Effects of Biodegradable Mulch Films with Different Thicknesses on the Quality of Watermelon Under Protected Cultivation

Abstract

1. Introduction

2. Materials and Methods

2.1. Study Site and Cultivation Conditions

2.2. Experimental Design

2.3. Soil Sampling and Analysis

2.4. Assessment of Growth and Quality of Watermelon

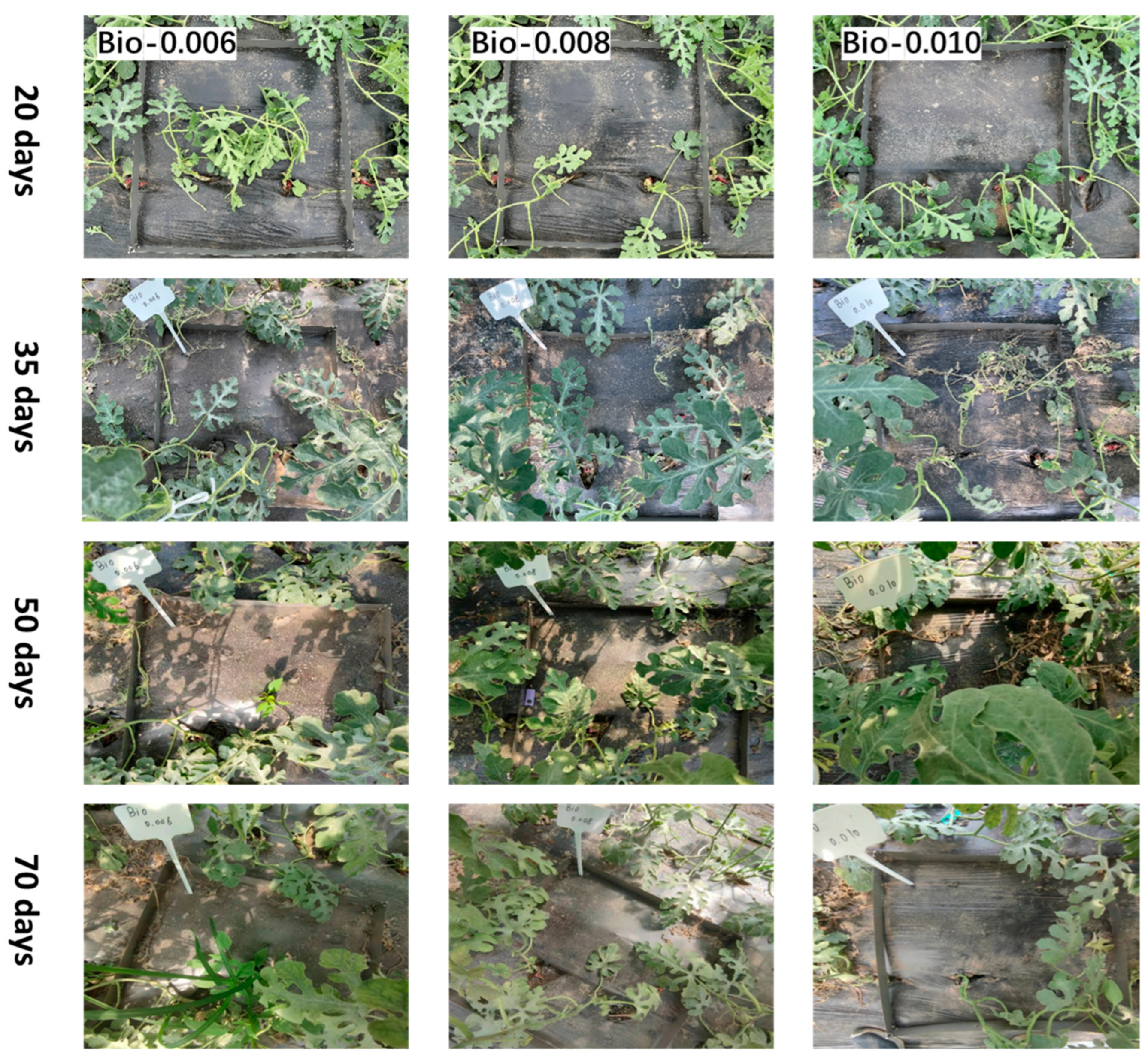

2.5. Analysis of the Degradation and Mechanical Properties of Mulch Films

2.6. Statistical Analysis

3. Results

3.1. Effects of Different Mulch Films on Soil Properties

3.2. Effects of Mulch Films on Watermelon Growth

3.3. Effects of Mulch Films on Nutritional Quality of Watermelon

3.4. Changes in Surface Morphology and Mechanical Properties of Mulch Films After Use

4. Discussion

4.1. Mechanical Performance and Degradation Behavior of Mulch Films

4.2. Integrated Yield and Quality Performance of Watermelon Under Different Mulch Films

4.3. Practical Application Prospects and Environmental Implications of BDMs

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Maoto, M.M.; Beswa, D.; Jideani, A.I. Watermelon as a potential fruit snack. Int. J. Food Prop. 2019, 22, 355–370. [Google Scholar] [CrossRef]

- Mashilo, J.; Shimelis, H.; Maja, D.; Ngwepe, R.M. Meta-analysis of qualitative and quantitative trait variation in sweet watermelon and citron watermelon genetic resources. Genet. Resour. Crop Evol. 2023, 70, 13–35. [Google Scholar] [CrossRef]

- Meghwar, P.; Ghufran Saeed, S.M.; Ullah, A.; Nikolakakis, E.; Panagopoulou, E.; Tsoupras, A.; Smaoui, S.; Mousavi Khaneghah, A. Nutritional benefits of bioactive compounds from watermelon: A comprehensive review. Food Biosci. 2024, 61, 104609. [Google Scholar] [CrossRef]

- Çürük, S.; Sermenli, T.; Mavi, K.; Evrendilek, F. Yield and fruit quality of watermelon (Citrullus lanatus (Thumb.) Matsum. & Nakai.) and melon (Cucumis melo L.) under protected organic and conventional farming systems in a mediterranean region of turkey. Biol. Agric. Hortic. 2004, 22, 173–183. [Google Scholar] [CrossRef]

