Abstract

The feasibility of unconventional feed for ruminants must be analyzed for appropriate use as sources of energy or protein that contribute to a sustainable production system addressing concerns about climate change, greenhouse gas emissions, and food security. The objective of this study was to evaluate the nutritive value of by-products including bean residue (BR), bean straw (BS), cassava bagasse (CB), corn straw (CS), orange bagasse (OB), peanut shell (PS), sugarcane bagasse (SB), soybean hull (SH), and sugarcane straw (SS). Chemical composition, in vitro degradability, and fermentative parameters were analyzed and subjected to multivariate and principal component analyses. Crude protein content was highly variable among by-products with BR and SH presenting the highest values (p < 0.001). These values did not differ between BR and SH, while the lowest values were observed in OB, PS, SB, SS, CS, and CB. Neutral detergent fiber content was higher in SB, PS, CS, and SS (p < 0.001), while greater in vitro degradability was found for CB, BR, OB, BS, and SH (p < 0.001). However, the in vitro gas production (p < 0.001) and total short-chain fatty acid concentration (p < 0.001) were higher in CB, BR, BS, and OB. Multivariate cluster analysis showed three distinct groups with the most degradable in group 1 followed by group 2. These results demonstrate that the by-products used in this study did not impair in vitro fermentation, and thus have the potential to be used in the diets of ruminants and to improve the sustainability of the livestock production sector.

1. Introduction

The increasing demand for animal products, driven by the rapid growth of the global population [1], presents significant challenges for ruminant production. These challenges include the need to increase food production and security while minimizing environmental impact in the context of accelerated climate change. Although ruminants are generally misjudged for their low feed efficiency, they have direct impacts on environmental protection, sustainable food security, satisfying livelihoods, and economic opportunity. Furthermore, they also have the potential to utilize non-human-edible resources to produce the same amount of animal protein, making them an important component of sustainable food production strategies [2].

Achieving sustainability in livestock production and reducing its environmental impact require changes in the production system. These changes include improvements in feed management and waste generation [3]. Agro-industrial by-products obtained from food-processing operations offer a sustainable alternative for ruminant production since they can serve as animal feed [4,5]. These by-products display a wide range of nutritional value, with some being highly suitable as feed ingredients, while others have limited value. Although these by-products are derived from edible raw materials, they are often not fit for human consumption. However, ruminants have the ability to convert low-quality fiber into high-quality protein products (meat and milk) through an efficient digestion process. This conversion process provides essential amino acids for humans that cannot be obtained solely from vegetables [6].

The in vitro gas production technique is a valuable tool for determining chemical characteristics and estimating the degradability of nutrients. It also allows for the matching of by-products inclusion to animal requirements [7] and the ranking of feeds in terms of carbohydrates and antinutritional factors [8]. Therefore, the aim of this study was to evaluate different by-products as potential ruminant feedstuffs using their chemical composition and in vitro gas production.

2. Materials and Methods

All the procedures using animals were approved by the institutional Committee for Animal Use in Research of the Center for Nuclear Energy in Agriculture, University of São Paulo (CENA/USP) (Protocol: 011/2016).

2.1. Origin of Samples and Location

The in vitro assay was carried out at the Laboratory of Animal Nutrition at the Center for Nuclear Energy in Agriculture, University of São Paulo (LANA/CENA/USP), in Piracicaba, São Paulo, Brazil. The by-product samples were collected from farms and agro-industries in the metropolitan region of Piracicaba, in the state of São Paulo, located in the southeastern region of Brazil.

2.2. Chemical Analyses

The by-products used were bean residue (BR), bean straw (BS), cassava bagasse (CB), corn straw (CS), orange bagasse (OB), peanut hull (PH), sugarcane bagasse (SB), soybean hull (SH), and sugarcane straw (SS). To reduce the inherent variability found in by-products, two samples were collected from different farms or agro-industries for each one. All samples were dried (55 °C, 72 h) in an air-forced oven and ground to pass through a 1 mm sieve in a Wiley mill (Marconi, Piracicaba, SP, Brazil). The contents of dry matter (DM; # 934.01), ashes (# 942.05), and crude protein (CP; # 2001.11) were determined according to the Association of Official Analytical Chemists [9]; ashes were used to calculate the organic matter (OM) content. Neutral detergent fiber (NDF), acid detergent fiber (ADF), lignin, hemicellulose, and cellulose were determined according to Van Soest, Robertson, and Lewis [10] and adapted by Mertens [11]. Total carbohydrates (TCs) and soluble carbohydrates (SolCs) were calculated according to Sniffen et al. [12].

