Improving Energy Efficiency and Greenhouse Gas Emissions in Small Farm Wheat Production Scenarios Using Data Envelopment Analysis

Abstract

1. Introduction

2. Materials and Methods

2.1. Study Area

2.2. Wheat Production System in the Delta of Egypt

2.3. Energy Use Analysis

2.3.1. Fuel Consumption (FC)

2.3.2. Energy for Machinery

2.3.3. Human Labor

2.3.4. Spraying

2.3.5. Fertilizers

2.4. Data Envelopment Analysis (DEA)

2.5. Estimation of GHG Emissions

3. Results and Discussion

3.1. The Analysis of the Wheat Production System Energy

3.2. The Agricultural Mechanization and Fuel Consumption Energy in the Wheat Production System

3.3. The Indicators of Energy for the Wheat Production Scenarios

3.4. Optimum Energy Savings and Energy Requirements for Wheat Production in the Old Delta Lands

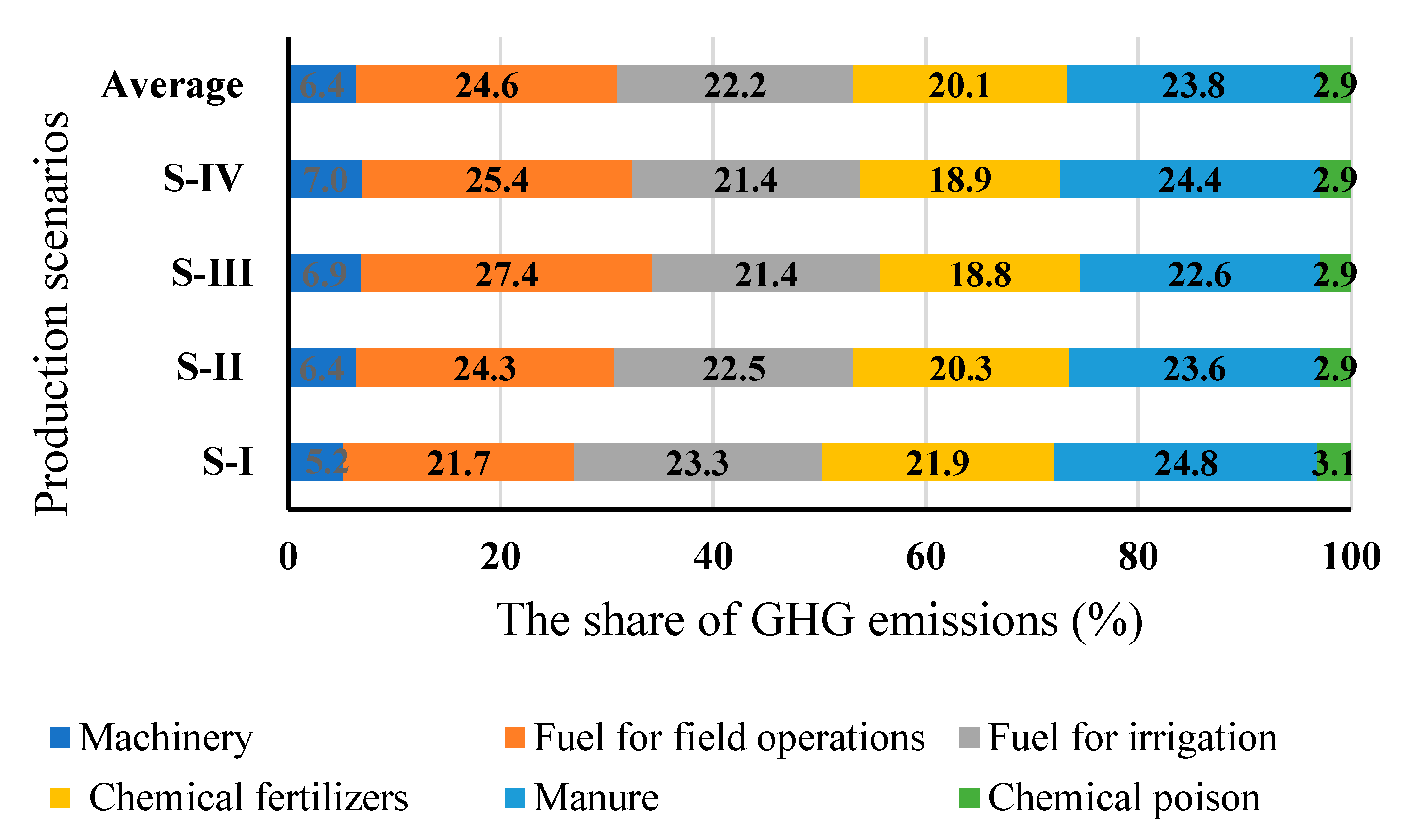

3.5. GHG Emissions Analysis

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- FAO. Crop Prospects and Food Situation, Quarterly Global Report NO. 4; Food and Agriculture Organization of the United Nations: Roma, Italy, 2022. [Google Scholar]

- Sayed, H.A.A.; Ding, Q.; Odero, A.J.; Korohou, T. Selection of Appropriate Mechanization to Achieve Sustainability for Smallholder Farms: A Review. Al-Azhar J. Agric. Eng. 2022, 2, 52–60. [Google Scholar] [CrossRef]

- FAO. The Future of Food and Agriculture: Trends and Challenges; Food and Agriculture Organization of the United Nations: Roma, Italy, 2017. [Google Scholar]

- Šarauskis, E.; Romaneckas, K.; Kumhála, F.; Kriaučiūnienė, Z. Energy Use and Carbon Emission of Conventional and Organic Sugar Beet Farming. J. Clean. Prod. 2018, 201, 428–438. [Google Scholar] [CrossRef]

