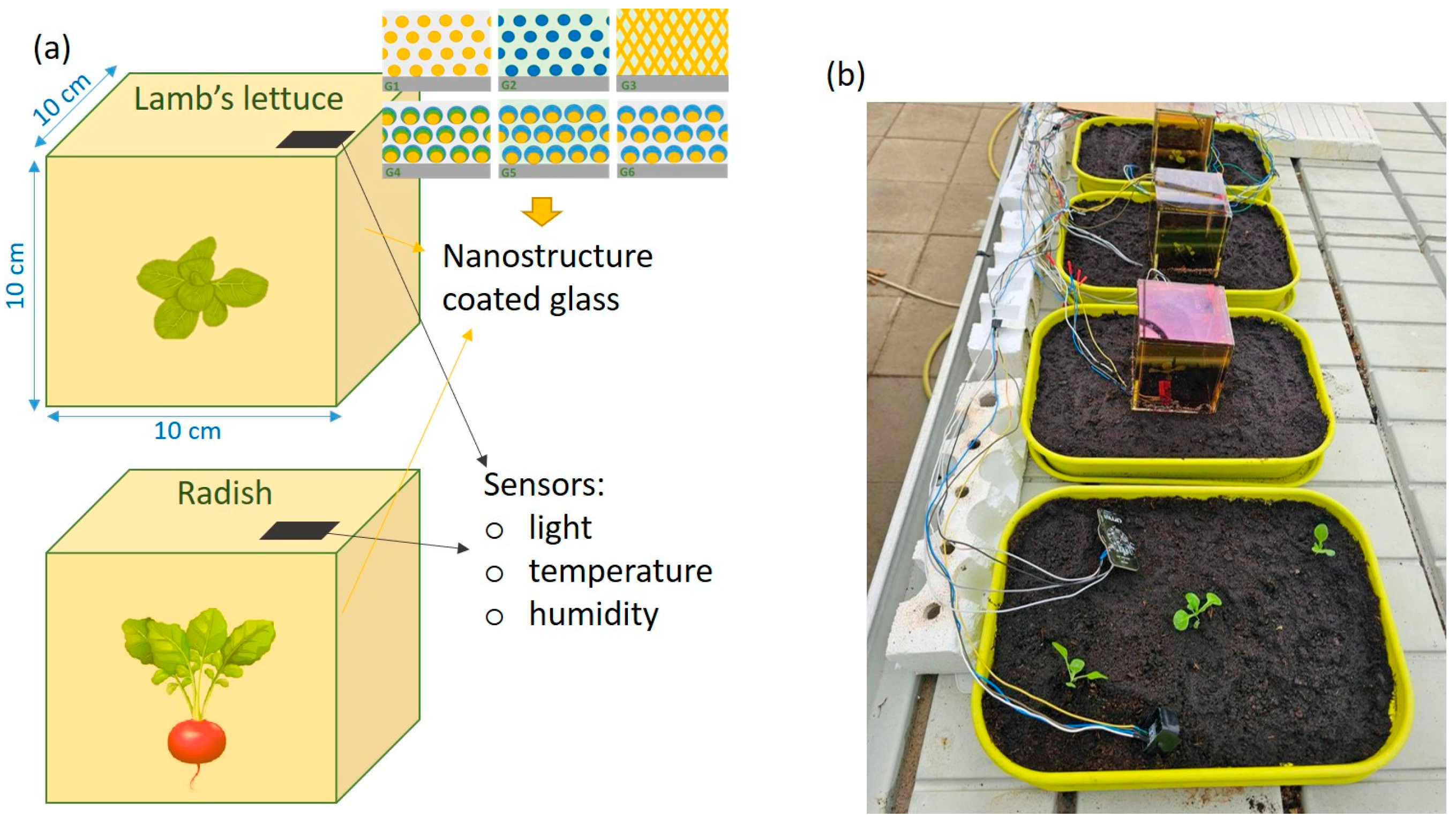

2.3. Greenhouse Experimental Design

2.4. Plant Morphology and Yield Measurements

2.5. Leaf Color Analysis

2.6. Statistical Analysis

3. Results

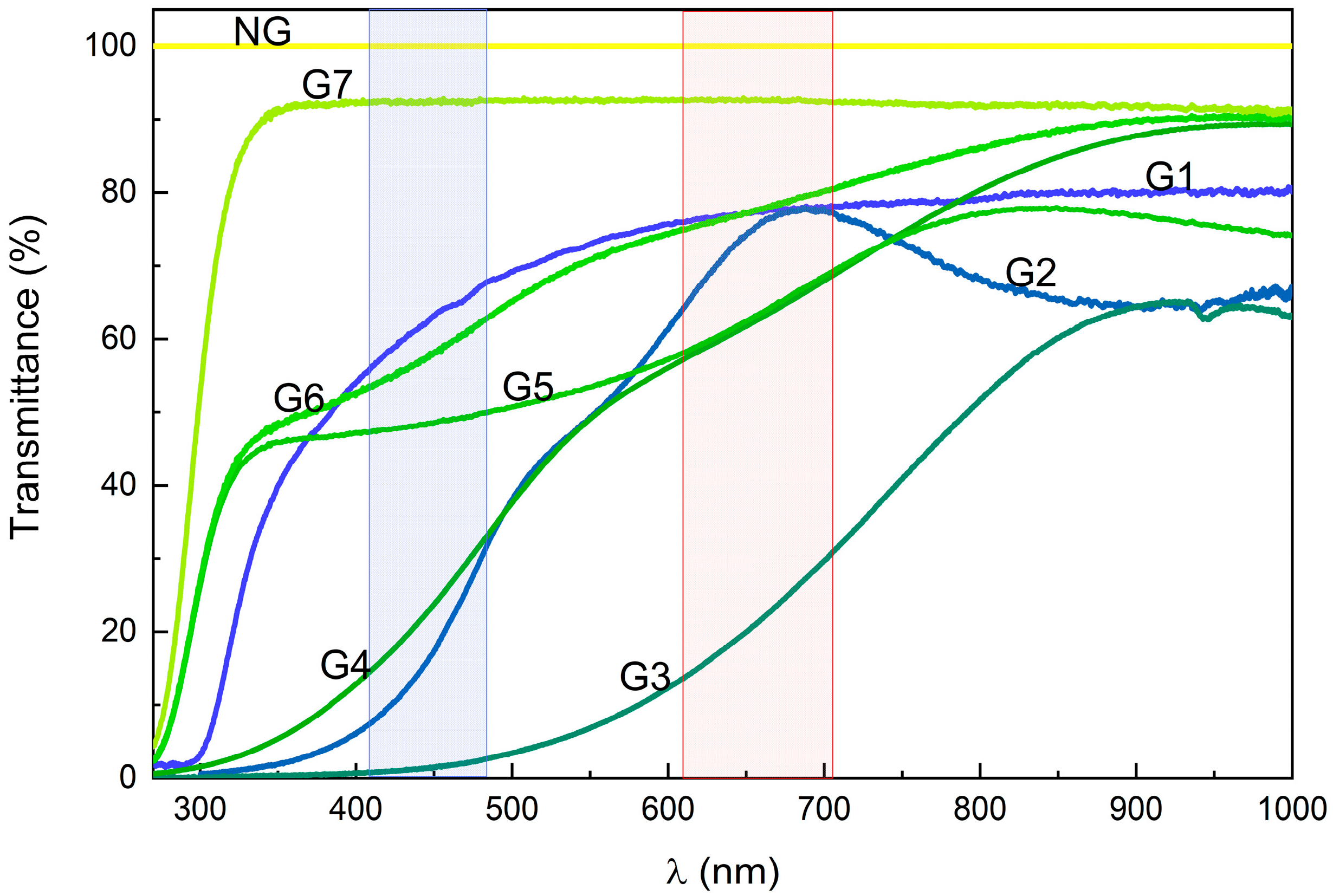

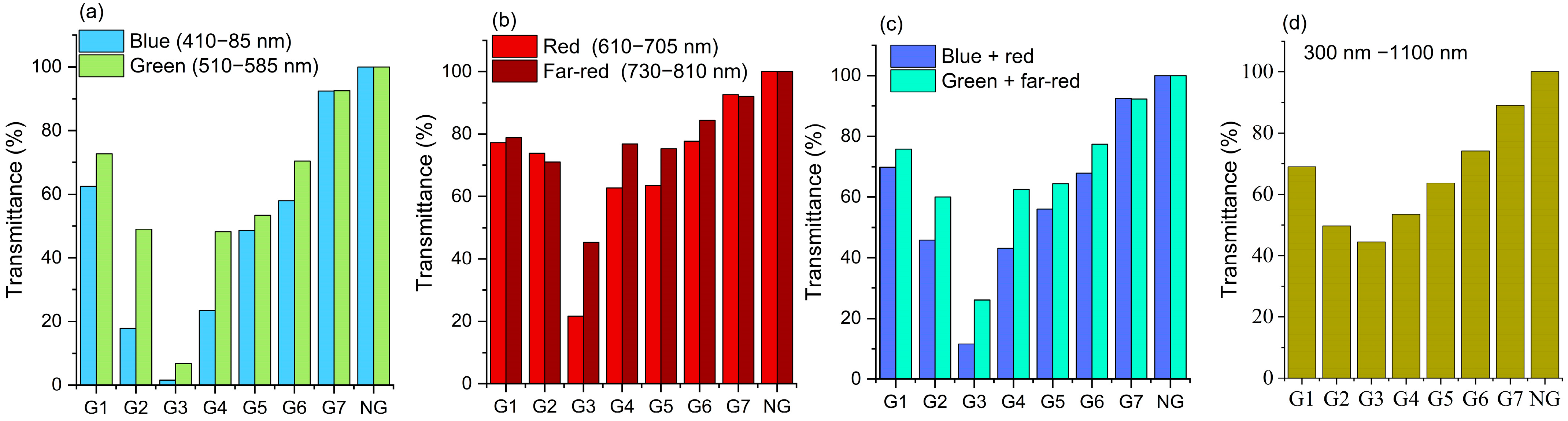

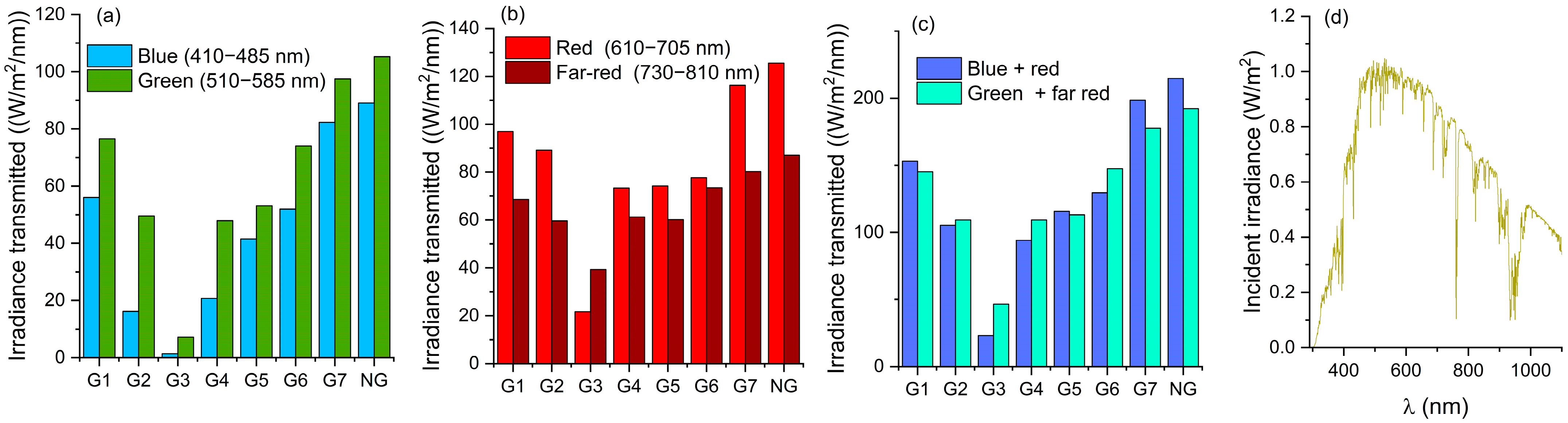

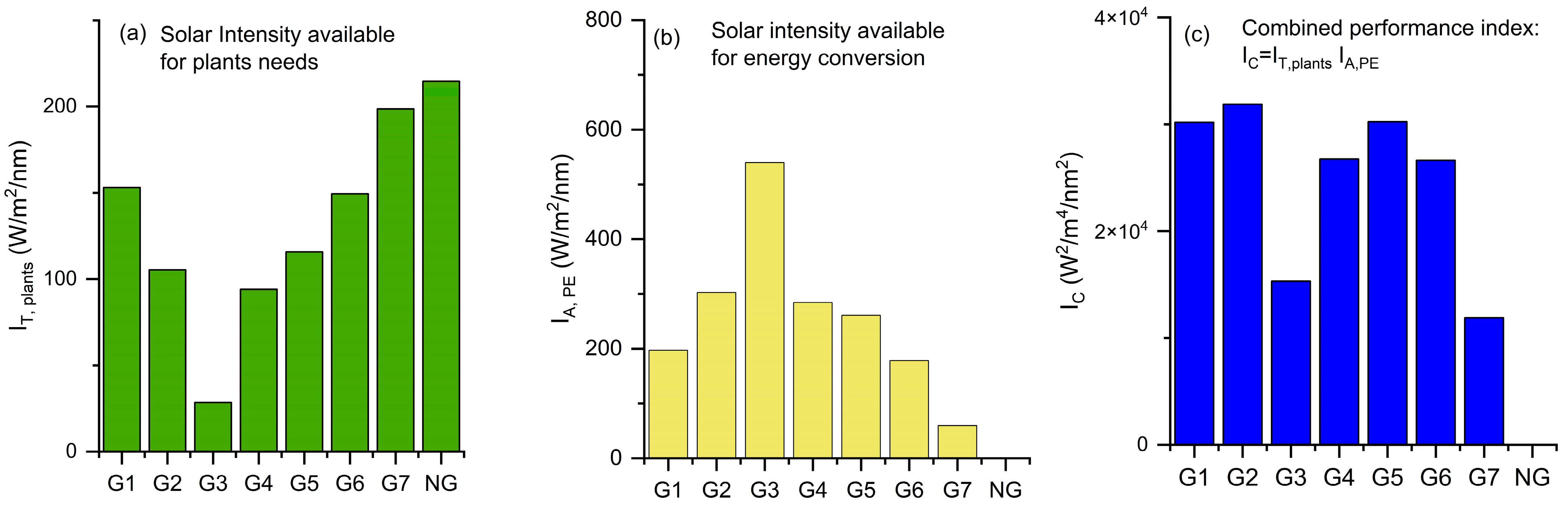

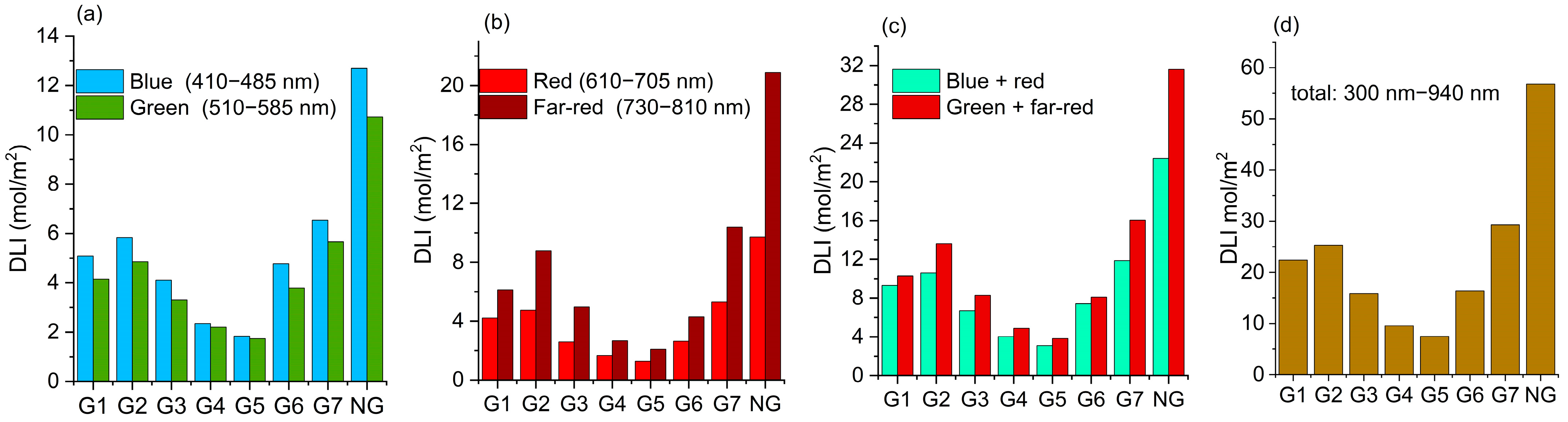

3.1. Optical Properties of Nanostructured Coatings

3.1.1. Laboratory Results

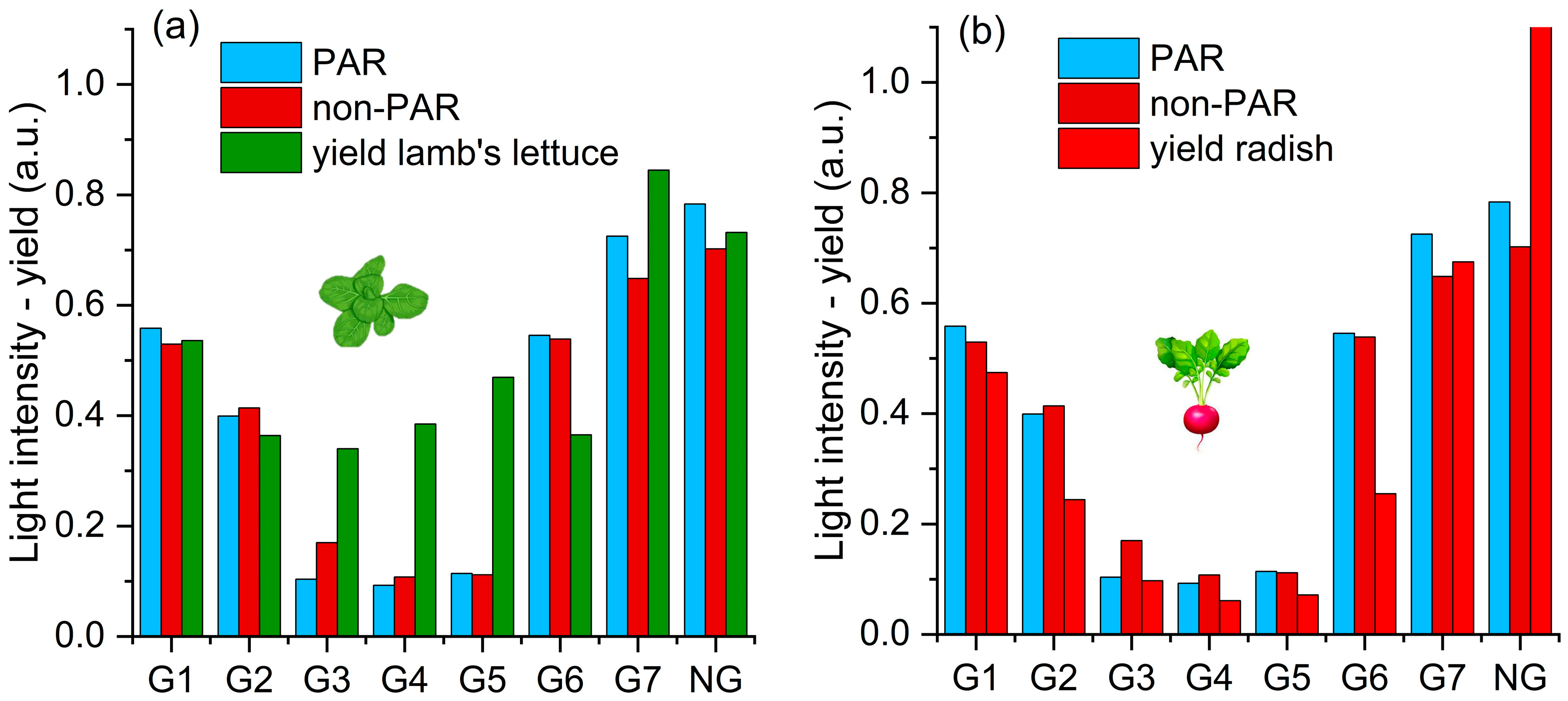

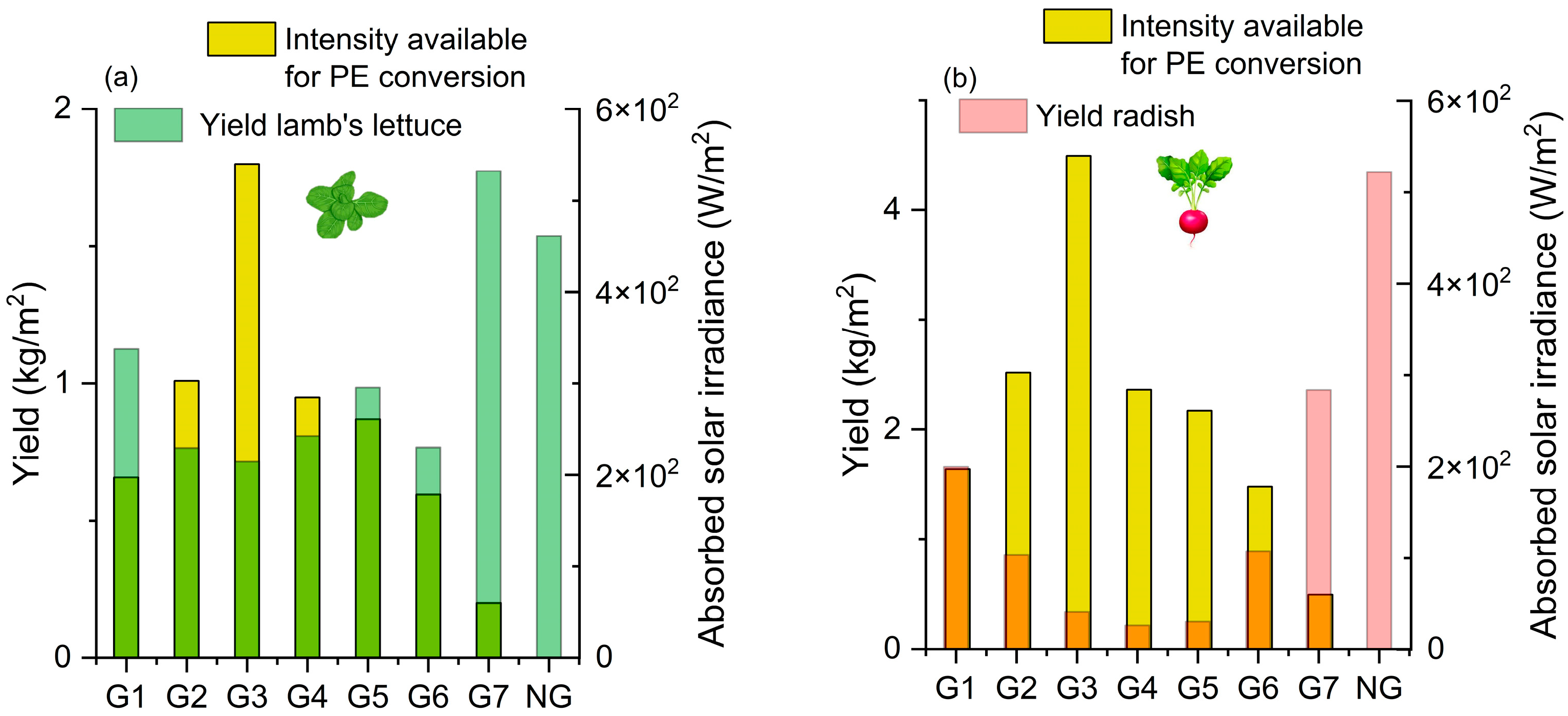

3.1.2. Field Results

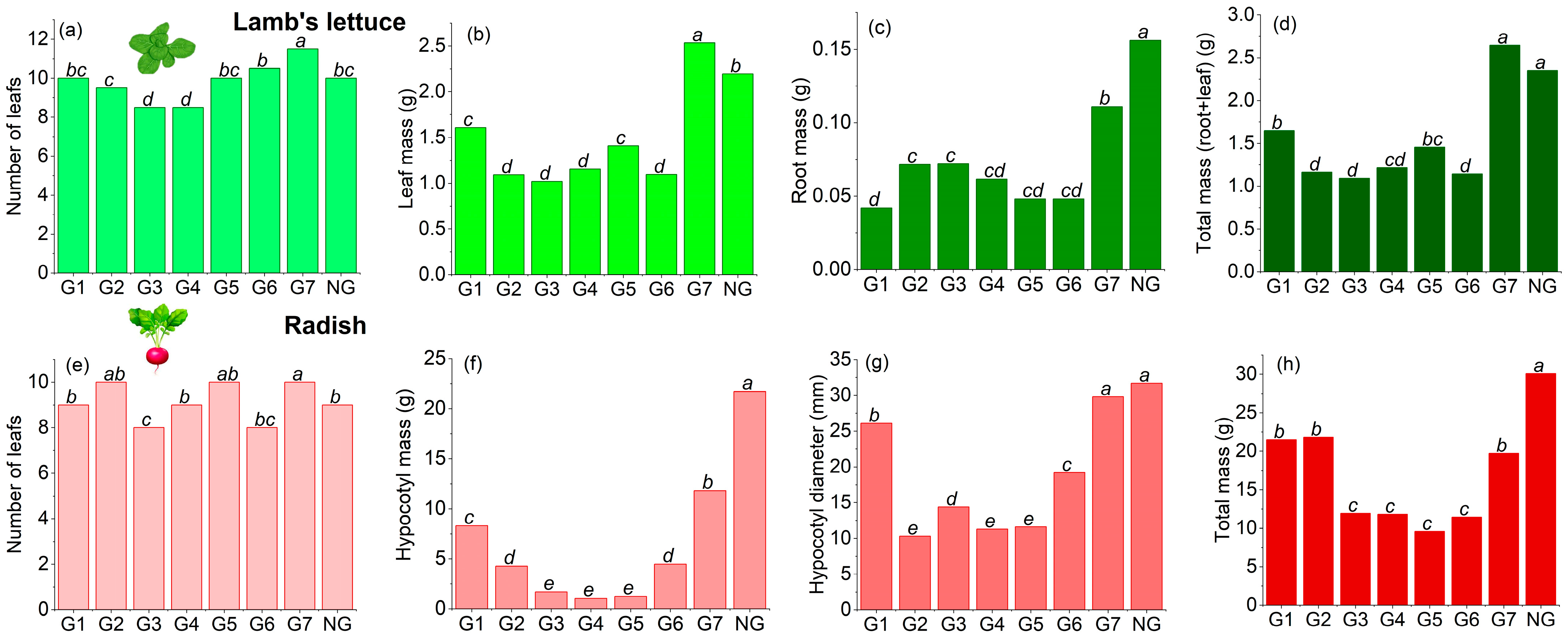

3.2. Plant Properties Under Different Coatings