2.3. In Vitro Gas Production Assay

Two identical in vitro gas production (IVGP) trials were carried out one week apart. The IVGP and in vitro degradability (IVD) were determined following the procedures of Theodorou et al. [13], using a semi-automatic system, as described by Mauricio et al. [14] with adaptations previously described by Abdalla et al. [15], Bizzuti et al. [16], Ligoski et al. [17], and Sakita et al. [18]. Briefly, dry substrate samples were weighed (i.e., 0.5 g) into Ankom #F57 filter bags (Ankom F-57, Macedon, NY, USA) and then sealed and incubated in 160 mL serum bottles (one per bottle) containing 25 mL of ruminal fluid as the inoculum and 50 mL of incubation medium [19]

Three rumen-cannulated Santa Inês male sheep (body weight = 60 ± 2.5 kg (mean ± SD)) were used as rumen fluid donors. The animals had ad libitum access to mineral supplements, water, and Tifton-85-hay (Cynodon spp.) with a concentrate mixture (i.e., 70% ground corn and 30% soybean meal). Ruminal contents were collected from each animal before the morning feed and kept at 39 °C under anaerobic conditions until inoculation was carried out. Three inocula were prepared (ruminal content from two animals for each inoculum, 1–2; 2–3; 3–1), using a 50:50 solid:liquid ratio [19]. For each substrate, two bottles were incubated (location 1 and location 2) (experimental unit), and each experimental unit was incubated in each one of the three inocula. The bottles were sealed with rubber stoppers and aluminum caps and incubated at 39 °C for 24 h in a forced ventilation oven. Gas pressure (in psi) was measured using a pressure transducer and a datalogger [14] at 3, 6, 12, and 24 h after closing the bottles to estimate total gas produced (mL) using the equation obtained with linear regression (n = 500; R2 = 0.99), as described by Soltan et al. [20]: V = 7.365 × psi, where V is the gas volume (mL) and psi is pressure measured with the transducer.

After each gas pressure measurement, a subsample of gas (2.5 mL) was collected into 10 mL vacuum tubes to determine the methane (CH4) concentration using a gas chromatograph (Shimadzu GC 2014, Chiyodaku, Tokyo, Japan) equipped with flame ionization detector (FID) and a capillary HP-molesieve column (GC 30 m × 0.53 mm × 25 µm). The GC conditions were a column temperature of 60 °C, injector temperature of 200 °C, detector temperature of 240 °C, and the carrier gas (Helium) in constant flux at 10 mL/min. A calibration curve was prepared using 99.5% pure CH4 standard (Praxair Industrial Gases, Osasco, Brazil). Methane production estimation was calculated according to Longo et al. [21]: CH4 (mL g−1 DM) = (VGP + HS) * %CH4, where VGP is the volume of gas produced (mL); HS is the bottle head space (85 mL); %CH4 is the methane percentage in the subsample; and CH4 is the methane concentration (mL g−1 DM). Methane efficiency (%) was calculated as (CH4/VGP) × 100 and expressed the percentage of methane in every mL of gas produced.

2.4. Organic Matter Degradability and Ruminal Fermentation Parameters

After 24 h, the bags were recovered from the bottles and immediately immersed in cold water (−4 °C) to inhibit further fermentation. The 24 h period was selected based on previous research, which has demonstrated that a plateau in results can be reached within this timeframe if the particle size of the substrate is approximately 1 mm [22]. All bags were treated with a neutral detergent solution for one hour at 90 °C and then washed with hot water and acetone in sequence. The bags were placed in a muffle furnace at 550 °C for 4 h, and the ashes were weighed and used to determine the truly degraded organic matter (TDOM).

Microbial efficiency was estimated by calculating the partitioning factor (PF) using the ratio of TDOM (in mg) and total gas production (in mL) in a 24 h incubation period [23]. After the in vitro fermentation was terminated, a 2 mL subsample of the fermentation fluid was collected from each bottle to determine the concentration of ammonium nitrogen (NH3-N), using the micro-Kjeldahl method [9], and the concentration of short-chain fatty acids (SCFAs), using the methodology of Palmquist and Conrad [24], with gas chromatography (GC 2014 Shimadzu, Tokyo, Japan) equipped with FID and with the column GP 10% SP-1200/1 H3PO4 80/100 Chromosorc WAW (ct. no. 11965, 6′ × 1/8″ stainless steel, SUpelco, Bellefonte, PA, USA) as described by Lima et al. [25].

