Erosion Control Effects of a Polymer-Based Soil Conditioner on Red Soil in Okinawa, Japan

Abstract

1. Introduction

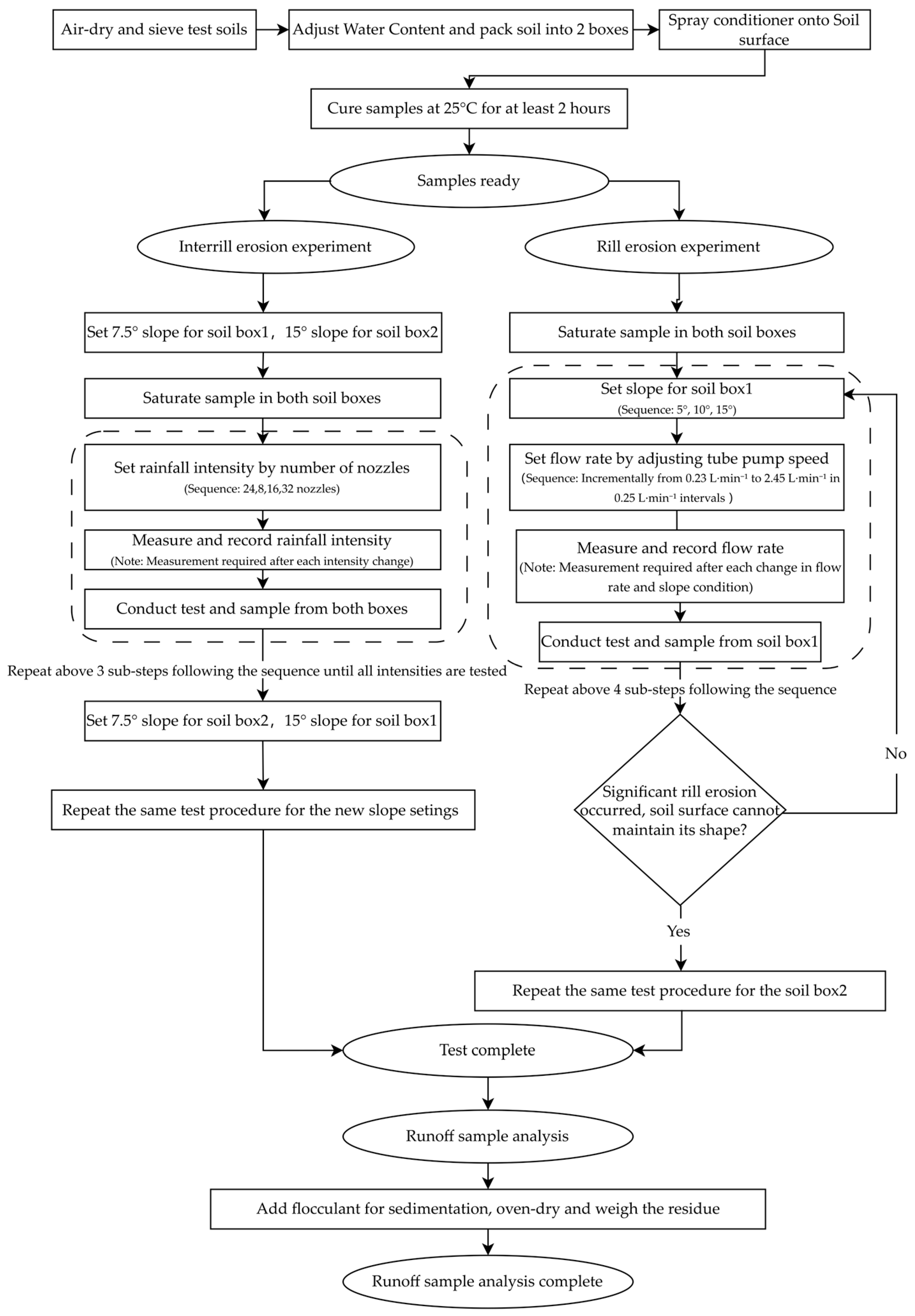

2. Materials and Methods

2.1. Preparation for Laboratory Experiments

2.1.1. Conditioner and Tested Soil Characteristics

2.1.2. Preparation for Test Soils

2.2. WEPP Erosion Framework and Target Parameters

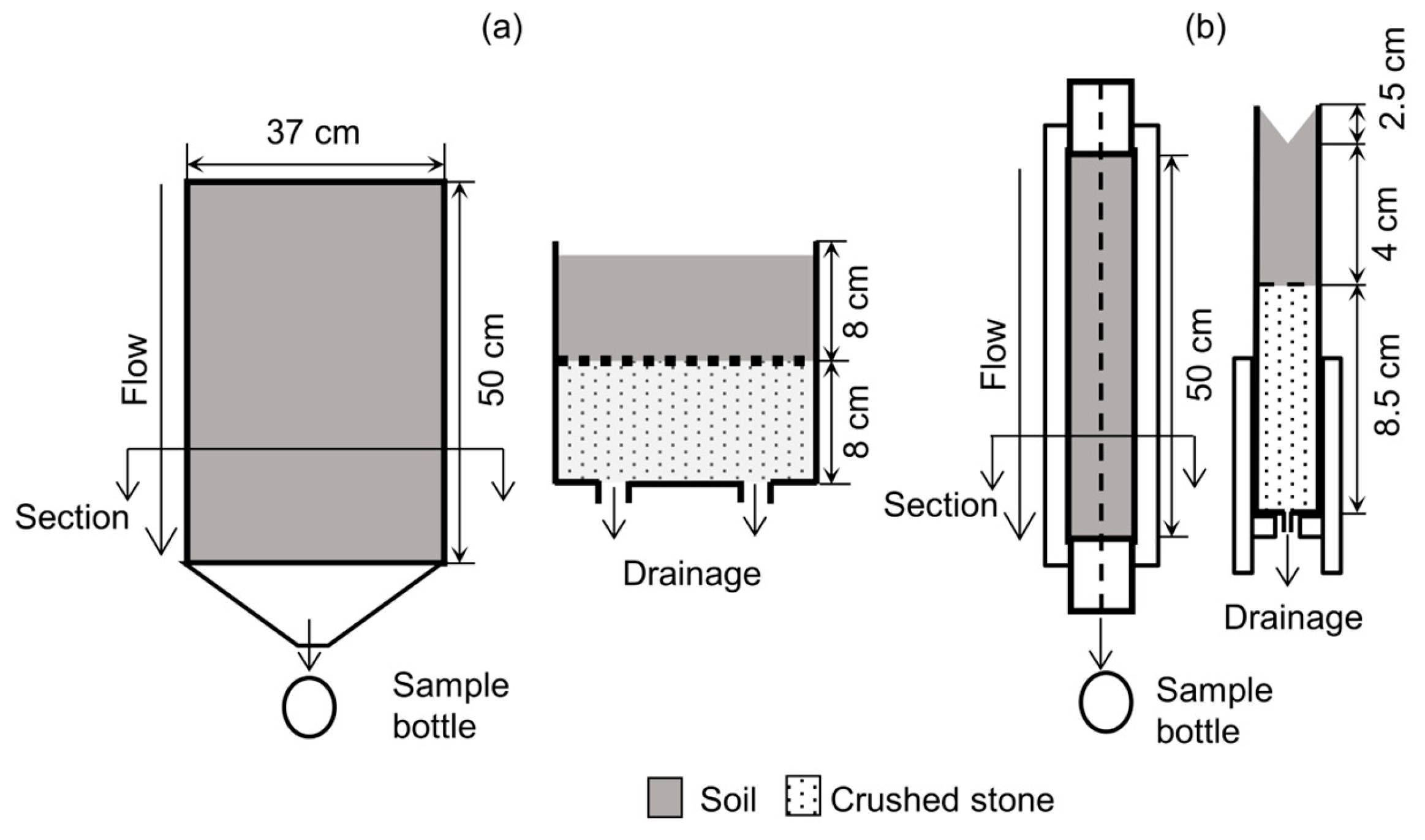

2.3. Interrill Erosion Experiment

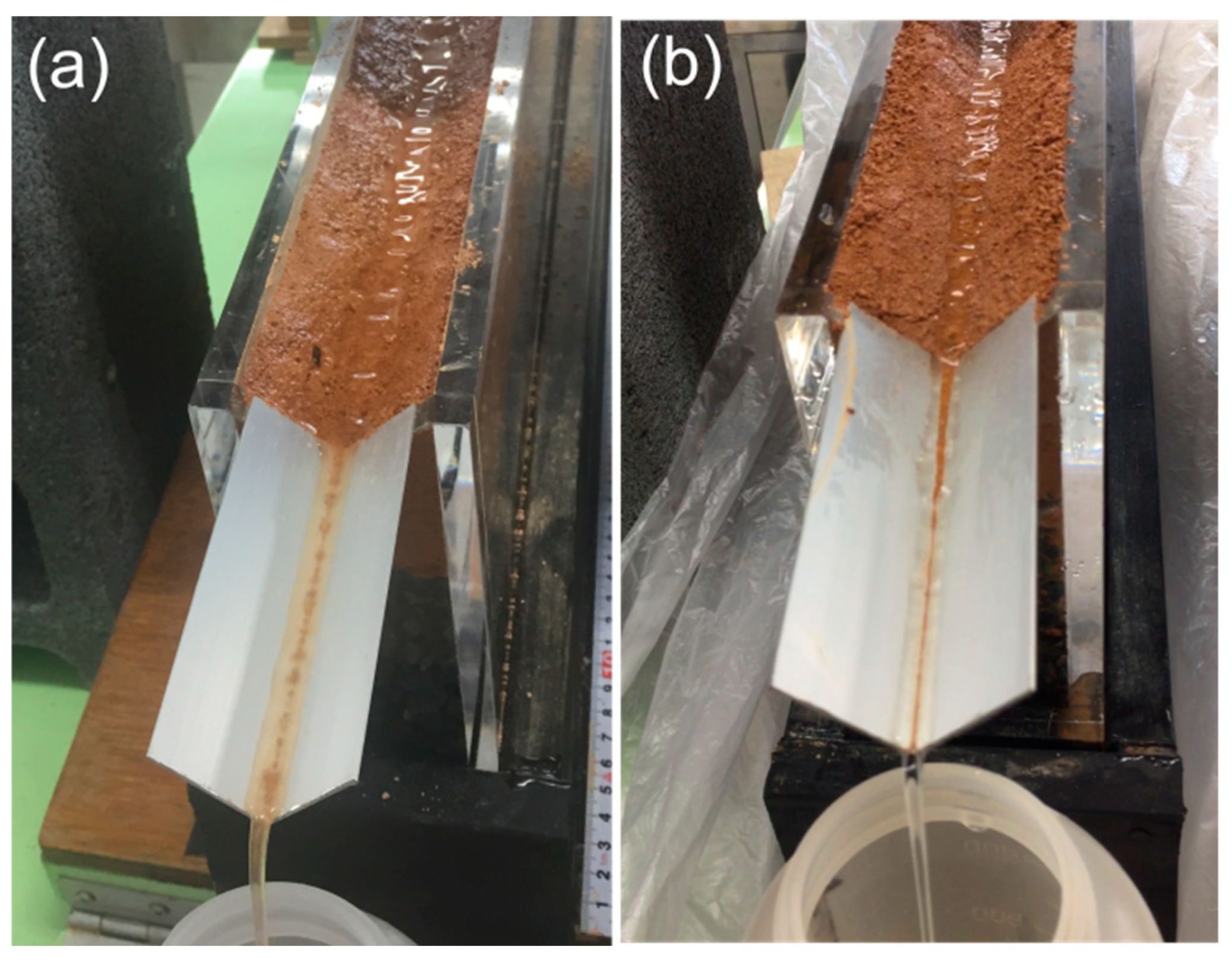

2.4. Rill Erosion Experiment

2.5. Inputs for WEPP Simulation

3. Results

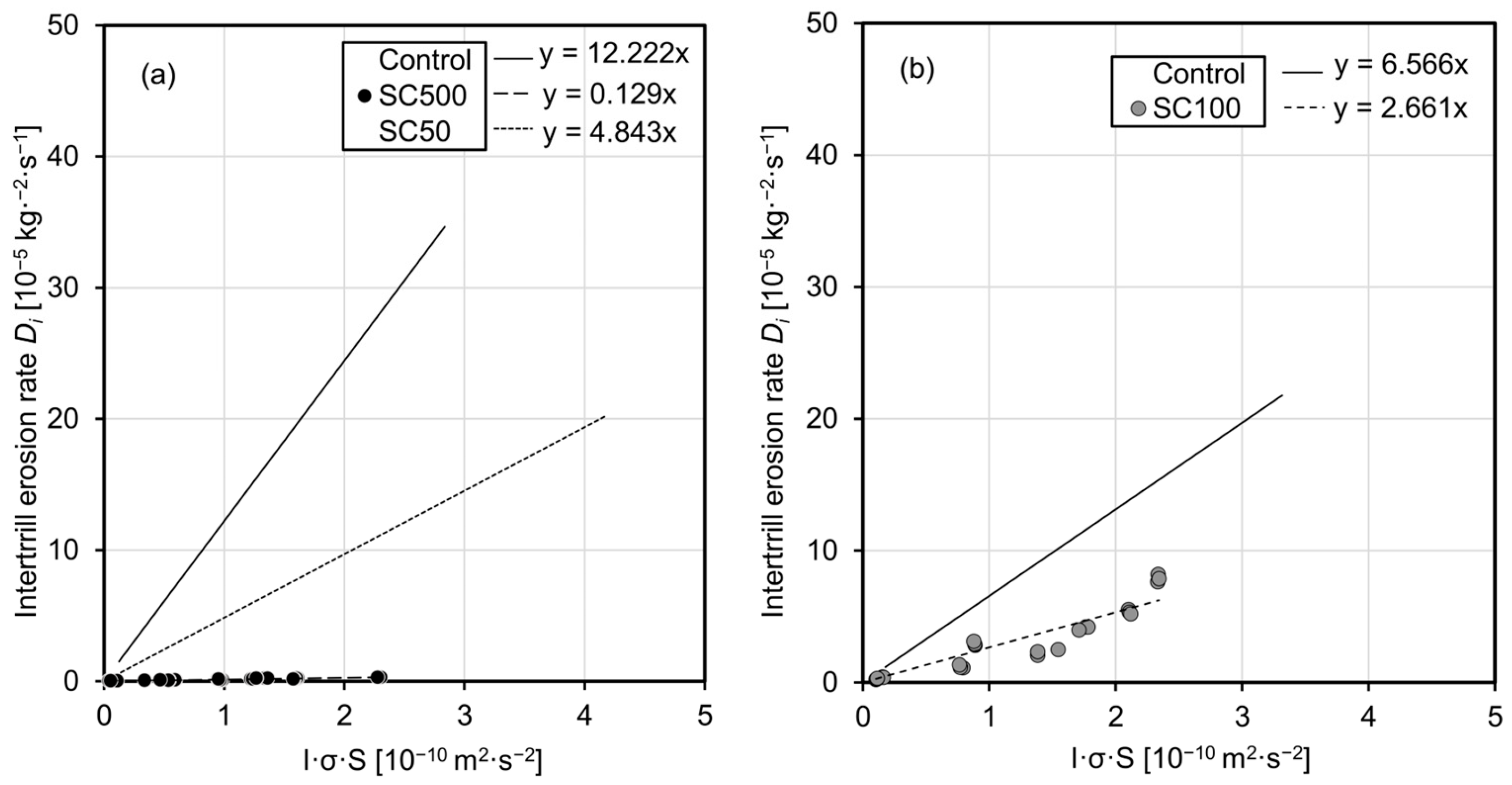

3.1. Interrill Erosion Experiments

3.2. Rill Erosion Experiments

