Starch Granule Size Distribution and Pasting Properties from 14 Soft Wheat Varieties in Huaihe River Basin

Abstract

1. Introduction

2. Results

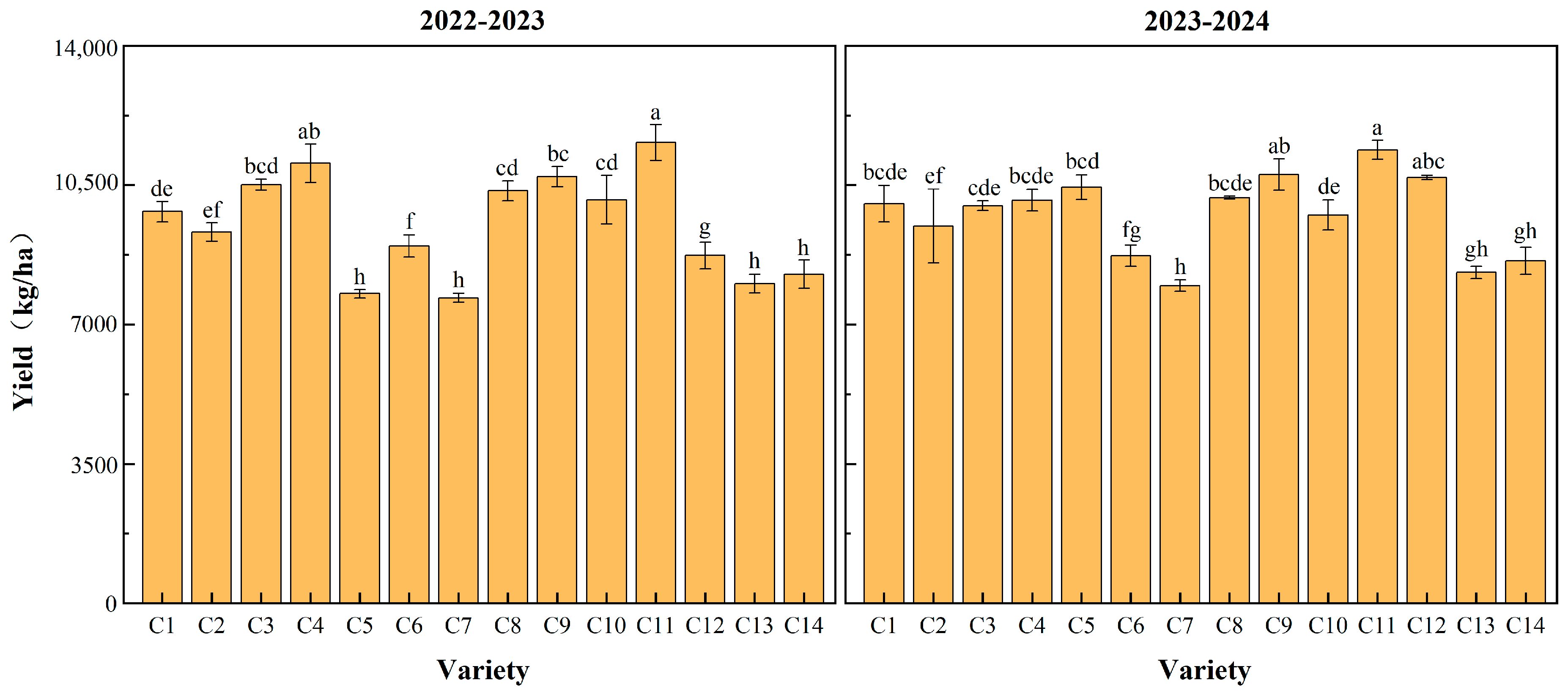

2.1. Yield

2.2. Volume Distibution

2.3. Grain Quality Characteristics

2.4. Starch Granule Number Distribution

2.5. Pasting Properties of Wheat Starch

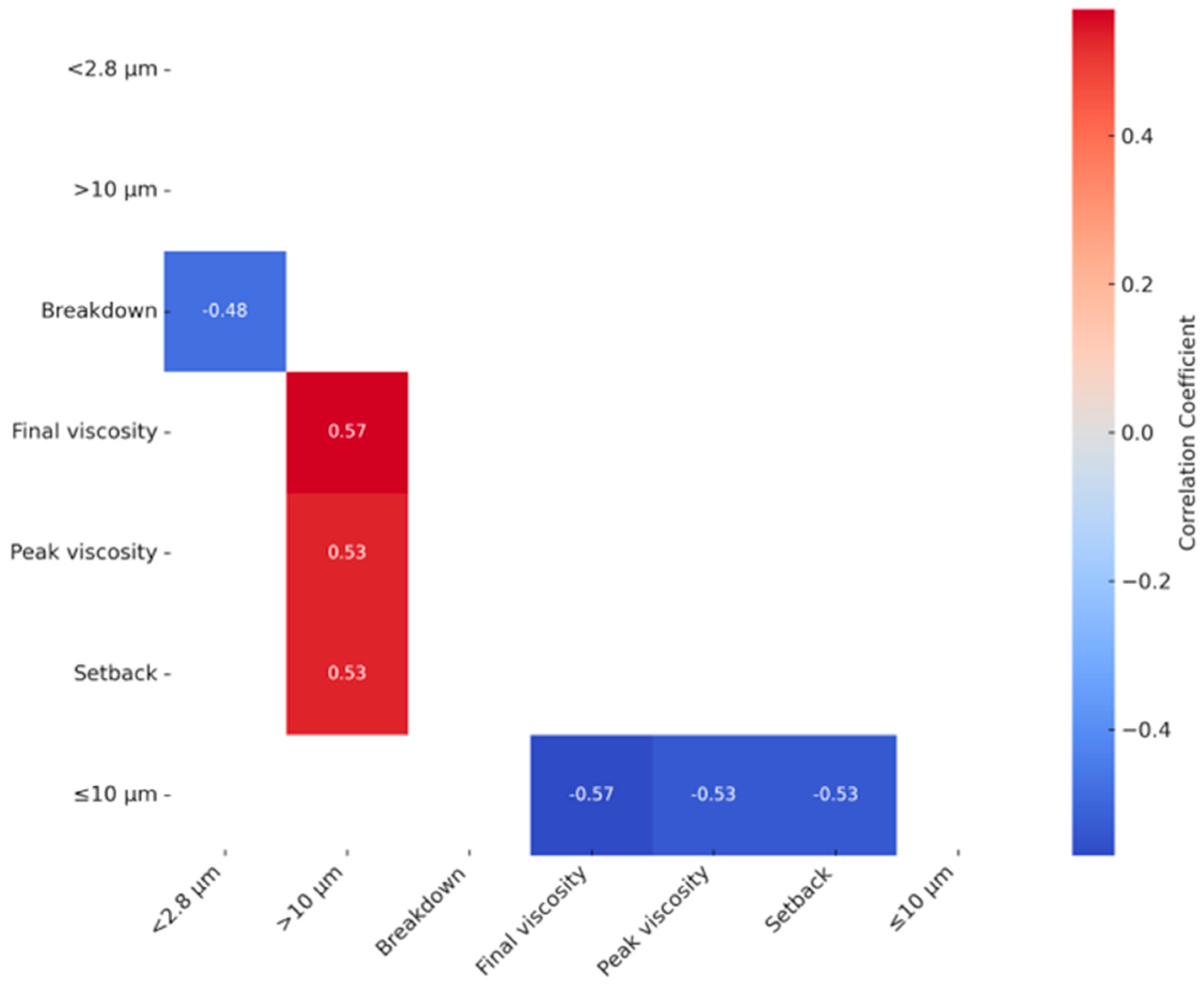

2.6. Correlation Between Granule Size and Pasting Properties

3. Discussion

4. Materials and Methods

4.1. Experimental Site and Plant Material

4.2. Experimental Design and Field Management

4.3. Yield and Grain Quality Evaluation

4.4. Starch Extraction and Granule Size Analysis

4.5. Pasting Properties Analysis

4.6. Statistical Analysis

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Bhatta, A. Effects of Soluble and Insoluble Fibres on Pasting and Retrogradation of Wheat Flour and Quality of Bread. Master’s Thesis, Chulalongkorn University, Bangkok, Thailand, 2020. [Google Scholar]

- Biduski, B.; Werlang, S.; Colussi, R.; Pinto, V.Z.; Zavareze, E.D.R.; Gutkoski, L.C.; Bertolin, T.E. Starches properties from soft, medium-hard, and hard Brazilian wheat upon annealing. Starch-Stärke 2022, 74, 2100267. [Google Scholar] [CrossRef]

- Devi, A.; Sindhu, R.; Khatkar, B. Effect of fats and oils on pasting and textural properties of wheat flour. J. Food Sci. Technol. 2020, 57, 3836–3842. [Google Scholar] [CrossRef]

- Capouchova, I.; Petr, J.; Maresova, D. Evaluation of size distribution of starch granules in selected wheat varieties by the Low Angle Laser Light Scattering method. Plant Soil Environ. 2003, 49, 12–17. [Google Scholar] [CrossRef]

- Zeng, J.; Li, G.; Gao, H.; Ru, Z. Comparison of A and B starch granules from three wheat varieties. Molecules 2011, 16, 10570–10591. [Google Scholar] [CrossRef] [PubMed]