The potential cumulative gas produced (A) (mL), lag time (L; the initial time before degradation start), T½ (time (h) to obtain the half value of A), and the fractional rate of fermentation (µ½) were calculated using the generalized Mitscherlich model as proposed by France et al. [26]:

, where Y is the cumulative gas production (in mL), b is the fractional rate of gas production, t is the incubation time (in hours), L is the lag time (in hours), and c is the shape parameter.

2.5. Statistical Analyses

Data were analyzed as a randomized complete block design using the MIXED procedure of SAS (v. 9.4, SAS Inc., Cary, NC, USA), and the means were compared using the Tukey test at 5% significance. Additionally, France’s model was applied using the NLIN procedure. Treatments (substrates) were considered fixed effects and block (IVGP trial) and inoculum (repetition) were considered random effects according to the following model: Yijk = μ + Ti + Rj + aij + Ik + eijk, where Yijk is the expected response; μ is the general average; T is the fixed parameter associated to treatment i; Rj is the random parameter associated with block j~NID (0, σ2R normally and independently distributed with mean 0 and variance σ2); aij is the error associated with treatment i in block j~NID (0, σ2a); Ik is the random parameter associated with inoculum; and eijk is the experimental error associated with treatment i, block j, and inoculum k~NID (0, σ2e).

Multivariate hierarchical cluster analysis was performed with Ward’s method, using R statistical software [27], for grouping the by-products regarding chemical composition, in vitro gas production, organic matter degradability, and ruminal fermentative kinetics. The similarity and dissimilarity measures were calculated as squared Euclidean distances. The grouping of the by-products obtained from the cluster analysis was then used as a grouping variable for a principal component analysis (PCA). Both cluster and PCA were performed using the ‘factoextra’ [28] package in R.

3. Results

3.1. Chemical Composition

Dry matter (p = 0.101) and ash content (p = 0.208) were not different among treatments (Table 1). The CP content was different among the by-products, with BR and SH (p < 0.001) presenting the greatest values but not differing from each other. A lower NDF content was obtained for CB, while greater values were observed for SB, PS, CS, and SS (p < 0.0001). The same pattern was found for ADF, LIG, and CEL contents (p < 0.0001), where CB presented lower values and greater values for SB and PS. For the SolC content, greater values for CB and lower values for SB, PS, CS, and SS were observed (p < 0.001).

Table 1.

Chemical composition (g kg−1 DM) of the by-product samples used.

3.2. In Vitro Gas Production and Short-Chain Fatty Acids

Treatments CB, BR, OB, BS, and SH did not differ among each other regarding IVD (Table 2) but were greater than SS, SB, CS, and PS. The greatest value of IVGP was demonstrated by CB, and lower values were found for SS, SB, CS, and PS (p < 0.0001). The same pattern in response was observed for CH4, with greater values for CB and BR (p = 0.0015). Lower values of PF were demonstrated by PS and SB (p = 0.0001).

Table 2.

In vitro degradability, in vitro gas production, net methane, and the partitioning factor for the evaluated by-products.

The SCFA concentrations were different among by-products after 24 h of incubation (p < 0.0001, Table 3). A lower total SCFA was demonstrated by SS, SB, CS, and PS (p < 0.05), and the same pattern in response was found for the acetate concentration. The greatest concentration of propionate and the lowest A:P ratio were demonstrated by CB (p < 0.05).

Table 3.

Short-chain fatty acid concentration (mmol L−1) of the by-products after a 24 h incubation period.

3.3. Kinetic Fermentative Parameters

The greatest gas accumulation (A) was obtained for CB, BR, OB, BS, and SH (p < 0.001), while the lowest was obtained for SB and PS (p > 0.05) (Table 4). The values of µ½ followed a similar trend in A, where the greatest values were for BR and BS (p < 0.001).

Table 4.

Kinect parameters related to rumen fermentation.