3.3. Estimation of Sediment Yield in Farmland by WEPP Simulations

4. Discussion

4.1. Effect of Different Application Amounts of Soil Conditioner

4.2. Different Reduction Effects on Kunigami Maaji and Shimajiri Maaji

4.3. Assessment of Erosion Control Performance and Limitations in WEPP Simulation

4.4. Key Factors Affecting Conditioner Performance in Field Application

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Pimentel, D.; Harvey, C.; Resosudarmo, P.; Sinclair, K.; Kurz, D.; McNair, M.; Crist, S.; Shpritz, L.; Fitton, L.; Saffouri, R.; et al. Environmental and economic costs of soil erosion and conservation benefits. Science 1995, 267, 1117–1123. [Google Scholar] [CrossRef]

- Yang, D.; Kanae, S.; Oki, T.; Koike, T.; Musiake, K. Global potential soil erosion with reference to land use and climate changes. Hydrol. Process. 2003, 17, 2913–2928. [Google Scholar] [CrossRef]

- Lal, R. Soil erosion impact on agronomic productivity and environment quality. Crit. Rev. Plant Sci. 1998, 17, 319–464. [Google Scholar] [CrossRef]

- Pimentel, D.; Burgess, M. Soil erosion threatens food production. Agriculture 2013, 3, 443–463. [Google Scholar] [CrossRef]

- Pimentel, D. Soil erosion: A food and environmental threat. Environ. Dev. Sustain. 2006, 8, 119–137. [Google Scholar] [CrossRef]

- Kojima, R.; Osawa, K.; Matsuura, M.; Fujisawa, H.; Tomisaka, M.; Matsui, H. Identification of soil erodibilities for an application of wepp model with biological ground cover by algae and fungi. J. Jpn. Soc. Civ. Eng. Ser. G Environ. Res. 2018, 74, I_233–I_239. [Google Scholar] [CrossRef] [PubMed]

- Zamami, Y.; Chibana, C.; Kinjo, K. The Particle Size Distribution of the Soils Distributed in Okinawa and the Particle Size of Suspended Solids in Turbid Water. Annual report of Okinawa Prefectural Institute of Health and Environment, No. 48. 2014, pp. 63–66. Available online: https://www.pref.okinawa.jp/_res/projects/default_project/_page_/001/006/587/48-p63-66.pdf (accessed on 10 April 2024).

