1. Introduction

Tomato is one of the important crops that are most widely grown and consumed due to its outstanding flavor and great nutritional content [

1,

2]. The geographical, environmental, and economic conditions are the main important factors for producers of agricultural products. Sufficient food production is required due to the rising population and worldwide food demand [

3]. Tomatoes are planted both in the greenhouse and open fields. Therefore, developing a sustainable production system is essential for improved crop growth and a consistently high tomato yield [

4]. The economy is one of the most important reasons for producing greenhouse tomatoes.

There are possibilities to lessen environmental impacts throughout the manufacturing process. Knowing how energy is consumed and pollution is released in food production is required to develop appropriate policies. In several parts of the world, researchers have looked at how fertilizer application affects plant growth, but the results of these studies have differed based on the cultivation method and type of fertilizer in each study. Therefore, it is necessary to ensure a suitable nutrient management strategy for effective resource management and sustainable tomato production. The current method of fertilizing strongly relies on the application of chemical fertilizer instead of using organic types [

2]. Conventional farming types are based on the use of chemical and synthetic fertilizers and biocides, causing nitrate leaching [

5], groundwater pollution [

6], freshwater contamination [

7], soil acidification [

8], water eutrophication [

9], the loss of biodiversity and habitat [

10], and soil degradation [

11,

12], and consequently hurt human health, ecosystem quality, and resources.

Instead of synthetic fertilizers, organic nutrient management methods utilize biological and physical controls that minimize groundwater contamination [

13], boost microbial biodiversity, and reduce reliance on excessive inputs [

14]. According to several types of research, organic foods provide benefits for enhancing human health [

15], preserving the environment, and maintaining biodiversity [

16,

17]. As a result, these crops have gained widespread public acceptance, especially in developed countries [

18,

19,

20]. According to several kinds of research that compare conventional and organic agricultural techniques, the yield of organic agriculture is between 5% and 35% lower than conventional agriculture, depending on the crop type and situation [

21,

22,

23]. Organic fertilizers and amendments can increase plant growth, biomass, and crop yield [

24,

25]. On the other hand, it is necessary to highlight the barriers to the role of organic fertilizers. Considering that greenhouse and open fields are two different farming types, understanding the amount of emissions and their source is therefore important in increasing efficiency and thus reducing environmental problems.

These days, in many countries, environmental challenges are the most significant global issue [

26]. In recent years, one of the most important topics of the global community has been having sufficient knowledge of the environmental status of regions and assessing the pattern of global change [

27]. The life cycle assessment (LCA) approach is essential for the environmental study of processes as well as agricultural production and services [

28]. The LCA approach is a collection of procedures for gathering and assessing the input, output, materials, and environmental impacts connected with a manufacturing system across its life cycle [

29]. This method assists decision-makers in selecting the least environmentally damaging product or process [

30].

To date, the direct influences of chemical and organic fertilizer application on tomato growth in the greenhouse and open field production systems are still not fully understood. The LCA existing tomato studies have mostly concentrated on energy use and environmental impacts analysis [

31,

32], organic and conventional production [

29,

33,

34,

35], and greenhouse or open field cultivation [

29,

32,

36]. So far, there has been no LCA research comparing organic and conventional tomatoes in the greenhouse and open field. In addition, it is important to signify the barriers to the effectiveness of organic fertilizers such as manure and compost in tomato cultivation. Therefore, this study focused on investigating the effects of chemical and organic fertilizers on the environmental impact assessment of greenhouse and open field tomatoes. It was hypothesized that the use of organic fertilizers could decrease the negative environmental impacts in both greenhouse and open fields for sustainable agricultural development.

2. Materials and Methods

2.1. Crop Cultivation Methods and Data Collection

Since there are different methods for producing tomatoes, the four most important scenarios were selected, focusing on two types of nutrient management options (organic and conventional), and two types of cultivation methods (open field and greenhouse). The organic and conventional greenhouse scenarios (scenarios 1 and 2) were evaluated in Iran, the organic open-field scenario (scenario 3) in Turkey, and the conventional open-field scenario (scenario 4) in the Czech Republic.

Table 1 indicates the fundamental properties of the production system considered in this study.