- Othman, Y.A.; Leskovar, D.I. Degradable mulch as an alternative to polyethylene for watermelon production. HortTechnology 2022, 32, 226–233. [Google Scholar] [CrossRef]

- Li, W.; Yan, W.; Shengnan, W.; Yingchao, Q.; Deng, W.R.; Di, Y.R. Review of Biodegradable Mulching Film Materials. Modern Agr. Res. 2023, 29, 115–118. [Google Scholar]

- Ammala, A.; Bateman, S.; Dean, K.; Petinakis, E.; Sangwan, P.; Wong, S.; Yuan, Q.; Yu, L.; Patrick, C.; Leong, K. An overview of degradable and biodegradable polyolefins. Prog. Polym. Sci. 2011, 36, 1015–1049. [Google Scholar] [CrossRef]

- Gao, H.; Yan, C.; Liu, Q.; Ding, W.; Chen, B.; Li, Z. Effects of plastic mulching and plastic residue on agricultural production: A meta-analysis. Sci. Total Environ. 2019, 651, 484–492. [Google Scholar] [CrossRef]

- Rillig, M.C.; Kim, S.W.; Zhu, Y.-G. The soil plastisphere. Nat. Rev. Microbiol. 2024, 22, 64–74. [Google Scholar] [CrossRef] [PubMed]

- Wang, F.; Wang, Q.; Adams, C.A.; Sun, Y.; Zhang, S. Effects of microplastics on soil properties: Current knowledge and future perspectives. J. Hazard. Mater. 2022, 424, 127531. [Google Scholar] [CrossRef] [PubMed]

- Hu, M.; MIAO, Q.; SHI, H. Mulching effects of different films on soil water, heat and yield of spring maize. Soil 2018, 50, 628–632. [Google Scholar]

- Haider, T.P.; Völker, C.; Kramm, J.; Landfester, K.; Wurm, F.R. Plastics of the Future? The Impact of Biodegradable Polymers on the Environment and on Society. Angew. Chem. Int. Ed. Engl. 2019, 58, 50–62. [Google Scholar] [CrossRef]

- Xiong, L.; Li, Z.; Shah, F.; Wang, P.; Yuan, Q.; Wu, W. Biodegradable mulch film enhances the environmental sustainability compared with traditional polyethylene film from multidimensional perspectives. Chem. Eng. J. 2024, 492, 152219. [Google Scholar] [CrossRef]