- Esch, L.; Ngai, Q.Y.; Barclay, J.E.; McNelly, R.; Hayta, S.; Smedley, M.A.; Smith, A.M.; Seung, D. Increasing amyloplast size in wheat endosperm through mutation of PARC6 affects starch granule morphology. New Phytol. 2023, 240, 224–241. [Google Scholar] [CrossRef] [PubMed]

- Gao, M.; Moussavi, M.; Myers, D. Analysis and specification of starch granule size distributions. J. Vis. Exp. 2021, 169, 61586. [Google Scholar] [CrossRef]

- Fahy, B.; Chen, J.; Seung, D. Tuning starch granule size distributions in durum wheat using genetic variation at a single locus. Theor. Appl. Genet. 2025, 138, 227–241. [Google Scholar] [CrossRef] [PubMed]

- Geng, Z.; Zhang, P.; Yao, J.; Yang, D.; Ma, H.; Rayas-Duarte, P. Physicochemical and rheological properties of Chinese soft wheat flours and their relationships with cookie-making quality. Cereal Chem. 2012, 89, 237–241. [Google Scholar] [CrossRef]

- Tanaka, E.; Ral, J.F.; Li, S.; Gaire, R.; Cavanagh, C.R.; Cullis, B.R.; Whan, A. Increased accuracy of starch granule type quantification using mixture distributions. Plant Methods 2017, 13, 107. [Google Scholar] [CrossRef]

- Dai, Z. Starch Granule Size Distribution in Grains at Different Positions on the Spike of Wheat (Triticum aestivum L.). Starch-Stärke 2009, 61, 582–589. [Google Scholar] [CrossRef]

- Keres, I.; Alaru, M.; Talgre, L.; Luik, A.; Eremeev, V.; Sats, A.; Jõudu, I.; Riisalu, A.; Loit, E. Impact of weather conditions and farming systems on size distribution of starch granules and flour yield of winter wheat. Agriculture 2020, 10, 22. [Google Scholar] [CrossRef]

- Kim, K.-H.; Kim, J.-Y. Understanding Wheat Starch Metabolism in Properties, Environmental Stress Condition, and Molecular Approaches for Value-Added Utilization. Plants 2021, 10, 2282. [Google Scholar] [CrossRef]