- Okinawa Prefectural Government. The Second the Master Plan for Countermeasures of Red Soil Erosion Prevention. 2023; p. 15. Available online: https://www.pref.okinawa.jp/_res/projects/default_project/_page_/001/004/801/akatuchikihonkeikaku2-2.pdf (accessed on 10 April 2024).

- Okinawa Prefectural Government. Final Report of the Master Plan for Countermeasures of Red Soil Erosion Prevention. 2022. Available online: https://www.pref.okinawa.jp/_res/projects/default_project/_page_/001/004/801/01akatuchihyouka.pdf (accessed on 10 April 2024).

- Seybold, C.A. Polyacrylamide review: Soil conditioning and environmental fate. Commun. Soil Sci. Plant Anal. 1994, 25, 2171–2185. [Google Scholar] [CrossRef]

- Liu, J.; Shi, B.; Jiang, H.; Bae, S.; Huang, H. Improvement of water-stability of clay aggregates admixed with aqueous polymer soil stabilizers. CATENA 2009, 77, 175–179. [Google Scholar] [CrossRef]

- Wallace, G.A.; Wallace, A. Control of soil erosion by polymeric soil conditioners. Soil Sci. 1986, 141, 363. [Google Scholar] [CrossRef]

- Green, V.S.; Stott, D.E. Polyacrylamide: A review of the use, effectiveness, and cost of a soil erosion control amendment. In Sustaining the Global Farm: Selected Papers from the 10th International Soil Conservation Organization Meeting; Stott, D.E., Mohtar, R.H., Steinhardt, G.C., Eds.; Purdue University and USDA-ARS National Soil Erosion Research Laboratory: West Lafayette, Indiana, 2001; pp. 384–389. [Google Scholar]

- Flanagan, D.C.; Gilley, J.E.; Franti, T.G. Water Erosion Prediction Project (WEPP): Development History, Model Capabilities, and Future Enhancements. Trans. ASABE 2007, 50, 1603–1612. [Google Scholar] [CrossRef]

- Laflen, J.M.; Flanagan, D.C.; Ascough II, J.C.; Weltz, M.A.; Stone, J.J. The WEPP model and its applicability for predicting erosion on rangelands. In Proceeding of Symposium Variability in Rangeland Water Erosion Processes; Soil Science Society of America, INC., Special Publication: Madison, WI, USA, 1994; Volume 38, pp. 11–22. [Google Scholar]

- Amore, E.; Modica, C.; Nearing, M.A.; Santoro, V.C. Scale effect in USLE and WEPP application for soil erosion computation from three Sicilian basins. J. Hydrol. 2004, 293, 100–114. [Google Scholar] [CrossRef]

- Klik, A.; Jester, W.; Rauter, C. Sediment transport in a small agricultural watershed—Evaluation of WEPP simulations with measured data. In Sediment Budgets 2 (Proceedings of Symposium S1 Held During the Seventh IAHS Scientific Assembly at Foz do Iguaçu, Brazil, 3–9 April 2005); Horowitz, A.J., Walling, D.E., Eds.; IAHS Publ. 292: Wallingford, UK, 2005; pp. 127–135. [Google Scholar]

- Ramsankaran, R.; Kothyari, U.C.; Rawat, J.S. Simulation of surface runoff and sediment yield using the water erosion prediction project (WEPP) model: A study in Kaneli watershed, Himalaya. Hydrol. Sci. J. 2009, 54, 513–525. [Google Scholar] [CrossRef]

- Shen, Z.Y.; Gong, Y.W.; Li, Y.H.; Hong, Q.; Xu, L.; Liu, R.M. A comparison of WEPP and SWAT for modeling soil erosion of the Zhangjiachong Watershed in the Three Gorges Reservoir Area. Agric. Water Manag. 2009, 96, 1435–1442. [Google Scholar] [CrossRef]

- Laflen, J.M.; Elliot, W.; Simanton, J.R.; Holzhey, C.S.; Kohl, K.D. WEPP: Soil erodibility experiments for rangeland and cropland soils. J. Soil Water Conserv. 1991, 46, 39–44. [Google Scholar] [CrossRef]

- Verhaegen, T. The use of small flumes for the determination of soil erodibility. Earth Surf. Process. Landf. 1987, 12, 185–194. [Google Scholar] [CrossRef]

- Romero, C.C.; Stroosnijder, L.; Baigorria, G.A. Interrill and rill erodibility in the northern Andean Highlands. CATENA 2007, 70, 105–113. [Google Scholar] [CrossRef]