3.4. Cluster and Principal Component Analysis

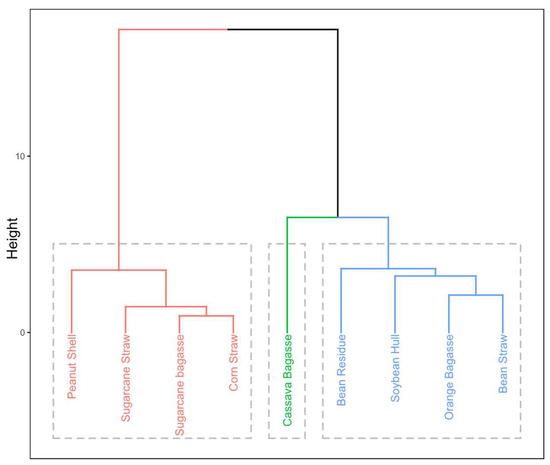

The cluster analysis resulted in the formation of three clusters (Figure 1): red, green, and blue. The level of similarity within each group was greater than 62%. The red group was composed of PS, SS, SB, and CS, the green group was composed solely of CB, and the blue group was composed of BR, SH, OB, and BS.

Figure 1.

Multivariate cluster analysis plot showing groups of different by-products based on similarities in chemical composition, in vitro degradability, and fermentation parameters.

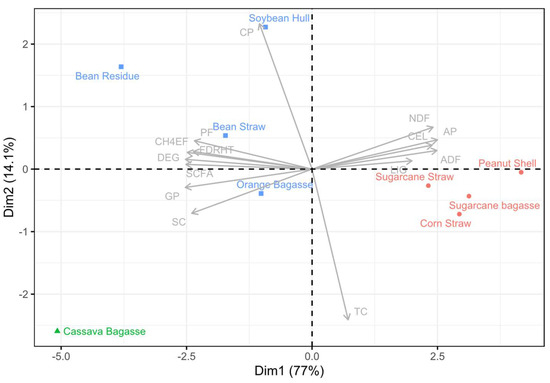

The clusters obtained using the cluster analysis were then used as a grouping variable for the PCA (Figure 2). The PCA results showed that components 1 and 2 explain 91.1% of the variability among the by-products. Component 1 (Dim1) explained 77.2% of the variability and appears to be related to the gas production and variables that may influence it, such as fiber content, degradability, and the A:P ratio. Component 2 (Dim2) explained 14% of the variability, and it appears to be characterized by an inverse relationship between the CP and TC contents.

Figure 2.

PCA showing the grouping and separation of the by-products based on chemical composition, in vitro degradability, and fermentative parameters. ADF: acid detergent fiber; AP: acetate/propionate ratio; CEL: cellulose; CH4EF: methane efficiency; CP: crude protein; DEG: degradability; FDRHT: gas production rate; GP: total gas produced; LIG: lignin; NDF: neutral detergent fiber; PF: partitioning factor; SC: soluble carbohydrates; SCFA: short-chain fatty acid; TC: total carbohydrate.

The by-products from the red group clustered near the variables associated with a high structural fiber content (CEL, ADF, LIG), and as a consequence, are opposed to variables such as degradability, gas, and the SCFA concentration. Their low CP and TC contents also explain their location near the center of the Dim2 axis.

The by-products from the blue group are located towards the middle-upper portion of the Dim2 axis, indicating a middle to high CP content and a middle to lower TC content. With the exception of BR, they all have moderate degradability, SCFA production, and CH4 efficiency.

CB, in the green cluster, was located on the lower left portion of the biplot, indicating lower CP and structural fiber contents and high total carbohydrates, degradability, gas production, CH4 efficiency, and propionate production.

4. Discussion

The chemical composition of the by-products varied because of the different origins of the substrates [29]. Huber [30] and the FAO [31] classified substrates according to their nutritional value, considering the value of NDF, ADF, OM, CP, and SolC. In this context, the wide variation in the chemical composition of the by-products used in this study offers flexibility in the formulation of diets according to the requirements to be achieved. We classified the products as follows: SH and BR as protein feed (i.e., 18% or more of crude protein); PS, CS, SS, and SB as roughage (i.e., more than 18% crude fiber); and BS, CB, and OB as energetic feed (i.e., less than 20% crude protein and less than 18% crude fiber).

A multivariate cluster analysis was used to classify the by-products based on their chemical composition, in vitro gas production, organic matter degradability, and ruminal fermentative kinetics. The analysis revealed one clear cluster consisting of three groups. Group 1 included cassava bagasse, which was found to be the most degradable by-product due to its high digestible starch content, as described by Souza et al. [32] and Bizzuti et al. [16]. Group 2 included orange bagasse, bean straw, bean residue, and soybean hull, all of which showed greater degradability than the ingredients in Group 3. Group 3 consisted of peanut shell, sugarcane straw, sugarcane bagasse, and corn straw, which had the highest values of NDF, ADF, and lignin, suggesting that they are fiber by-products.