- Li, M.; Daygon, V.D.; Solah, V.; Dhital, S. Starch granule size: Does it matter? Crit. Rev. Food Sci. Nutr. 2023, 63, 3683–3703. [Google Scholar] [CrossRef]

- Li, W.-Y.; Yan, S.-H.; Yin, Y.-P.; Li, Y.; Liang, T.-B.; Gu, F.; Dai, Z.-M.; Wang, Z.-L. Comparison of starch granule size distribution between hard and soft wheat cultivars in eastern China. Agric. Sci. China 2008, 7, 907–914. [Google Scholar] [CrossRef]

- Liao, R.; Liu, G.; Chen, J.; Zhang, L. Interdecadal variability of summer extreme rainfall events over the Huaihe River Basin and associated atmospheric circulation. Atmosphere 2022, 13, 1189. [Google Scholar] [CrossRef]

- Ma, M.; Wen, Y.; Zhang, C.; Xu, Z.; Li, H.; Sui, Z.; Corke, H. Extraction and characterization of starch granule-associated surface and channel lipids from small-granule starches that affect physicochemical properties. Food Hydrocoll. 2022, 126, 107370. [Google Scholar] [CrossRef]

- He, Z. Wheat Quality Requirements in China. In Wheat: Chemistry and Technology; Springer: Dordrecht, The Netherlands, 2001; pp. 413–424. [Google Scholar] [CrossRef]

- Miransari, M.; Smith, D. Sustainable wheat (Triticum aestivum L.) production in saline fields: A review. Crit. Rev. Biotechnol. 2019, 39, 999–1014. [Google Scholar] [CrossRef]

- Park, H.-Y.; Ryu, A.-R.; Kim, H.R.; Shin, K.-S.; Hong, J.S.; Choi, H.-D. Effects of citrus peel hydrolysates on retrogradation of wheat starch. Foods 2021, 10, 2422. [Google Scholar] [CrossRef]

- Peng, M.; Gao, M.; Abdel-Aal, E.M.; Hucl, P.; Chibbar, R.N. Separation and characterization of A- and B-type starch granules in wheat endosperm. Cereal Chem. 1999, 76, 375–379. [Google Scholar] [CrossRef]

- Shang, J.; Zhao, B.; Liu, C.; Li, L.; Hong, J.; Liu, M.; Zhang, X.; Lei, Y.; Zheng, X. Impact of wheat starch granule size on viscoelastic behaviors of noodle dough sheet and the underlying mechanism. Food Hydrocoll. 2023, 134, 108111. [Google Scholar] [CrossRef]

- Shen, H.; Yan, M.; Liu, X.; Ge, X.; Zeng, J.; Gao, H.; Zhang, G.; Li, W. Wheat starch particle size distribution regulates the dynamic transition behavior of gluten at different stages of dough mixing. Int. J. Biol. Macromol. 2023, 244, 125371. [Google Scholar] [CrossRef] [PubMed]

- Li, W.; Yan, S.; Shi, X.; Zhang, C.; Shao, Q.; Xu, F.; Wang, J. Starch granule size distribution from twelve wheat cultivars in east China’s Huaibei region. Can. J. Plant Sci. 2016, 96, 176–182. [Google Scholar] [CrossRef]

- Shewry, P.R.; Koksel, H.; Taylor, J.R. ICC Handbook of 21st Century Cereal Science and Technology; Academic Press: Cambridge, MA, USA, 2023. [Google Scholar]

- Smith, A.M.; Denyer, K.; Martin, C. The synthesis of the starch granule. Annu. Rev. Plant Biol. 1997, 48, 67–87. [Google Scholar] [CrossRef]

- Tester, R.F.; Karkalas, J.; Qi, X. Starch—Composition, fine structure and architecture. J. Cereal Sci. 2004, 39, 151–165. [Google Scholar] [CrossRef]

- Wan, L.; Wang, X.; Liu, H.; Xiao, S.; Ding, W.; Pan, X.; Fu, Y. Retrogradation inhibition of wheat starch with wheat oligopeptides. Food Chem. 2023, 427, 136723. [Google Scholar] [CrossRef]

- Woodbury, T.J.; Mauer, L.J. Oligosaccharide, sucrose, and allulose effects on the pasting and retrogradation behaviors of wheat starch. Food Res. Int. 2023, 171, 113002. [Google Scholar] [CrossRef]

- Meraz, M.; Alvarez-Ramirez, J.; Vernon-Carter, E.J.; Reyes, I.; Hernandez-Jaimes, C.; Martinez-Martinez, F. A Two Competing Substrates Michaelis–Menten Kinetics Scheme for the Analysis of In Vitro Starch Digestograms. Starch-Stärke 2020, 72, 1900170. [Google Scholar] [CrossRef]

- Xu, Y.; Chen, X.; Xu, X.; Wang, B.; Du, X.; Chen, P. Investigation on morphological structure and crystal transition of maize starch gelatinized in pure glycerol. J. Cereal Sci. 2020, 92, 102924. [Google Scholar] [CrossRef]

- Yu, A.; Li, Y.; Ni, Y.; Yang, W.; Yang, D.; Cui, Z.; Wang, Z.; Yin, Y. Differences of starch granule distribution in grains from different spikelet positions in winter wheat. PLoS ONE 2014, 9, e114342. [Google Scholar] [CrossRef] [PubMed]

- Zeng, M.; Morris, C.F.; Batey, I.L.; Wrigley, C.W. Sources of variation for starch gelatinization, pasting, and gelation properties in wheat. Cereal Chem. 1997, 74, 63–71. [Google Scholar] [CrossRef]

- Wang, H.-D.; Zhang, P.-P.; Zhang, P.; Ma, H.-X.; Yao, J.-B.; Jiang, P.; Song, G.-C. Soft wheat quality traits in Jiangsu province and their relationship with cookie making quality. Acta Agron. Sin. 2020, 46, 491–502. [Google Scholar] [CrossRef]

