Abstract

Composting is an interesting option to recycle big quantities of organic waste because it helps to mitigate different environmental problems. Complementary characteristics of rice straw (RS) and sewage sludge (SS) create a suitable mixture to be used in a composting process. This work studies industrial-scale RS and SS composting to assess both its viability and optimization. Windrow composting was conducted during two seasons. The complete characterisation (moisture, pH, electrical conductivity, total, oxidisable and water-soluble organic carbon, humic substances, organic and mineral nitrogen, macronutrients, micronutrients, heavy metals) of starting materials, samples taken periodically and final composts were carried out. During the first season, an RS:SS ratio of 1:8 (w:w fresh weight) was used, which led to a process with adequate temperatures for biodegradation, but not for ensuring materials’ sanitation. During the second season, the RS:SS ratio was increased (1:6) to enhance the energy process and, thus, temperatures. Although this increase took place, degradation slowed down as oxidisable organic carbon and water-soluble organic carbon indicated. During both seasons, final composts presented adequate pH, high N-richness, and interesting macro- and micronutrient values. Notwithstanding, they also presented certain salinity and high ammonium contents, which must be considered for their field application. The obtained composts have interesting agronomic characteristics, which suggest their potential as an alternative to conventional fertilisers.

1. Introduction

Within the EU Green Deal framework with its Farm to Fork Strategy [1], an integrated nutrient management action plan will be drawn up. The objective of this plan is to reduce and prevent further pollution from excessive fertiliser use and to foster the recycling of nutrients from different organic waste kinds as fertilisers. This will contribute to delivering the “zero-pollution ambition”. This Strategy aims to reward farmers who have already moved towards sustainable practices. Farming practices that remove greenhouse gas emissions from the atmosphere contribute to the climate neutrality objective and should be recognised via either the Common Agriculture Policy (CAP) or other public initiatives [2].

Rice (Oryza sativa) is a cereal of primary importance for human consumption. Spain is one of the main rice-producing countries in Europe, with a cultivated rice area of 103,000 ha and annual production of around 750,000 t. The Valencia province is responsible for 16% of total Spanish production [3], which is cultivated mainly in the Albufera Natural Park (ANP). This rice production generates large amounts of rice straw after harvesting, with about 100 million kg of waste per year. To eliminate it, rice straw open burning in fields is commonly practiced by rice farmers. However, this activity negatively impacts both the environment and public health. Burning straw in situ may contribute significantly to air pollution levels in surrounding areas because CO2, CH4, CO, NOX, SO2, black carbon, organic carbon, and coarse and fine particles, are emitted, which cause local population allergic, respiratory and cardiorespiratory problems [4,5] on the one hand, and increase the carbon footprint on the other hand. As a consequence, this practice is increasingly being restricted in many countries of the world. In Valencia, rice straw burning is now limited [6]. The delivery of CAP agri-environmental aid to farmers is conditioned to the use of alternative management systems. Rice straw can be incorporated into soil but, unlike most cereals, this material is resistant to bacterial decomposition due to its poor wettability and its composition, being formed by cellulose (38.3%), hemicelluloses (31.6%), lignin (11.8%) and silica (up to 20%) [7,8]. Furthermore, as rice fields are inundated shortly after harvest, straw decomposition is hindered, which generates unpleasant odours and irrigation channels are clogged if straw has not been ploughed deep enough [9]. Alternative management is to remove the straw from fields and use it in construction materials, paper production, mushroom production, or as an energy source, animal feed and poultry litter [10]. However, removing straw is expensive [9].

Furthermore, the continuously growing population and more economic activities produce enormous quantities of sewage sludge. This waste results from urban wastewater treatment. The amount of sewage sludge generated in Spain is around 1.2 million tons per year (dry matter) [11]. This waste can be used for agriculture and building materials, eliminated by incineration or left to accumulate in rubbish dumps. Its composition is variable depending on its origin and previous treatment. In agriculture, it is a source of organic matter and nutrients, such as nitrogen (N) and phosphorus (P). Its agronomic value and its negative aspects (heavy metals content and pathogenic microorganisms) have been extensively studied [12,13,14]. Furthermore, its direct application to fields has different disadvantages, such as odour nuisances, high-level moisture, and complicated storage and handling [15].

Composting is an option to recycle big quantities of organic waste. This biooxidative process involves the mineralisation and partial humification of organic matter, which leads to a stabilised final product free of phytotoxicity and pathogens [16]. Within the circular economy and sustainable agriculture framework, soil amendment with compost is an agronomically interesting practice as well as an attractive waste management strategy.

Sewage sludge composting is a common practice that needs bulking agents due to the high moisture, small particle size and pasty texture of sludge. These bulking agents decrease moisture content, allow adequate gas exchange and prevent excessive compaction [17]. Many authors have studied the composting process on different sewage sludge scales with distinct materials [18,19,20,21], and the composting process of rice straw with other waste types [22,23,24]. However, despite the complementary characteristics of sewage sludge and rice straw creating a suitable mixture to be used in the composting process [25], all this has been poorly studied. Roca-Pérez et al., (2009) [26] and Ferrer et al., (2002) [27] studied the composting of sewage sludge with rice straw exclusively in pilot- and medium-scale experiments, respectively. Further research on an industrial scale is needed to confirm the viability of these processes on a larger scale. Small- and medium-scale trials can provide valuable information, but composting processes can vary significantly on a larger scale due to factors like feedstock variability, process management and resource availability. Therefore, industrial-scale studies are necessary to ensure the viability and profitability of composting processes and to allow their optimal implementation.

The aim of this work was to, therefore, study the composting process of rice straw and sewage sludge in industrial-scale experiments to optimise it and to achieve the recycling and valorisation of such organic waste.

2. Materials and Methods

2.1. Composting Process, Materials and Conditions

Experiments were conducted using mixtures of rice straw (RS) and sewage sludge (SS). For the purposes of this study, the composting process was evaluated during two different seasons, season 1 (S1) and season 2 (S2), with two replicates with one pile each. Composting experiments started in September 2019 during S1 and in June 2020 during S2. The ratios of the waste types utilised during each season were 1:8 and 1:6 RS:SS (w:w fresh weight) during S1 and S2, respectively.

Trials were carried out at the ‘La Vintena’ commercial facility (Depuración de Aguas del Mediterráneo, DAM) sited in Carcaixent (39°6′32.207” N; 0°29′6.87” W), Valencia. In this composting plant, which covers an area of 21,000 m2, windrows were prepared in paved and covered open buildings using a front-end loader. During both seasons, RS (RS1: RS used in the two replicates of S1 and RS2: RS employed in the two replicates of S2) came from the rice commercial orchards in the ANP. The anaerobically digested SS for S1 (SS1: SS used in the two replicates of S1) was obtained from the Alzira-Carcaixent DAM Water Treatment Plant (39°6′32.312” N; 0°29′12.857” W) and for S2 (SS2: SS used in the two replicates of S2), it was obtained from the Pinedo DAM Water Treatment Plant (39°26′7.489” N; 0°20′37.332” W), both situated close to the city of Valencia. The dimensions of each pile at the beginning of processes, the shape of a triangular prism, were about 15 m long × 4.0 m wide × 1.70 m high, which corresponded to a volume of 102 m3. Each windrow was constructed in duplicate with 64.7 kg (7.20 kg RS and 57.5 kg SS) and 42.7 kg (6.14 kg RS and 36.5 kg SS) on average of waste during S1 and S2, respectively (fresh weight). These raw materials were weighed before being piled. Composting was carried out without modifying the usual protocol followed in the above-cited facility. The researchers did not attempt to influence the course of the composting process.