3.2.1. Plant Morphology

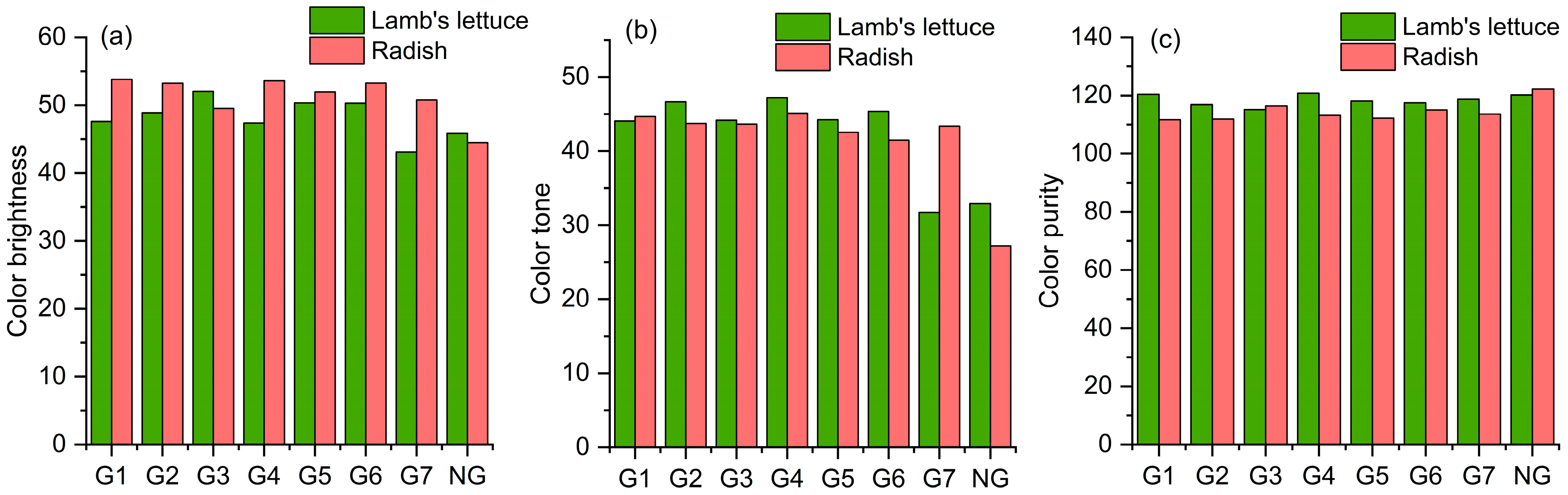

3.2.2. Leaf Color

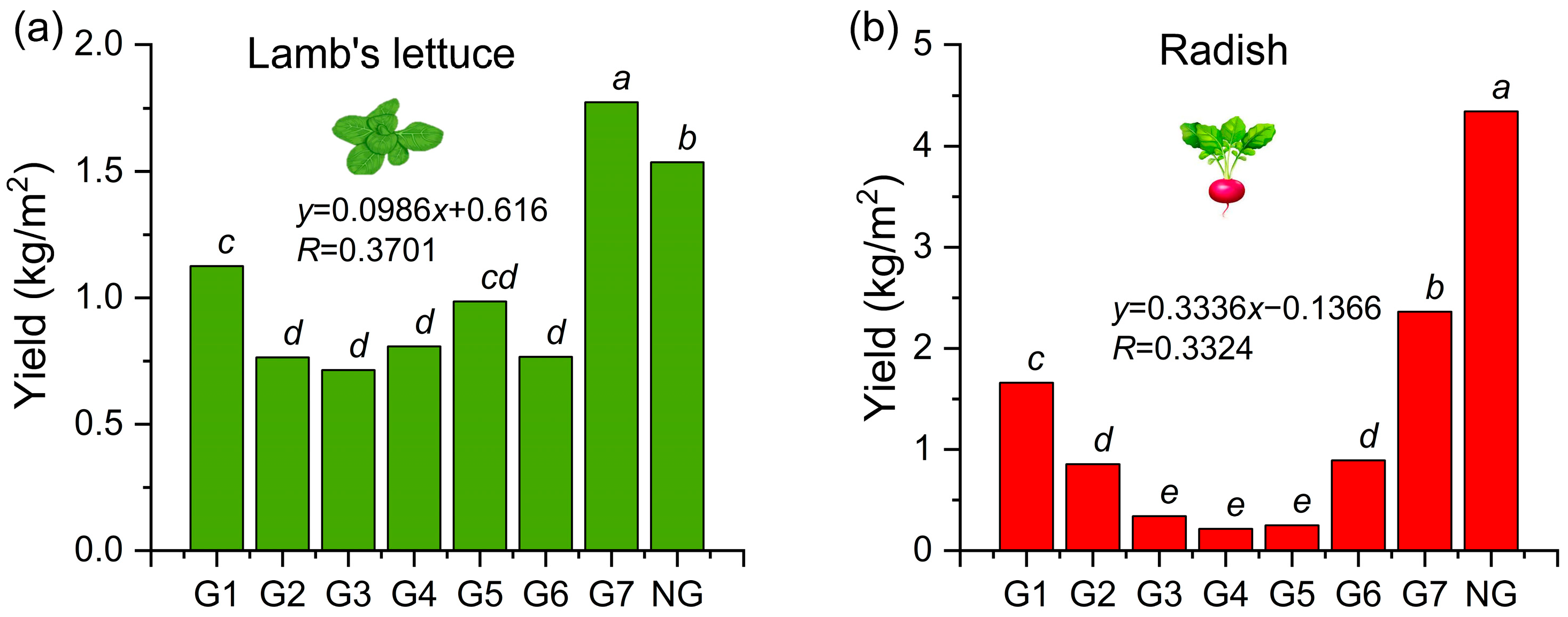

3.2.3. Yield

4. Discussion

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| QD | quantum dot |

| NP | nanoparticle |

| QW | quantum wire |

| T | transmittance |

| PV | photovoltaics |

| PCE | photoelectric conversion efficiency |

References

- Aznar-Sánchez, J.A.; Velasco-Muñoz, J.F.; López-Felices, B.; Román-Sánchez, I.M. An Analysis of Global Research Trends on Greenhouse Technology: Towards a Sustainable Agriculture. Int. J. Environ. Res. Public Health 2020, 17, 664. [Google Scholar] [CrossRef] [PubMed]