- Yamaguchi, A.; Kanashiki, N.; Ishizaki, H.; Kobayashi, M.; Osawa, K. Relationship between soil erodibility by concentrated flow and shear strength of a Haplic Acrisol with a cationic polyelectrolyte. CATENA 2022, 217, 106506. [Google Scholar] [CrossRef]

- Takahashi, J.; Nishino, K. Emulsion Composition and Soil Erosion Prevention Material. World Intellectual Property Organization Patent WO2022018919A1, 27 January 2022. Available online: https://patents.google.com/patent/WO2022018919A1/en?oq=WO2022018919A1 (accessed on 10 April 2024).

- Henderson, A.M. Ethylene-vinyl acetate (EVA) copolymers: A general review. IEEE Electr. Insul. Mag. 1993, 9, 30–38. [Google Scholar] [CrossRef]

- Zeng, L.; Liang, M.; Cai, W.; Tang, J.; Liu, G.; Zhang, J.; Wang, S.; Yang, K. Investigation on effect of EVA on properties of desert sand-based permeable materials. Case Stud. Constr. Mater. 2023, 18, e02038. [Google Scholar] [CrossRef]

- Gribniak, V.; Kaklauskas, G.; Bacinskas, D. Shrinkage in reinforced concrete structures: A computational aspect. J. Civ. Eng. Manag. 2008, 14, 49–60. [Google Scholar] [CrossRef]

- Kodikara, J.; Barbour, S.; Fredlund, D. Desiccation cracking of soil layers. In Proceedings of the Asian Conference on Unsaturated Soils UNSAT ASIA 2000; CRC Press: Boca Raton, FL, USA, 2000; pp. 693–698. [Google Scholar] [CrossRef]

- FAO. World Reference Base for Soil Resources 2014: International Soil Classification System for Naming Soils and Creating Legends for Soil Maps; World Soil Resources Reports No. 106; FAO: Rome, Italy, 2014. [Google Scholar]

- Japanese Industrial Standards Association. Test Method for Ignition Loss of Soils (JIS A 1226: 2020); Japanese Industrial Standards Association: Tokyo, Japan, 2020. [Google Scholar]

- Japanese Industrial Standards Association. The Method for Particle Size Distribution of Soils (JIS A 1204: 2020); Japanese Industrial Standards Association: Tokyo, Japan, 2020. [Google Scholar]

- Matsusaka, Y.; Otawa, M.; Yamada, Y.; Hamazaki, T. Soils of Okinawa and Kume Islands. Natl. Inst. Agric. Sci. 1971, 22, 305–404. Available online: https://agriknowledge.affrc.go.jp/RN/2030826392.pdf (accessed on 10 November 2023).

- Japan Meteorological Agency. Surface Weather Observing Systems Data (Monthly), 2004. 2025. Available online: https://www.data.jma.go.jp/stats/etrn/view/monthly_s1.php?prec_no=91&block_no=47936&year=2024&month=&day=10&view=a5 (accessed on 25 September 2025).

- Nicks, A.D.; Lane, L.J.; Gander, G.A. Weather generator. In USDA-Water Erosion Prediction Project: Hillslope Profile and Watershed Model Documentation; Flanagan, D.C., Nearing, M.A., Eds.; NSERL Report No. 10; USDA-ARS National Soil Erosion Research Laboratory: West Lafayette, IN, USA, 1995; Chapter 2. [Google Scholar]

- Japan Meteorological Agency. Automated Meteorological Data Acquisition System Data, 1994–2009. 2024. Available online: https://www.data.jma.go.jp/risk/obsdl/index.php (accessed on 10 November 2023).

- Japan Meteorological Agency. Surface Weather Observing Systems Data, 1964–2014. 2024. Available online: https://www.data.jma.go.jp/risk/obsdl/index.php (accessed on 10 November 2023).

- Okinawa Prefectural Government. Established Rules Relating to Red Soil Erosion Prevention Ordinance. 1995. Available online: https://www.pref.okinawa.jp/_res/projects/default_project/_page_/001/023/458/jyourei.pdf (accessed on 10 April 2024).

