Effects of Sodic Water Irrigation and Neutralizing Amendments on Physiological, Biochemical, and Nutritional Quality Traits of Fodder Sorghum

Abstract

1. Introduction

2. Materials and Methods

2.1. Experimental Site

2.2. Climate and Weather

2.3. Treatments Details and Crop Management

2.4. Physico-Chemical Properties of Soil and Irrigation Water

2.5. Sampling, Determination and Calculations

2.5.1. Production Economics

2.5.2. Physiological and Biochemical Traits

2.5.3. Proximate/Nutritional Quality Traits

2.6. Statistical Analysis

3. Results

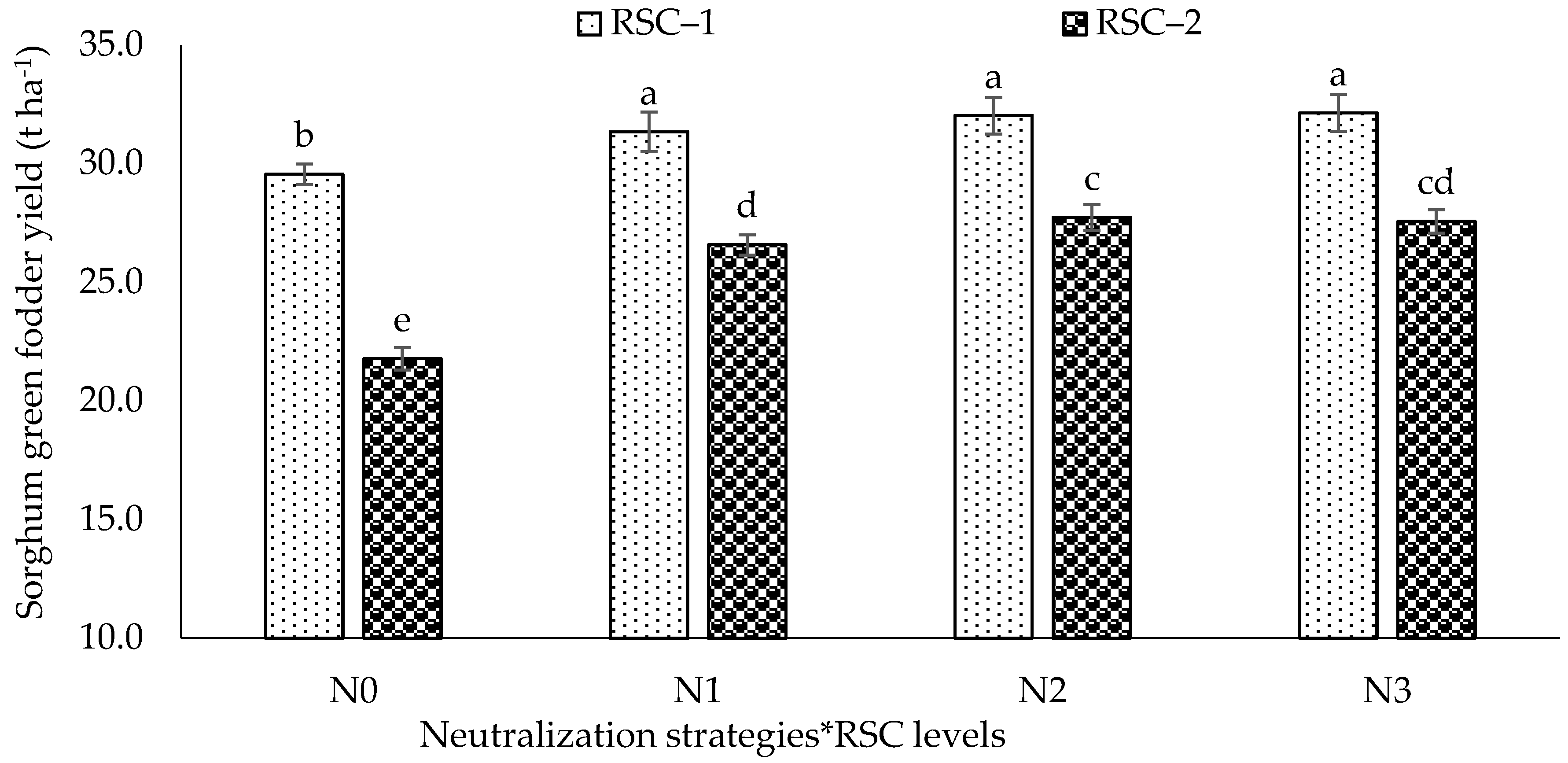

3.1. Productivity and Profitability

3.2. Physiological and Biochemical Attributes

3.3. Fodder Quality Attributes

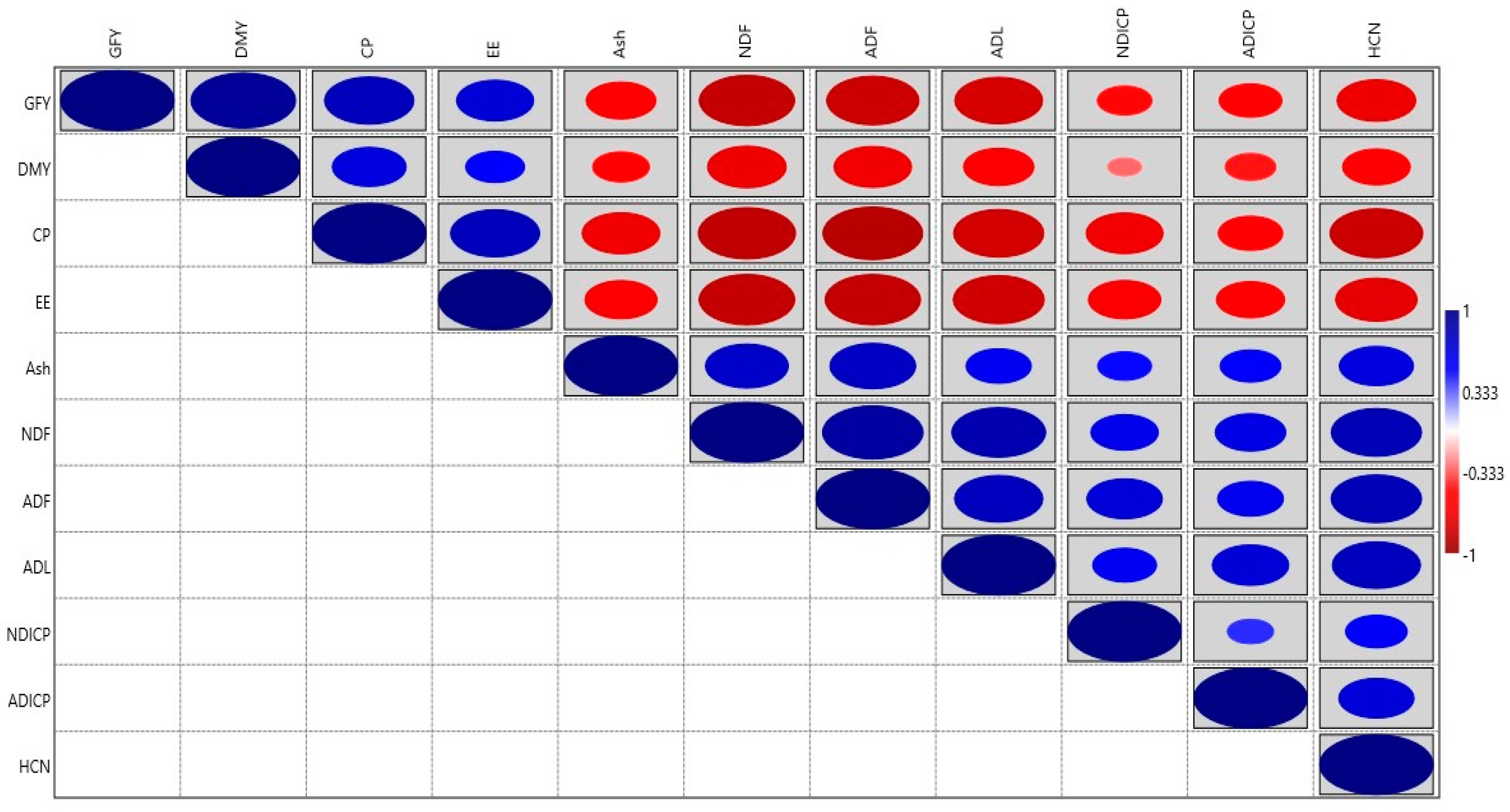

3.4. Correlation Studies

4. Discussion

4.1. Productivity and Profitability

4.2. Physiological and Biochemical Attributes

4.3. Fodder Quality Attributes

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

References

- Hazra, M.; Avishek, K. Water resources evaluation through water accounting: A means to achieve sustainable development. Bioscan 2010, 1, 43–50. [Google Scholar]

- Chauhan, B.S.; Mahajan, G.; Sardana, V.; Timsina, J.; Jat, M.L. Productivity and sustainability of the rice-wheat cropping system in the Indo-Gangetic Plains of the Indian subcontinent: Problems, opportunities, and strategies. Adv. Agron. 2012, 117, 315–369. [Google Scholar] [CrossRef]

- Panigrahy, S.; Upadhyay, G.; Ray, S.S.; Parihar, J.S. Mapping of cropping system for the Indo-Gangetic plain using multi–date SPOT NDVI–VGT data. J. Indian Soc. Remote Sens. 2010, 38, 627–632. [Google Scholar] [CrossRef]