- Watanabe, S.; Nishitsuji, Y.; Hayakawa, K.; Shi, Y.C. Pasting properties of A- and B-type wheat starch granules and annealed starches in relation to swelling and solubility. Int. J. Biol. Macromol. 2024, 261, 129738. [Google Scholar] [CrossRef] [PubMed]

- Stoddard, F.L. Survey of starch particle-size distribution in wheat and related species. Cereal Chem. 1999, 76, 145–149. [Google Scholar] [CrossRef]

| Year | Variety | Particle Diameter of Starch Granule/μm | |||||

|---|---|---|---|---|---|---|---|

| <2.8 μm | 2.8–10 μm | 10–22 μm | >22 μm | ≤10 μm | >10 μm | ||

| 2022–2023 | Annon 0711 | 9.33 ± 0.06 h | 27.20 ± 0.08 c | 30.61 ± 0.12 e | 32.86 ± 0.18 d | 36.53 ± 0.06 gh | 63.47 ± 0.06 de |

| Quanmai 31 | 9.20 ± 0.02 hi | 24.93 ± 0.13 f | 31.79 ± 0.11 d | 34.08 ± 0.08 c | 34.13 ± 0.14 j | 65.87 ± 0.14 b | |

| Mengmai 0818 | 9.81 ± 0.19 g | 30.41 ± 0.1 b | 27.88 ± 0.31 h | 31.9 ± 0.39 e | 40.22 ± 0.09 e | 59.78 ± 0.09 g | |

| Lomai 28 | 8.38 ± 0.29 j | 22.50 ± 0.34 g | 32.64 ± 1.18 c | 36.48 ± 1.09 a | 30.88 ± 0.23 k | 69.12 ± 0.23 a | |

| Zheng Mai 132 | 10.64 ± 0.26 e | 30.31 ± 0.21 b | 28.94 ± 0.21 g | 30.1 ± 0.45 fg | 40.95 ± 0.29 d | 59.05 ± 0.29 h | |

| Bainong 307 | 10.07 ± 0.19 fg | 30.56 ± 0.4 b | 29.84 ± 0.1 f | 29.54 ± 0.32 g | 40.63 ± 0.38 de | 59.37 ± 0.38 gh | |

| Zhou Mai 30 | 11.86 ± 0.06 b | 31.37 ± 0.03 a | 29.77 ± 0.03 f | 27.00 ± 0.07 i | 43.23 ± 0.07 b | 56.77 ± 0.07 j | |

| Huacheng 865 | 10.62 ± 0.01 e | 30.29 ± 0.02 b | 29.16 ± 0.07 fg | 29.92 ± 0.1 g | 40.92 ± 0.03 d | 59.08 ± 0.03 h | |

| Longke 1109 | 11.04 ± 0.01 d | 26.79 ± 0.06 d | 33.86 ± 0.02 b | 28.31 ± 0.1 h | 37.83 ± 0.08 f | 62.17 ± 0.08 f | |

| XuNong 029 | 11.39 ± 0.02 c | 25.48 ± 0.13 e | 35.04 ± 0.14 a | 28.10 ± 0.04 h | 36.86 ± 0.15 g | 63.14 ± 0.15 e | |

| Huacheng 2019 | 10.36 ± 0.05 ef | 25.82 ± 0.15 e | 33.10 ± 0.14 bc | 30.72 ± 0.17 f | 36.18 ± 0.16 h | 63.82 ± 0.16 d | |

| Huaimai 44 | 12.65 ± 0.25 a | 31.18 ± 0.14 a | 30.80 ± 0.11 e | 25.36 ± 0.10 j | 43.83 ± 0.12 a | 56.17 ± 0.12 k | |

| Wanken 22 | 8.99 ± 0.09 i | 26.72 ± 0.11 d | 28.70 ± 0.05 g | 35.59 ± 0.23 b | 35.70 ± 0.20 i | 64.30 ± 0.20 c | |

| Wanken 9 | 11.83 ± 0.25 b | 30.26 ± 0.23 b | 30.67 ± 0.47 e | 27.24 ± 0.09 i | 42.09 ± 0.39 c | 57.91 ± 0.39 i | |

| F-Value | 92.89 ** | 187.73 ** | 66.434 ** | 384.371 ** | 144.52 ** | 144.52 ** | |

| 2023–2024 | Annon 0711 | 8.56 ± 0.41 i | 28 ± 0.63 c | 30.11 ± 0.68 e | 33.33 ± 1.36 d | 36.56 ± 0.83 gh | 63.44 ± 0.83 cd |

| Quanmai 31 | 11.04 ± 0.65 bc | 25.73 ± 0.55 f | 32.6 ± 0.69 bc | 30.62 ± 1.12 f | 36.77 ± 0.43 g | 63.23 ± 0.43 d | |

| Mengmai 0818 | 9.04 ± 0.39 h | 31.21 ± 0.54 b | 27.38 ± 0.59 h | 32.36 ± 1.33 e | 40.25 ± 0.8 e | 59.75 ± 0.8 f | |

| Lomai 28 | 7.61 ± 0.73 j | 23.3 ± 0.84 g | 32.14 ± 0.85 c | 36.94 ± 0.1 a | 30.92 ± 0.95 j | 69.08 ± 0.95 a | |

| Zheng Mai 132 | 9.87 ± 0.67 ef | 31.11 ± 0.84 b | 28.44 ± 0.69 g | 30.57 ± 1.63 f | 40.99 ± 0.99 d | 59.01 ± 0.99 g | |

| Bainong 307 | 9.3 ± 0.4 gh | 31.36 ± 0.45 b | 29.34 ± 0.61 f | 30 ± 0.9 f | 40.66 ± 0.53 de | 59.34 ± 0.53 fg | |

