Weed Strategy Considering the Weed Control Effect and Weed Control Uniformity with Microsprinkler Irrigation

Abstract

:1. Introduction

2. Materials and Methods

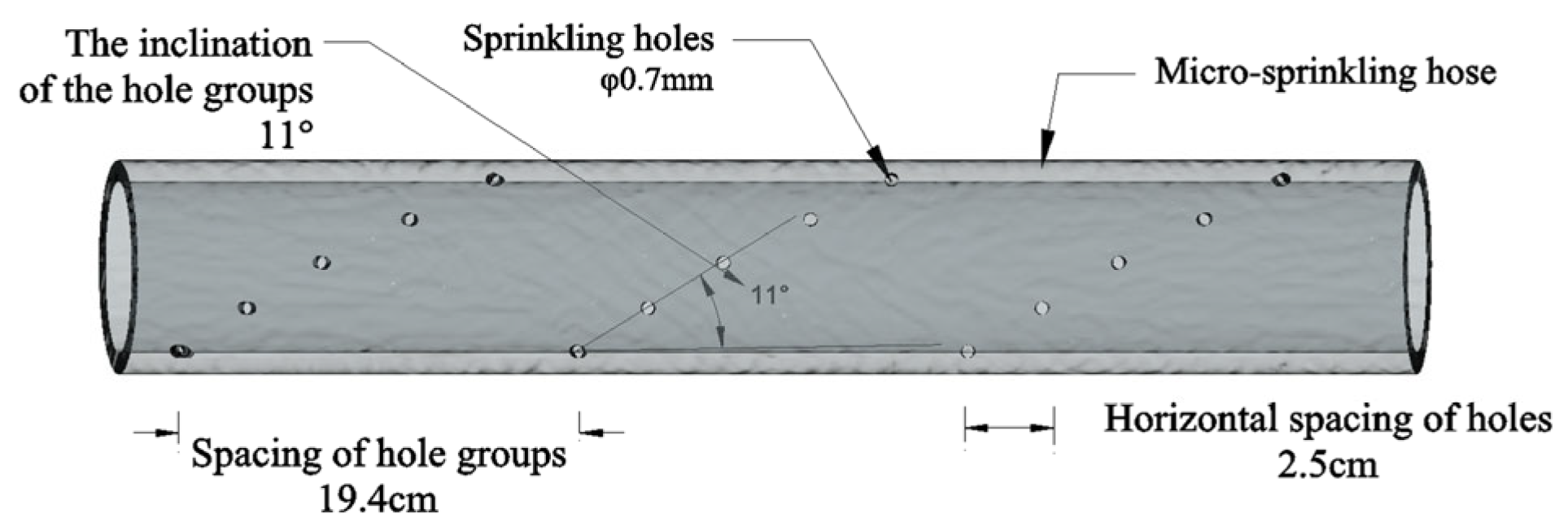

2.1. Materials

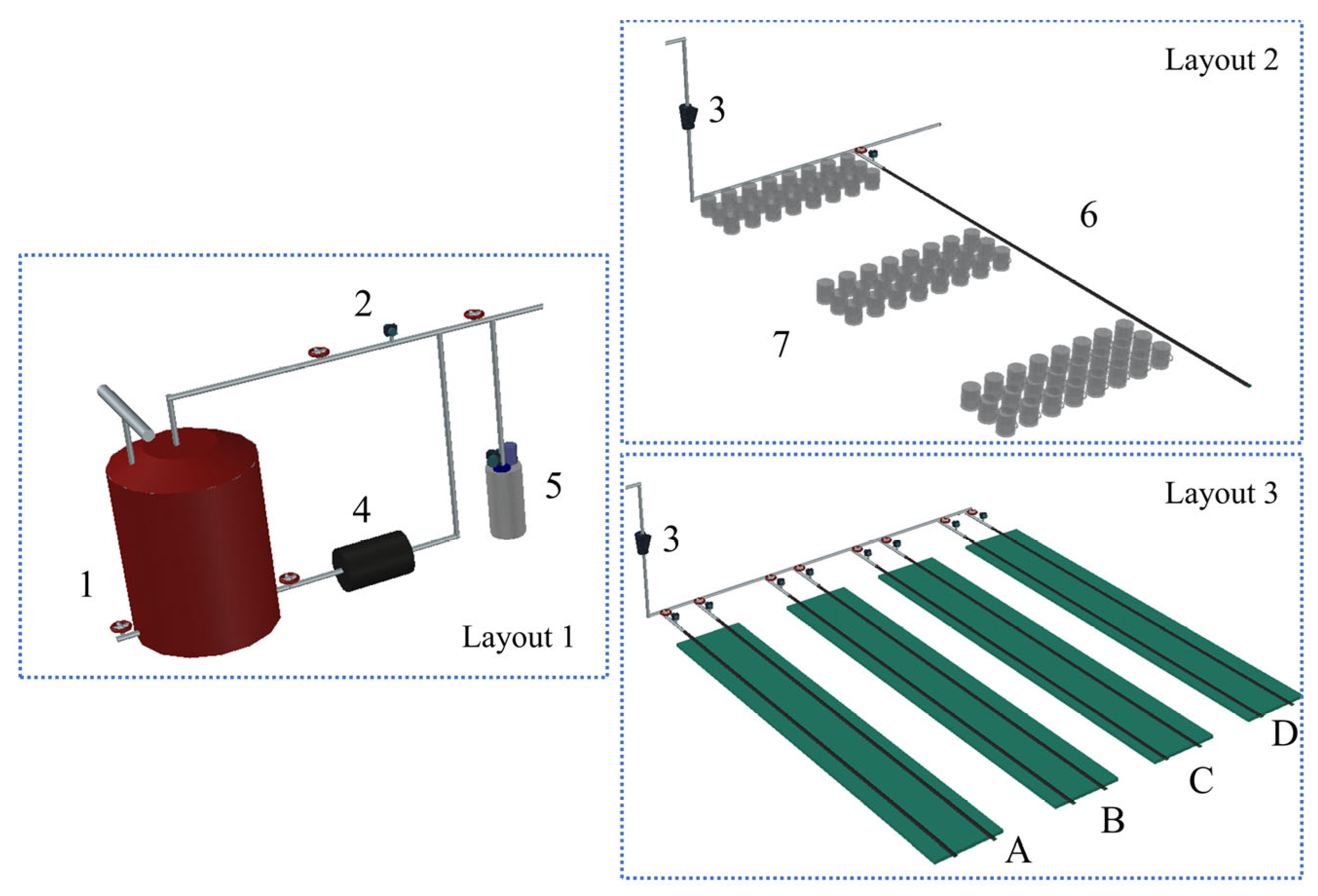

2.2. System Design and Experimental Arrangement

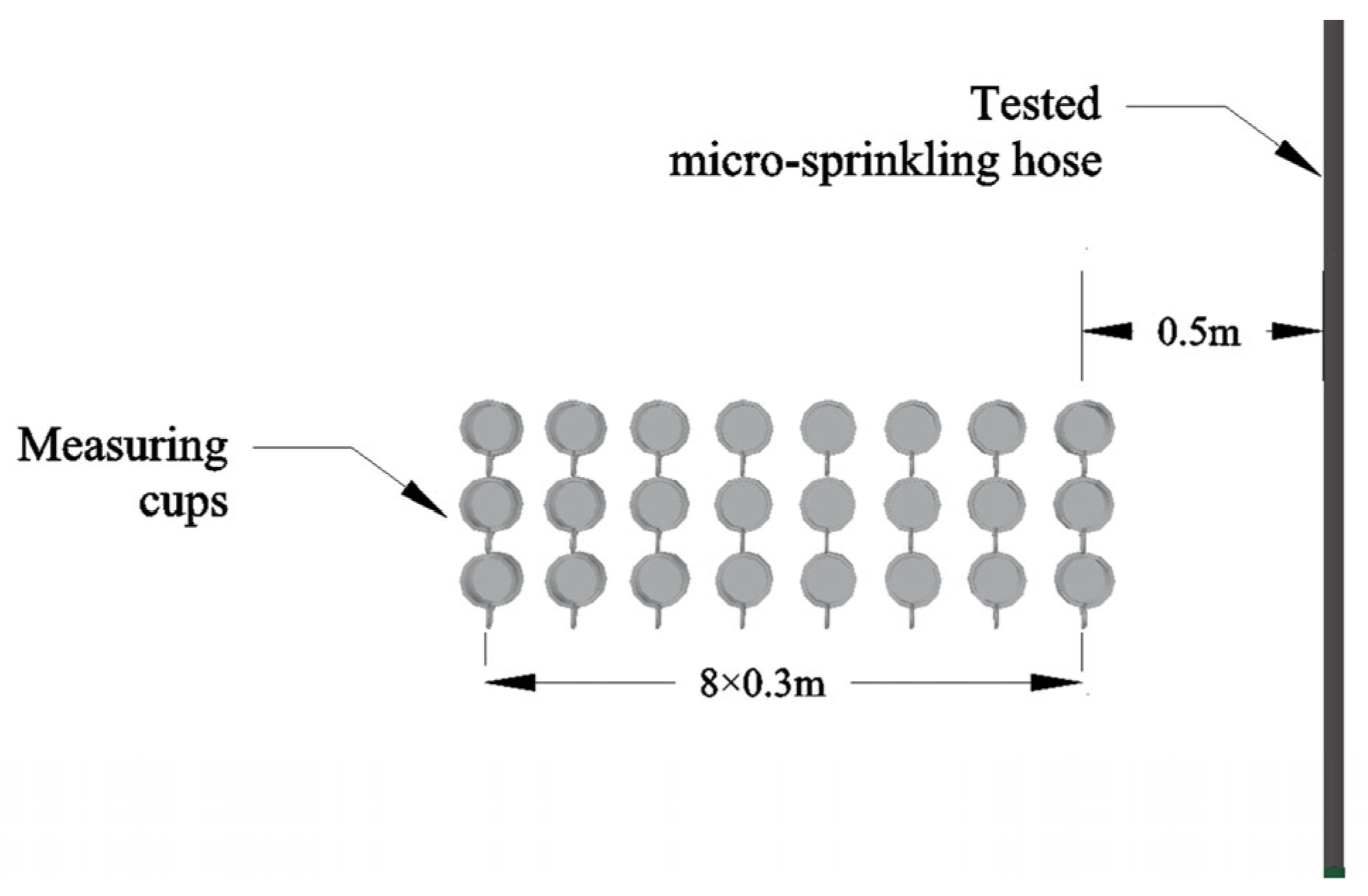