- Singh, Y.; Sidhu, H.S. Management of cereal crop residues for sustainable rice-wheat production system. Proc. Indian Natl. Sci. Acad. 2014, 80, 95–144. [Google Scholar] [CrossRef]

- Dutta, S.; Chowhan, P. Assessment of groundwater quality of masuda tehsil, Ajmer district, Rajasthan. Ecoscan 2009, 3, 281–284. [Google Scholar]

- Yadav, R.K.; Dagar, J.C. Innovations in utilization of poor quality water for sustainable agricultural production. In Innovative Saline Agriculture; Dagar, J.C., Sharma, P.C., Sharma, D.K., Singh, A.K., Eds.; Springer: Delhi, India, 2016; pp. 219–264. [Google Scholar] [CrossRef]

- Minhas, P.S.; Bajwa, M.S. Use and management of poor quality waters for the rice-wheat based production system. J. Crop Prod. 2001, 4, 273–306. [Google Scholar] [CrossRef]

- Minhas, P.S.; Qadir, M.; Yadav, R.K. Groundwater irrigation induced soil sodification and response options. Agric. Water Manag. 2019, 215, 74–85. [Google Scholar] [CrossRef]

- Manchanda, H.R. Quality of Underground Water of Haryana. Ph.D. Thesis, Haryana Agricultural University, Hisar, India, 1976. [Google Scholar]

- Kumar, K.; Saha, B.N.; Saha, S.; Prabhakar, M.K.; Das, A.; Sashikhant; Singh, R.P.S.; Basak, N.; Verma, O.P. Assessment of ground water quality under intensively rice-wheat cultivated semi–arid regions of Haryana, India. Ecoscan 2015, 9, 127–132. [Google Scholar]

- Grattan, S.R.; Oster, J.D. Use and reuse of saline–sodic waters for irrigation of crops. J. Crop Prod. 2003, 7, 131–162. [Google Scholar] [CrossRef]

