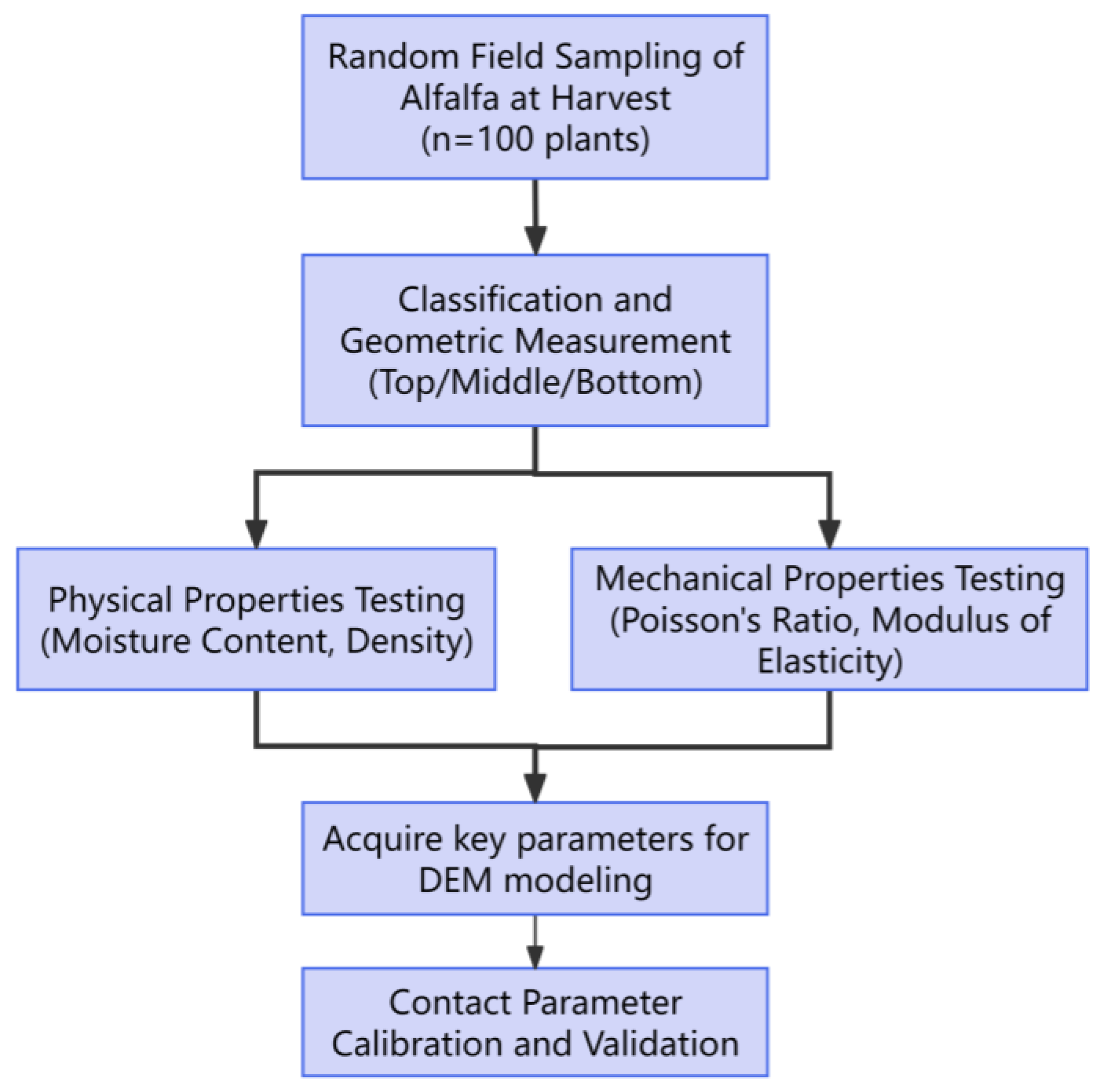

3.2. Calibration of Impact Recovery Coefficient for Alfalfa Stems

The coefficient of restitution determines the energy loss after a collision, directly influencing the simulated bouncing height of the stems and their separation behavior after impact with the roller teeth. An inaccurate coefficient of restitution will lead to distortion in the simulated material flow trajectory. Restitution coefficients can be classified into three types based on physical principles: kinematic restitution coefficient, dynamic collision restitution coefficient, and energy restitution coefficient [