- Gruda, N.; Bisbis, M.; Tanny, J. Influence of Climate Change on Protected Cultivation: Impacts and Sustainable Adaptation Strategies—A Review. J. Clean. Prod. 2019, 225, 481–495. [Google Scholar] [CrossRef]

- Panwar, N.L.; Kaushik, S.C.; Kothari, S. Solar Greenhouse an Option for Renewable and Sustainable Farming. Renew. Sustain. Energy Rev. 2011, 15, 3934–3945. [Google Scholar] [CrossRef]

- Paris, B.; Vandorou, F.; Balafoutis, A.T.; Vaiopoulos, K.; Kyriakarakos, G.; Manolakos, D.; Papadakis, G. Energy Use in Greenhouses in the EU: A Review Recommending Energy Efficiency Measures and Renewable Energy Sources Adoption. Appl. Sci. 2022, 12, 5150. [Google Scholar] [CrossRef]

- Maraveas, C.; Kotzabasaki, M.I.; Bayer, I.S.; Bartzanas, T. Sustainable Greenhouse Covering Materials with Nano- and Micro-Particle Additives for Enhanced Radiometric and Thermal Properties and Performance. AgriEngineering 2023, 5, 1347–1377. [Google Scholar] [CrossRef]

- Liantas, G.; Chatzigeorgiou, I.; Ravani, M.; Koukounaras, A.; Ntinas, G.K. Energy Use Efficiency and Carbon Footprint of Greenhouse Hydroponic Cultivation Using Public Grid and PVs as Energy Providers. Sustainability 2023, 15, 1024. [Google Scholar] [CrossRef]

- Livera, A.; Lodolini, E.M.; Saraginovski, N.; Crescenzi, S.; Neri, D.; Manganaris, G.A. Current trends and challenges of agrivoltaic systems towards sustainable production of temperate fruit crops under intensive orchard setups. Sci. Hortic. 2025, 348, 114210. [Google Scholar] [CrossRef]

- Asa, S.; Reher, T.; Rong, J. A multidisciplinary view on agrivoltaics: Future of energy and agriculture. Renew. Sustain. Energy Rev. 2024, 200, 114515. [Google Scholar] [CrossRef]

- Trommsdorff, M.; Gruber, S.; Keinath, T.; Hopf, M.; Hermann, C.; Schönberger, F.; Gudat, C.; Torres Boggio, A.; Gajewski, M.; Högy, P.; et al. Agrivoltaics: Opportunities for Agriculture and the Energy Transition, A Guideline for Germany. Fraunhofer ISE. 2024. Available online: www.ise.fraunhofer.de/en (accessed on 20 October 2025).