- Madin, M.; Nelson, K.; Fatema, K.; Schoengold, K.; Dalal, A.; Onyekwelu, I.; Rayan, R.; Norouzi, S.S. Synthesis of current evidence on factors influencing the suitability of synthetic biodegradable mulches for agricultural applications: A systematic review. J. Agr. Food Res. 2024, 16, 101095. [Google Scholar] [CrossRef]

- Zhang, X.; You, S.; Tian, Y.; Li, J. Comparison of plastic film, biodegradable paper and bio-based film mulching for summer tomato production: Soil properties, plant growth, fruit yield and fruit quality. Sci. Hortic. 2019, 249, 38–48. [Google Scholar] [CrossRef]

- Han, Y.; Lu, L.; Wang, L.; Liu, Z.; Huang, P.; Chen, S.; Li, Y.; Sun, M.; He, C.; Wang, J.; et al. In-situ straw return, combined with plastic film use, influences soil properties and tomato quality and yield in greenhouse conditions. Agr. Commun. 2024, 2, 100028. [Google Scholar] [CrossRef]

- Wang, Z.; Li, M.; Flury, M.; Schaeffer, S.M.; Chang, Y.; Tao, Z.; Jia, Z.; Li, S.; Ding, F.; Wang, J. Agronomic performance of polyethylene and biodegradable plastic film mulches in a maize cropping system in a humid continental climate. Sci. Total Environ. 2021, 786, 147460. [Google Scholar] [CrossRef]

- Yin, M.; Li, Y.; Fang, H.; Chen, P. Biodegradable mulching film with an optimum degradation rate improves soil environment and enhances maize growth. Agric. Water Manag. 2019, 216, 127–137. [Google Scholar] [CrossRef]

- Costa, R.; Saraiva, A.; Carvalho, L.; Duarte, E. The use of biodegradable mulch films on strawberry crop in Portugal. Sci. Hortic. 2014, 173, 65–70. [Google Scholar] [CrossRef]

- Cozzolino, E.; Di Mola, I.; Ottaiano, L.; Bilotto, M.; Petriccione, M.; Ferrara, E.; Mori, M.; Morra, L. Assessing yield and quality of melon (Cucumis melo L.) improved by biodegradable mulching film. Plants 2023, 12, 219. [Google Scholar] [CrossRef]

- Sellami, M.H.; Di Mola, I.; Ottaiano, L.; Cozzolino, E.; del Piano, L.; Mori, M. Evaluation of Biodegradable Mulch Films on Melon Production and Quality under Mediterranean Field Conditions. Agronomy 2024, 14, 2075. [Google Scholar] [CrossRef]

- Akhir, M.A.M.; Mustapha, M. Formulation of biodegradable plastic mulch film for agriculture crop protection: A review. Polym. Rev. 2022, 62, 890–918. [Google Scholar] [CrossRef]

- Amare, G.; Desta, B. Coloured plastic mulches: Impact on soil properties and crop productivity. Chem. Biol. Technol. Ag. 2021, 8, 1–9. [Google Scholar] [CrossRef]

- Moreno, M.; Moreno, A. Effect of different biodegradable and polyethylene mulches on soil properties and production in a tomato crop. Sci. Hortic. 2008, 116, 256–263. [Google Scholar] [CrossRef]

- NY/T 1121.6-2006; Soil Testing-Part 6: Determination of Soil Organic Matter. Ministry of Agriculture of the PRC: Beijing, China, 2006.

- NY/T 1121.24-2012; Soil Testing. Part 24: Determination of Total Nitrogen in Soil. Automatic Kjeldahl Apparatus Method. Ministry of Agriculture of the PRC: Beijing, China, 2012.

- NY/T 88-1988; Soil Total Phosphorus Determination Method. Ministry of Agriculture of the PRC: Beijing, China, 1988.

- LY/T 1228-2015; Nitrogen Determination Methods of Forest Soils. China Standard Publishing House: Beijing, China, 2016.

- NY/T 1121.25–2012; Soil Testing-Part 25: Method for Determination of Available Phosphorus by Continuous Flow Analyzer. Ministry of Agriculture of the PRC: Beijing, China, 2012.

- NY/T 1377-2007; Determination of pH in Soil. Ministry of Agriculture of the PRC: Beijing, China, 2007.

- Sadrnia, H.; Rajabipour, A.; Jafary, A.L.I.; Javadi, A.; Mostofi, Y. Classification and Analysis of Fruit Shapes in Long Type Watermelon Using Image Processing. Int. J. Agric. Biol. 2007, 9, 1. [Google Scholar]

- GB13735—2017; Polyethylene Blown Mulch Film for Agricultural Uses. General Administration of Quality Supervision, Inspection and Quarantine of the PRC: Beijing, China, 2017.