- Levy, G.H.; Mamedov, A.I.; Goldstein, D. Sodicity and water quality effects on slaking of aggregates from semi–arid soils. Soil Sci. 2003, 168, 552–562. [Google Scholar] [CrossRef]

- Oster, J.D. Amendments use to mitigate the adverse effects of alkali irrigation water. In Extended Summaries, International Conference on Sustained Management of Sodic Lands; Uttar Pradesh Council of Agricultural Research: Lucknow, India, 2004; pp. 89–91. [Google Scholar]

- Bali, A.; Singh, A.; Minhas, P.S.; Yadav, R.K. Effect of plant bioregulators and their combinations on growth and yield of wheat under sodicity stress induced by alkali water irrigation. J. Soil Salin. Water Qual. 2020, 12, 45–49. [Google Scholar]

- Sheoran, P.; Kumar, A.; Kumar, A.; Raju, R.; Sharma, R.; Parjapat, K.; Barman, A.; Singh, R.K.; Kumar, S.; Sharma, P.C.; et al. Impact of pressmud application in reclamation of high RSC irrigation water induced soil sodification and sustaining rice (Oryza sativa)–wheat (Triticum aestivum) production in Indo-Gangetic plains. Indian J. Agric. Sci. 2020, 90, 206–211. [Google Scholar] [CrossRef]

- Rana, K.S.; Choudhary, A.K.; Sepat, S.; Bana, R.S.; Dass, A. Methodological and Analytical Agronomy; Post Graduate School, Indian Agricultural Research Institute: New Delhi, India, 2014; p. 276. [Google Scholar]

- Sheoran, P.; Basak, N.; Kumar, A.; Yadav, R.K.; Singh, R.; Sharma, R.; Kumar, S.; Singh, R.K.; Sharma, P.C. Ameliorants and salt tolerant varieties improve rice-wheat production in soils undergoing sodification with alkali water irrigation in Indo-Gangetic Plains of India. Agric. Water Manag. 2021, 243, 106492. [Google Scholar] [CrossRef]

- Sheoran, P.; Kumar, A.; Singh, A.; Kumar, A.; Parjapat, K.; Sharma, R.; Singh, R.K.; Yadav, R.K.; Dang, Y.P.; Sharma, P.C. Pressmud alleviates soil sodicity stress in a rice-wheat rotation: Effects on soil properties, physiological adaptation and yield-related traits. Land Degrad. Dev. 2021, 32, 2735–2748. [Google Scholar] [CrossRef]

- Singh, Y.P.; Mishra, V.K.; Bharadwaj, A.K.; Arora, S.; Singh, A.K.; Singh, S.; Haefele, S.M. Synergy of reduced gypsum and pressmud–a cost effective approach for sustainable reclamation of degraded sodic lands. Indian J. Agric. Sci. 2019, 89, 1027–1032. [Google Scholar] [CrossRef]

- Singh, S.; Singh, S.; Kumar, P.; Tikkoo, A. Response of crop rotations to sodic waters and amendments in loamy sands of southern Haryana. Ann. Arid Zone 2008, 47, 111–116. [Google Scholar]

- Singh, Y.P.; Arora, S.; Mishra, V.K.; Dixit, H.; Gupta, R.K. Composting of municipal solid waste and farm wastes for its use as amendment in sodic soil. J. Soil Water Conserv. 2017, 16, 172–177. [Google Scholar] [CrossRef]

- Negim, O. Effect of addition pressmud and gypsum by product to reclamation of highly calcareous saline sodic soil. AASCIT J. Environ. 2015, 1, 76–84. [Google Scholar]

- Gupta, N.; Tripathi, S.; Balomajumdar, C. Characterization of pressmud: A sugar industry waste. Fuel 2011, 90, 389–394. [Google Scholar] [CrossRef]

- Anonymous. 20th Livestock Census–2019, All India Report. Department of Animal Husbandry and Dairying, Ministry of Fisheries, Animal Husbandry and Dairying, Government of India. p. 16. Available online: https://dahd.nic.in/sites/default/filess/Key%20Results%2BAnnexure%2018.10.2019.pdf (accessed on 10 June 2021).

- Anonymous. IGFRI, Vision. 2050. Indian Grassland and Fodder Research Institute Jhansi (UP). Available online: https://www.igfri.res.in/cms/Publication/Miscellaneous/IGFRI,%20Jhansi%20(Vision%202050).pdf (accessed on 10 June 2021).

- Singh, R. Availability and Utilization Pattern of Green Fodder in Punjab. Master’s Thesis, Department of Agricultural Economics, Punjab Agricultural University, Ludhiana, India, 2016. [Google Scholar]

- Hazra, K.K.; Venkatesh, M.S.; Ghosh, P.K.; Ganeshamurthy, A.N.; Kumar, N.; Nadarajan, N.; Singh, A.B. Long–term effect of pulse crops inclusion on soil–plant nutrient dynamics in puddled rice (Oryza sativa L.)–wheat (Triticum aestivum L.) cropping system on an Inceptisol of Indo-Gangetic plain zone of India. Nutr. Cycl. Agroecosyst. 2014, 100, 95–110. [Google Scholar] [CrossRef]

- Bhatt, R.; Kukal, S.S. Soil moisture dynamics during intervening period in rice-wheat sequence as affected by different tillage methods at Ludhiana, Punjab, India. Soil Environ. 2015, 34, 82–88. [Google Scholar]

- Bhatt, R.; Kukal, S.S. Delineating soil moisture dynamics as affected by tillage in wheat, Rice and establishment methods of rice during intervening period. J. Appl. Nat. Sci. 2015, 7, 364–368. [Google Scholar] [CrossRef]

- Bhatt, R.; Kukal, S.S. Soil temperature, evaporation and water tension dynamics at upper vadose zone during intervening period. Trends Biosci. 2015, 8, 795–800. [Google Scholar]

- Bhatt, R.; Kukal, S.S.; Busari, M.A.; Arora, S.; Yadav, M. Sustainability issues on rice-wheat cropping system. Int. Soil Water Conserv. Res. 2016, 4, 64–74. [Google Scholar] [CrossRef]

- CSSRI. Reclaimation and Management of salt Affected Soils; Central Soil Salinity Research Institute: Karnal, India, 2004; p. 160.