| Zhou Mai 30 | 9.6 ± 0.41 fg | 26.62 ± 0.77 e | 29.27 ± 0.6 f | 34.51 ± 1.32 c | 36.21 ± 0.92 hi | 63.79 ± 0.92 bc | |

| Huacheng 865 | 9.86 ± 0.45 ef | 31.09 ± 0.62 b | 28.66 ± 0.51 fg | 30.39 ± 1.09 f | 40.95 ± 0.75 d | 59.05 ± 0.75 g | |

| Longke 1109 | 10.27 ± 0.44 de | 27.59 ± 0.63 d | 33.36 ± 0.55 b | 28.78 ± 1.09 g | 37.86 ± 0.72 f | 62.14 ± 0.72 e | |

| XuNong 029 | 10.62 ± 0.46 cd | 26.28 ± 0.75 e | 34.54 ± 0.48 a | 28.56 ± 1.18 gh | 36.9 ± 0.93 g | 63.1 ± 0.93 d | |

| Huacheng 2019 | 11.88 ± 0.45 a | 31.98 ± 0.52 a | 31.29 ± 0.57 d | 24.84 ± 1.31 j | 43.87 ± 0.88 a | 56.13 ± 0.88 j | |

| Huaimai 44 | 11.1 ± 0.43 b | 32.17 ± 0.62 a | 30.3 ± 0.49 e | 26.43 ± 1.04 i | 43.26 ± 0.72 b | 56.74 ± 0.72 i | |

| Wanken 22 | 8.22 ± 0.54 i | 27.52 ± 0.69 d | 28.2 ± 0.61 g | 36.06 ± 1.4 b | 35.74 ± 0.96 i | 64.26 ± 0.96 b | |

| Wanken 9 | 11.06 ± 0.32 bc | 31.06 ± 0.56 b | 30.17 ± 1.04 e | 27.7 ± 1.27 h | 42.13 ± 0.7 c | 57.87 ± 0.7 h | |

| F-Value | 58.973 ** | 432.32 ** | 63.236 ** | 138.485 ** | 342.416 ** | 342.415 ** | |

| Year | Variety | Diameter of Starch Granule (%) | |||||

|---|---|---|---|---|---|---|---|

| <2.8 μm | 2.8–10 μm | 10–22 μm | >22 μm | ≤10 μm | >10 μm | ||

| 2022–2023 | Annon 0711 | 47.9 ± 0.37 e | 32.19 ± 0.24 f | 12.79 ± 0.09 c | 7.12 ± 0.06 c | 80.09 ± 0.13 gh | 19.91 ± 0.13 bc |

| Quanmai 31 | 46.92 ± 0.03 f | 31.65 ± 0.08 g | 13.74 ± 0.07 a | 7.68 ± 0.03 b | 78.57 ± 0.09 i | 21.43 ± 0.09 a | |

| Mengmai 0818 | 44.70 ± 0.45 h | 37.32 ± 0.38 a | 11.37 ± 0.09 e | 6.61 ± 0.15 ef | 82.02 ± 0.08 e | 17.98 ± 0.08 e | |

| Lomai 28 | 49.34 ± 0.17 d | 33.3 ± 0.11 e | 11.40 ± 0.06 e | 5.96 ± 0.01 g | 82.64 ± 0.06 d | 17.36 ± 0.06 f | |

| Zheng Mai 132 | 45.37 ± 0.88 gh | 35.7 ± 0.48 c | 12.19 ± 0.32 d | 6.74 ± 0.09 de | 81.07 ± 0.41 f | 18.93 ± 0.41 d | |

| Bainong 307 | 47.81 ± 0.7 e | 32.44 ± 0.31 f | 12.88 ± 0.29 bc | 6.87 ± 0.10 d | 80.25 ± 0.39 g | 19.75 ± 0.39 c | |

| Zhou Mai 30 | 49.79 ± 0.2 cd | 30.41 ± 0.04 h | 13.24 ± 0.1 b | 6.56 ± 0.07 f | 80.2 ± 0.16 gh | 19.8 ± 0.16 bc | |

| Huacheng 865 | 47.81 ± 0.47 e | 36.44 ± 0.16 b | 10.44 ± 0.37 g | 5.31 ± 0.09 i | 84.25 ± 0.36 ab | 15.75 ± 0.36 hi | |

| Longke 1109 | 45.63 ± 0.23 g | 34.14 ± 0.07 d | 12.35 ± 0.08 d | 7.89 ± 0.10 a | 79.76 ± 0.17 h | 20.24 ± 0.17 b | |

| XuNong 029 | 51.03 ± 0.58 b | 32.65 ± 0.44 f | 11.04 ± 0.23 ef | 5.28 ± 0.04 i | 83.69 ± 0.26 c | 16.31 ± 0.26 g | |

| Huacheng 2019 | 52.19 ± 0.63 a | 32.26 ± 0.43 f | 10.87 ± 0.16 f | 4.68 ± 0.06 j | 84.45 ± 0.21 a | 15.55 ± 0.21 i | |

| Huaimai 44 | 49.43 ± 0.16 d | 34.55 ± 0.10 d | 10.82 ± 0.03 fg | 5.21 ± 0.03 i | 83.97 ± 0.06 bc | 16.03 ± 0.06 gh | |

| Wanken 22 | 50.51 ± 0.02 bc | 30.62 ± 0.07 h | 13.00 ± 0.02 bc | 5.87 ± 0.02 gh | 81.13 ± 0.05 f | 18.87 ± 0.05 d | |

| Wanken 9 | 52.41 ± 0.06 a | 28.75 ± 0.11 i | 13.05 ± 0.09 bc | 5.79 ± 0.00 h | 81.16 ± 0.09 f | 18.84 ± 0.09 d | |

| F-Value | 92.89 ** | 187.73 ** | 66.434 ** | 384.371 ** | 144.52 ** | 144.52 ** | |