- GB/T 35795-2017; Fully Biodegradable Agricultural Ground Cover Films. General Administration of Quality Supervision, Inspection and Quarantine of the PRC: Beijing, China, 2017.

- Mu, X.G.; Gao, H.; Li, M.-H.; Zhao, X.-R.; Guo, N.; Jin, L.; Li, J.-S.; Ye, L. Effects of Different Types of Plastic Film Mulching on Soil Quality, Root Growth, and Yield. Environ. Sci. 2023, 44, 3439–3449. [Google Scholar]

- Bandopadhyay, S.; Sintim, H.Y.; DeBruyn, J.M. Effects of biodegradable plastic film mulching on soil microbial communities in two agroecosystems. PeerJ 2020, 8, e9015. [Google Scholar] [CrossRef]

- Kasirajan, S.; Ngouajio, M. Polyethylene and biodegradable mulches for agricultural applications: A review. Agron. Sustain. Dev. 2012, 32, 501–529. [Google Scholar] [CrossRef]

- Kyrikou, I.; Briassoulis, D. Biodegradation of Agricultural Plastic Films: A Critical Review. J. Polym. Environ. 2007, 15, 125–150. [Google Scholar] [CrossRef]

- Wu, L.; Zhao, S.; Wang, P.; Yin, B.; Ma, Y.; Zhao, Z. Recovery performance of new plastic mulch films with different thickness. J. China Agric. Univ. 2022, 27, 173–184. [Google Scholar]

- Guo, H.; Yu, X.; Jin, W.; He, N.; Guo, W. Establishment of prediction model for tensile mechanics of plastic film and prediction of film thickness. J. Chin. Agric. Mech. 2020, 41, 173–178. [Google Scholar]

- Zhang, J.; Wang, X.; Zhang, L.; Yu, C.; Jiang, Y.; Zhang, H.; Liu, X.; Qiao, Y.; Wang, X.; Hou, S. Effects of mechanical tensile properties of plastic film on plastic recycling method. Trans. Chin. Soc. Agric. Eng. 2015, 31, 41–47. [Google Scholar]

- Sun, S.; Zhang, W.; Liu, C.; Zhou, J.; Zhu, K. Degradation property of oxo-biodegradable plastic film and its mulching effect on soil moisture, soil temperature and maize growth in rainfed Northeast China. China Chin. J. Eco-Agric. 2019, 27, 72–80. [Google Scholar]

- Cowan, J.S.; Saxton, A.M.; Liu, H.; Leonas, K.K.; Inglis, D.; Miles, C.A. Visual Assessments of Biodegradable Mulch Deterioration Are Not Indicative of Changes in Mechanical Properties. HortScience 2016, 51, 245–254. [Google Scholar] [CrossRef]

- Briassoulis, D. Mechanical behaviour of biodegradable agricultural films under real field conditions. Polym. Degrad. Stabil. 2006, 91, 1256–1272. [Google Scholar] [CrossRef]

- Tokiwa, Y.; Calabia, B.P.; Ugwu, C.U.; Aiba, S. Biodegradability of Plastics. Int. J. Mol. Sci. 2009, 10, 3722–3742. [Google Scholar] [CrossRef]

- Andrady, A.L.; Neal, M.A. Applications and societal benefits of plastics. Philos. T R. Soc. B 2009, 364, 1977–1984. [Google Scholar] [CrossRef]

- Gu, X.-B.; Li, Y.-N.; Du, Y.-D. Biodegradable film mulching improves soil temperature, moisture and seed yield of winter oilseed rape (Brassica napus L.). Soil. Till Res. 2017, 171, 42–50. [Google Scholar] [CrossRef]

- Wang, Z.; Wu, Q.; Fan, B.; Zhang, J.; Li, W.; Zheng, X.; Lin, H.; Guo, L. Testing biodegradable films as alternatives to plastic films in enhancing cotton (Gossypium hirsutum L.) yield under mulched drip irrigation. Soil. Till Res. 2019, 192, 196–205. [Google Scholar] [CrossRef]

- Guo, S.; Tian, R.; Wang, Y. The reviews of sugar accumulation in Watermelon fruits. Chin. Agr. Sci. Bull. 2010, 26, 271–274. [Google Scholar]

