Mechanical Weed Control: Sensor-Based Inter-Row Hoeing in Sugar Beet (Beta vulgaris L.) in the Transylvanian Depression

Abstract

1. Introduction

2. Materials and Methods

2.1. Experimental Site and Design

- V1: Untreated control (UC);

- V2: Conventional herbicide application (HWC);

- V3: Mixture of 2× hoeing plus 3× chemical weed control method (HWC + MWC).

2.2. Implementation of the Herbicide Treatments

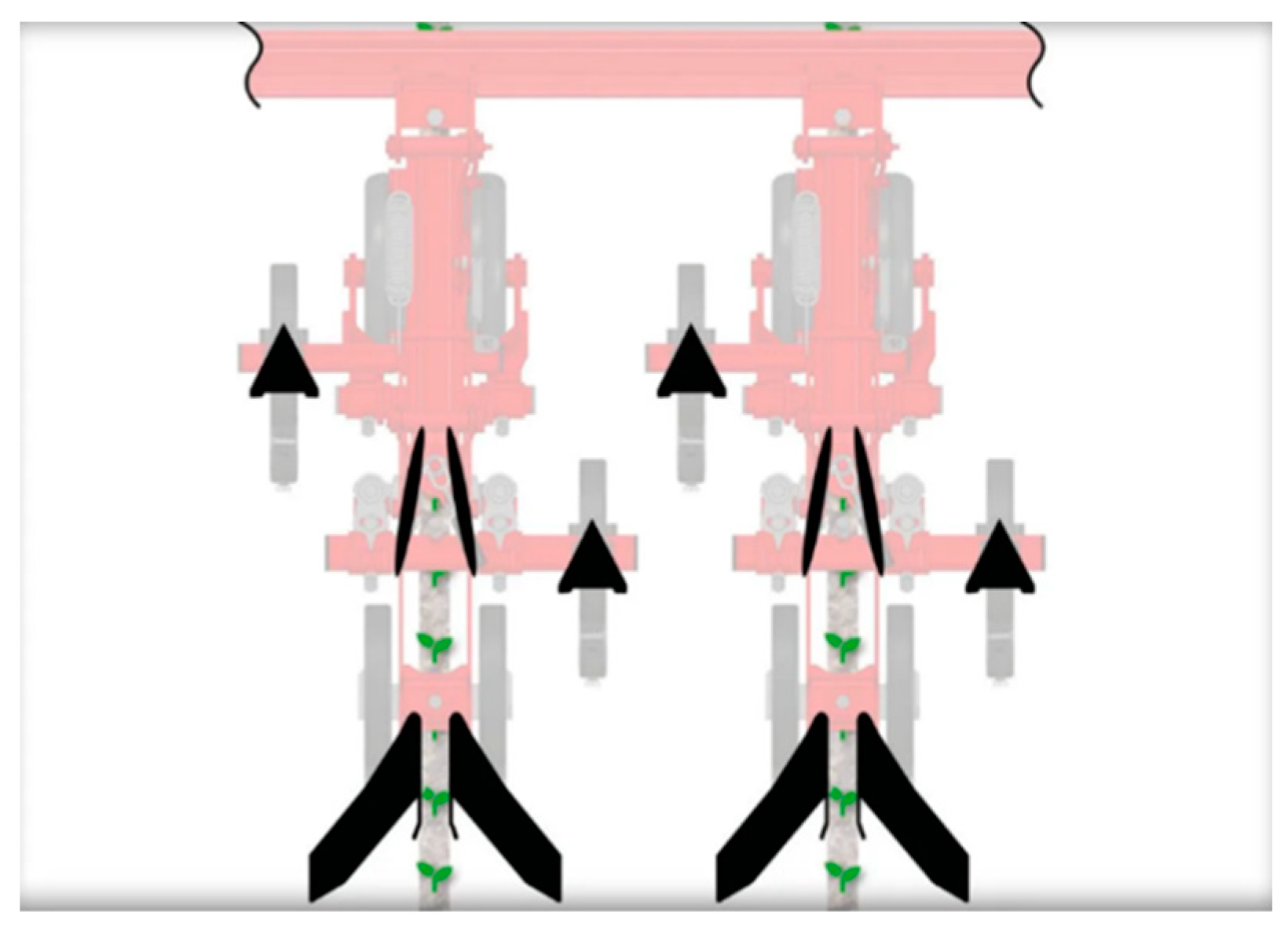

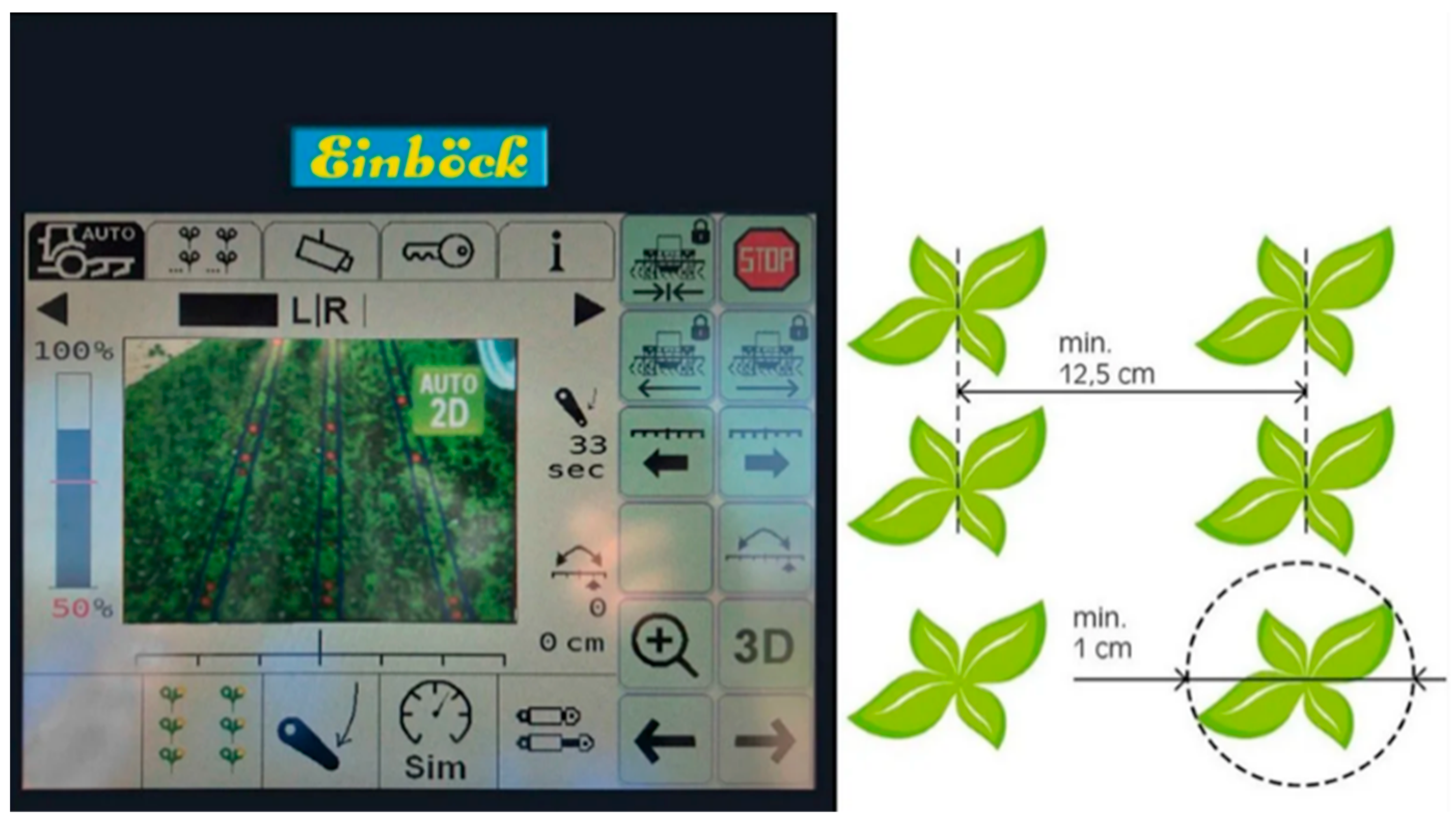

2.3. Description of the Camera-Based Row-Detection System Used in the Chopstar, Einböck

2.4. Implementation of the Mechanical Treatments

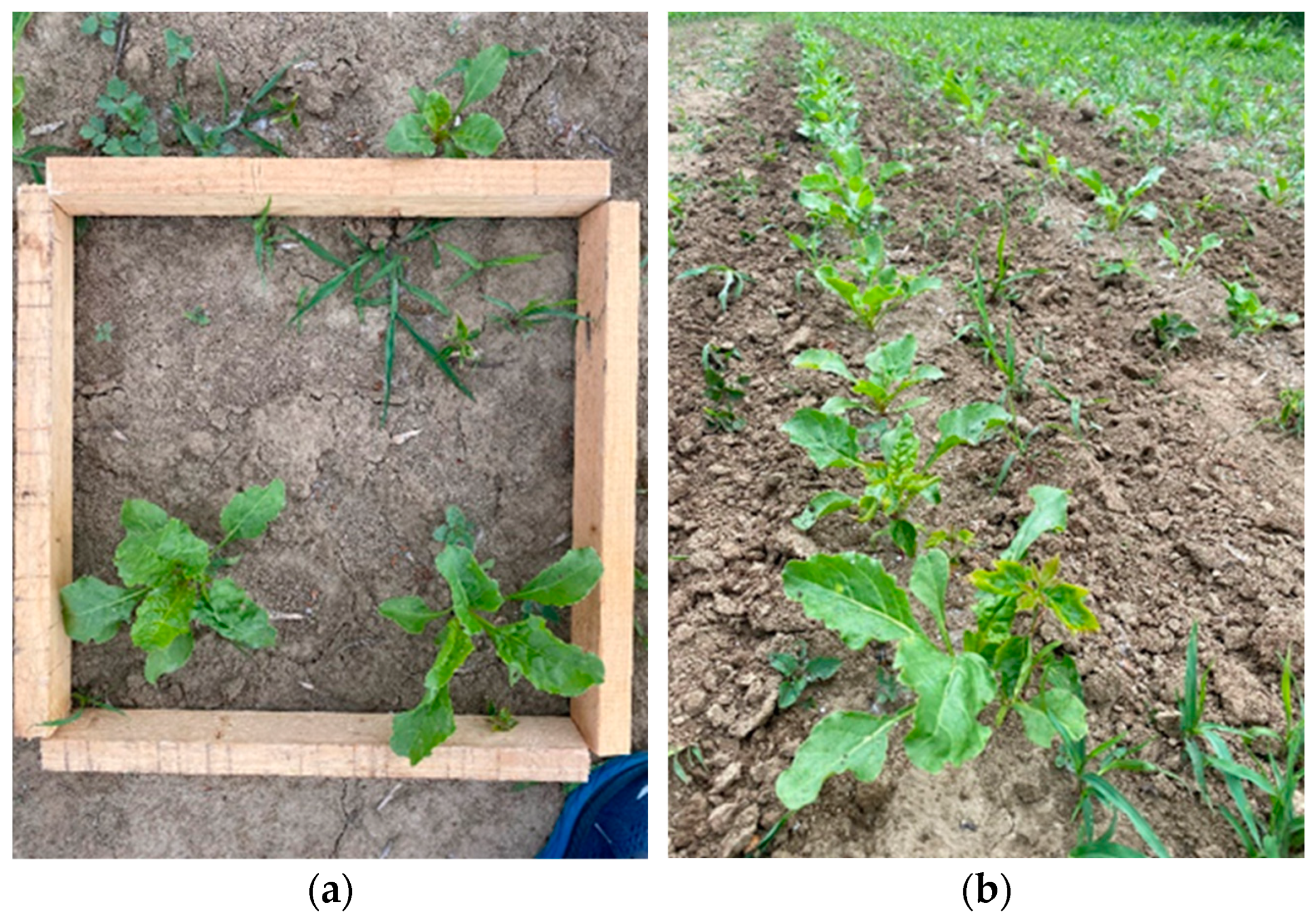

2.5. Data Acquisition

2.6. Data Analysis

3. Results

3.1. The Five Most Abundant Weed Species at Each Trial Site

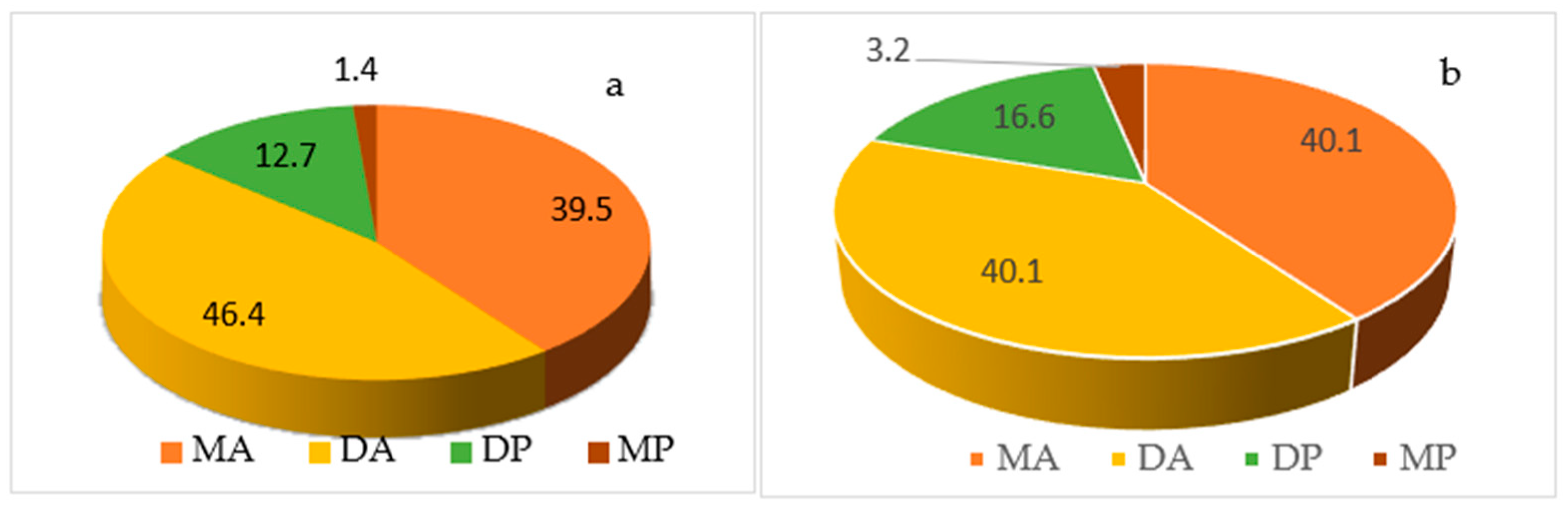

3.2. Weed Control Efficacy in 2021

3.3. Weed Control Efficacy in 2022

3.4. Sugar Beet Yield

4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Hamed, L.M.M.; Absy, R.; Elmenofy, W.; Emara, E.I.R. Enhancing Sugar Beet (Beta vulgaris L.) Yield and Quality: Evaluating the Efficiency of Chemical and Mechanical Weed Control Strategies. Agronomy 2023, 13, 2951. [Google Scholar] [CrossRef]