- Fan, J.; Liu, C.; Xie, J.; Han, L.; Zhang, C.; Guo, D.; Niu, J.; Jin, H.; McConkey, B.G. Life Cycle Assessment on Agricultural Production: A Mini Review on Methodology, Application, and Challenges. Int. J. Environ. Res. Public Health 2022, 19, 9817. [Google Scholar] [CrossRef]

- Tilman, D.; Reich, P.B.; Knops, J.M.H. Biodiversity and Ecosystem Stability in a Decade-Long Grassland Experiment. Nature 2006, 441, 629–632. [Google Scholar] [CrossRef] [PubMed]

- Ilahi, S.; Wu, Y.; Raza, M.A.A.; Wei, W.; Imran, M.; Bayasgalankhuu, L. Optimization Approach for Improving Energy Efficiency and Evaluation of Greenhouse Gas Emission of Wheat Crop using Data Envelopment Analysis. Sustainability 2019, 11, 3409. [Google Scholar] [CrossRef]

- Mousavi-Avval, S.H.; Rafiee, S.; Mohammadi, A. Optimization of Energy Consumption and Input Costs for Apple Production in Iran Using Data Envelopment Analysis. Energy 2011, 36, 909–916. [Google Scholar] [CrossRef]

- Toma, E.; Dobre, C.; Dona, I.; Cofas, E. DEA Applicability in Assessment of Agriculture Efficiency on Areas with Similar Geographically Patterns. Agric. Agric. Sci. Procedia 2015, 6, 704–711. [Google Scholar] [CrossRef]

- Streimikis, J.; Saraji, M.K. Green Productivity and Undesirable Outputs in Agriculture: A Systematic Review of DEA Approach and Policy Recommendations. Econ. Res. Istraz. 2022, 35, 819–853. [Google Scholar] [CrossRef]

- Nabavi-Pelesaraei, A.; Hosseinzadeh-Bandbafha, H.; Qasemi-Kordkheili, P.; Kouchaki-Penchah, H.; Riahi-Dorcheh, F. Applying Optimization Techniques to Improve of Energy Efficiency and GHG (Greenhouse Gas) Emissions of Wheat Production. Energy 2016, 103, 672–678. [Google Scholar] [CrossRef]

- SIS. Egypt and Climate Change-SIS. Available online: https://www.sis.gov.eg/Story/160255/Egypt-and-Climate-Change?lang=en-us (accessed on 8 February 2023).