The greenhouse organic (GH-O) and conventional (GH-C) systems (scenarios 1 and 2) were located in Isfahan Province, Iran (32°39′40″ N, 51°40′49″ E). In scenario 1, tomatoes were cultivated from March to November 2021 (275 days). The cultivation in this system was based on organic fertilizers and biocides (

Table 1). The cultivation system in scenario 2 was based on chemical fertilizers and the period time was 306 days from April 2021 to January 2022. Isfahan is renowned as a significant agricultural location in Iran with more than 5000 greenhouses producing vegetables around the province [

37,

38]. Air temperature, humidity, ventilation, and the volume of water were controlled according to the standards defined for tomato cultivation in greenhouses.

The temperature and humidity were adjusted according to the standards defined for tomato cultivation.

The third scenario was the open field organic system (OF-O) located in Bafra, Turkey (41°32′26″ N, 35°51′4″ E). Turkey is the world’s fourth largest tomato grower, with tomato varieties accounting for 40% of the country’s total vegetable supply. Farmers have continued to farm tomatoes due to the crop’s economic potential in Turkey’s important vegetable-growing regions [

39].

In this scenario, tomatoes were cultivated from May to September 2021 (148 days). The organic fertilizers used in this scenario included cattle manure, vinasse, and manure compost. Scenario 4 was the open field conventional system (OF-C) based on chemical fertilizers and tomatoes cultivated from April to August 2022 in Brno, Czech Republic (49°11′42″ N, 16°36′28″ E).

The foreground data for the systems included fuel, electricity, agricultural machinery, irrigation, water source, fertilizers, and biocides. The foreground data were collected using questionnaires. The appropriate sample number for this investigation was determined using Cochran’s formula [

40,

41]:

where n is the required sample number, N is the population size, t is the t value at 95% confidence limit (1.96), s is the standard deviation (SD), and d is the permissible error (5%).

Table 1 shows the main characteristics of each scenario.

2.2. Life Cycle Analysis Method

In this study, the LCA method, which has been used effectively in agricultural systems for decades, was chosen to assess the environmental impact of tomato production in greenhouses and open fields. The LCA approach defined in ISO standards (ISO, 2006) involves four phases: aim and scope definition, inventory analysis, impact assessment, and interpretation [

42]. The four phases are as follows:

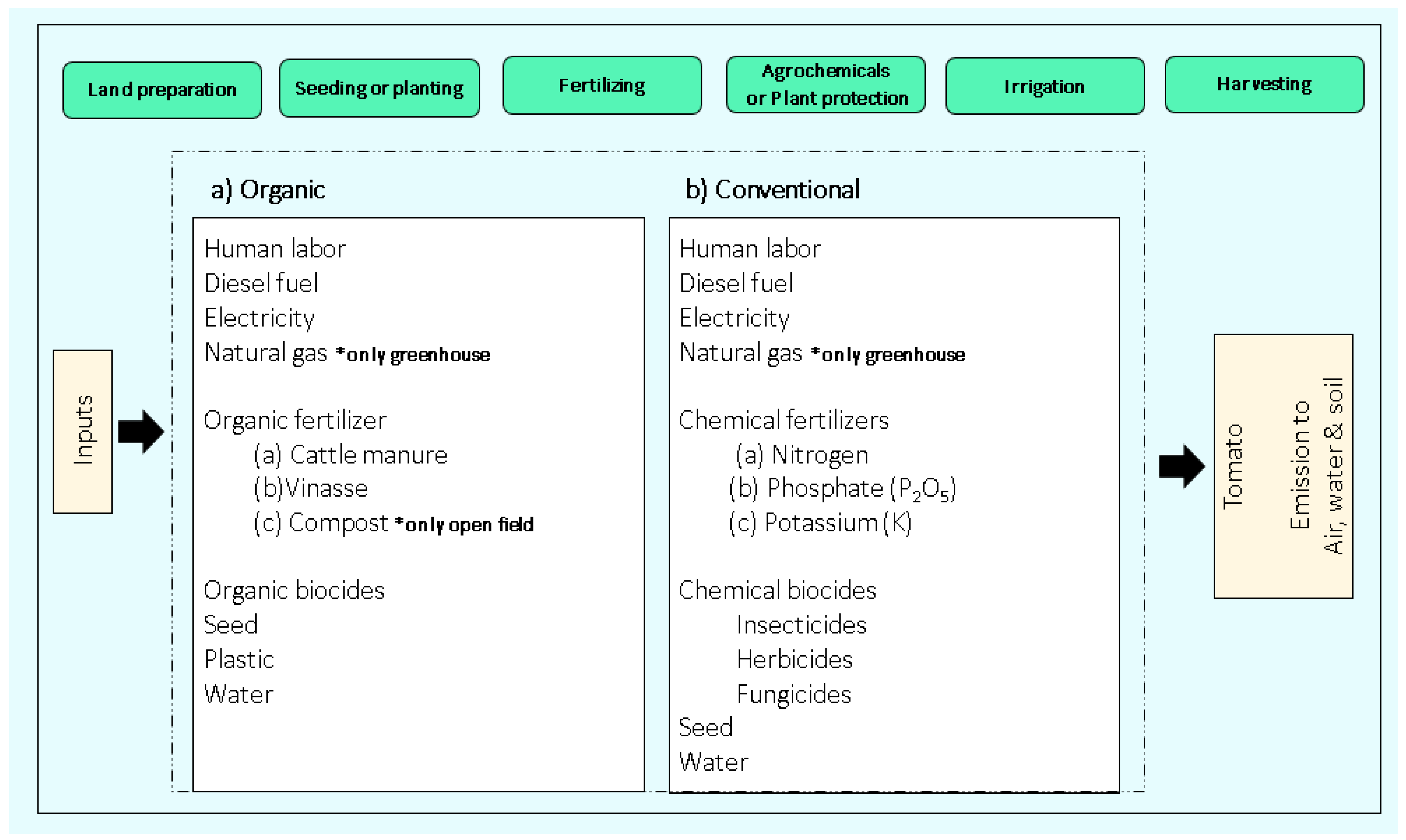

Phase 1: This phase included the goal of the study, functional unit, and system boundary. The research’s purpose must first be clear. This study aims to investigate the environmental effects of greenhouse and open field tomatoes in organic and conventional nutrient management. The functional unit is linked to the inputs and outputs and acts as a comparison condition. According to ISO 2006, three distinct functional units for assessing crops have been proposed based on a unit area, currency unit, and mass unit. One ton of tomatoes (mass unit) is considered the functional unit for this research. The processes that need to be included in the LCA are determined by the system boundary. The system boundary selection should be following the topic of the study. In the current study, the system boundary starts from the cradle and ends at the farm gate with the harvest of tomatoes (

Figure 1).

Phase 2: The Life Cycle Inventory (LCI) includes information on all environmental inputs and outputs at each step of the life cycle. Two data sets (foreground data and background data) were used to build the LCI [

36]. In this study interviews with farmers were used to gather the inventory data (foreground data) for the agricultural stage. The background data were taken from the Ecoinvent V.3.5 and AGRIBALYSE v1.2/v1.3 databases [

43].

Table 2 shows the inventory data of tomato cultivation in each scenario per hectare. These databases were used to calculate the environmental emissions due to organic and chemical fertilizers, biocides, diesel fuel, natural gas, and human labor. The inputs are used to calculate the amount of pollutants emitted into the environment.

Table 3 shows the emissions from burning per liter of diesel and m

3 of national gas. The calculation method and emission factors for the application of inputs in the open field and greenhouse tomato cultivation are given in

Appendix A.

Phase 3: This phase (life cycle impact assessment = LCIA) attempts to conduct a quantitative analysis of the findings from the life cycle assessment section. Four categories in LCIA included: classification, characterization, normalization, and weighting. In this phase based on environmental consequences, the set of data from the preceding step is interpreted.

The ReCiPe 2016 model was used for the assessment of the environmental impact in this study. The overall purpose of the ReCiPe method is to condense a lengthy list of life cycle inventory data into a small number of indicator scores. The ReCiPe midpoint technique includes 18 environmental impact indicators, which are further divided into four groups of damage (human health, ecosystem quality, resources, and climate change).

Phase 4: In this phase of data interpretation the purpose of analyzing the findings is to identify the constraints, suggestions, and results of the life cycle impact assessment phase to support decision-makers. All procedures finally lead to the analysis of the data. As a consequence, judgments about environmental contaminants are simplified. In this study, the effect of organic and conventional tomato cultivation in the greenhouse and the open field was evaluated in three categories: human health, ecosystem quality, and resources.

3. Results

Table 4 shows the environmental impact categories for organic and conventional tomatoes in the open field and greenhouse based on a one-ton yield. The result showed that scenario three in comparison with the other scenarios had higher impact categories. In total, OF tomatoes had higher damage categories in comparison with GH tomatoes.