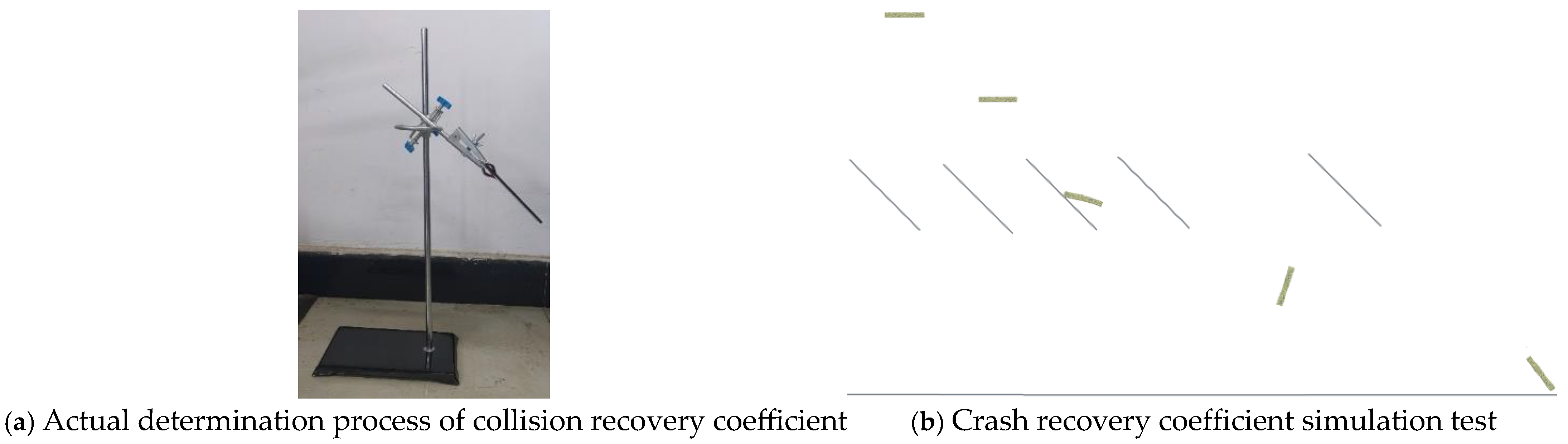

20]. This study employs the kinematic restitution coefficient for collisions between alfalfa stems and PU rubber/standard rubber. It is defined as the ratio of the normal component of the center-of-mass velocity after collision to that before collision between the alfalfa stem and the target plate. The experimental setup is shown in

Figure 3. The rubber impact plate was clamped at a 45° inclination. Alfalfa stems were released from height 2

h, colliding with the rubber plate positioned at height

h. The stems subsequently landed at horizontal distance

L. Neglecting air resistance, the restitution coefficient

eN is formulated according to kinematic principles as [

21]:

where

is the normal component velocity of the stem after collision, m/s;

VN is the normal component velocity of the stem before collision, m/s;

v is the vertical component velocity of the stem before reaching the rubber plate, m/s;

v’ is the horizontal component velocity of the stem at the moment of collision with the rubber plate, m/s;

L is the horizontal distance traveled by the stem after collision, m;

h is the vertical height between the stem’s landing position and the rubber plate, m.

Straight main stems free of nodes, pests/diseases, and mechanical damage were selected for testing. The average maximum horizontal distances for alfalfa stems were L1 = 162.8, 153.2, 159.7 mm and L2 = 140.4, 147.3, 139.5 mm.

Since the friction coefficient and rolling friction coefficient between alfalfa stems and PU rubber/standard rubber do not directly affect the horizontal distance in this test, these coefficients were set to 0. Bench tests determined the restitution coefficient ranges between alfalfa stems and PU rubber/standard rubber as 0.325~0.475, 0.3~0.45, and 0.36~0.42, respectively. Each simulation was repeated 10 times and averaged, with 7 simulation groups conducted [

22]. The restitution coefficient

x1 and horizontal distance results

y1 are presented in

Table 6 and

Table 7.