In agreement with the cluster analysis, the by-products have the same grouping as the PCA plot. The lower IVD and IVGP observed for roughage feeds (Group 3) corroborate the results found by Chen, Lee, and Yu [33] and Liu et al. [34], who found a lower performance for roughage substrates due to their greater fiber content than concentrate feeds. In general, concentrate feeds provide more soluble carbohydrates for fermentation, thereby, a greater IVGP but a lower IVD are expected compared to the ruminal fermentation of by-products. However, by-products such as CB presented a high concentration of soluble carbohydrate content but lower fiber as cellulose and lignin, as observed in Group 1 in the present study and corroborated by Souza et al. [32] and Bizzuti et al. [16], indicating the remaining digestible starch in this by-product leads to higher performance.

Cassava bagasse and BR have been identified as by-products with desirable characteristics from a nutritional perspective for ruminants, although with a higher CH4 production. Both by-products were located away from the center horizontal axis grouping near the variables such as high degradability, high SCFA production, lower A:P ratio, and higher PF (i.e., more degraded substrate being converted into microbial mass). Despite these similarities, CB and BR also have contrasting characteristics. Both are located far away from the center vertical axis but in opposing positions. CB is a substrate with a higher TC content and low protein, and BR is the opposite having high protein and low carbohydrates. They both are substrates with similar fermentative responses but different bromatological characteristics, which may allow for flexibility in their use for ruminant nutrition.

With regard to CH4 production, greater values were obtained for the by-products with more easily fermentable carbohydrates that provide H2 and CO2 for CH4 synthesis by methanogenic microorganisms [15,35,36]. Methane production can be a result of an inefficient conversion of potentially available energy from the feed, representing metabolic and financial losses [37,38].

Short-chain fatty acids are the main source of energy for ruminants, and the balance of the acetate and propionate ratio (A:P) production determines the partition of energy and the availability of H2 free in the rumen for the methanogens [39]. Getachew et al. [8] showed that the A:P ratio indicates the proportionality of digestible NDF in the feeds. This is evidenced by the lowest A:P ratio observed for CB and BR in the current study because high starch content leads to a proportionally greater propionate production, thus decreasing the A:P ratio. The better fermentative parameters observed in the energetic ingredients can be explained by the increased concentration of soluble carbohydrates as well as the lower levels of lignin and ADF content.

The bulky feed group can be linked to greater NDF and lignin content, along with a lower SolC content. A high lignin content can make it difficult for microorganisms to access potentially degradable components in the NDF fraction [40,41], thus increasing the time for the initial colonization (i.e., lag time) and decreasing the gas production and substrate degradability.

By-products are considered valuable feed ingredients worldwide and provide a viable source of protein and energy for ruminants without competing with human-edible feeds. The chemical composition varies greatly among the evaluated by-products, resulting in different degradation patterns and potential applications [4]. These by-products can serve as alternative sources for various feed components in the ration or supplements. The availability of these by-products may vary by region and country, and they can play a crucial role in reducing production costs for small-scale animal husbandry.

5. Conclusions

The chemical composition varied widely among the evaluated by-products, resulting in different degradation patterns and potential applications. For instance, cassava bagasse and orange bagasse were characterized as energy sources, while soybean hulls and bean residues could provide protein. Additionally, peanut shells, corn straw, and sugarcane bagasse were shown to be sources of fiber. Agro-industrial by-products exhibited potential for use in ruminant diets without disrupting fermentation processes and are thus likely to contribute to a vertically integrated food chain that integrates animal production, the agro-industry, and environmental sustainability.

Author Contributions

Conceptualization, B.E.B. and A.L.A.; data curation, B.E.B. and S.P.-M.; formal analysis, B.E.B. and S.P.-M.; funding acquisition, A.L.A.; investigation, B.E.B., W.S.C. and V.S.O.; methodology, B.E.B., V.S.O., F.d.O.S.v.C., W.S.C. and P.M.T.L.; project administration, B.E.B. and A.L.A.; resources, A.L.A. and H.L.; supervision, A.L.A.; writing—original draft, B.E.B.; writing—review and editing, P.M.T.L., A.L.A., F.d.O.S.v.C., S.P.-M., V.S.O. and H.L. All authors have read and agreed to the published version of the manuscript.