Figure 2 shows the tomato yield (ton ha

−1) in different scenarios and the result shows that the average yield of GH tomatoes was higher than that of OF tomatoes. The average yield of GH-O, GH-C, OF-O, and OF-C was 97.3, 102.1, 75.6, and 81.3-ton ha

−1, respectively. The open-field production systems (scenario three and four) has a lower amount of yield compared with the greenhouse production systems (scenarios one and two). According to

Table 4, there was no environmental impact difference between organic and conventional greenhouse tomatoes except in water consumption (WCP), freshwater eutrophication (FEP), and land use (LOP)

. In the open field scenarios (scenarios three and four) there was a significant difference between organic and conventional tomatoes in human non-carcinogenic toxicity (HTPnc), ionizing radiation (IRP), stratospheric ozone depletion (ODP), mineral resource scarcity (SOP), water consumption (WSP), freshwater ecotoxicity (FETP), freshwater eutrophication (FEP), marine ecotoxicity (METP), and marine eutrophication (MEP). According to these results, conventional open field tomatoes were more environmentally friendly than organic tomatoes.

Table 5 reported the emissions of diesel fuel and natural gas into the air in different scenarios. The results of the diesel fuel emissions showed that there was a significant difference between open field and greenhouse scenarios but there was no significant difference between organic and conventional tomatoes. The emission of natural gas is only related to greenhouses scenarios and no difference between organic and conventional tomatoes was noticed. The coefficients for converting pollutants calculated by the above equations to their functional values are also presented in

Table 3.

The emissions by fertilizers, human labor, and biocides to air, water, and soil have been illustrated in

Table 6. The results showed that there was a difference between the scenarios and that the emissions in OF were higher than in the GH scenarios. Except for phosphate emission, the organic OF scenario had the highest emissions among other scenarios.