- Zahrawi, A.A.; Aly, A.M. A Review of Agrivoltaic Systems: Addressing Challenges and Enhancing Sustainability. Sustainability 2024, 16, 8271. [Google Scholar] [CrossRef]

- Torres, M.A.; Muñoz, D.; Burgos, C.; Casagrande, D.; Ortiz, J.; Reyes, H. Design and Performance Evaluation of a Photovoltaic Greenhouse as an Energy Hub with Battery Storage and an Electric Vehicle Charger. Sustainability 2024, 16, 981. [Google Scholar] [CrossRef]

- Matulić, D.; Andabaka, Ž.; Radman, S.; Fruk, G.; Leto, J.; Rošin, J.; Rastija, M.; Varga, I.; Tomljanović, T.; Čeprnja, H.; et al. Agrivoltaics and Aquavoltaics: Potential of Solar Energy Use in Agriculture and Freshwater Aquaculture in Croatia. Agriculture 2023, 13, 1447. [Google Scholar] [CrossRef]

- Gauffin, H. Agrivoltaic Implementation in Greenhouses: A Techno-Economic Analysis of Agrivoltaic Installations for Greenhouses in Sweden; KTH Royal Institute of Technology: Stockholm, Sweden, 2022. [Google Scholar]

- Aroca-Delgado, R.; Pérez-Alonso, J.; Callejón-Ferre, Á.J.; Velázquez-Martí, B. Compatibility between Crops and Solar Panels: An Overview from Shading Systems. Sustainability 2018, 10, 743. [Google Scholar] [CrossRef]

- Emmott, C.J.M.; Röhr, J.A.; Campoy-Quiles, M.; Kirchartz, T.; Urbina, A.; Ekins-Daukes, N.J.; Nelson, J. Organic Photovoltaic Greenhouses: A Unique Application for Semi-Transparent PV? Energy Environ. Sci. 2015, 8, 1317–1328. [Google Scholar] [CrossRef]

- Paradiso, R.; Cocetta, G.; Proietti, S. Beyond red and blue: Unveiling the hidden action of green wavelengths on plant physiology, metabolisms and gene regulation in horticultural crops. Environ. Exp. Bot. 2025, 230, 106089. [Google Scholar] [CrossRef]

- Di Mola, I.; Ottaiano, L.; Cozzolino, E.; Sabatino, L.; Sifola, M.I.; Mormile, P.; El-Nakhel, C.; Rouphael, Y.; Mori, M. Optical Characteristics of Greenhouse Plastic Films Affect Yield and Some Quality Traits of Spinach (Spinacia oleracea L.) Subjected to Different Nitrogen Doses. Horticulturae 2021, 7, 200. [Google Scholar] [CrossRef]

- Hemming, S.; Mohammadkhani, V.; Kempkes, F.; Peters, A.; Lieffrig, V.; Harada, K.; van Spronsen, M.; van der Werff, T.; Louter, C. Feasibility Study Thin Glasses for Greenhouse Roof Designs. Available online: https://www.glastuinbouwnederland.nl/content/user_upload/20038_Eindrapport_Haalbaarheidstudie_Hoogisolerende_kas_3.0.PDF (accessed on 9 June 2025).

- Stallknecht, E.J.; Runkle, E.S. Opportunities and challenges with advanced greenhouse glazing materials. Acta Hortic. 2023, 1377, 205–218. [Google Scholar] [CrossRef]

- Teitel, M.; Vitoshkin, H.; Geoola, F.; Karlsson, S.; Stahl, N. Greenhouse and screenhouse cover materials: Literature review and industry perspective. Acta Hortic. 2018, 1227, 31–44. [Google Scholar] [CrossRef]

- Vasiliev, M.; Rosenberg, V.; Goodfield, D.; Lyford, J.; Li, C. High-transparency clear window-based agrivoltaics. Sustain. Build. 2023, 6, 5. [Google Scholar] [CrossRef]

- Luo, H.; Vasiliev, M.; He, T.; Wang, P.; Lyford, J.; Rosenberg, V.; Li, C. Transparent solar photovoltaic windows provide a strong potential for self-sustainable food production in forward-looking greenhouse farming architectures. Clean. Eng. Technol. 2025, 24, 100895. [Google Scholar] [CrossRef]

- Pandey, G.; Parks, S.; Thomas, R.G. Polymer and photo-selective covers on plant and fruit development: A review. Agron. J. 2023, 115, 3074–3091. [Google Scholar] [CrossRef]

- Periša, I.; Tkalčević, M.; Isaković, S.; Basioli, L.; Ivanda, M.; Bernstorff, S.; Mičetić, M. Ge/Al and Ge/Si3N4/Al Core/Shell Quantum Dot Lattices in Alumina: Boosting the Spectral Response by Tensile Strain. Materials 2022, 15, 6211. [Google Scholar] [CrossRef] [PubMed]

- Tkalčević, M.; Boršćak, D.; Periša, I.; Bogdanović-Radović, I.; Šarić Janković, I.; Petravić, M.; Bernstorff, S.; Mičetić, M. Multiple Exciton Generation in 3D-Ordered Networks of Ge Quantum Wires in Alumina Matrix. Materials 2022, 15, 5353. [Google Scholar] [CrossRef] [PubMed]

- Tkalčević, M.; Bubaš, M.; Sancho-Parramon, J.; Periša, I.; Salamon, K.; Bernstorff, S.; Bogdanović Radović, I.; Provatas, G.; Peter, R.; Mičetić, M. Ge and Core/Shell Ge/Al Quantum Dot Lattices in Amorphous SiC Matrix for Application in Photo- and Thermosensitive Devices. ACS Appl. Nano Mater. 2025, 8, 10395–10408. [Google Scholar] [CrossRef]

- Tkalčević, M.; Basioli, L.; Salamon, K.; Šarić, I.; Sancho-Parramon, J.; Bubaš, M.; Bogdanović-Radović, I.; Bernstorff, S.; Fogarassy, Z.; Balazsi, K.; et al. Ge Quantum Dot Lattices in Alumina Prepared by Nitrogen Assisted Deposition: Structure and Photoelectric Conversion Efficiency. Sol. Energy Mater. Sol. Cells 2020, 218, 110722. [Google Scholar] [CrossRef]