- Cheng, K.L.; Bray, R.H. Determination of calcium and magnesium in soil and plant material. Soil Sci. 1951, 72, 449. [Google Scholar] [CrossRef]

- Weatherley, P. Studies in the water relations of the cotton plant. New Phytol. 1950, 491, 81–97. [Google Scholar] [CrossRef]

- Dionisio-Sese, M.L.; Tobita, S. Antioxidant responses of rice seedlings to salinity stress. Plant Sci. 1998, 1351, 1–9. [Google Scholar] [CrossRef]

- Hiscox, J.D.; Israelstam, G.F. A method for the extraction of chlorophyll from leaf tissue without maceration. Can. J. Bot. 1979, 57, 1332–1334. [Google Scholar] [CrossRef]

- Yemm, E.W.; Willis, A.J. The estimation of carbohydrates in plant extracts by anthrone. Biochem. J. 1954, 57, 508–514. [Google Scholar] [CrossRef]

- Bradford, M.M. A rapid and sensitive method for the quantitation of microgram quantities of protein utilizing the principle of protein–dye binding. Anal. Biochem. 1976, 721, 248–254. [Google Scholar] [CrossRef]

- Bates, L.S.; Waldren, R.P.; Teare, I.D. Rapid determination of free proline for water–stress studies. Plant Soil 1973, 391, 205–207. [Google Scholar] [CrossRef]

- AOAC. Official Methods of Analysis, 18th ed.; Association of Official Analytical Chemists: Arlington, VA, USA, 2005. [Google Scholar]

- Van Soest, P.J.; Robertson, J.B.; Lewis, B.A. Methods for dietary fiber, neutral detergent fiber, and non–starch polysaccharides in relation to animal nutrition. J. Dairy Sci. 1991, 74, 3583–3597. [Google Scholar] [CrossRef] [PubMed]

- Horrocks, R.D.; Vallentine, J.F. Harvested Forages, 1st ed.; Academic Press: London, UK, 1999; p. 426. [Google Scholar]

- Lithourgidis, A.S.; Vasilakoglou, I.B.; Dhima, K.V.; Dordas, C.A.; Yiakoulaki, M.D. Forage yield and quality of common vetch mixtures with oat and triticale in two seeding ratios. Field Crops Res. 2006, 99, 106–113. [Google Scholar] [CrossRef]

- Jackson, M.L. Soil Chemical Analysis; Prentice Hall of India Pvt. Ltd.: New Delhi, India, 1967; p. 498. [Google Scholar]

- Richards, L.A. Diagnosis and Improvement of Saline and Alkaline Soils; Handbook No. 60; US Department of Agriculture: Washington, DC, USA, 1968.

- Jackson, M.L. Soil Chemical Analysis; Prentice Hall India: New Delhi, India, 1973; p. 498. [Google Scholar]

- Hanlon, E.A. Elemental determination by atomic absorption spectrophotometry. In Handbook of Reference Methods for Plant Analysis; Kalra, Y.P., Ed.; CRC Press: Boca Raton, FL, USA, 1998; pp. 157–164. [Google Scholar]

- Soni, P.G.; Yadav, R.K.; Kumar, A.; Kumar, R.; Datt, C.; Paul, K.; Kumar, G. Sorghum fodder production and its nutrient composition under different residual sodium carbonate levels in irrigation water. Indian J. Anim. Nutr. 2016, 33, 345–349. [Google Scholar] [CrossRef]

- Soni, P.G.; Yadav, R.K.; Kumar, A.; Kumar, R.; Yadav, T.; Paul, K.; Joshi, D. Effect of different levels of RSC water and their neutralization with gypsum/H2SO4 on quality parameters of fodder sorghum. In Abstracts, XVI Biennial Animal Nutrition Conference: Innovative Approaches for Animal Feeding and Nutritional Research, Animal Nutrition Society of India, ICAR–National Dairy Research Institute, Karnal, India, 6–8 February 2016; Animal Nutrition Society of India: Karnal, India, 2016; p. 184. [Google Scholar]

- Saqib, A.I.; Ahmed, K.; Qadir, G.; Nawaz, M.Q.; Rizwan, M.; Zaka, M.A.; Warraich, I.A. Comparison the efficient reclamation of different inorganic materials with organic amendments to rice-wheat crop sustainable production in salt–affected soils. Cercet. Agron. Mold. 2017, 50, 19–29. [Google Scholar] [CrossRef]

- Rao, V.; Lakshmi, G.V.; Latha, M. High RSC irrigation water effects on growth, yield attributes and yield of rice in coastal Andhra Pradesh. Int. J. Res. Chem. Environ. 2014, 4, 10–14. [Google Scholar]

- Singh, Y.P.; Singh, R.; Sharma, D.K.; Mishra, V.K.; Arora, S. Optimizing gypsum levels for amelioration of sodic soils to enhance grain yield and quality of rice (Oryza sativa L.). J. Indian Soc. Soil Sci. 2016, 64, 33–40. [Google Scholar] [CrossRef]