- Yan, Z.; Li, W.; Yan, T.; Chang, S.; Hou, F. Evaluation of Energy Balances and Greenhouse Gas Emissions from Different Agricultural Production Systems in Minqin Oasis, China. Peer J. 2019, 2019, e6890. [Google Scholar] [CrossRef]

- Kastner, T.; Rivas, M.J.I.; Koch, W.; Nonhebel, S. Global Changes in Diets and the Consequences for Land Requirements for Food. Proc. Natl. Acad. Sci. USA 2012, 109, 6868–6872. [Google Scholar] [CrossRef]

- Yuan, S.; Peng, S. Trends in the Economic Return on Energy Use and Energy Use Efficiency in China’s Crop Production. Renew. Sustain. Energy Rev. 2017, 70, 836–844. [Google Scholar] [CrossRef]

- Mondani, F.; Aleagha, S.; Khoramivafa, M.; Ghobadi, R. Evaluation of Greenhouse Gases Emission Based on Energy Consumption in Wheat Agroecosystems. Energy Rep. 2017, 3, 37–45. [Google Scholar] [CrossRef]

- Wu, H.; MacDonald, G.K.; Galloway, J.N.; Zhang, L.; Gao, L.; Yang, L.; Yang, J.; Li, X.; Li, H.; Yang, T. The Influence of Crop and Chemical Fertilizers Combinations on Greenhouse Gas Emissions: A Partial Life-Cycle Assessment of Fertilizers Production and Use in China. Resour. Conserv. Recycl. 2021, 168, 105303. [Google Scholar] [CrossRef]

- Timsina, J.; Dutta, S.; Devkota, K.P.; Chakraborty, S.; Neupane, R.K.; Bista, S.; Amgain, L.P.; Majumdar, K. Assessment of Nutrient Management in Major Cereals: Yield Prediction, Energy-Use Efficiency and Greenhouse Gas Emission. Curr. Res. Environ. Sustain. 2022, 4, 100147. [Google Scholar] [CrossRef]

- Sayed, H.A.A.; Ding, Q.; Abdelhamid, M.A.; Alele, J.O.; Alkhaled, A.Y.; Refai, M. Application of Machine Learning to Study the Agricultural Mechanization of Wheat Farms in Egypt. Agriculture 2023, 13, 70. [Google Scholar] [CrossRef]

- Cochran, W.G. The Estimation of Sample Size. Sampl. Tech. 1977, 3, 72–90. [Google Scholar]

- Ozkan, B.; Akcaoz, H.; Karadeniz, F. Energy Requirement and Economic Analysis of Citrus Production in Turkey. Energy Convers. Manag. 2004, 45, 1821–1830. [Google Scholar] [CrossRef]

- Yilmaz, I.; Akcaoz, H.; Ozkan, B. An Analysis of Energy Use and Input Costs for Cotton Production in Turkey. Renew. Energy 2005, 30, 145–155. [Google Scholar] [CrossRef]

- Singh, H.; Mishra, D.; Nahar, N.M. Energy Use Pattern in Production Agriculture of a Typical Village in Arid Zone, India—Part I. Energy Convers. Manag. 2002, 43, 2275–2286. [Google Scholar] [CrossRef]

- Kitani, O. CIGR Handbook of Agricultural Engineering, Volume V Energy and Biomass Engineering, Chapter 1 Natural Energy and Biomass, Part 1.3 Biomass Resources, ASABE. 1999; pp. 6–11. Available online: https://elibrary.asabe.org/abstract.asp?JID=6&AID=36411&CID=cig51999&T=1 (accessed on 12 May 2023).