- Zhou, C.; Zhao, S.; Huang, W.; Li, D.; Liu, Z. Study on the stabilization mechanisms of clayey slope surfaces treated by spraying with a new soil additive. Appl. Sci. 2019, 9, 1245. [Google Scholar] [CrossRef]

- Huang, W.; Liu, Z.; Zhou, C.; Yang, X. Enhancement of soil ecological self-repair using a polymer composite material. CATENA 2020, 188, 104443. [Google Scholar] [CrossRef]

- Vermang, J.; Norton, L.D.; Huang, C.; Cornelis, W.M.; da Silva, A.M.; Gabriels, D. Characterization of soil surface roughness effects on runoff and soil erosion rates under simulated rainfall. Soil Sci. Soc. Am. J. 2015, 79, 903–916. [Google Scholar] [CrossRef]

- Bahddou, S.; Otten, W.; Whalley, W.R.; Shin, H.-C.; El Gharous, M.; Rickson, R.J. Changes in soil surface properties under simulated rainfall and the effect of surface roughness on runoff, infiltration and soil loss. Geoderma 2023, 431, 116341. [Google Scholar] [CrossRef]

- Helming, K.; Römkens, M.J.M.; Prasad, S.N. Surface roughness related processes of runoff and soil loss: A flume study. Soil Sci. Soc. Am. J. 1998, 62, 243–250. [Google Scholar] [CrossRef]

- Nearing, M.A.; Parker, S.C. Detachment of soil by flowing water under turbulent and laminar conditions. Soil Sci. Soc. Am. J. 1994, 58, 1612–1614. [Google Scholar] [CrossRef]

- Imbufe, A.U.; Patti, A.F.; Burrow, D.; Surapaneni, A.; Jackson, W.R.; Milner, A.D. Effects of potassium humate on aggregate stability of two soils from Victoria, Australia. Geoderma 2005, 125, 321–330. [Google Scholar] [CrossRef]

- Özdemir, N.; Kassım, H. Effects of soil conditioner and humic acid applications on the development of some soil quality parameters. Soil Stud. 2022, 11, 1. [Google Scholar] [CrossRef]

- Wagner, S.; Cattle, S.; Scholten, T. Soil-aggregate formation as influenced by clay content and organic-matter amendment. J. Plant Nutr. Soil Sci. 2007, 170, 173–180. [Google Scholar] [CrossRef]

- Legout, C.; Leguédois, S.; Le Bissonnais, Y. Aggregate breakdown dynamics under rainfall compared with aggregate stability measurements. Eur. J. Soil Sci. 2005, 56, 225–238. [Google Scholar] [CrossRef]

- Ascough II, J.C.; Flanagan, D.C.; Nearing, M.A.; Engel, B.A. Sensitivity and first-order/monte carlo uncertainty analysis of the WEPP hillslope erosion model. Trans. ASABE 2013, 56, 437–452. [Google Scholar] [CrossRef]

- Haynes, J.L. Ground rainfall under vegetative canopy of crops. Agron. J. 1940, 32, 176–184. [Google Scholar] [CrossRef]

- Ma, B.; Yu, X.; Ma, F.; Li, Z.; Wu, F. Effects of crop canopies on rain splash detachment. PLoS ONE 2014, 9, e99717. [Google Scholar] [CrossRef]

- Gyssels, G.; Poesen, J.; Bochet, E.; Li, Y. Impact of plant roots on the resistance of soils to erosion by water: A review. Prog. Phys. Geogr. 2005, 29, 189–217. [Google Scholar] [CrossRef]

- Hussein, M.H.; Laflen, J.M. Effects of crop canopy and residue on rill and interrill soil erosion. Trans. ASABE 1982, 25, 1310–1315. [Google Scholar] [CrossRef]

- Renard, K.G.; Foster, G.R.; Weesies, G.A.; McCool, D.K.; Yoder, D.C. Predicting soil erosion by water: A guide to conservation planning with the Revised Universal Soil Loss Equation (RUSLE). In USDA Agriculture Handbook No. 703; U.S. Department of Agriculture: Washington, DC, USA, 1997. [Google Scholar]

| Property | Value |

|---|---|

| pH | 4.9 |

| Boiling point | 100 °C |

| Flammable | No |

| Density | 1.1 g·cm−3 |

| Water solubility | Water-emulsifiable |

| Clay (%) | Silt (%) | Sand (%) | Coarse Fragments (%) | Organic Matter (%) | |

|---|---|---|---|---|---|

| Kunigami Maaji (Soil A) | 33.94 | 47.91 | 18.15 | 0.04 | 7.77 |

| Shimajiri Maaji (Soil B) | 5.10 | 44.10 | 50.80 | 52.60 | 6.76 |

| Treatment Code | Application Amount (g·m−2) | Equivalent Field Amount (t·ha−1) | Dilution Factor | Soil Water Content (%) |