The experimental data from

Table 6 and

Table 7 were fitted to a quadratic polynomial curve [

23], yielding the curve equation shown in

Figure 4:

The coefficient of determination R2 for both PU rubber and alfalfa stems in Equation (7) is close to 1, indicating that the equation provides a reliable fit. Substituting the bench-tested average horizontal distances (162.8 mm, 153.2 mm, and 159.7 mm) into Equation (7) yielded x1P = 0.426, 0.375, and 0.386.

Figure 4.

Simulation test restitution coefficient and horizontal distance fitting curve.

Figure 4.

Simulation test restitution coefficient and horizontal distance fitting curve.

Seven repeated verification tests were conducted in the EDEM software and averaged, yielding simulated horizontal distances of 156.37 mm, 148.16 mm, and 152.03 mm. The relative errors compared to bench tests were 3.95%, 3.29%, and 4.8%, respectively. The bench test and simulation results were fundamentally consistent. Therefore, in the EDEM simulation tests, the restitution coefficients (x1P) between alfalfa stems and PU rubber for the top, middle, and root stem sections were 0.426, 0.375, and 0.386, respectively.

The coefficient of determination R2 for both ordinary rubber and alfalfa stems in Equation (8) is close to 1, indicating that the equation provides reliable fitting results. Substituting the bench-tested average horizontal distances (140.4 mm, 147.3 mm, and 139.5 mm) into Equation (8) yielded x1R = 0.345, 0.385, 0.350. Seven repeated verification tests in the EDEM software and averaging yielded simulated horizontal distances of 144.82 mm, 155.84 mm, and 145.53 mm. The relative errors compared to bench tests were 3.15%, 5.8%, and 4.32%, respectively. The bench test and simulation results were fundamentally consistent. Therefore, in the EDEM simulation tests, the restitution coefficients x1R between alfalfa stems and standard rubber for the top, middle, and root stem sections were 0.345, 0.385, and 0.350, respectively.

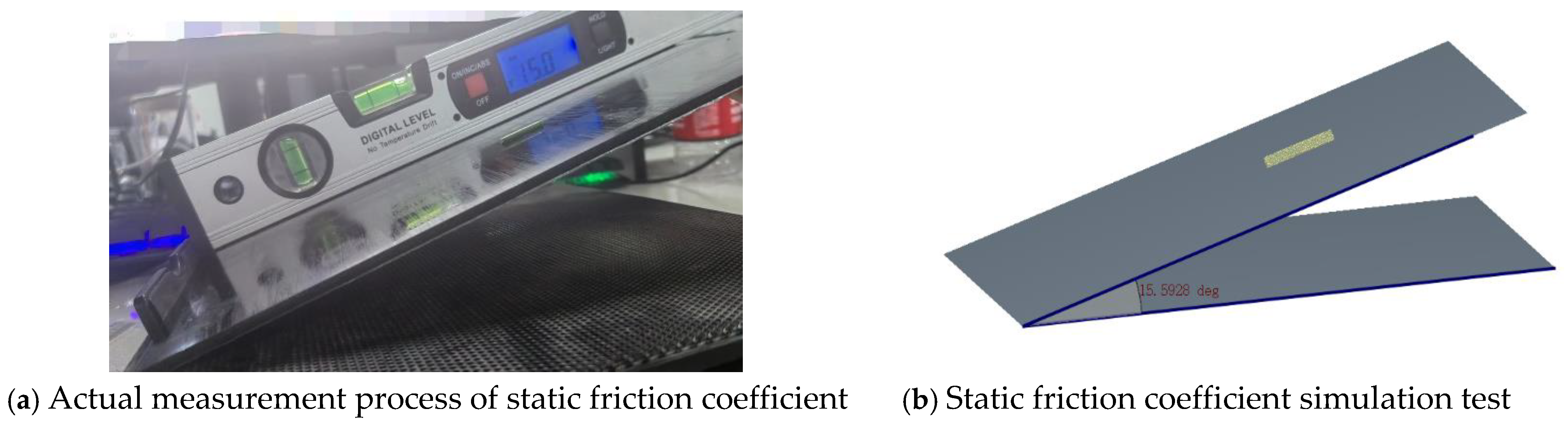

3.3. Calibration of the Static Friction Coefficient for Alfalfa Stems

The static friction coefficient primarily influences the difficulty of stem slippage and the initial motion state on the roller tooth surface, making it a key simulation parameter that determines the feeding efficiency and clogging risk of the mower-conditioner. The static friction coefficient is primarily influenced by rubber type and surface roughness. Therefore, the static friction coefficient between alfalfa stems and both PU rubber and standard rubber was calibrated using the inclined plane sliding test. Alfalfa stems were placed on the rubber plate, which was then rotated slowly and uniformly about one edge. Rotation ceased when stem slippage initiated. The inclination angle was recorded using a digital inclinometer (precision: 0.1°) [