- Velandia, M.; Galinato, S.; Wszelaki, A. Economic Evaluation of Biodegradable Plastic Films in Tennessee Pumpkin Production. Agronomy 2020, 10, 51. [Google Scholar] [CrossRef]

| Treat. | Days After Mulching | ||||||

|---|---|---|---|---|---|---|---|

| 10 | 20 | 30 | 40 | 50 | 60 | ||

| Year 2023 | |||||||

| BS | 20.1 ± 0.38 | 22.3 ± 0.65 | 23.1 ± 0.82 | 21.8 ± 1.26 | 23.6 ± 0.51 | 24.1 ± 1.06 | |

| Bio-0.006 | 22.5 ± 1.08 | 22.8 ± 0.22 | 24.1 ± 0.64 | 22.5 ± 1.04 | 24.1 ± 0.22 | 25.5 ± 0.36 | |

| Bio-0.008 | 22.7 ± 2.14 | 23.8 ± 0.10 | 24.1 ± 1.71 | 23.3 ± 0.86 | 24.5 ± 0.31 | 26.0 ± 0.88 | |

| Bio-0.010 | 24.1 ± 1.15 | 24.1 ± 0.91 | 25.4 ± 2.01 | 23.7 ± 1.05 | 24.7 ± 0.25 | 26.3 ± 0.57 | |

| PE-0.010 | 24.2 ± 1.31 | 25.2 ± 0.12 | 25.3 ± 0.82 | 23.7 ± 0.84 | 26.2 ± 0.41 | 27.1 ± 0.42 | |

| Year 2024 | |||||||

| BS | 23.3 ± 0.49 | 22.5 ± 0.36 | 22.4 ± 1.15 | 22.1 ± 0.80 | 23.3 ± 0.61 | 25.3 ± 0.55 | |

| Bio-0.006 | 25.7 ± 0.45 | 24.5 ± 0.12 | 24.8 ± 1.11 | 21.7 ± 0.85 | 23.4 ± 0.42 | 25.7 ± 0.45 | |

| Bio-0.008 | 24.7 ± 0.44 | 23.6 ± 0.06 | 23.0 ± 0.70 | 22.7 ± 0.68 | 24.7 ± 0.38 | 26.9 ± 0.60 | |

| Bio-0.010 | 25.1 ± 0.50 | 24.9 ± 0.12 | 23.5 ± 0.68 | 23.7 ± 2.59 | 24.0 ± 0.15 | 26.2 ± 0.35 | |

| PE-0.010 | 25.3 ± 0.56 | 25.5 ± 0.96 | 25.6 ± 1.01 | 24.5 ± 1.78 | 26.5 ± 0.91 | 27.6 ± 0.78 | |

| Significance | |||||||

| Mulching (M) | <0.01 | ||||||

| Time (T) | <0.001 | ||||||

| M × T | <0.05 | ||||||

| Treat. | Days After Planting | ||||||

|---|---|---|---|---|---|---|---|

| 10 | 20 | 30 | 40 | 50 | 60 | ||

| Year 2023 | |||||||

| BS | 51.0 ± 1.56 | 58.1 ± 1.38 | 60.1 ± 2.81 | 61.9 ± 2.24 | 58.1 ± 0.98 | 64.2 ± 2.01 | |

| Bio-0.006 | 53.2 ± 2.22 | 62.5 ± 2.88 | 66.1 ± 2.58 | 60.5 ± 3.15 | 61.5 ± 2.29 | 63.2 ± 2.87 | |

| Bio-0.008 | 56.3 ± 3.21 | 62.1 ± 1.20 | 67.9 ± 3.24 | 64.9 ± 2.28 | 73.5 ± 3.61 | 75.6 ± 3.19 | |

| Bio-0.010 | 62.3 ± 2.78 | 64.4 ± 2.54 | 70.8 ± 1.89 | 75.2 ± 3.04 | 75.6 ± 3.13 | 74.9 ± 2.52 | |

| PE-0.010 | 65.1 ± 3.15 | 66.3 ± 3.21 | 77.8 ± 2.96 | 76.0 ± 2.47 | 74.4 ± 2.31 | 76.1 ± 2.47 | |

| Year 2024 | |||||||

| BS | 49.9 ± 9.75 | 49.0 ± 1.40 | 49.3 ± 2.32 | 62.1 ± 8.47 | 51.4 ± 3.76 | 63.6 ± 3.30 | |

| Bio-0.006 | 56.4 ± 2.20 | 61.8 ± 1.40 | 64.5 ± 2.55 | 67.0 ± 4.32 | 52.4 ± 0.92 | 63.5 ± 3.80 | |