|---|---|---|---|---|

| Control | 0 | 0 | − | − |

| SC500 | 500 | 5.00 | 4 | 25 |

| SC100 | 100 | 1.00 | 15 | 15 |

| SC50 | 50 | 0.50 | 25 | 25 |

| Test Soil Code | Interrill Experiments | Rill Experiments |

|---|---|---|

| Rainfall Intensity (mm·h−1) | Flow Rate (L·min−1) | |

| Soil A Control | 16.75–68.58 | 0.23–2.16 |

| Soil A SC500 | 5.69–56.42 | 0.23–2.11 |

| Soil A SC100 | 14.34–75.54 | 0.23–1.15 |

| Soil A SC50 | 15.96–90.08 | 0.24–2.28 |

| Soil B Control | 15.72–78.32 | 0.32–2.45 |

| Soil B SC100 | 17.72–75.64 | 0.32–2.41 |

| Test Soil Code | Kib [Reduction] | Runoff Ratio | r | p-Value | Krb [Reduction] | τcb | r | p-Value |

|---|---|---|---|---|---|---|---|---|

| kg·m−4·s [%] | s·m−1 [%] | Pa | ||||||

| Soil A * untreated | 1.222 × 106 [-] | 95–102% | 0.90 | <0.001 | 3.452 × 10−3 [-] | 1.686 | 0.86 | <0.001 |

| Soil A SC500 | 0.013 × 106 [99%] | 41–73% | 0.95 | <0.001 | ES ** | >7.840 | 0.32 | <0.001 |

| Soil A SC100 | n/a * | 97–101% | n/a * | n/a * | 0.011 × 10−3 [99%] | >5.828 | 0.85 | <0.1 |

| Soil A SC50 | 0.484 × 106 [61%] | 82–102% | 0.94 | <0.001 | 1.210 × 10−3 [65%] | 3.082 | 0.95 | <0.01 |

| Soil B untreated | 0.656 × 106 [-] | 97–105% | 0.96 | <0.001 | 3.939 × 10−3 [-] | 0.945 | 0.92 | <0.001 |

| Soil B SC100 | 0.266 × 106 [59%] | 79–91% | 0.93 | <0.01 | 0.001 × 10−3 [99%] | >6.122 | 0.28 | <0.01 |

| Input | Output | |||||||

|---|---|---|---|---|---|---|---|---|

| Test Soil/Code | Kib | Krb | τcb | Annual Runoff | SY (Reduction) | SYi | SYr | |

| kg·m−4·s | s·m−1 | Pa | mm | kg·m−2·y−1 (%) | kg·m−2·y−1 | kg·m−2·y−1 | ||

| Soil A | untreated | 1.222 × 106 | 3.452 × 10−3 | 1.686 | 437.49 | 21.974 (-) | 1.811 | 20.163 |

| SC500 | 0.013 × 106 | 0.001 × 10−3 | 7.840 | 437.49 | 0.019 (99) | 0.019 | 0.000 | |

| SC50 | 0.484 × 106 | 1.210 × 10−3 | 3.082 | 437.49 | 5.998 (73) | 0.725 | 5.273 | |

| Soil B | untreated | 0.656 × 106 | 3.939 × 10−3 | 0.945 | 212.41 | 8.433 (-) | 0.604 | 7.829 |

| SC100 | 0.266 × 106 | 0.001 × 10−3 | 6.122 | 212.41 | 0.231 (97) | 0.231 | 0.000 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xin, Y.; Osawa, K.; Matsui, H.; Chiba, S.; Takahashi, J.; Honda, K. Erosion Control Effects of a Polymer-Based Soil Conditioner on Red Soil in Okinawa, Japan. Agronomy 2025, 15, 2362. https://doi.org/10.3390/agronomy15102362

Xin Y, Osawa K, Matsui H, Chiba S, Takahashi J, Honda K. Erosion Control Effects of a Polymer-Based Soil Conditioner on Red Soil in Okinawa, Japan. Agronomy. 2025; 15(10):2362. https://doi.org/10.3390/agronomy15102362

Chicago/Turabian StyleXin, Yang, Kazutoshi Osawa, Hiroyuki Matsui, Susumu Chiba, Junpei Takahashi, and Kazuma Honda. 2025. "Erosion Control Effects of a Polymer-Based Soil Conditioner on Red Soil in Okinawa, Japan" Agronomy 15, no. 10: 2362. https://doi.org/10.3390/agronomy15102362

APA StyleXin, Y., Osawa, K., Matsui, H., Chiba, S., Takahashi, J., & Honda, K. (2025). Erosion Control Effects of a Polymer-Based Soil Conditioner on Red Soil in Okinawa, Japan. Agronomy, 15(10), 2362. https://doi.org/10.3390/agronomy15102362