- Tataridas, A.; Kanatas, P.; Chatzigeorgiou, A.; Zannopoulos, S.; Travlos, I. Sustainable Crop and Weed Management in the Era of the EU Green Deal: A Survival Guide. Agronomy 2022, 12, 589. [Google Scholar] [CrossRef]

- Grzanka, M.; Sobiech, Ł.; Idziak, R.; Filipczak, A.; Skrzypczak, G. Impact of Chemical Weed Management in Sugar Beet (Beta vulgaris) on Productivity, Quality and Economics. J. Plant Prot. Res. 2023, 63, 459–467. [Google Scholar] [CrossRef]

- Ptak, M.; Skowrońska, A.; Pińkowska, H.; Krzywonos, M. Sugar Beet Pulp in the Context of Developing the Concept of Circular Bioeconomy. Energies 2022, 15, 175. [Google Scholar] [CrossRef]

- Çakmakçı, R.; Salık, M.A.; Çakmakçı, S. Assessment and Principles of Environmentally Sustainable Food and Agriculture Systems. Agriculture 2023, 13, 1073. [Google Scholar] [CrossRef]

- Wijerathna-Yapa, A.; Pathirana, R. Sustainable Agro-Food Systems for Addressing Climate Change and Food Security. Agriculture 2022, 12, 1554. [Google Scholar] [CrossRef]

- Geldermann, U.; Kogel, K.H. Nature’s Concept. The ‘New Agriculture’ Amidst Ecology, Economy and the Demythologization of the Gene. J. Agron. Crop Sci. 2002, 188, 368–375. [Google Scholar]

- Tudi, M.; Daniel Ruan, H.; Wang, L.; Lyu, J.; Sadler, R.; Connell, D.; Chu, C.; Phung, D.T. Agriculture Development, Pesticide Application and Its Impact on the Environment. Int. J. Environ. Res. Public Health 2021, 18, 1112. [Google Scholar] [CrossRef]

- Hillocks, R.J. Farming with Fewer Pesticides: EU Pesticide Review and Resulting Challenges for UK agriculture. Crop Prot. 2012, 31, 85–93. [Google Scholar] [CrossRef]

- Oliveira, M.C.; Osipitan, O.A.; Begcy, K.; Werle, R. Cover Crops, Hormones and Herbicides: Priming an Integrated Weed Management Strategy. Plant Sci. 2020, 301, 110550. [Google Scholar] [CrossRef]

- Bručienė, I.; Buragienė, S.; Šarauskis, E. Weeding Effectiveness and Changes in Soil Physical Properties Using Inter-Row Hoeing and a Robot. Agronomy 2022, 12, 1514. [Google Scholar] [CrossRef]

- Vasel, E.H.; Ladewig, E.; Märländer, B. Weed Composition and Herbicide use Strategies in Sugar Beet Cultivation in Germany. J. Cultiv. Plants 2012, 64, 112–125. [Google Scholar] [CrossRef]

- Kunz, C.; Weber, J.F.; Gerhards, R. Benefits of Precision Farming Technologies for Mechanical Weed Control in Soybean and Sugar Beet—Comparison of Precision Hoeing with Conventional Mechanical Weed Control. Agronomy 2015, 5, 130–142. [Google Scholar] [CrossRef]

- Gummert, A.; Laedewig, E.; Märländer, B. Guidelines for Integrated Pest Management in Sugar Beet Cultivation—Weed Control. J. Kult. 2012, 64, 105–111. [Google Scholar] [CrossRef]

- Bowman, G. Steel in the Field: A Farmer’s Guide to Weed Management Tools. Sustainable Agriculture Network Handbook, Series No. 2; U.S. Department of Agriculture: Beltsville, MD, USA, 1997. [Google Scholar]

- Van Der Weide, R.Y.; Bleeker, P.O.; Achten, V.T.J.M.; Lotz, L.A.P.; Fogelberg, F.; Melander, B. Innovation in Mechanical Weed Control in Crop Rows. Weed Res. 2008, 48, 215–224. [Google Scholar] [CrossRef]

- Melander, B.; Rasmussen, G. Effects of Cultural Methods and Physical Weed Control on Intra-row Weed Numbers, Manual Weeding and Marketable Yield in Direct- Sown Leek and Bulb Onion. Weed Res. 2001, 41, 491–508. [Google Scholar] [CrossRef]

- Zawada, M.; Legutko, S.; Gościańska-Łowińska, J.; Szymczyk, S.; Nijak, M.; Wojciechowski, J.; Zwierzyński, M. Mechanical Weed Control Systems: Methods and Effectiveness. Sustainability 2023, 15, 15206. [Google Scholar] [CrossRef]

- Bručienė, I.; Aleliūnas, D.; Šarauskis, E.; Romaneckas, K. Influence of Mechanical and Intelligent Robotic Weed Control Methods on Energy Efficiency and Environment in Organic Sugar Beet Production. Agriculture 2021, 11, 449. [Google Scholar] [CrossRef]

- Gerhards, R.; Späth, M.; Sökefeld, M.; Peteinatos, G.G.; Nabout, A.; Ayala, V.R. Automatic Adjustment of Harrowing Intensity in Cereals using Digital Image Analysis. Weed Res. 2001, 61, 68–77. [Google Scholar] [CrossRef]