- Choudhary, O.P.; Josan, A.S.; Bajwa, M.S.; Kapur, M.L. Effect of sustained sodic and saline–sodic irrigations and application of gypsum and farmyard manure on yield and quality of sugarcane under semi–arid conditions. Field Crops Res. 2004, 87, 103–116. [Google Scholar] [CrossRef]

- Choudhary, O.P.; Ghuman, B.S.; Singh, B.; Thuy, N.; Buresh, R.J. Effects of long–term use of sodic water irrigation, amendments and crop residues on soil properties and crop yields in rice-wheat cropping system in a calcareous soil. Field Crops Res. 2011, 121, 363–372. [Google Scholar] [CrossRef]

- Choudhary, O.P.; Grattan, S.R.; Minhas, P.S. Sustainable crop production using saline and sodic irrigation waters. In Alternative Farming Systems, Biotechnology, Drought Stress and Ecological Fertilisation; Lichtfouse, E., Ed.; Sustainable Agriculture Reviews 6; Springer Science + Business Media: Berlin/Heidelberg, Germany, 2011; pp. 293–318. [Google Scholar] [CrossRef]

- Minhas, P.S.; Bali, A.; Bhardwaj, A.K.; Singh, A.; Yadav, R.K. Structural stability and hydraulic characteristics of soils irrigated for two decades with waters having residual alkalinity and its neutralization with gypsum and sulfuric acid. Agric. Water Manag. 2021, 244, 106609. [Google Scholar] [CrossRef]

- Munns, R.; James, R.A.; Läuchli, A. Approaches to increasing the salt tolerance of wheat and other cereals. J. Exp. Bot. 2006, 57, 1025–1043. [Google Scholar] [CrossRef] [PubMed]

- Ashraf, M.; Shahzad, S.M.; Akhtar, N.; Imtiaz, M.; Ali, A. Salinization/sodification of soil and physiological dynamics of sunflower irrigated with saline–sodic water amending by potassium and farm yard manure. J. Water Reuse Desal. 2017, 7, 476–487. [Google Scholar] [CrossRef]

- Prapagar, K.; Indraratne, S.P.; Premanandharajah, P. Effect of soil amendments on reclamation of saline–sodic soil. Trop. Agric. Res. 2012, 23, 168–176. [Google Scholar] [CrossRef]

- Kumar, A.; Mann, A.; Lata, C.; Kumar, N.; Sharma, P.C. Salinity induced physiological and molecular responses of halophytes. In Research Developments in Saline Agriculture; Dagar, J.C., Ed.; Springer Nature: Singapore, 2019; pp. 331–356. [Google Scholar] [CrossRef]

- Soni, P.G.; Yadav, R.K.; Kumar, A.; Kumar, R.; Gajender; Yadav, T.; Sharma, A.; Kushwaha, M. Effect of water quality regimes, irrigation schedules, RSC levels and neutralizer on physiological and biochemical behaviour of fodder sorghum (Sorghum bicolor). Indian J. Agric. Sci. 2020, 90, 1702–1707. [Google Scholar] [CrossRef]

- Shah, S.A.; Iqbal, F.; Haq, Z.U. Effect of different amendments on crop production under poor quality tube well water. Sarhad J. Agric. 2007, 23, 87–94. [Google Scholar]

- Dai, L.Y.; Zhang, L.J.; Ruan, Y.Y.; Fan, J.J.; Hu, K. Effects of saline–sodic stress on the blade structure and resistant indexes in sweet sorghum (Sorghum bicolor L. Moench). J. Agro Environ. Sci. 2012, 31, 468–475. [Google Scholar]

- Soni, P.G.; Yadav, R.K.; Yadav, G.; Yadav, T. Utilization of high residual sodium carbonate water neutralized with chemical amendments for fodder sorghum (Sorghum bicolor) production. Indian J. Agron. 2017, 62, 382–385. [Google Scholar]

| Treatments | Productivity (q ha−1) | Profitability of RW System With/Without Sorghum | SPE (kg ha−1 day−1) | SEE (INR ha−1 day−1) | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| WEY-RG | WEY-RS | WY | WEY-WS | WEY-RW | Additional WEY-SGF | GR-RW | NR-RW | A-GR-S | A-NR-S | BCR-System | |||

| (INR × 103 ha−1) | |||||||||||||

| Study years | |||||||||||||

| 2017–2018 | 58.39 B | 3.41 B | 39.53 | 16.79 B | 120.33 | 22.21 B | 215.09 B | 147.65 B | 39.69 B | 15.26 B | 2.38 | 39.05 | 402.33 |

| 2018–2019 | 67.28 A | 3.53 A | 39.69 | 17.40 A | 125.98 | 25.03 A | 231.81 A | 161.78 A | 46.06 A | 20.79 A | 2.47 | 41.37 | 451.41 |

| SEd± | 0.76 | 0.03 | 0.82 | 0.22 | 2.01 | 0.49 | 3.62 | 3.62 | 1.01 | 1.01 | 0.04 | 0.63 | 11.44 |

| CD (p = 0.05) | 1.87 | 0.08 | NS | 0.54 | NS | 1.20 | 15.59 | 15.59 | 4.36 | 4.36 | NS | 2.73 | 49.22 |

| RSC levels | |||||||||||||

| RSC-1 | 66.53 A | 3.59 A | 42.30 A | 17.94 A | 130.51 A | 25.83 A | 236.80 A | 168.06 A | 46.89 A | 22.04 A | 2.58 A | 42.83 A | 474.44 A |

| RSC-2 | 59.13 B | 3.35 B | 36.92 B | 16.25 B | 115.80 B | 21.41 B | 210.10 B | 141.36 B | 38.86 B | 14.01 B | 2.26 B | 37.59 B | 379.29 B |