- Erdal, G.; Esengün, K.; Erdal, H.; Gündüz, O. Energy Use and Economical Analysis of Sugar Beet Production in Tokat Province of Turkey. Energy 2007, 32, 35–41. [Google Scholar] [CrossRef]

- Singh, J. On Farm Energy Use Pattern in Different Cropping Systems in Haryana, India. Master Thesis, International Institute of Management, University of Flensburg, Flensburg, Germany, 2002. [Google Scholar]

- Mohammadi, A.; Omid, M. Economical Analysis and Relation between Energy Inputs and Yield of Greenhouse Cucumber Production in Iran. Appl. Energy 2010, 87, 191–196. [Google Scholar] [CrossRef]

- Esengun, K.; Erdal, G.; Gündüz, O.; Erdal, H. An Economic Analysis and Energy Use in Stake-Tomato Production in Tokat Province of Turkey. Renew. Energy 2007, 32, 1873–1881. [Google Scholar] [CrossRef]

- Demircan, V.; Ekinci, K.; Keener, H.M.; Akbolat, D.; Ekinci, C. Energy and Economic Analysis of Sweet Cherry Production in Turkey: A Case Study from Isparta Province. Energy Convers. Manag. 2006, 47, 1761–1769. [Google Scholar] [CrossRef]

- Gündoǧmuş, E. Energy Use on Organic Farming: A Comparative Analysis on Organic versus Conventional Apricot Production on Small Holdings in Turkey. Energy Convers. Manag. 2006, 47, 3351–3359. [Google Scholar] [CrossRef]

- Franzluebbers, A.J.; Francis, C.A. Energy Output:Input Ratio of Maize and Sorghum Management Systems in Eastern Nebraska. Agric. Ecosyst. Environ. 1995, 53, 271–278. [Google Scholar] [CrossRef]

- Mohammadi, A.; Tabatabaeefar, A.; Shahin, S.; Rafiee, S.; Keyhani, A. Energy Use and Economical Analysis of Potato Production in Iran a Case Study: Ardabil Province. Energy Convers. Manag. 2008, 49, 3566–3570. [Google Scholar] [CrossRef]

- Mandal, K.G.; Saha, K.P.; Ghosh, P.K.; Hati, K.M.; Bandyopadhyay, K.K. Bioenergy and Economic Analysis of Soybean-Based Crop Production Systems in Central India. Biomass Bioenergy 2002, 23, 337–345. [Google Scholar] [CrossRef]

- Mobtaker, H.G.; Keyhani, A.; Mohammadi, A.; Rafiee, S.; Akram, A. Sensitivity Analysis of Energy Inputs for Barley Production in Hamedan Province of Iran. Agric. Ecosyst. Environ. 2010, 137, 367–372. [Google Scholar] [CrossRef]

- ASABE. Agricultural Machinery Management Data. American Society of Agricultural and Biological Engineers EP496.3. 2006; pp. 384–390. Available online: https://webstore.ansi.org/preview-pages/ASABE/preview_ASAE+EP496.3+FEB2006+(R2015)+Cor.1.pdf (accessed on 12 May 2023).

- Charnes, A.; Cooper, W.W.; Rhodes, E. Measuring the Efficiency of Decision Making Units. Eur. J. Oper. Res. 1978, 2, 429–444. [Google Scholar] [CrossRef]

- Banker, R.D.; Charnes, A.; Cooper, W.W. Some Models for Estimating Technical and Scale Inefficiencies in Data Envelopment Analysis. Manag. Sci. 1984, 30, 1078–1092. [Google Scholar] [CrossRef]

- Sueyoshi, T.; Goto, M. Should the US Clean Air Act Include CO2 Emission Control? Examination by Data Envelopment Analysis. Energy Policy 2010, 38, 5902–5911. [Google Scholar] [CrossRef]

- Dyer, J.A.; Desjardins, R.L. Carbon Dioxide Emissions Associated with the Manufacturing of Tractors and Farm Machinery in Canada. Biosyst. Eng. 2006, 93, 107–118. [Google Scholar] [CrossRef]

- Dyer, J.A.; Desjardins, R.L. Simulated Farm Fieldwork, Energy Consumption and Related Greenhouse Gas Emissions in Canada. Biosyst. Eng. 2003, 85, 503–513. [Google Scholar] [CrossRef]

- Pathak, H.; Wassmann, R. Introducing Greenhouse Gas Mitigation as a Development Objective in Rice-Based Agriculture: I. Generation of Technical Coefficients. Agric. Syst. 2007, 94, 807–825. [Google Scholar] [CrossRef]