2.2. Process Monitoring, Sampling and Preparation

Pile temperatures were measured automatically every hour at four points using thermometric probes connected to loggers inserted at a depth of 1 m (KTT 220, Kimo, Mumbai, India). The average daily environment temperatures during the experimental periods were obtained from the meteorological station of the same municipality of the Carcaixent study site.

At the beginning of trials, raw material samples were collected to be characterised: four of RS and four of SS. During the composting process, eight samples were taken from the east and west sides of each pile at different times. They were composed of six subsamples taken at the top, middle and bottom in different pile locations. During S1, compost piles were sampled at 0, 7, 16, 27, 37, 50, 63, 72, 84, 94, 104, 114, 127 and 140 days of the composting process. During S2, samples were taken at 0, 7, 18, 30, 42, 52, 63, 73, 84, 98, 113, 127 and 165 days of composting. In both cases, the final sample was sieved compost. Each sample was mixed uniformly and divided into two parts. One part was refrigerated (4 °C) until analyses were performed. The other was oven-dried (60 °C), ground with a cutting mill (SM 100, Retsch, Haan, Germany), then sieved through a 0.25 mm mesh sieve and stored for further analyses.

2.3. Analytical Determinations

Determinations were: granulometry (25 mm, 5 mm and 2 mm), moisture (drying at 105 °C to constant weight), pH (1:25 water extract), electrical conductivity [(EC), 1:5 water extract], total organic carbon [(TOC), ashing at 560 °C], oxidisable organic carbon [(OOC), oxidisation with K2Cr2O7], water-soluble organic carbon [(WSOC), 1:10 water extract], humic substances [(HS), extraction with 0.1 N Na2P2O7 + NaOH], humic acids [(HA), precipitation of humic substances extract at pH 2], organic N (Kjeldahl method), ammonium and nitrate N (2 N KCl extract), macronutrients (HCl digestion), micronutrients and heavy metals (aqua regia digestion) and chromium (Cr) VI (colourimetry with s-diphenylcarbazide) following the Official Methods of the Spanish Ministry of Agriculture, Food and Fisheries [28] with minor modifications (used reactives Panreac Co., Ltd., Barcelona, Spain).The humic acids E4/E6 ratio was also determined by the method described by Chen et al., (1977) [29]. Escherichia coli and Salmonella spp. were determined following the standard procedures ISO 7251:2005 [30] and ISO 6579-1:2017 [31], respectively.

pH was measured with a pH meter (Basic 20, Crison, Barcelona, Spain), EC by a conductimeter (Sensor+ EC7, Hach, Barcelona, Spain), WSOC content by a Total Organic Carbon Analyzer (TOC-VCSN, Shimadzu, Kyoto, Japan), the humic acids E4/E6 ratio and Cr VI by a UV-VIS spectrophotometer (UV-1800, Shimadzu, Kyoto, Japan), organic and mineral N using a 8200 Kjeltec (Foss, Tecator AB, Hoeganaes, Sweden) and the total concentrations of P, potassium (K), calcium (Ca), magnesium (Mg), sodium (Na), iron (Fe), copper (Cu), manganese (Mn), zinc (Zn), nickel (Ni), lead (Pb), cadmium (Cd), mercury (Hg) and Cr were measured in simultaneous inductively coupled plasma atomic emission spectrometry (iCAP-AES 6000, Thermo Scientific, Cambridge, UK). The C/N ratio values were calculated with the values of total organic carbon and total nitrogen (TN). TN was calculated by adding the three determined forms (organic, ammonium and nitrate).

2.4. Statistical Analysis

Data were subjected to an ANOVA to test for significant differences between treatments. Before carrying out any statistical analysis, the normality of all the data was studied using the Kolmogorov–Smirnov test. If the hypothesis of normality was discarded at the 95% confidence level, data were transformed according to the logarithmic function. The variance of the transformed or non-transformed data was partitioned with a variance analysis (ANOVA, Statgraphics Centurion for Windows, Statistical Graphics Corp., The Plains, VA, USA) into one source of variability. The significance of the comparisons made between seasons was analysed with Fisher’s least significance difference (LSD) test at p < 0.05.

3. Results and Discussion

3.1. Characteristics of the Raw Materials and Initial Mixtures

Moisture, pH and EC of RS, SS and the initial mixtures (IMs) were initially characterised independently during both seasons (Table 1). Although RS was harvested in rice fields during different seasons and sludge did not come from the same wastewater treatment plants (WWTPs), the values obtained for these parameters did not statistically differ, except for moisture. RS2 presented significantly higher moisture values (16.6%) than RS1 (7.03%). Despite these differences, in both RS:SS ratios (1:8 and 1:6) RS counteracted the excessive moisture of SS. The IMs showed adequate contents with 73.5% during S1 (IM1) and 69.9% during S2 (IM2) when taking into account that a range of 60–70% provides maximum microbial activity [32]. The pH of both IMs was suitable for starting the composting process (7.22 in IM1 and 7.53 in IM2). Although the microorganisms responsible for degradation act within wide pH ranges, the recommended range for this process is around 5.5 to 8.5 because most of the enzymes present in microorganisms are active within this pH range [33]. The larger amount of RS used in IM2 together with slightly, but not significantly, higher pH values in RS2 generated a mixture with significantly higher alkaline pH values. In addition, IM2 showed lower conductivity (5.52 dS/m vs. 8.12 of IM1), possibly due to the lower conductivity of the raw materials, but it was not possible to determine EC in RS given its hygroscopic nature.

Table 1.

Moisture, electrical conductivity and pH of raw materials and initial mixtures.

One of the main constituents of composted organic waste is organic carbon. Total carbon consists of TOC and inorganic carbon in the form of carbonates and bicarbonates. TOC generally represents more than 90% of the total carbon in composts [34]. No significant differences in the TOC and OOC concentrations were observed for IMs, although there were differences in these parameters for SS1 and SS2 and the proportion of straw was higher in S2 (Table 2).

Table 2.

Total organic carbon, oxidisable organic carbon, humic substances, humic acids and fulvic acids concentrations of raw materials and initial mixtures.

Humic substances, a major reservoir of organic carbon in soils and aquatics environments, are divided into humin (a fraction that is not soluble in water at any pH), humic acids (a fraction that is not soluble in water under acidic conditions) and fulvic acids (soluble in water under all pH conditions) [35]. The results obtained for HS, HA and FA are shown in Table 2. RS2 had significantly higher HS and HA concentrations than RS1. These higher concentrations, together with the higher proportion of straw used during S2, produced an IM with a significantly larger amount of HS and HA.