Funding

The National Council for Scientific and Technological Development/Conselho Nacional de Desenvolvimento Científico e Tecnológico (CNPq) funded the first author’s scholarship (Grant #169631/2017-6) and the research productivity fellowship of A.L.A. (Grant # 303395_2019-2).

Data Availability Statement

The data presented in this study are available on request from the corresponding author.

Acknowledgments

We acknowledge the support of the Animal Nutrition Laboratory team of the Center for Nuclear Energy in Agriculture (CENA) at The University of São Paulo (USP).

Conflicts of Interest

The authors declare no conflict of interest. The funders had no role in the design of this study; in the collection, analyses, or interpretation of data; in the writing of the manuscript; or in the decision to publish the results.

References

- Halmemies-Beauchet-Filleau, A.; Rinne, M.; Lamminen, M.; Mapato, C.; Ampapon, T.; Wanapat, M.; Vanhatalo, A. Review: Alternative and novel feeds for ruminants: Nutritive value, product quality and environmental aspects. Animal 2018, 12, s295–s309. [Google Scholar] [CrossRef] [PubMed]

- Mottet, A.; Haan, C.; Falcucci, A.; Tempio, G.; Opio, C.; Gerber, P. Livestock: On our plates or eating at our table? A new analysis of the feed/food debate. Glob. Food Secur. 2017, 14, 1–8. [Google Scholar] [CrossRef]

- Röös, E.; Bajzelj, B.; Smith, P.; Patel, M.; Little, D.; Garnett, T. Protein futures for Western Europe: Potential land use and climate impacts in 2050. Reg. Environ. Chang. 2017, 17, 367–377. [Google Scholar] [CrossRef]

- Ajila, C.M.; Brar, S.K.; Verma, M.; Tyagi, R.D.; Godbout, S.; Valéro, J.R. Bio-processing of agro-by-products to animal feed. Crit. Rev. Biotechnol. 2012, 32, 382–400. [Google Scholar] [CrossRef]

- Salami, S.A.; Luciano, G.; O’Grandy, M.N.; Biondi, L.; Newbold, C.J.; Kerry, J.P.; Priolo, A. Sustainability of feeding plant by-products: A review of the implications for ruminant meat production. Anim. Feed Sci. Technol. 2019, 251, 37–55. [Google Scholar] [CrossRef]

- Berchielli, T.T.; Pires, A.V.; Oliveira, S.G. Nutrição de Ruminantes, 2nd ed.; Funep: Jaboticabal, Brazil, 2011; 616p. [Google Scholar]

- Getachew, G.; Blummel, M.; Makkar, H.P.S.; Becker, K. In vitro gas measuring techniques for assessment of nutritional quality of feeds: A review. Anim. Feed Sci. Technol. 1998, 72, 261–281. [Google Scholar] [CrossRef]

- Getachew, G.; Robinson, P.H.; DePeters, E.J.; Taylor, S.J. Relationships between chemical composition, dry matter degradation and in vitro gas production of several ruminant feeds. Anim. Feed Sci. Technol. 2004, 111, 57–71. [Google Scholar] [CrossRef]

- Association of Official Analytical Chemistry—AOAC. Official Methods of Analysis of AOAC International; AOAC International: Gaithersburg, MD, USA, 2011. [Google Scholar]

- Van Soest, P.J.; Robertson, J.B.; Lewis, B.A. Methods for Dietary Fiber, Neutral Detergent Fiber, and Nonstarch Polysaccharides in Relation to Animal Nutrition. J. Dairy Sci. 1991, 74, 3583–3597. [Google Scholar] [CrossRef] [PubMed]

- Mertens, D.R. Gravimetric determination of amylase-treated neutral detergent fiber in feeds with refluxing in beakers or crucibles: Collaborative study. J. AOAC Int. 2003, 85, 1217–1240. [Google Scholar]

- Sniffen, C.J.; O’Connor, J.D.; Van Soest, P.J.; Fox, D.G.; Russel, J.B. A net carbohydrate and protein system for evaluating cattle diets. II. Carbohydrate and protein availability. J. Anim. Sci. 1992, 70, 3562–3577. [Google Scholar] [CrossRef]

- Theodorou, M.K.; Wilian, B.A.; Dhanoa, M.S.; McAllan, A.B.; Drance, J. A simple gas production method using a pressure transducer to determine the fermentation kinetics of ruminant feeds. Anim. Feed Sci. Technol. 1994, 48, 185–197. [Google Scholar] [CrossRef]