- Lal, R. Carbon Emission from Farm Operations. Environ. Int. 2004, 30, 981–990. [Google Scholar] [CrossRef]

- Xiaomei, L.; Kotelko, M. An Integrated Manure Utilization System (Imus): Its Social and Environmental Benefits. In Proceedings of the 3rd International Methane and Nitrous Oxide Mitigation Conference, Beijing, China, 17–21 November 2003; pp. A375–A376. [Google Scholar]

- Paulsen, M.R.; Kalita, P.K.; Rausch, K.D. Postharvest Losses Due to Harvesting Operations in Developing Countries: A Review. In Proceedings of the American Society of Agricultural and Biological Engineers Annual International Meeting 2015, New Orleans, LA, USA, 26–29 July 2015; American Society of Agricultural and Biological Engineers: Saint Joseph, MI, USA, 2015; Volume 1, pp. 562–596. [Google Scholar]

- Sattar, M.; Mueen-u-Din; Ali, M.; Ali, L.; Waqar, M.Q.; Ali, M.A.; Khalid, L. Grain Losses of Wheat as Affected by Different Harvesting and Threshing Techniques. Int. J. Res. Agric. For. 2015, 2, 20–26. [Google Scholar]

- Safa, M.; Samarasingh, S.; Mohssen, M. A Field Study of Energy Consumption in Wheat Production in Canterbury, New Zealand. Energy Convers. Manag. 2011, 52, 2526–2532. [Google Scholar] [CrossRef]

- Sharif, A. Technical Adaptations for Mechanized SRI Production to Achieve Water Saving and Increased Profitability in Punjab, Pakistan. Paddy Water Environ. 2011, 9, 111–119. [Google Scholar] [CrossRef]

- Kirui, O. The Agricultural Mechanization in Africa: Micro-Level Analysis of State Drivers and Effects. SSRN Electron. J. 2019. [Google Scholar] [CrossRef]

- Nagendra, M.S.; Venkataramana, S.K. Mechanization for Seed Sowing Trends and Threats. In Proceedings of the Climate Smart Agriculture for Livelihood Security: Challenges and Opportunities, Tiruchirappalli, India, 13–14 September 2019; p. 380. [Google Scholar]

- Amoozad-Khalili, M.; Rostamian, R.; Esmaeilpour-Troujeni, M.; Kosari-Moghaddam, A. Economic Modeling of Mechanized and Semi-Mechanized Rainfed Wheat Production Systems Using Multiple Linear Regression Model. Inf. Process. Agric. 2020, 7, 30–40. [Google Scholar] [CrossRef]

- Ashraf, M.N.; Mahmood, M.H.; Sultan, M.; Banaeian, N.; Usman, M.; Ibrahim, S.M.; Butt, M.U.B.U.; Waseem, M.; Ali, I.; Shakoor, A.; et al. Investigation of Input and Output Energy for Wheat Production: A Comprehensive Study for Tehsil Mailsi (Pakistan). Sustainability 2020, 12, 6884. [Google Scholar] [CrossRef]

- Ansari, R.; Liaqat, M.U.; Khan, H.I.; Mushtaq, S. Energy Efficiency Analysis of Wheat Crop under Different Climate- and Soil-Based Irrigation Schedules. Proceedings 2017, 2, 184. [Google Scholar]

- Padilla-Fernandez, M.D.; Nuthall, P.L. Technical efficiency in the production of sugar cane in central negros area, philippines: An application of data envelopment analysis. J. ISSAAS 2009, 15, 77–90. [Google Scholar]

- Chauhan, N.S.; Mohapatra, P.K.J.; Pandey, K.P. Improving Energy Productivity in Paddy Production through Benchmarking—An Application of Data Envelopment Analysis. Energy Convers. Manag. 2006, 47, 1063–1085. [Google Scholar] [CrossRef]