| 2023–2024 | Annon 0711 | 43.36 ± 0.76 bc | 28.07 ± 1.1 ef | 12.46 ± 0.26 cd | 16.11 ± 0.8 c | 71.43 ± 0.84 de | 28.57 ± 0.84 cd |

| Quanmai 31 | 36.76 ± 0.31 ef | 31.48 ± 0.38 cd | 11.66 ± 0.23 de | 20.1 ± 0.61 a | 68.24 ± 0.38 efg | 31.76 ± 0.38 abc | |

| Mengmai 0818 | 47.18 ± 0.98 a | 30.59 ± 0.55 cdc | 10.52 ± 0.58 e | 11.71 ± 0.48 fgh | 77.77 ± 1.06 ab | 22.23 ± 1.06 fg | |

| Lomai 28 | 46.95 ± 1.23 a | 26.27 ± 2.11 fg | 12.92 ± 1.96 bcd | 13.86 ± 0.87 de | 73.22 ± 2.83 cd | 26.78 ± 2.83 de | |

| Zheng Mai 132 | 35.74 ± 0.36 f | 34.27 ± 0.72 ab | 11.49 ± 0.22 de | 18.5 ± 0.32 ab | 70.01 ± 0.52 def | 29.99 ± 0.52 bcd | |

| Bainong 307 | 41.99 ± 1.66 cd | 28.33 ± 0.87 ef | 14 ± 1.09 abc | 15.69 ± 0.87 cd | 70.31 ± 1.94 def | 29.69 ± 1.94 bcd | |

| Zhou Mai 30 | 42.18 ± 0.7 cd | 23.69 ± 2.38 g | 14.35 ± 0.25 ab | 18.08 ± 0.57 b | 65.87 ± 2.45 g | 32.43 ± 0.62 ab | |

| Huacheng 865 | 44.62 ± 0.1 b | 32.51 ± 0.85 bc | 11.38 ± 0.63 de | 11.49 ± 0.17 fgh | 77.13 ± 0.8 ab | 22.87 ± 0.8 fg | |

| Longke 1109 | 37.86 ± 0.55 e | 29.71 ± 0.51 de | 14.86 ± 1.18 a | 19.27 ± 1.29 ab | 67.57 ± 0.62 fg | 34.13 ± 2.45 a | |

| XuNong 029 | 40.91 ± 0.97 d | 36.27 ± 0.5 a | 10.75 ± 0.72 e | 12.06 ± 0.49 efg | 77.18 ± 1.19 ab | 22.82 ± 1.19 fg | |

| Huacheng 2019 | 47.4 ± 1.15 a | 31.18 ± 0.21 cd | 12.79 ± 0.69 bcd | 10.28 ± 0.58 gh | 78.59 ± 1.03 a | 23.07 ± 1.26 fg | |

| Huaimai 44 | 42.87 ± 0.09 c | 32.72 ± 0.74 bc | 12.15 ± 0.38 de | 12.26 ± 0.32 ef | 75.59 ± 0.69 abc | 24.41 ± 0.69 efg | |

| Wanken 22 | 47 ± 0.3 a | 28.12 ± 3.28 ef | 12.84 ± 1.04 bcd | 12.03 ± 2.54 efg | 75.13 ± 3.53 bc | 24.87 ± 3.53 ef | |

| Wanken 9 | 46.72 ± 0.13 a | 30.21 ± 1.22 cde | 11.55 ± 0.54 de | 9.87 ± 0.49 h | 76.93 ± 1.26 ab | 21.41 ± 1.03 g | |

| F-Value | 45.78 ** | 12.629 ** | 5.462 ** | 28.666 ** | 14.411 ** | 14.411 ** | |

| Year | Variety | Diameter of Starch Granule (%) | |||||

|---|---|---|---|---|---|---|---|

| <2.8 μm | 2.8–10 μm | 10–22 μm | >22 μm | ≤10 μm | >10 μm | ||

| 2022–2023 | Annon 0711 | 97.34 ± 0.08 ab | 2.54 ± 0.07 f | 0.10 ± 0.00 a | 0.02 ± 0.00 a | 99.88 ± 0.00 b | 0.12 ± 0.00 de |

| Quanmai 31 | 96.91 ± 0 cd | 2.94 ± 0.00 d | 0.13 ± 0.00 a | 0.02 ± 0.00 a | 99.85 ± 0.00 b | 0.15 ± 0.00 a | |

| Mengmai 0818 | 95.89 ± 0.07 f | 3.97 ± 0.07 a | 0.12 ± 0.00 b | 0.02 ± 0.00 a | 99.86 ± 0.00 a | 0.14 ± 0.00 bc | |

| Lomai 28 | 96.41 ± 0.21 f | 3.45 ± 0.21 b | 0.13 ± 0.01 b | 0.01 ± 0.00 b | 99.86 ± 0.00 b | 0.14 ± 0.00 ab | |

| Zheng Mai 132 | 96.64 ± 0.12 def | 3.23 ± 0.11 c | 0.11 ± 0.01 b | 0.02 ± 0.00 a | 99.87 ± 0.01 b | 0.13 ± 0.01 c | |

| Bainong 307 | 96.86 ± 0.07 cde | 3.01 ± 0.07 d | 0.11 ± 0.00 b | 0.02 ± 0.00 a | 99.87 ± 0.00 b | 0.13 ± 0.00 c | |

| Zhou Mai 30 | 97.25 ± 0.04 b | 2.62 ± 0.04 ef | 0.11 ± 0.00 bc | 0.02 ± 0.00 a | 99.87 ± 0.00 b | 0.13 ± 0.00 cd | |

| Huacheng 865 | 97.21 ± 0.07 b | 2.68 ± 0.06 ef | 0.09 ± 0.00 bc | 0.01 ± 0.00 c | 99.9 ± 0.00 b | 0.10 ± 0.00 fg | |