24]; the setup is shown in

Figure 5. The bench test was repeated 10 times and averaged to determine the static friction coefficient

fs between alfalfa stems and the rubber materials. The static friction coefficient is expressed as:

where

α is the static friction critical angle, (°).

Straight primary stems free of nodes, pests/diseases, and mechanical damage were selected. Average inclination angles obtained were α1 = 23.88°, 16.4°, 13.46° and α2 = 32.5°, 34.42°, 32.7°.

The restitution coefficients between alfalfa stems and PU rubber/standard rubber were set to calibrated values. The rolling friction coefficient does not directly affect inclination angles in this test; thus, it was set to 0. Bench tests determined static friction coefficient ranges between alfalfa stems and PU rubber/standard rubber as 0.4~0.478, 0.26~0.35, and 0.178~0.292, respectively. Each simulation was repeated 10 times and averaged across 7 simulation groups. Static friction coefficients

x2 and inclination angles

y2 are presented in

Table 8 and

Table 9.

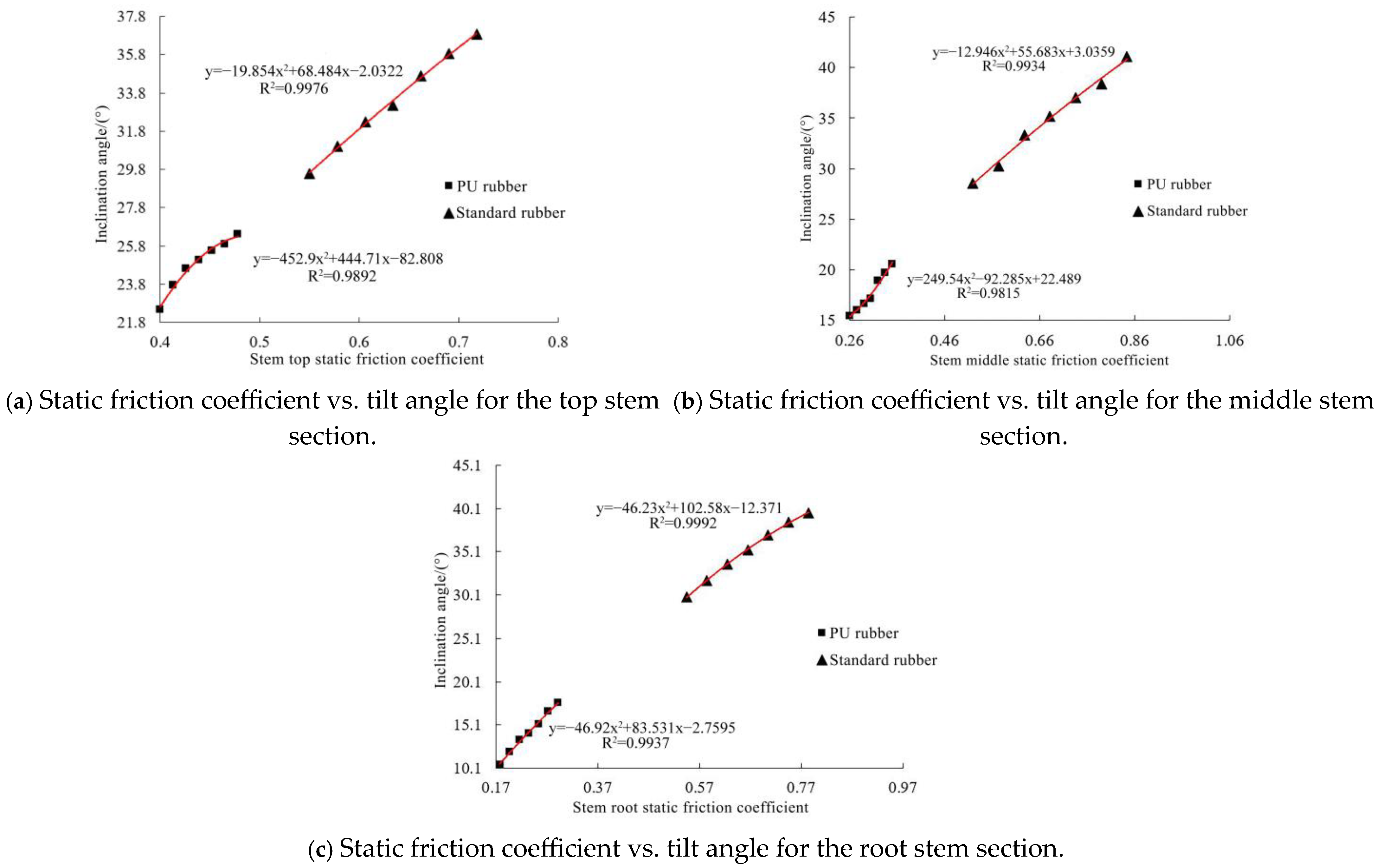

The experimental data from

Table 8 and

Table 9 were fitted to a quadratic polynomial fitting curve, as shown in

Figure 6, yielding the curve equation:

The coefficient of determination R2 for both PU rubber and alfalfa stems in Equation (10) is close to 1, indicating that the equation provides a reliable fit. Substitution of the bench-tested average inclination angles (23.88°, 16.4°, and 13.46°) into Equation (10) yielded x2P = 0.417, 0.284, and 0.222.

Seven repeated EDEM validation trials yielded average simulated inclination angles of 23.75°, 16.11°, and 14.02°. Relative errors compared to bench tests were 3.35%, 1.77%, and 4.16%, respectively. Bench and simulation results were broadly consistent. Thus, the static friction coefficients x2P between alfalfa stems and PU rubber were 0.417 (top), 0.284 (middle), and 0.222 (root).

The coefficient of determination R2 for both ordinary rubber and alfalfa stems in Equation (11) is close to 1. Substituting bench-tested averages (32.5°, 34.42°, 32.7°) into Equation (11) gave x2R = 0.613, 0.667, 0.422. Seven repeated EDEM trials yielded simulated angles of 32.12°, 34.7°, 32.5°, with relative errors of 1.16%, 0.84%, 0.60%. Bench and simulation results were broadly consistent. Thus, the static friction coefficients between alfalfa stems and standard rubber were 0.613 (top), 0.667 (middle), and 0.422 (root).