- Soltani, A.; Rajabi, M.H.; Zeinali, E.; Soltani, E. Energy Inputs and Greenhouse Gases Emissions in Wheat Production in Gorgan, Iran. Energy 2013, 50, 54–61. [Google Scholar] [CrossRef]

| Scenario * (Small Farm) | Wheat Agricultural Operations on Old Lands | ||||||

|---|---|---|---|---|---|---|---|

| Organic Fertilization | Tillage | Sowing | Chemical Fertilization | Spraying | Harvesting | Threshing | |

| S-I (<1 ha) | ◊ | √ | ◊ | ◊ | √ | ◊ | √ |

| S-II (1–1.5 ha) | ◊ | √ | ◊ | ◊ | √ | √ | √ |

| S-III (1.5–2 ha) | √ | √ | ◊ | ◊ | √ | √ | √ |

| Wheat Agricultural Operations on Newly Reclaimed Lands | |||||||

| S-IV (<2 ha) | √ | √ | √ | ◊ | √ | √ | √ |

| Item | Unit | Energy Equivalent (MJ unit−1) | Reference |

|---|---|---|---|

| Inputs | |||

| 1. Human labor | h | 1.96 | [21,22,23] |

| 2. Agricultural machinery | kg | 138 | [24] |

| 3. Diesel fuel | L | 56.31 | [23,25,26] |

| 4. Chemical fertilizers | |||

| (a) Nitrogen (N) | kg | 66.14 | [22,27,28] |

| (b) Phosphorus (P) | 12.44 | ||

| (c) Potassium (K) | 11.15 | ||

| 5. Manure | kg | 0.3 | [21,23,29] |

| 6. Chemical poison | |||

| (a) Herbicide | L | 238 | [26,30,31] |

| (b) Pesticide | 199 | [30] | |

| (c) Fungicide | 92 | [30] | |

| 7. Water for Irrigation | m3 | 1.02 | [32] |

| 8. Seeds | kg | 15.7 | [26] |

| Outputs | |||

| 1. Wheat grain yield | kg | 14.7 | [26,33] |

| 2. Wheat straw yield | kg | 9.25 | [34] |

| Input-Output (MJ) | Equivalent (kg CO2-eq MJ−1) | References |

|---|---|---|

| 1. Machinery | 0.071 | [39] |

| 2. Diesel fuel | 2.76 | [40] |

| 3. Chemical fertilizers | ||

| (a) Nitrogen (N) | 1.3 | [41,42] |

| (b) Phosphorus (P) | 0.2 | [41,42] |

| (c) Potassium (K) | 0.15 | [41,42] |

| 4. Manure | 0.126 | [43] |

| 5. Chemical poison | ||

| (a) Herbicide | 6.3 | [41,42] |

| (b) Pesticides | 5.1 | [41,42] |

| (c) Fungicide | 3.9 | [41,42] |

| Item | Old Lands | Newly Reclaimed Lands | Mean | SE | Share (%) | ||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| S-I (<1 ha) | S-II (1–1.5 ha) | S-III (1.5–2 ha) | S-IV (<2 ha) | ||||||||

| Energy | % | Energy | % | Energy | % | Energy | % | ||||

| Direct Inputs | |||||||||||

| 1. Human labor | 1051 | 2.29 | 687 | 1.54 | 498 | 1.17 | 219 | 0.58 | 614 | 349 | 1.4 |

| 2. Diesel fuel for machinery | 6533 | 14.24 | 7371 | 16.48 | 8014 | 18.83 | 6681 | 17.78 | 7150 | 682 | 16.8 |

| 3. Diesel fuel for Irrigation | 7036 | 15.33 | 6814 | 15.23 | 6250 | 14.69 | 5629 | 14.98 | 6432 | 629 | 15.1 |

| 4. Water | 7098 | 15.47 | 6858 | 15.33 | 6579 | 15.46 | 6229 | 16.58 | 6691 | 374 | 15.7 |

| Indirect Inputs | |||||||||||

| 1. Agricultural machinery | 1092 | 2.38 | 1351 | 3.02 | 1397 | 3.28 | 1289 | 3.43 | 1282 | 134 | 3.0 |

| 2. Chemical fertilizers | |||||||||||

| (a) Nitrogen (N) | 15,741 | 34.31 | 14,639 | 32.73 | 13,065 | 30.70 | 11,806 | 31.42 | 13,813 | 1731 | 32.3 |