- Mauricio, R.M.; Mould, F.L.; Dhanoa, M.S.; Owen, W.; Channa, K.S.; Theodorou, M.K. A semi-automated in vitro gas production technique for ruminant feedstuff evaluation. Anim. Feed Sci. Technol. 1999, 79, 321–330. [Google Scholar] [CrossRef]

- Abdalla, A.L.; Louvandini, H.; Sallam, S.M.A.H.; Bueno, I.C.S.; Figueira, A.V.O. In vitro evaluation, in vivo quantification, and microbial diversity studies of nutritional strategies for reducing enteric methane production. Trop. Anim. Health Prod. 2012, 44, 953–964. [Google Scholar] [CrossRef]

- Bizzuti, B.E.; Faria, L.A.; Costa, W.S.; Lima, P.M.T.; Ovani, V.S.; Kruger, A.M.; Louvandini, H.; Abdalla, A.L. Potential use of cassava by-product as ruminant feed. Trop. Anim. Health Prod. 2021, 53, 108. [Google Scholar] [CrossRef] [PubMed]

- Ligoski, B.; Gonçalves, L.F.; Claudio, F.L.; Alves, E.M.; Kruger, A.M.; Bizzuti, B.E.; Lima, P.M.T.; Abdalla, A.L.; Paim, T.P. Silage of intercropping corn, palisade grass, and pigeon pea increases protein content and reduces in vitro methane production. Agronomy 2020, 10, 1784. [Google Scholar] [CrossRef]

- Sakita, G.Z.; Lima, P.M.T.; Abdalla Filho, A.L.; Bompadre, T.F.V.; Ovani, V.S.; Chaves, C.M.S.; Bizzuti, B.E.; Costa, W.S.; Paim, T.P.; Campioni, T.S.; et al. Treating tropical grass with fibrolytic enzymes from the fungus Trichoderma reesei: Effects on animal performance, digestibility and enteric methane emissions of growing lambs. Anim. Feed Sci. Technol. 2022, 286, 115253. [Google Scholar] [CrossRef]

- Bueno, I.C.S.; Filho, S.L.C.; Gobbo, S.P.; Louvandini, H.; Vitti, D.M.; Abdalla, A.L. Influence of inoculum source in a gas production method. Anim. Feed Sci. Technol. 2005, 123, 95–105. [Google Scholar] [CrossRef]

- Soltan, Y.A.; Morsy, A.S.; Sallan, S.M.A.; Lucas, R.S.; Louvandini, H.; Kreuzer, M.; Abdalla, A. Contribution of condensed tannins and mimosine to the methane mitigation caused by feeding Leucaena leucocephala. Arch. Anim. Nutr. 2013, 67, 169–184. [Google Scholar] [CrossRef]

- Longo, C.; Bueno, I.C.S.; Nozella, E.; Goddoy, P.; Filho, S.C.; Abdalla, A.L. The influence of head-space and inoculum dilution on in vitro ruminal methane measurements. Int. Congr. Ser. 2006, 1293, 62–65. [Google Scholar] [CrossRef]

- Yáñez-Ruiz, D.R.; Bannink, A.; Dijkstra, J.; Kebreab, E.; Morgavi, D.P.; O’Kiely, P.; Reynolds, C.K.; Schwarm, A.; Shingfiedl, K.J.; Hristov, A.N. Design, implementation and interpretation of in vitro batch culture experiments to assess enteric methane mitigation in ruminants—A review. Anim. Feed Sci. Technol. 2016, 216, 1–18. [Google Scholar] [CrossRef]

- Blümmel, M.; Makkar, H.P.S.; Becker, K. In vitro gas production: A technique revisited. J. Anim. Physiol. Anim. Nutr. 1997, 77, 24–34. [Google Scholar] [CrossRef]

- Palmquist, D.L.; Conrad, H.R. Origin of plasma fatty acids in lactating cows fed high grain or high fat diets. J. Dairy Sci. 1971, 54, 1025–1033. [Google Scholar] [CrossRef] [PubMed]

- Lima, P.D.M.T.; Moreira, G.D.; Sakita, G.; Natel, A.S.; De Mattos, W.T.; Gimenes, F.M.A.; Gerdes, L.; McManus, C.; Abdalla, A.L.; Louvandini, H. Nutritional evaluation of the legume Macrotyloma axillare using in vitro and in vivo bioassays in sheep. J. Anim. Physiol. Anim. Nutr. 2017, 102, e669–e676. [Google Scholar] [CrossRef] [PubMed]