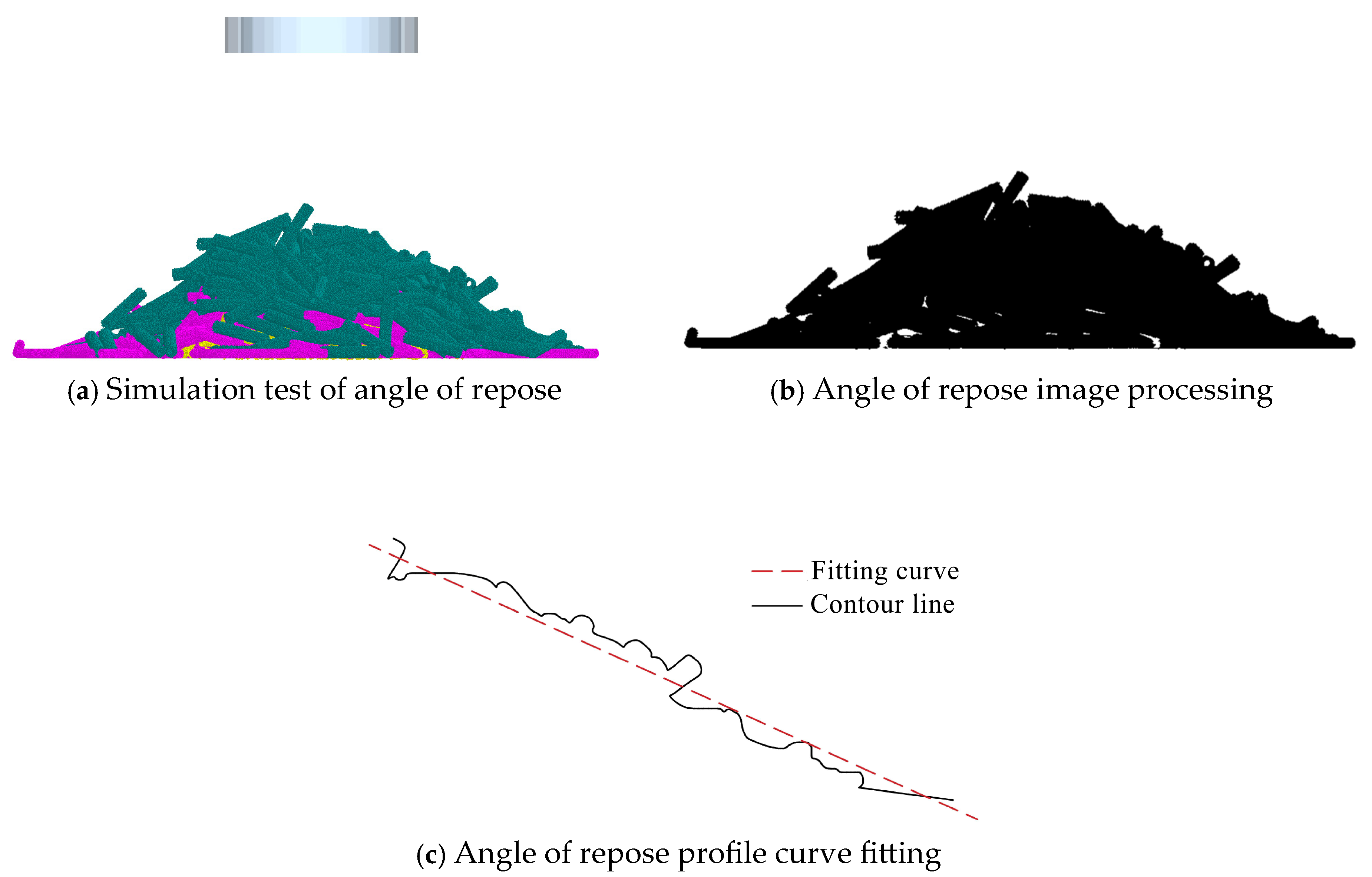

3.4. Calibration of the Rolling Friction Coefficient for Alfalfa Stems

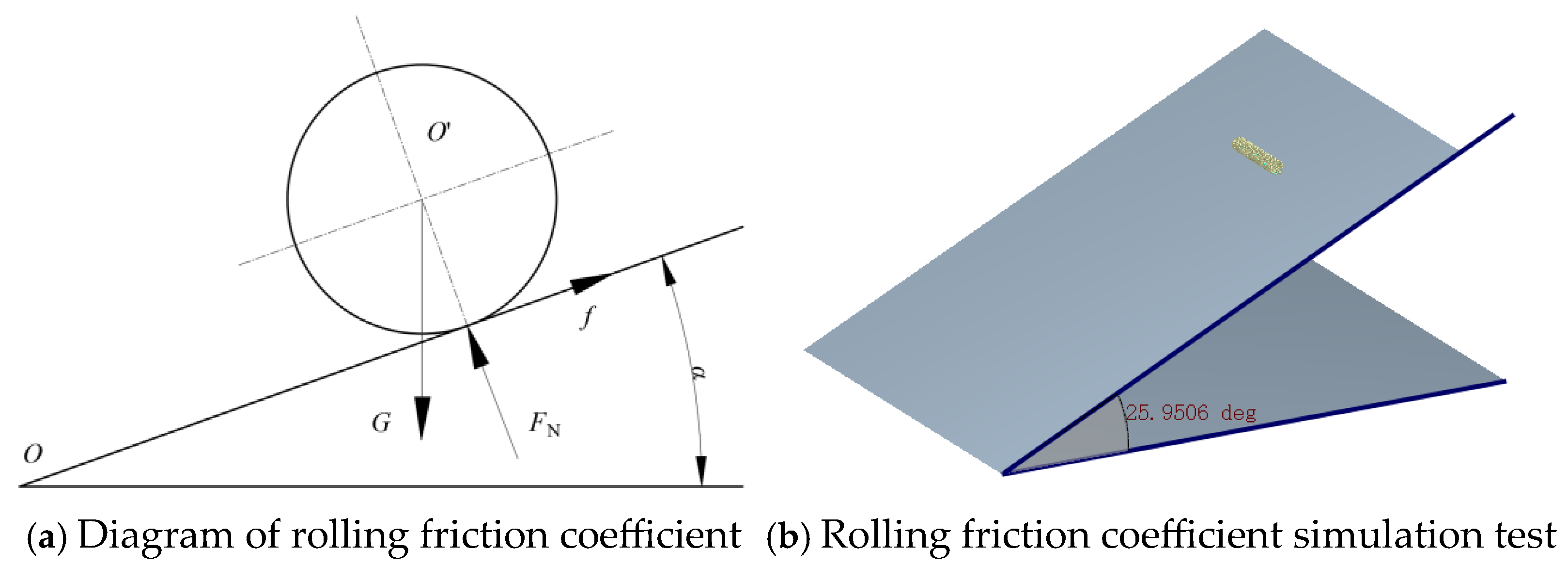

The rolling friction coefficient influences the tendency of stems to roll and serves as a key parameter for simulating the rolling behavior of alfalfa stems during the simulation process. Rolling friction refers to the resistance to rolling caused by deformation at the contact interface when an object rolls or tends to roll without slipping on another surface. In this test, based on the law of conservation of energy, alfalfa stems were placed parallel to the axis of rotation on a rubber plate. Measurement followed the inclined plane rolling principle: the rubber plate was rotated slowly and uniformly about one edge; rotation ceased when the stems began rolling. The inclination angle was recorded using a digital inclinometer (precision: 0.1°); the setup is shown in

Figure 7. The bench test was repeated 10 times and averaged to determine the rolling friction coefficient

f between alfalfa stems and PU rubber/standard rubber, as per established methodology. The coefficient is formulated as:

where

M is the rolling friction torque, N;

FN is the normal force exerted by the alfalfa stem on the rubber plate, N;

G is the gravitational force of the alfalfa stem, N;

α is the rolling friction angle, (°);

r is the radius of the alfalfa stem, mm.

Straight primary stems free of nodes, pests/diseases, and mechanical damage were selected. Average inclination angles obtained were α1 = 12.46°, 14.28°, 16.6° and α2 = 11.94°, 11.36°, 8.59°.

The restitution coefficients and static friction coefficients between alfalfa stems and PU rubber/standard rubber were set to calibrated values. Bench tests determined rolling friction coefficient ranges between alfalfa stems and PU rubber/standard rubber as 0.173~0.236, 0.21~0.277, and 0.262~0.344, respectively. Each simulation was repeated 10 times and averaged across 7 simulation groups. Rolling friction coefficients

x3 and inclination angles

y3 are presented in

Table 10 and

Table 11.