| (b) Phosphorus (P) | 740 | 1.61 | 711 | 1.59 | 651 | 1.53 | 592 | 1.58 | 674 | 66 | 1.6 |

| (c) Potassium (K) | 199 | 0.43 | 186 | 0.42 | 159 | 0.37 | 133 | 0.35 | 169 | 29 | 0.4 |

| 3. Manure | 871 | 1.90 | 835 | 1.87 | 771 | 1.81 | 750 | 2.00 | 807 | 56 | 1.9 |

| 4. Seed | 3827 | 8.34 | 3684 | 8.24 | 3636 | 8.54 | 2870 | 7.64 | 3504 | 430 | 8.2 |

| 5. Chemical poison | |||||||||||

| (a) Herbicide | 906 | 1.98 | 850 | 1.90 | 821 | 1.93 | 736 | 1.96 | 828 | 71 | 1.9 |

| (b) Pesticides | 710 | 1.55 | 663 | 1.48 | 639 | 1.50 | 568 | 1.51 | 645 | 59 | 1.5 |

| (c) Fungicide | 79 | 0.17 | 79 | 0.18 | 74 | 0.17 | 72 | 0.19 | 76 | 3 | 0.2 |

| Total Inputs | 45,885 | 44,726 | 42,555 | 37,575 | 42,685 | 3676 | |||||

| Outputs | |||||||||||

| 1. Wheat grain yield | 89,949 | 64.49 | 96,212 | 65.00 | 108,457 | 67.61 | 85,891 | 65.78 | 95,127 | 9848 | 65.7 |

| 2. Wheat straw yield | 49,534 | 35.51 | 51,812 | 35.00 | 51,961 | 32.39 | 44,690 | 34.22 | 49,499 | 3393 | 34.3 |

| Total outputs | 139,483 | 148,024 | 160,418 | 130,581 | 144,626 | 12,710 | |||||

| DMU No. | DMU Name | Input-Oriented CRS Efficiency | RTS |

|---|---|---|---|

| 1 | S-I | 0.83 | Increasing |

| 2 | S-II | 0.92 | Increasing |

| 3 | S-III | 1.00 | Constant |

| Inputs | S-I | S-II | ||||||

|---|---|---|---|---|---|---|---|---|

| Optimum Energy Requirements (MJ ha−1) | Saving Energy (MJ ha−1) | ESTR (%) | Share (%) | Optimum Energy Requirements (MJ ha−1) | Saving Energy (MJ ha−1) | ESTR (%) | Share (%) | |

| 1. Human labor | 433 | 619 | 59 | 7 | 459 | 228 | 33 | 4 |

| 2. Chemical fertilizers | 12,065 | 4616 | 28 | 49 | 12,804 | 2732 | 18 | 51 |

| 3. Fuel for Irrigation | 5434 | 1602 | 23 | 17 | 5767 | 1047 | 15 | 19 |

| 4. Manure | 670 | 201 | 23 | 2 | 711 | 124 | 15 | 2 |

| 5. Seed | 3162 | 666 | 17 | 7 | 3355 | 329 | 9 | 6 |

| 6. Chemical poison | 1335 | 361 | 21 | 4 | 1417 | 128 | 8 | 2 |

| 7. Water | 5720 | 1378 | 19 | 15 | 6071 | 787 | 11 | 15 |

| Total energy | 28,819 | 9441 | 25 | 100 | 30,584 | 5375 | 15 | 100 |

| Input | GHG Emissions (kg CO2-eq ha−1) | GHG Emissions of Target Inputs Units by DEA | GHG Emissions of Target Inputs Units by DEA | GHG Emissions (kg CO2-eq ton−1) | GHG Emissions of Target Inputs Units by DEA | GHG Emissions of Target Inputs Units by DEA | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| S-I | S-II | S-III | S-IV | Average | S-I | S-II | S-I | S-II | S-III | S-IV | Average | S-I | S-II | |