- Plant, R.E. Site-Specific Management: The Application of Information Technology to Crop Production. Comput. Electron. Agric. 2001, 30, 9–29. [Google Scholar] [CrossRef]

- Khan, N.; Ray, R.L.; Sargani, G.R.; Ihtisham, M.; Khayyam, M.; Ismail, S. Current Progress and Future Prospects of Agriculture Technology: Gateway to Sustainable Agriculture. Sustainability 2021, 13, 4883. [Google Scholar] [CrossRef]

- Karunathilake, E.M.B.M.; Le, A.T.; Heo, S.; Chung, Y.S.; Mansoor, S. The Path to Smart Farming: Innovations and Opportunities in Precision Agriculture. Agriculture 2023, 13, 1593. [Google Scholar] [CrossRef]

- Radočaj, D.; Plaščak, I.; Jurišić, M. Global Navigation Satellite Systems as State-of-the-Art Solutions in Precision Agriculture: A Review of Studies Indexed in the Web of Science. Agriculture 2023, 13, 1417. [Google Scholar] [CrossRef]

- Gerhards, R.; Christensen, S. Real-Time Weed Detection, Decision Making and Patch Spraying in Maize, Sugarbeet, Winter Wheat and Winter Barley. Weed Res. 2003, 43, 385–392. [Google Scholar] [CrossRef]

- Tillett, N.D.; Hague, T.; Miles, S.J. Inter-Row Vision Guidance for Mechanical Weed Control in Sugar Beet. Comput. Electron. Agric. 2002, 33, 163–177. [Google Scholar] [CrossRef]

- Shen, N.; Chen, L.; Liu, J.; Wang, L.; Tao, T.; Wu, D.; Chen, R. A Review of Global Navigation Satellite System (GNSS)-Based Dynamic Monitoring Technologies for Structural Health Monitoring. Remote Sens. 2019, 11, 1001. [Google Scholar] [CrossRef]

- Slaughter, D.C.; Giles, D.K.; Downey, D. Autonomous Robotic Weed Control Systems: A Review. Comput. Electron. Agric. 2008, 61, 63–78. [Google Scholar] [CrossRef]

- Nørremark, M.; Griepentrog, H.W.; Nielsen, J.; Søgaard, H.T. Evaluation of an Autonomous GPS-based System for Intra-row Weed Control by Assessing the Tilled Area. Precis. Agric. 2012, 13, 149–162. [Google Scholar] [CrossRef]

- Machleb, J.; Peteinatos, G.; Kollenda, B.; Andújar, D. Sensor-Based Mechanical Weed Control: Present State and Prospects. Comput. Electron. Agric. 2020, 176, 105638. [Google Scholar] [CrossRef]

- Fountas, S.; Malounas, I.; Athanasakos, L.; Avgoustakis, I.; Espejo-Garcia, B. AI-Assisted Vision for Agricultural Robots. AgriEngineering 2022, 4, 674–694. [Google Scholar] [CrossRef]

- Rašovský, M.; Pačuta, V.; Ducsay, L.; Lenická, D. Quantity and Quality Changes in Sugar Beet (Beta vulgaris Provar. Altissima Doel) Induced by Different Sources of Biostimulants. Plants 2022, 11, 2222. [Google Scholar] [CrossRef] [PubMed]

- Machleb, J.; Peteinatos, G.G.; Sökefeld, M.; Gerhards, R. Sensor-Based Intrarow Mechanical Weed Control in Sugar Beets with Motorized Finger Weeders. Agronomy 2021, 11, 1517. [Google Scholar] [CrossRef]

- Restuccia, A.; Scavo, A. Sustainable Weed Management. Plants 2023, 12, 1673. [Google Scholar] [CrossRef] [PubMed]

- Pannacci, E.; Bartolini, S. Evaluation of Chemical Weed Control Strategies in Biomass Sorghum. J. Plant Prot. Res. 2018, 58, 404–412. [Google Scholar] [CrossRef]

- Ghatrehsamani, S.; Jha, G.; Dutta, W.; Molaei, F.; Nazrul, F.; Fortin, M.; Bansal, S.; Debangshi, U.; Neupane, J. Artificial Intelligence Tools and Techniques to Combat Herbicide Resistant Weeds—A Review. Sustainability 2023, 15, 1843. [Google Scholar] [CrossRef]

- Xie, D.; Chen, L.; Liu, L.; Chen, L.; Wang, H. Actuators and Sensors for Application in Agricultural Robots: A Review. Machines 2022, 10, 913. [Google Scholar] [CrossRef]

- Triantafyllou, A.; Sarigiannidis, P.; Bibi, S. Precision Agriculture: A Remote Sensing Monitoring System Architecture. Information 2019, 10, 348. [Google Scholar] [CrossRef]

- USAMV. PoliFact, ANOVA and Duncan’s Test PC Program for Variant Analyses Made for Completely Randomized Polyfactorial Experiment; USAMV: Cluj-Napoca, Romania, 2020. [Google Scholar]

- Rasmussen, J. A Model for Prediction of Yield Response in Weed Harrowing. Weed Res. 1991, 31, 401–408. [Google Scholar] [CrossRef]

- Ministry of Agriculture and Rural Development. Available online: https://www.madr.ro/culturi-de-camp/plante-tehnice/sfecla-de-zahar.html (accessed on 14 November 2023).