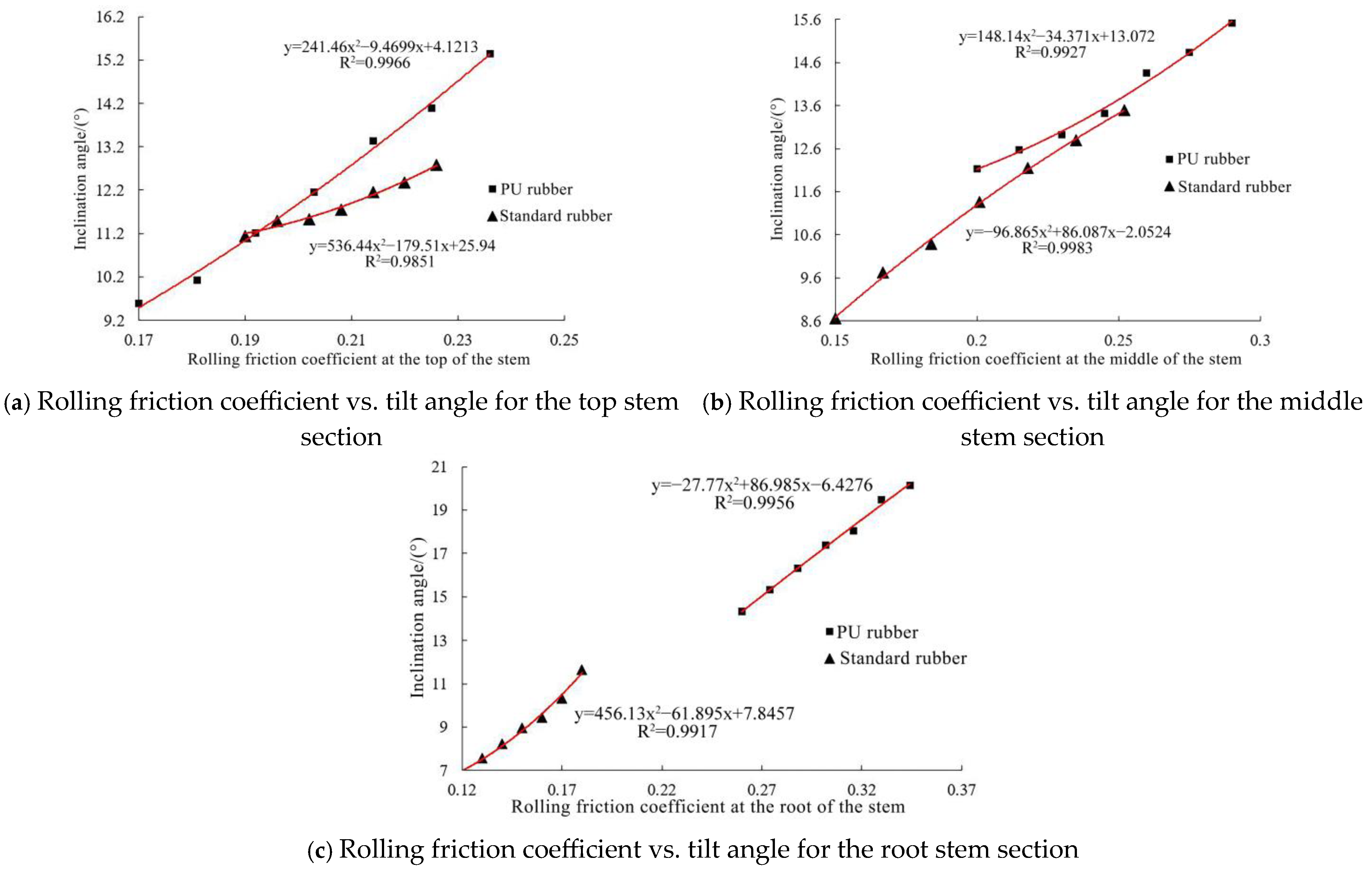

The experimental data from

Table 10 and

Table 11 were fitted to a quadratic polynomial fitting curve, as shown in

Figure 8, yielding the curve equation:

The coefficient of determination R2 for both PU rubber and alfalfa stems in Equation (13) is close to 1, indicating that the equation provides reliable fitting results. Substitution of the bench-tested average inclination angles (12.46°, 14.28°, and 16.6°) into Equation (13) yielded x3P = 0.213, 0.226, and 0.292.

For PU rubber: Seven repeated EDEM validation trials yielded average simulated inclination angles of 13.27°, 12.87°, and 17.01°. Relative errors compared to bench tests were 6.5%, 9.7%, and 2.4%, respectively. Bench and simulation results were broadly consistent. Thus, the rolling friction coefficients x3P between alfalfa stems and PU rubber were 0.213 (top), 0.226 (middle), and 0.292 (root).

The coefficient of determination R2 for both ordinary rubber and alfalfa stems in Equation (14) is close to 1, indicating that the equation provides reliable fitting results. Substituting bench-tested averages (11.94°, 11.36°, 8.59°) into Equation (14) gave x3R = 0.214, 0.196, 0.147. Seven repeated EDEM trials yielded simulated angles of 12.16°, 11.34°, 8.61°, with relative errors of 1.84%, 0.17%, 0.23%. Bench and simulation results were broadly consistent. Thus, the rolling friction coefficients x3R between alfalfa stems and standard rubber were 0.214 (top), 0.196 (middle), and 0.147 (root).