2.2.1. Water Distribution Test

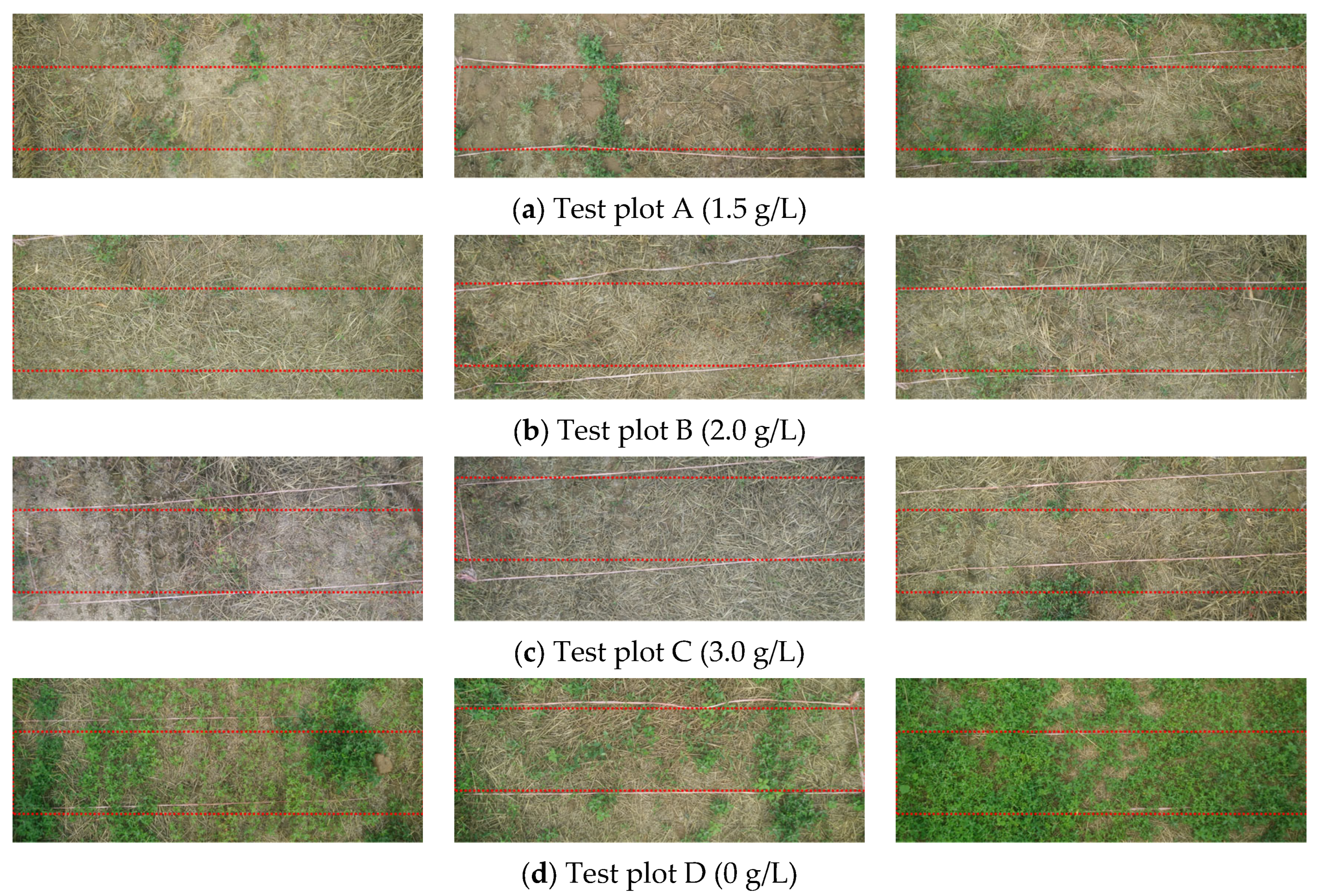

2.2.2. Field Application Experiment

2.3. Evaluation Index and Determination Method

- (1)

- Weed control effect calculation formula [11]:

- (2)

- Distribution uniformity coefficient DU: In actual field applications, due to the differences in application devices or artificial uncontrollable factors (the water distribution of microsprinkler hoses is not uniform), the actual amount of herbicide applied in some areas did not reach the amount calculated to achieve optimal application. This index focuses on areas with a low control effect, which is conducive to ensuring the necessary minimum application amount.