- Bhadra, T.; Paul, S.K. Weed Management in Sugar Beet: A Review. Fundam. Appl. Agric. 2020, 5, 147–158. [Google Scholar] [CrossRef]

- Bayat, M.; Kavhiza, N.; Orujov, E.; Zargar, M.; Akhrarov, M.; Temewei, A.G. Integrated Weed Control Methods Utilizing Planting Pattern in Sugar Beet. Res. Crops 2019, 20, 413–418. [Google Scholar] [CrossRef]

- Idziak, R.; Sobczak, A.; Waligóra, H.; Szulc, P.; Majchrzak, L. Effect of Multifunctional Adjuvants on Physical and Chemical Features of Spray Liquid and Efficacy in Sugar Beet. Appl. Sci. 2023, 13, 8768. [Google Scholar] [CrossRef]

- Tahat, M.M.; Alananbeh, K.M.; Othman, Y.A.; Leskovar, D.I. Soil Health and Sustainable Agriculture. Sustainability 2020, 12, 4859. [Google Scholar] [CrossRef]

- Lotz, L.; Van Der Weide, R.; Hoereman, G.; Joosten, L. Weed Management and Policies: From Prevention and Precision Technology to Certifying Individual Farms. In Proceedings of the 12th EWRS Symposium, Wageningen, The Netherlands, 24–27 June 2022; pp. 2–3. [Google Scholar]

- Melander, B.; Rasmussen, I.A.; Bàrberi, P. Integrating Physical and Cultural Methods of Weed Control-Examples from European Research. Weed Sci. 2005, 53, 369–381. [Google Scholar] [CrossRef]