Microorganisms in composting processes require not only an energy source (degradable organic carbon) but also N for their development and activity [16]. Table 3 shows the organic, mineral and total N concentrations and the C/N ratio. The total N concentrations in both raw materials and mixtures showed significant differences between seasons. Organic N in RS1 (0.775%) was almost half that in RS2 (1.33%), probably due to RS1 coming from the previous season and the important N losses that occurred during its storage. These differences were not detected in the IMs because N was provided mainly by SS. In mineral N, only significant differences were seen in NO3−-N. Indeed SS2 showed lower values than SS1 (453 mg kg−1 and 2047, respectively), which resulted in significantly lower NO3−-N in IM2 than in IM1. An adequate C/N ratio in IMs is fundamental for the appropriate degradation of materials by means of microbiological activity throughout the process. The IM1 and IM2 C/N ratios were 13.5 and 12.1, respectively, which are far from 25 to 30 which is generally considered optimal. However, in a study about the influence of different C/N ratios on the microbiological activity of distinct RS and SS blends, Roca-Pérez et al., (2005) [36] indicate C/N values of around 17 as being adequate because they lead to greater microorganism growth and better mixture homogeneity with, consequently, greater microbiological attachment. Likewise, Ferrer et al., (2002) [27] adequately composted SS and RS in a study about the effects of urea addition and municipal solid waste (MSW)-compost extract inoculation during SS and RS composting, for which they used mixtures with C/N ratios ranging from 11.8 to 13.7.

Table 3.

Organic, mineral and total nitrogen concentrations, C/N ratio and macronutrient concentrations of raw materials and initial mixtures.

SS showed a higher concentration of macronutrients than RS, except for K (Table 3). This low content was due to the fact that K is highly soluble in water and remains dissolved in the effluent during the wastewater treatment process [37]. SS showed wide variability in all the elements due to the different origins of the wastewater treated in WWTPs. Similarly, RS contents were also variable because they came from harvests of different campaigns. The values agree with the range obtained by Iranzo et al., (2004), [25] during the characterisation of 30 RS and 7 SS as composting materials. Significant differences in raw materials led to different concentrations in the IMs, except for Mg. Both mixtures presented interesting macronutrient values, especially P, which was higher than those reported in previous studies [26].

SS presented substantially higher micronutrient and heavy metals contents than RS (Table 4). Heavy metals are normal in industrial and domestic wastewater and come from different sources of waste, such as batteries, paints, fertilisers, pesticides, pigments and galvanised pipes [38,39]. Both SS did not exceed the quality standards in force at the time for treated SS (threshold concentrations of Cd, Cu, Ni, Pb, Zn and Cr are 20, 1000, 300, 750, 2500 and 1000 mg kg−1 dry weight for soils with pH ˂ 7 and 40, 1750, 400, 1200, 4000 and 1500 dry weight for soils with pH > 7 respectively) [40] and fertilising products (threshold concentrations of Cd, Cu, Ni, Pb, Zn and Cr are 0.7, 70, 25, 45, 200 and 70 mg kg−1 dry weight for the higher quality products (class A); 2, 300, 90, 150, 500 and 250 mg kg−1 dry weight for the medium quality products (class B) and 3, 400, 100, 200, 1000 and 300 mg kg−1 dry weight for the lower quality products (class C) respectively) [41]. In macronutrient contents, significant differences in raw materials led to different concentrations in the mixtures of almost all the micronutrients (Zn, Ni, Pb, Cd and Cr). Similar Fe contents were obtained in both IMs in spite of significant differences in raw materials. On the contrary, IM1 and IM2 differed in Cu and Mn, but neither straws nor sludges were significantly different, probably due to the distinct RS:SS ratios.

Table 4.

Micronutrients and heavy metals concentrations of raw materials and initial mixtures.

3.2. Composting Process

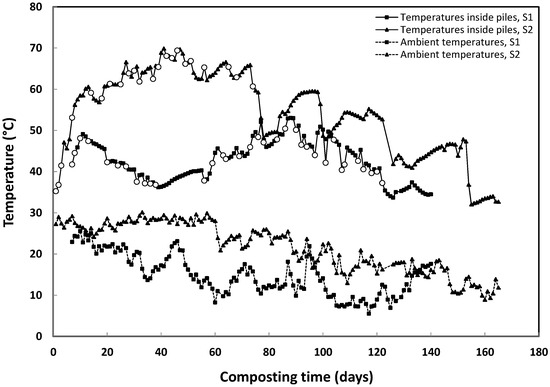

Temperature and aeration are essential parameters in a composting process [17]. The composting material was turned and mixed by a bridge turner for its cooling and aeration 34 and 22 times during S1 and S2, respectively. Turning was carried out according to the temperature measured every hour daily. In the beginning, turning was conducted very frequently to achieve the homogenisation of materials. Proper aeration allows temperature control, eliminates excess moisture and CO2, and provides O2 for biological processes [16]. The temperature values obtained inside each pile during the processes, and the ambient temperatures and turnings carried out during both seasons, are shown in Figure 1. During S1, the process occurred within the upper range of mesophilic temperatures (T < 55 °C). These temperatures allow greater mass loss because they maximise the biodegradation rate [42]. However, thermophilic temperatures (T > 55 °C) were not reached because the maximum value was 53 °C, obtained on days 88 and 89. Although this temperature may be insufficient to ensure the complete sanitation of the resulting products, the microbiological analyses of final composts showed E. coli contents less than 1000 MPN g−1 and the absence of Salmonella spp. in 25 g, meeting the legislation requirements [41]. The difficulty in reaching high temperatures was probably due to the initial stability of the employed SS. Indeed Maulini-Duran et al., (2002) [43] demonstrated that composting processes of wastewater sewage sludge biologically treated by anaerobic digestion attained lower temperatures than raw sludge composting due to the significant stabilisation of organic matter in digested sludge. According to the obtained data, an increase in the initial proportion of RS was considered to favour a more vigorous process and to increase the RS management capacity of the commercial facility. Thus during S2, the RS:SS ratio of 1:6 (w:w) was used. This ratio made it possible to reach higher temperatures: from 67 °C to 70 °C for 40–48 composting days. This compost was acceptable in sanitation terms (absence of Salmonella spp. in 25 g and <1000 MPN g−1 of Escherichia coli). During both processes, at around 127 days of composting the temperature began to not substantially increase after turnings, which indicates the beginning of the maturation phase.

Figure 1.

Evolution of ambient and inside the pile’s temperatures during the composting processes. White circles indicate turnings (o).

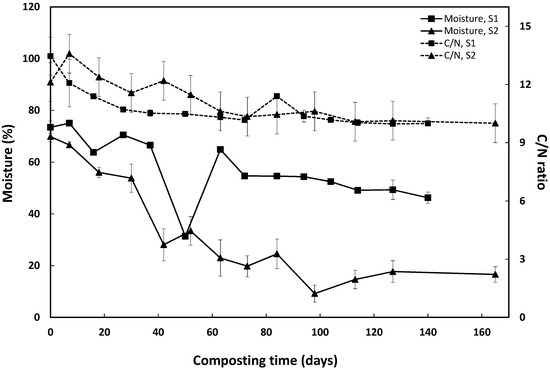

In addition to temperature, moisture content and the C/N ratio also strongly influence microbial activity. The evolution of these parameters during both seasons is shown in Figure 2. Moisture content decreased in the first 50 days during both S1 and S2, but this decrease during S1 was accompanied by a significant drop in temperatures, unlike S2. When moisture is very low, the process can be prematurely stopped and the inhibition of microbiological activity may occur by entraining temperature reduction [42]. Therefore, during S1, intensive watering was carried out using a hose connected to a tank attached to a forklift truck to reach the highest points of piles. Despite the low moisture content during S2, no irrigation was performed because temperatures indicated adequate process progress. During both seasons, the C/N ratio gradually lowered until it stabilised by the end of composting. This trend is usual in such processes and agrees with other studies of SS composting with different bulking agents [37,44].