| Longke 1109 | 96.59 ± 0.03 ef | 3.27 ± 0.02 c | 0.12 ± 0.00 cd | 0.02 ± 0.00 a | 99.86 ± 0.00 b | 0.14 ± 0.00 bc | |

| XuNong 029 | 97.13 ± 0.05 bc | 2.77 ± 0.05 e | 0.09 ± 0.00 de | 0.01 ± 0.00 c | 99.90 ± 0.00 b | 0.10 ± 0.00 g | |

| Huacheng 2019 | 97.25 ± 0.09 b | 2.64 ± 0.09 ef | 0.10 ± 0.00 de | 0.01 ± 0.00 c | 99.89 ± 0.00 b | 0.11 ± 0.00 f | |

| Huaimai 44 | 96.63 ± 0.03 def | 3.26 ± 0.03 c | 0.10 ± 0.00 de | 0.01 ± 0.00 c | 99.89 ± 0.00 b | 0.11 ± 0.00 f | |

| Wanken 22 | 97.28 ± 0.01 b | 2.60 ± 0.01 f | 0.11 ± 0.00 ef | 0.01 ± 0.00 c | 99.88 ± 0.00 b | 0.12 ± 0.00 e | |

| Wanken 9 | 97.6 ± 0.01 a | 2.29 ± 0.01 g | 0.10 ± 0.00 f | 0.01 ± 0.00 c | 99.89 ± 0.00 b | 0.11 ± 0.00 f | |

| F-Value | 13.42 ** | 69.44 ** | 14.376 ** | 31.692 ** | 3.842 ** | 31.00 ** | |

| 2023–2024 | Annon 0711 | 96.69 ± 0.77 abc | 3.08 ± 0.68 fgh | 0.21 ± 0.09 de | 0.01 ± 0 b | 99.78 ± 0.09 ab | 0.22 ± 0.09 de |

| Quanmai 31 | 93.82 ± 0.06 g | 5.83 ± 0.05 b | 0.32 ± 0 bc | 0.02 ± 0 a | 99.66 ± 0 de | 0.34 ± 0 ab | |

| Mengmai 0818 | 96.42 ± 0.26 bcde | 3.39 ± 0.24 defg | 0.18 ± 0.02 e | 0.01 ± 0 b | 99.81 ± 0.02 a | 0.19 ± 0.02 e | |

| Lomai 28 | 96.78 ± 0.35 ab | 3.01 ± 0.33 fgh | 0.19 ± 0.04 e | 0.02 ± 0 a | 99.79 ± 0.04 ab | 0.21 ± 0.04 de | |

| Zheng Mai 132 | 92.96 ± 0.31 h | 6.67 ± 0.3 a | 0.35 ± 0.01 ab | 0.02 ± 0 a | 99.63 ± 0.01 de | 0.37 ± 0.01 ab | |

| Bainong 307 | 95.91 ± 0.08 def | 3.82 ± 0.09 cde | 0.26 ± 0.02 cd | 0.01 ± 0 b | 99.73 ± 0.02 bc | 0.27 ± 0.02 cd | |

| Zhou Mai 30 | 94.2 ± 0.56 g | 5.4 ± 0.55 b | 0.39 ± 0.01 a | 0.01 ± 0 b | 99.6 ± 0.01 e | 0.4 ± 0.01 a | |

| Huacheng 865 | 95.8 ± 0.06 ef | 3.98 ± 0.07 cd | 0.21 ± 0.01 de | 0.01 ± 0 b | 99.78 ± 0.01 ab | 0.22 ± 0.01 de | |

| Longke 1109 | 96.05 ± 0.31 cdef | 3.63 ± 0.28 def | 0.31 ± 0.04 bc | 0.01 ± 0 b | 99.68 ± 0.04 cd | 0.32 ± 0.04 bc | |

| XuNong 029 | 94.44 ± 0.24 g | 5.32 ± 0.21 b | 0.22 ± 0.02 de | 0.02 ± 0 a | 99.76 ± 0.02 ab | 0.24 ± 0.02 de | |

| Huacheng 2019 | 97.24 ± 0.13 a | 2.58 ± 0.13 h | 0.17 ± 0.01 e | 0.01 ± 0 b | 99.82 ± 0.01 a | 0.18 ± 0.01 e | |

| Huaimai 44 | 95.36 ± 0.14 f | 4.4 ± 0.14 c | 0.23 ± 0 de | 0.01 ± 0 b | 99.76 ± 0 ab | 0.24 ± 0 de | |

| Wanken 22 | 96.85 ± 0.2 ab | 2.96 ± 0.21 gh | 0.18 ± 0.03 e | 0.01 ± 0 b | 99.81 ± 0.03 a | 0.19 ± 0.03 e | |

| Wanken 9 | 96.56 ± 0.4 abcd | 3.25 ± 0.38 efg | 0.18 ± 0.02 e | 0.01 ± 0 b | 99.81 ± 0.02 a | 0.19 ± 0.02 e | |

| F-Value | 28.789 ** | 30.707 ** | 9.864 ** | 12.444 ** | 10.24 ** | 10.24 ** | |

| Year | Variety | Peak Viscosity | Trough Viscosity | Final Viscosity | Breakdown Viscosity | Setback |

|---|---|---|---|---|---|---|

| 2022–2023 | Annon 0711 | 988 ± 52 de | 445 ± 11 e | 1388 ± 52 de | 543 ± 63 de | 943 ± 63 de |

| Quanmai 31 | 930 ± 2 ef | 484 ± 13 d | 1330 ± 2 ef | 446 ± 12 ef | 846 ± 12 ef | |

| Mengmai 0818 | 1113 ± 56 bc | 396 ± 111 f | 1513 ± 56 bc | 717 ± 45 bc | 1117 ± 45 bc | |