| Bio-0.008 | 63.9 ± 2.03 | 64.3 ± 3.16 | 69.9 ± 1.83 | 74.8 ± 5.48 | 57.9 ± 1.17 | 64.8 ± 2.04 | |

| Bio-0.010 | 63.5 ± 2.35 | 67.8 ± 3.25 | 73.1 ± 2.97 | 78.4 ± 3.9 | 61.3 ± 2.69 | 70.8 ± 2.32 | |

| PE-0.010 | 66.7 ± 2.86 | 66.9 ± 1.78 | 75.6 ± 2.22 | 80.6 ± 3.59 | 74.6 ± 0.91 | 79.3 ± 1.89 | |

| Significance | |||||||

| Mulching (M) | <0.01 | ||||||

| Time (T) | <0.001 | ||||||

| M × T | <0.05 | ||||||

| Treat. | pH | TOC % | TP % | TN % | AN mg/kg | EP mg/kg | |

|---|---|---|---|---|---|---|---|

| Year 2023 | |||||||

| BS | 7.89 ± 0.07 | 1.09 ± 0.13 | 0.16 ± 0.03 | 0.17 ± 0.02 | 396.7 ± 22.2 a | 183.1 ± 15.4 a | |

| Bio-0.006 | 8.02 ± 0.04 | 1.17 ± 0.16 | 0.17 ± 0.02 | 0.15 ± 0.01 | 217.4 ± 20.0 b | 189.5 ± 10.1 a | |

| Bio-0.008 | 8.11 ± 0.10 | 1.45 ± 0.24 | 0.15 ± 0.02 | 0.20 ± 0.03 | 163.3 ± 16.2 c | 201.1 ± 17.3 a | |

| Bio-0.010 | 8.07 ± 0.06 | 1.42 ± 0.17 | 0.14 ± 0.01 | 0.18 ± 0.01 | 170.1 ± 18.7 c | 184.1 ± 11.8 a | |

| PE-0.010 | 8.23 ± 0.12 | 1.15 ± 0.35 | 0.13 ± 0.02 | 0.15 ± 0.01 | 161.8 ± 14.3 c | 146.6 ± 14.1 b | |

| Year 2024 | |||||||

| BS | 7.78 ± 0.02 | 1.12 ± 0.16 | 0.18 ± 0.05 | 0.15 ± 0.02 | 418.3 ± 26.1 a | 179.2 ± 7.8 a | |

| Bio-0.006 | 7.89 ± 0.05 | 1.29 ± 0.26 | 0.15 ± 0.03 | 0.15 ± 0.03 | 230.2 ± 16.6 b | 181.9 ± 12.7 a | |

| Bio-0.008 | 8.13 ± 0.04 | 1.56 ± 0.37 | 0.19 ± 0.01 | 0.17 ± 0.04 | 151.9 ± 40.2 c | 196.8 ± 13.6 a | |

| Bio-0.010 | 7.99 ± 0.11 | 1.34 ± 0.32 | 0.18 ± 0.01 | 0.14 ± 0.03 | 161.3 ± 14.3 c | 179.6 ± 8.7 a | |

| PE-0.010 | 8.27 ± 0.07 | 1.11 ± 0.18 | 0.16 ± 0.02 | 0.12 ± 0.02 | 137.8 ± 4.7 c | 157.6 ± 5.8 b | |

| Significance | |||||||

| Mulching (M) | ns | ns | ns | ns | ** | * | |

| Year (Y) | ns | ns | ns | ns | ns | ns | |

| M × Y | ns | ns | ns | ns | ns | ns | |

| Treat. | Plant Height (cm) | Chlorophyll Content (SPAD) | Fruit Shape Index | Individual Fruit Weight (kg) | Estimated Yield (kg/ha) | |

|---|---|---|---|---|---|---|

| Year 2023 | ||||||

| BS | 272.2 ± 12.10 b | 54.21 ± 1.31 a | 1.32 ± 0.03 a | 1.21 ± 0.11 c | 40,365 | |

| Bio-0.006 | 266.1 ± 14.27 b | 57.96 ± 3.74 a | 1.01 ± 0.01 b | 1.57 ± 0.17 a | 52,335 | |