Figure 2.

Evolution of contents moisture and C/N ratio during the composting processes. Vertical bars indicate standard deviation (n = 8).

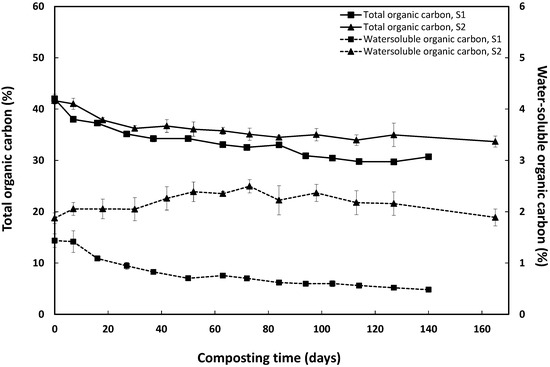

The decrease in the C/N ratio was supported by reductions in total and water-soluble organic C (Figure 3). At the end of composting, TOC reduction was greater during S1 (27%) than during S2 (19%). Microbial degradation, which causes decomposition and loss of organic matter, would have been promoted by both moisture conditions during S1 and material homogeneity being better as a result of the lower RS:SS ratio. WSOC content is an indicator of the quantities of readily degradable substances in or generated from organic materials [45]. The initial values of 1.44% and 1.88% for IM1 and IM2, respectively, were lower than those usually generated in mixtures with other raw materials due to the relative initial stability of the previously digested sludge. Indeed Sanchez-Monedero et al., (2001) [46] reported WSOC content to be 2.43% for an IM while composting primary aerobic sewage sludge and cotton waste. During S1, this parameter decreased throughout the process (67%). However, during S2, it behaved differently because the amount of the bulking agent was larger. The final value (1.89%) was practically the same as the initial value as a result of a balance between the degradation rates of labile organic compounds and the mineralisation of the resulting fractions.

Figure 3.

Evolution of contents of total and water-soluble organic carbon during the composting processes. Vertical bars indicate standard deviation (n = 8).

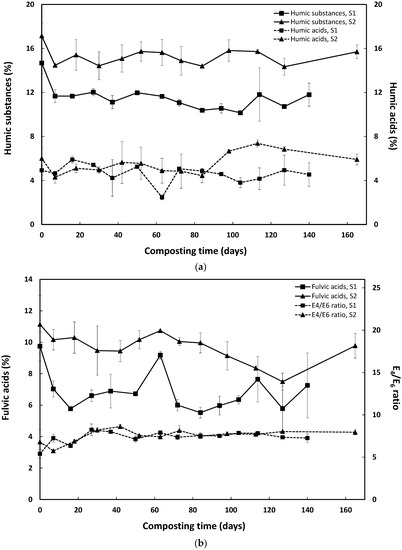

The evaluation of the degree of organic matter humification during composting is an agronomic criterion for assessing compost quality [23]. Organic matter humification during composting is evidenced by the formation of humic acids with increases in molecular weight, aromatic characteristics and functional groups [16]. As the process progresses, humic substances are produced, humic acids increase, while the fulvic acid fraction decreases or remains unchanged [16,47]. In our study, the data obtained for HS, HA, FA contents and the E4/E6 ratio of humic acids generally showed wide variability (Figure 4). This variability was due to both the extreme sensitivity of the analytical method and the material’s wide variability. A similar variation was observed by Canet and Pomares in 1995 [48] in a study of MSW composting on the industrial scale.

Figure 4.

Evolution of humic substances and humic acids contents (a) and fulvic acids contents and E4/E6 ratio of the humic acids (b) during the composting processes. Vertical bars indicate standard deviation (n = 8).

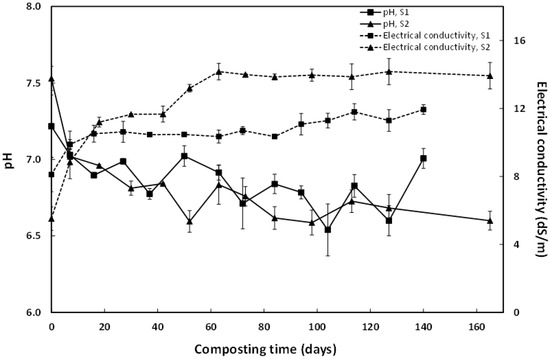

The evolution of pH and EC during processes is shown in Figure 5. Microbial activity during a composting process can be favoured by adequate pH, with optimum values between 5.5 and 8.0 [16]. During both seasons, the pH values fell within this optimal range. pH evolution during composting usually moves towards neutrality as a result of the gradual disappearance of the simplest and most reactive organic forms throughout the process. In our study, the pH values at the beginning of processes were slightly alkaline, probably due to the large quantity of ammonium released from the N components present in sludge. However, during composting, the pH values were under 7 most of the time due to the production of organic acids by carbohydrate and lipid degradation [23].

Figure 5.

Evolution of pH and EC during the composting processes. Vertical bars indicate standard deviation (n = 8).

Large increases in EC were observed in the initial phase for both seasons, caused by the release of soluble salts like ammonium and phosphate that result from the decomposition of readily biodegradable organic substrates [49]. However, these values stabilised as the process progressed because of a balance between a decrease due to the reduction of water-soluble substances, ammonia volatilisation and the precipitation of mineral salts [22] and an increase in the total salt concentration because organic matter disappeared. The incorporation of a larger amount of straw in IM2 resulted in a greater increase in the degree of salinity, with a rise of 152% versus 47% for S1.

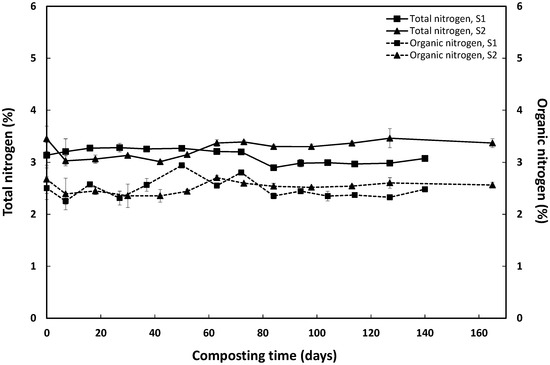

During a composting process, N is lost by NH3 volatilisation, leaching and denitrification. At the same time, N concentration increases as a consequence of a concentration effect due to the weight reduction of a pile. In our study, as an outcome of both situations the initial total N and the final total N were close during both seasons (3.13% initial N —3.07% final N and 3.45% initial N —3.37% final N, for S1 and S2, respectively) (Figure 6).

Figure 6.

Evolution of total and organic nitrogen during the composting processes. Vertical bars indicate standard deviation (n = 8).