| Month/Year | 2021 | 2022 |

|---|---|---|

| mm | ||

| March | 50.21 | 17.10 |

| April | 36.12 | 69.42 |

| May | 82.04 | 48.67 |

| June | 28.41 | 8.71 |

| July | 49.32 | 18.63 |

| August | 27.51 | 35.22 |

| September | 8.06 | 70.42 |

| Total | 281.67 | 268.17 |

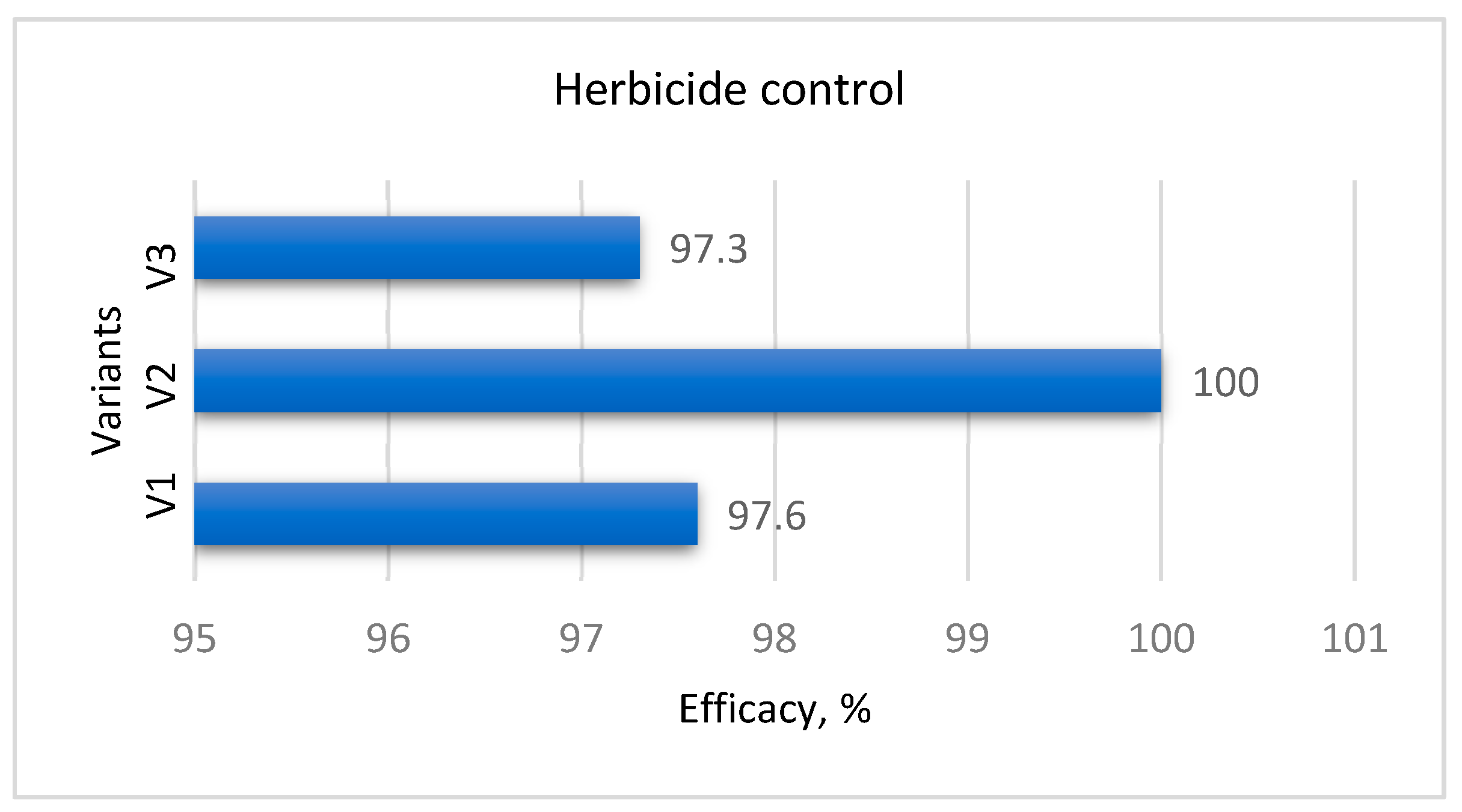

| No. | Variants | Description |

|---|---|---|

| V1 | Untreated control (UC) | No weed control |

| V2 | Conventional herbicide application (HWC) | 3× Chemical weed control only; spraying 3 times with a mix of 3 herbicides and 5 different substances |

| V3 | Mixture of 2× hoeing plus 3× chemical weed control method (HWC + MWC) | 3× Chemical weed control only; spraying 3 times with a mix of 3 herbicides and 5 different substances + 2× mechanical weed control with goose feet at the stages of 6 leaves (BBCH 19) and 9 leaves (BBCH 3) of sugar beet |

| BBCH 2021 | BBCH 2022 | Active Ingredients | Product Name | FM | CT g L−1 | AR, g ha−1 | Supplier |

|---|---|---|---|---|---|---|---|

| 10, 14, 19 | 10, 14, 19 | ethofumesate | Betanal tandem | SC | 190 | 285 | Bayer Crop Science |

| 10, 14, 19 | 10, 14, 19 | phenmedipham | Betanal Tandem | SC | 200 | 300 | Bayer Crop Science |

| 03, 10, 14 | 10, 14, 19 | metamitron | Goltix | SC | 700 | 630 | Adama |

| 03 | glyphopsate | Clean up | SL | 360 | 1080 | Nufarm | |

| 10, 14, 19 | lenacil | Venzar 500 | SC | 500 | 125 | FMC Corporation | |

| 14, 19 | clopyralid | Lontrel 300 | SL | 300 | 225 | Corteva Agriscience | |

| 19 | 19 | quizalofop-p-tefuril | Pantera 40 | EC | 40 | 40 | Arysta Life science |