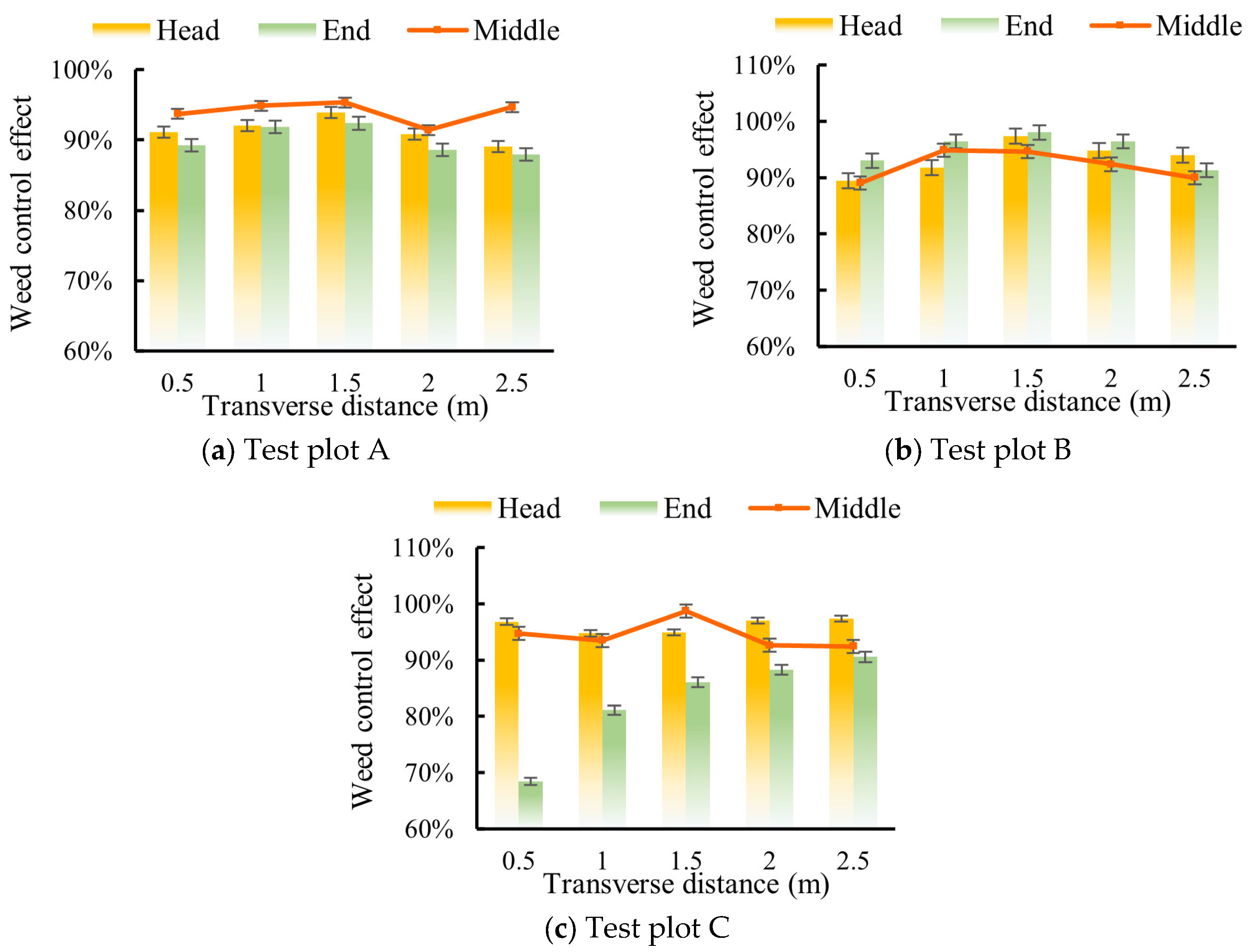

3. Results

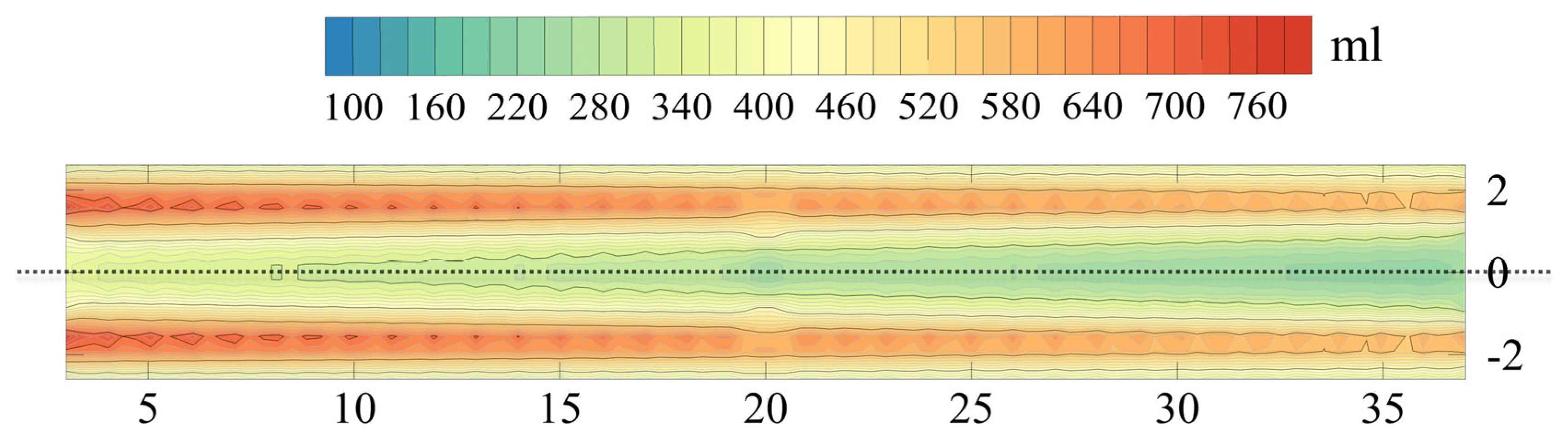

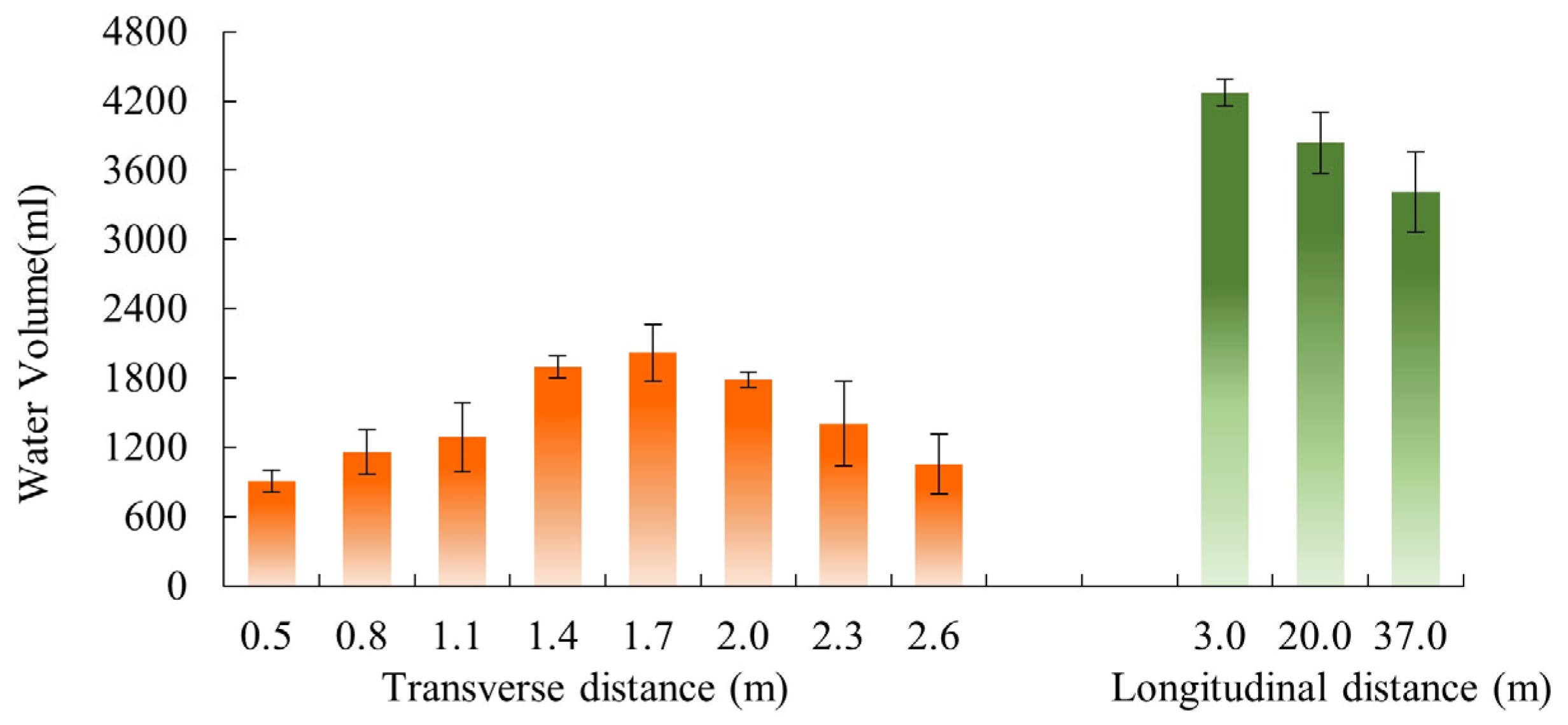

3.1. Water Distribution Characteristics

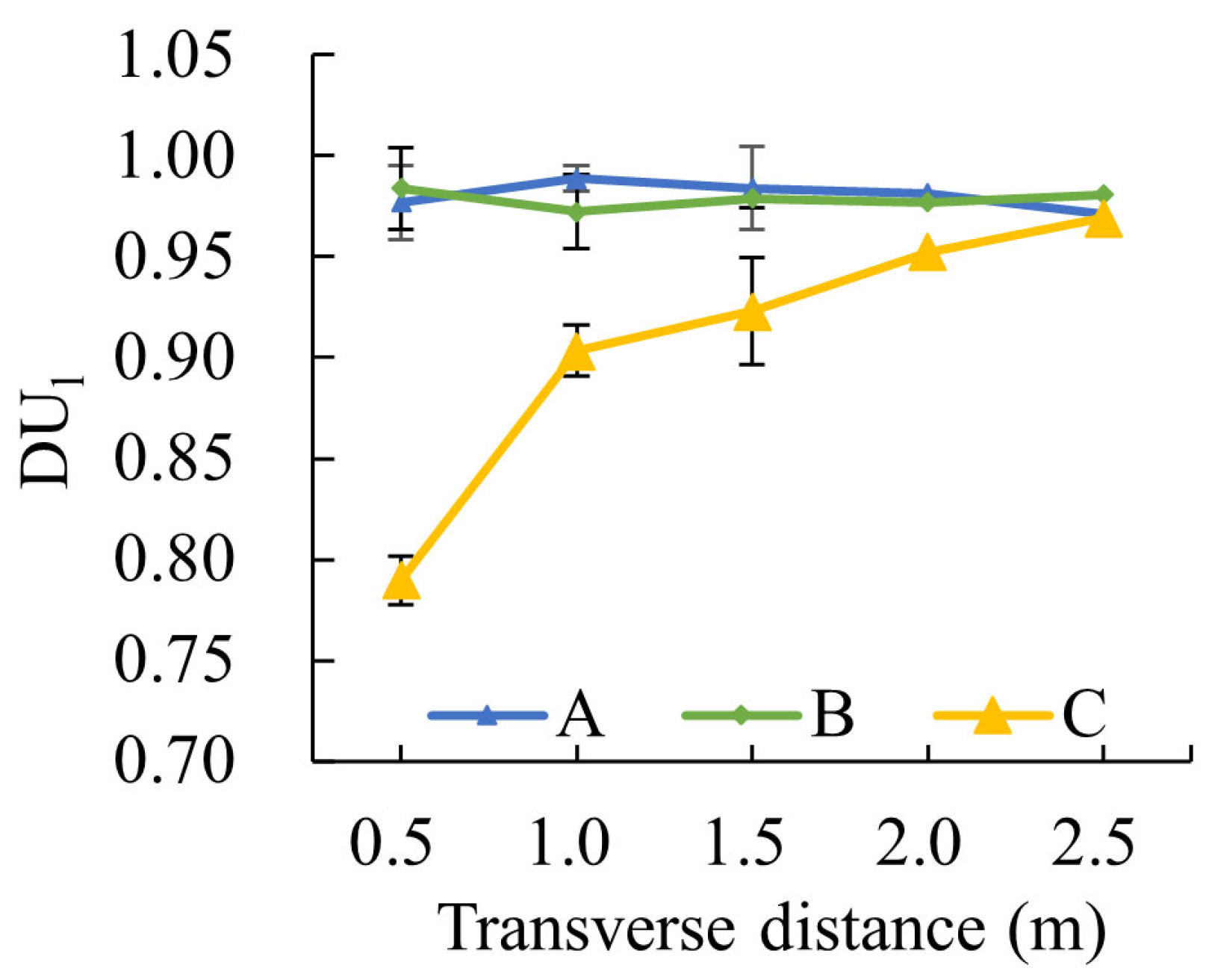

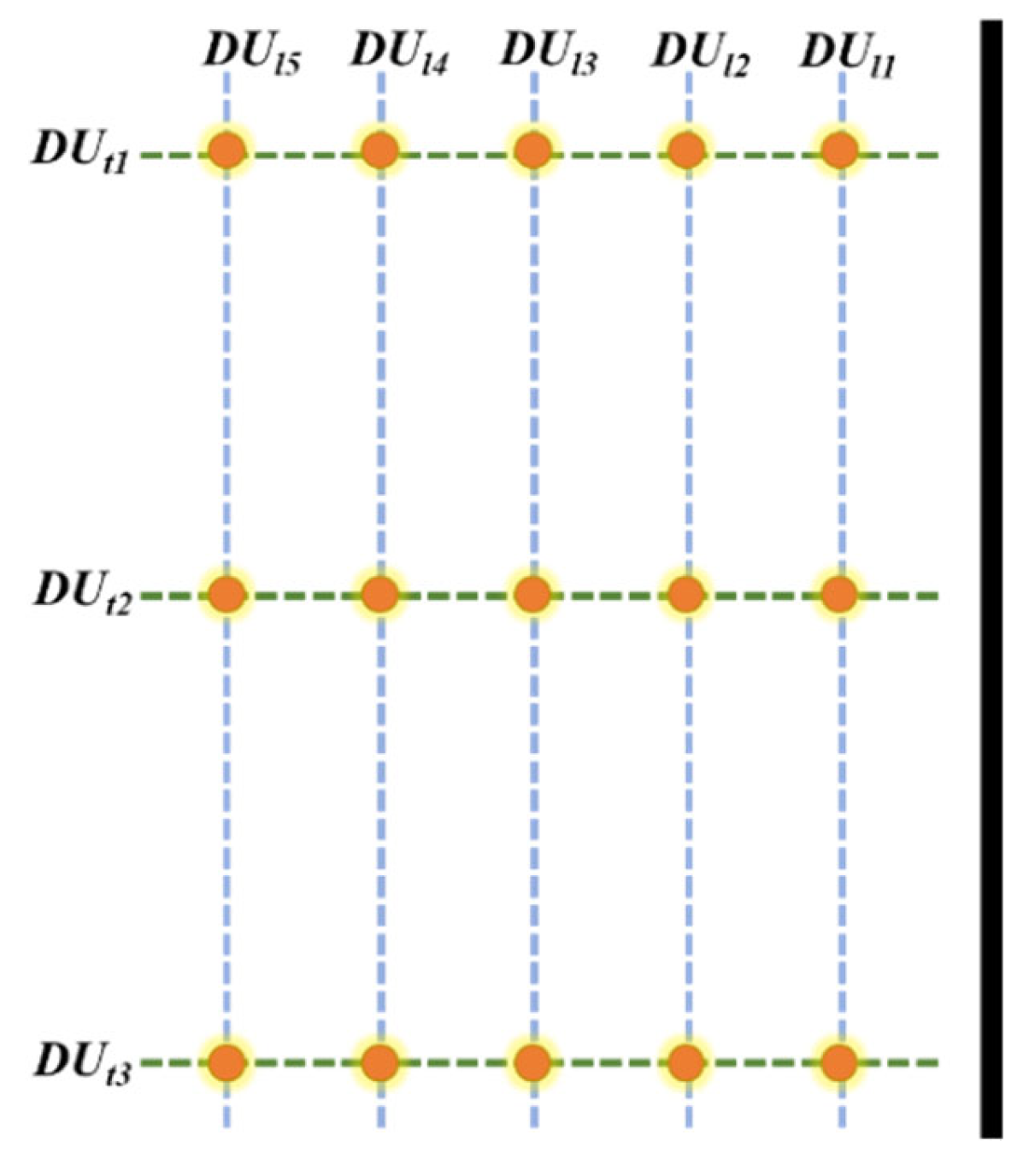

3.2. DU in the Longitudinal and Transverse Directions

3.3. Newly Developed Comprehensive DU

4. Discussion

4.1. Application Concentration

4.2. The Cumulative Herbicide Residual

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Declaration of Competing Interest

References

- Ceng, X.; Li, Y.; Niu, X.; Wang, S. Existing problems and countermeasures in the production, operation, use