| Bio-0.008 | 281.4 ± 13.71 ab | 57.39 ± 2.69 a | 1.03 ± 0.01 b | 1.46 ± 0.25 ab | 48,660 | |

| Bio-0.010 | 278.5 ± 11.34 b | 48.74 ± 2.50 b | 1.29 ± 0.02 a | 1.35 ± 0.10 b | 44,850 | |

| PE-0.010 | 296.7 ± 13.37 a | 46.80 ± 1.86 b | 1.31 ± 0.03 a | 1.47 ± 0.11 ab | 48,990 | |

| Year 2024 | ||||||

| BS | 276.6 ± 14.03 b | 56.18 ± 1.31 a | 1.31 ± 0.02 a | 1.19 ± 0.12 c | 39,660 | |

| Bio-0.006 | 257.2 ± 16.48 b | 59.46 ± 3.74 a | 1.00 ± 0.02 b | 1.60 ± 0.30 a | 53,325 | |

| Bio-0.008 | 286.0 ± 13.45 b | 57.02 ± 2.69 a | 0.98 ± 0.03 b | 1.45 ± 0.20 ab | 48,330 | |

| Bio-0.010 | 252.6 ± 27.57 b | 49.70 ± 2.50 b | 1.34 ± 0.02 a | 1.45 ± 0.14 ab | 48,330 | |

| PE-0.010 | 313.4 ± 20.53 a | 46.02 ± 0.06 c | 1.30 ± 0.04 a | 1.33 ± 0.16 b | 44,340 | |

| Significance | ||||||

| Mulching (M) | * | * | * | * | - | |

| Year (Y) | * | ns | ns | ns | - | |

| M × Y | ns | ns | ns | ns | - | |

| Treat. | Soluble Sugar Content (mg/g) | VC Content (μmol/L) | Protein Content (mg/g) | Brix Difference (°Brix) | |

|---|---|---|---|---|---|

| Year 2023 | |||||

| BS | 21.07 ± 2.70 b | 9.21 ± 0.43 | 33.51 ± 2.74 | 2.7 ± 0.32 a | |

| Bio-0.006 | 28.23 ± 1.45 a | 9.08 ± 0.78 | 31.27 ± 4.63 | 1.6 ± 0.24 b | |

| Bio-0.008 | 27.35 ± 1.47 ab | 9.14 ± 1.16 | 34.24 ± 6.33 | 1.7 ± 0.11 b | |

| Bio-0.010 | 25.76 ± 1.81 b | 9.22 ± 0.74 | 36.82 ± 7.12 | 1.9 ± 0.28 b | |

| PE-0.010 | 22.41 ± 2.32 b | 9.19 ± 0.39 | 37.18 ± 2.85 | 2.9 ± 0.47 a | |

| Year 2024 | |||||

| BS | 20.44 ± 2.11 c | 9.16 ± 0.51 | 38.03 ± 5.22 | 2.5 ± 0.25 ab | |

| Bio-0.006 | 29.15 ± 2.90 a | 9.04 ± 1.07 | 32.16 ± 9.07 | 1.7 ± 0.36 b | |

| Bio-0.008 | 27.73 ± 0.98 ab | 9.03 ± 0.65 | 32.26 ± 5.83 | 1.7 ± 0.21 b | |

| Bio-0.010 | 25.06 ± 1.25 b | 9.23 ± 1.02 | 36.79 ± 5.29 | 2.0 ± 0.45 ab | |

| PE-0.010 | 24.30 ± 2.01 b | 9.28 ± 0.11 | 40.38 ± 1.60 | 2.3 ± 0.50 a | |

| Significance | |||||

| Mulching (M) | * | ns | ns | * | |

| Year (Y) | * | ns | ns | ns | |

| M × Y | ns | ns | ns | ns | |

| Mulch Type | Thickness | Tensile Load (N) | Tensile Strength (MPa) | Elongation at Break (%) | Tensile Load (N) | Tear Strength (kN/m) | WVTR | |||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| (μm) | MD | TD | MD | TD | MD | TD | MD | TD | MD | TD | (g·m−2·24 h−1) | |

| Bio-0.006 | 6.16 ± 0.52 | 1.85 ± 0.23 | 1.15 ± 0.21 | 19.34 ± 2.19 | 15.08 ± 2.02 | 138.87 ± 68.66 | 443.48 ± 98.42 | 0.7 ± 0.07 | 1.14 ± 0.26 | 106.61 ± 13.54 | 137.23 ± 3.23 | 768.11 ± 13.1 |