| 1. Machinery | 77.5 | 95.9 | 99.2 | 91.6 | 91.0 | 77.5 | 95.9 | 12.7 | 14.7 | 13.4 | 15.7 | 14.1 | 12.7 | 14.7 |

| 2. Diesel fuel | 665.1 | 695.2 | 699.2 | 603.3 | 665.7 | 586.6 | 644.0 | 108.7 | 106.2 | 94.8 | 103.3 | 103.2 | 95.9 | 98.4 |

| 3. Chemical fertilizers | ||||||||||||||

| (a) Nitrogen (N) | 309.4 | 287.7 | 256.8 | 232.1 | 271.5 | 223.3 | 237.0 | 50.6 | 44.0 | 34.8 | 39.7 | 42.3 | 36.5 | 36.2 |

| (b) Phosphorus (P) | 11.9 | 11.4 | 10.5 | 9.5 | 10.8 | 9.1 | 9.7 | 1.9 | 1.7 | 1.4 | 1.6 | 1.7 | 1.5 | 1.5 |

| (c) Potassium (K) | 2.7 | 2.5 | 2.1 | 1.8 | 2.3 | 1.9 | 2.0 | 0.4 | 0.4 | 0.3 | 0.3 | 0.4 | 0.3 | 0.3 |

| 4. Manure | 365.9 | 350.9 | 323.9 | 314.9 | 338.9 | 281.6 | 298.8 | 59.8 | 53.6 | 43.9 | 53.9 | 52.8 | 46.0 | 45.7 |

| 5. Chemical poison | ||||||||||||||

| (a) Herbicide | 24.0 | 22.5 | 21.7 | 19.5 | 21.9 | 18.9 | 20.1 | 3.9 | 3.4 | 2.9 | 3.3 | 3.4 | 3.1 | 3.1 |

| (b) Pesticides | 18.2 | 17.0 | 16.4 | 14.6 | 16.5 | 14.2 | 15.1 | 3.0 | 2.6 | 2.2 | 2.5 | 2.6 | 2.3 | 2.3 |

| (c) Fungicide | 3.3 | 3.3 | 3.2 | 3.1 | 3.2 | 2.7 | 2.9 | 0.5 | 0.5 | 0.4 | 0.5 | 0.5 | 0.4 | 0.4 |

| Total | 1478.0 | 1486.5 | 1432.9 | 1290.2 | 1421.9 | 1215.9 | 1325.4 | 241.5 | 227.1 | 194.2 | 220.8 | 220.9 | 198.7 | 202.5 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sayed, H.A.A.; Ding, Q.; Hendy, Z.M.; Alele, J.O.; Al-Mashhadany, O.H.; Abdelhamid, M.A. Improving Energy Efficiency and Greenhouse Gas Emissions in Small Farm Wheat Production Scenarios Using Data Envelopment Analysis. Agronomy 2023, 13, 1973. https://doi.org/10.3390/agronomy13081973

Sayed HAA, Ding Q, Hendy ZM, Alele JO, Al-Mashhadany OH, Abdelhamid MA. Improving Energy Efficiency and Greenhouse Gas Emissions in Small Farm Wheat Production Scenarios Using Data Envelopment Analysis. Agronomy. 2023; 13(8):1973. https://doi.org/10.3390/agronomy13081973

Chicago/Turabian StyleSayed, Hassan A. A., Qishuo Ding, Zeinab M. Hendy, Joseph O. Alele, Osamah H. Al-Mashhadany, and Mahmoud A. Abdelhamid. 2023. "Improving Energy Efficiency and Greenhouse Gas Emissions in Small Farm Wheat Production Scenarios Using Data Envelopment Analysis" Agronomy 13, no. 8: 1973. https://doi.org/10.3390/agronomy13081973

APA StyleSayed, H. A. A., Ding, Q., Hendy, Z. M., Alele, J. O., Al-Mashhadany, O. H., & Abdelhamid, M. A. (2023). Improving Energy Efficiency and Greenhouse Gas Emissions in Small Farm Wheat Production Scenarios Using Data Envelopment Analysis. Agronomy, 13(8), 1973. https://doi.org/10.3390/agronomy13081973