and management of pesticide in China. Xi’an, Shaanxi, China 2002, 3. Available online: https://kns.cnki.net/kcms/detail/detail.aspx?FileName=IGNE200210001065&DbName=CPFD2002 (accessed on 28 March 2023).

- Bu, Y.; Kong, Y.; Zhi, Y.; Wang, J.; Dan, Z. Pollution of Chemical Pesticides on Environment and Suggestion for Prevention and Control Countermeasures. J. Agric. Sci. Technol. 2014, 16, 19–25. [Google Scholar]

- Kavlock, R.J.; Ankley, G.T. A perspective on the risk assessment process for endocrine-disruptive effects on wildlife and human health. Risk Anal. 1996, 16, 731–739. [Google Scholar] [CrossRef] [PubMed]

- Zhao, H.; Wu, P.; Zhu, D.; Zhang, K.; Feng, Y.; Tan, Z. Spraying Hydraulic Performance of Double Travelling Rain Guns for Hose Reel Irrigator under Low Pressure. Water Sav. Irrig. 2019, 6, 6–9. [Google Scholar]

- Gao, S.; Li, Q.; Cai, Y.; Bao, L.; Ren, P. Design of Flow Variable Spraying Device. M. Agric. Equip. 2019, 40, 8–42. [Google Scholar]

- Liu, Y. Solar Power Large Span Translational Administer Sprinkler Design and Test; Anhui Agricultural University: Anhui, China, 2017. [Google Scholar]

- Hui, X.; Mei, P.; Wang, X. Research of the Detection Method of Indirect ELISA for Acetochlor Residue in Soil. Chem. Bioeng. 2008, 25, 72–74. [Google Scholar]

- Talaviya, T.; Shah, D.; Patel, N.; Yagnik, H.; Shah, M. Implementation of artificial intelligence in agriculture for optimisation of irrigation and application of pesticides and herbicides. Artif. Intell. Agric. 2020, 4, 58–73. [Google Scholar] [CrossRef]

- Hura, C.; Leanca, M.; Rusu, L.; Hura, B.A. Risk assessment of pollution with pesticides in food in the Eastern Romania area (1996–1997). Toxicol. Lett. 1999, 107, 103–107. [Google Scholar] [CrossRef] [PubMed]

- Guo, X.; Feng, Y.; Li, G.; Li, Y.; Zhang, R. Control Efficiency and Safety Evaluation of 3% Foramsulfuron OD on Weeds in Summer Corn Field. J. Shanxi Agric. Sci. 2019, 47, 259–261. [Google Scholar]