- France, J.; Dhanoa, M.S.; Theodorou, S.J.; Lister, D.R.; Davies, D.R.; Isac, D. A model to interpret gas accumulation profiles associated with in vitro degradation of ruminant feeds. J. Theor. Biol. 1993, 163, 99–111. [Google Scholar] [CrossRef]

- R Core Team. R: A Language and Environment for Statistical Computing; R Foundation for Statistical Computing: Vienna, Austria, 2022. Available online: https://www.R-project.org/ (accessed on 25 November 2022).

- Kassambara, A.; Mundt, F. Factoextra: Extract and Visualize the Results of Multivariate Data Analyses. R package Version 1.0.7. 2020. Available online: https://CRAN.R-project.org/package=factoextra (accessed on 25 November 2022).

- Depeters, E.J.; Fadel, J.G.; Arosemena, A. Digestion kinetics of neutral detergent fiber and chemical composition within some selected by-product feedstuffs. Anim. Feed Sci. Technol. 1997, 67, 27–140. [Google Scholar] [CrossRef]

- Huber, J.T. Upgrading Residue and By-Products for Animals; CRC Press: Boca Raton, FL, USA, 1981; Volume 131. [Google Scholar]

- United Nations Development Programme Food and Agriculture Organization of the United Nations—FAO. Feedstuff; Fish Feed Technology: Rome, Italy, 1978; ISBN 92-5-100901-5. [Google Scholar]

- Souza, C.B.; Jonathan, M.; Saad, S.M.I.; Schols, H.A.; Venema, K. Characterization and in vitro digestibility of by–products from Brazilian food industry: Cassava bagasse, orange bagasse and passion fruit peel. Bioact. Carbohydr. Diet. Fiber 2018, 16, 90–99. [Google Scholar] [CrossRef]

- Chen, C.; Lee, T.; Yu, B. Improving the prediction of methane production determined by in vitro gas production technique for ruminants. Ann. Anim. Sci. 2016, 16, 565–584. [Google Scholar] [CrossRef]

- Liu, C.; Li, D.; Chen, W.; Li, y.; Wu, H.; Meng, Q.; Hou, Z. Estimating ruminal crude protein degradation from beef catle feedstuff. Sci. Rep. 2019, 9, 11368. [Google Scholar] [CrossRef]

- Siqueira, G.B. Energia e Proteína na Nutrição de Ruminantes. Ph.D. Thesis, Universidade Federal do Tocantins, Palmas, Brazil, 2007. [Google Scholar]

- Lan, W.; Yang, C. Ruminal methane production: Associated microorganisms and the potential of applying hydrogen-utilizing bacteria for mitigation. Sci. Total Environ. 2019, 654, 1270–1283. [Google Scholar] [CrossRef]

- McAllister, T.A.; Newbold, C.J. Redirecting rumen fermentation to reduce methanogenesis. Aust. J. Exp. Agric. 2008, 48, 7–13. [Google Scholar] [CrossRef]

- Kozloski, G.V. Bioquímica dos Ruminantes, 3rd ed.; Editora UFMS: Santa Maria, Brazil, 2016. [Google Scholar]

- Dijkstra, J.; Ellis, J.L.; Kebreab, E.; Strathe, A.B.; Lópes, S.; Frande, J.; Bannink, A. Ruminal pH regulation and nutritional consequences of low pH. Anim. Feed Sci. Technol. 2012, 172, 22–33. [Google Scholar] [CrossRef]

- Freitas, A.W.P.; Pereira, J.C.; Rocha, F.C. Avaliação da divergência nutricional de genótipos de cana-de-açúcar (Saccharum ssp.). Rev. Bras. Zootec. 2006, 35, 229–236. [Google Scholar] [CrossRef]

- Mizubuti, I.Y.; Ribeiro, E.L.A.; Pereira, E.S.; Pinto, A.P.; Franco, A.L.C.; Syperreck, M.A.; Dórea, J.R.R.; Cunha, G.E.; Capelar, M.G.M.; Muniz, E.B. Cinética de fermentação ruminal in vitro de alguns co-produtos gerados na cadeia produtiva do biodiesel pela técnica de produção de gás. Semin. Ciênc. Agrár. 2011, 32, 2021–2028. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).