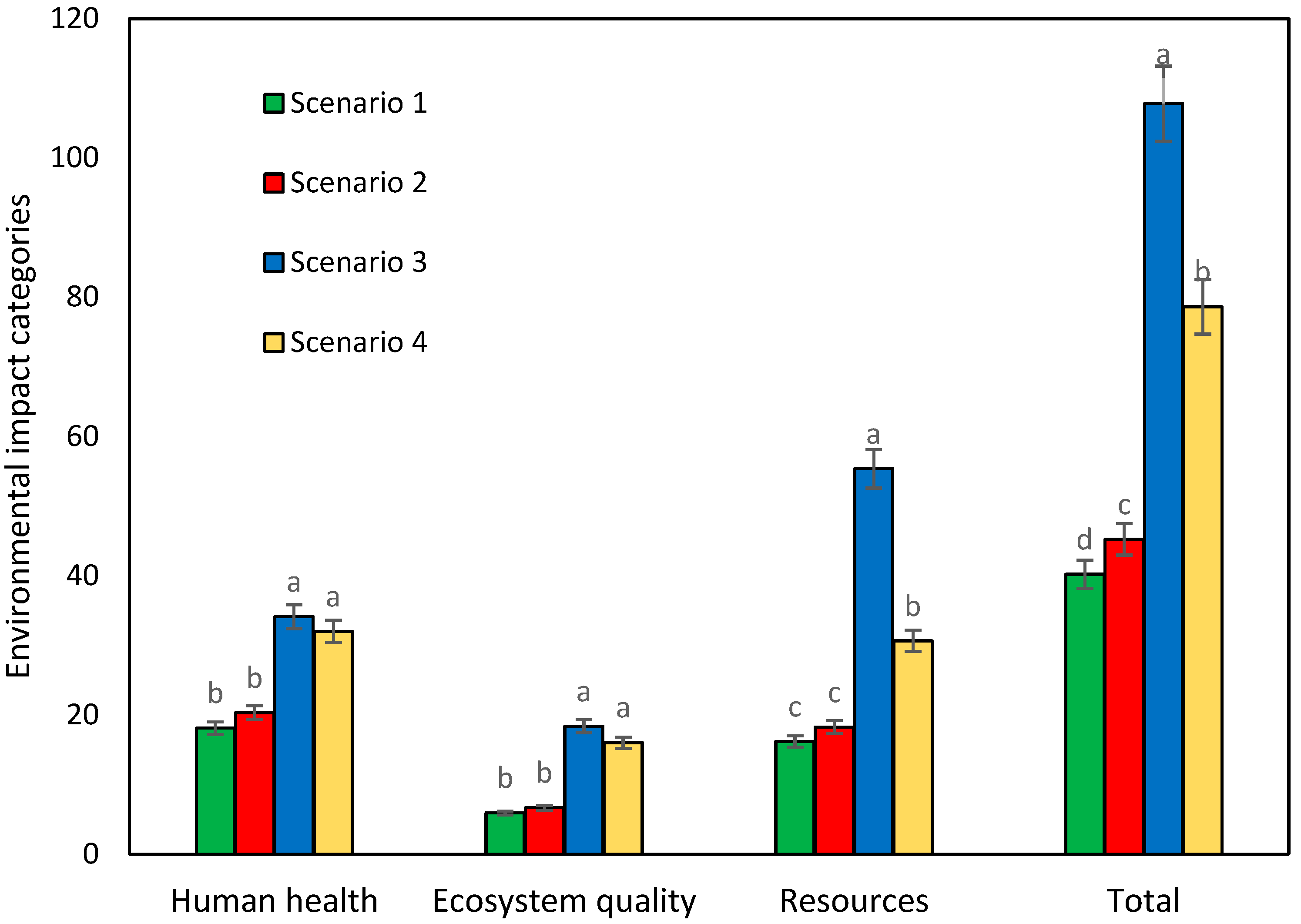

Figure 3 shows the environmental damage assessment of tomato production in different scenarios. Scenario three had the highest impact on human health, ecosystem quality, and resources and scenario one had the lowest impact among other scenarios.

Figure 4 shows the contribution of inputs to the environmental impact categories in different scenarios. In scenario one (GH-O), electricity and diesel fuel were the major contributors to human health and ecosystem quality. In this scenario, the main contribution to resources is related to diesel fuel, electricity, and natural gas. In scenario two (GH-C) and scenario four (OF-C), chemical fertilizers (Nitrogen, Phosphate, Potassium) had the highest contribution to human health, ecosystem quality, and resources. In scenario three (OF-O), diesel fuel and compost fertilizer were the major contributors to all environmental impact categories (

Figure 4).

Human health categories: according to

Table 4, PMFP, HTPc, HTPnc, IRP, EOFP, and ODP are the impact assessment of the human health category.

Figure 4 shows the share of inputs to the environmental impact categories in different scenarios; the share of inputs was different in the scenarios. Among different inputs, in scenario one electricity was at 61%, in scenario two nitrogen fertilizer was at 33%, in scenario three diesel was at 49%, and in scenario four diesel, with 30%, had the highest share in the human health category.

Ecosystem quality categories: the impact assessment of ecosystem quality categories included FETP, FEP, LOP, METP, MEP, HOFP, TAP, and TETP (

Table 4). Each input had a distinguished share in the ecosystem quality category: in scenario one was diesel with 49%; in scenario two it was phosphate fertilizer with 52%; in scenario three it was compost with 71%; and in scenario four phosphate fertilizer, with 30%, had the highest share.

Resources categories: fossil fuel potential (FFP), surplus ore potential (SOP), and water consumption potential (WCP) were considered resource categories. In scenarios one and four, diesel, with 43% and 41%, respectively, had the highest share of resource categories. In scenario two, it was nitrogen fertilizer with 31% and in scenario three, compost, with 58%, had the highest share of resource categories.

4. Discussion

The main goal of this study was to investigate the environmental impact of organic and conventional tomato production in the greenhouse and open fields. Life cycle assessment is a standard method that can evaluate the environmental impact of a product, a farming system, or a production process [

44] and, for this research, LCA was used to assess the environmental impact of different scenarios. Contrary to many studies that focused only on one impact category, in the present study three damage assessments (human health, ecosystem quality, resources) of tomato production were evaluated.

The greenhouse organic production method (scenario one) had the lowest and the OF organic system (scenario three) had the highest environmental impact on human health, ecosystem quality, and resources. In total, OF tomatoes (scenarios three and four) had higher damage categories in comparison with GH tomatoes (scenarios one and two), which can be due to the use of agricultural machinery and more fuel consumption in the open field than in the greenhouse. The diesel fuel consumption for scenarios one–four were 58.45, 62, 226.8, and 252.03 L ha

−1, respectively (

Table 2). The open field system of farming consumes significant amounts of diesel fuel for the operation of agricultural machinery and irrigation, and the use of chemicals and transport contributes to a negative effect on the ecosystem, human health, and resources and needs to be reduced [