| SEd± | 0.76 | 0.03 | 0.82 | 0.22 | 2.01 | 0.49 | 3.62 | 3.62 | 1.01 | 1.01 | 0.04 | 0.63 | 11.44 |

| CD (p = 0.05) | 1.87 | 0.08 | 2.02 | 0.54 | 8.64 | 1.20 | 15.59 | 15.59 | 4.36 | 4.36 | 0.16 | 2.73 | 49.22 |

| Neutralization strategies | |||||||||||||

| N0 | 52.61 D | 3.25 C | 33.14 C | 14.24 C | 103.37 D | 21.20 C | 187.53 D | 130.60 C | 38.49 C | 13.64 C | 2.36 C | 34.13 D | 357.19 C |

| N1 | 63.38 C | 3.48 B | 40.61 B | 17.64 B | 125.25 C | 23.93 B | 227.27 C | 146.13 B | 43.44 B | 18.59 B | 2.12 D | 40.87 C | 392.48 B |

| N2 | 65.92 B | 3.54 AB | 41.64 B | 17.84 B | 129.08 B | 24.68 A | 234.20 B | 170.01 A | 44.81 A | 19.96 A | 2.69 A | 42.13 B | 480.86 A |

| N3 | 69.42 A | 3.62 A | 43.06 A | 18.66 A | 134.91 A | 24.67 A | 244.78 A | 172.12 A | 44.77 A | 19.92 A | 2.51 B | 43.72 A | 476.93 A |

| SEd± | 1.03 | 0.04 | 0.71 | 0.25 | 1.16 | 0.30 | 2.10 | 2.10 | 0.48 | 0.48 | 0.02 | 0.32 | 5.86 |

| CD (p = 0.05) | 2.06 | 0.09 | 1.42 | 0.51 | 2.53 | 0.61 | 4.58 | 4.58 | 1.04 | 1.04 | 0.04 | 0.71 | 12.78 |

| Varietal effect | |||||||||||||

| CSR 30 basmati-KRL 210-Sugargraze | 64.77 A | 3.32 B | 41.85 A | 16.21 B | 126.27 A | 23.67 | 229.11 A | 160.95 A | 42.97 | 18.12 | 2.49 A | 41.08 A | 444.20 A |

| PB 1121-HD 2967- Sugargraze | 60.90 B | 3.62 A | 37.37 B | 17.99 A | 120.04 B | 23.57 | 217.78 B | 148.48 B | 42.78 | 17.93 | 2.36 B | 39.35 B | 409.53 B |

| SEd± | 0.73 | 0.03 | 0.50 | 0.18 | 0.56 | 0.21 | 1.00 | 1.00 | 0.39 | 0.39 | 0.01 | 0.17 | 3.02 |

| CD (p = 0.05) | 1.46 | 0.06 | 1.00 | 0.36 | 1.18 | NS | 2.12 | 2.12 | NS | NS | 0.02 | 0.36 | 6.41 |

| Treatments | Physiological Attributes | Biochemical Attributes | Gas Exchange Attributes * | K/Na | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| RWC (%) | MII (%) | TCC (μg ml−1 FW) | TSC * (μg mg−1 DW) | TSP * (mg g−1 FW) | Proline * (μg mg−1 FW) | Fv/Fm | gS | E | Y (II) | Pn | 20 DAS | 60 DAS | ||||

| 20 DAS | 60 DAS | 20 DAS | 60 DAS | 20 DAS | 60 DAS | |||||||||||

| Study years | ||||||||||||||||

| 2018 | 75.29 | 65.78 B | 12.41 | 18.86 | 1.65 | 1.34 B | 11.26 B | 15.88 B | 3.20 | 0.65 | 1.47 | 3.20 | 0.55 | 21.60 | 1.92 B | 2.13 B |

| 2019 | 76.25 | 70.70 A | 13.38 | 18.33 | 1.71 | 1.42 A | 12.25 A | 17.47 A | 3.10 | 0.66 | 1.47 | 3.37 | 0.56 | 22.59 | 2.11 A | 2.56 A |

| SEd± | 1.14 | 0.89 | 0.42 | 0.62 | 0.05 | 0.01 | 0.26 | 0.25 | 0.03 | 0.01 | 0.05 | 0.09 | 0.01 | 1.01 | 0.04 | 0.04 |

| CD (p = 0.05) | NS | 2.18 | NS | NS | NS | 0.03 | 0.64 | 0.60 | NS | NS | NS | NS | NS | NS | 0.10 | 0.11 |

| RSC levels | ||||||||||||||||

| RSC-1 | 79.41 A | 73.54 A | 11.08 B | 16.12 B | 1.79 A | 1.47 A | 10.34 B | 14.64 B | 2.71 B | 0.69 A | 1.64 A | 3.71 A | 0.58 A | 24.94 A | 2.34 A | 2.70 A |

| RSC-2 | 72.13 B | 62.94 B | 14.71 A | 21.06 A | 1.57 B | 1.29 B | 13.17 A | 18.71 A | 3.59 A | 0.62 B | 1.30 B | 2.86 B | 0.53 B | 19.25 B | 1.69 B | 1.98 B |

| SEd± | 1.14 | 0.89 | 0.42 | 0.62 | 0.05 | 0.01 | 0.26 | 0.25 | 0.03 | 0.01 | 0.05 | 0.09 | 0.01 | 1.01 | 0.04 | 0.04 |

| CD (p = 0.05) | 2.80 | 2.18 | 1.03 | 1.52 | 0.19 | 0.03 | 0.64 | 0.60 | 0.12 | 0.02 | 0.12 | 0.22 | 0.02 | 2.47 | 0.10 | 0.11 |