- Gou, W. Experimental Study on Hydraulic Performance of Thin Wall Micro Spray Belt; Tianjin Agricultural University: Tianjing, China, 2019. [Google Scholar]

- Zhang, G. Dichloroquinolinic acid should not be used in the middle and late period of rice growth. Plant Prot. Technol. Ext. 2002, 1, 29. [Google Scholar]

- Zhong, Q.; Shen, C.; Chen, R.; Lian, H.; Zhang, Z.; Zhang, J. Effects of three herbicides in rice field on the safety of peanut after stubble. Agric. Technol. 2018, 38, 5–7. [Google Scholar]

- Liu, Y.; Liu, H.; Zhang, X.; Zhang, W.; Yang, X. Herbicide hazards and their prevention and remediation. Sci. Technol. Tianjin Agric. Forest. 2005, 6, 18–20. [Google Scholar]

- Ma, H.; Li, G.; Wu, W.; Liu, L. Effects of meteorological factors on herbicide application and application techniques. M. Agric. Sci. Technol. 2006, 5, 77–78. [Google Scholar]

- Chen, L.; Huang, Y. Cause analysis and prevention and control of herbicide application in maize field. J. Agric. Res. Env. 2012, 29, 23–25. [Google Scholar]

- He, Y.; Jiang, S.; Shu, X.; Tong, G.; Zhong, M. Research progress on environmental residual status and remediation strategies of quinclorac herbicide. Chin. J. Pestic. Sci. 2021, 23, 31–41. [Google Scholar]

- Chang, F. Some suggestions for the safe use of herbicides. M. Agric. 2018, 5, 29. [Google Scholar]

| Parameters | Values |

|---|---|

| Annual average sunshine hours | 3200–3300 |

| Annual average temperature (°C) | 8 |

| Frost-free period (day) | 150 |

| Annual average rainfall (mm) | 164.4 |

| Ions | HCO3−, HSO4−, Cl−, Ca2+, K+, Mg2+ |

| pH | 7.3–9.5 |

| Total hardness (mg/L) | 200–350 |

| Mineralization (mg/L) | 400–600 |

| Herbicide Content (g) | Water Volume (L) | Concentration (g/L) | Application Duration (s) | |

|---|---|---|---|---|

| Test plot A | 30 | 20 | 1.5 | 443 |

| Test plot B | 30 | 15 | 2.0 | 332 |

| Test plot C | 30 | 10 | 3.0 | 221 |

| Control plot D | 0 | - | 0 | - |

| Treatments | Longitudinal Sampling Points (m) | Transverse Sampling Points (m) | Comprehensive DU | ||

|---|---|---|---|---|---|

| 3 | 20 | 37 | |||

| A | 0.5 | 0.992609 | 0.992288 | 0.996254 | 0.994397 |

| 1 | 0.995442 | 0.995759 | 0.99184 | ||

| 1.5 | 0.999826 | 0.999507 | 0.996555 | ||

| 2 | 0.997147 | 0.996827 | 0.999225 | ||

| 2.5 | 0.986443 | 0.98612 | 0.990111 | ||

| B | 0.5 | 0.985245 | 0.986992 | 0.985432 | 0.991168 |

| 1 | 0.996892 | 0.99866 | 0.997081 | ||

| 1.5 | 0.990278 | 0.992035 | 0.990467 | ||

| 2 | 0.992019 | 0.993779 | 0.992208 | ||

| 2.5 | 0.988164 | 0.989917 | 0.988352 | ||

| C | 0.5 | 0.750906 | 0.758269 | 0.857296 | 0.921321 |

| 1 | 0.908547 | 0.914981 | 0.998489 | ||

| 1.5 | 0.931751 | 0.938048 | 0.977263 | ||

| 2 | 0.964605 | 0.970709 | 0.947207 | ||

| 2.5 | 0.982422 | 0.988421 | 0.930907 | ||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, H.; Shi, W.; Zha, Q.; Ling, G.; Wang, W.; Hu, X. Weed Strategy Considering the Weed Control Effect and Weed Control Uniformity with Microsprinkler Irrigation. Agronomy 2023, 13, 1034. https://doi.org/10.3390/agronomy13041034

Wang H, Shi W, Zha Q, Ling G, Wang W, Hu X. Weed Strategy Considering the Weed Control Effect and Weed Control Uniformity with Microsprinkler Irrigation. Agronomy. 2023; 13(4):1034. https://doi.org/10.3390/agronomy13041034

Chicago/Turabian StyleWang, Hui, Wenpeng Shi, Qing Zha, Gang Ling, Wene Wang, and Xiaotao Hu. 2023. "Weed Strategy Considering the Weed Control Effect and Weed Control Uniformity with Microsprinkler Irrigation" Agronomy 13, no. 4: 1034. https://doi.org/10.3390/agronomy13041034

APA StyleWang, H., Shi, W., Zha, Q., Ling, G., Wang, W., & Hu, X. (2023). Weed Strategy Considering the Weed Control Effect and Weed Control Uniformity with Microsprinkler Irrigation. Agronomy, 13(4), 1034. https://doi.org/10.3390/agronomy13041034