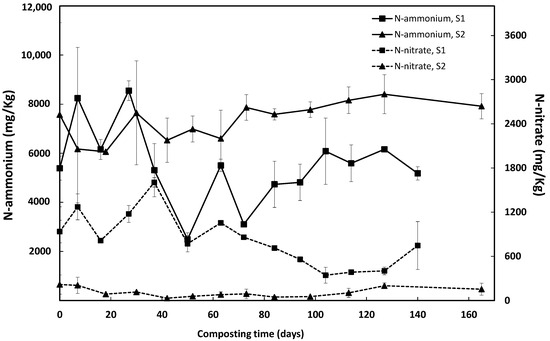

The mineral N, NH4+-N and NO3−-N concentrations (Figure 7) varied throughout the process during both seasons. During S1, the NH4+-N concentration lowered by 4% after 140 days of composting. This reduction could have been due to nitrification and NH3 volatilisation [50]. However, volatilisation was not favoured due to the moderate pH values of processes (pH < 8) [51]. On the contrary, during S2 NH4+-N increased by 5% after 165 days of composting, probably because of the predominance of the ammonification process, which converts organic N into NH4+ [23].

Figure 7.

Evolution of ammonium and nitrate nitrogen during the composting processes. Vertical bars indicate standard deviation (n = 8).

The expected increase in NO3−-N, which is normally seen at the end of composting processes, was not observed in either season. No important leaching losses occurred as the conditions under which composting was conducted did not favour the formation of leachates. Indeed, windrows were built under cover to avoid the influence of possible precipitation, and irrigation was occasional (once during S1) or nil (during S2). The most likely explanation for the lack of NO3−-N accumulation would be that important denitrification would have taken place during S1 and, in agreement with the TOC and WSOC results, the higher RS:SS ratio during S2 would have slowed down the process and, therefore, that of nitrification.

3.3. Yields Obtained and Analytical Characteristics of the Composts

After completing the process, the composted mixtures were sieved. The amounts of compost obtained per season were 14,135 kg (weight basis) of C1 (average of the two composts obtained during S1) and 7960 kg of C2 (average of the two composts obtained during S2). The composts generated per kg of initial RS, the RS required for the formation of one kg of compost and the yields obtained during both seasons are shown in Table 5. During S2, a larger quantity of RS was used to produce one kg of compost compared to S1. As one of the present study objectives was to valorise the maximum amount of RS possible, the composting process during S2 would be the most appropriate. Increasing the bulking agent during S2 resulted in significantly lower yields in wet weight, but similarly to dry weight, which suggests that changes were due mainly to water losses.

Table 5.

Compost generated per kg of initial rice straw, the rice straw required for the formation of one kg of compost and the yields obtained in two seasons.

In both seasons, compost granulometry met legislation requirements (>90% compost particles >25 mm, <2% gravel particles >5 mm, <1.5% impurities >2 mm) [52]. The final moisture, pH and EC values of composts are shown in Table 6. As a result of the low moisture contents throughout the process, C2 (26.2%) was significantly drier than C1 (46.2%) and met the legislation requirement of 40% maximum moisture [52]. The pH values in both C1 and C2 (6.94 and 6.96, respectively) fell within the recommended range according to previous studies [53]. Indeed these values are especially interesting for their application in soils like the alkaline ones found in the Valencia region. C1 and C2 significantly differed in EC, and had higher values than IM1 and IM2, due to lack of watering and the salt concentration as a result of reduced organic matter. Both composts had high EC values, which should be considered in their doses for field application purposes. However, given the nutrient richness of the sludge composts, the ratio of salt input per unit of compost may be advantageous compared to other poorer composts, such as MSW. Furthermore, the improvement in soil structure that compost application produces can favour salt washing and might, thus, reduce salinity problems.

Table 6.

Moisture, electrical conductivity and pH of the generated composts.

The total, oxidisable and WSOC of composts are indicated in Table 7. TOC in C1 and C2 corresponded to 52.4% and 56.5% of total organic matter, respectively, being higher than the minimum content (35%) indicated in the legislation [52]. Due to the different organic matter evolution during composting, C1 and C2 significantly differed in TOC and OCC values, although no significant differences were observed in the IMs. The larger amount of RS during S2 would have slowed down the process. The higher proportion of RS led to an increase in plant components, such as cellulose, hemicellulose and lignin, the last of which is the most difficult component to degrade. While composting SS and green waste, after 135 days of composting Jouraiphy et al., (2005) [54] found that 61% and 70% of cellulose and hemicellulose, respectively, was degraded, but only 37% of lignin. This slower process resulted in less mature composts according to the final WSOC values with 1.86% for C2 versus 0.475% for C1 and despite the process taking more days than during the first season. According to Bernal et al., (1998) [55] and Hue and Liu (1995) [56], who set WSOC at <1.7% and WSOC at <1%, respectively, as a limit for mature composts from a wide range of wastes, C1 would be a mature compost, while C2 would not.

Table 7.

Total organic carbon, oxidisable organic carbon, water-soluble organic carbon, humic substances, humic acids and fulvic acids concentrations of the generated composts.

HS contents were significantly different in composts, as they were in the IMs, with values of 9.62% and 15.6% for C1 and C2, respectively (Table 7). HA and FA were higher in C2 than in C1 (8.38% HA and 7.17% FA vs. 4.28% HA and 5.34% FA) where a bigger straw fraction was used. The values in both composts agree with the 13.4% HS, 7.97% HA and 5.21% FA reported by Zhao et al., (2016) [17] for an RS compost with SS.

Table 8 presents the N contents and C/N ratios. The total N in all the composts was high, with higher values in C2 than in C1. There was good sustaining N despite the many performed turnings because the final contents were in the same order as those in the IMs. Values were higher than those reported by other authors in SS and RS composts, such as Jusoh et al., (2013) [53] (1.80%) and Zhao et al., (2016) (1.86%) [17]. In the same way, total N was high compared to most manures [57,58], which shows its interesting potential as an N organic fertiliser. High ammonium levels stood out, which were not negative because N richness is very important in an organic fertiliser, but it must be taken into account to obtain the correct dose of compost. The final C/N ratio values of 10.1 and 9.72 for C1 and C2, respectively, met legislation requirements for fertilizing products (C/N < 20) [52] and agreed with those considered by Fialho et al., (2010) [59], who estimated that final values to be about 10, which indicates slow microbial activity and the material’s stabilisation.

Table 8.

Organic, mineral and total nitrogen concentrations, C/N ratio and macronutrient concentrations of the generated composts.

As seen in Table 8, macronutrient contents increased during both processes due to the drop in the total mass. Significant differences between both seasons were observed for all the nutrients. Similar P2O5 (4.97%), K2O (1.04%), MgO (1.25%) and Na2O (0.307%) contents were obtained by Ferrer et al., (2002) [27] in an SS and RS compost.