| Neutralization strategies | ||||||||||||||||

| N0 | 66.23 C | 57.87 D | 16.30 A | 23.43 A | 1.45 C | 1.24 C | 15.79 A | 19.19 A | 3.73 A | 0.63 B | 1.33 B | 2.83 C | 0.53 B | 19.67 B | 1.05 D | 1.59 D |

| N1 | 74.55 B | 68.90 C | 13.43 B | 19.54 B | 1.71 B | 1.37 B | 13.36 B | 17.95 B | 3.13 B | 0.66 A | 1.59 A | 3. 48 AB | 0.56 A | 23.45 A | 1.94 C | 2.20 C |

| N2 | 80.50 A | 70.96 B | 10.98 C | 16.71 C | 1.77 A | 1.43 A | 10.11 C | 15.83 C | 2.80 D | 0.64 B | 1.41 B | 3. 12 BC | 0. 55 AB | 21.33 B | 2.44 B | 2.60 B |

| N3 | 81.79 A | 75.22 A | 10.88 C | 14.68 D | 1.79 A | 1.47 A | 7.76 D | 13.74 D | 2.94 C | 0.67 A | 1.56 A | 3.71 A | 0.57 A | 23.93 A | 2.63 A | 2.98 A |

| SEd± | 1.07 | 1.01 | 0.33 | 0.48 | 0.02 | 0.03 | 0.53 | 0.49 | 0.06 | 0.01 | 0.05 | 0.20 | 0.01 | 0.92 | 0.06 | 0.07 |

| CD (p = 0.05) | 2.15 | 2.02 | 0.67 | 0.97 | 0.05 | 0.07 | 1.05 | 0.98 | 0.13 | 0.01 | 0.10 | 0.41 | 0.03 | 1.84 | 0.12 | 0.15 |

| Treatments | DM (%) | DMY (t ha−1) | CP (%) | CPY (q ha−1) | EE (%) | EEY (q ha−1) | Ash (%) | Ash yield (q ha−1) | NDF (%) | ADF (%) | ADL (%) | NDICP (%) | ADICP (%) | HCN (mg kg−1) | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Study years | |||||||||||||||

| 2018 | 21.73 A | 5.73 B | 9.19 | 5.30 B | 1.87 | 1.08 B | 8.08 | 4.62 | 66.33 A | 37.07 A | 5.45 | 3.34 | 1.52 | 91.92 | 110.01 A |

| 2019 | 20.05 B | 6.13 A | 9.23 | 5.68 A | 1.85 | 1.14 A | 8.06 | 4.93 | 64.45 B | 36.36 B | 5.41 | 3.27 | 1.50 | 91.94 | 101.28 B |

| SEd± | 0.11 | 0.14 | 0.08 | 0.16 | 0.01 | 0.02 | 0.04 | 0.13 | 0.38 | 0.27 | 0.13 | 0.03 | 0.02 | 0.04 | 2.77 |

| CD (p = 0.05) | 0.26 | 0.35 | NS | 0.39 | NS | 0.06 | NS | NS | 0.92 | 0.66 | NS | NS | NS | NS | 6.78 |

| RSC levels | |||||||||||||||

| RSC-1 | 20.33 B | 6.33 A | 9.73 A | 6.16 A | 1.92 A | 1.21 A | 7.97 B | 5.05 A | 63.88 B | 35.69 B | 5.22 B | 3.21 B | 1.47 B | 92.03 A | 95.58 B |

| RSC-2 | 21.45 A | 5.52 B | 8.69 B | 4.82 B | 1.81 B | 1.00 B | 8.17 A | 4.50 B | 66.89 A | 37.74 A | 5.65 A | 3.40 A | 1.55 A | 91.83 B | 115.71 A |

| SEd± | 0.11 | 0.14 | 0.08 | 0.16 | 0.01 | 0.02 | 0.04 | 0.13 | 0.38 | 0.27 | 0.13 | 0.03 | 0.01 | 0.04 | 2.77 |

| CD (p = 0.05) | 0.26 | 0.35 | 0.20 | 0.39 | 0.03 | 0.06 | 0.09 | 0.32 | 0.92 | 0.66 | 0.31 | 0.15 | 0.07 | 0.09 | 6.78 |

| Neutralization strategies | |||||||||||||||

| N0 | 21.88 A | 5.56 B | 8.33 D | 4.67 C | 1.70 C | 0.95 C | 8.43 A | 4.68 | 68.34 A | 39.37 A | 5.74 A | 3.69 A | 1.68 A | 91.57 B | 127.16 A |

| N1 | 20.86 B | 6.02 A | 9.14 C | 5.52 B | 1.85 B | 1.12 B | 7.91 B | 4.76 | 65.14 B | 36.22 B | 5.51 B | 3.39 B | 1.55 B | 92.09 A | 110.20 B |

| N2 | 20.39 B | 6.06 A | 9.80 A | 5.95 A | 1.95 A | 1.18 A | 7.98 B | 4.82 | 64.12 C | 35.33 C | 5.29 C | 2.79 C | 1.48 B | 92.02 A | 96.65 C |

| N3 | 20.43 B | 6.07 A | 9.56 B | 5.82 A | 1.94 A | 1.18 A | 7.96 B | 4.83 | 63.95 C | 35.94 B | 5.19 C | 3.34 B | 1.33 C | 92.04 A | 88.58 D |

| SEd± | 0.33 | 0.12 | 0.09 | 0.13 | 0.02 | 0.02 | 0.06 | 0.10 | 0.32 | 0.20 | 0.06 | 0.07 | 0.03 | 0.06 | 3.25 |

| CD (p = 0.05) | 0.65 | 0.23 | 0.18 | 0.26 | 0.05 | 0.05 | 0.12 | NS | 0.63 | 0.40 | 0.13 | 0.14 | 0.06 | 0.12 | 6.51 |