45]. Another important factor in agricultural production is using pesticides to increase yield and improve the quality of crops, but they have detrimental effects on the environment [

46]. Accumulating pollutants such as nitrate in agricultural products and endangering the health of humans and animals are examples of the harmful effects of the excessive use of chemical fertilizers. Organic nutrient management is based on the use of biological and physical controls instead of synthetic fertilizer and the result is to prevent groundwater pollution and to increase microbial biodiversity, and these are less reliant on external inputs [

47,

48,

49]. The main sources of N

2O emissions to the atmosphere are nitrification proceeded by denitrification processes carried out by soil microorganisms, though these emissions can change based on agricultural waste management, soil tillage, the nitrogen fertilizer used, and climate conditions. Blengini and Busto stated that the most significant impact on ecosystem quality came from the usage of fossil fuels with a diesel content [

49]. This energy consumption contributes to environmental impact and directly or indirectly affects the ecosystem quality, human health, and resources.

Figure 4 shows the high share of diesel fuel in all the environmental impact categories.

In greenhouse cropping systems, the total environmental impact of organic tomatoes was lower than conventional tomatoes (

Figure 3). Many studies mention that the use of pesticides and chemical fertilizers enhances agricultural productivity and improves crop quality, but affects the environment negatively [

32]. In this study, open field tomato production presented high environmental effects since fertilizers were applied in organic and conventional scenarios resulting in high emissions to air, water, and soil (

Table 5 and

Table 6, and

Figure 4). Liang et al. (2019) reported that N fertilizer contributed to well over half (63.3–73.1%) of the total environmental index in a cropping system including agricultural materials production and the arable farming system [

50].

Figure 2 shows that the tomato yield (ton ha

−1) in different scenarios and the yield in greenhouse scenarios were higher than in open field scenarios. Martínez-Blanco et al. (2011) stated that the average control of the microclimate owing to greenhouse protection led to a significant increase in productivity and a significant decrease in the usage of pesticides and irrigation water. They also stated that the management of the greenhouses could enhance yield by nearly 50% and reduce pesticide requirements and water consumption [

51]. The amount of irrigation water for the greenhouse scenarios (scenarios one and two) were 340.5 and 490.1 m

3 ha

−1, respectively, and the amount for the open field scenarios were 5670 and 6504 m

3 ha

−1, respectively. The results showed more water consumption in open fields than in greenhouses and this can affect the resources and the ecosystem quality.

Organic nutrient management has been advocated as a way to lessen negative environmental effects which also enhances soil quality, biodiversity, human health, and ecosystem quality [

52,

53]. The use of organic fertilizers in organic nutrient management can increase crop yields but requires careful consideration [

54,

55]. On the other hand, it is necessary to highlight the barriers to the role of organic fertilizers. According to

Figure 4, compost had the highest contribution in all the environmental impact categories rather than other inputs in scenario three. The application of fertilizer based on type or dosage has a great impact on the environment [

49]. As a result, the application of compost had a negative environmental effect on tomato production. He et al. (2018) stated that significant environmental impacts in organic systems were related to the major usage of organic manure [

49].

5. Conclusions

The findings of this study imply that each product system had advantages and disadvantages. One disadvantage of greenhouses is the need for energy for air conditioning in the warm seasons and to heat the space of the greenhouse in the cold months. The simplicity of management and year-round crop harvesting is the advantage of the greenhouse. Since open fields rely on agricultural machinery due to their large size, the disadvantages of this agricultural method are the scarcity of fossil fuels, the environmental damage caused by their use, and rising worldwide raw oil costs. Often, organic nutrient management is suggested as a solution to reduce the negative impact of conventional agriculture on the environment but the lower performance of the yield in the organic nutrient management compared with the conventional method is one of the main disadvantages of this system. Therefore, more land is usually needed to produce the same amount of food in organic management. The use of organic amendment and fertilizers in organic management can increase crop yields but requires careful consideration. However, following the result of this study, the use of compost in an organic open-field scenario was not suggested to be a good option for tomato cultivation, because of its negative environmental impact on human health, ecosystem quality, and resources. In environmental analyses, diesel fuel also generates significant emissions. The results of this research showed that scenario two (GH-C) had the highest yield among other scenarios, and scenario one (GH-O) had the lowest environmental damage and was the best system. In addition, the prediction and optimization of energy consumption and environmental effects should also be considered for further research to help greenhouse owners. Furthermore, it is important to examine organic and conventional nutrient management over several years.