The micronutrient and heavy metal contents of composts are shown in Table 9. Although the composting process intrinsically reduces the availability of heavy metals compared to other organic waste stabilisation methods, the heavy metals content in composted waste materials must be controlled to protect soil quality and avoid contamination [60]. Cu, Ni, Pb, Cr and Hg for C1 and C2 concentrations would allow their inclusion in class B fertiliser products by Spanish legislation [41]. However, Cd and Zn concentrations were slightly higher than the maximum permitted values (2 mg kg−1 for Cd and 500 mg kg−1 for Zn). Higher Cd and Zn values of 2.5 and 610 mg kg−1 have also been reported by Roca-Pérez et al., (2009) [26] in SS and RS composts. In general, the micronutrients and heavy metals values increase during the composting process due to the microbial degradation of the organic matter and loss of volatile solids [60]. Therefore, despite the IMs containing Cd and Zn at the allowed values, their concentrations during composting led to high Cd and Zn values. Starting with raw materials with lower Cd and Zn values could have avoided exceeding limitations. New legislation has been recently published in Spain [61] to set standards for sustainable nutrition in agricultural soils. The concentrations of the heavy metals in C1 and C2 would comply with the established levels. Valuable micronutrient concentrations suitable for agricultural use were obtained in both seasons, and the high Fe levels in C1 and Mn in C1 and C2 are especially interesting. In S1, both micronutrients and heavy metals (except Mn and Cd) showed much higher contents compared to the IMs than during S2, which confirms greater organic matter degradation as the TOC, OCC and WSOC values also indicate.

Table 9.

Micronutrients and heavy metals content of the generated composts.

4. Conclusions

The results of this study indicate that industrial-scale RS and SS composting is a viable solution for the recycling and valorisation of large quantities of both waste types due to their complementary characteristics. Indeed, the RS and SS mixtures presented adequate features for initiating the composting process, as well as very interesting macro- and micronutrient contents. The RS:SS ratio of 1:8 (w:w fresh weight) during S1 led to a process with adequate temperatures for organic matter biodegradation, but not enough thermophilic. The usual protocol followed in the facility, which includes many turnings, the fact that digested and relatively stable SS was used, and the fast decreasing moisture noted by 50 days, could have impeded reaching high enough temperatures. To overcome this problem, a decision was made to increase the RS proportion in the IMs to an RS:SS ratio of 1:6 (w:w fresh weight) with the added objective of valorising larger quantities of this waste. The number of turnings in the second half of the process was also reduced. As a result, higher temperatures were reached, but TOC, OCC and WSOC indicated less material degradation throughout the process, as well as less stable final composts compared to S1. Poor moisture management would have affected composting. As temperatures indicated adequate process progress, no corrective measures were taken, and lack of moisture would have slowed down biodegradation.

In both seasons, final composts presented adequate granulometry and pH values. Moisture content was adequate in C2 but slightly higher than legislation requirements in C1. Compost showed certain salinity that, albeit not a major issue, must be considered for their dose for field applications. Similarly, the high ammonium contents must be taken into account for their correct application. Compost presented high N richness, as well as interesting macro- and micronutrient values, especially P, Fe and Mn. Heavy metals concentrations would allow their inclusion in class B fertilizer products by Spanish legislation except for Cd, in C2 and for Zn in both composts. Microbiological requirements were met in both seasons. Although obtained composts have interesting characteristics which render them worthy fertilisers, further research is necessary to increase their quality, considering other parameters, such as antibiotics, organic compounds, dioxins and furans.

Author Contributions

Conceptualization, R.C.; Formal analysis, I.R.-C.; Funding acquisition, R.C.; Investigation, I.R.-C.; Methodology, I.R.-C.; Supervision, A.Q.; Validation, A.P.-P.; Writing—original draft, I.R.-C.; Writing—review & editing, A.Q. and A.P.-P. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by FEADER, Ministerio de Agricultura y Pesca, Alimentación y Medio Ambiente and Generalitat Valenciana. Programa de Desarrollo Rural de la Comunitat Valenciana 2014–2020, AGCOOP_B/2018/037. The project was carried out by a consortium made up of three entities: Instituto Valenciano de Investigaciones Agrarias (IVIA), Cooperatives-Agroalimentàries de la Comunitat Valenciana (CACV) and Depuración de Aguas del Mediterráneo S.L. (DAM).

Data Availability Statement

Not applicable.

Conflicts of Interest

The authors declare no conflict of interest.

References

- European Commission. Farm to Fork Strategy. Available online: https://food.ec.europa.eu/horizontal-topics/farm-fork-strategy_en (accessed on 26 June 2023).

- European Commission. Common Agricultural Policy. Available online: https://agriculture.ec.europa.eu/common-agricultural-policy_en (accessed on 26 June 2023).

- Cooperativas Agro-Alimentarias de España. Arroz España. Datos de Producción. Available online: https://www.agronegocios.es/wp-content/uploads/2020/12/Arroz2021Coop.pdf (accessed on 26 June 2023).

- Tipayarom, D.; Oanh, N.K. Effects from open rice straw burning emission on air quality in the Bangkok Metropolitan Region. Sci. Asia 2007, 33, 339–345. [Google Scholar] [CrossRef]

- Junpen, A.; Pansuk, J.; Kamnoet, O.; Cheewaphongphan, P.; Garivait, S. Emission of air pollutants from rice residue open burning in Thailand. Atmosphere 2018, 9, 449. [Google Scholar] [CrossRef]

- Resolución de 30 de Mayo de 2023, de la Consellera de Agricultura, Desarrollo Rural, Emergencia Climática y Transición Ecológica, por la que se Amplia de Forma Excepcional el Período de Quema de Residuos Vegetales Generados en Labores Agrícolas Mediante Uso del Fuego. Available online: https://dogv.gva.es/datos/2023/05/31/pdf/2023_6081.pdf (accessed on 26 June 2023).

- Buzarovska, A.; Bogoeva, G.G.; Grozdanov, A.; Avella, M.; Gentile, G.; Errico, M. Potential use of rice straw as filler in eco-composite materials. Aust. J. Crop Sci. 2008, 1, 37–42. [Google Scholar]

- Khandanlou, R.; Ahmad, M.B.; Shameli, K.; Hussein, M.Z.; Zainuddin, N.; Kalantari, K. Mechanical and Thermal Stability Properties of Modified Rice Straw Fiber Blend with Polycaprolactone Composite. J. Nanomater. 2014, 2014, 675258. [Google Scholar] [CrossRef]

- Albiach, R.; Pomares, F.; Ribó, M.; Pérez-Piqueres, A.; Canet, R. Enzyme activity in soil after different procedures for managing rice straw. Recur. Rurais 2017, 12, 33–38. [Google Scholar] [CrossRef]

- Singh, L.; Brar, B.S. A review on rice straw management strategies. Nat. Environ. Pollut. Technol. 2021, 20, 1485–1493. [Google Scholar] [CrossRef]

- Ministerio para la Transición Ecológica y el Reto Demográfico (MITECO). Lodos de Depuración de Aguas Residuales. Available online: https://www.miteco.gob.es/es/calidad-y-evaluacion-ambiental/temas/prevencion-y-gestion-residuos/flujos/lodos-depuradora.html (accessed on 26 June 2023).