| Treatments | Nutritive/Energy Indices | Nutrient Contents | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| DMD (%) | DMI (%) | NEl (mcal kg−1) | RFV (%) | TDN (%) | N (%) | P (%) | Ca (%) | Mg (%) | Fe (mg kg−1) | Mn (mg kg−1) | Cu (mg kg−1) | Zn (mg kg−1) | |

| Study years | |||||||||||||

| 2018 | 60.02 B | 1.81 B | 1.33 B | 84.36 B | 53.49 B | 1.47 | 0.22 | 0.39 | 0.28 | 209.98 | 114.83 B | 16.50 B | 47.08 B |

| 2019 | 60.58 A | 1.86 A | 1.35 A | 87.62 A | 54.41 A | 1.48 | 0.22 | 0.39 | 0.29 | 210.37 | 117.84 A | 18.06 A | 49.55 A |

| SEd± | 0.21 | 0.01 | 0.01 | 0.47 | 0.35 | 0.01 | 0.00 | 0.00 | 0.00 | 1.73 | 0.78 | 0.13 | 0.38 |

| CD (p = 0.05) | 0.51 | 0.03 | 0.02 | 1.16 | 0.85 | NS | NS | NS | NS | NS | 1.91 | 0.33 | 0.92 |

| RSC levels | |||||||||||||

| RSC-1 | 61.09 A | 1.88 A | 1.36 A | 89.06 A | 55.27 A | 1.56 A | 0.23 A | 0.40 A | 0.29 | 215.10 A | 119.62 A | 17.87 A | 48.76 |

| RSC-2 | 59.50 B | 1.80 B | 1.31 B | 82.92 B | 52.63 B | 1.39 B | 0.21 B | 0.38 B | 0.28 | 205.25 B | 113.04 B | 16.69 B | 47.87 |

| SEd± | 0.21 | 0.01 | 0.01 | 0.47 | 0.35 | 0.01 | 0.00 | 0.00 | 0.00 | 1.73 | 0.78 | 0.13 | 0.38 |

| CD (p = 0.05) | 0.51 | 0.03 | 0.02 | 1.16 | 0.85 | 0.03 | 0.01 | 0.01 | NS | 4.23 | 1.91 | 0.33 | NS |

| Neutralization strategies | |||||||||||||

| N0 | 58.23 C | 1.76 C | 1.27 C | 79.41 C | 50.52 C | 1.33 D | 0.20 C | 0.36 D | 0.27 D | 191.61 D | 105.96 D | 16.30 D | 45.40 D |

| N1 | 60.68 B | 1.84 B | 1.35 B | 86.81 B | 54.59 B | 1.46 C | 0.22 B | 0.41 A | 0.28 C | 206.69 C | 115.62 C | 16.77 C | 47.22 C |

| N2 | 61.37 A | 1.87 A | 1.37 A | 89.11 A | 55.73 A | 1.57 A | 0.23 A | 0.39 C | 0.29 B | 225.22 A | 122.95 A | 18.39 A | 51.42 A |

| N3 | 60.91 B | 1.88 A | 1.36 B | 88.63 A | 54.96 B | 1.53 B | 0.23 A | 0.40 B | 0.30 A | 217.18 B | 120.79 B | 17.67 B | 49.22 B |

| SEd± | 0.15 | 0.01 | 0.01 | 0.50 | 0.26 | 0.01 | 0.00 | 0.00 | 0.00 | 1.69 | 0.69 | 0.15 | 0.87 |

| CD (p = 0.05) | 0.31 | 0.02 | 0.01 | 1.00 | 0.51 | 0.03 | 0.01 | 0.00 | 0.00 | 3.39 | 1.39 | 0.31 | 1.73 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Makarana, G.; Yadav, R.K.; Sheoran, P.; Kumar, R.; Kumar, A.; Ram, H.; Yadav, M.R.; Kumar, D.; Kumar, S.; Minkina, T.; et al. Effects of Sodic Water Irrigation and Neutralizing Amendments on Physiological, Biochemical, and Nutritional Quality Traits of Fodder Sorghum. Agronomy 2023, 13, 1128. https://doi.org/10.3390/agronomy13041128

Makarana G, Yadav RK, Sheoran P, Kumar R, Kumar A, Ram H, Yadav MR, Kumar D, Kumar S, Minkina T, et al. Effects of Sodic Water Irrigation and Neutralizing Amendments on Physiological, Biochemical, and Nutritional Quality Traits of Fodder Sorghum. Agronomy. 2023; 13(4):1128. https://doi.org/10.3390/agronomy13041128

Chicago/Turabian StyleMakarana, Govind, Rajender Kumar Yadav, Parvender Sheoran, Rakesh Kumar, Ashwani Kumar, Hardev Ram, Malu Ram Yadav, Dinesh Kumar, Saurabh Kumar, Tatiana Minkina, and et al. 2023. "Effects of Sodic Water Irrigation and Neutralizing Amendments on Physiological, Biochemical, and Nutritional Quality Traits of Fodder Sorghum" Agronomy 13, no. 4: 1128. https://doi.org/10.3390/agronomy13041128

APA StyleMakarana, G., Yadav, R. K., Sheoran, P., Kumar, R., Kumar, A., Ram, H., Yadav, M. R., Kumar, D., Kumar, S., Minkina, T., Movsesyan, H. S., Mandzhieva, S. S., & Rajput, V. D. (2023). Effects of Sodic Water Irrigation and Neutralizing Amendments on Physiological, Biochemical, and Nutritional Quality Traits of Fodder Sorghum. Agronomy, 13(4), 1128. https://doi.org/10.3390/agronomy13041128