- Omelianovych, O.; Sandhu, S.; Ewusi, M.A.; Larina, L.; Kim, B.; Trinh, B.T.; Szaniel, A.; Yoon, I.; Lee, J.-J.; Choi, H.-S. Stable and Efficient Perovskite Solar Cells by Controlling the Crystal Growth via Introduction of Plasmonic TiN Nanoparticles. Adv. Funct. Mater. 2024, 34, 2407343. [Google Scholar] [CrossRef]

- Nekić, N.; Sancho-Parramon, J.; Bogdanović-Radović, I.; Grenzer, J.; Hübner, R.; Bernstorff, S.; Ivanda, M.; Buljan, M. Ge/Si core/shell quantum dots in alumina: Tuning the optical absorption by the core and shell size. Nanophotonics 2017, 6, 1055–1062. [Google Scholar] [CrossRef][Green Version]

- Borowski, P.; Myśliwiec, J. Recent Advances in Magnetron Sputtering: From Fundamentals to Industrial Applications. Coatings 2025, 15, 922. [Google Scholar] [CrossRef]

- SpectraSuite, Version 2.0; Ocean Optics: Dunedin, FL, USA, 2013. Available online: https://spectrasuite.software.informer.com/ (accessed on 17 May 2021).

- Lešić, R.; Borošić, J.; Buturac, I.; Herak-Ćustić, M.; Poljak, M.; Romić, D. Povrćarstvo, 3rd ed.; Zrinski: Čakovec, Croatia, 2016. [Google Scholar]

- Rubatzky, W.E.; Yamaguchi, M. World Vegetables Principles, Production, and Nutritive Values, 2nd ed.; Chapman & Hall: New York, NY, USA, 1997. [Google Scholar]

- Markovic, I.; Ilic, J.; Markovic, D.; Simonovic, V.; Kosanic, N. Color measurement of food products using CIE L*a*b* and RGB color space. J. Hyg. Eng. Des. 2013, 4, 50–53. [Google Scholar]

- SAS, Version SAS®/STAT 9.3; SAS Institute Inc.: Cary, NC, USA, 2010.

- Leon-Salas, W.D.; Rajendran, J.; Vizcardo, M.A.; Postigo-Malaga, M. Measuring Photosynthetically Active Radiation with a Multi-Channel Integrated Spectral Sensor. In Proceedings of the 2021 IEEE International Symposium on Circuits and Systems (ISCAS), Daegu, Republic of Korea, 22–28 May 2021. [Google Scholar] [CrossRef]

- Matysiak, B.; Kowalski, A. White, blue and red LED lighting on growth, morphology and accumulation of flavonoid compounds in leafy greens. Zemdirb.-Agric. 2019, 106, 281–286. [Google Scholar] [CrossRef]

- Currey, C.J.; Konjoian, P. How Increasing Light Improves Radish Yields. 2023. Available online: https://www.greenhousegrower.com/production/how-increasing-light-improves-radish-yields/ (accessed on 20 October 2025).

- Pathare, P.B.; Opara, U.L.; Al-Said, F.A.J. Color Measurement and Analysis in Fresh and Processed Foods: A review. Food Bioprocess Technol. 2013, 6, 36–60. [Google Scholar] [CrossRef]

- Liu, J.; van Iersel, M.W. Photosynthetic Physiology of Blue, Green, and Red Light: Light Intensity Effects and Underlying Mechanisms. Front. Plant Sci. 2021, 12, 619987. [Google Scholar] [CrossRef]

- Olle, M.; Alsina, I. Influence of Wavelength of Light on Growth, Yield and Nutritional Quality of Greenhouse Vegetables. Proc. Latv. Acad. Sci. Sect. B. Nat. Exact Appl. Sci. 2019, 73, 1–9. [Google Scholar] [CrossRef]

- Baneshi, M.; Gonome, H.; Maruyama, S. Wide-range Spectral Measurement of Radiative Properties of Commercial Greenhouse Covering Plastics and Their Impacts into the Energy Management in a Greenhouse. Energy 2020, 210, 118535. [Google Scholar] [CrossRef]

- Timmermans, G.H.; Hemming, S.; Baeza, E.; van Thoor, E.A.J.; Schenning, A.P.H.J.; Debije, M.G. Advanced Optical Materials for Sunlight Control in Greenhouses. Adv. Opt. Mater. 2020, 8, 2000738. [Google Scholar] [CrossRef]

- Frutos-Totosa, A.; Hernández-Adasme, C.; Martínez, V.; Mestre, T.; Díaz-Mula, H.M.; Botella, M.A.; Flores, P.; Martínez-Moreno, A. Light Spectrum Effects on Rocket and Lamb’s Lettuce Cultivated in a Vertical Indoor Farming System. Sci. Hortic. 2023, 321, 112221. [Google Scholar] [CrossRef]

- Avgoustaki, D.D.; Vatsika, G.; Vatistas, C.; Bartzanas, T. Influence of Different DLI Treatments on Valerianella locusta Plants Grown in an Indoor Vertical Farm. Acta Hortic. 2025, 1426, 175–182. [Google Scholar] [CrossRef]

- Zha, L.; Liu, W. Effects of Light Quality, Light Intensity, and Photoperiod on Growth and Yield of Cherry Radish Grown under Red Plus Blue LEDs. Hortic. Environ. Biotechnol. 2018, 59, 511–518. [Google Scholar] [CrossRef]

- Kuleshova, T.E.; Zhelnacheva, P.V.; Ezerina, E.M.; Vertebny, V.E.; Khomyakov, Y.V.; Panova, G.G.; Kochetov, A.A.; Sinyavina, N.G. Influence of the Light Spectral Composition on Photosynthetic, Electro- and Morphophysiological Indicators of Small Radish in Conditions of Light Culture. Russ. J. Plant Physiol. 2024, 71, 59. [Google Scholar] [CrossRef]

- Hu, H.; Zhang, J.; Sun, X.; Zhang, X. Estimation of Leaf Chlorophyll Content of Rice Using Image Color Analysis. Can. J. Remote Sens. 2013, 39, 185–190. [Google Scholar] [CrossRef]

- Madeira, A.C.; Ferreira, A.; de Varennes, A.; Vieira, M.I. SPAD Meter Versus Tristimulus Colorimeter to Estimate Chlorophyll Content and Leaf Color in Sweet Pepper. Commun. Soil Sci. Plant Anal. 2003, 34, 2461–2470. [Google Scholar] [CrossRef]

- Conesa, A.; Manera, F.C.; Brotons, J.M.; Fernandez-Zapata, J.C.; Simón, I.; Simón-Grao, S.; Alfosea-Simón, M.; Martínez Nicolás, J.J.; Valverde, J.M.; García-Sanchez, F. Changes in the Content of Chlorophylls and Carotenoids in the Rind of Fino 49 Lemons During Maturation and Their Relationship With Parameters from the CIELAB Color Space. Sci. Hortic. 2019, 243, 252–260. [Google Scholar] [CrossRef]

- Zdarova, D.A.; Zolotukhina, A.A.; Belyaeva, A.S. A Comparative Study of Colorimetry and Reflectance Spectroscopy for Estimating Pigment Content in Plant Leaves. In Proceedings of the 2025 Systems of Signal Synchronization, Generating and Processing in Telecommunications (SYNCHROINFO), Tyumen, Russia, 30 June–3 July 2025. [Google Scholar] [CrossRef]