- Pomares, F. Valor fertilizante de los lodos de las depuradoras de aguas residuales. ITEA 1982, 49, 47–67. [Google Scholar]

- Canet, R.; Pomares, F.; Tarazona, F.; Estela, M. Sequential fractionation and plant availability of heavy metals as affected by sewage sludge applications to soil. Commun. Soil Sci. Plant Anal. 1998, 29, 697–716. [Google Scholar] [CrossRef]

- Dumontet, S.; Scopa, A.; Kerje, S.; Krovacek, K. The importance of pathogenic organisms in sewage and sewage sludge. J Air Waste Manag. Assoc. 2001, 51, 848–860. [Google Scholar] [CrossRef]

- Coulomb, I. Composting. In Sludge Treatment and Disposal; ISWA’s Working Group on Sewage & Waterworks Sludge, Ed.; European Environment Agency: Copenhagen, Denmark, 1997; pp. 22–26. [Google Scholar]

- Bernal, M.P.; Alburquerque, J.A.; Moral, R. Composting of animal manures and chemical criteria for compost maturity assessment. A review. Bioresour. Technol. 2009, 100, 5444–5453. [Google Scholar] [CrossRef]

- Zhao, X.L.; Li, B.Q.; Ni, J.P.; Xie, D.T. Effect of four crop straws on transformation of organic matter during sewage sludge composting. J. Integr. Agric. 2016, 15, 232–240. [Google Scholar] [CrossRef]

- Doublet, J.; Francou, C.; Poitrenaud, M.; Houot, S. Influence of bulking agents on organic matter evolution during sewage sludge composting; consequences on compost organic matter stability and N availability. Bioresour. Technol. 2011, 102, 1298–1307. [Google Scholar] [CrossRef] [PubMed]

- Toledo, M.; Márquez, P.; Siles, J.A.; Chica, A.F.; Martín, M.A. Co-composting of sewage sludge and eggplant waste at full scale: Feasibility study to valorize eggplant waste and minimize the odoriferous impact of sewage sludge. J. Environ. Manag. 2019, 247, 205–213. [Google Scholar] [CrossRef]

- Guo, Y.; Rene, E.R.; Wang, J.; Ma, W. Biodegradation of polyaromatic hydrocarbons and the influence of environmental factors during the co-composting of sewage sludge and green forest waste. Bioresour. Technol. 2020, 297, 122434. [Google Scholar] [CrossRef]

- Lu, Y.; Zheng, G.; Zhou, W.; Wang, J.; Zhou, L. Bioleaching conditioning increased the bioavailability of polycyclic aromatic hydrocarbons to promote their removal during co-composting of industrial and municipal sewage sludges. Sci. Total Environ. 2019, 665, 1073–1082. [Google Scholar] [CrossRef] [PubMed]

- Rashad, F.M.; Saleh, W.D.; Moselhy, M.A. Bioconversion of rice straw and certain agro-industrial wastes to amendments for organic farming systems: 1. Composting, quality, stability and maturity indices. Bioresour. Technol. 2010, 101, 5952–5960. [Google Scholar] [CrossRef] [PubMed]

- El-Rhaman, A.; Zeinab, M.; Hegazy, A.S.I.; Mostafa, M.A.M.; El-Sedfy, O.M.F. Evaluation of stability and maturity of composted rice straw, olive pomace and some agricultural wastes. Arab Univ. J. Agric. Sci. 2018, 26, 267–279. [Google Scholar] [CrossRef]

- Karanja, A.W.; Njeru, E.M.; Maingi, J.M. Assessment of physicochemical changes during composting rice straw with chicken and donkey manure. Int. J. Recycl. Org. Waste Agric. 2019, 8, 65–72. [Google Scholar] [CrossRef]

- Iranzo, M.; Cañizares, J.V.; Roca-Perez, L.; Sainz-Pardo, I.; Mormeneo, S.; Boluda, R. Characteristics of rice straw and sewage sludge as composting materials in Valencia (Spain). Bioresour. Technol. 2004, 95, 107–112. [Google Scholar] [CrossRef]

- Roca-Pérez, L.; Martínez, C.; Marcilla, P.; Boluda, R. Composting rice straw with sewage sludge and compost effects on the soil-plant system. Chemosphere 2009, 75, 781–787. [Google Scholar] [CrossRef]

- Ferrer, E.; Canet, R.; Pomares, F.; Moreno, R. Effects of inoculation and urea addition on the composting of sewage sludge and rice straw. WIT Trans. Ecol. Environ. 2002, 56, 297–303. [Google Scholar] [CrossRef]

- MAPA. Métodos Oficiales de Análisis de Suelos y Aguas para el Riego. In Plantas, Productos Orgánicos Fertilizantes, Suelos, Aguas, Productos Fitosanitarios, Fertilizantes Inorgánicos; Ministerio de Agricultura, Pesca y Alimentación: Madrid, Spain, 1994; Volume 3, p. 662. [Google Scholar]

- Chen, Y.; Senesi, N.; Schnitzer, M. Information provided on humic substances by the E4/E6 ratios. Soil Sci. Soc. Am. J. 1977, 41, 352–358. [Google Scholar] [CrossRef]

- ISO 7251:2005; Microbiology of Food and Animal Feeding Stuffs—Horizontal Method for the Detection and Enumeration of Presumptive Escherichia coli—Most Probable Number Technique. ISO: Geneva, Switzerland, 2005; p. 13.

- ISO 6579-1:2017; Microbiology of the Food Chain—Horizontal Method for the Detection, Enumeration and Serotyping of Salmonella—Part 1: Detection of Salmonella spp. ISO: Geneva, Switzerland, 2017; p. 50.

- Liang, C.; Das, K.C.; McClendon, R.W. The influence of temperature and moisture contents regimes on the aerobic microbial activity of a biosolids composting blend. Bioresour. Technol. 2003, 86, 131–137. [Google Scholar] [CrossRef] [PubMed]

- Neves, A.C.; da Costa, P.; de Oliveira Silva, C.A.; Pereira, F.R.; Mol, M.P.G. Analytical methods comparison for pH determination of composting process from green wastes. Environ. Eng. Manag. J. 2021, 20, 133–139. [Google Scholar] [CrossRef]

- Azim, K.; Soudi, B.; Boukhari, S.; Perissol, C.; Roussos, S.; Thami Alami, I. Composting parameters and compost quality: A literature review. Org. Agric. 2018, 8, 141–158. [Google Scholar] [CrossRef]

- Aiken, G.R.; McKnight, D.M.; Wershaw, R.L.; MacCarthy, P. An introduction to humic substances in soil, sediment, and water. In Humic Substances in Soil, Sediment, and Water: Geochemistry, Isolation, and Characterization; Aiken, G.R., McKnight, D.M., Wershaw, R.L., MacCarthy, P., Eds.; Wiley: Hoboken, NJ, USA, 1985; pp. 1–9. [Google Scholar] [CrossRef]

- Roca-Pérez, L.; Arévalo, J.; Boluda, R. The influence of C/N ratio moisture and pH on the aerobic microbial activity of rice straw and sewage sludge blends. In Sustainable Organic Waste Management for Environmental Protection and Food Safety; Bernal, M.P., Moral, R., Clemente, R., Paredes, C., Eds.; FAO-CSIC: Murcia, Spain, 2005; pp. 247–249. [Google Scholar]

- Moretti, S.M.L.; Bertoncini, E.I.; Abreu-Junior, C.H. Composting sewage sludge with green waste from tree pruning. Sci. Agric. 2015, 72, 432–439. [Google Scholar] [CrossRef]