| Lomai 28 | 1180 ± 111 b | 358 ± 13 g | 1580 ± 111 b | 822 ± 124 ab | 1222 ± 124 ab | |

| Zheng Mai 132 | 856 ± 6 f | 575 ± 16 b | 1256 ± 6 f | 282 ± 16 h | 682 ± 16 h | |

| Bainong 307 | 909 ± 22 ef | 505 ± 3 cd | 1309 ± 22 ef | 404 ± 20 fg | 804 ± 20 fg | |

| Zhou Mai 30 | 745 ± 8 g | 614 ± 9 a | 1145 ± 8 g | 130 ± 7 i | 530 ± 7 i | |

| Huacheng 865 | 1073 ± 33 cd | 433 ± 5 e | 1473 ± 33 cd | 640 ± 31 cd | 1040 ± 31 cd | |

| Longke 1109 | 1135 ± 36 bc | 387 ± 19 f | 1535 ± 36 bc | 749 ± 55 b | 1149 ± 55 b | |

| XuNong 029 | 1001 ± 28 de | 440 ± 15 e | 1401 ± 28 de | 561 ± 43 d | 961 ± 43 d | |

| Huacheng 2019 | 1282 ± 67 a | 373 ± 4 fg | 1682 ± 67 a | 908 ± 68 a | 1308 ± 68 a | |

| Huaimai 44 | 891 ± 21 f | 523 ± 20 c | 1291 ± 21 f | 368 ± 41 fgh | 768 ± 41 fgh | |

| Wanken 22 | 866 ± 6 f | 570 ± 17 b | 1266 ± 6 f | 296 ± 20 h | 696 ± 201 h | |

| Wanken 9 | 874 ± 8 f | 563 ± 15 b | 1274 ± 8 f | 311 ± 14 gh | 711 ± 14 gh | |

| F-Value | 22.04 ** | 75.04 ** | 22.04 ** | 40.11 ** | 40.11 ** | |

| 2023–2024 | Annon 0711 | 974 ± 54 bc | 440 ± 17 e | 1151 ± 90 cd | 534 ± 68 cd | 711 ± 93 cde |

| Quanmai 31 | 916 ± 4 cdef | 479 ± 20 d | 1258 ± 39 bcd | 437 ± 23 ef | 779 ± 33 bcd | |

| Mengmai 0818 | 1050 ± 92 ab | 392 ± 14 f | 1316 ± 92 bc | 658 ± 96 ab | 924 ± 88 bc | |

| Lomai 28 | 970 ± 47 bcd | 369 ± 9 fg | 1369 ± 142 abc | 601 ± 49 bc | 1000 ± 134 b | |

| Zheng Mai 132 | 853 ± 10 efg | 570 ± 21 ab | 1211 ± 357 bcd | 283 ± 25 gh | 641 ± 357 de | |

| Bainong 307 | 835 ± 30 fg | 500 ± 10 cd | 1366 ± 30 abc | 335 ± 22 gh | 865 ± 20 bcd | |

| Zhou Mai 30 | 829 ± 29 g | 591 ± 17 a | 1052 ± 102 d | 239 ± 34 h | 461 ± 106 e | |

| Huacheng 865 | 927 ± 26 cde | 429 ± 4 e | 1438 ± 38 ab | 498 ± 25 de | 1009 ± 41 b | |

| Longke 1109 | 817 ± 10 g | 382 ± 22 fg | 1177 ± 98 cd | 435 ± 12 ef | 795 ± 95 bcd | |

| XuNong 029 | 999 ± 66 abc | 435 ± 14 e | 1409 ± 87 abc | 564 ± 72 bcd | 974 ± 84 b | |

| Huacheng 2019 | 1072 ± 45 a | 353 ± 9 g | 1625 ± 110 a | 718.33 ± 54 a | 1272 ± 111 a | |

| Huaimai 44 | 884 ± 19 defg | 518 ± 27 c | 1192 ± 88 bcd | 366 ± 45 fg | 674 ± 104 cde | |

| Wanken 22 | 859 ± 9 efg | 565 ± 16 ab | 1581 ± 38 a | 294 ± 18 gh | 1016 ± 22 b | |

| Wanken 9 | 867 ± 10 efg | 558 ± 11 b | 1204 ± 65 bcd | 309 ± 9 gh | 645 ± 75 de | |

| F-Value | 7.83 ** | 61.43 ** | 3.41 ** | 20.74 ** | 5.67 ** |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rehman, A.; Zhou, W.; Yan, S.; Chen, J.; Yang, T.; Li, J.; Liu, Y.; Zhang, R.; Li, W. Starch Granule Size Distribution and Pasting Properties from 14 Soft Wheat Varieties in Huaihe River Basin. Agronomy 2025, 15, 2489. https://doi.org/10.3390/agronomy15112489

Rehman A, Zhou W, Yan S, Chen J, Yang T, Li J, Liu Y, Zhang R, Li W. Starch Granule Size Distribution and Pasting Properties from 14 Soft Wheat Varieties in Huaihe River Basin. Agronomy. 2025; 15(11):2489. https://doi.org/10.3390/agronomy15112489

Chicago/Turabian StyleRehman, Abdul, Wenyin Zhou, Suhui Yan, Juan Chen, Tingting Yang, Jing Li, Yang Liu, Ruilian Zhang, and Wenyang Li. 2025. "Starch Granule Size Distribution and Pasting Properties from 14 Soft Wheat Varieties in Huaihe River Basin" Agronomy 15, no. 11: 2489. https://doi.org/10.3390/agronomy15112489

APA StyleRehman, A., Zhou, W., Yan, S., Chen, J., Yang, T., Li, J., Liu, Y., Zhang, R., & Li, W. (2025). Starch Granule Size Distribution and Pasting Properties from 14 Soft Wheat Varieties in Huaihe River Basin. Agronomy, 15(11), 2489. https://doi.org/10.3390/agronomy15112489