- Cozzolino, E.; Di Mola, I.; Ottaiano, L.; El-Nakhel, C.; Mormile, P.; Rouphael, Y.; Mori, M. The Potential of Greenhouse Diffusing Cover Material on Yield and Nutritive Values of Lamb’s Lettuce Grown under Diverse Nitrogen Regimes. Italus Hortus 2020, 27, 55–67. [Google Scholar] [CrossRef]

- Maraveas, C.; Loukatos, D.; Bartzanas, T.; Arvanitis, K.G.; Uijterwaal, J.F. Smart and Solar Greenhouse Covers: Recent Developments and Future Perspectives. Front. Energy Res. 2021, 9, 783587. [Google Scholar] [CrossRef]

- Fernández, E.F.; Villar-Fernández, A.; Montes-Romero, J.; Ruiz-Torres, L.; Rodrigo, P.M.; Manzaneda, A.J.; Almonacid, F. Global Energy Assessment of the Potential of Photovoltaics for Greenhouse Farming. Appl. Energy 2022, 309, 118474. [Google Scholar] [CrossRef]

- Aira, J.-R.; Gallardo-Saavedra, S.; Eugenio-Gozalbo, M.; Alonso-Gómez, V.; Muñoz-García, M.-Á.; Hernández-Callejo, L. Analysis of the Viability of a Photovoltaic Greenhouse with Semi-Transparent Amorphous Silicon (a-Si) Glass. Agronomy 2021, 11, 1097. [Google Scholar] [CrossRef]

| Glass | Structure | P (W) | t (s) | Matrix | NPs | T (°C) | d (nm) |

|---|---|---|---|---|---|---|---|

| G1 | (Ge/Al2O3) × 20 | 10/130 | 45/100 | Al2O3 | Ge | 500 | 82 |

| G2 | ((Ti + Si3N4)/Si3N4) × 20 | (65 + 100)/100 | 15/20 | Si3N4 | TiN | 300 | 156 |

| G3 | Ge+ Al2O3 | 20 + 100 | 1800 | Al2O3 | Ge | 400 | 53 |

| G4 | (Ge/Si3N4/Al/Al2O3) × 20 | 25/25/25/140 | 10/40/40/200 | Al2O3 | Ge/Si3N4/Al | 500 | 82 |

| G5 | (Ge/Si/Si3N4) × 10 | 10/50/150 | 80/75/15 | Si3N4 | Ge/Si | 500 | 53 |

| G6 | (Ge/Si/SiC) × 10 | 10/50/150 | 80/75/15 | SiC | Ge/Si | 500 | 0.0 |

| G7 | Soda–lime glass | -- | -- | -- | -- | -- | -- |

| Glass 1 | Blue Light 410–485 nm | Green Light 510–585 nm | Red Light 610–705 nm | Far-Red Light 730–810 nm | DLI 410–940 nm |

|---|---|---|---|---|---|

| G1 | 5.09 | 4.15 | 4.21 | 6.13 | 22.37 |

| G2 | 5.83 | 4.85 | 4.75 | 8.77 | 25.31 |

| G3 | 4.11 | 3.31 | 2.59 | 4.96 | 15.82 |

| G4 | 2.35 | 2.2 | 1.67 | 2.67 | 9.55 |

| G5 | 1.83 | 1.74 | 1.27 | 2.09 | 7.47 |

| G6 | 4.77 | 3.79 | 2.64 | 4.29 | 16.39 |

| G7 | 6.54 | 5.66 | 5.31 | 10.38 | 29.26 |

| NG | 12.69 | 10.72 | 9.71 | 20.88 | 56.78 |

| Color | L* | a* | b* | C* | H | |||||

|---|---|---|---|---|---|---|---|---|---|---|

| Glass 1 | LL 2 | RD | LL | RD | LL | RD | LL | RD | LL | RD |

| G1 | 47.60 c 3 | 53.81 a | −22.30 cd | −16.29 ab | 37.99 c | 41.51 ab | 44.05 c | 44.67 a | 120.40 ab | 111.63 c |

| G2 | 48.88 bc | 53.22 a | −21.06 c | −16.17 ab | 41.54 a | 40.56 abc | 46.65 ab | 43.73 ab | 116.88 cd | 111.86 c |

| G3 | 52.04 a | 49.53 b | −18.77 b | −19.41 c | 39.97 ab | 38.59 bc | 44.16 c | 43.64 ab | 115.15 d | 116.45 b |

| G4 | 47.38 c | 53.59 a | −24.16 d | −17.77 bc | 40.54 ab | 41.79 a | 47.19 a | 45.12 a | 120.80 a | 113.18 bc |

| G5 | 50.31 b | 51.95 ab | −20.78 c | −16.04 ab | 39.03 bc | 39.40 abc | 44.22 c | 42.54 bc | 118.07 bc | 112.19 c |

| G6 | 50.29 b | 53.25 a | −20.91 c | −17.56 bc | 40.23 ab | 37.58 c | 45.36 bc | 41.48 c | 117.44 cd | 115.04 bc |

| G7 | 43.07 d | 50.75 ab | −15.22 a | −17.39 bc | 27.80 d | 39.72 abc | 31.72 d | 43.37 abc | 118.68 abc | 113.61 bc |

| NG | 45.83 cd | 44.48 c | −16.59 a | −14.53 a | 28.41 d | 23.00 d | 32.90 d | 27.20 d | 120.21 ab | 122.26 a |

| LSD0.05 | 1.6794 | 3.4059 | 1.8626 | 2.4223 | 1.6383 | 2.9954 | 1.4437 | 1.9237 | 2.5045 | 4.1178 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Benko, B.; Salamon, K.; Periša, I.; Fabek Uher, S.; Radman, S.; Opačić, N.; Mičetić, M. Nanostructured Ge-Based Glass Coatings for Sustainable Greenhouse Production: Balancing Light Transmission, Energy Harvesting, and Crop Performance. Agronomy 2025, 15, 2559. https://doi.org/10.3390/agronomy15112559

Benko B, Salamon K, Periša I, Fabek Uher S, Radman S, Opačić N, Mičetić M. Nanostructured Ge-Based Glass Coatings for Sustainable Greenhouse Production: Balancing Light Transmission, Energy Harvesting, and Crop Performance. Agronomy. 2025; 15(11):2559. https://doi.org/10.3390/agronomy15112559

Chicago/Turabian StyleBenko, Božidar, Krešimir Salamon, Ivana Periša, Sanja Fabek Uher, Sanja Radman, Nevena Opačić, and Maja Mičetić. 2025. "Nanostructured Ge-Based Glass Coatings for Sustainable Greenhouse Production: Balancing Light Transmission, Energy Harvesting, and Crop Performance" Agronomy 15, no. 11: 2559. https://doi.org/10.3390/agronomy15112559

APA StyleBenko, B., Salamon, K., Periša, I., Fabek Uher, S., Radman, S., Opačić, N., & Mičetić, M. (2025). Nanostructured Ge-Based Glass Coatings for Sustainable Greenhouse Production: Balancing Light Transmission, Energy Harvesting, and Crop Performance. Agronomy, 15(11), 2559. https://doi.org/10.3390/agronomy15112559