- Gakwisiri, C.; Raut, N.; Al-Saadi, A.; Al-Aisri, S.; Al-Ajmi, A. A critical review of removal of zinc from wastewater. In Proceedings of the World Congress on Engineering, London, UK, 4–6 July 2012; Volume 1, pp. 627–630. [Google Scholar]

- Kumar, R.; Chawla, J.; Kaur, I. Removal of cadmium ion from wastewater by carbon-based nanosorbents: A review. J. Water Health 2015, 13, 18–33. [Google Scholar] [CrossRef]

- Ministerio de Agricultura, Pesca y Alimentación. Real Decreto 1310/1990, de 29 de octubre de 1990, por el que se regula la utilización de los lodos de depuración en el sector agrario. In Boletín Oficial del Estado, 262, 1 de Noviembre de 1990; Ministerio de Agricultura, Pesca y Alimentación: Madrid, Spain, 1990; pp. 32339–32340. [Google Scholar]

- Ministerio de la Presidencia. Real Decreto 506/2013, de 28 junio de 2013, sobre productos fertilizantes. In Boletín Oficial del Estado, 164, de 10 de julio de 2013; Ministerio de la Presidencia: Madrid, Spain, 2013; pp. 51119–51207. [Google Scholar]

- Stentiford, E.I. Composting Control: Principles and Practice. In The Science of Composting; de Bertoldi, M., Sequi, P., Lemmes, B., Papi, T., Eds.; Springer: Dordrecht, The Netherlands, 1996; pp. 49–59. [Google Scholar] [CrossRef]

- Maulini-Duran, C.; Artola, A.; Font, X.; Sánchez, A. A systematic study of the gaseous emissions from biosolids composting: Raw sludge versus anaerobically digested sludge. Bioresour. Technol. 2013, 147, 43–51. [Google Scholar] [CrossRef]

- Amir, S.; Hafidi, M.; Merlina, G.; Hamdi, H.; Jouraiphy, A.; El Gharous, M.; Revel, J.C. Fate of phthalic acid esters during composting of both lagooning and activated sludges. Process Biochem. 2005, 40, 2183–2190. [Google Scholar] [CrossRef]

- Canet, R.; Albiach, R.; Ferrer, E.; Flores, P.; Pomares, F. Evolution of chemical and physicochemical properties of MSW compost during three long-term maturing treatments. In Sustainable Organic Waste Management for Environmental Protection and Food Safety, Proceedings of the 11th International Conference of the FAO ESCORENA Network on the Recycling of Agricultural, Municipal and Industrial Residues in Agriculture, Murcia, Spain, 6–9 October 2004; FAO: Rome, Italy; CSIC: Madrid, Spain, 2004. [Google Scholar]

- Sánchez-Monedero, M.Á.; Roig, A.; Bernal Calderón, M.P. The water-soluble organic fraction and its relationships to the degree of maturity of organic matter during composting. Bioprocess. Solid Waste Sludge 2001, 1, 6. Available online: http://hdl.handle.net/10261/16132 (accessed on 26 June 2023).

- Tuomela, M.; Vikman, M.; Hatakka, A.; Itävaara, M. Biodegradation of lignin in a compost environment: A review. Bioresour. Technol. 2000, 72, 169–183. [Google Scholar] [CrossRef]

- Canet, R.; Pomares, F. Changes in physical, chemical and physicochemical parameters during the composting of municipal solid wastes in two plants in Valencia. Bioresour. Technol. 1995, 51, 259–264. [Google Scholar] [CrossRef]

- Gómez-Brandón, M.; Lazcano, C.; Domínguez, J. The evaluation of stability and maturity during the composting of cattle manure. Chemosphere 2008, 70, 436–444. [Google Scholar] [CrossRef] [PubMed]

- Paredes, C.; Bernal, M.P.; Cegarra, J.; Roig, A. Bio-degradation of olive mill wastewater sludge by its co-composting with agricultural wastes. Bioresour. Technol. 2002, 85, 1–8. [Google Scholar] [CrossRef] [PubMed]

- Martins, O.; Dewes, T. Loss of nitrogenous compounds during composting of animal wastes. Bioresour. Technol. 1992, 42, 103–111. [Google Scholar] [CrossRef]

- Ministerio de la Presidencia y para las Administraciones Territoriales. Real Decreto 999/2017, de 24 noviembre de 2017, por el que se modifica el Real Decreto 506/2013, de 28 junio, sobre productos fertilizantes. In Boletín Oficial del Estado, 296, de 6 de Diciembre de 2017; Ministerio de la Presidencia y para las Administraciones Territoriales: Madrid, Spain, 2017; pp. 119396–119450. [Google Scholar]

- Jusoh, M.L.C.; Manaf, L.A.; Latiff, P.A. Composting of rice straw with effective microorganisms (EM) and its influence on compost quality. J. Environ. Health Sci. Eng. 2013, 10, 17. [Google Scholar] [CrossRef] [PubMed]

- Jouraiphy, A.; Amir, S.; El Gharous, M.; Revel, J.C.; Hafidi, M. Chemical and spectroscopic analysis of organic matter transformation during composting of sewage sludge and green plant waste. Int. Biodeterior. Biodegrad. 2005, 56, 101–108. [Google Scholar] [CrossRef]

- Bernal, M.P.; Paredes, C.; Sanchez-Monedero, M.A.; Cegarra, J. Maturity and stability parameters of composts prepared with a wide range of organic wastes. Bioresour. Technol. 1998, 63, 91–99. [Google Scholar] [CrossRef]

- Hue, N.V.; Liu, J. Predicting compost stability. Compost Sci. Util. 1995, 3, 8–15. [Google Scholar] [CrossRef]

- Rayne, N.; Aula, L. Livestock Manure and the Impacts on Soil Health: A Review. Soil Syst. 2020, 4, 64. [Google Scholar] [CrossRef]

- Dadrasnia, A.; de Bona Muñoz, I.; Yáñez, E.H.; Lamkaddam, I.U.; Mora, M.; Ponsá, S.; Ahmed, M.; Argelaguet, L.L.; Williams, P.M.; Oatley-Radcliffe, D.L. Sustainable nutrient recovery from animal manure: A review of current best practice technology and the potential for freeze concentration. J. Clean. Prod. 2021, 315, 128106. [Google Scholar] [CrossRef]

- Fialho, L.L.; Da Silva, W.T.L.; Milori, D.M.; Simões, M.L.; Martin-Neto, L. Characterization of organic matter from composting of different residues by physicochemical and spectroscopic methods. Bioresour. Technol. 2010, 101, 1927–1934. [Google Scholar] [CrossRef] [PubMed]

- Smith, S.R. A critical review of the bioavailability and impacts of heavy metals in municipal solid waste composts compared to sewage sludge. Environ. Int. 2009, 35, 142–156. [Google Scholar] [CrossRef] [PubMed]

- Ministerio de la Presidencia, Relaciones con las Cortes y Memoria Democrática. Real Decreto 1051/2022, de 27 de diciembre de 2022, por el que se establecen normas para la nutrición sostenible en los suelos agrarios. In Boletín Oficial del Estado, 312, de 29 de Diciembre de 2022; Ministerio de la Presidencia, Relaciones con las Cortes y Memoria Democrática: Madrid, Spain, 2022; pp. 188873–188916. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).