| No. | 2021 | 2022 | ||

|---|---|---|---|---|

| Weed Species | % | Weed Species | % | |

| 1 | Matricaria chamomilla | 29 | Polygonum aviculare | 23 |

| 2 | Cirsium arvense | 21 | Galium aparine | 21 |

| 3 | Chenopodium album | 19 | Capsella bursa-pastoris | 18 |

| 4 | Xanthium italicum | 15 | Echinochloa crus-galli | 16 |

| 5 | Setaria viridis | 12 | Veronica persica | 12 |

| 6 | Other species | 4 | Other species | 10 |

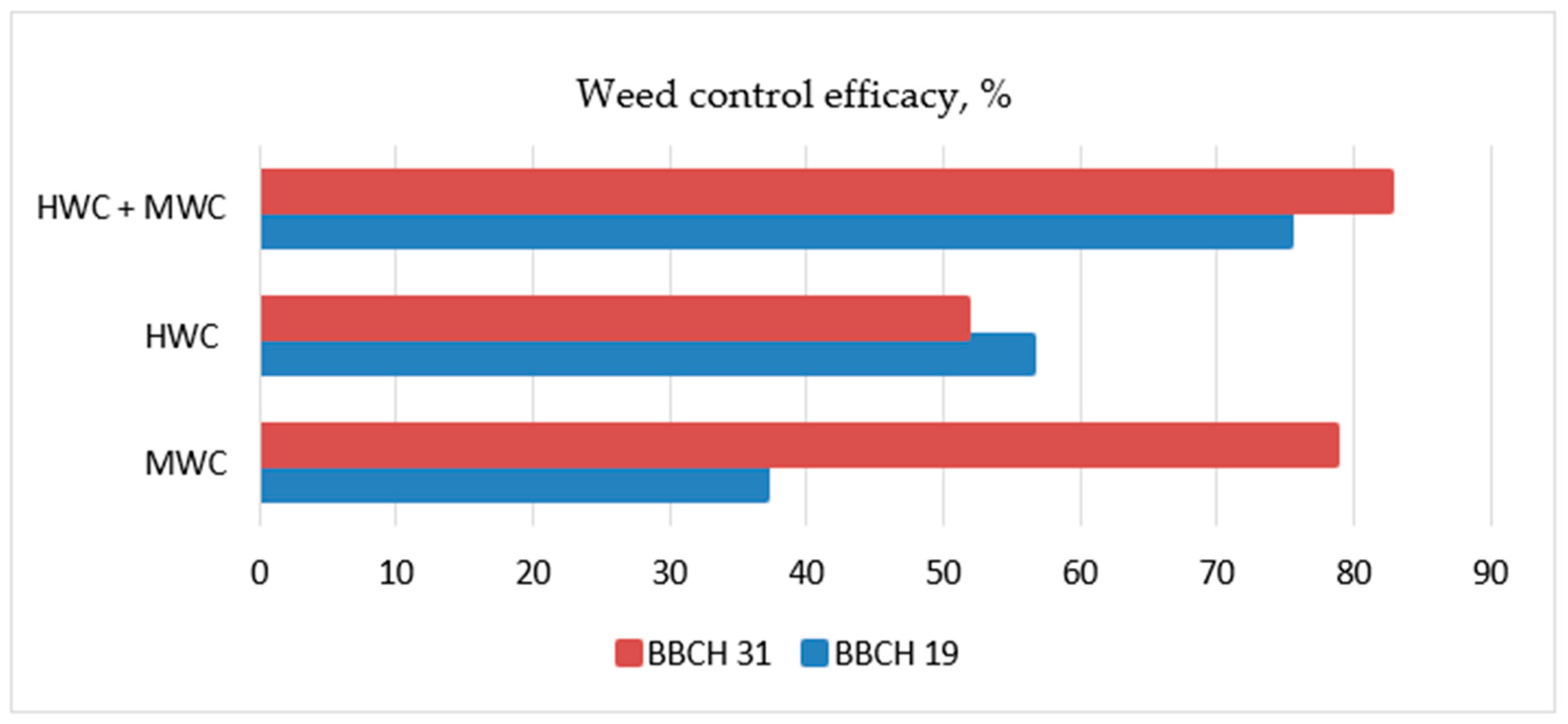

| Treatment BBCH 19 | Weed Density (Plants m−2) | WCE, % |

|---|---|---|

| UC | 49.67 a | 100 (Ct.) a |

| MWC | 31.33 b | 36.93 c |

| HWC | 21.67 ab | 56.37 ab |

| MWC + HWC | 12.33 c | 75.20 ab |

| Treatment BBCH 31 | Weed Density (Plants m−2) | WCE, % |

|---|---|---|

| UC | 108.33 a | 100 (Ct.) a |

| MWC | 10.67 c | 78.52 b |

| HWC | 24.0 b | 51.68 c |

| MWC + HWC | 8.67 c | 82.55 b |

| Treatment/ Year | Indicatory | UC | MWC | HWC | HWC + MWC |

|---|---|---|---|---|---|

| 2021 | Yield, t ha−1 | 24.18 a | 36.41 b | - | 48.57 c |

| Differences, ± | Ct. | +12.23 ** | - | +24.39 *** | |

| % | 100 (Ct.) | 150.58 | - | 200.87 | |

| 2022 | Yield, t ha−1 | 28.12 a | 42.34 b | 50.22 c | 56.48 c |

| Differences, ± | Ct. | +14.22 ** | +22.10 *** | +28.36 *** | |

| % | 100 (Ct.) | 150.57 | 178.59 | 200.86 | |

| 2021: LSD p 5% = 5.41 t ha−1; LSD p 1% = 12.13 t ha−1; LSD p 0.1% = 14.41 t ha−1 2022: LSD p 5% = 6.21 t ha−1; LSD p 1% = 10.51 t ha−1; LSD p 0.1% = 16.31 t ha−1 | |||||

| Year | UM | 2015 | 2016 | 2017 | 2018 | 2019 | 2020 |

|---|---|---|---|---|---|---|---|

| Surface | 1000 × ha | 26.59 | 24.92 | 28.20 | 25.72 | 22.73 | 22.76 |

| Medium yield | t ha−1 | 39.14 | 40.61 | 41.64 | 38.03 | 40.35 | 34.20 |

| Total yield | 1000 × t | 1040.65 | 1012.19 | 1174.50 | 978.27 | 917.16 | 778.30 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Parasca, S.C.; Spaeth, M.; Rusu, T.; Bogdan, I. Mechanical Weed Control: Sensor-Based Inter-Row Hoeing in Sugar Beet (Beta vulgaris L.) in the Transylvanian Depression. Agronomy 2024, 14, 176. https://doi.org/10.3390/agronomy14010176

Parasca SC, Spaeth M, Rusu T, Bogdan I. Mechanical Weed Control: Sensor-Based Inter-Row Hoeing in Sugar Beet (Beta vulgaris L.) in the Transylvanian Depression. Agronomy. 2024; 14(1):176. https://doi.org/10.3390/agronomy14010176

Chicago/Turabian StyleParasca, Sergiu Cioca, Michael Spaeth, Teodor Rusu, and Ileana Bogdan. 2024. "Mechanical Weed Control: Sensor-Based Inter-Row Hoeing in Sugar Beet (Beta vulgaris L.) in the Transylvanian Depression" Agronomy 14, no. 1: 176. https://doi.org/10.3390/agronomy14010176

APA StyleParasca, S. C., Spaeth, M., Rusu, T., & Bogdan, I. (2024). Mechanical Weed Control: Sensor-Based Inter-Row Hoeing in Sugar Beet (Beta vulgaris L.) in the Transylvanian Depression. Agronomy, 14(1), 176. https://doi.org/10.3390/agronomy14010176