| Bio-0.008 | 6.56 ± 0.73 | 2.16 ± 0.08 | 1.72 ± 0.34 | 29.92 ± 3.78 | 18.59 ± 3.35 | 296.36 ± 50.22 | 416.28 ± 46.49 | 0.88 ± 0.11 | 1.22 ± 0.17 | 112.46 ± 12.10 | 185.38 ± 25.75 | 714.47 ± 50.14 |

| Bio-0.010 | 11.58 ± 0.4 3 | 2.24 ± 0.25 | 1.75 ± 0.23 | 25.23 ± 5.31 | 18.25 ± 0.94 | 297.58 ± 25.49 | 473.16 ± 78.22 | 1.24 ± 0.16 | 1.59 ± 0.04 | 133.56 ± 17.41 | 184.61 ± 42.17 | 437.70 ± 16.76 |

| PE | 9.74 ± 0.27 | 2.99 ± 0.81 | 1.77 ± 0.03 | 32.67 ± 1.14 | 25.22 ± 3.43 | 287.88 ± 21.33 | 399.68 ± 12.54 | 1.71 ± 0.62 | 1.39 ± 0.02 | 152.21 ± 10.32 | 183.45 ± 6.11 | 354.15 ± 7.6 |

| Mulch Type | Thickness | Tensile Load (N) | Tensile Strength (MPa) | Elongation at Break (%) | Tensile Load (N) | Tear Strength (kN/m) | |||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| (μm) | MD | TD | MD | TD | MD | TD | MD | TD | MD | TD | |

| Bio-0.008 | 8.28 ± 0.66 | 1.25 ± 0.47 | 0.84 ± 0.19 | 15.06 ± 5.69 | 15.16 ± 2.57 | 49.18 ± 5.24 | 78.25 ± 7.91 | 0.50 ± 0.23 | 1.10 ± 0.34 | 45.23 ± 8.43 | 71.58 ± 24.49 |

| Bio-0.010 | 10.18 ± 0.24 | 1.89 ± 0.7 | 0.73 ± 0.25 | 18.51 ± 6.83 | 18.51 ± 2.21 | 83.90 ± 7.45 | 92.32 ± 8.49 | 0.71 ± 0.17 | 1.17 ± 0.24 | 51.14 ± 11.21 | 101.45 ± 22.52 |

| PE | 13.08 ± 0.41 | 2.93 ± 1.08 | 1.66 ± 0.09 | 24.16 ± 6.94 | 20.94 ± 1.78 | 251.10 ± 23.51 | 312.31 ± 28.49 | 1.73 ± 0.73 | 1.09 ± 0.22 | 113.31 ± 18.33 | 159.18 ± 17.08 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhao, H.; Wang, X.; Jin, P.; Zhou, J.; Wang, Y.; Dong, W.; Ren, H.; Li, B.; Gong, W. Effects of Biodegradable Mulch Films with Different Thicknesses on the Quality of Watermelon Under Protected Cultivation. Agronomy 2025, 15, 2336. https://doi.org/10.3390/agronomy15102336

Zhao H, Wang X, Jin P, Zhou J, Wang Y, Dong W, Ren H, Li B, Gong W. Effects of Biodegradable Mulch Films with Different Thicknesses on the Quality of Watermelon Under Protected Cultivation. Agronomy. 2025; 15(10):2336. https://doi.org/10.3390/agronomy15102336

Chicago/Turabian StyleZhao, Haikang, Xidong Wang, Penghui Jin, Jihua Zhou, Yan Wang, Wentao Dong, Huiqing Ren, Bingru Li, and Wenwen Gong. 2025. "Effects of Biodegradable Mulch Films with Different Thicknesses on the Quality of Watermelon Under Protected Cultivation" Agronomy 15, no. 10: 2336. https://doi.org/10.3390/agronomy15102336

APA StyleZhao, H., Wang, X., Jin, P., Zhou, J., Wang, Y., Dong, W., Ren, H., Li, B., & Gong, W. (2025). Effects of Biodegradable Mulch Films with Different Thicknesses on the Quality of Watermelon Under Protected Cultivation. Agronomy, 15(10), 2336. https://doi.org/10.3390/agronomy15102336